Testing Effects on Shear Transformation Zone Size of Metallic Glassy Films Under Nanoindentation

Abstract

:1. Introduction

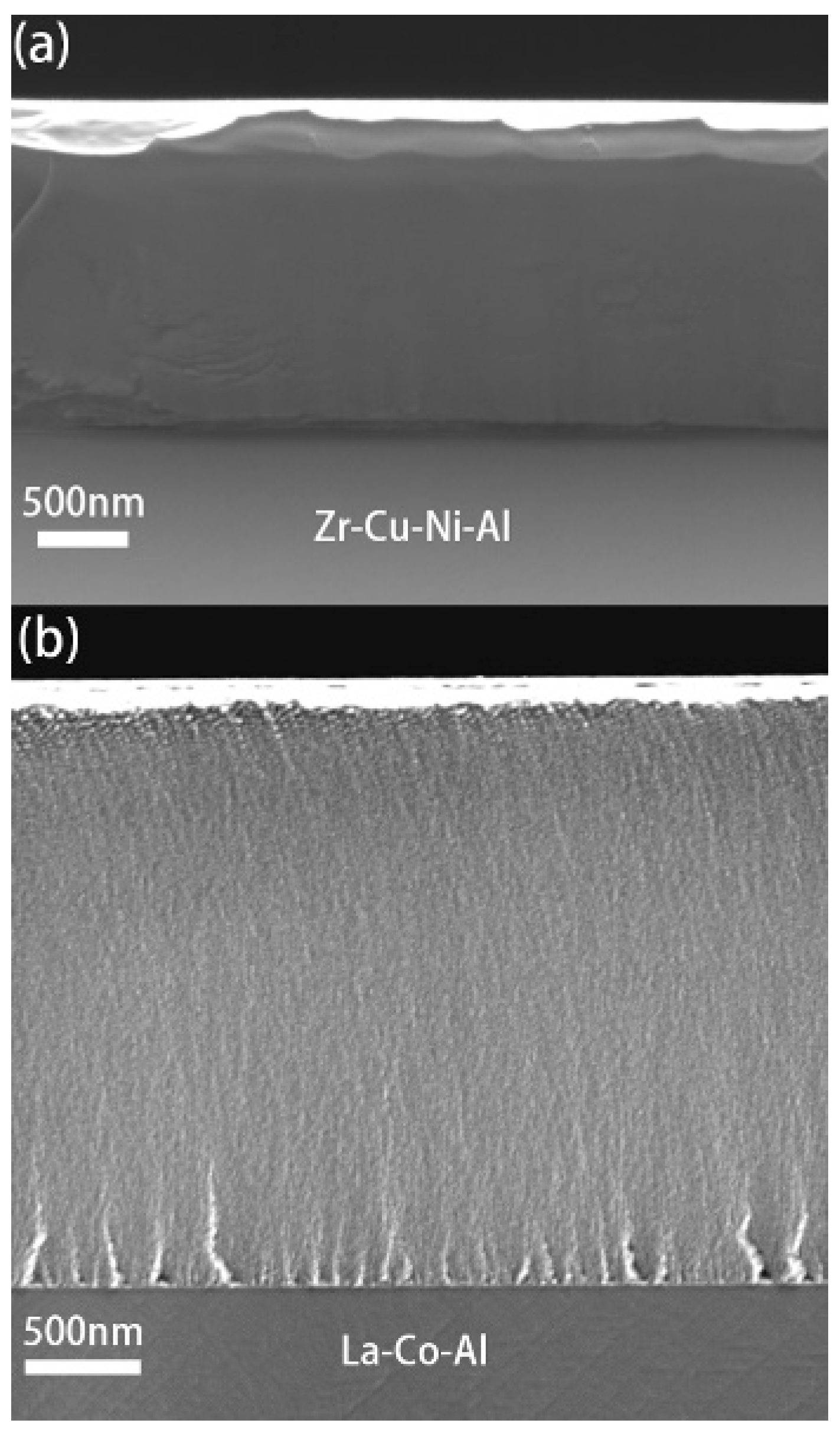

2. Materials and Methods

3. Results and Discussion

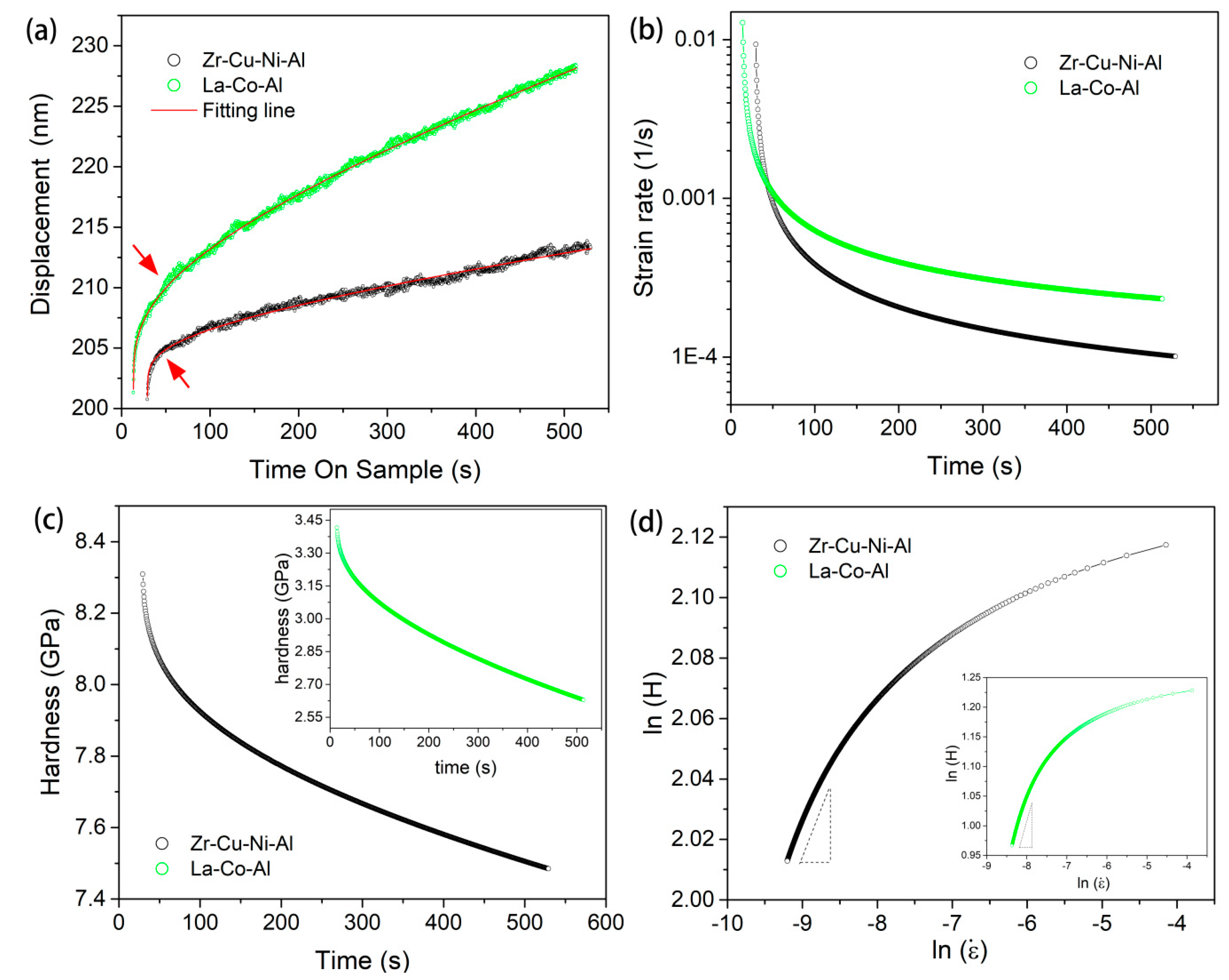

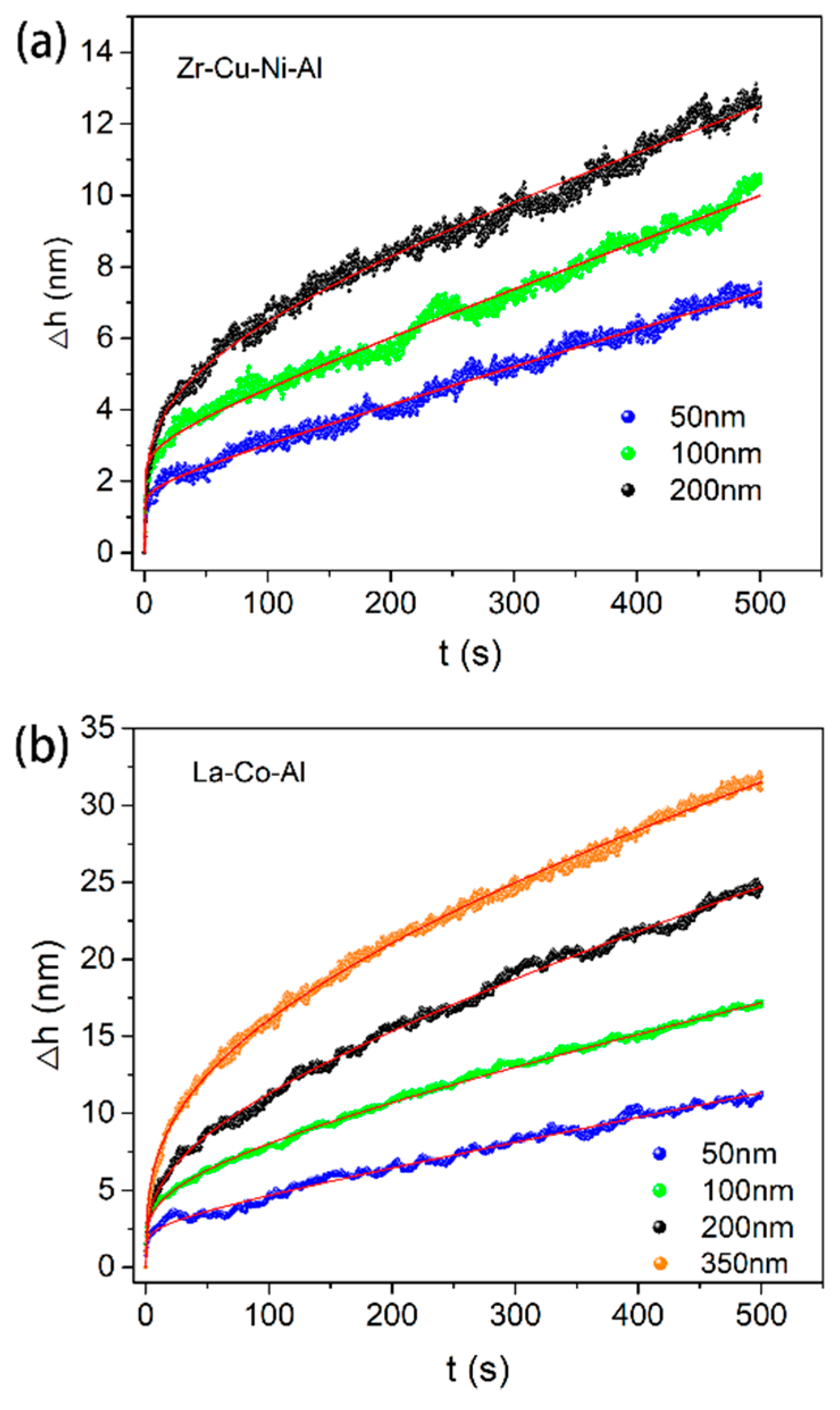

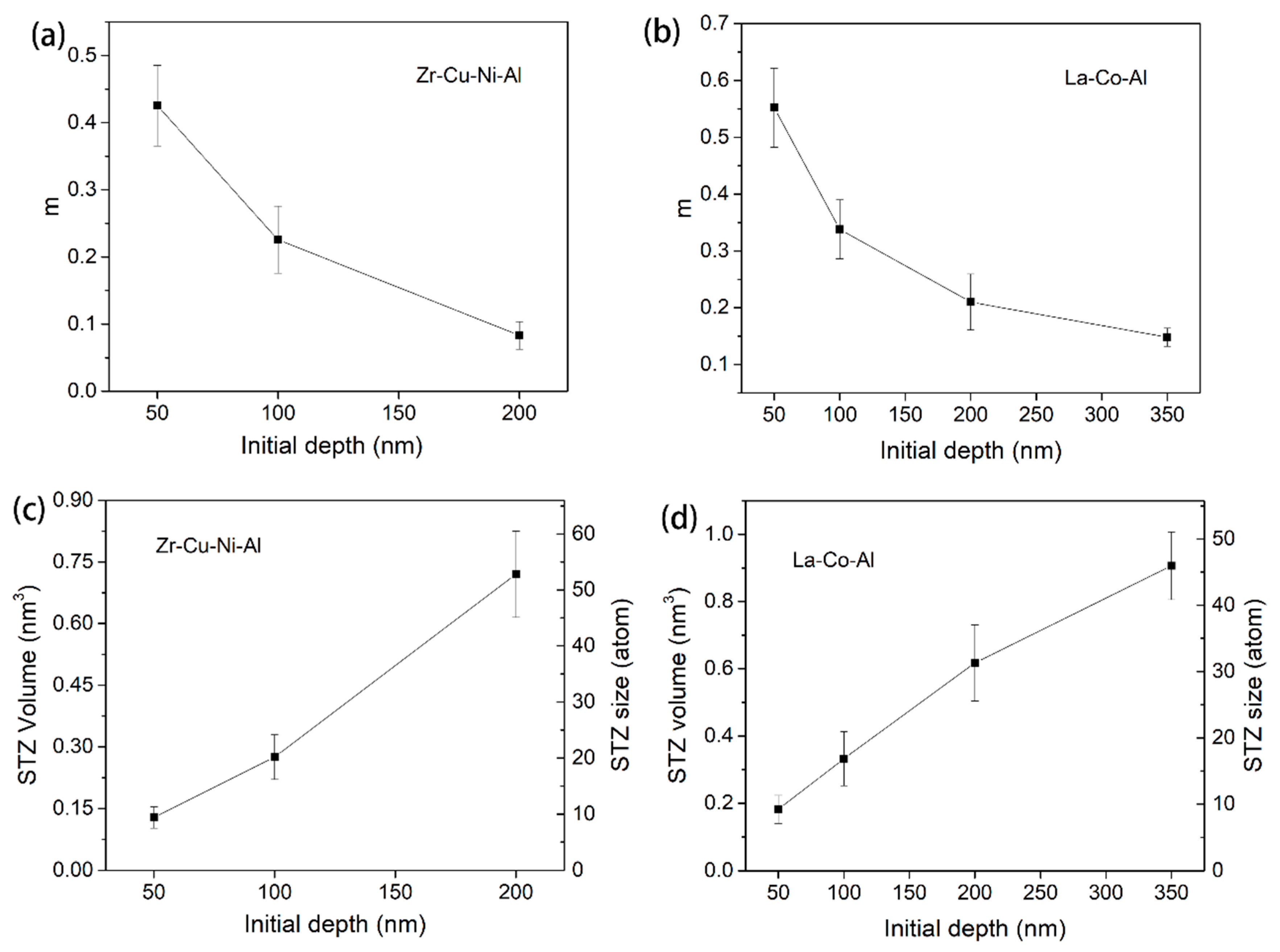

3.1. Indentation Size Effect

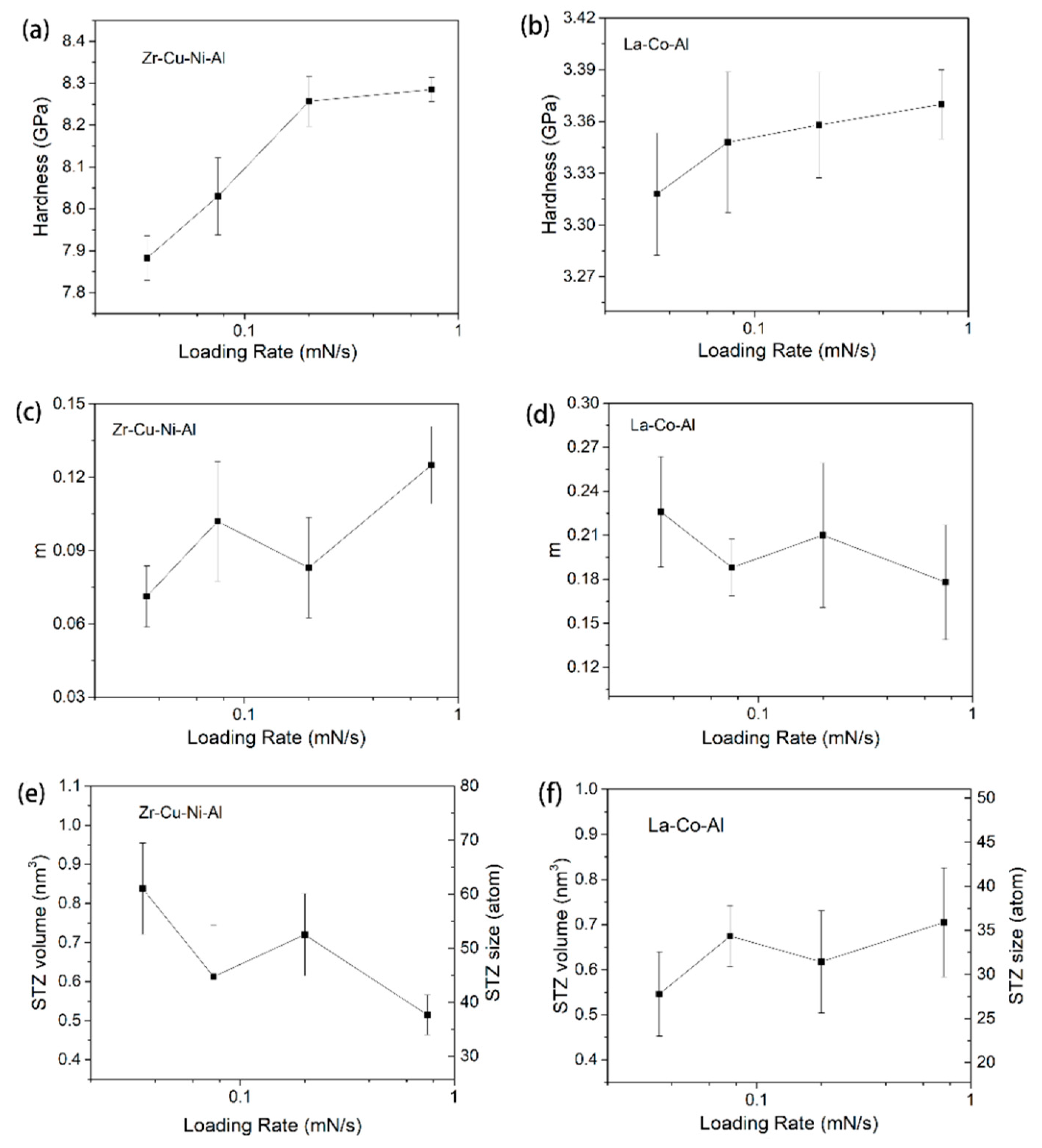

3.2. Loading Rate Effect

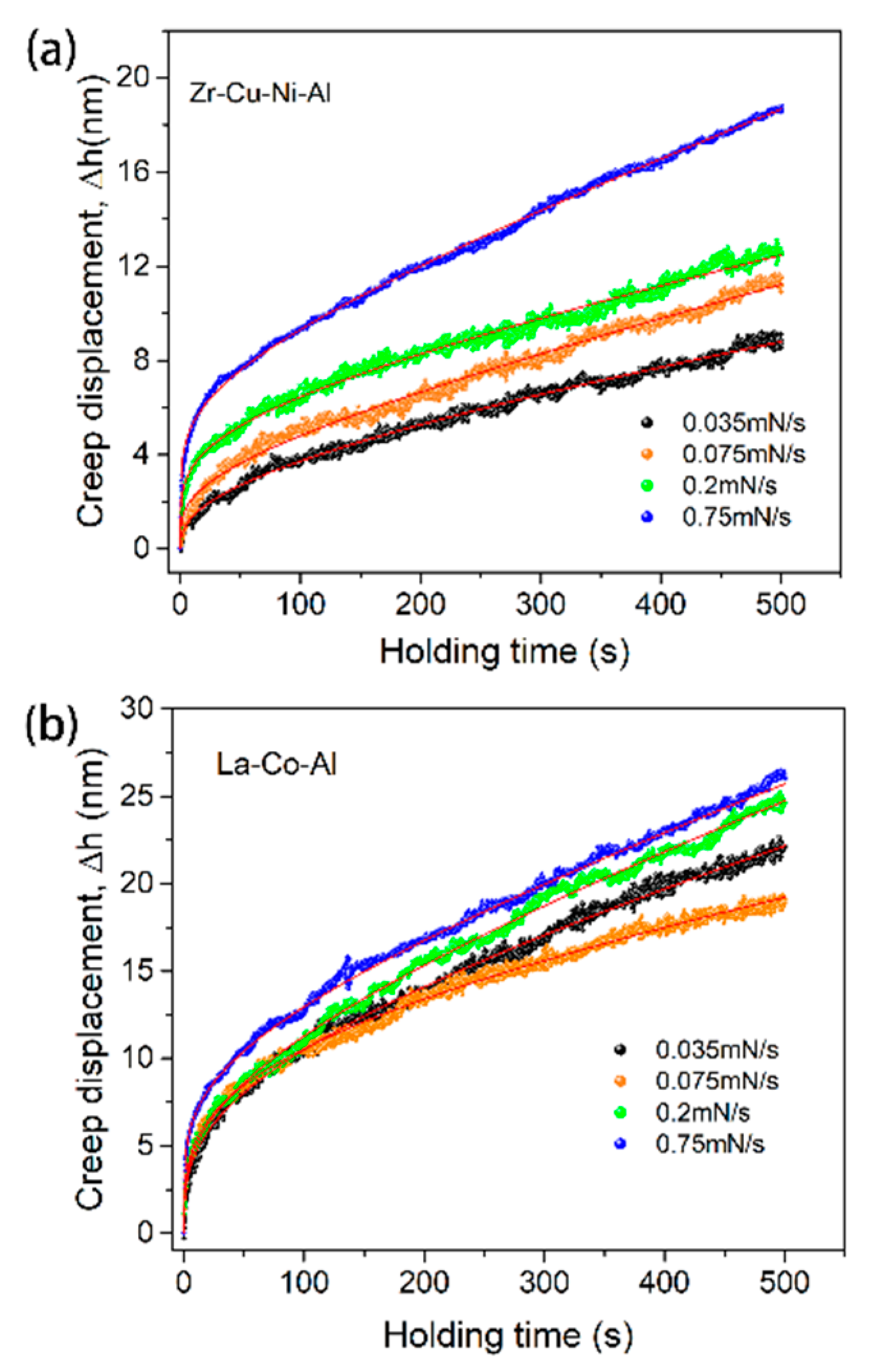

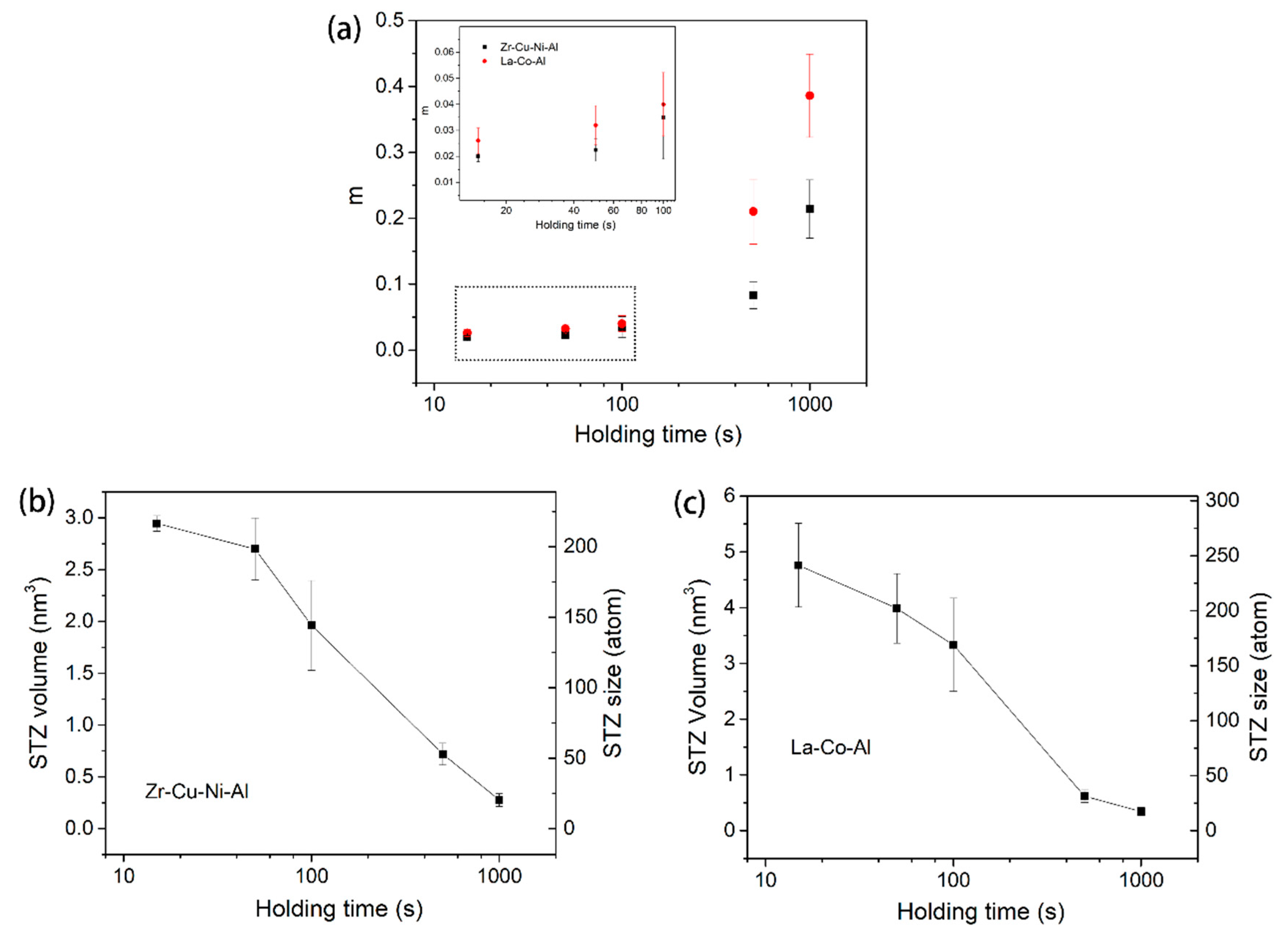

3.3. Holding Time Effect

4. Conclusions

- (1)

- The estimated STZ sizes using the creep method correspond well with the theoretical simulation. Under the same testing conditions, STZ size is detected to be larger in Zr-Cu-Ni-Al than in La-Co-Al, which could be due to the higher glass transition temperature (Tg).

- (2)

- The indentation size effect can be clearly observed in both samples; STZ size increases quickly with increasing pressed depth.

- (3)

- The loading rate effect on STZ size is weak and composition-dependent. STZ size decreases slightly in Zr-Cu-Ni-Al and changes little in La-Co-Al, even though the loading rate is increased by more than an order of magnitude.

- (4)

- Holding time is particularly important in estimating STZ size. STZ size would artificially decrease from several hundreds of atoms to no more than twenty as the holding stage increases from 15 s to 1000 s.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Klement, W.; Willens, R.; Duwez, P. Non-crystalline structure in solidified gold-silicon alloys. Nature 1960, 187, 869–870. [Google Scholar] [CrossRef]

- Loffler, J.F. Bulk metallic glasses. Intermetallics 2003, 11, 529–540. [Google Scholar] [CrossRef]

- Schuh, C.A.; Hufnagel, T.C.; Ramamurty, U. Mechanical behavior of amorphous alloys. Acta Mater. 2007, 55, 4067–4109. [Google Scholar] [CrossRef]

- Inoue, A.; Shen, B.; Koshiba, H.; Kato, H.; Yavari, A.R. Cobalt-based bulk glassy alloy with ultrahigh strength and soft magnetic properties. Nat. Mater. 2003, 2, 661–663. [Google Scholar] [CrossRef] [PubMed]

- Leamy, H.J.; Chen, H.S.; Wang, T.T. Plastic flow and fracture of metallic glass. Metall. Trans. 1972, 3, 699–708. [Google Scholar] [CrossRef]

- Argon, A. Plastic deformation in metallic glasses. Acta Metal. Mater. 1979, 27, 47–58. [Google Scholar] [CrossRef]

- Mayr, S.G. Activation energy of shear transformation zones: A key for understanding rheology of glasses and liquids. Phys. Rev. Lett. 2006, 97, 195501. [Google Scholar] [CrossRef] [PubMed]

- Manning, M.L.; Langer, J.S.; Carlson, J.M. Strain localization in a shear transformation zone model for amorphous solids. Phys. Rev. E 2007, 76, 056106. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zink, M.; Samwer, K.; Johnson, W.L.; Mayr, S.G. Plastic deformation of metallic glasses: Size of shear transformation zones from molecular dynamics simulations. Phys. Rev. B 2006, 73, 172203. [Google Scholar] [CrossRef]

- Li, L.; Homer, E.R.; Schuh, C.A. Shear transformation zone dynamics model for metallic glasses incorporating free volume as a state variable. Acta Mater. 2013, 61, 3347–3359. [Google Scholar] [CrossRef] [Green Version]

- Johnson, W.; Samwer, K. A Universal Criterion for Plastic Yielding of Metallic Glasses with a (T/Tg)2/3 Temperature Dependence. Phys. Rev. Lett. 2005, 95, 195501. [Google Scholar] [CrossRef] [PubMed]

- Pan, D.; Inoue, A.; Sakurai, T.; Chen, M.W. Experimental characterization of shear transformation zones for plastic flow of bulk metallic glasses. Proc. Natl. Acad. Sci. USA 2008, 105, 14769–14772. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kramer, L.; Maier-Kiener, V.; Champion, Y.; Sarac, B.; Pippan, R. Activation volume and energy of bulk metallic glasses determined by nanoindentation. Mater. Des. 2018, 155, 116–124. [Google Scholar] [CrossRef]

- Maier-Kiener, V.; Durst, K. Advanced Nanoindentation Testing for Studying Strain-Rate Sensitivity and Activation Volume. JOM 2017, 69, 2246–2255. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Pan, D.; Yokoyama, Y.; Fujita, H.; Liu, T.Y.; Kohara, H.S.; Inoue, A.; Chen, M.W. Correlation between structural relaxation and shear transformation zone volume of a bulk metallic glass. Appl. Phys. Lett. 2009, 95, 141909. [Google Scholar] [CrossRef]

- Bhattacharyya, A.; Singh, G.; Prasad, K.E.; Narasimhan, R.; Ramamurty, U. On the strain rate sensitivity of plastic flow in metallic glasses. Mat. Sci. Eng. A 2015, 625, 245–251. [Google Scholar] [CrossRef]

- Choi, I.C.; Yoo, B.G.; Kim, Y.J.; Jang, J.I. Indentation creep revisited. J. Mater. Res. 2012, 27, 3–11. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. An improved technique for determining hardness and elastic-modulus using load and displacement sensing indentation experiments. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

- Ginder, R.S.; Nix, W.D.; Pharr, G.M. A simple model for indentation creep. J. Mech. Phys. Solids 2018, 112, 552–562. [Google Scholar] [CrossRef]

- Yoo, B.G.; Kim, Y.J.; Choi, I.C.; Shim, S.T.; Tsui, Y.; Bei, H.B.; Ramamurty, U.; Jang, J.I. Increased time-dependent room temperature plasticity in metallic glass nanopillars and its size-dependency. Int. J. Plast. 2012, 37, 108–118. [Google Scholar] [CrossRef]

- Feng, G.; Ngan, A.H.W. Creep and strain burst in indium and aluminium during nanoindentation. Scr. Mater. 2001, 45, 971–976. [Google Scholar] [CrossRef]

- Afrin, N.A.; Ngan, H.W. Creep of micron-sized Ni3Al columns. Scr. Mater. 2006, 54, 7–12. [Google Scholar] [CrossRef]

- Chen, J.; Bull, S.J. The investigation of creep of electroplated Sn and Ni–Sn coating on copper at room temperature by nanoindentation. Surf. Coat. Technol. 2009, 203, 1609–1617. [Google Scholar] [CrossRef]

- Zhang, T.H.; Ye, J.H.; Feng, Y.H.; Ma, Y. On the spherical nanoindentation creep of metallic glassy thin films at room temperature. Mater. Sci. Eng. A 2017, 685, 294–299. [Google Scholar] [CrossRef] [Green Version]

- Ma, Y.; Ye, J.H.; Peng, G.J.; Zhang, T.H. Nanoindentation study of size effect on shear transformation zone size in a Ni–Nb metallic glass. Mater. Sci. Eng. A 2015, 627, 153–160. [Google Scholar] [CrossRef]

- Ma, Y.; Peng, G.J.; Jiang, W.F.; Chen, H.; Zhang, T.H. Nanoindentation study on shear transformation zone in a Cu-Zr-Al metallic glassy film with different thickness. J. Non-Cryst. Solids 2016, 442, 67–72. [Google Scholar] [CrossRef]

- Ma, Y.; Peng, G.J.; Feng, Y.H.; Zhang, T.H. Nanoindentation investigation on the creep mechanism in metallic glassy films. Mater. Sci. Eng. A 2016, 651, 548–555. [Google Scholar] [CrossRef] [Green Version]

- Chen, H.; Song, Y.X.; Zhang, T.H.; Ma, Y. Structure relaxation effect on hardness and shear transformation zone volume of a Ni-Nb metallic glassy film. J. Non-Cryst. Solids 2018, 499, 257–263. [Google Scholar] [CrossRef]

- Chen, H.; Zhang, T.H.; Ma, Y. Effect of applied stress on the mechanical properties of a Zr-Cu-Ag-Al bulk metallic glass with two different structure states. Materials 2017, 10, 711. [Google Scholar] [CrossRef] [PubMed]

- Li, H.; Nag, A.H.W. Indentation size effects on the strain rate sensitivity of nanocrystalline Ni–25at. % Al thin films. Scr. Mater. 2005, 52, 827–831. [Google Scholar] [CrossRef]

- Peykov, D.; Martin, E.; Chromic, R.R.; Gauvin, R.; Trudeau, M. Evaluation of strain rate sensitivity by constant load nanoindentation. J. Mater. Sci. 2012, 47, 7189–7200. [Google Scholar] [CrossRef]

- Li, W.H.; Shin, K.; Lee, C.G.; Wei, B.C.; Zhang, T.H.; He, Y.Z. The characterization of creep and time-dependent properties of bulk metallic glasses using nanoindentation. Matere. Sci. Eng. A 2008, 478, 371–375. [Google Scholar] [CrossRef] [Green Version]

- Wang, F.; Li, J.M.; Huang, P.; Wang, W.L.; Lu, T.J.; Xu, K.W. Nanoscale creep deformation in Zr-based metallic glass. Intermetallics 2013, 38, 156–160. [Google Scholar] [CrossRef]

- Yoo, B.G.; Oh, J.H.; Kim, Y.J.; Park, K.W.; Lee, J.C.; Jang, J.I. Nanoindentation analysis of time-dependent deformation in as-cast and annealed Cu–Zr bulk metallic glass. Intermetallics 2010, 18, 1898–1901. [Google Scholar] [CrossRef]

- Ma, Y.; Peng, G.J.; Wen, D.H.; Zhang, T.H. Nanoindentation creep behavior in a CoCrFeCuNi high-entropy alloy film with two different structure states. Mater. Sci. Eng. A 2015, 621, 111–117. [Google Scholar] [CrossRef]

- Ma, Y.; Feng, Y.H.; Debela, T.T.; Zhang, T.H. Nanoindentation study on the creep characteristics of high-entropy alloy films: Fcc versus bcc structures. Int. J. Refract. Met. H 2016, 54, 395–400. [Google Scholar] [CrossRef]

- Chen, J.; Bull, S.J. On the relationship between plastic zone radius and maximum depth during nanoindentation. Surf. Coat. Technol. 2006, 201, 4289–4293. [Google Scholar] [CrossRef]

- Chen, J.; Bull, S.J. On the factors affecting the critical indenter penetration for measurement of coating hardness. Vacuum 2009, 83, 911–920. [Google Scholar] [CrossRef]

- Li, H.; Nag, A.H.W. Size effects of nanoindentation creep. J. Mater. Res. 2004, 19, 513–522. [Google Scholar] [CrossRef]

- Wei, Q.; Cheng, S.; Ramesh, K.T.; Ma, E. Effect of nanocrystalline and ultrafine grain sizes on the strain rate sensitivity and activation volume: Fcc versus bcc metals. Mater. Sci. Eng. A 2004, 381, 71–79. [Google Scholar] [CrossRef]

- Bernal, J.D. Geometry of the structure of monatomic liquid. Nature 1960, 185, 68–70. [Google Scholar] [CrossRef]

- Saha, R.; Nix, W.D. Effects of the substrate on the determination of thin film mechanical properties by nanoindentation. Acta. Mater. 2002, 50, 23–38. [Google Scholar] [CrossRef]

- Chen, J.; Bull, S.J. Relation between the ratio of elastic work to the total work of indentation and the ratio of hardness to Young’s modulus for a perfect conical tip. J. Mater. Res. 2009, 24, 590–598. [Google Scholar] [CrossRef]

- Chen, J.; Bull, S.J. A critical examination of the relationship between plastic deformation zone size and Young’s modulus to hardness ratio in indentation testing. J. Mater. Res. 2006, 21, 2617–2627. [Google Scholar] [CrossRef]

- Schuh, C.A.; Nieh, T.G. A nanoindentation study of serrated flow in bulk metallic glasses. Acta Mater. 2003, 51, 87–99. [Google Scholar] [CrossRef]

- Ma, Y.; Peng, G.J.; Feng, Y.H.; Zhang, T.H. Nanoindentation investigation on creep behavior of amorphous CuZrAl/nanocrystalline Cu nanolaminates. J. Non-Cryst. Solids 2017, 465, 8–16. [Google Scholar] [CrossRef]

- Yu, H.B.; Wang, W.H.; Bai, H.Y.; Wu, Y.; Chen, M.W. Relating activation of shear transformation zones to β relaxations in metallic glasses. Phys. Rev. B 2010, 81, 220201. [Google Scholar] [CrossRef]

- Cheng, Y.Q.; Ma, E. Atomic-level structure and structure–property relationship in metallic glasses. Prog. Mater. Sci. 2011, 56, 379–473. [Google Scholar] [CrossRef]

- Choi, I.C.; Zhao, Y.; Kim, Y.J.; Yoo, B.G.; Suh, J.Y.; Ramamurty, U.; Jang, J.I. Indentation size effect and shear transformation zone size in a bulk metallic glass in two different structural states. Acta Mater. 2012, 60, 6862–6868. [Google Scholar] [CrossRef]

- Ma, Y.; Peng, G.J.; Debela, T.T.; Zhang, T.H. Nanoindentation study on the characteristic of shear transformation zone volume in metallic glassy films. Scr. Mater. 2015, 108, 52–55. [Google Scholar] [CrossRef]

- Lu, J.; Ravichandran, G.; Johnson, W.L. Deformation behavior of the Zr41.2Ti13.8Cu12.5Ni10Be22.5 bulk metallic glass over a wide range of strain-rates and temperatures. Acta Mater. 2003, 51, 3429–3443. [Google Scholar] [CrossRef]

- Choi, I.C.; Zhao, Y.; Yoo, B.G.; Kim, Y.J.; Suh, J.Y.; Ramamurty, U.; Jang, J.I. Estimation of the shear transformation zone size in a bulk metallic glass through statistical analysis of the first pop-in stresses during spherical nanoindentation. Scr. Mater. 2012, 66, 923–926. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, Y.; Song, Y.; Huang, X.; Chen, Z.; Zhang, T. Testing Effects on Shear Transformation Zone Size of Metallic Glassy Films Under Nanoindentation. Micromachines 2018, 9, 636. https://doi.org/10.3390/mi9120636

Ma Y, Song Y, Huang X, Chen Z, Zhang T. Testing Effects on Shear Transformation Zone Size of Metallic Glassy Films Under Nanoindentation. Micromachines. 2018; 9(12):636. https://doi.org/10.3390/mi9120636

Chicago/Turabian StyleMa, Yi, Yuxuan Song, Xianwei Huang, Zhongli Chen, and Taihua Zhang. 2018. "Testing Effects on Shear Transformation Zone Size of Metallic Glassy Films Under Nanoindentation" Micromachines 9, no. 12: 636. https://doi.org/10.3390/mi9120636

APA StyleMa, Y., Song, Y., Huang, X., Chen, Z., & Zhang, T. (2018). Testing Effects on Shear Transformation Zone Size of Metallic Glassy Films Under Nanoindentation. Micromachines, 9(12), 636. https://doi.org/10.3390/mi9120636