A Generic Control Architecture for Hybrid Micro-Machines

Abstract

1. Introduction

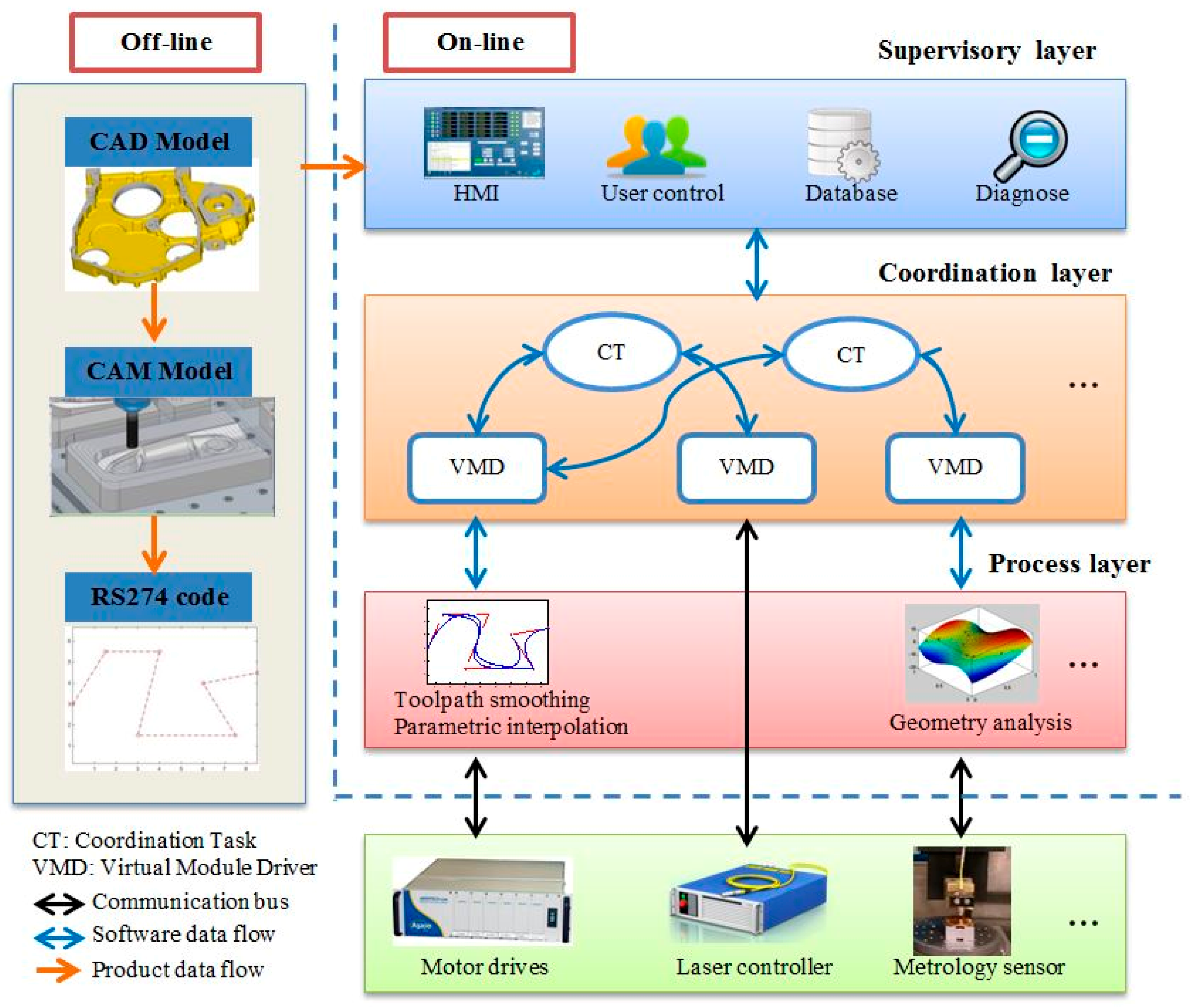

2. Novel Control Architecture

2.1. Supervisory Layer

2.2. Coordination Layer

- Enable or disable the laser controller.

- Start or stop the laser emission.

- Set the laser output power.

- Set the laser output frequency.

- When a functional module is upgraded, only the corresponding VMD component should be adapted for the new data protocol or communication bus, but maintains the original software interface. The whole system can work seamlessly without modifying any other software components.

- If a new functional module is to be added, a corresponding VMD component should be developed. If it needs to interact with other functional modules, a new CT should be developed by invoking the given interfaces provided by the related VMDs. The other part of the system will not be affected.

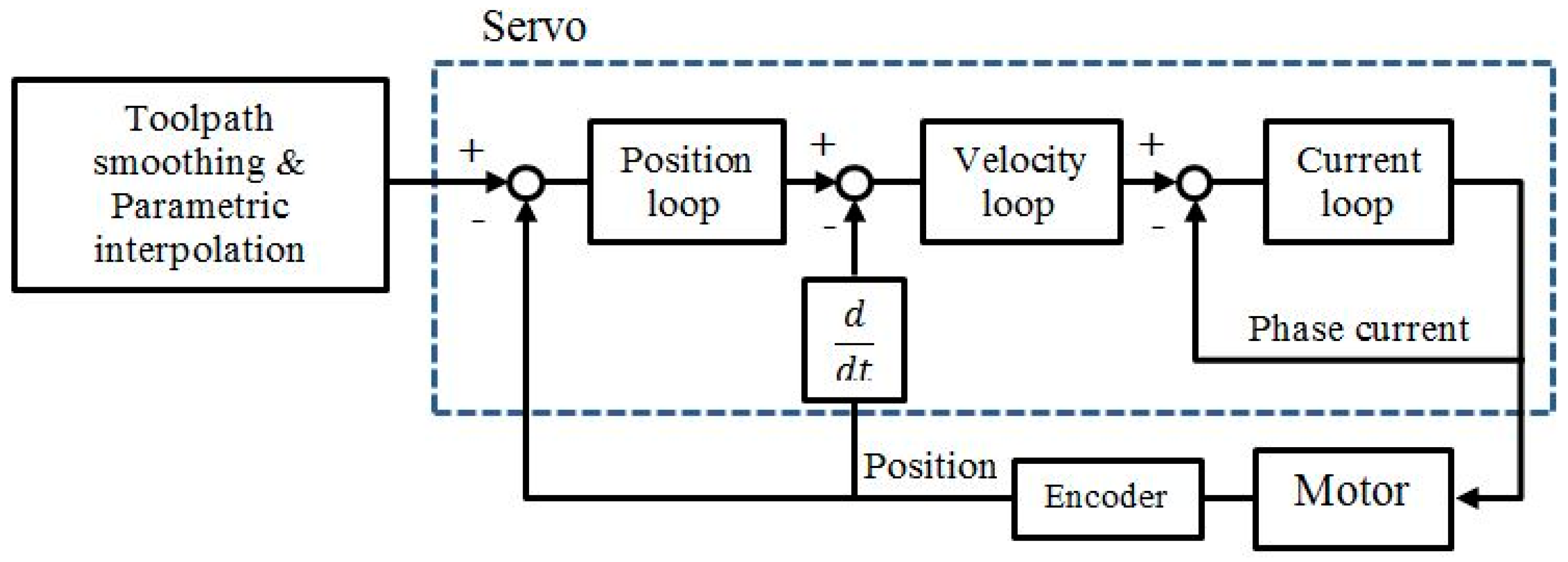

2.3. Process Layer

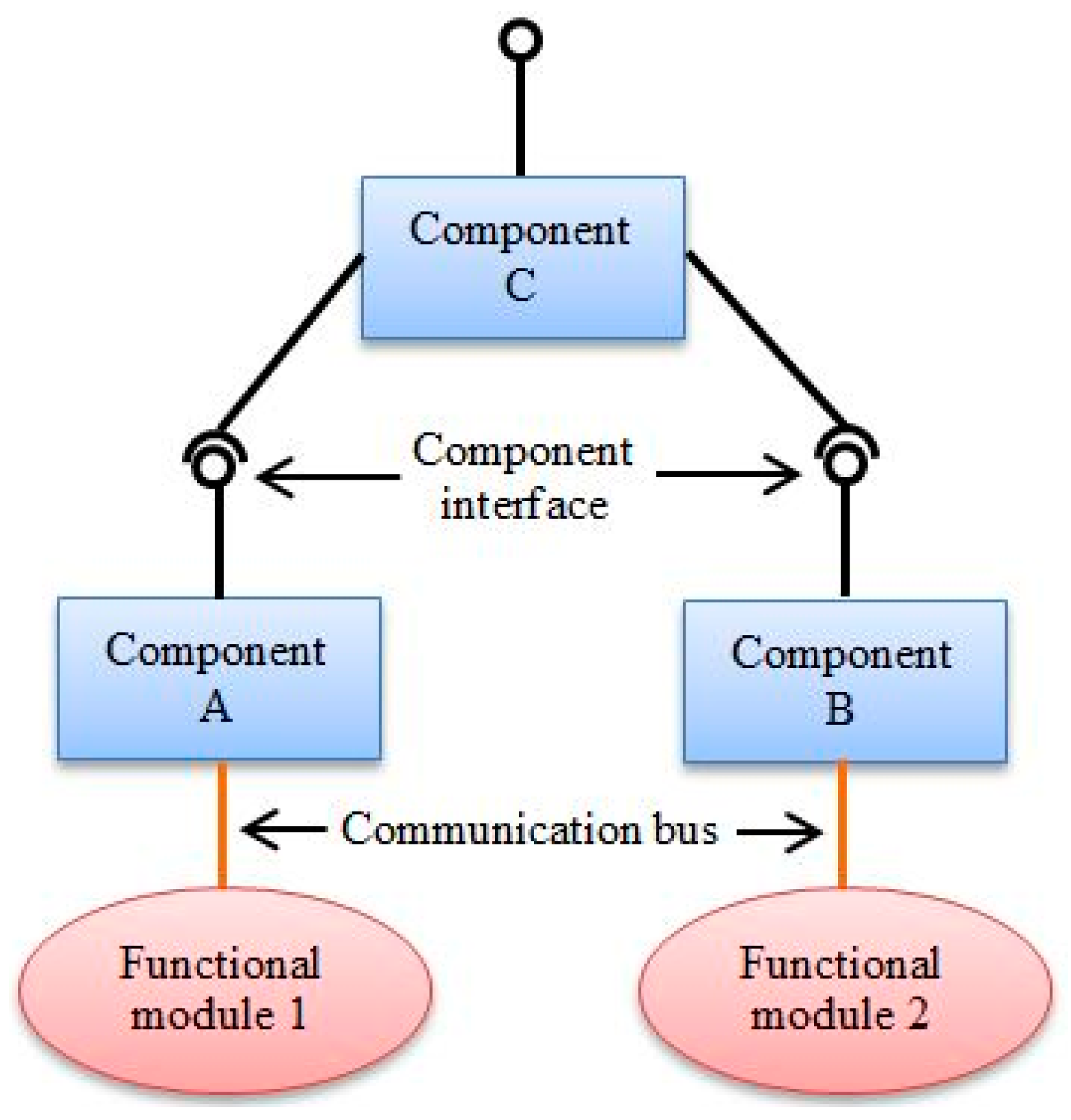

3. Component-Based Technology

- Software components are reusable. Component provides service to the system via its interface, the data structure and algorithms are encapsulated. If two components have the compatible provided interface and required interface, they can replace each other without breaking the system. The development of the system is, therefore, accelerated.

- The system scalability and flexibility are increased. Components are treated as the building blocks of the CNC system. Various control architectures can be constructed by combining the necessary components.

- The system maintainability is improved. An upgraded component can replace the old component, while the other components in the system are not affected. The component is linked dynamically at run-time. There is no need to re-compile other components.

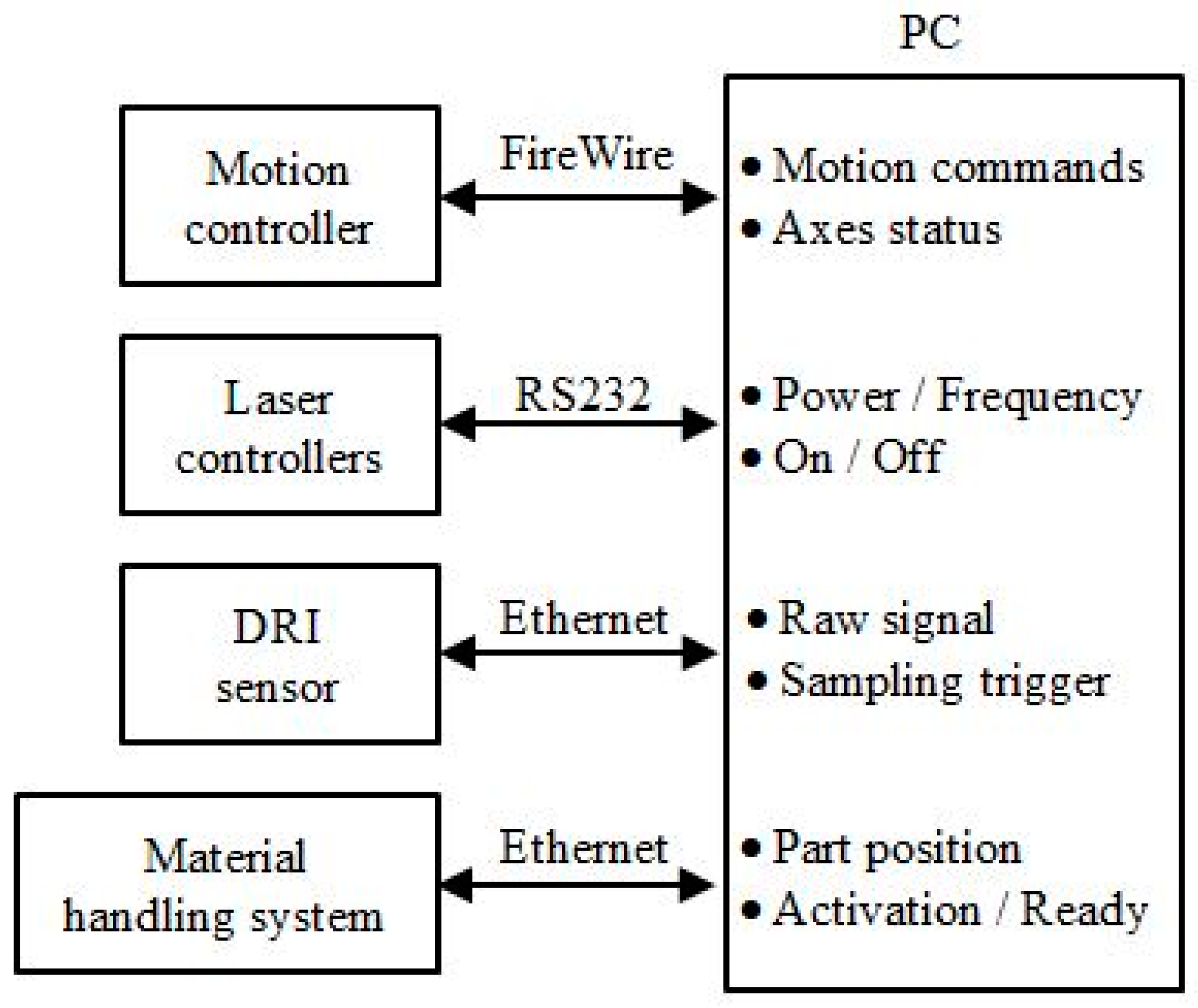

4. System Integration of a Six-Axis Hybrid Micro-Machine

4.1. Overview of the System Integration

4.2. Integration of Motion Controller

4.3. Integration of Laser Controllers

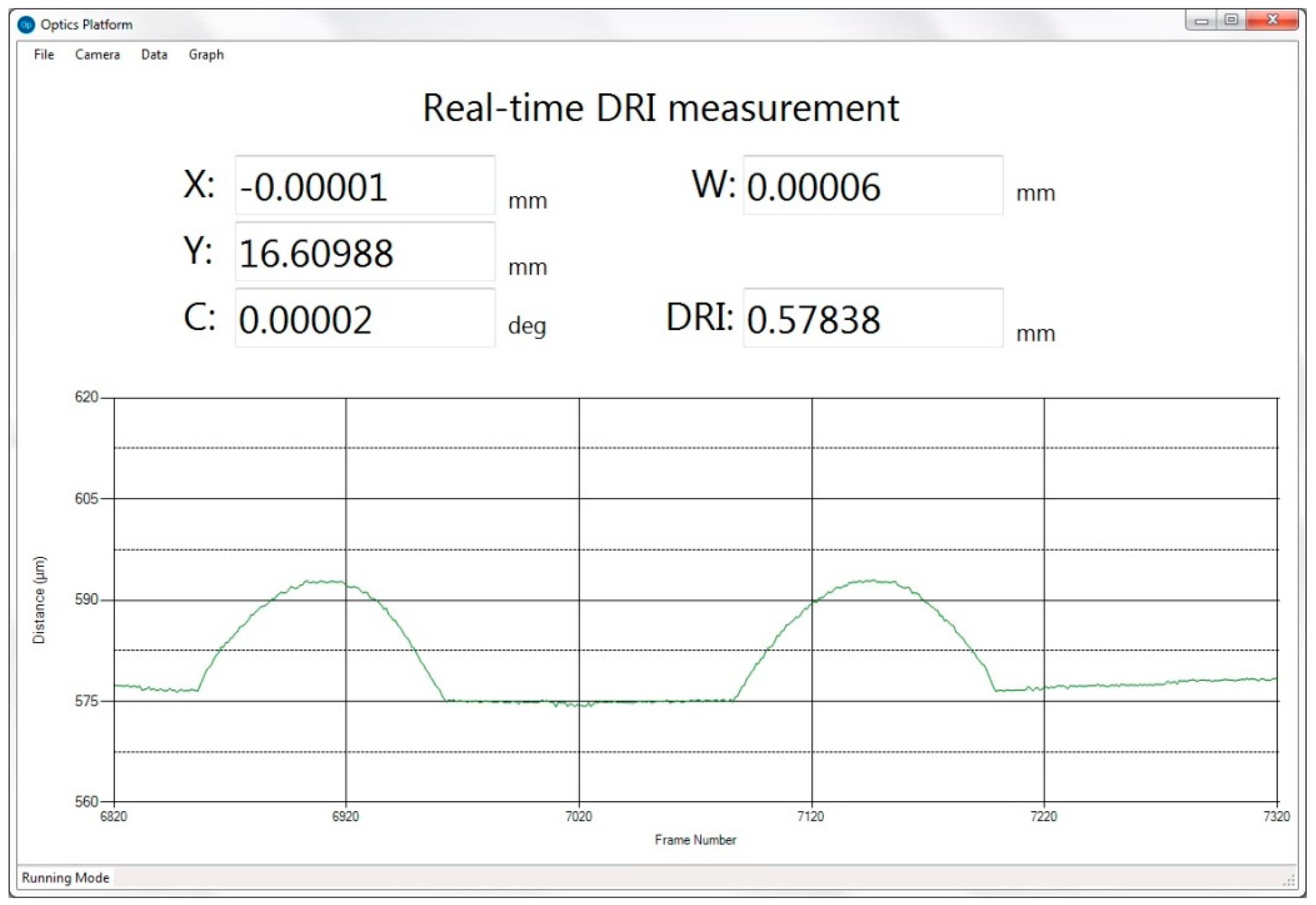

4.4. Integration of DRI in-Line Metrology System

4.5. Integration of a Material Handling System

5. Conclusions and Future Work

- Supervisory layer: it is in charge of the human-machine interaction and monitoring.

- Coordination layer: it provides an abstraction for each functional module and hosts the coordination tasks.

- Process layer: it executes the intelligent algorithms in real-time for related functional modules.

Author Contributions

Funding

Conflicts of Interest

References

- Luo, X.; Cheng, K.; Webb, D.; Wardle, F. Design of ultraprecision machine tools with applications to manufacture of miniature and micro components. J. Mater. Process. Technol. 2005, 167, 515–528. [Google Scholar] [CrossRef]

- Lauwers, B.; Klocke, F.; Klink, A.; Tekkaya, A.E.; Neugebauer, R.; McIntosh, D. Hybrid processes in manufacturing. CIRP Ann. Manuf. Technol. 2014, 63, 561–583. [Google Scholar] [CrossRef]

- Chang, W. Development of Hybrid Micro Machining Approaches and Test-Bed. Ph.D. Thesis, Heriot-Watt University, Edinburgh, UK, 2012. [Google Scholar]

- Chavoshi, S.Z.; Luo, X. Hybrid Micro-machining Processes: A Review. Precis. Eng. 2015, 41, 1–23. [Google Scholar] [CrossRef]

- Bulla, B.; Klocke, F.; Dambon, O.; Hünten, M. Ultrasonic Assisted Diamond Turning of Hardened Steel for Mould Manufacturing. Key Eng. Mater. 2012, 516, 437–442. [Google Scholar] [CrossRef]

- Kumar, M.; Melkote, S.N. Process capability study of laser assisted micro milling of a hard-to-machine material. J. Manuf. Process. 2012, 14, 41–51. [Google Scholar] [CrossRef]

- Karg, M.C.H.; Ahuja, B.; Wiesenmayer, S.; Kuryntsev, S.V.; Schmidt, M. Effects of process conditions on the mechanical behavior of aluminium wrought alloy EN AW-2219 (AlCu6Mn) additively manufactured by laser beam melting in powder bed. Micromachines 2017, 8, 1–11. [Google Scholar] [CrossRef]

- Fujita, S.; Yoshida, T. OSE: Open system environment for controller. In Proceedings of the 7th International Machine Tool Engineers Conference, Tokyo, Japan; 1996; pp. 234–243. [Google Scholar]

- Michaloski, J.; Birla, S.; Yen, C.J.; Igou, R.; Weinert, G. An open system framework for component-based CNC machines. ACM Comput. Surv. 2000, 32, 23. [Google Scholar] [CrossRef]

- Pritschow, G.; Daniel, C.; Junghans, G.; Sperling, W. Open System Controllers—A Challenge for the Future of the Machine Tool Industry. CIRP Ann. Manuf. Technol. 1993, 42, 449–452. [Google Scholar] [CrossRef]

- Pritschow, G.; Altintas, Y.; Jovane, F.; Koren, Y.; Mitsuishi, M.; Takata, S.; van Brussel, H.; Weck, M.; Yamazaki, K. Open controller architecture–past, present and future. CIRP Ann. Manuf. Technol. 2001, 50, 463–470. [Google Scholar] [CrossRef]

- Liang, S.Y.; Hecker, R.L.; Landers, R.G. Machining Process Monitoring and Control: The State-of-the-Art. J. Manuf. Sci. Eng. 2004, 126, 297–310. [Google Scholar] [CrossRef]

- Delta Tau Powser PMAC. Available online: http://www.deltatau.com/dt_powerpmac/powerpmachome.aspx (accessed on 11 April 2018).

- SIEMENS SINUMERIK CNC. Available online: https://www.siemens.com/global/en/home/products/automation/systems/cnc-sinumerik.html (accessed on 11 April 2018).

- Lutz, P.; Sperling, W. OSACA—The vendor neutral Control Architecture. In Proceedings of the European Conference Integration in Manufacturing, Dresden, Germany, 1997. [Google Scholar]

- Koren, Y.; Shpitalni, M. Design of reconfigurable manufacturing systems. J. Manuf. Syst. 2010, 29, 130–141. [Google Scholar] [CrossRef]

- Putnik, G.; Sluga, A.; Elmaraghy, H.; Teti, R.; Koren, Y.; Tolio, T.; Hon, B. Scalability in manufacturing systems design and operation: State-of-the-art and future developments roadmap. CIRP Ann. Manuf. Technol. 2013, 62, 751–774. [Google Scholar] [CrossRef]

- Monostori, L.; Kádár, B.; Bauernhansl, T.; Kondoh, S.; Kumara, S.; Reinhart, G.; Sauer, O.; Schuh, G.; Sihn, W.; Ueda, K. Cyber-physical systems in manufacturing. CIRP Ann. Manuf. Technol. 2016, 65, 621–641. [Google Scholar] [CrossRef]

- Krüger, J.; Wang, L.; Verl, A.; Bauernhansl, T.; Carpanzano, E.; Makris, S.; Fleischer, J.; Reinhart, G.; Franke, J.; Pellegrinelli, S. Innovative control of assembly systems and lines. CIRP Ann. Manuf. Technol. 2017, 66, 707–730. [Google Scholar] [CrossRef]

- Mabkhot, M.M.; Al-Ahmari, A.M.; Salah, B.; Alkhalefah, H. Requirements of the Smart Factory System: A Survey and Perspective. Machines 2018, 6, 23. [Google Scholar] [CrossRef]

- Zhong, W.; Luo, X.; Chang, W.; Ding, F.; Cai, Y. A real-time interpolator for parametric curves. Int. J. Mach. Tools Manuf. 2018, 125, 133–145. [Google Scholar] [CrossRef]

- Crnkovic, I.; Sentilles, S.; Vulgarakis, A.; Chaudron, M.R.V. A Classification Framework for Software Component Models. IEEE Trans. Softw. Eng. 2011, 37, 593–615. [Google Scholar] [CrossRef]

- Bruyninckx, H.; Klotzbücher, M.; Hochgeschwender, N.; Kraetzschmar, G.; Gherardi, L.; Brugali, D. The BRICS component model: A model-based development paradigm for complex robotics software systems. In Proceedings of the 28th Annual ACM Symposium On Applied Computing, Coimbra, Portugal, 18–22 March 2013; pp. 1758–1764. [Google Scholar]

- AUTOSAR. Available online: https://www.autosar.org/ (accessed on 19 April 2018).

- OPC Foundation. Available online: https://opcfoundation.org/ (accessed on 18 April 2018).

- Chang, W.; Zhong, W.; Ding, F.; Wardie, F.; Luo, X. Development of a compact ultra-precision six-axis hybrid micro-machine. In Proceedings of the 2017 World Congress on Micro and Nano Manufacturing, Kaohsiung, Taiwan, 27–30 March 2017. [Google Scholar]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Luo, X.; Zhong, W.; Chang, W. A Generic Control Architecture for Hybrid Micro-Machines. Micromachines 2018, 9, 305. https://doi.org/10.3390/mi9060305

Luo X, Zhong W, Chang W. A Generic Control Architecture for Hybrid Micro-Machines. Micromachines. 2018; 9(6):305. https://doi.org/10.3390/mi9060305

Chicago/Turabian StyleLuo, Xichun, Wenbin Zhong, and Wenlong Chang. 2018. "A Generic Control Architecture for Hybrid Micro-Machines" Micromachines 9, no. 6: 305. https://doi.org/10.3390/mi9060305

APA StyleLuo, X., Zhong, W., & Chang, W. (2018). A Generic Control Architecture for Hybrid Micro-Machines. Micromachines, 9(6), 305. https://doi.org/10.3390/mi9060305