Analysis of Shape Geometry and Roughness of Ti6Al4V Parts Fabricated by Nanosecond Laser Ablation

Abstract

1. Introduction

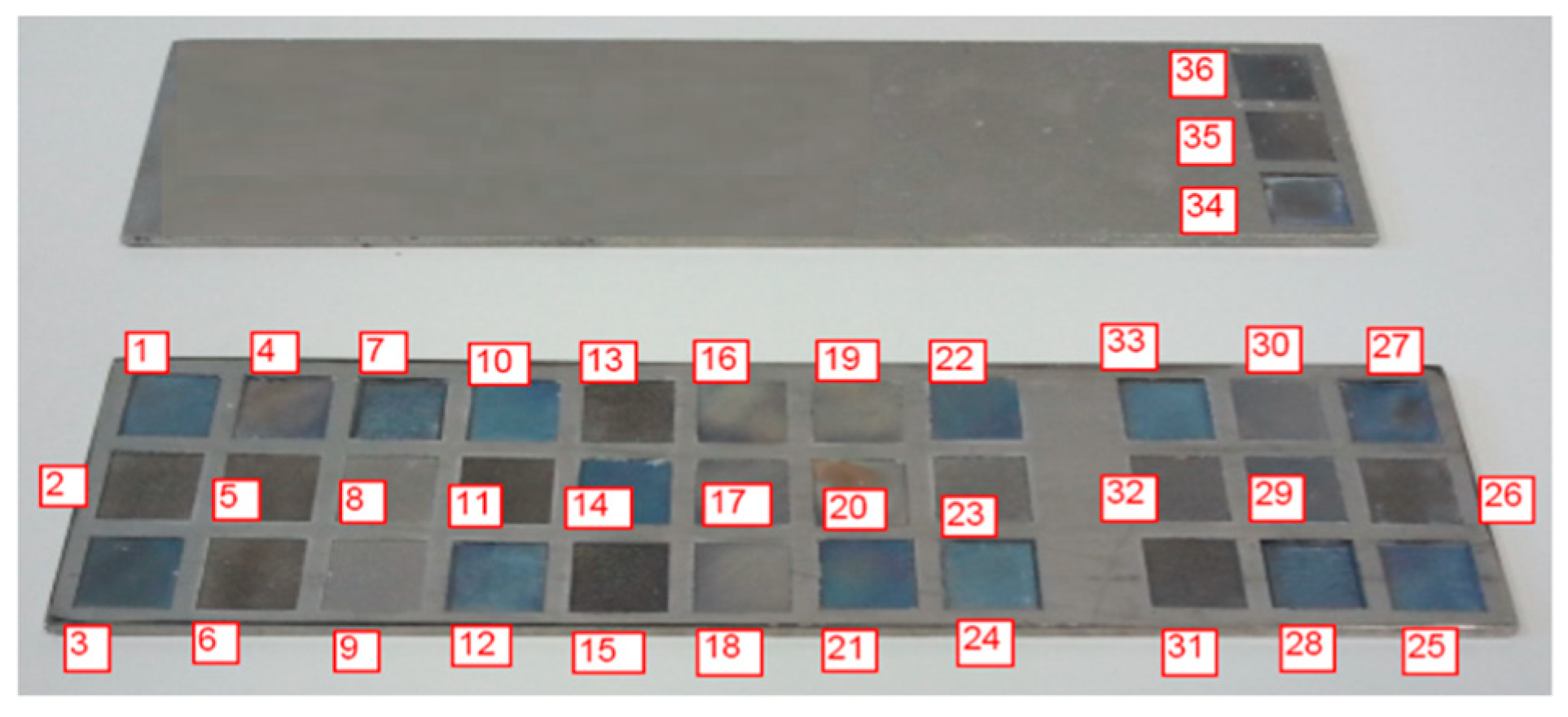

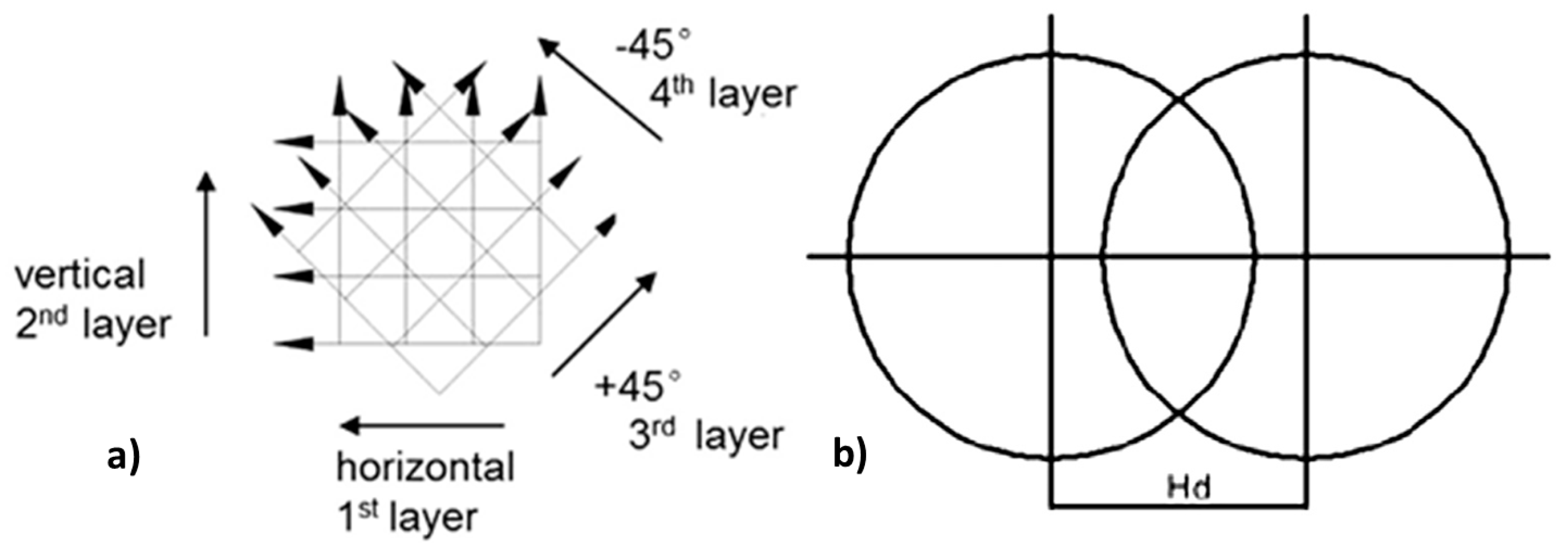

2. Materials and Methods

2.1. Laser Machine Setup and Materials

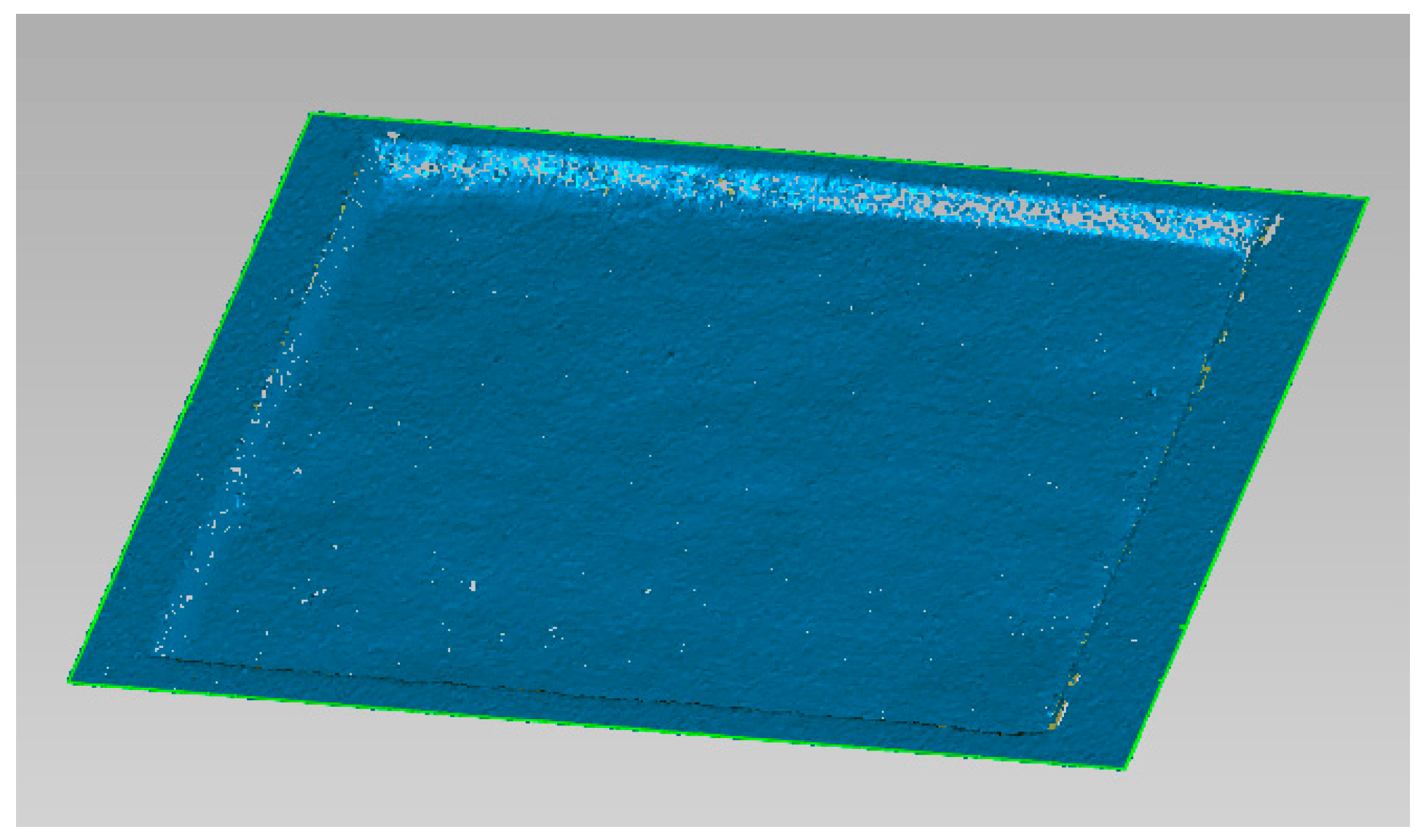

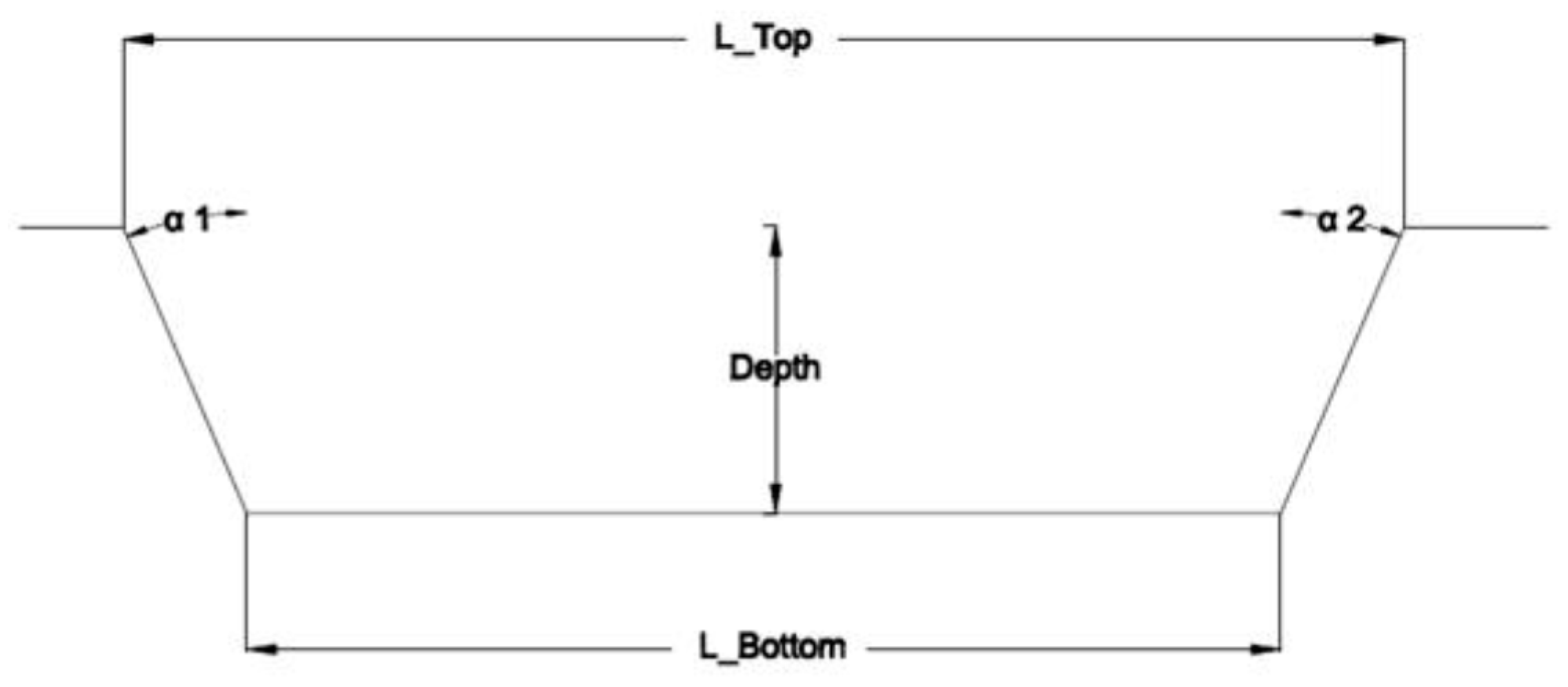

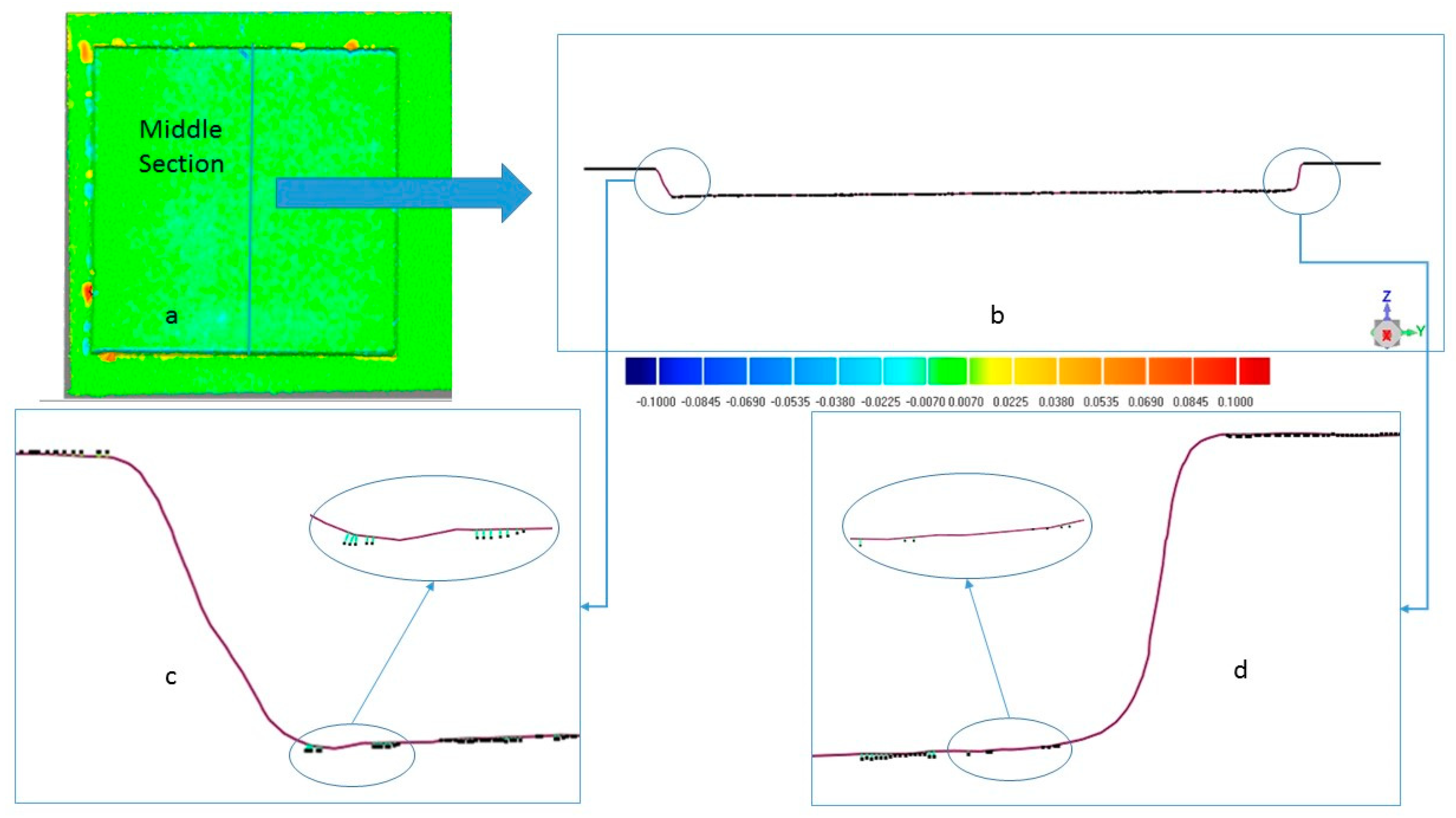

2.2. Dimensional Measurements

3. Results

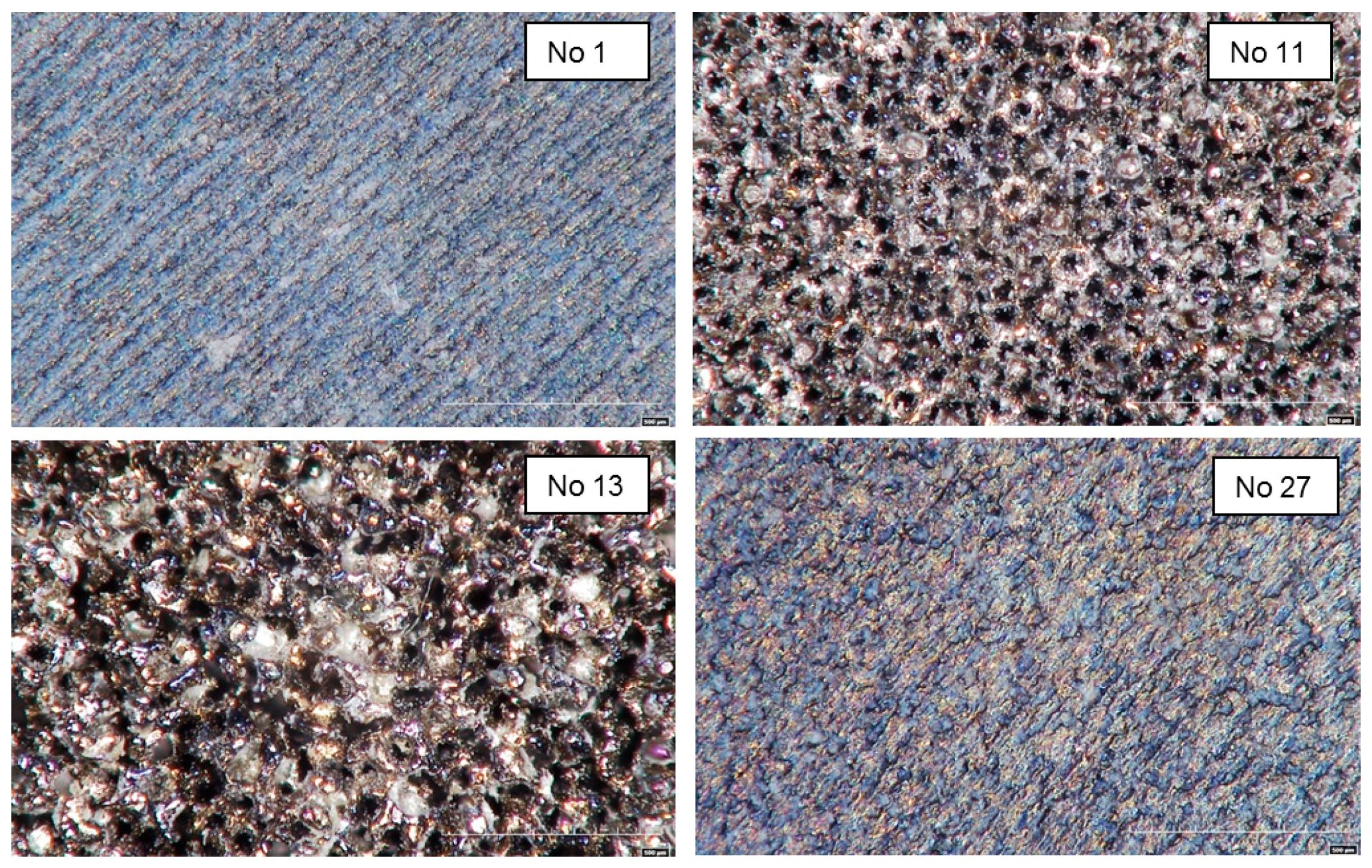

3.1. Measurement Results

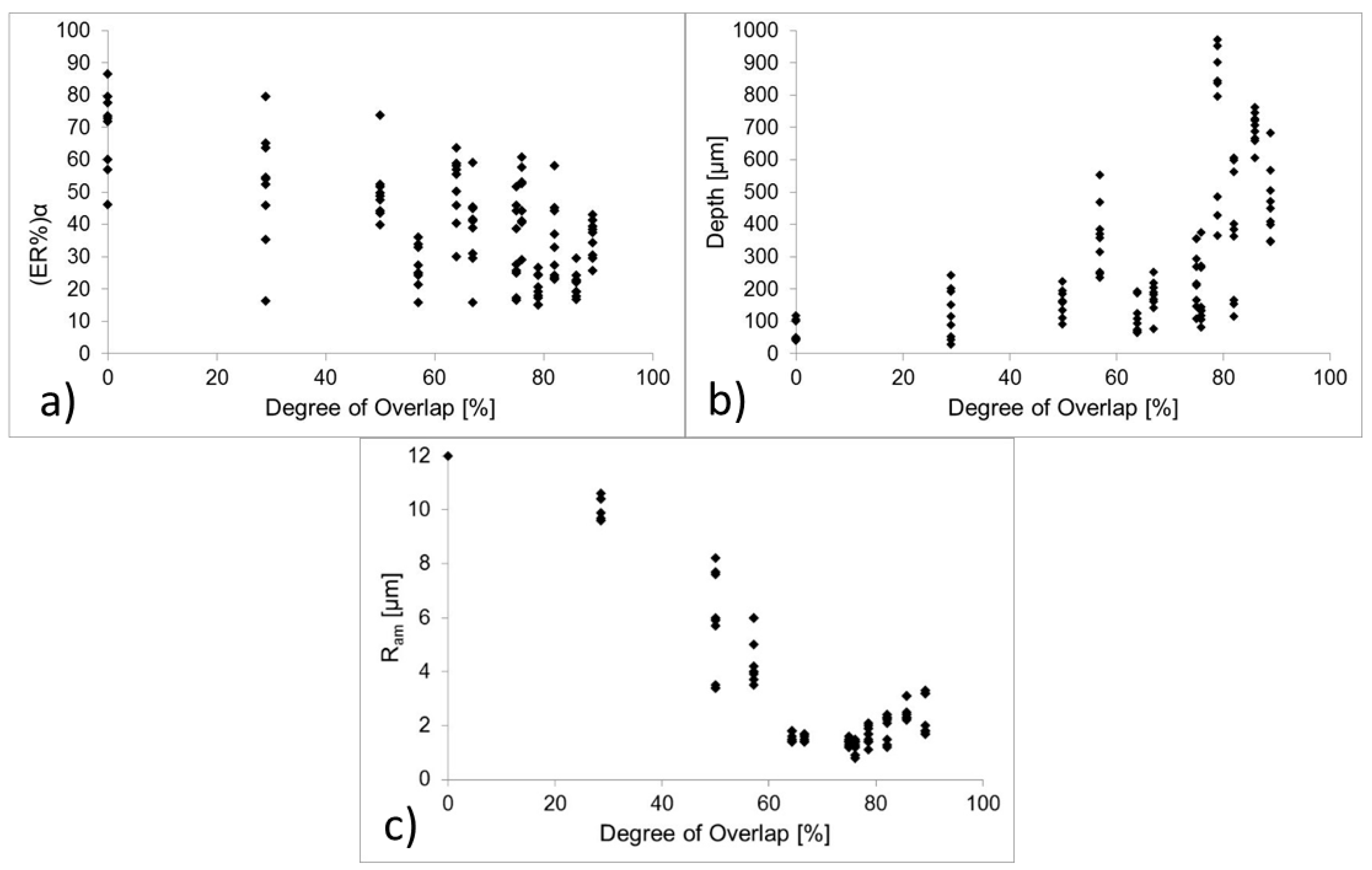

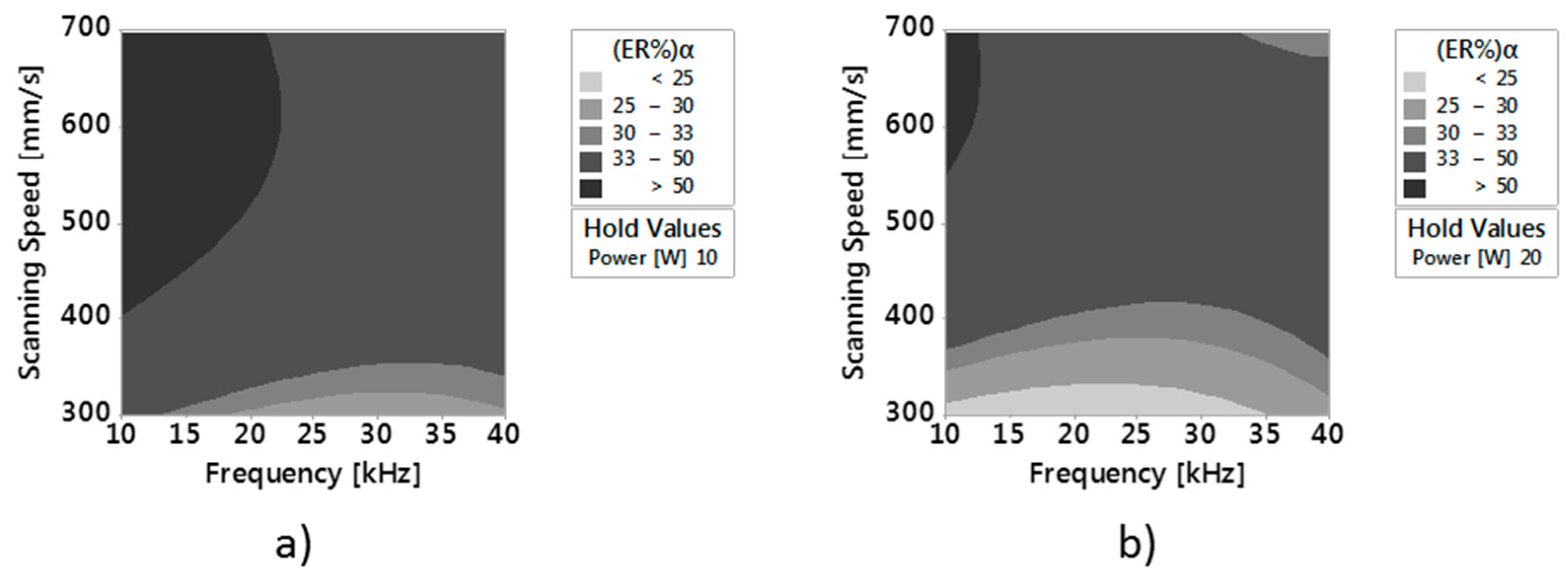

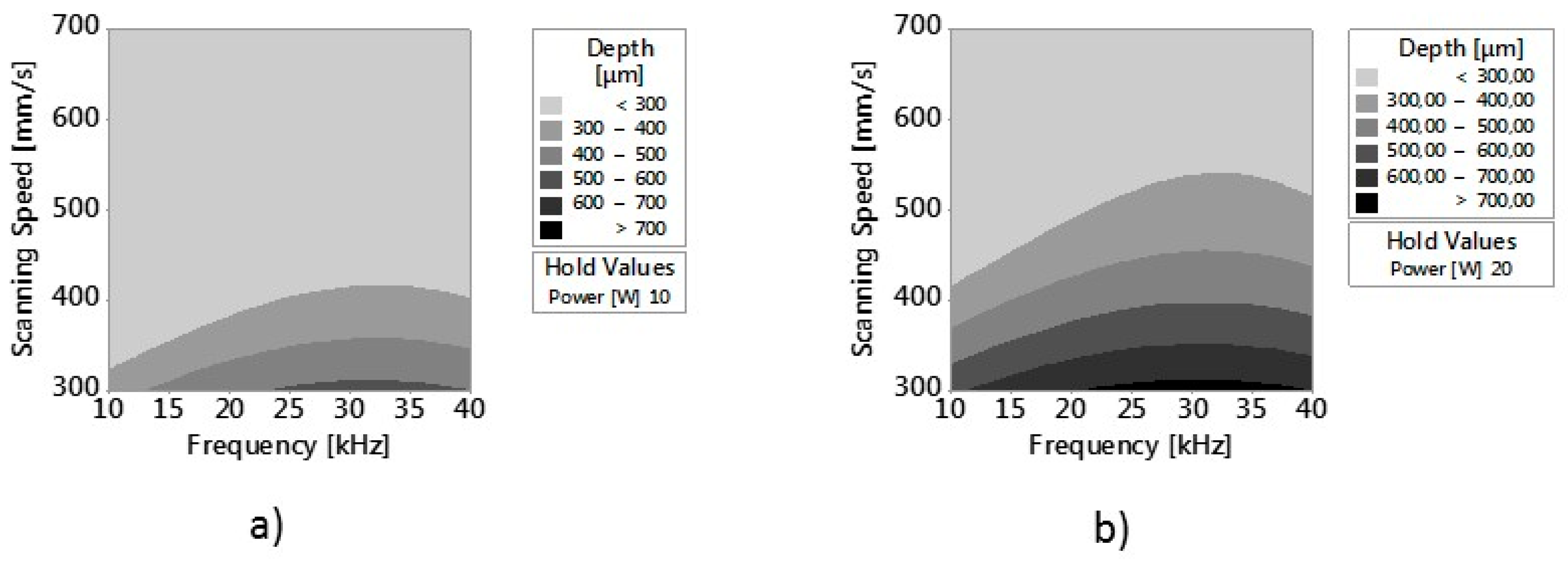

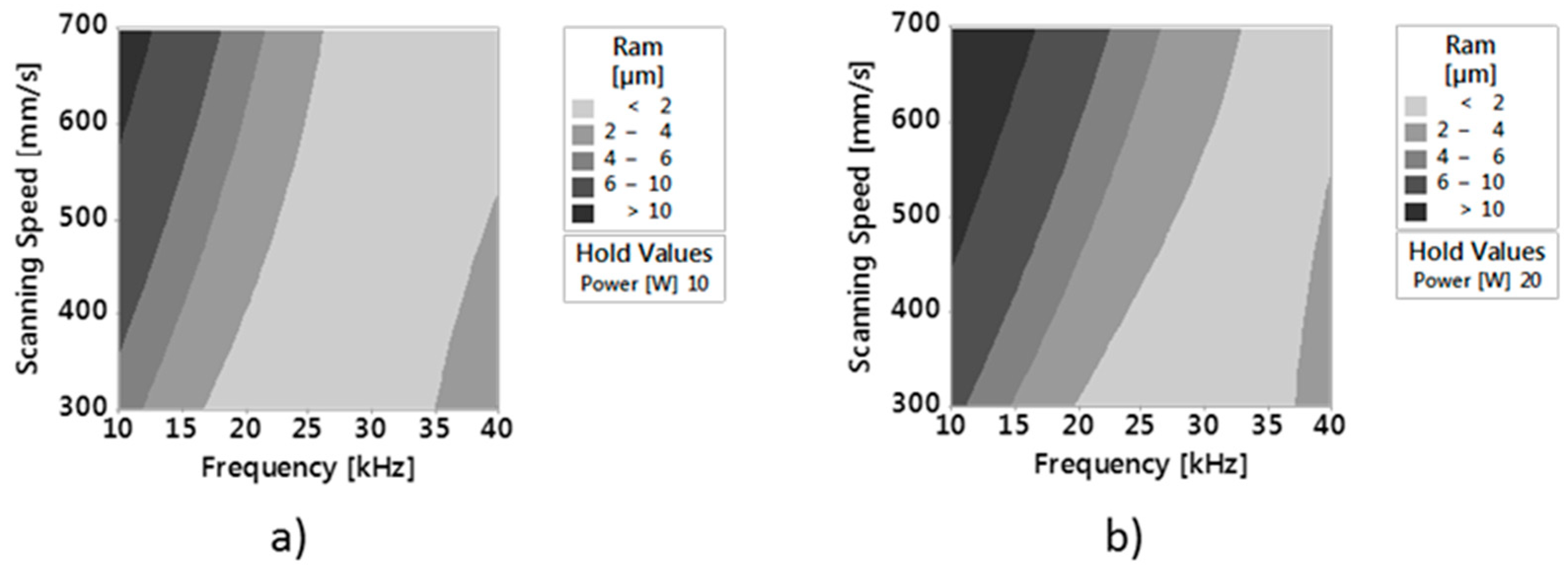

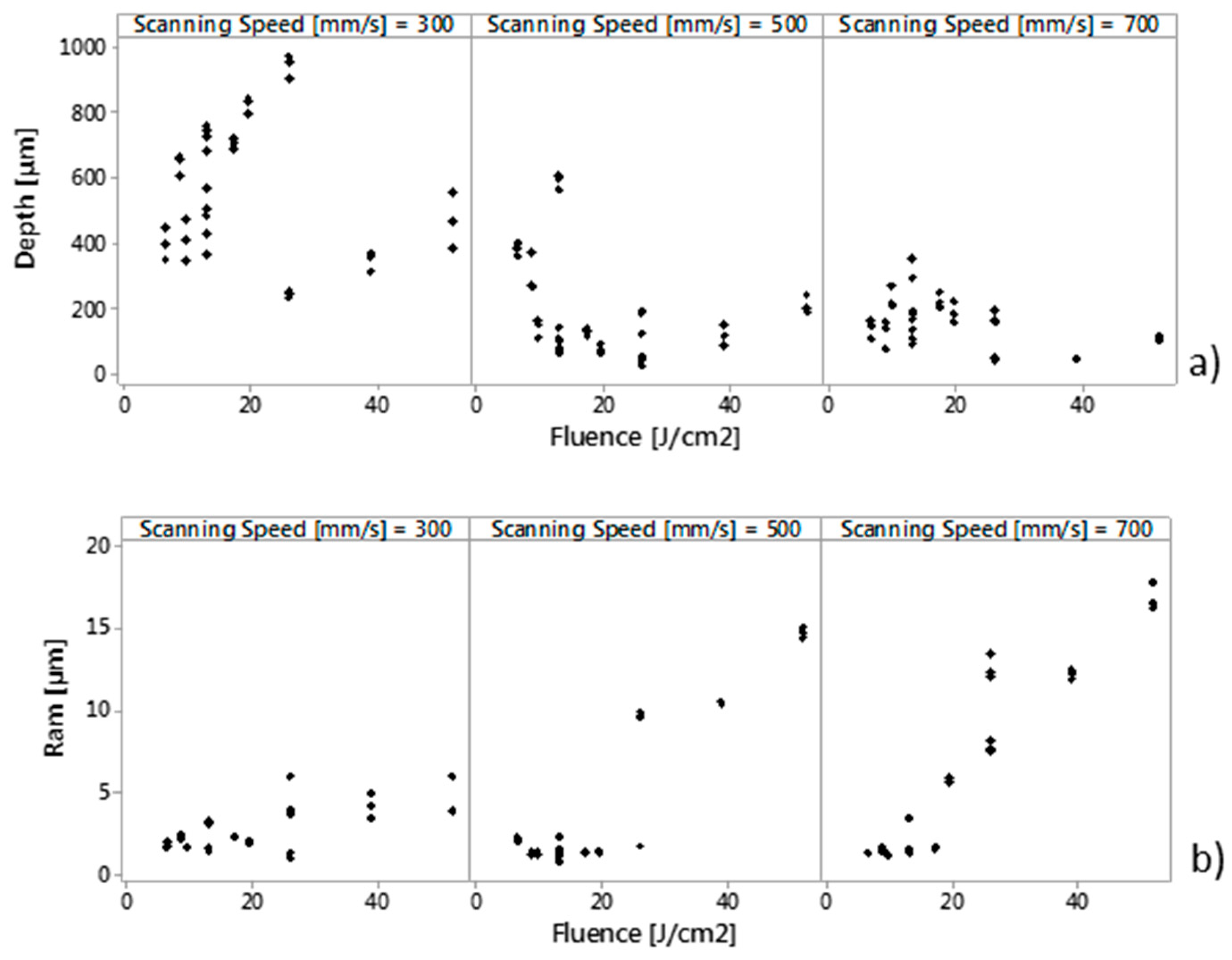

3.2. Effect of Degree of Overlap on (ER%)α, Depth and Ram

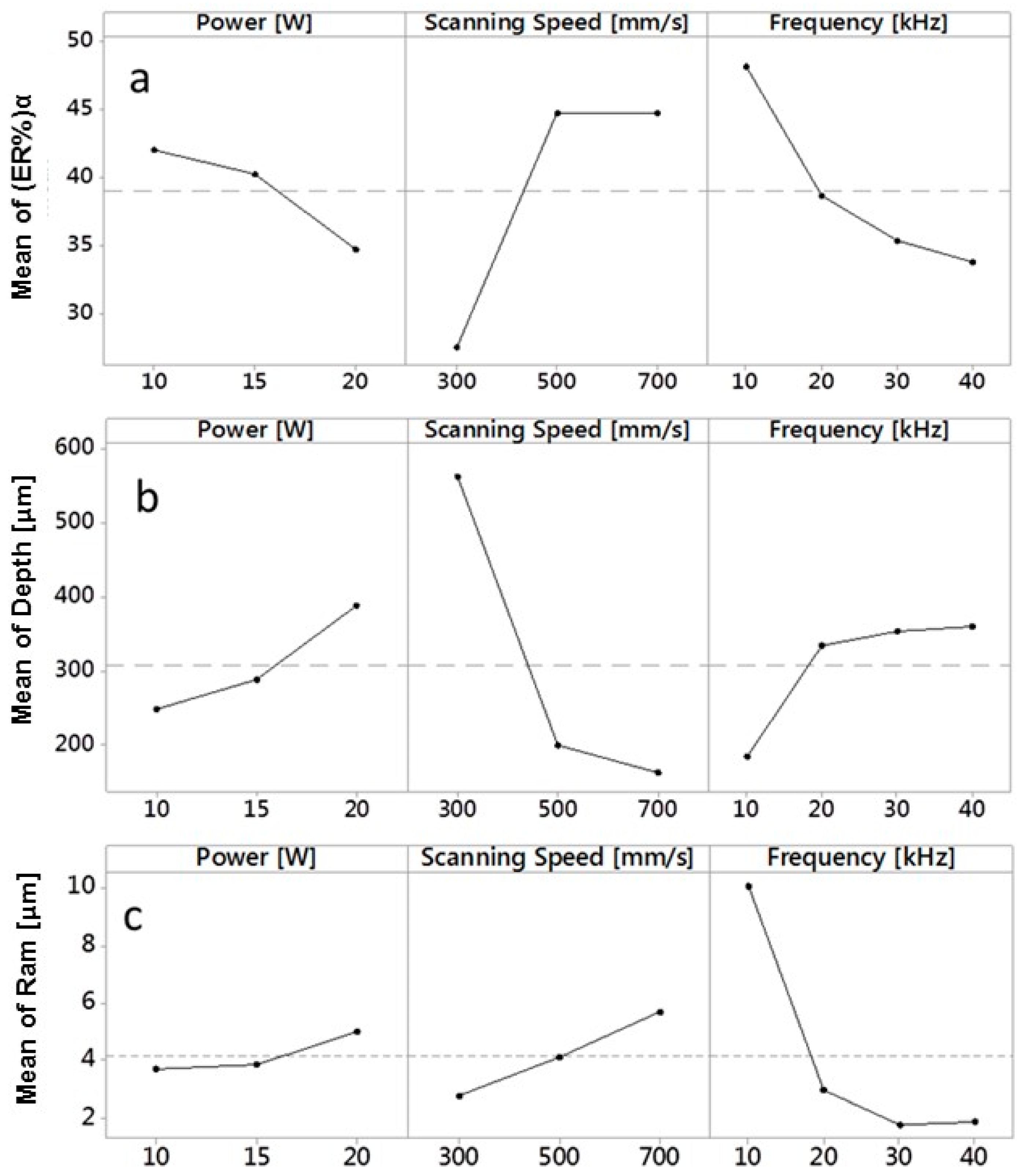

4. Discussion

- The slope of the curves confirms results of ANOVA on significance of input process parameters on analyzed results;

- The lowest value of (ER%)α can be obtained setting P = 20 W, v = 300 mm/min, Fp = 40 kHz.

- The lowest value of Ram can be obtained for P = 10 W, v = 300 mm/min and Fp = 30 kHz;

- A peak of Depth is present for P = 20 W, v = 300 mm/min, Fp = 40 kHz.

5. Conclusions

- Wall shape angles can be controlled setting appropriate values of process parameters.

- Values of roughness lower than 2 µm can be obtained setting proper values of power, frequency and scanning speed

- Values of roughness lower than 2 µm and of (ER%)α lower than 25% can be obtained with an average power of 20 W, Frequency between 20 kHz and 35 kHz and scanning speeds equal to or slightly higher than 300 mm/min.

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| P | average laser power |

| Fp | frequency |

| v | scanning speed |

| Hd | hatch distance |

| O | degree of overlap |

| D | laser spot diameter |

| ER | error index |

| Xm | single measured dimension |

| XCAD | single CAD dimension |

| Ram | arithmetic average roughness |

| α | probability error |

| L_Top | channel top Width, |

| L_Bottom | channel bottom width |

| α1, α2 | channel side angles |

References

- Heyl, P.; Olschewski, T.; Wijnaendts, R.W. Manufacturing of 3D structures for micro-tools using laser ablation. Microelectron. Eng. 2001, 57, 775–780. [Google Scholar] [CrossRef]

- Pham, D.T.; Dimov, S.S.; Petkov, P.V.; Petkov, S.P. Laser milling. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2002, 216, 657–667. [Google Scholar] [CrossRef]

- Pham, D.T.; Dimov, S.S.; Ji, C.; Petkov, P.V.; Dobrev, T. Laser milling as a rapid micromanufacturing process. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2004, 218, 1–7. [Google Scholar] [CrossRef]

- Campanelli, S.L.; Casalino, G.; Contuzzi, N. Multi-objective optimization of laser milling of 5754 aluminium alloy. Opt. Laser Technol. 2013, 52, 48–56. [Google Scholar] [CrossRef]

- Teixidor, D.; Ferrer, I.; Ciurana, J.; Özel, T. Optimization of process parameters for pulsed laser milling of micro-channels on AISI H13 tool steel. Robot. Comput. Integr. Manuf. 2013, 29, 209–218. [Google Scholar] [CrossRef]

- Darwish, S.; Ahmed, N.; Alahmari, A.M.; Mufti, N.A. A comparison of laser beam machining of micro-channels under dry and wet mediums. Int. J. Adv. Manuf. Technol. 2016, 83, 1539–1555. [Google Scholar] [CrossRef]

- Chen, H.C.; Chang, L.B.; Jeng, M.J.; Lai, C.S. Characterization of laser carved micro channel polycrystalline silicon solar cell. Solid State Electron. 2011, 61, 23–28. [Google Scholar] [CrossRef]

- Karazi, S.M.; Issa, A.; Brabazon, D. Comparison of ANN and DoE for the prediction of laser-machined micro-channel dimensions. Opt. Lasers Eng. 2009, 47, 956–964. [Google Scholar] [CrossRef]

- Schille, J.; Schneider, L.; Loeschner, U.; Ebert, R.; Scully, P.; Goddard, N.; Steiger, B.; Exner, H. Micro processing of metals using a high repetition rate femtosecond laser: From laser process parameter study to machining examples. In Proceedings of the 30th International Congress on Applications of Lasers and Electro-Optics ICALEO, Orlando, FL, USA, 23–27 October 2011; pp. 773–782. [Google Scholar]

- Bulushev, E.; Bessmeltsev, V.; Dostovalov, A.; Goloshevsky, N.; Wolf, A. High-speed and crack-free direct-writing of microchannels on glass by an IR femtosecond laser. Opt. Lasers Eng. 2016, 79, 39–47. [Google Scholar] [CrossRef]

- Rysava, Z.; Bruschi, S. Comparison between EBM and DMLS Ti6Al4V Machinability Characteristics under Dry Micro-Milling Conditions. Mater. Sci. Forum 2016, 836–837, 177–184. [Google Scholar] [CrossRef]

- Álvarez, I.; Enguita, J.M.; Frade, M.; Marina, J.; Ojea, G. On-Line Metrology with Conoscopic Holography: Beyond Triangulation. Sensors 2009, 9, 7021–7037. [Google Scholar] [CrossRef] [PubMed]

- Sirat, G.; Psaltis, D. Conoscopic Holography. Opt. Lett. 1985, 10, 4–6. [Google Scholar] [CrossRef] [PubMed]

- Rotella, G.; Orazi, L.; Alfano, M.; Candamano, S. CIRP Journal of Manufacturing Science and Technology Innovative high-speed femtosecond laser nano-patterning for improved adhesive bonding of Ti6Al4V titanium alloy. CIRP J. Manuf. Sci. Technol. 2017, 18, 101–106. [Google Scholar] [CrossRef]

- Dai, F.Z.; Geng, J.; Tan, W.S.; Ren, X.D.; Lu, J.Z.; Huang, S. Friction and wear on laser textured Ti6Al4V surface subjected to laser shock peening with contacting foil. Opt. Laser Technol. 2018, 103, 142–150. [Google Scholar] [CrossRef]

- Almeida, I.; Division, P. Surface Modification of Ti6Al4V Alloy by Pulsed Lasers: Microstructure and Hydrophobic 2 fR. Mater. Res. 2017, 20, 8–14. [Google Scholar] [CrossRef]

- Besl, P.J.; McKay, N.D. Method for registration of 3D shapes. IEEE Trans. Pattern Anal. Mach. Intell. 1992, 14, 239–256. [Google Scholar] [CrossRef]

- Montgomery, D.C.; Runger, G.C. Applied Statistics and Probability for Engineers, 3rd ed.; John Wiley & Sons: Hoboken, NJ, USA, 2003. [Google Scholar]

| Sample | Average Laser Power (W) | Scanning Speed (mm/s) | Frequency (kHz) | Degree of Overlap (%) |

|---|---|---|---|---|

| 1 | 10 | 500 | 40 | 82 |

| 2 | 20 | 500 | 10 | 29 |

| 3 | 10 | 500 | 30 | 76 |

| 4 | 15 | 300 | 40 | 89 |

| 5 | 10 | 500 | 10 | 29 |

| 6 | 15 | 500 | 10 | 29 |

| 7 | 20 | 300 | 20 | 79 |

| 8 | 15 | 700 | 20 | 50 |

| 9 | 10 | 700 | 20 | 50 |

| 10 | 10 | 300 | 20 | 79 |

| 11 | 10 | 700 | 10 | 0 |

| 12 | 20 | 300 | 30 | 86 |

| 13 | 20 | 700 | 10 | 0 |

| 14 | 20 | 700 | 40 | 75 |

| 15 | 20 | 300 | 10 | 57 |

| 16 | 20 | 500 | 30 | 76 |

| 17 | 10 | 500 | 20 | 64 |

| 18 | 10 | 700 | 30 | 67 |

| 19 | 15 | 500 | 20 | 64 |

| 20 | 15 | 500 | 30 | 76 |

| 21 | 15 | 700 | 40 | 75 |

| 22 | 20 | 700 | 30 | 67 |

| 23 | 20 | 700 | 20 | 50 |

| 24 | 15 | 300 | 30 | 86 |

| 25 | 10 | 300 | 30 | 86 |

| 26 | 15 | 700 | 10 | 0 |

| 27 | 20 | 300 | 40 | 89 |

| 28 | 15 | 300 | 20 | 79 |

| 29 | 15 | 700 | 30 | 67 |

| 30 | 10 | 700 | 40 | 75 |

| 31 | 15 | 300 | 10 | 57 |

| 32 | 10 | 300 | 10 | 57 |

| 33 | 20 | 500 | 40 | 82 |

| 34 | 10 | 300 | 40 | 89 |

| 35 | 15 | 500 | 40 | 82 |

| 36 | 20 | 500 | 20 | 64 |

| Geometrical Entities | Average Laser Power (W) | Scanning Speed (mm/s) | Frequency (kHz) |

|---|---|---|---|

| ER L Top (ER% L_Top) | NS | NS | S |

| ER L Bottom (ER% L_bottom) | NS | S | S |

| (ER%)α | S | S | S |

| Depth | S | S | S |

| Ram | S | S | S |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Campanelli, S.L.; Lavecchia, F.; Contuzzi, N.; Percoco, G. Analysis of Shape Geometry and Roughness of Ti6Al4V Parts Fabricated by Nanosecond Laser Ablation. Micromachines 2018, 9, 324. https://doi.org/10.3390/mi9070324

Campanelli SL, Lavecchia F, Contuzzi N, Percoco G. Analysis of Shape Geometry and Roughness of Ti6Al4V Parts Fabricated by Nanosecond Laser Ablation. Micromachines. 2018; 9(7):324. https://doi.org/10.3390/mi9070324

Chicago/Turabian StyleCampanelli, Sabina Luisa, Fulvio Lavecchia, Nicola Contuzzi, and Gianluca Percoco. 2018. "Analysis of Shape Geometry and Roughness of Ti6Al4V Parts Fabricated by Nanosecond Laser Ablation" Micromachines 9, no. 7: 324. https://doi.org/10.3390/mi9070324

APA StyleCampanelli, S. L., Lavecchia, F., Contuzzi, N., & Percoco, G. (2018). Analysis of Shape Geometry and Roughness of Ti6Al4V Parts Fabricated by Nanosecond Laser Ablation. Micromachines, 9(7), 324. https://doi.org/10.3390/mi9070324