1. Introduction

Magnetometers are widely employed in geodesic surveys and aircraft attitude control systems as geomagnetic field detecting sensors [

1,

2,

3]. As one of the most critical components in the attitude determination systems of spacecraft, they need to be both highly sensitive and accurate. However, the measurement range of the magnetometers can be less than that of sensors used on earth [

4,

5,

6,

7]. Additionally, miniaturization is important for the application of magnetometers in small satellites [

8,

9,

10,

11]. Compared to microelectromechanical system (MEMS) magnetometers based on the fluxgate effect [

12,

13], Hall effect [

14,

15], and magnetoresistance [

16,

17], microtorsional resonant magnetometers based on the Lorentz force have the advantages of a high quality factor and high reliability [

18,

19,

20,

21]. Meanwhile, its MEMS fabrication process is relatively simple [

22,

23]. Many Lorentz force-based sensors have high requirements for the sensitivity of capacitance measurement, which must be better than 10 aF [

24,

25,

26]. Combining this with new fabrication methods or other sensors, more new devices were developed [

27,

28]. In this paper, a MEMS torsional resonant magnetometer based on the Lorentz force was studied, and the relevant parameters were optimized.

2. Principles and Simulations

The MEMS structures of the magnetometer include torsional structures, torsional beams, metal plates, a coil, and a glass substrate (

Figure 1). The Lorentz force is introduced by the current in the coil and the external horizontal magnetic field, and leads to differential displacement of the torsional structure, which can be detected with two sensing capacitors fabricated on the torsional structure. The torsion is along the

y axis. All the rotation direction conforms to the right-hand rule.

Assuming that

k is the elastic coefficient of the torsional beam, and

Θ is half the rotational inertia of the torsional structures, then after derivation, the intrinsic frequency and critical damping of the resonance system could be obtained as follows:

where

α is the damping ratio of the torsional system;

k is a function of the length, width of the torsional beam, and the width and height of the torsional structure; and

Θ is a function of the above parameters and the density of the torsional beam material.

To increase the sensitivity of the sensor, a structure of folded torsional beams and a double-layer excitation coil was designed based on simulation and testing results for the structures of a preliminary fabrication. The structural parameters were also optimized.

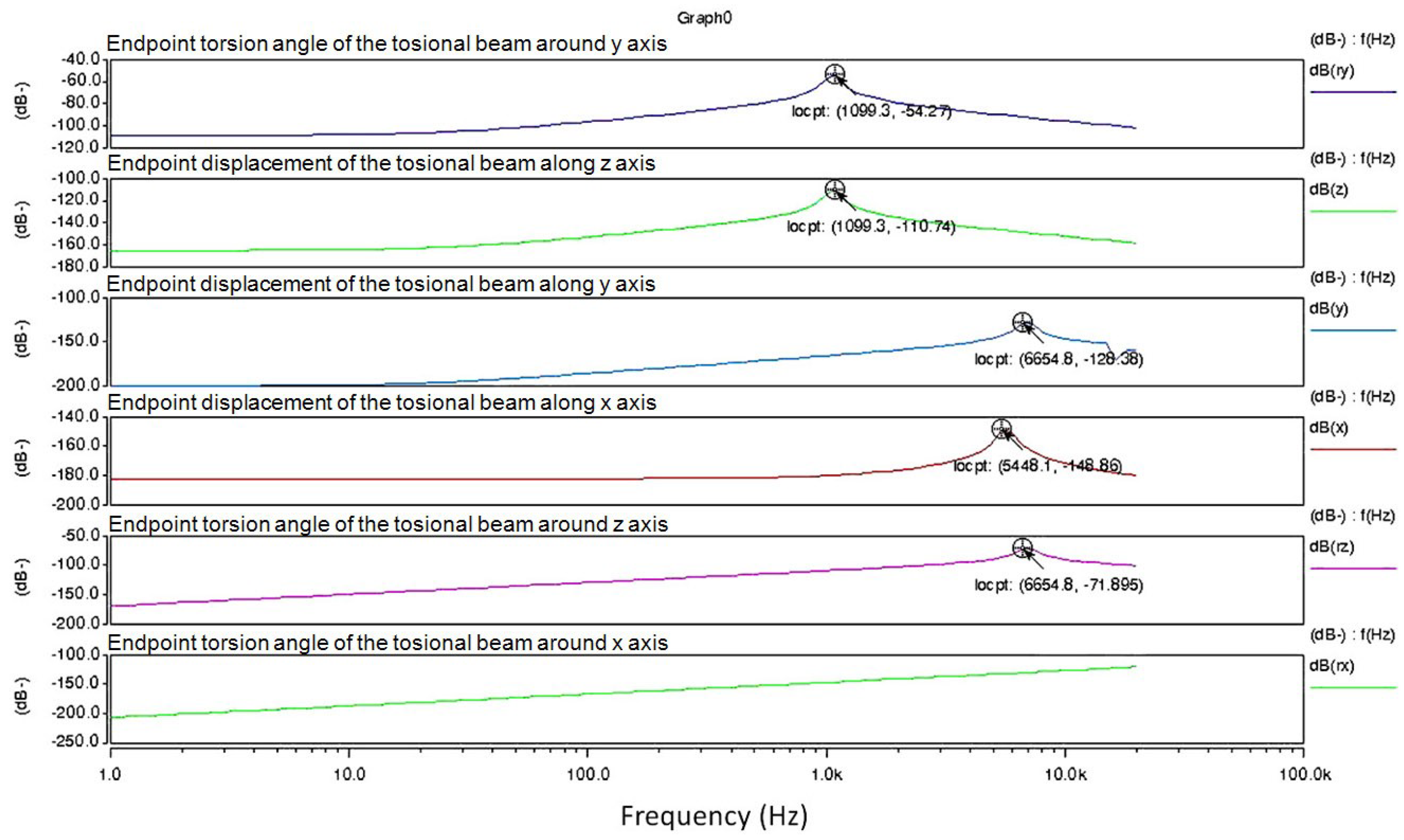

Based on the principle and structure of the sensor, maximum system sensitivity can be achieved when the excitation signal frequency is in accordance with the resonance frequency of the torsional system. Using the small signal alternating current (AC) sweep analysis in the Architect module of CoventorWare, the endpoint displacement of the torsional beams was obtained along three perpendicular directions and around three axes (

Figure 2). It can be seen that the resonant frequencies in the

z and

ry directions were very similar (about 1100 Hz). However, the resonant frequencies in the

x,

y, and

rz directions were approximately 5 kHz to 6 kHz, which is far from 1100 Hz. With appropriate excitation signal frequencies, the vibrations in these directions could be suppressed. There was no peak in the vibration in the

rx direction. When the frequency was less than 1100 Hz, its attenuation was approximately −150 dB.

Simulations indicated that the resonant frequencies in the ry and z directions were roughly the same, and there was no resonance peak in the rx direction. This is because its endpoint also vibrated in the z direction (vertical movement) when the torsional pendulum vibrated in the ry direction (around the y axis). The intensity in ry was approximately −54.3 dB at 1100 Hz, and the vibrating amplitude in the rx direction was approximately −150 dB, which was far less than that of the ry direction. Therefore, the torsional vibration around the y axis achieved its maximum intensity when the excitation signal frequency was the same as the resonant frequency of ry. However, the vibration amplitudes in the other directions were far less than those in this direction. From the perspective of the resonant frequency, these results demonstrated the rationality of the structure design.

3. Fabrication

The MEMS fabrication process included dry etching, a lift-off process, anodic bonding, chemical mechanical planarization (CMP), physical vapor deposition, electroplating, and inductively coupled plasma (ICP) etching. The materials used in the microfabrication process were a Pyrex glass substrate and a low-resistivity silicon wafer with a diameter of 4 inches and a thickness of 200 μm.

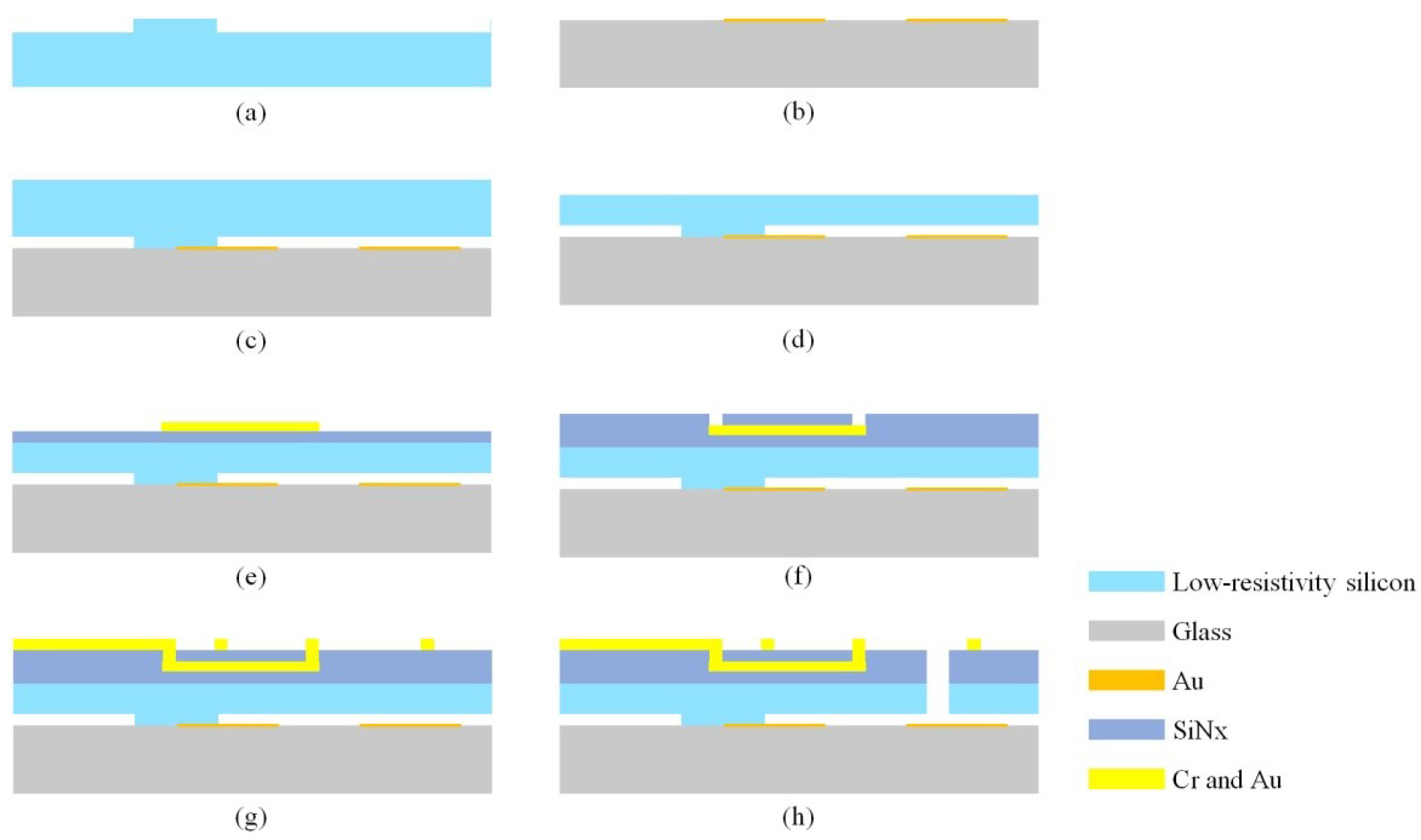

The optimized fabrication process is shown in

Figure 3. First, a step was etched on the backside of the low-resistivity silicon for glass–silicon bonding, as shown in

Figure 3a. Then, the metal plates were fabricated on the glass substrate with the lift-off process, as shown in

Figure 3b. Subsequently, a low-resistivity silicon wafer was attached to the glass substrate through anodic bonding (

Figure 3c), and the silicon wafer was polished using CMP (

Figure 3d). Then, silicon nitride (SiNx) was deposited for insulation (

Figure 3e), and gold was patterned to fabricate the coil layer using plasma-enhanced chemical vapor deposition (PECVD) (

Figure 3f–g). Finally, the torsional structures were released with ICP, as shown in

Figure 3h.

Based on preliminary fabrications and tests, the thickness of the low-resistivity silicon wafer was further decreased to 60 µm with CMP before depositing the SiNx insulating layer. This improvement greatly enlarged the torsional angle and increased the convenience of the subsequent ICP process. Thinning the structure layer effectively increased the success rate of the ICP and ensured good mechanical properties of the torsional beam. However, it also created undesirable structural risks. For example, the back of the silicon wafer has a step structure, which forms a cavity with the glass substrate. The pressure on the silicon wafer during the CMP process may break this structure. Therefore, this cavity area should be reduced to prevent the silicon wafer from being crushed.

To reduce the silicon–gold contact resistance introduced by the bonding process, an etching process was added before silicon–glass bonding to remove the oxide layer on the low-resistivity silicon. With this additional process, the resistance of the torsional structure was approximately 1 kΩ, which was very close to the simulation result. By peeling the torsional structure from the device and measuring it with a probe, its resistance was found to be only 500 Ω. This indicates that the silicon–gold contact resistance was reduced to approximately 500 Ω. The oxide film etching process produced low-resistivity silicon directly bonded to the gold material, avoiding reduction in the conductivity caused by the oxide layer on the silicon. This benefited the subsequent high-precision measurement of the capacitance.

To increase the sensitivity, the torsional beams of the device were designed as folded beams to reduce the elastic coefficient. In addition, two coil layers were achieved in the devices, which greatly increased the sensitivity without increasing the fabrication difficulty.

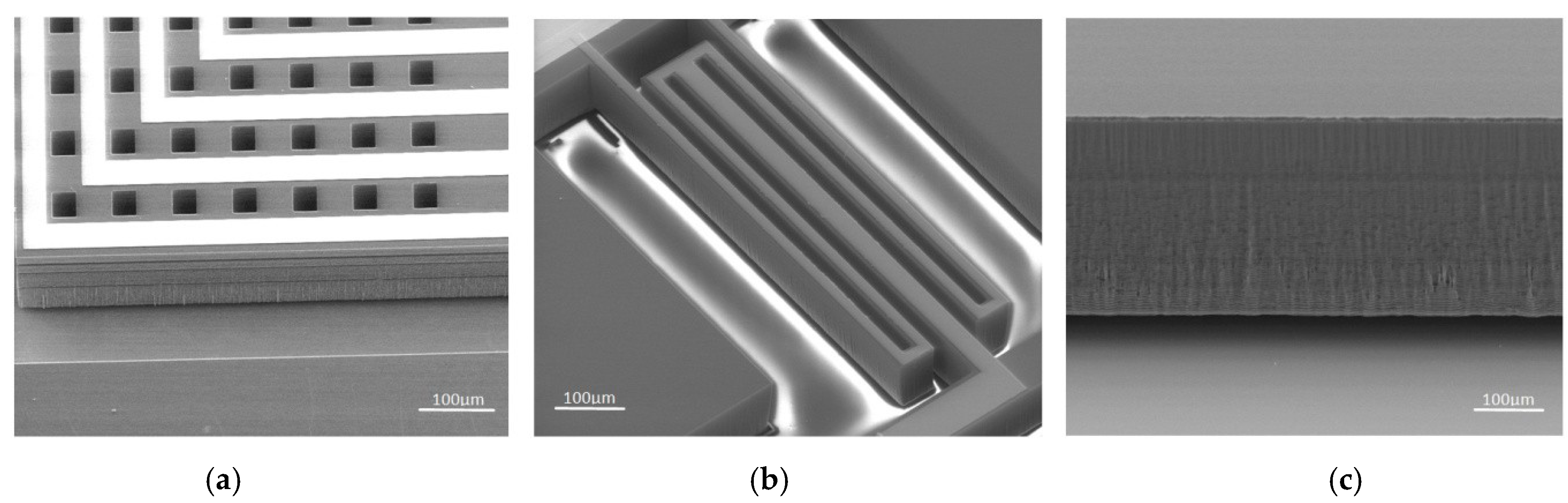

Figure 4 shows the fabrication results for the key structures. It can be seen that the folded beam structure was intact, and the sidewall of the torsional structures and coil were of good quality. Damping holes were released completely by ICP, reducing the squeeze film air damping effect. These results indicate that by reducing the thickness of the structural layer, both the fabrication quality and the ICP success rate were improved.

Six gold wires were required for the connections between the gold poles of the shell package and the MEMS structures: Two wires for connections of the excitation coils, two for connections of the capacitor plates, and the remaining two for connections of the torsional pendulums fabricated from the low-resistivity silicon.

There were four gold pillars located at both sides of the tube for bonding. However, there was little Kovar alloy present except for the pins. If the magnetic sensor was well placed for the measurement of a horizontal magnetic field, both the interference and shielding of the external magnetic field caused by the gold pillars could be ignored.

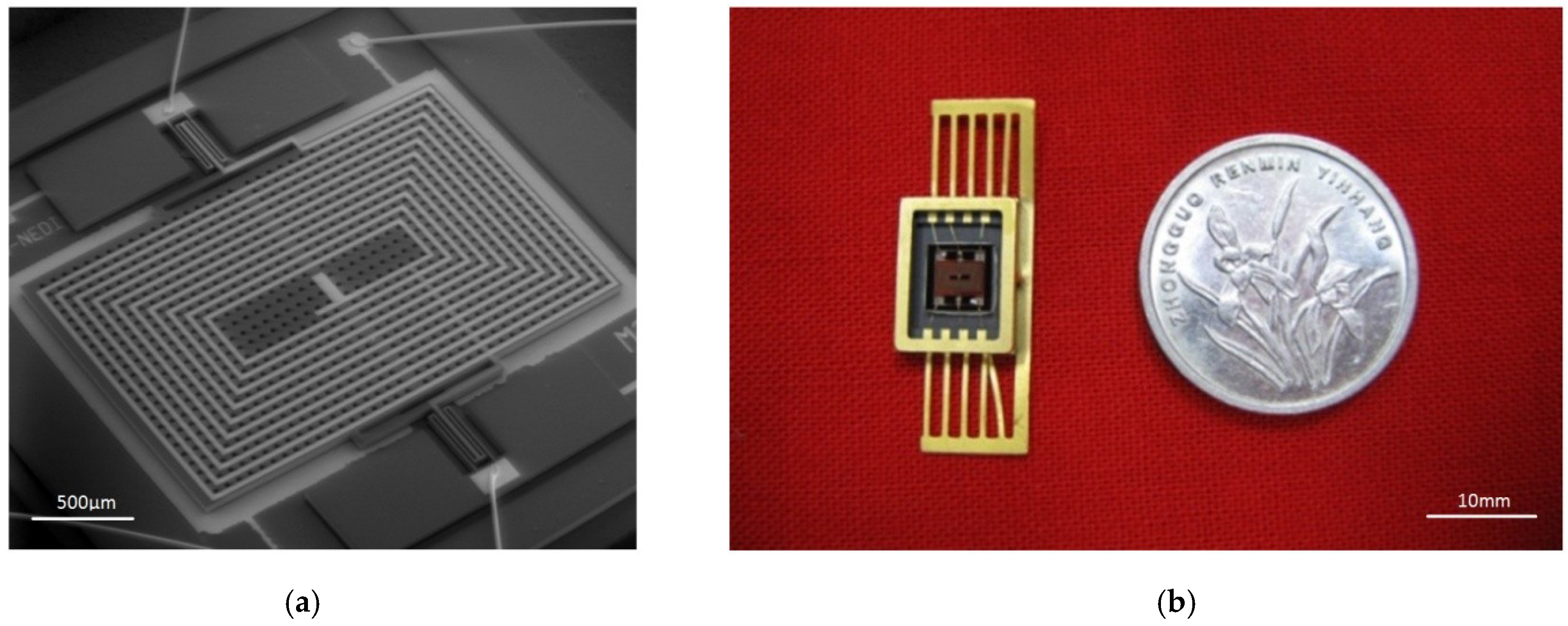

The MEMS structure and the packaged torsional resonant magnetometer are shown in

Figure 5a,b.

4. Driving and Detection Circuit

The driving and detection circuit of this MEMS torsional resonant magnetometer included two printed circuit boards (PCBs), connected with a pin header. The bottom PCB was a signal carrier generator, which could generate a very stable and accurate carrier signal on the MHz level. The upper PCB was the miniature magnetometer and a circuit for the signal preprocessing, including a driving circuit, a pre-amplifier circuit, a subsequent amplifier circuit, and a full wave rectifier and demodulator circuit.

The upper PCB had a four-layer structure, where the internal power layer and the Ground (GND) layer were in the middle. Meanwhile, a large number of GND wires were placed on the top and bottom layers to reduce the environmental noises introduced to the pre-amplifier circuit. Because the radiations of the high-frequency carrier signals will cause interferences with other circuits, and the wire of the high-frequency carrier signal is directly connected to the structure of the torsional pendulum, this connecting wire should be as short as possible. In this device, the bandwidth was closely related to the quality factor (Q) value. It was about 0.65 Hz in vacuum and 232 Hz in air.

Figure 6 is the integrated driving circuit and signal conditioning circuit of the MEMS torsional resonant magnetometer.

5. Testing and Analysis

In this magnetometer, the beam length was 500 μm, and the beam width was 20 μm. The thickness of the resonator was 60 μm. The area of the torsional pendulum structure was about 3000 μm × 2000 μm. The torsional beam parameters are shown in

Table 1. To investigate how relevant parameters influenced device performance, six different types of magnetometers were designed with different MEMS structures. As presented in

Table 1, the differences included the shapes and dimensions of the torsional beams, the number of coil turns, the diameter of the damping holes, and the dimensions of the torsional pendulums.

Here, the difference between the two straight beams was the beam width, w, and the differences between the two folded beams were the beam width and the connection length between the main beam and the side beam. There were two types of exciting coil layers, single layer (M1, M2, and M3) and double-layer (M4, M5, and M6). Meanwhile, there were also two different coil arrangements (7 turns with a 50 μm width and 11 turns with a 30 μm width) for each type.

Except for M3, the size of the torsional pendulums was 3000 μm × 2000 μm. For the structural limitation, the samples with the narrow excitation coils had 864 damping holes with a diameter of 30 μm, and the samples with the wider excitation coils had 364 damping holes with a diameter of 50 μm.

5.1. Sensitivity

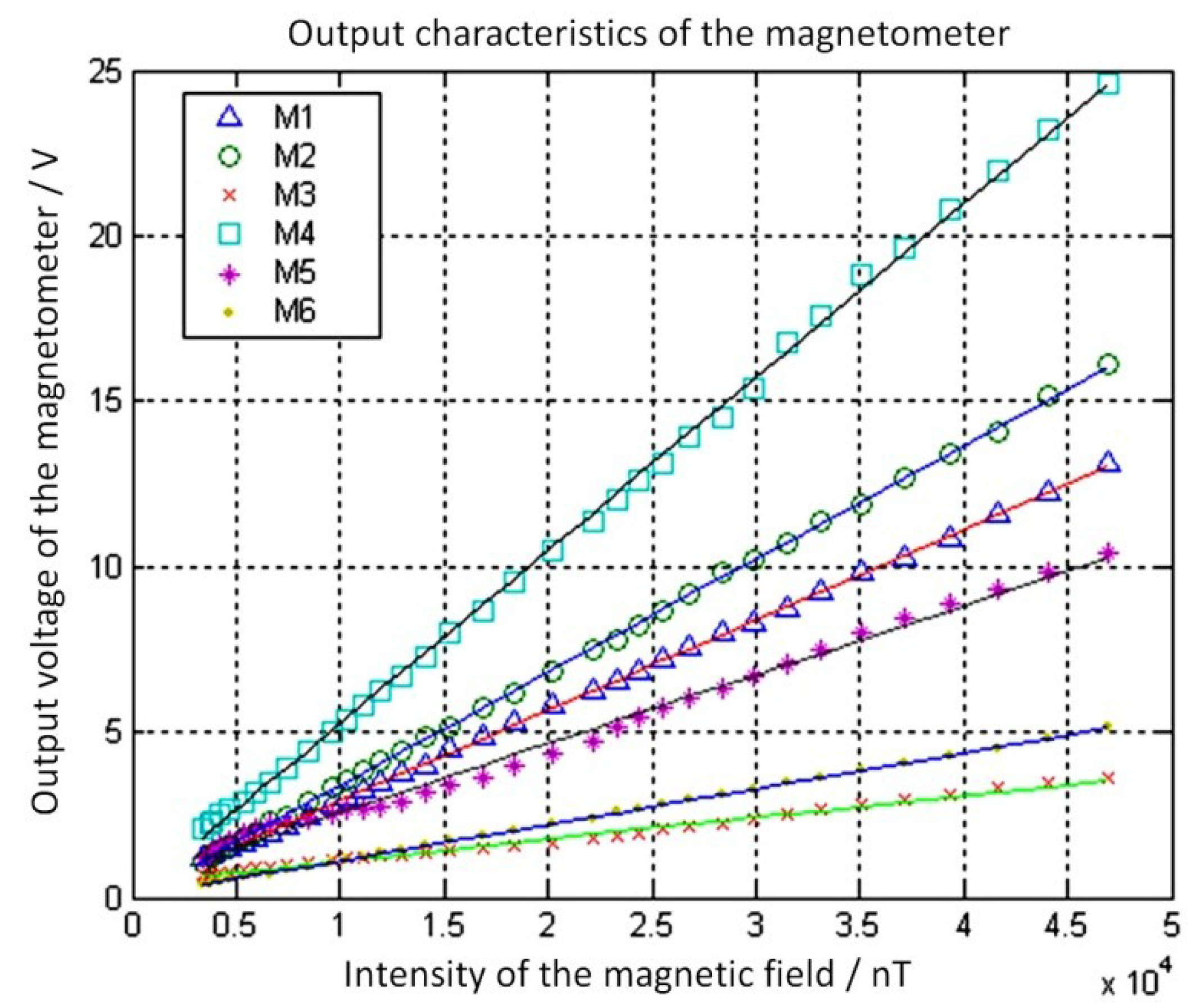

The output properties of the different magnetometer models were tested in a magnetic field intensity range of 0–50 μT with an energizing current amplitude of 1 mA and a vacuum of 10 Pa at room temperature. The test results are shown in

Figure 7. For simplicity, the measured voltage was the peak-to-peak AC voltage signal without synchronous demodulation, which had the same frequency as the driving signal.

For the different magnetometer types, it was clear that there was a very good linear correlation between the output voltage and the magnetic field intensity. In contrast, their sensitivity differences were obvious. As shown in

Table 2, the sensitivity of the M4 model was about 8 times that of the M6 model. This was due to the different MEMS structures and parameters, including the torsional beam structures, torsional beam parameters, coil types, torsional pendulum sizes, and the parameters and quantities of the damping holes.

5.2. Resonant Frequency and Quality Factor

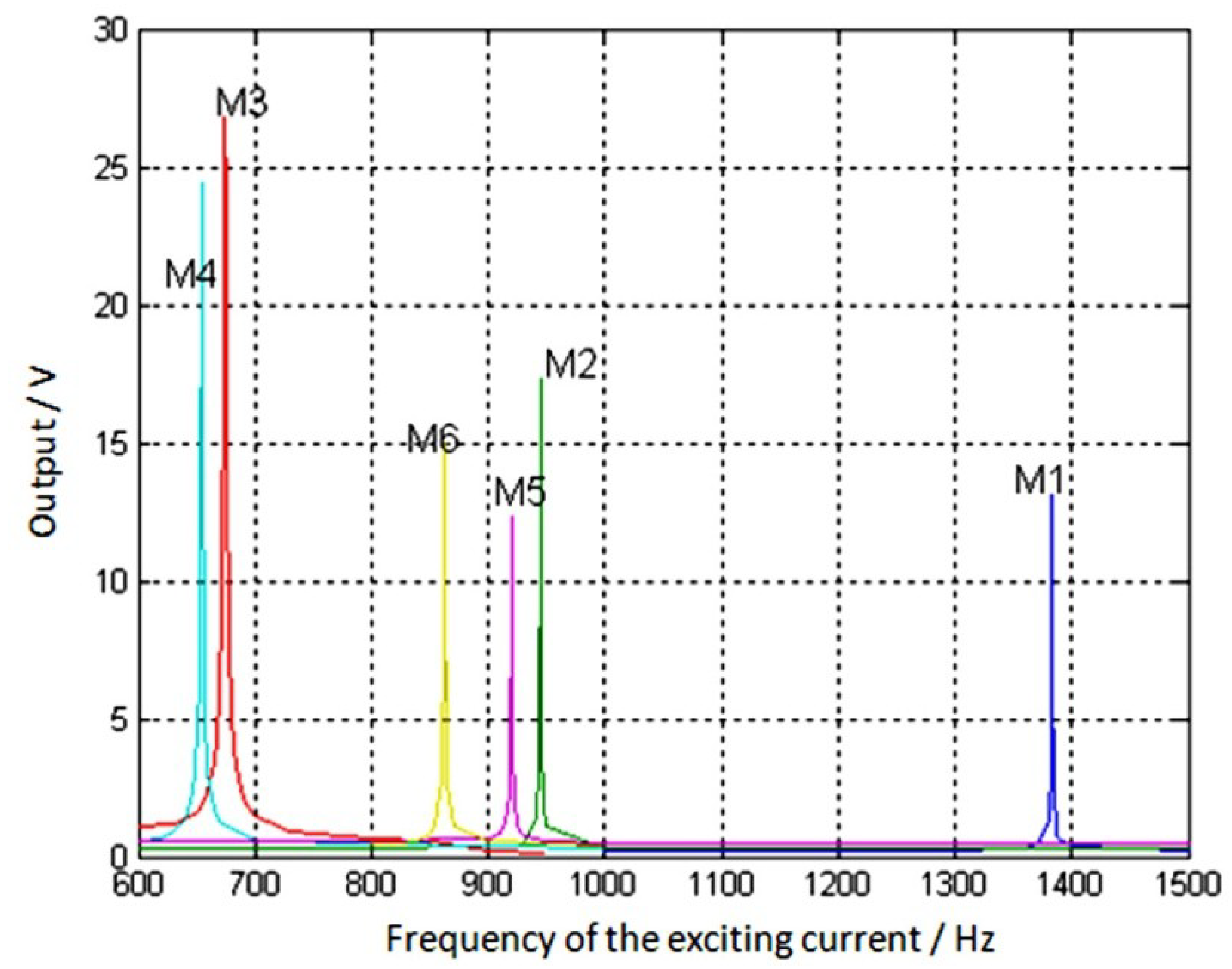

With a constant outside magnetic field strength and varying excitation current frequency, amplitude changes were observed in the magnetometer output voltages. The frequency characteristics of the exciting current for the different samples are shown in

Figure 8.

Because the vacuum level in the test environment was 10 Pa, the damping ratio,

α, of the magnetometer torsional pendulum resonant system was close to 0. Therefore, the quality factor,

Q, could be obtained as follows:

where

f0 is the resonant frequency of the torsional pendulum, and

fu and

fd are the upper and lower frequency limits, respectively, when the output amplitude decreases to

(−3 dB) of the peak.

From Equation (3) and

Figure 9, the resonant frequency and the quality factor for each sample were obtained. As shown in

Table 3, the resonant frequency test results were generally in agreement with the theoretical analysis, and the error was about 15%.

5.3. Analysis of the Structural Parameters

The parameters of different magnetometer types were analyzed, and their performance was compared to verify the parameter choices.

5.3.1. Resistance of the Excitation Coil

Ten samples of each type were selected, and the coil resistance was measured. The results showed that the resistance of the double coils was twice that of a single coil with the same number of turns and width. As the upper and lower coils were approximately the same length, it was reasonable that the resistance of the double coil layer was approximately twice that of the single coil layer. This indicates that the fabrication based on the novel design was successful. There were no short circuiting phenomena between the upper and the lower coils due to low fabrication quality of the SiNx insulating layer. According to the measurement results, the double coil process resulted in a high yield. In

Table S3, we list the measured and calculated coil resistances.

5.3.2. Initial Value of the Capacitor Polar Plate

The initial capacitor value, C0, between the torsional structure and the capacitor polar plate beneath was simulated by CoventorWare, resulting in a value of 2.663 pF. It was also measured with a capacitance–voltage (C–V) characteristic tester, with results ranging from 2.6 pF to 2.7 pF, which was in good agreement with the simulation result.

5.3.3. Elastic Coefficient of the Torsional Beam

When other structural parameters remained the same, the sensitivity of the M1-type device with a straight beam (width of 25 µm) was 272 mV/µT, whereas the M2-type device with the folded beam (main beam width of 30µm, side beam width of 30 µm) was 342 mV/µT. The sensitivity ratio was thus .

The simulation analysis showed that the capacitance variance of M1 was , while that of M2 was with an exciting current of 30 mA and a magnetic field intensity of 50 µT. For this type of magnetometer, the ratio of the capacitance variance amplitudes, the ratio of the magnetometer output voltage amplitudes, and the ratio of the sensitivities were the same. Based on the simulation results, the sensitivity ratio of these two devices was , which agreed well with the experimental data. In addition, it can be seen that the sensitivity of the folded beam device was 1.3 times that of the straight beam device.

Because the excitation coil was led out along the torsional beam, the excitation coil and the torsional beam had the same width. However, the equivalent width of the folded beam was different from that of the straight beam, making their allowable currents different. According to previous experience with the MEMS process, the maximum allowable current of a gold coil with a sectional size of 1 µm × 1 µm was 4 mA, which was proportional to the coil width and thickness. Due to the difference in the equivalent width, the maximum allowable current ratio of the folded beam type and the straight beam type device was approximately 1.2 (30/25). The current amplitude was approximately proportional to the amplitude of the capacitance variance under small angle torsion. Additionally, the sensitivity of the folded beam type was approximately 1.6 (1.3 × 1.2) times that of the straight beam type at the maximum allowable current. Thus, the sensitivity was clearly improved with the folded beam structure.

For comparison of straight beam-type devices with different widths (M1 and M4), from Equation (1),

was obtained. The moment of inertia (

Θ) was the same for the two devices, and the elastic coefficient of a straight beam,

k, was proportional to

, where

w and

γ are the width of the straight beam and a coefficient related to

w/

h, respectively. For the M1 device,

, and

was 0.254. For the M4 device,

, and

was 0.282 [

30]. Therefore, the theoretical resonance frequency ratio between M1 and M4 could be obtained as follows:

The practical frequency ratio of the two devices was , which agreed well with the theoretical results. According to Equation (3), the elastic coefficient of the torsional beam was proportional to the cube of the beam width. Therefore, decreasing the width could notably decrease the elastic coefficient of the torsional beam, thus increasing the torsional angle under the same torque.

5.3.4. Layer Quantity of the Exciting Coil

According to the analysis, the torque generated by the magnetic sensor was the sum of the torques generated by each turn of the exciting coil perpendicular to the magnetic field. In the double coil structure, the number of exciting coils in that direction was twice that of the single coil structure. Therefore, the torque amplitude,

M, was theoretically twice that of the single coil structure. The maximal twisting angle of the magnetometer torsional pendulum could be calculated as follows:

where

Q is the quality factor. Analysis of the performance of the capacitance measurement circuit showed that the amplitude of the output voltage was directly proportional to the capacitance variance amplitude, Δ

C, and thus was also directly proportional to the maximal twisting angle,

φr, of the torsional pendulum when the twisting angle was small. The M1-type device had a single exciting coil with a torsion beam width of

w1 = 25 µm,

Q = 2350.1, and sensitivity = 272 mV/μT. The M4-type device had a double exciting coil with a torsion beam width

w4 = 15 µm,

Q = 485.9, and sensitivity = 523 mV/μT. Other than these previously mentioned differences, these two device types had the same structures. The structural parameters and test data for the M1- and M4-type devices were input into Equation (4) to obtain the ratio between the torques of the M4 exciting coil and the M1 exciting coil as follows:

According to the theoretical analysis, the expected torque ratio between the M4-type and M1-type devices was 2, which was basically consistent with the test value of 2.23. This indicates that the design of the double exciting coil structure was effective, and the increased excitation torque of the device was approximately double the original value. Analysis of the device linearity showed that its sensitivity was also double the original value.

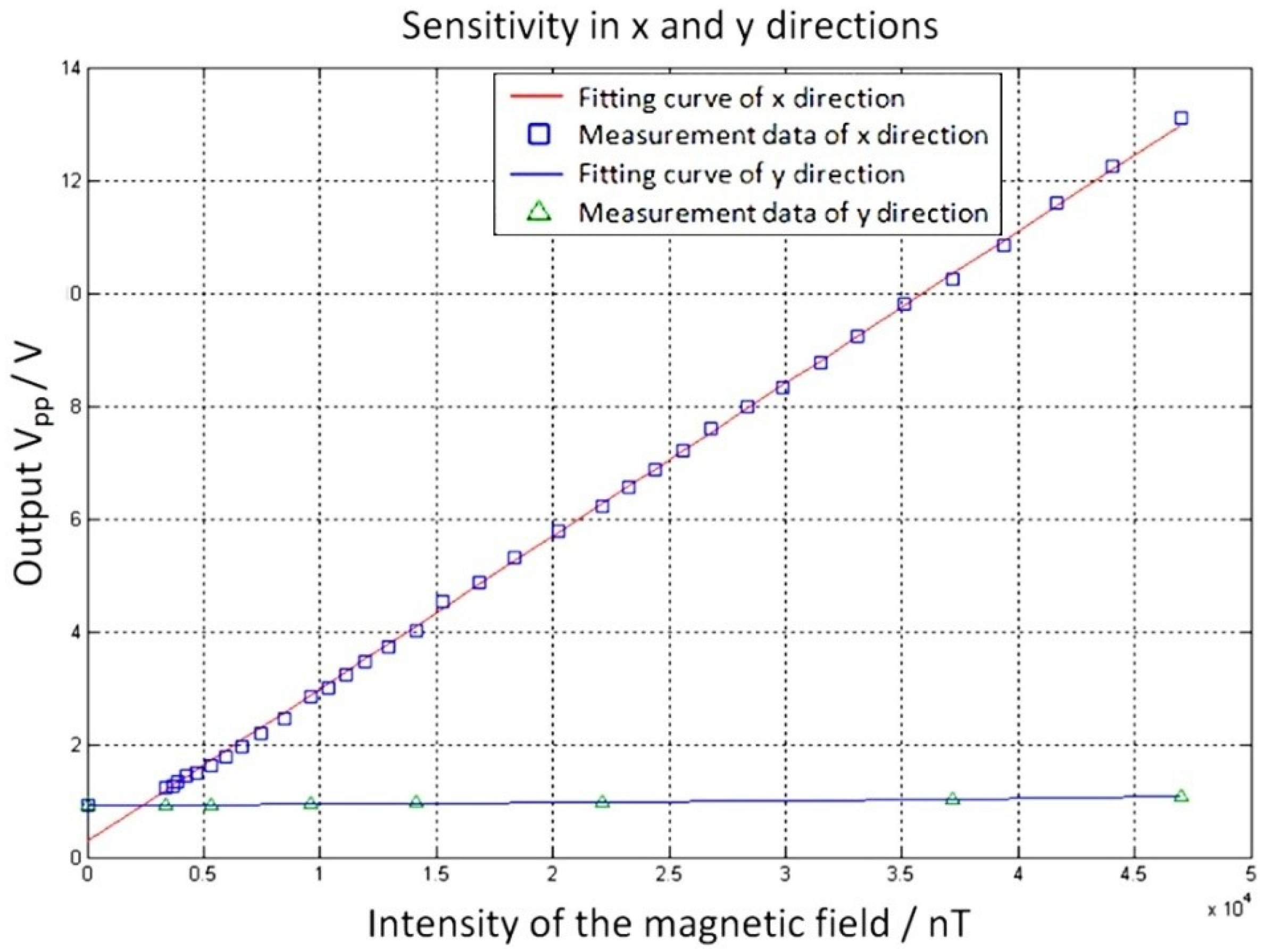

5.4. Sensitivity in the Orthogonal Axis

This magnetometer could only sense the magnetic field in the horizontal plane perpendicular to the torsion beam (the

x axis in

Figure 1). To investigate its sensitivity in the orthogonal axis, the sensitivity was tested in the

x and

y directions. From

Figure 9, the sensitivity along the

x axis and

y axis was

Kx = 270 mV/µT and

Ky = 3.25 mV/µT. The sensitivity in the

x direction was about 83 times that in the

y direction. Therefore, the sensor could be regarded as a monoaxial sensitive sensor.

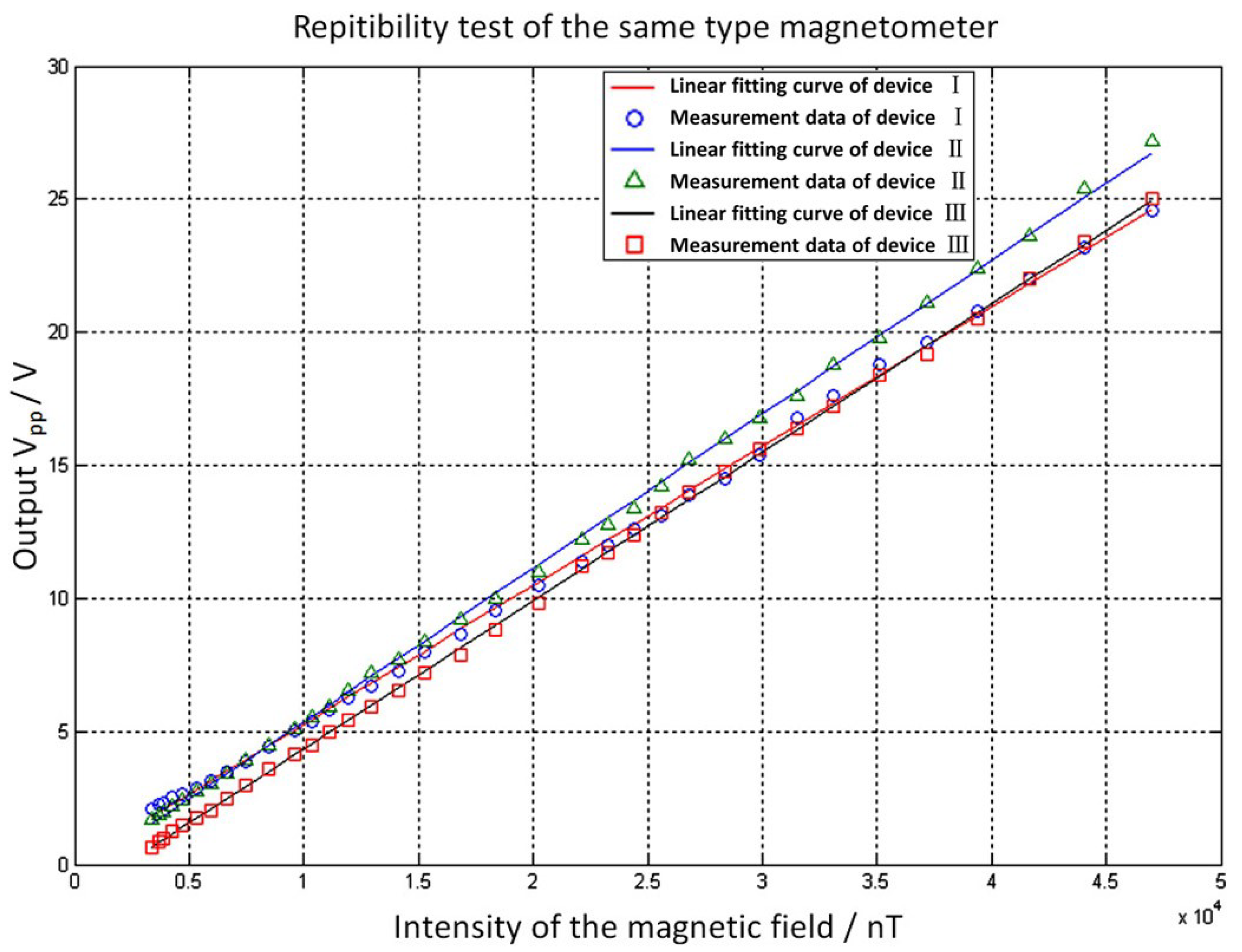

5.5. Repeatability

The M3-type device was selected to test the repeatability of the output characteristics. With a pressure intensity of

P = 5 Pa, an excitation voltage frequency of

f0 = 673.9 Hz, and an excitation voltage peak value of

Vpp = 300 mV, the intensity of the external magnetic field was adjusted three times from 0 nT to 30,000 nT to investigate the change in output voltage with each adjustment of the magnetic field intensity. Linear fitting was performed for each of the three measurements, and the resulting curves are shown in

Figure 10.

The performances reflected by the linear fitting curves for the three measurements are summarized in

Table 4. The linear correlation coefficient of the data and the sensitivity of the fitting curve were very close, indicating good repeatability.

Next, the main causes of repeatability error were analyzed when the magnetometer was placed in a magnetic field with a variable external magnetic field intensity. As some of the components on the circuit board and the package shells contained nickel, iron, cobalt, and the Kovar alloy compounded from such materials, these components were prone to magnetization and would generate a static magnetic field of a given intensity. When the strength of the magnetic field changed, these materials were also magnetized with an altered strength, and the influence of the magnetic field they generated would also vary. This caused the sensor to output different values for a magnetic field with the same strength during different measurements, thus decreasing the repeatability of the sensor.

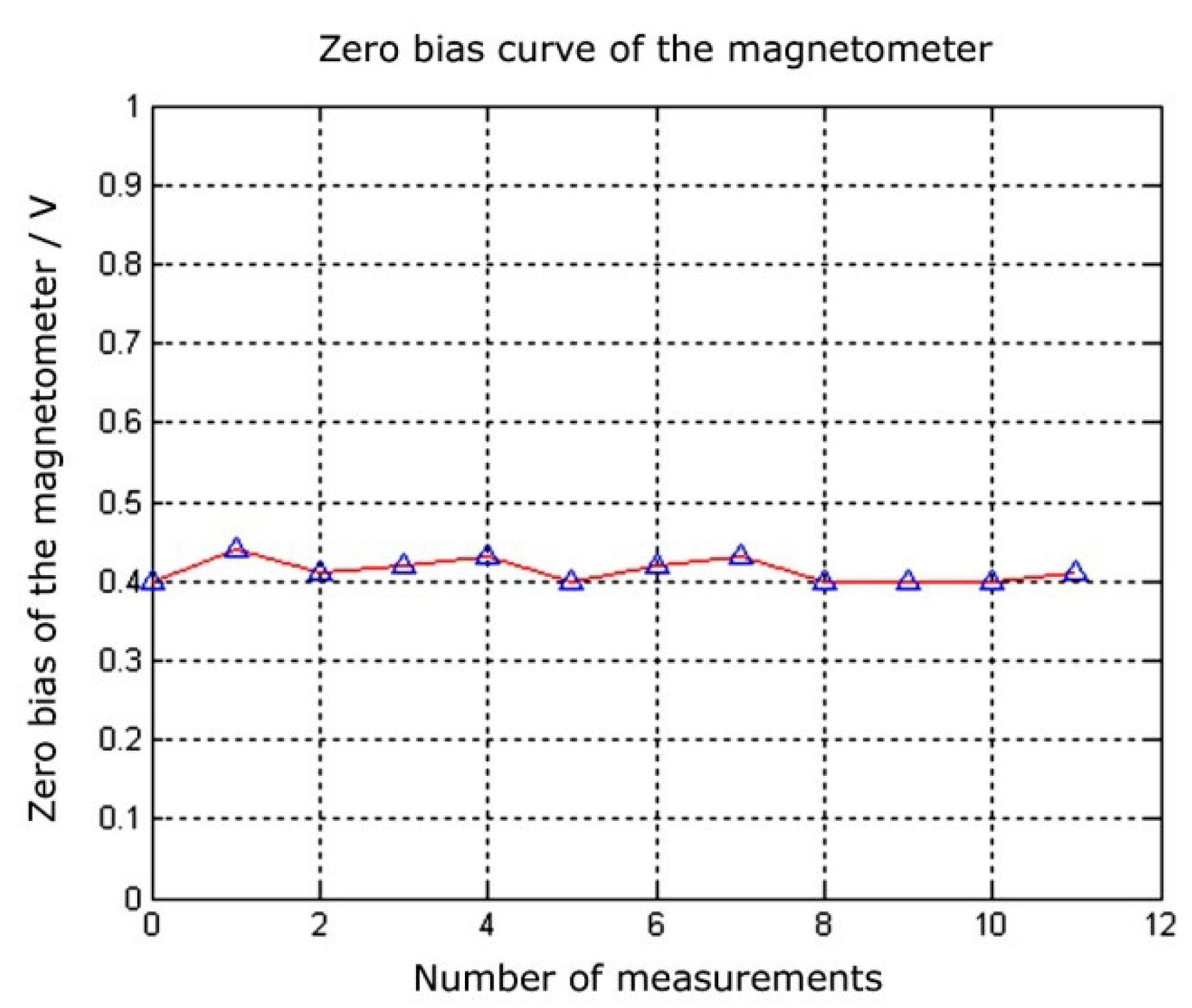

Meanwhile, during multiple measuring processes with the same magnetometer, the zero deviations of the prototype were recorded for each measurement. The resulting curve is shown in

Figure 11. The zero deviations of the prototype ranged between 0.40 V and 0.44 V, with an average of 0.413 V. The standard deviation was approximately 14 mV. This standard deviation was very small relative to the output amplitudes, which satisfied the repeatability requirement.

5.6. Noise

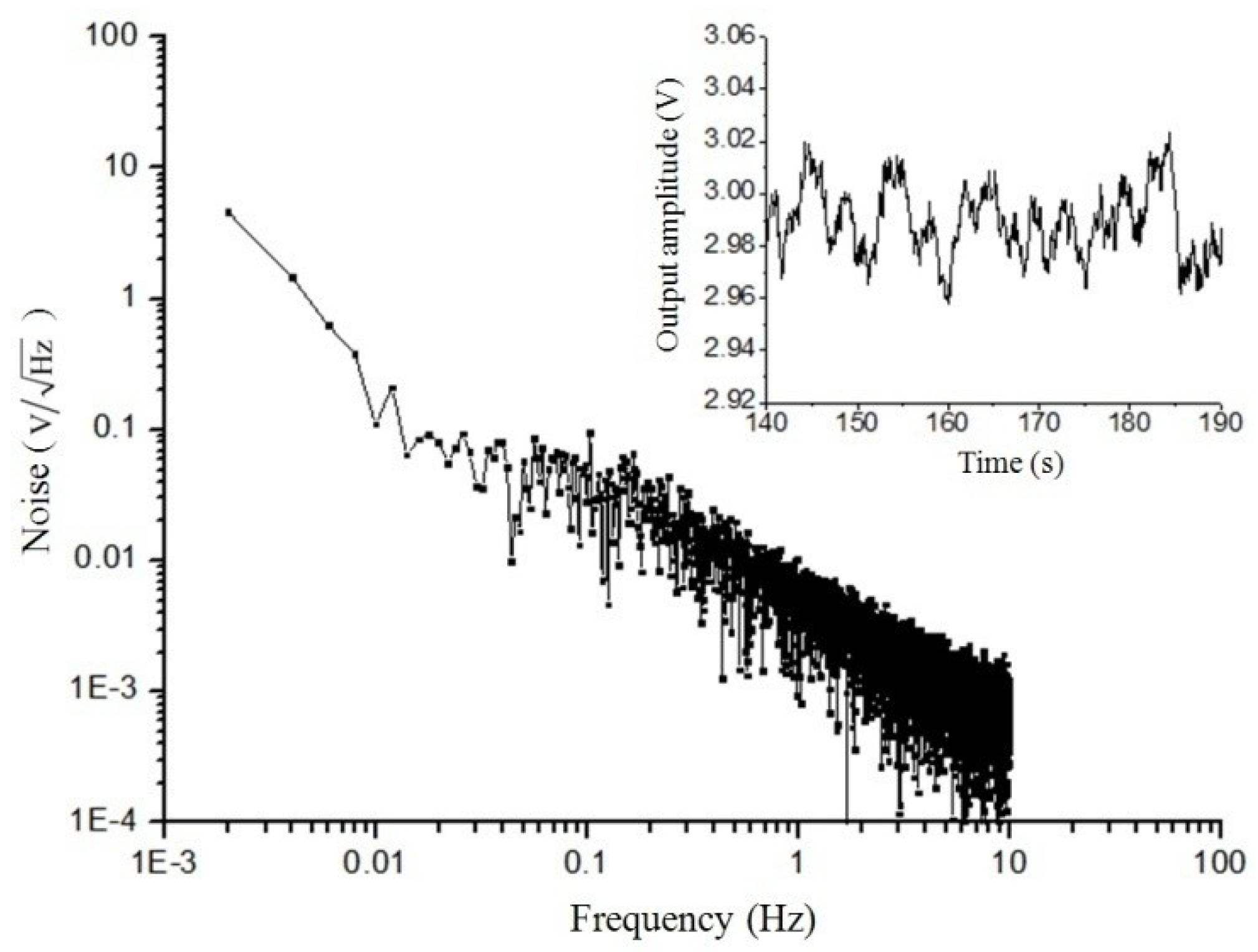

Noise was one of the most important parameters of the sensor.

Figure 12 shows the noise spectrum of the sensor. The inset shows a typical time trace. Its noise peak-to-peak value was 60 mV. Since the sensitivity of the sample in this range was 1 V/μT, the noise was

.

6. Conclusions

A MEMS torsional resonant magnetometer was designed based on the Lorentz force. MEMS processes were analyzed and optimized based on fabrication experiments and tests. Detailed tests were conducted on the prototypes to verify the choice of design parameters. Experimental measurements showed that the capacitance change could reach 100 fF under the condition of a 10 Pa air pressure when an external magnetic field of 50 μT was applied. Such sensitivity effectively decreased the difficulties in the signal processing. Experiments indicated that the resolution of the device was better than 30 nT. Additional tests demonstrated good repeatability of the measurement process as well as the zero deviations of the device.

To increase the sensitivity, the drive current I, coil length L, pendulum width W, and beam length l should be maximized. At the same time, the plate distance d0, beam thickness h, beam width w, and shear modulus G should be minimized. The quality factor should be as high as possible, which can be realized by increasing the size and the number of holes.

Compared to other MEMS magnetometers, the structures of this torsional resonant magnetometer were easier to fabricate. The test results demonstrated that it could meet the requirements of attitude determination systems of low earth orbit satellites.