Topic Review: Application of Raman Spectroscopy Characterization in Micro/Nano-Machining

Abstract

1. Introduction

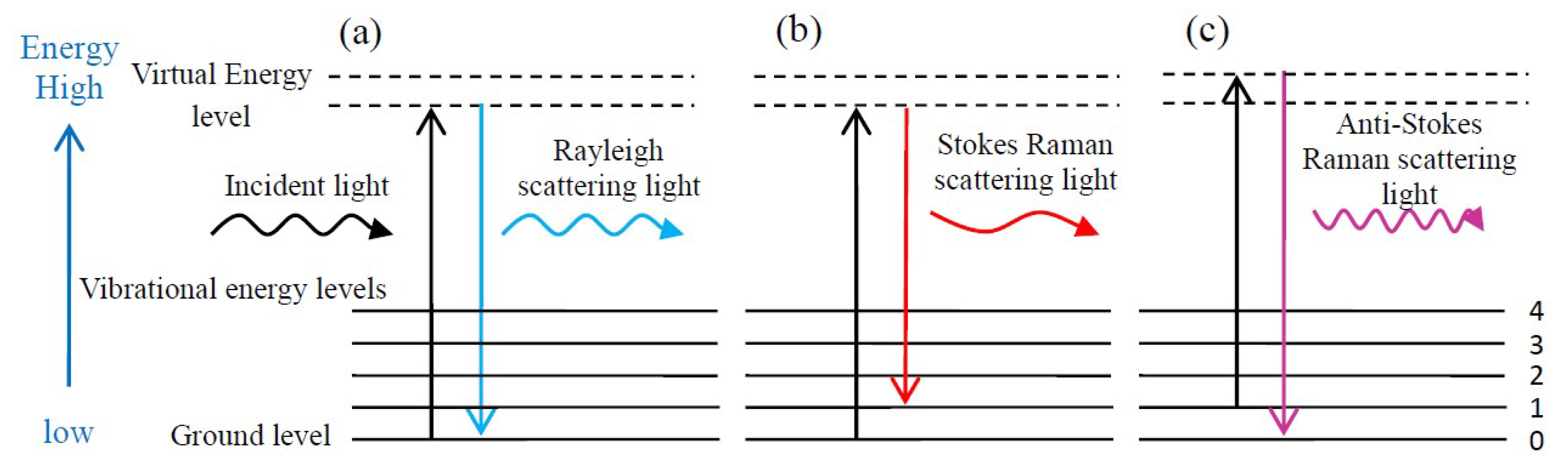

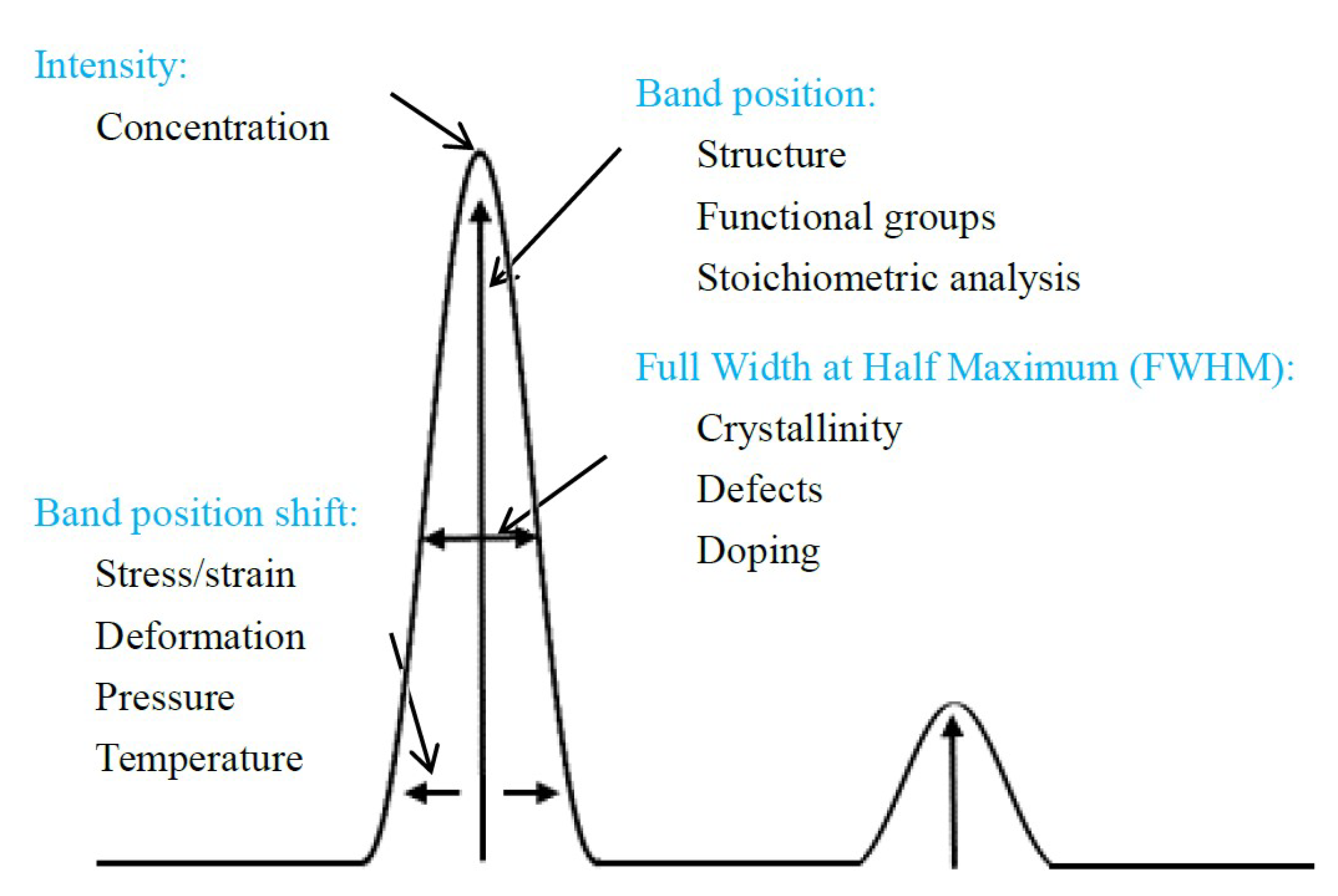

2. Theory of Raman Spectroscopy

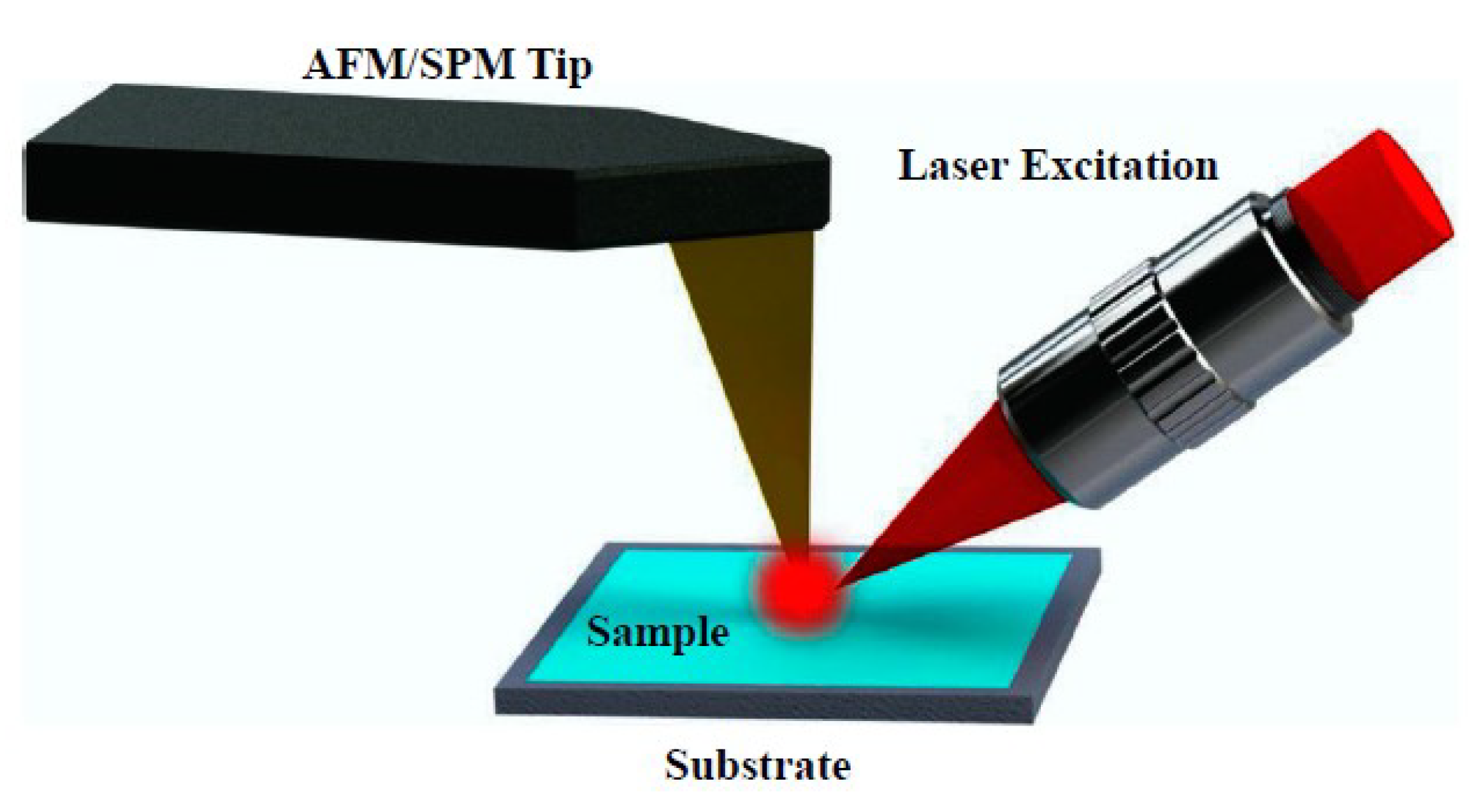

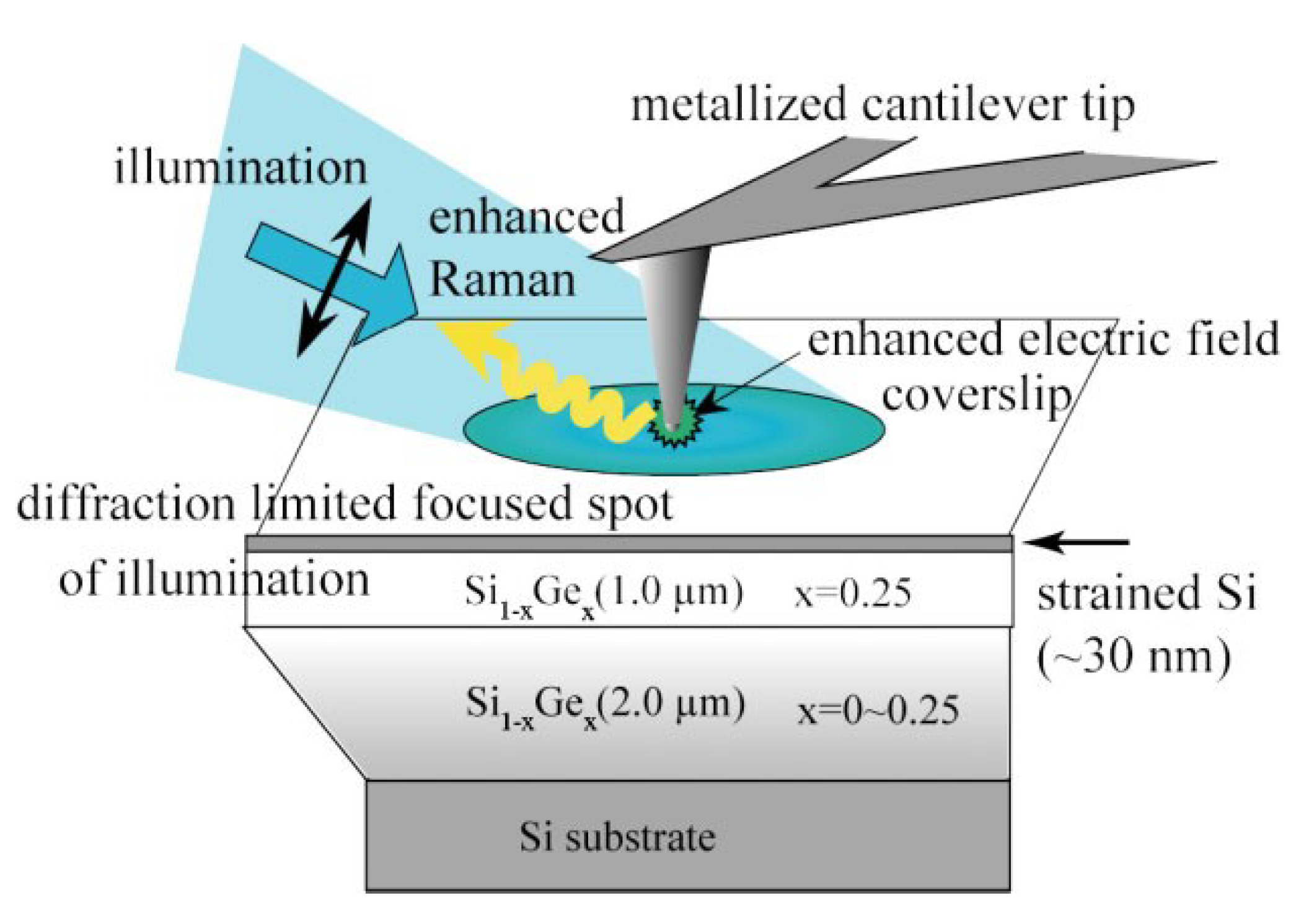

2.1. Principle of Raman Spectroscopy

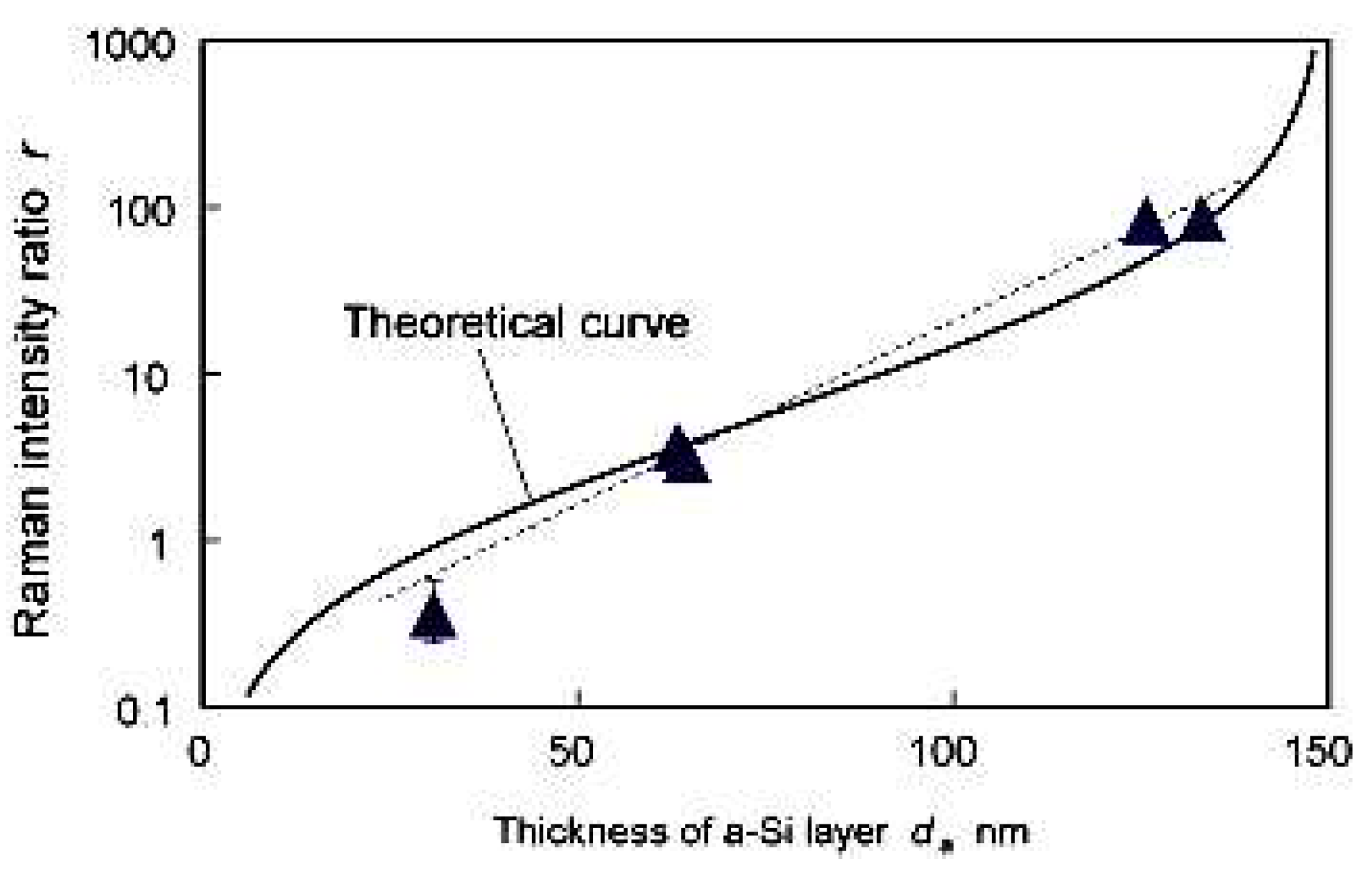

2.2. Penetration Depth with Different Laser Wavelengths

2.3. Laser Spot Size and Spectral Resolution of Raman Spectroscopy

3. Raman Spectroscopy Characterization in Micro/Nano-Machining

3.1. Basis Information

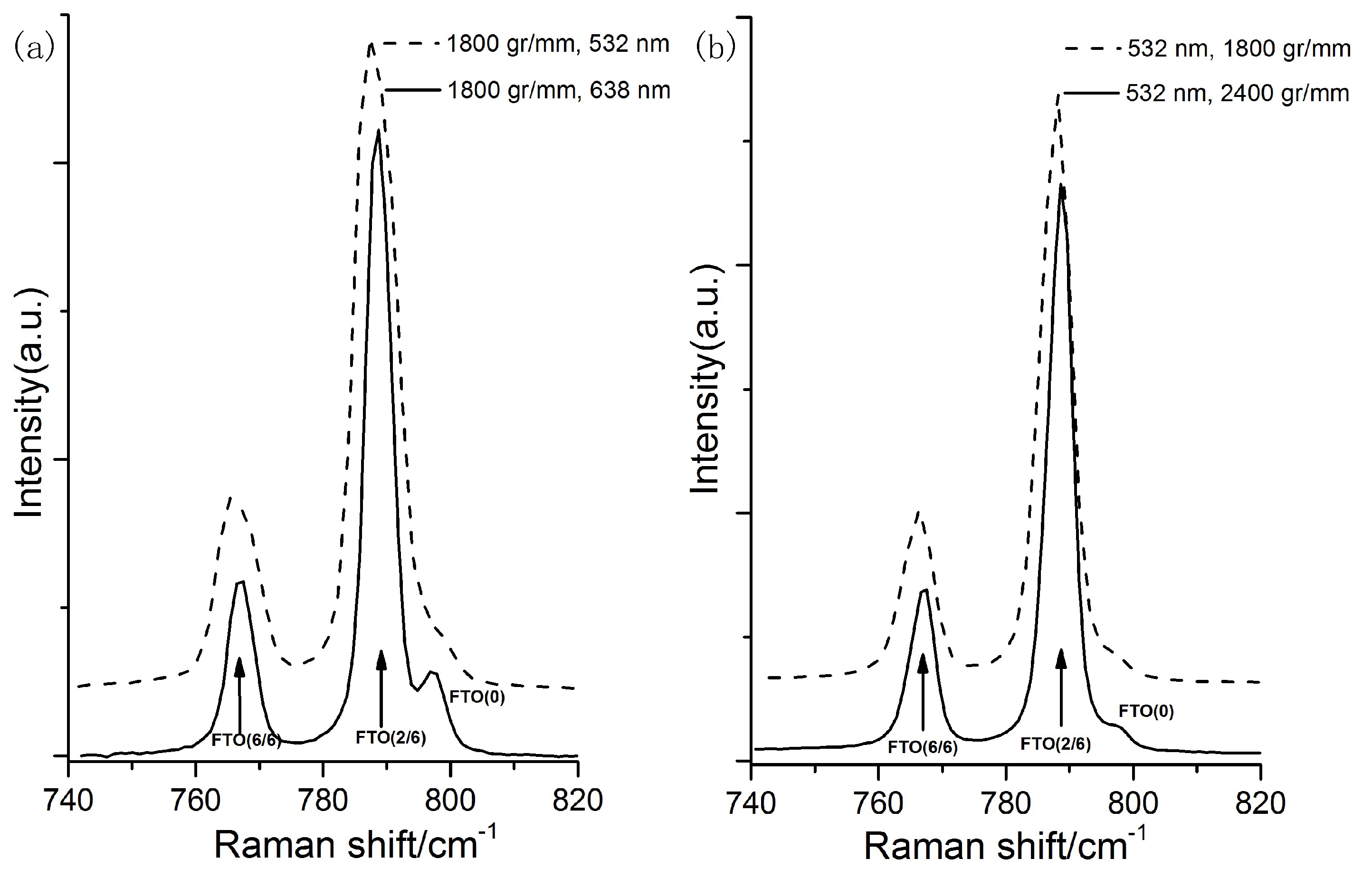

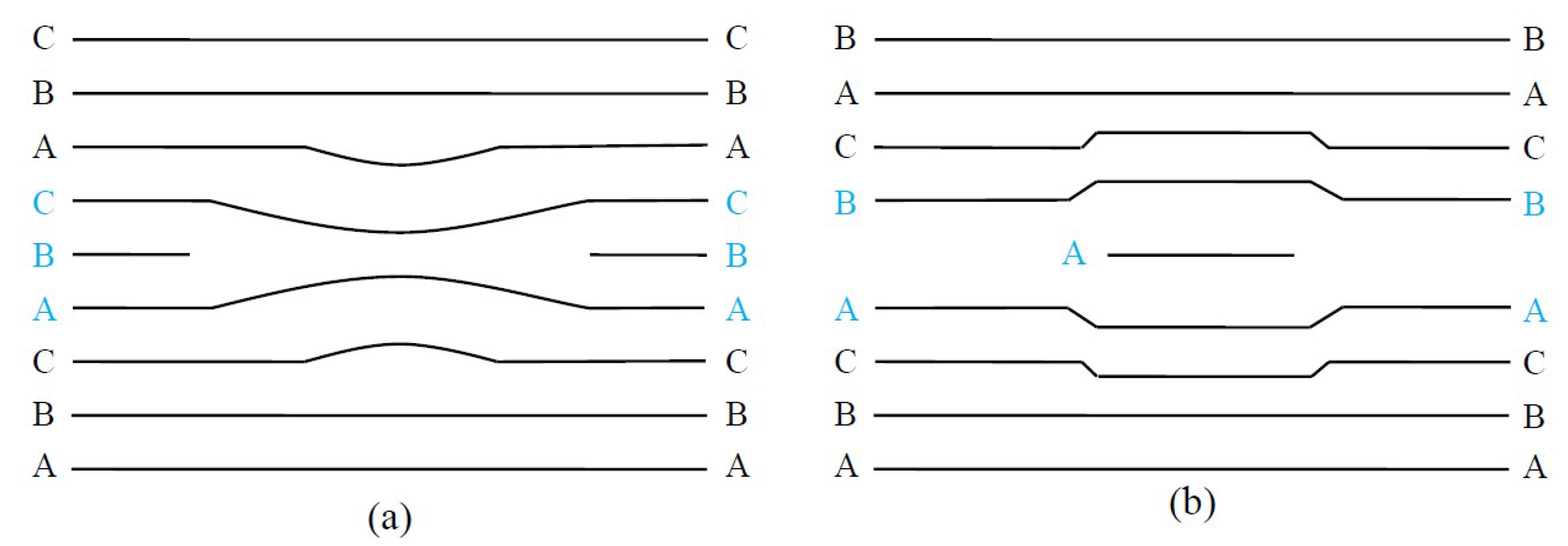

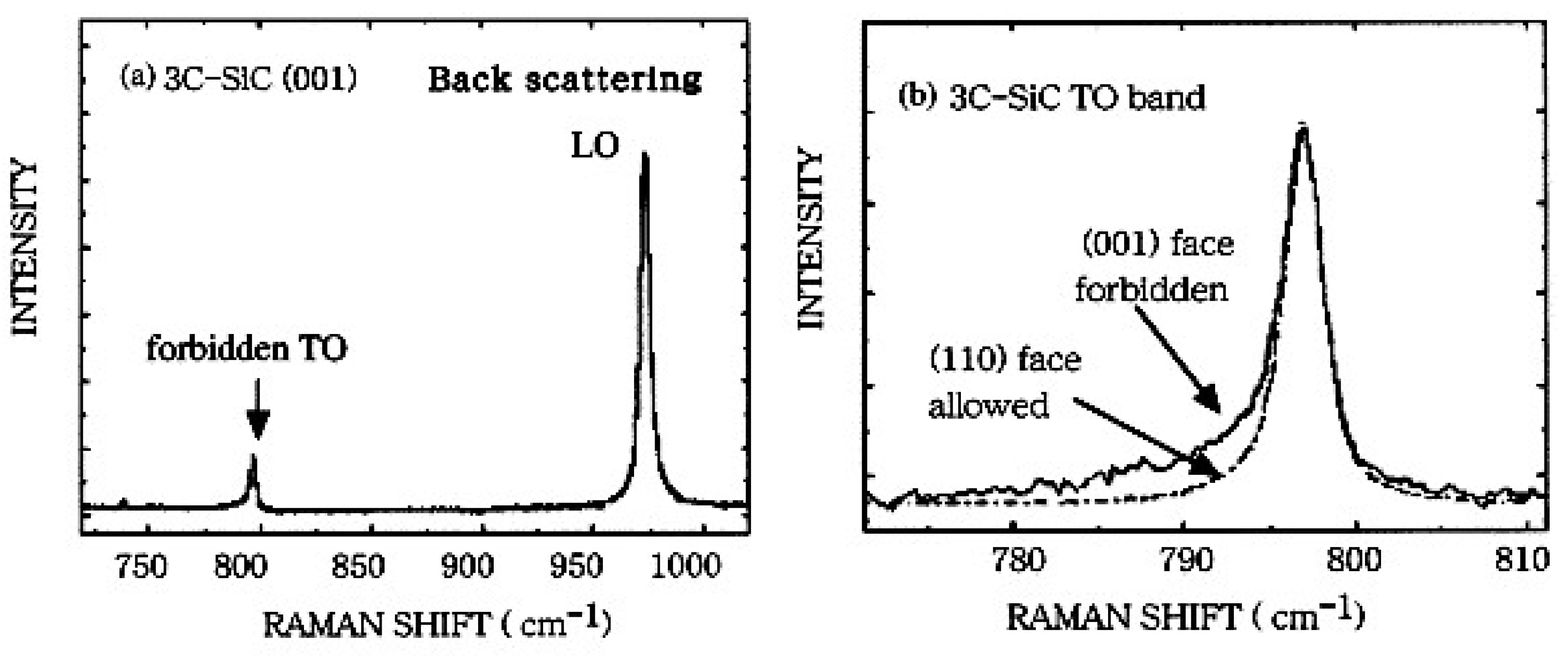

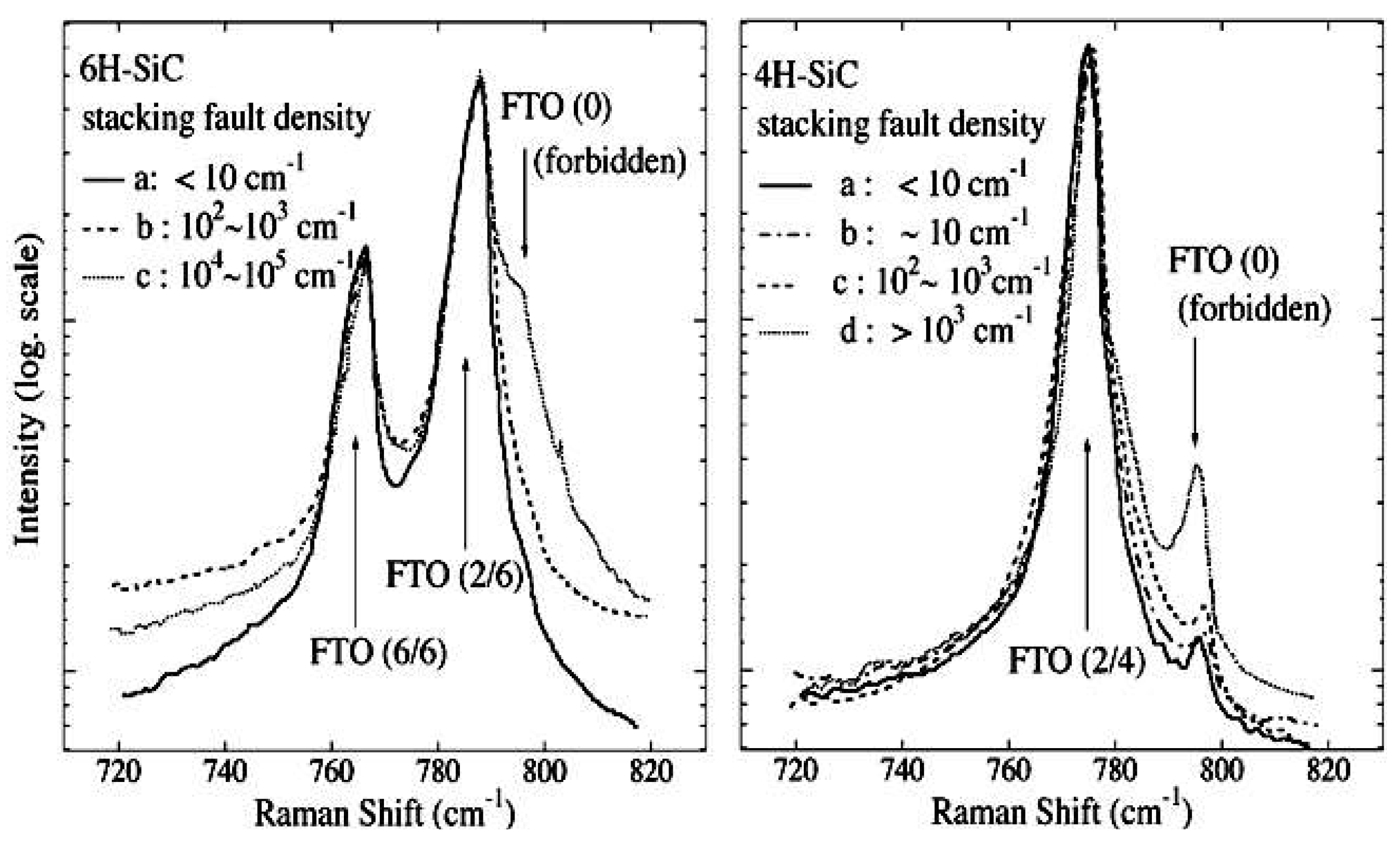

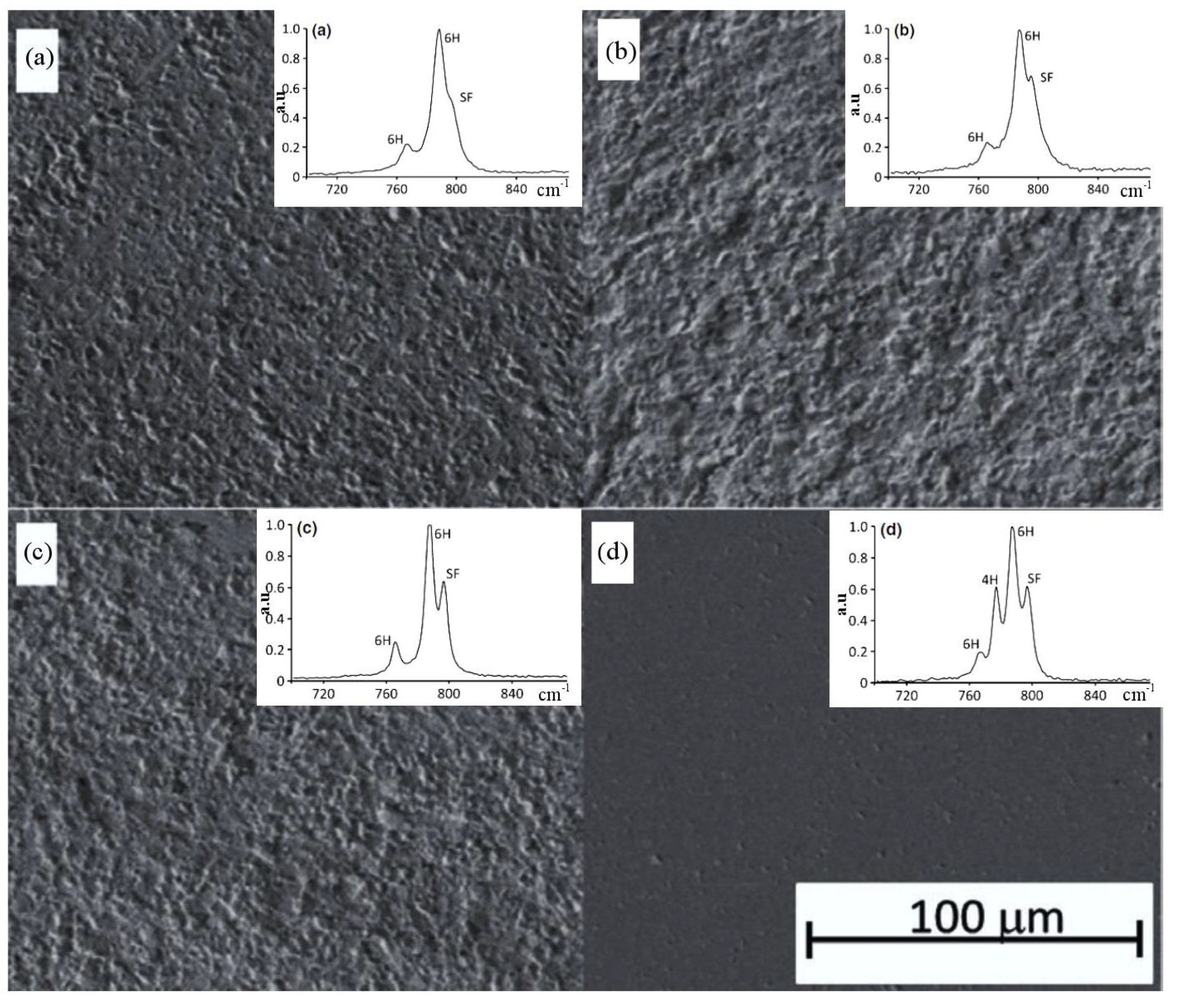

3.2. Stacking Faults Characterization

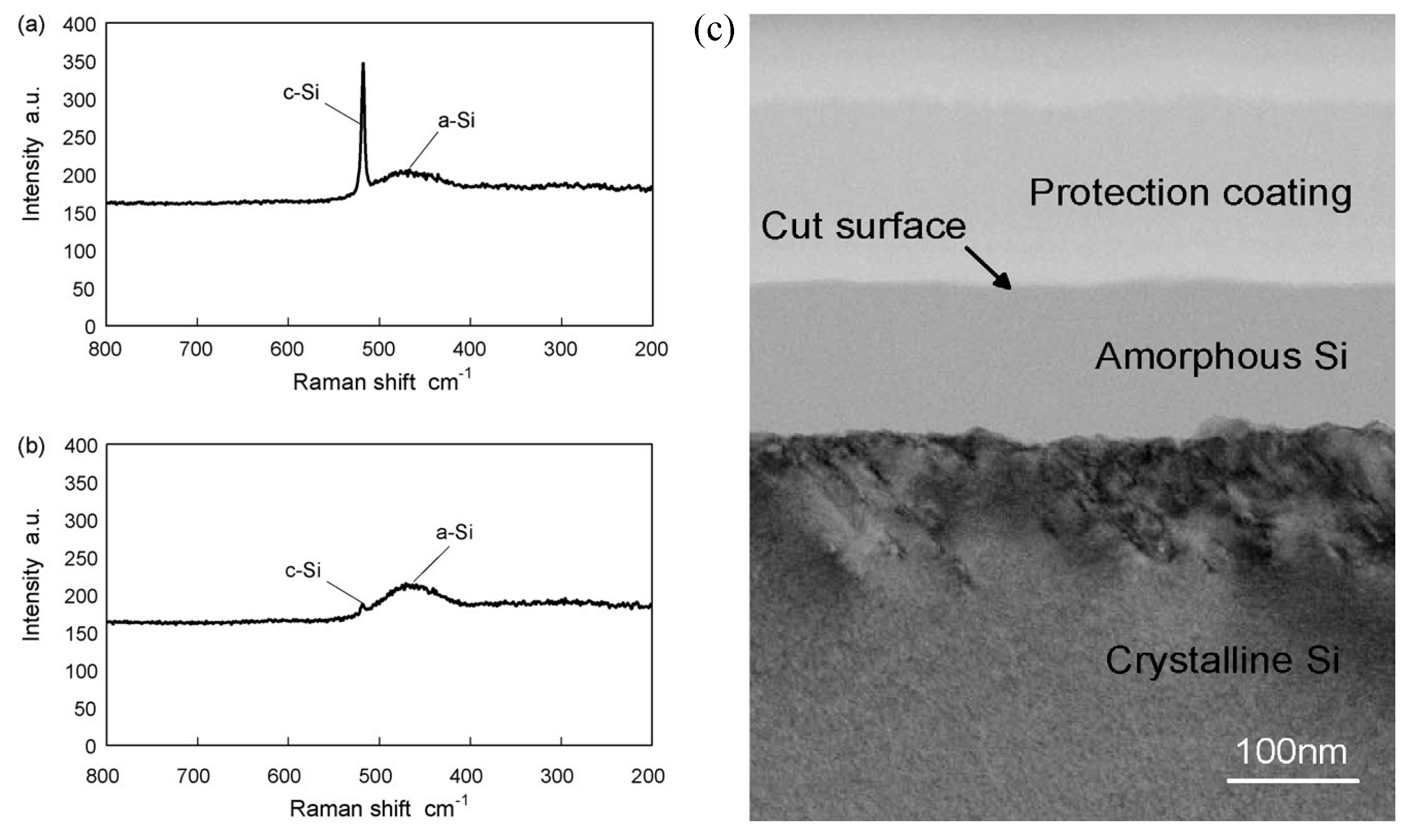

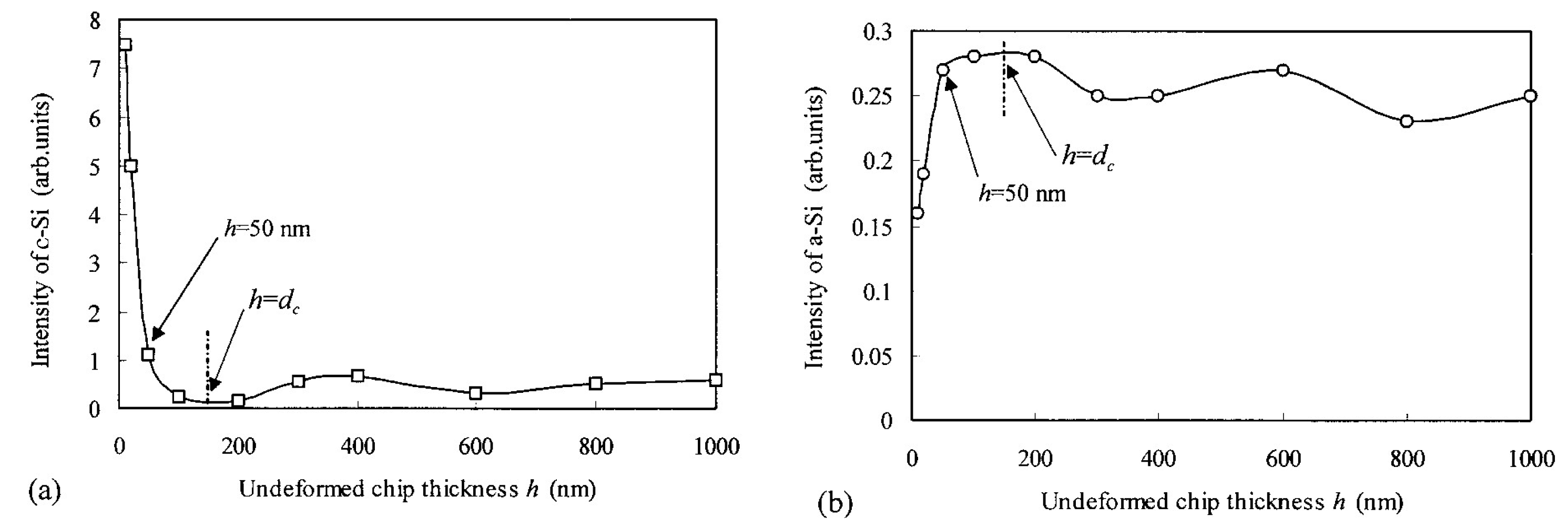

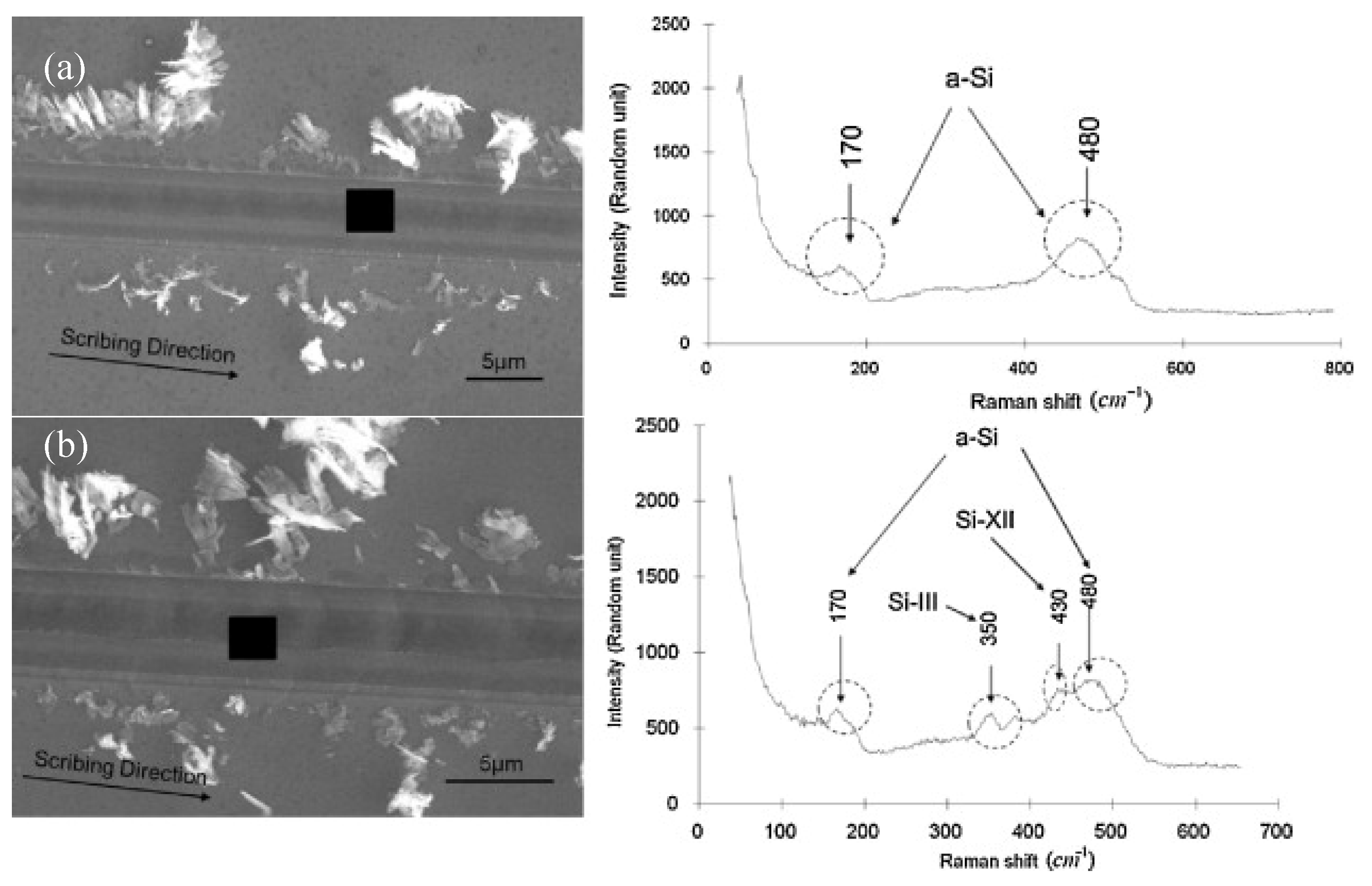

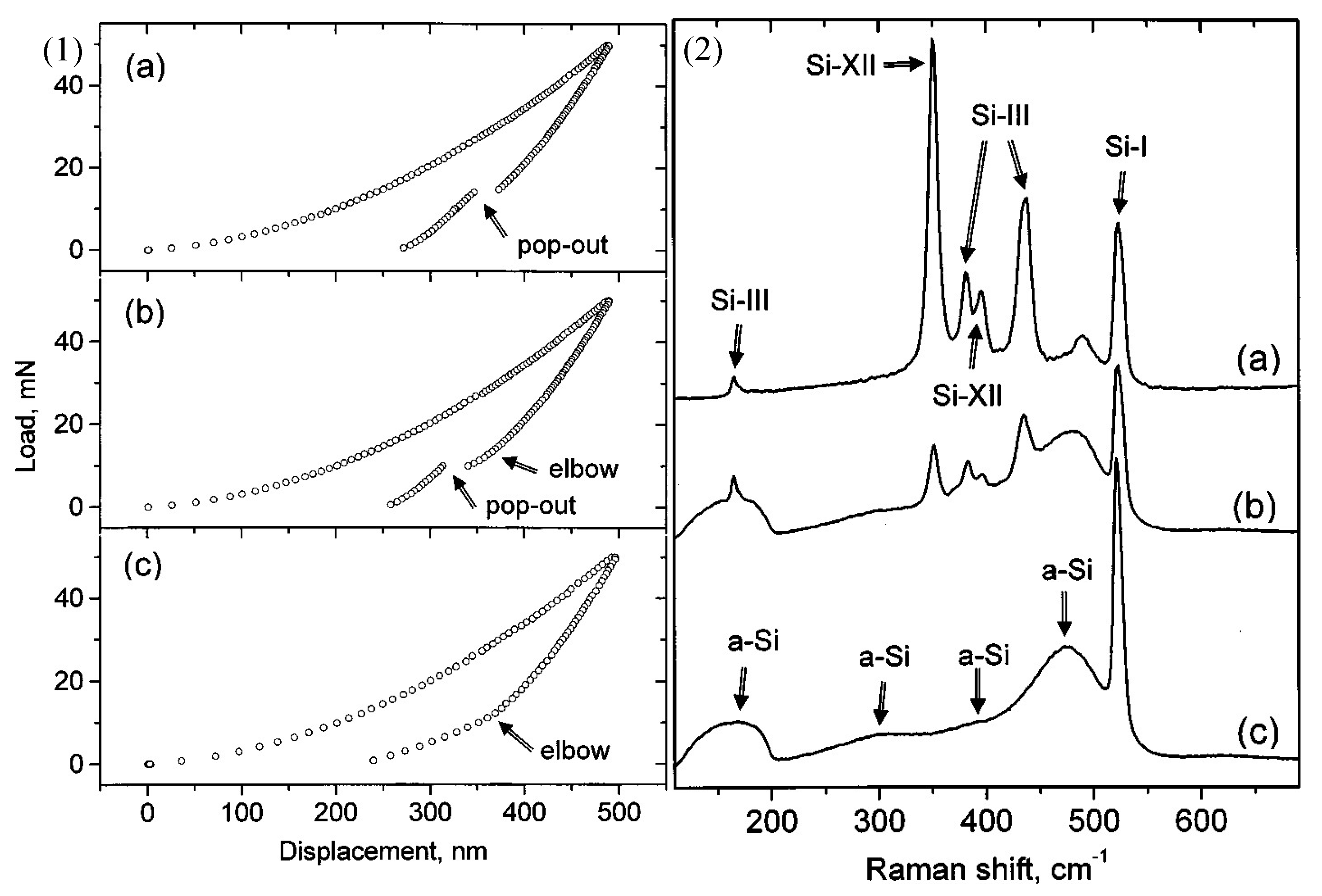

3.3. Phase Transformation Characterization

3.4. Residual Stress Analysis

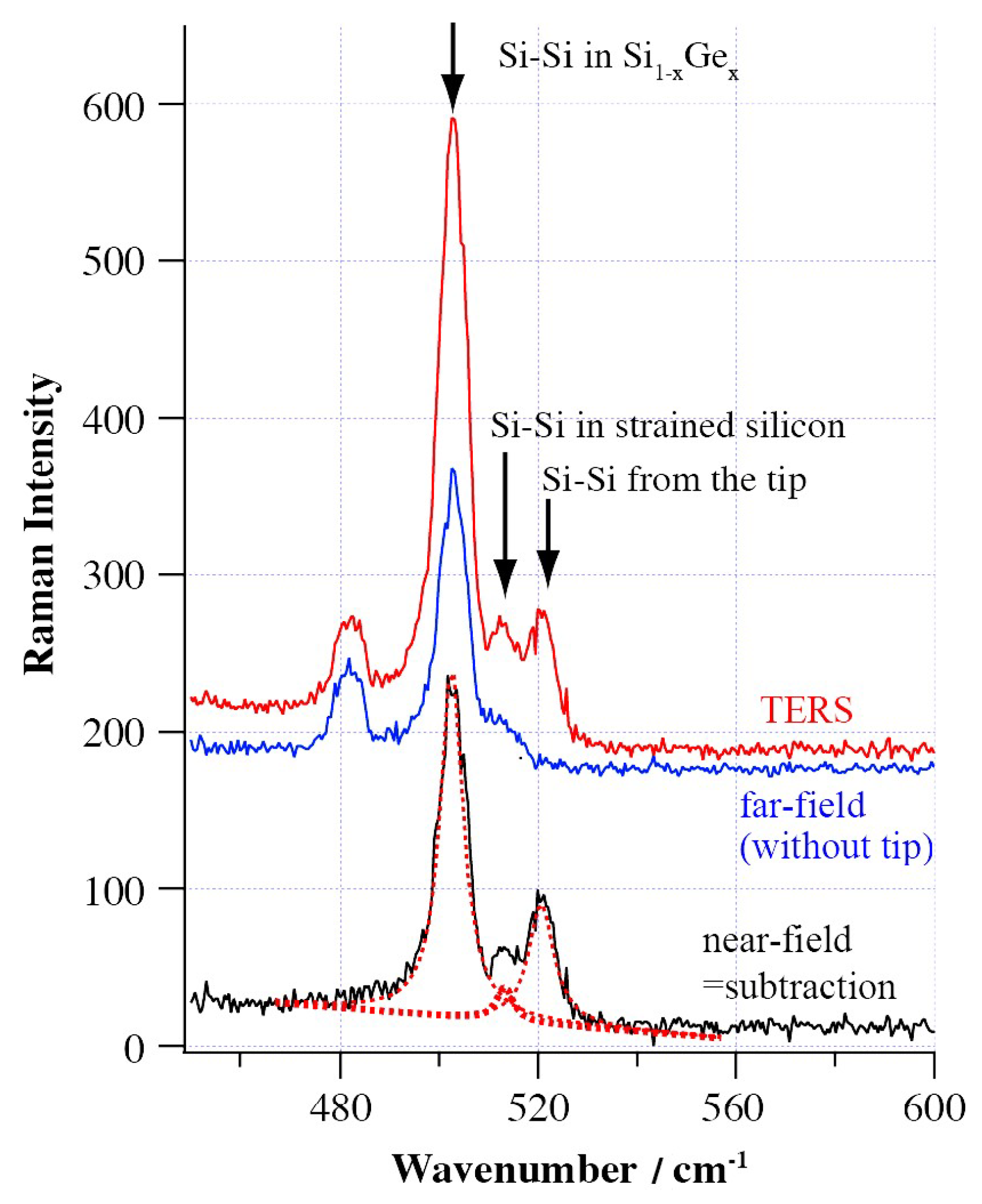

4. Future Prospects

5. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Msaoubi, R.; Outeiro, J.C.; Chandrasekaran, H.; Dillon, O.W., Jr.; Jawahir, I.S. A Review of surface integrity in machining and its impact on functional performance and life of machined products. Sustain. Manuf. 2008, 1, 203–236. [Google Scholar] [CrossRef]

- Novovic, D.; Dewes, R.C.; Aspinwall, D.K.; Voice, W.; Bowen, P. The effect of machined topography and integrity on fatigue life. Mach. Tools Manuf. 2004, 44, 125–134. [Google Scholar] [CrossRef]

- Hickey, D.P.; Jones, K.S.; Elliman, R.G. Amorphization and graphitization of single crystal diamond–A transmission electron microscopy study. Diam. Related Mater. 2009, 18, 1353–1359. [Google Scholar] [CrossRef]

- Yan, J.; Gai, X.; Harada, H. Subsurface damage of single crystalline silicon carbide in nanoindentation tests. J. Nanosci. Nanotechnol. 2010, 10, 7808–7811. [Google Scholar] [CrossRef] [PubMed]

- Meng, B.B.; Zhang, Y.; Zhang, F.H. Material removal mechanism of 6H-SiC studied by nano-scratching with Berkovich indenter. Appl. Phys. A 2016, 122, 247. [Google Scholar] [CrossRef]

- Tonshoff, H.K.; Schmieden, W.V.; Inasaki, I.; Konig, W.; Spur, G. Abrasive machining of silicon. Ann. CIRP 1990, 39, 621–630. [Google Scholar] [CrossRef]

- Xu, Z.W.; Fang, F.Z.; Fu, Y.Q.; Zhang, S.J.; Han, T.; Li, J.M. Fabrication of micro/nano-structures using focused ion beam implantation and XeF2 gas-assisted etching. Micromech. Microeng. 2009, 19, 054003. [Google Scholar] [CrossRef]

- Jeong, S.M.; Park, S.E.; Oh, H.S.; Lee, H.M. Fracture strength evaluation of semiconductor silicon wafering process induced damage. In Proceedings of the Fifteenth Annual Meeting of American Society for Precision Engineering, Scottsdale, AZ, USA, 22–27 October 2000; pp. 119–123. [Google Scholar]

- Bismayer, U.; Brinksmeier, E.; Guttler, B.; Seibt, H.; Menz, C. Measurement of subsurface damage in silicon wafers. Precis Eng. 1994, 16, 139–143. [Google Scholar] [CrossRef]

- Milita, S.; Tiec, Y.L.; Pernot, E.; Cioccio, L.D.; Hartwig, J.; Baruchel, J.; Servidori, M.; Letertre, F. X-ray diffraction imaging investigation of silicon carbide on insulator structures. Appl. Phys. A Mater. Sci. Process. 2002, 75, 621–627. [Google Scholar] [CrossRef]

- Buczkowski, A.; Orschel, B.; Kim, S.; Rouvimov, S.; Snegirev, B.; Fletcher, M.; Kirscht, F. Photoluminescence intensity analysis in application to contactless characterization of silicon wafers. Electrochem. Soc. 2003, 15, G436–G442. [Google Scholar] [CrossRef]

- Nevin, W.A.; Gay, D.L.; Higgs, V. Photoluminescence study of interfacial defects in direct-bonded silicon wafers. J. Electrochem. Soc. 2003, 150, G591–G596. [Google Scholar] [CrossRef]

- Goto, H.; Satio, H.; Isogai, M.; Fujimori, H.; Shirai, H.; Aiba, Y. Nondestructive depth determination of subsurface microdefects in silicon wafers. Electrochem. Solid-State Lett. 2001, 4, G107–G108. [Google Scholar] [CrossRef]

- Satio, H.; Goto, H.; Isogai, M.; Shirai, H.; Aiba, Y. Nondestructive observation of depth and dimension of subsurface microdefects in Cachralski-grown and epitaxial silicon wafers. Electrochem. Soc. 2002, 149, G494–G496. [Google Scholar]

- Lu, W.K.; Pei, Z.J.; Sun, J.G. Non-destructive evaluation methods for subsurface damage in silicon wafers: A literature review. Mach. Mach. Mater. 2007, 2, 125–142. [Google Scholar] [CrossRef]

- Harris, D.C.; Bertolucci, M.D. Symmetry and spectroscopy: An Introduction to Vibrational and Electronic Spectroscopy, 1st ed.; Oxford University Press: New York, NY, USA, 1978. [Google Scholar]

- Zingarelli, J.C. Detection of Residual Stress in SiC MEMS Using μ-Raman Spectroscopy. Master’s Thesis, Air University, Dayton, OH, USA, 2002. [Google Scholar]

- Loudon, R. The Raman effect in crystals. Adv. Phys. 2006, 13, 813–864. [Google Scholar]

- Gogotsi, Y.; Baek, C.; Kirscht, F. Raman microspectroscopy study of processing-induced phase transformations and residual stress in silicon. Semicond. Sci. Technol. 1999, 14, 936–944. [Google Scholar] [CrossRef]

- Das, R.S.; Agrawal, Y.K. Raman spectroscopy: Recent advancements, techniques and applications. Vib. Spectrosc. 2011, 57, 163–176. [Google Scholar] [CrossRef]

- Parker, S.F. A review of the theory of Fourier-transform Raman spectroscopy. Spectrochim. Acta Part A Mol. Spectrosc. 1994, 50, 1841–1856. [Google Scholar] [CrossRef]

- Xie, Y.F.; Xu, L.; Wang, Y.Q.; Shao, J.D.; Wang, L.; Wang, H.Y.; Qian, H.; Yao, W.R. Label-free detection of the foodborne pathogens of Enterobacteriaceae by surface-enhanced Raman spectroscopy. Anal. Methods 2013, 5, 946–952. [Google Scholar] [CrossRef]

- Chan, J.W.; Esposito, A.P.; Talley, C.E.; Hollars, C.W.; Lane, S.M.; Huser, T. Reagentless identification of single bacterial spores in aqueous solution by confocal laser tweezers Raman spectroscopy. Anal. Chem. 2004, 76, 599–603. [Google Scholar] [CrossRef] [PubMed]

- Cheng, J.X.; Volkmer, A.; Lewis, D.B.; Xie, X.S. Multiplex coherent anti-stokes Raman scattering microspectroscopy and study of lipid vesicles. Phys. Chem. B 2002, 106, 8493–8498. [Google Scholar] [CrossRef]

- Cardona, M. Light Scattering in Solid; Springer: Berlin, Germany, 1975; p. 79. ISBN 978-3-662-22095-5. [Google Scholar]

- Mercier, B. Density fluctuations measurement by rayleigh scattering using a single photomultiplier. AIAA J. 2018, 56, 1310–1316. [Google Scholar] [CrossRef]

- Raman Spectroscopy. Available online: https://en.wikipedia.org/wiki/Raman_spectroscopy (accessed on 13 June 2018).

- Smekal, A. Zur quantentheorie der dispersion. Naturwissenschaften 1923, 11, 873–875. [Google Scholar] [CrossRef]

- Raman, C.V.; Krishnan, K.S. A new type of secondary radiation. Nature 1928, 121, 501–502. [Google Scholar] [CrossRef]

- Wu, G.Z. Raman Spectroscopy: An Intensity Approach; Science Press: Beijing, China, 2016; ISBN 9787030475077. [Google Scholar]

- Gogotsi, Y.; Domnich, V. High-Pressure Surface Science and Engineering; IOP Publishing Ltd.: London, UK, 2004; pp. 349–365. ISBN 0-7503-0881-8. [Google Scholar]

- Otto, A.K.; Rechtsteiner, G.A.; Felix, C.; Hampe, O.; Jarrold, M.F.; Van Duyne, R.P. Raman spectra and calculated vibrational frequencies of size-selected C16, C18, and C20 clusters. Chem. Phys. 1998, 109, 9651–9655. [Google Scholar] [CrossRef]

- Tian, Z.Q.; Yang, Z.L.; Ren, B.; Li, J.F.; Zhang, Y.; Lin, X.F.; Hu, J.W.; Wu, D.Y. Surface-enhanced Raman scattering from transition metals with special surface morphology and nanoparticle shape. Faraday Discuss. 2006, 132, 159–170. [Google Scholar] [CrossRef] [PubMed]

- Kurouski, D.; Van Duyne, R.P. In situ detection and identification of hair dyes using surface-enhanced Raman spectroscopy (SERS). Anal. Chem. 2015, 87, 2901–2906. [Google Scholar] [CrossRef] [PubMed]

- Porter, M.D.; Lipert, R.J.; Siperko, L.M.; Wang, G.F.; Narayanan, R. SERS as a bioassay platform: Fundamentals, design, and applications. Chem. Soc. Rev. 2008, 37, 1001–1011. [Google Scholar] [CrossRef] [PubMed]

- Sharma, B.; Frontiera, R.R.; Henry, A.I. SERS: Materials, applications, and the future. Mater. Today 2012, 15, 16–25. [Google Scholar] [CrossRef]

- Wang, K.H.; Huang, M.Z.; Chen, J.; Lin, L.L.; Kong, L.L.; Liu, X.; Wang, H.; Lin, M.S. A “drop-wipe-test” SERS method for rapid detection of pesticide residues in fruits. Raman Spectrosc. 2018, 49, 493–498. [Google Scholar] [CrossRef]

- Chafai, M.; Jaouhari, A.; Torres, A.; Antón, R.; Martín, E.; Jiménez, J.; Mitchel, W.C. Raman scattering from LO phonon-plasmon coupled modes and Hall-effect in n-type silicon carbide 4H–SiC. J. Appl. Phys. 2001, 90, 5211–5215. [Google Scholar] [CrossRef]

- Zhang, M.K.; Huang, J.; Hong, R.D.; Chen, X.P.; Wu, Z.Y. Annealing effects on structural, optical and electrical properties of Al implanted 4H-SiC. In Proceedings of the 2009 IEEE International Conference of Electron Devices and Solid-State Circuits (EDSSC), Xi’an, China, 25–27 December 2009. [Google Scholar]

- Loudon, R.J. Theory of the resonance Raman effect in crystals. J. Physique 1965, 26, 677–683. [Google Scholar] [CrossRef]

- Morhange, J.F.; Beserman, R.; Balkanski, M. Raman study of the vibrational properties of implanted silicon. Phys. Status Solidi B 2010, 23, 383–391. [Google Scholar] [CrossRef]

- Takahashi, J.I.; Makino, T. Raman scattering measurement of silicon-on-insulator substrates formed by high-dose oxygen-ion implantation. J. Appl. Phys. 1988, 63, 87–91. [Google Scholar] [CrossRef]

- Wolf, I.D. Micro-Raman spectroscopy to study local mechanical stress in silicon integrated circuits. Semicond. Sci. Technol. 1996, 11, 139–154. [Google Scholar] [CrossRef]

- Aspnes, D.E.; Studna, A.A. Dielectric functions and optical parameters of Si, Ge, GaP, GaAs, GaSb, InP, InAs, and InSb from 1.5 to 6.0 eV. Phys. Rev. B 1983, 27, 985–1009. [Google Scholar] [CrossRef]

- Derst, C.W.G.; Bhatia, K.L.; Kratschmer, W.; Kalbitzer, S. Optical properties of SiC for crystalline/amorphous pattern fabrication. Appl. Phys. Lett. 1989, 54, 1722–1724. [Google Scholar] [CrossRef]

- Narayana, D.K.L.; Rao, S.V.; Rao, D.N. Spectroscopic investigation of fs laser-induced defects in polymer and crystal media. SPIE Laser Damage 2012, 8530, 853004. [Google Scholar]

- Nakashima, S.; Harima, H. Characterization of defects in SiC crystals by Raman scattering. In Silicon Carbide; Springer: Berlin, Germany, 2004; pp. 585–605. [Google Scholar]

- Nakashima, S.; Tahara, K. Wave-vector dependence of Raman scattering intensity in folded modes of long-period α-SiC. Phys. Rev. B 1989, 40, 6345–6350. [Google Scholar] [CrossRef]

- Nakashima, S.; Hangyo, M. Raman intensity profiles and the stacking structure in SiC polytypes. Solid State Commun. 1991, 80, 21–24. [Google Scholar] [CrossRef]

- Amimoto, S.T.; Chang, D.J.; Birkitt, A.D. Stress Measurement in MEMS Using Raman Spectroscopy. In Proceedings of the SPIE on Micromachining and Microfabrication, Santa Clara, CA, USA, 21–22 September 1998; Volume 3512, pp. 123–129. [Google Scholar]

- Yan, J.W. Laser micro-Raman spectroscopy of single-point diamond machined silicon substrates. J. Appl. Phys. 2004, 95, 2094–2101. [Google Scholar] [CrossRef]

- Yan, J.W.; Asami, T.; Kuriyagawa, T. Nondestructive measurement of machining-induced amorphous layers in single-crystal silicon by laser micro-Raman spectroscopy. Precis. Eng. 2008, 32, 186–195. [Google Scholar] [CrossRef]

- Sze, S.M. Semiconductor Devices: Physics and Technology, 2nd ed.; John Wiley & Sons: Hoboken, NJ, USA, 2002; pp. 349–351. ISBN 0-471-33372-7. [Google Scholar]

- Käckell, P.; Furthmüller, J.; Bechstedt, F. Stacking faults in group-IV crystals: An ab initio study. Phys. Rev. B 1998, 58, 1326–1330. [Google Scholar]

- Nakashima, S.; Nakatake, Y.; Ishida, Y.; Takahashi, T.; Okumura, H. Sensitive detection of defects in α and β SiC by Raman scattering. Mater. Sci. Forum 2002, 389–393, 629–632. [Google Scholar] [CrossRef]

- Mitani, T.; Nakashima, S.; Okumura, H.; Nagasawa, H. Raman scattering analyses of stacking faults in 3C-SiC crystals. Mater. Sci. Forum 2006, 527–529, 343–346. [Google Scholar] [CrossRef]

- Takahashi, J.; Ohtani, N.; Katsuno, M.; Shinoyama, S. Sublimation growth of 6H- and 4H-SiC single crystals in the [11¯0 0] and [112¯0] directions. J. Cryst. Growth 1997, 181, 229–240. [Google Scholar] [CrossRef]

- Zhang, Y.; Ishimaru, M.; Varga, T.; Oda, T.; Hardiman, C. Nanoscale engineering of radiation tolerant silicon carbide. Phys. Chem. Chem. Phys. 2012, 14, 13429–13436. [Google Scholar]

- Ashraf, H. Investigation of Symmetries of Phonons in 4H and 6H-SiC by Infrared Absorption and Raman Spectroscopy. Master’s Thesis, Institute of Technology Linköping University, Linköping, Sweden, 2005. [Google Scholar]

- Schrader, B. Infrared and Raman Spectroscopy: Methods and Applications; Wiley-VCH: Weinheim, Germany, 1995; pp. 7–50. ISBN 3-527-26446-9. [Google Scholar]

- Nakashima, S.; Nakatake, Y.; Ishida, Y.; Talkahashi, T.; Okumura, H. Detection of defects in SiC crystalline films by Raman scattering. Physica B 2001, 308, 684–686. [Google Scholar] [CrossRef]

- Feldman, D.W.; Parker, J.H.; Choyke, W.J.; Patrick, L. Raman scattering in 6H-SiC. Phys. Rev. 1968, 170, 698–704. [Google Scholar] [CrossRef]

- Feldman, D.W.; Parker, J.H.; Choyke, W.J.; Patrick, L. Phonon dispersion curves by Raman scattering in SiC polytypes 3C, 4H, 6H, 15R and 21R. Phys. Rev. 1968, 173, 787–793. [Google Scholar] [CrossRef]

- Nakashima, S.; Nakatake, Y.; Harima, H.; Katsuno, M. Detection of stacking faults in 6H-SiC by Raman scattering. Appl. Phys. Lett. 2000, 77, 3612–3614. [Google Scholar] [CrossRef]

- Nakashima, S.; Ohta, H.; Hangyo, M.; Palosz, B. Phonon Raman scattering in disordered silicon carbides. Philos. Mag. B 1994, 70, 971–985. [Google Scholar] [CrossRef]

- Rohmfeld, S.; Hundhausen, M.; Ley, L. Raman scattering in polycrystalline 3C-SiC: Influence of stacking faults. Phys. Rev. B 1998, 58, 9858–9862. [Google Scholar] [CrossRef]

- Fang, F.Z.; Wu, H.; Zhou, W.; Hu, X.T. A study on mechanism of nano-cutting single crystal silicon. J. Mater. Process. Technol. 2007, 184, 407–410. [Google Scholar] [CrossRef]

- Stumpf, F.; Quba, A.A.A.; Singer, P.; Rumler, M.; Cherkashin, N.; Schamm-Chardon, S.; Cours, R.; Rommel, M. Detailed characterisation of focused ion beam induced lateral damage on silicon carbide samples by electrical scanning probe microscopy and transmission electron microscopy. J. Appl. Phys. 2018, 123, 125104. [Google Scholar] [CrossRef]

- Richter, H.; Wang, Z.P.; Ley, L. The one phonon Raman spectrum in microcrystalline silicon. Solid State Commun. 1981, 39, 625–629. [Google Scholar] [CrossRef]

- Zwick, A.; Carles, R. Multiple-order Raman scattering in crystalline and amorphous silicon. Phys. Rev. B 1993, 48, 6024. [Google Scholar] [CrossRef]

- Pizani, P.S.; Jasinevicius, R.; Duduch, J.G.; Porto, A.J.V. Ductile and brittle modes in single-point-diamond-turning of silicon probed by Raman scattering. J. Mater. Sci. Lett. 1999, 18, 1185–1187. [Google Scholar] [CrossRef]

- Goel, S.; Luo, X.C.; Agrawal, A.; Reuben, R.L. Diamond machining of silicon: A review of advances in molecular dynamics simulation. Int. J. Mach. Tools Manuf. 2015, 88, 131–164. [Google Scholar] [CrossRef]

- Kim, D.; Oh, S. Atomistic simulation of structural phase transformations in monocrystalline silicon induced by nanoindentation. Nanotechnology 2006, 17, 2259–2265. [Google Scholar] [CrossRef]

- Wu, H.; Melkote, S.N. Effect of crystallographic orientation on ductile scribing of crystalline silicon: Role of phase transformation and slip. Mater. Sci. Eng. A 2012, 549, 200–205. [Google Scholar] [CrossRef]

- Gogotsi, Y.; Zhou, G.; Ku, S.S.; Cetinkunt, S. Raman microspectroscopy analysis of pressure-induced metallization in scratching of silicon. Semicond. Sci. Technol. 2001, 16, 345–352. [Google Scholar] [CrossRef]

- Domnich, V.; Gogotsi, Y.; Dub, S. Effect of phase transformations on the shape of the unloading curve in the nanoindentation of silicon. Appl. Phys. Lett. 2000, 76, 2214–2216. [Google Scholar] [CrossRef]

- Fang, F.Z.; Wu, H.; Liu, Y.C. Modelling and experimental investigation on nanometric cutting of monocrystalline silicon. Int. J. Mach. Tools Manuf. 2005, 45, 1681–1686. [Google Scholar] [CrossRef]

- Cai, M.B.; Li, X.P.; Rahman, M. High-pressure phase transformation as the mechanism of ductile chip formation in nanoscale cutting of silicon wafer. Proc. Inst. Mech. Eng. B J. Eng. Manuf. 2007, 221, 1511–1519. [Google Scholar] [CrossRef]

- Cheong, W.C.D.; Zhang, L.C. Molecular dynamics simulation of phase transformations in silicon monocrystals due to nano-indentation. Nanotechnology 2000, 11, 173–180. [Google Scholar] [CrossRef]

- Groth, B.; Haber, R.; Mann, A. Raman micro-spectroscopy of polytype and structural changes in 6H-silicon carbide due to machining. Int. J. Appl. Ceram. Technol. 2015, 12, 795–804. [Google Scholar] [CrossRef]

- Nakashima, S.; Mitani, T.; Tomobe, M.; Kato, T.; Okumura, H. Raman characterization of damaged layers of 4H-SiC induced by scratching. Aip Adv. 2016, 6, 015207. [Google Scholar] [CrossRef]

- Ovsyannikov, S.V.; Shchennikov, V.V., Jr.; Shchennikov, V.V.; Ponosov, Y.S.; Antonova, I.V.; Smirnov, S.V. Raman characterization of hydrogen ion implanted silicon: “High-dose effect”? Physica B Condens. Matter 2008, 403, 3424–3428. [Google Scholar] [CrossRef]

- Feng, Z.C.; Lien, S.C.; Zhao, J.H.; Sun, X.W.; Lu, W. Structural and optical studies on ion-implanted 6H–SiC thin films. Thin Solid Films 2008, 516, 5217–5222. [Google Scholar] [CrossRef]

- Digregorio, J.F.; Furtak, T.E.; Petrovic, J.J. A technique for measuring residual stress in SiC whiskers within an alumina matrix through Raman spectroscopy. J. Appl. Phys. 1992, 71, 3524–3531. [Google Scholar] [CrossRef]

- Anastassakis, E.; Pinczuk, A.; Burstein, E.; Pollak, F.H.; Cardona, M. Effect of static uniaxial stress on the Raman spectrum of silicon. Solid State Commun. 1970, 8, 133–138. [Google Scholar] [CrossRef]

- Ganesan, S.; Maradudin, A.A.; Oitmaa, J. A lattice theory of morphic effects in crystals of the diamond structure. Ann. Phys.-N. Y. 1970, 56, 556–594. [Google Scholar] [CrossRef]

- Weinstein, B.A.; Piermarini, G.J. Raman scattering and phonon dispersion in Si and GaP at very high pressure. Phys. Rev. B 1975, 12, 1172–1186. [Google Scholar] [CrossRef]

- Liu, J.; Vohra, Y.K. Raman modes of 6H polytype of silicon carbide to ultrahigh pressures: A comparison with silicon and diamond. Phys. Rev Lett. 1994, 72, 4105–4108. [Google Scholar] [CrossRef] [PubMed]

- Zingarelli, J.C.; Marciniak, M.A.; Foley, J.R. Detection of Residual Stress in Silicon Carbide MEMS by μ-Raman Spectroscopy. Available online: https://www.cambridge.org/core/journals/mrs-online-proceedings-library-archive/article/detection-of-residual-stress-in-silicon-carbide-mems-by-raman-spectroscopy/35751FB9C6B7C09B2A9CCBBFE25F033D (accessed on 13 June 2018).

- Digregorio, J.F.; Furtak, T.E. Analysis of residual stress in 6H-SiC particles within Al2O3/SiC composites through Raman spectroscopy. J. Am. Ceram. Soc. 2010, 75, 1854–1857. [Google Scholar] [CrossRef]

- Rohmfeld, S.; Hundhausen, M.; Ley, L.; Zorman, C.A.; Mehregany, M. Quantitative evaluation of biaxial strain in epitaxial 3C-SiC layers on Si (100) substrates by Raman spectroscopy. J. Appl. Phys. 2002, 91, 1113–1117. [Google Scholar] [CrossRef]

- Sciti, D.; Guicciardi, S.; Celotti, G.; Deluca, M.; Pezzotti, G. Residual stress investigation in SiC/MoSi2(p) composites. Adv. Eng. Mater. 2010, 9, 393–399. [Google Scholar] [CrossRef]

- Stadelmann, R.; Lugovy, M.; Orlovskaya, N.; Mchaffey, P.; Radovic, M.; Sglavo, V.M.; Grasso, S.; Reece, M.J. Mechanical properties and residual stresses in ZrB2–SiC spark plasmasintered ceramic composites. J. Eur. Ceram. Soc. 2016, 36, 1527–1537. [Google Scholar] [CrossRef]

- Wing, B.L.; Esmonde-White, F.; Halloran, J.W. Microstress in reaction-bonded SiC from crystallization expansion of silicon. J. Am. Ceram. Soc. 2016, 99, 3705–3711. [Google Scholar] [CrossRef]

- Wing, B.L.; Halloran, J.W. Microstress in the matrix of a melt-infiltrated SiC/SiC ceramic matrix composite. J. Am. Ceram. Soc. 2017, 100, 5286–5294. [Google Scholar] [CrossRef]

- Zhu, W.L.; Zhu, J.L.; Nishino, S.; Pezzotti, G. Spatially resolved Raman spectroscopy evaluation of residual stresses in 3C-SiC layer deposited on Si substrates with different crystallographic orientations. Appl. Surf. Sci. 2006, 252, 2346–2354. [Google Scholar] [CrossRef]

- Jasinevicius, R.G.; Duduch, J.G.; Montanari, L.; Pizani, P.S. Phase transformation and residual stress probed by Raman spectroscopy in diamond-turned single crystal silicon. Proc. Inst. Mech. Eng. B J. Eng. Manuf. 2008, 222, 1065–1073. [Google Scholar] [CrossRef]

- Amer, M.S.; El-Ashry, M.A.; Dosser, L.R.; Hix, K.E.; Maguire, J.F.; Irwin, B. Femtosecond versus nanosecond laser machining: Comparison of induced stresses and structural changes in silicon wafers. Appl. Surf. Sci. 2005, 242, 162–167. [Google Scholar] [CrossRef]

- Wasyluk, J.; Adley, D.; Perova, T.S.; Rodin, A.M.; Callaghan, J.; Brennan, N. Micro-Raman investigation of stress distribution in laser drilled via structures. Appl. Surf. Sci. 2009, 255, 5546–5548. [Google Scholar] [CrossRef]

- Pelletier, M.J. Analytical Applications of Raman Spectroscopy; Blackwell Science: Oxford, UK, 1999; pp. 53–105. ISBN 0-6320-5305-4. [Google Scholar]

- Kollins, K.; Przybyla, C.; Amer, M.S. Residual stress measurements in melt infiltrated SiC/SiC ceramic matrix composites using Raman spectroscopy. J. Eur. Ceram. Soc. 2018, 38, 2784–2791. [Google Scholar] [CrossRef]

- Bailo, E.; Deckert, V. Tip-enhanced Raman scattering. Chem. Soc. Rev. 2008, 37, 921–930. [Google Scholar] [CrossRef] [PubMed]

- Li, L.Q.; Liu, K.P.; Suen, B.; Liu, Q.K.; King, A.; Talke, F.E. Numerical and experimental study of near-field heating using tip-enhanced Raman spectroscopy (TERS). Tribol. Lett. 2018, 66, 26. [Google Scholar] [CrossRef]

- Pozzi, E.A.; Goubert, G.; Chiang, N.; Jiang, N.; Chapman, C.T.; McAnally, M.O.; Henry, A.; Seideman, T.; Schatz, G.C.; Hersam, M.C.; et al. Ultrahigh-vacuum tip-enhanced raman spectroscopy. Chem. Rev. 2017, 117, 4961–4982. [Google Scholar] [CrossRef] [PubMed]

- Hayazawa, N.; Motohashi, M.; Saito, Y.; Ishitobi, H.; Ono, A.; Ichimura, T.; Verma, P.; Kawata, S. Visualization of localized strain of a crystalline thin layer at the nanoscale by tip-enhanced Raman spectroscopy and microscopy. J. Raman Spectrosc. 2007, 38, 684–696. [Google Scholar] [CrossRef]

- Zhu, L.; Georgi, C.; Hecker, M.; Rinderknecht, J. Nano-Raman spectroscopy with metallized atomic force microscopy tips on strained silicon structures. J. Appl. Phys. 2007, 101, 104305. [Google Scholar] [CrossRef]

| Category | 457.9 nm | 488.0 nm | 514.5 nm | 532.0 nm | 638.0 nm | |||||

| 2.710 eV | 2.542 eV | 2.410 eV | 2.332 eV | 1.945 eV | ||||||

| 10−3α | dp | 10−3α | dp | 10−3α | dp | 10−3α | dp | 10−3α | dp | |

| Si | 36.69 | 313 | 20.72 | 555 | 15.03 | 765 | 12.30 | 935 | 3.74 | 3072 |

| Ge | 613.71 | 19 | 606.03 | 19 | 597.95 | 19 | 558.55 | 21 | 152.73 | 75 |

| GaP | 10.11 | 1137 | 2.18 | 5275 | 0.94 | 12273 | 0.52 | 22115 | 0 | - |

| GaAs | 199.61 | 58 | 124.46 | 92 | 92.48 | 124 | 79.61 | 144 | 38.20 | 301 |

| GaSb | 605.83 | 19 | 588.26 | 20 | 487.41 | 24 | 436.25 | 26 | 213.52 | 54 |

| InP | 186.49 | 62 | 139.28 | 83 | 113.08 | 102 | 101.49 | 113 | 59.99 | 192 |

| InAs | 559.15 | 21 | 471.20 | 24 | 326.14 | 35 | 256.93 | 45 | 118.38 | 97 |

| InSb | 570.78 | 20 | 563.85 | 20 | 556.95 | 21 | 504.57 | 23 | 360.12 | 32 |

| Wavelength (nm) | hυ (eV) | Single Crystal SiC | Amorphous SiC | ||

|---|---|---|---|---|---|

| α | dp | α | dp | ||

| 207 | 5.994 | 1.5 × 106 | 8 | 1.5 × 106 | 8 |

| 225 | 5.515 | 3.0 × 105 | 38 | 1.5 × 106 | 8 |

| 248 | 5.003 | 6.0 × 104 | 192 | 1.2 × 106 | 10 |

| 276 | 4.496 | 2.0 × 104 | 575 | 1.0 × 106 | 12 |

| 310 | 4.003 | 4.0 × 103 | 2.875 × 103 | 8.0 × 105 | 14 |

| 354 | 3.505 | 1.6 × 103 | 7.188 × 103 | 5.0 × 105 | 23 |

| 413 | 3.004 | 30 | 3.833 × 105 | 4.0 × 105 | 29 |

| 496 | 2.502 | 15 | 7.667 × 105 | 3.0 × 105 | 38 |

| 620 | 2.001 | 8.0 | 1.438 × 106 | 1.6 × 105 | 72 |

| 827 | 1.500 | 5.0 | 2.300 × 106 | 5.0 × 104 | 230 |

| 1240 | 1.001 | 5.0 | 2.300 × 106 | 4.0 × 104 | 288 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, Z.; He, Z.; Song, Y.; Fu, X.; Rommel, M.; Luo, X.; Hartmaier, A.; Zhang, J.; Fang, F. Topic Review: Application of Raman Spectroscopy Characterization in Micro/Nano-Machining. Micromachines 2018, 9, 361. https://doi.org/10.3390/mi9070361

Xu Z, He Z, Song Y, Fu X, Rommel M, Luo X, Hartmaier A, Zhang J, Fang F. Topic Review: Application of Raman Spectroscopy Characterization in Micro/Nano-Machining. Micromachines. 2018; 9(7):361. https://doi.org/10.3390/mi9070361

Chicago/Turabian StyleXu, Zongwei, Zhongdu He, Ying Song, Xiu Fu, Mathias Rommel, Xichun Luo, Alexander Hartmaier, Junjie Zhang, and Fengzhou Fang. 2018. "Topic Review: Application of Raman Spectroscopy Characterization in Micro/Nano-Machining" Micromachines 9, no. 7: 361. https://doi.org/10.3390/mi9070361

APA StyleXu, Z., He, Z., Song, Y., Fu, X., Rommel, M., Luo, X., Hartmaier, A., Zhang, J., & Fang, F. (2018). Topic Review: Application of Raman Spectroscopy Characterization in Micro/Nano-Machining. Micromachines, 9(7), 361. https://doi.org/10.3390/mi9070361