Highly Dispersible and Stable Carbon Nanotube Ink with Silicone Elastomer for Piezoresistive Sensing

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

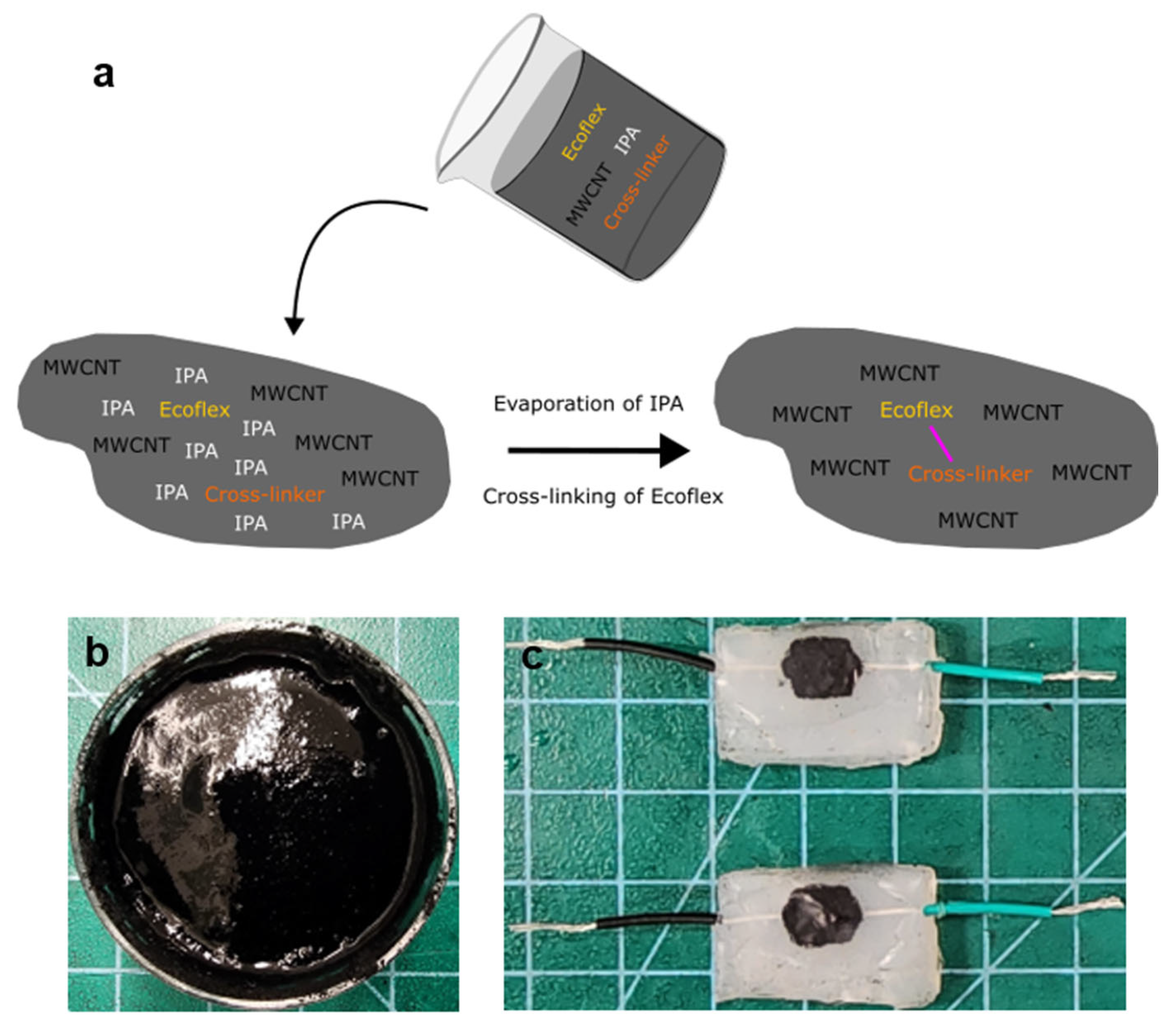

2.2. Preparation of the Conductive CNT Ink

2.3. Optical Imaging of the Conductive CNT Ink-Coated Surfaces

2.4. Fourier-Transform Infrared (FTIR) Spectroscopy

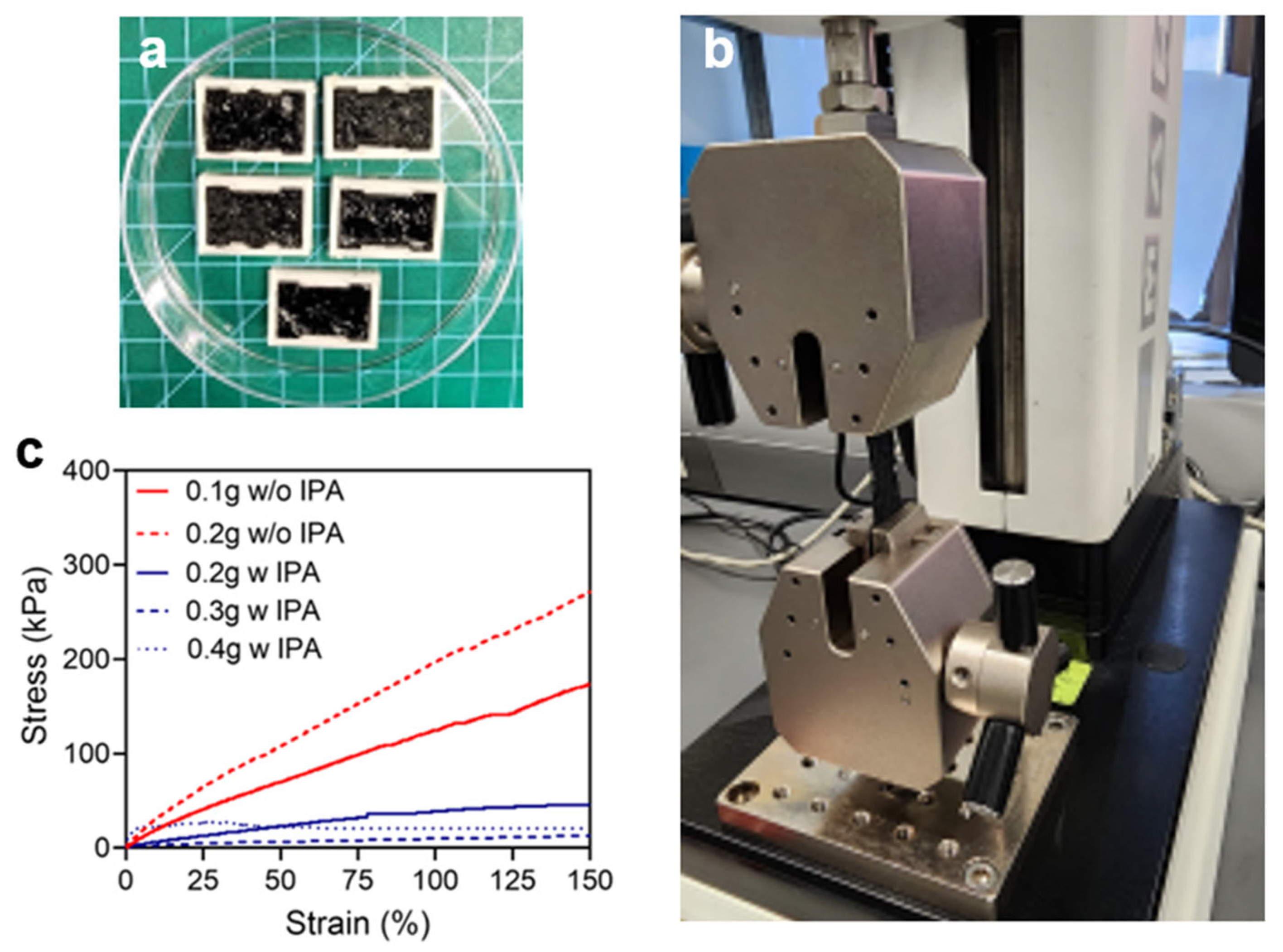

2.5. Tensile Strength Measurement

2.6. Electrical Resistance Measurement

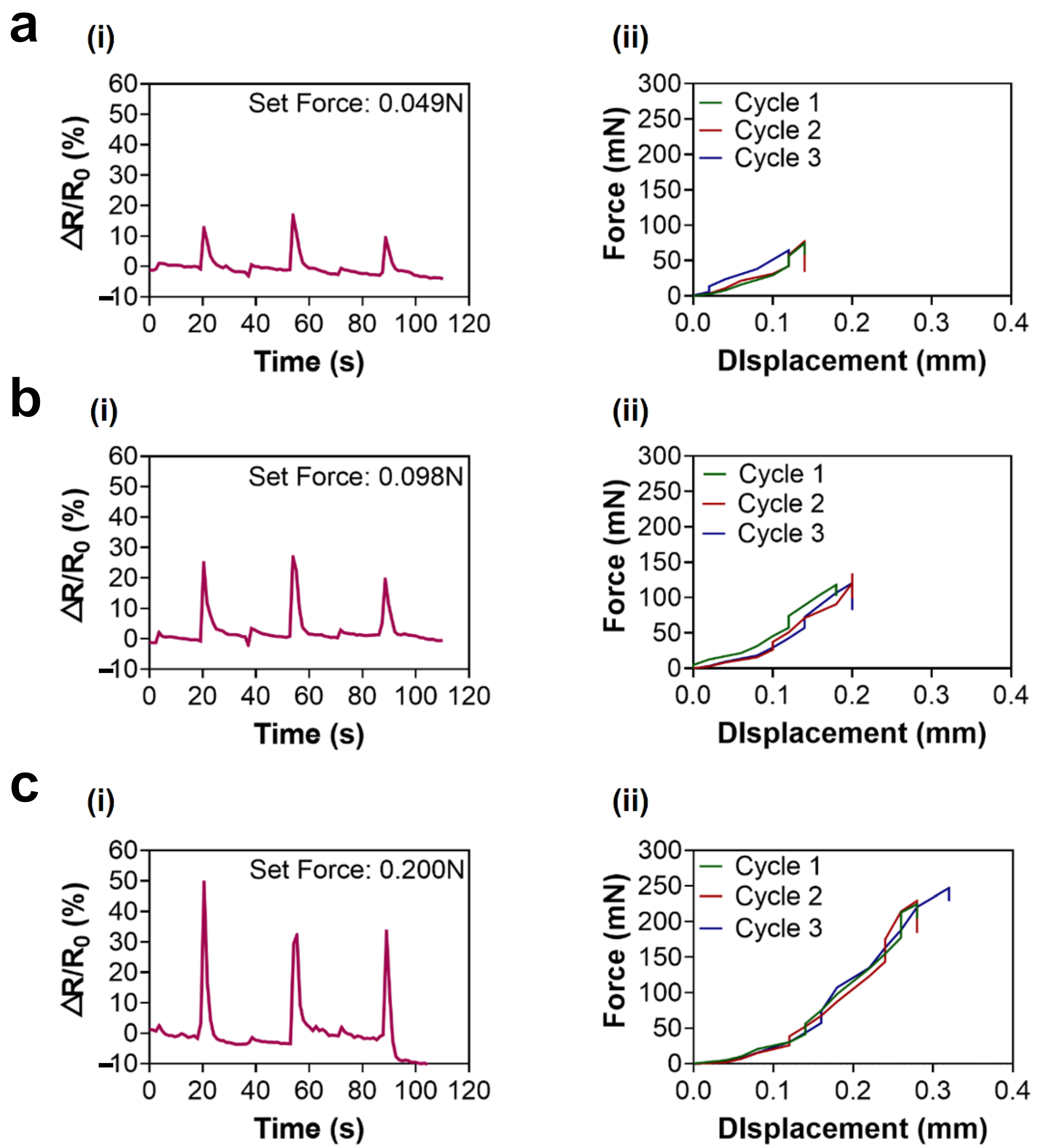

2.7. Compressive Force and Electrical Resistance

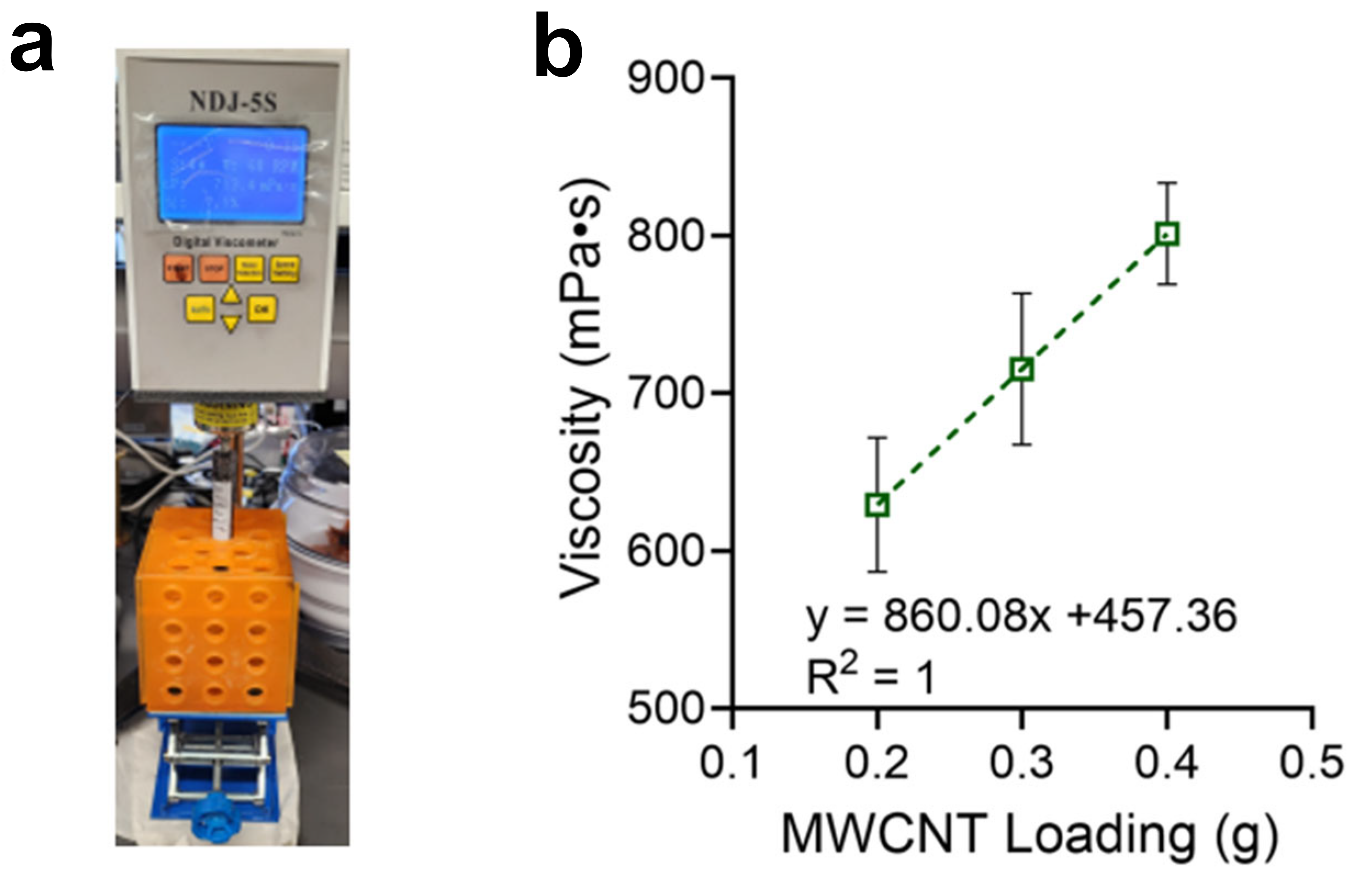

2.8. Analysis of Rheological Properties

3. Results and Discussion

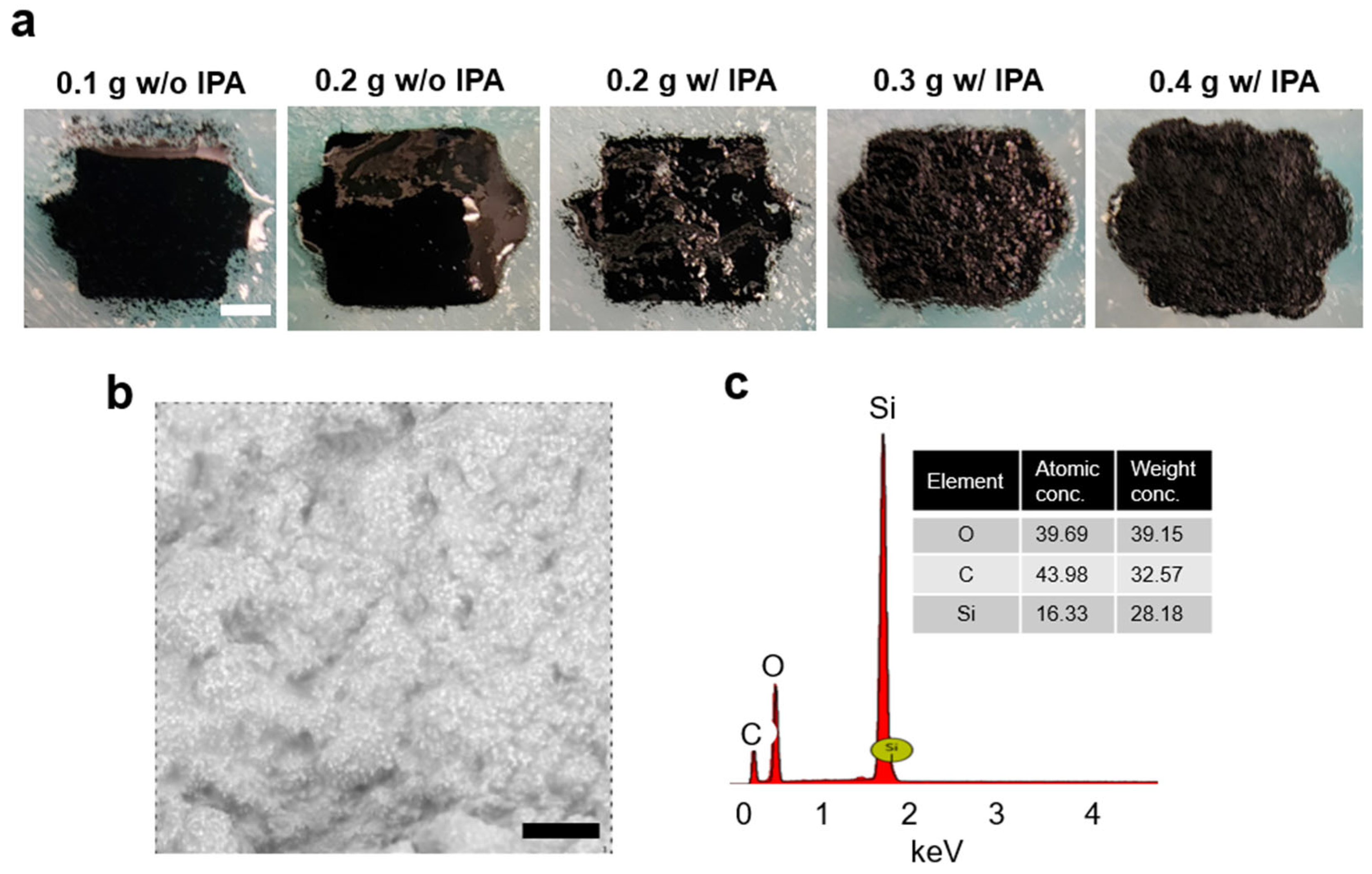

3.1. Optical Images of CNT Ink Samples with Various Concentrations of MWCNTs

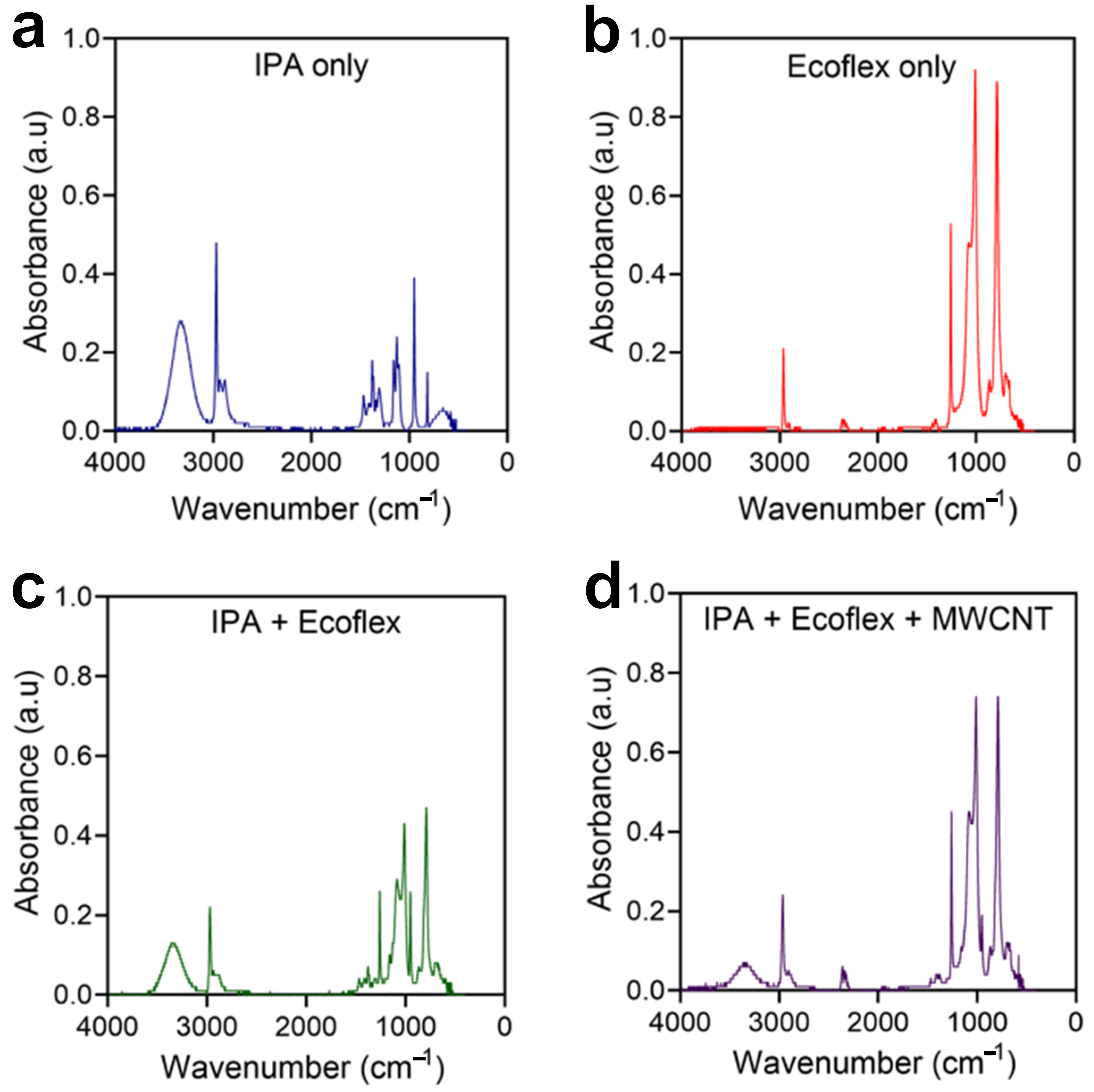

3.2. Chemical Analysis of the CNT Ink Elements and Their Chemical Structures

3.3. Tensile Strength Measurement with Various Concentrations of MWCNTs

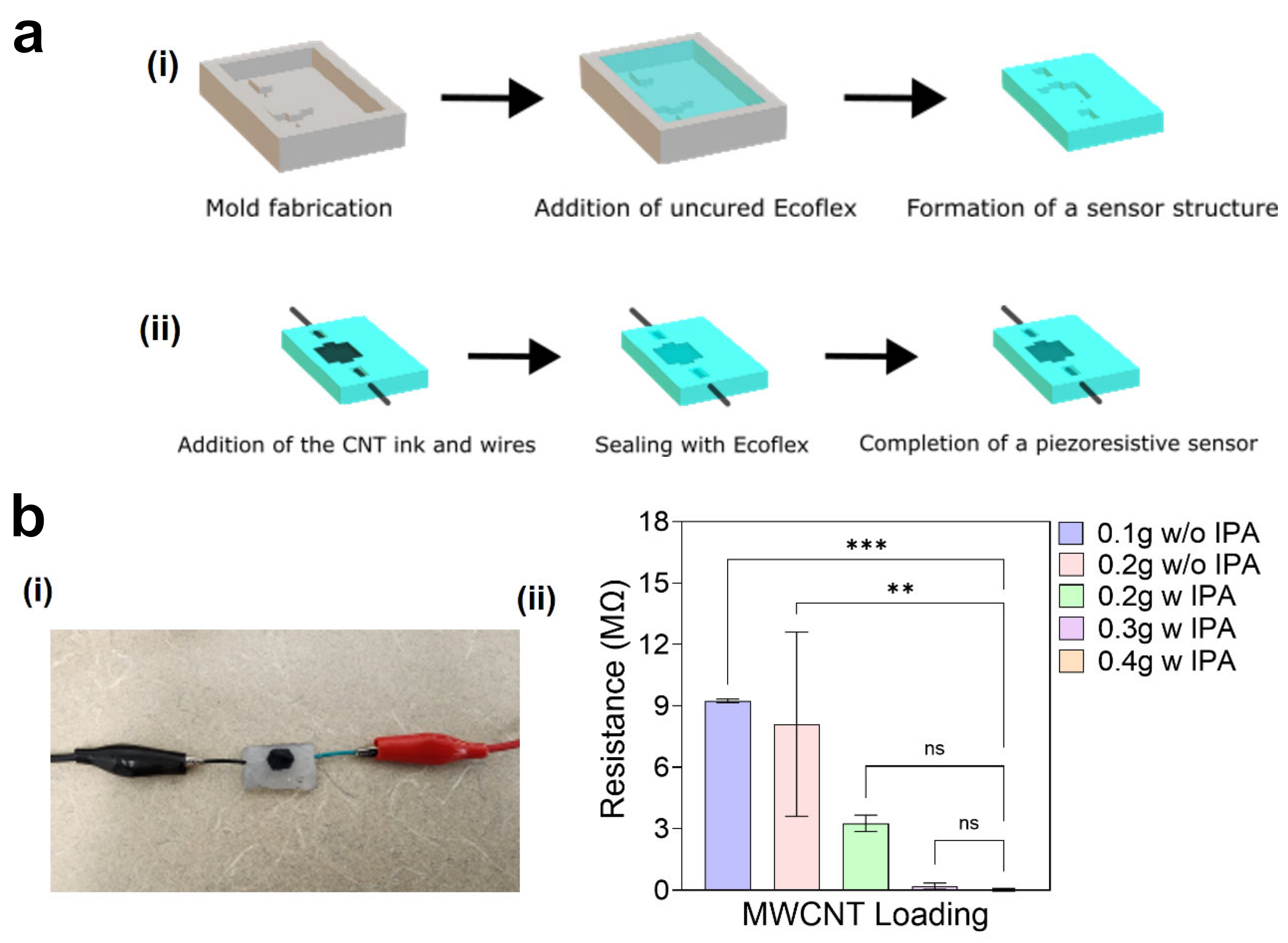

3.4. Electrical Resistance Measurement in the Form of a Piezoresistive Sensor

3.5. Compressive Force Measurement as a Piezoresistive Sensor

3.6. Investigation of Rheological Properties and a Coating Test

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Giffney, T.; Xie, M.; Yong, A.; Wong, A.; Mousset, P.; McDaid, A.; Aw, K. Soft Pneumatic Bending Actuator with Integrated Carbon Nanotube Displacement Sensor. Robotics 2016, 5, 7. [Google Scholar] [CrossRef]

- Wu, Z.; Ai, J.; Ma, Z.; Zhang, X.; Du, Z.; Liu, Z.; Chen, D.; Su, B. Flexible Out-of Plane Wind Sensors with a Self-Powered Feature Inspired by Fine Hairs of the Spider. ACS Appl. Mater. Interfaces 2019, 11, 44865–44873. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.Y.; Zhai, W.; Yu, Y.F.; Li, G.J.; Zhan, P.F.; Xu, J.W.; Zheng, G.Q.; Dai, K.; Liu, C.T.; Shen, C.Y. An Ultrasensitive, Durable and Stretchable Strain Sensor with Crack-Wrinkle Structure for Human Motion Monitoring. Chin. J. Polym. Sci. 2021, 39, 316–326. [Google Scholar] [CrossRef]

- Park, S.-J.; Kim, J.; Chu, M.; Khine, M. Highly Flexible Wrinkled Carbon Nanotube Thin Film Strain Sensor to Monitor Human Movement. Adv. Mater. Technol. 2022, 1, 1600053. [Google Scholar] [CrossRef]

- Lee, H.J.; Joyce, R.; Kim, G.; Kim, W.; Han, S.; Lee, J. Antenna-Shaped Biomimetic Tactile Sensor Using Elastomers and Conductive Liquid. ACS Appl. Electron. Mater. 2022, 4, 4863–4872. [Google Scholar] [CrossRef]

- De Volder, M.F.L.; Tawfick, S.H.; Baughman, R.H.; Hart, A.J. Carbon Nanotubes: Present and Future Commercial Applications. Science 2013, 339, 535–539. [Google Scholar] [CrossRef] [PubMed]

- Yoon, J.; Kim, U.; Yoo, Y.; Byeon, J.; Lee, S.K.; Nam, J.S.; Kim, K.; Zhang, Q.; Kauppinen, E.I.; Maruyama, S.; et al. Foldable Perovskite Solar Cells Using Carbon Nanotube-Embedded Ultrathin Polyimide Conductor. Adv. Sci. 2021, 8, 2004092. [Google Scholar] [CrossRef] [PubMed]

- Jang, D.; Park, J.-E.; Kim, Y.-K. Evaluation of (CNT@CIP)-Embedded Magneto-Resistive Sensor Based on Carbon Nanotube and Carbonyl Iron Powder Polymer Composites. Polymers 2022, 14, 542. [Google Scholar] [CrossRef] [PubMed]

- Amjadi, M.; Yoon, Y.J.; Park, I. Ultra-stretchable and skin-mountable strain sensors using carbon nanotubes-Ecoflex nanocomposites. Nanotechnology 2015, 26, 375501. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Ding, H.; Yan, B.; Lin, P.; Wu, D.; Shi, Z.; Chen, X.; Tian, Y.; Li, X. Nanoarchitectonics with MWCNT and Ecoflex film for flexible strain sensors: Wide linear range for wearable applications and monitoring of pressure distribution. Appl. Phys. A 2022, 128, 885. [Google Scholar] [CrossRef]

- Du, J.; Wang, L.; Shi, Y.; Zhang, F.; Hu, S.; Liu, P.; Li, A.; Chen, J. Optimized CNT-PDMS Flexible Composite for Attachable Health-Care Device. Sensors 2020, 20, 4523. [Google Scholar] [CrossRef] [PubMed]

- Demidenko, N.A.; Kuksin, A.V.; Molodykh, V.V.; Pyankov, E.S.; Ichkitidze, L.P.; Zaborova, V.A.; Tsymbal, A.A.; Tkachenko, S.A.; Shafaei, H.; Diachkova, E.; et al. Flexible Strain-Sensitive Silicone-CNT Sensor for Human Motion Detection. Bioengineering 2022, 9, 36. [Google Scholar] [CrossRef] [PubMed]

- Chiou, K.; Byun, S.; Kim, J.; Huang, J. Additive-free carbon nanotube dispersions, pastes, gels, and doughs in cresols. Proc. Natl. Acad. Sci. USA 2018, 115, 5703–5708. [Google Scholar] [CrossRef] [PubMed]

- Duan, Q.; Lan, B.; Lv, Y. Highly Dispersed, Adhesive Carbon Nanotube Ink for Strain and Pressure Sensors. ACS Appl. Mater. Interfaces 2022, 14, 1973–1982. [Google Scholar] [CrossRef] [PubMed]

- Zhu, W.-B.; Xue, S.-S.; Zhang, H.; Wang, Y.-Y.; Huang, P.; Tang, Z.-H.; Li, Y.-Q.; Fu, S.-Y. Direct ink writing of a graphene/CNT/silicone composite strain sensor with a near-zero temperature coefficient of resistance. J. Mater. Chem. C 2022, 10, 8226. [Google Scholar] [CrossRef]

- Lee, H.J.; Niiyama, R. Bleeding-Mimetic Damage-Detecting and Self-Healing Modular Skin. Adv. Robot. Res. 2025, 1, 202500009. [Google Scholar] [CrossRef]

- Hamidi, A.; Tadesse, Y. 3D printing of very soft elastomer and sacrificial carbohydrate glass/elastomer structures for robotic applications. Mater. Des. 2020, 187, 108324. [Google Scholar] [CrossRef]

- Lee, H.J.; Joyce, R.; Lee, J. Liquid Polymer/Metallic Salt-Based Stretchable Strain Sensor to Evaluate Fruit Growth. ACS Appl. Mater. Interfaces 2022, 14, 5983–5994. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license.

Share and Cite

Lee, H.J.; Rejimone, J.; Park, S.S.; Kim, K. Highly Dispersible and Stable Carbon Nanotube Ink with Silicone Elastomer for Piezoresistive Sensing. Micromachines 2026, 17, 14. https://doi.org/10.3390/mi17010014

Lee HJ, Rejimone J, Park SS, Kim K. Highly Dispersible and Stable Carbon Nanotube Ink with Silicone Elastomer for Piezoresistive Sensing. Micromachines. 2026; 17(1):14. https://doi.org/10.3390/mi17010014

Chicago/Turabian StyleLee, Hyun Jae, Justin Rejimone, Simon S. Park, and Keekyoung Kim. 2026. "Highly Dispersible and Stable Carbon Nanotube Ink with Silicone Elastomer for Piezoresistive Sensing" Micromachines 17, no. 1: 14. https://doi.org/10.3390/mi17010014

APA StyleLee, H. J., Rejimone, J., Park, S. S., & Kim, K. (2026). Highly Dispersible and Stable Carbon Nanotube Ink with Silicone Elastomer for Piezoresistive Sensing. Micromachines, 17(1), 14. https://doi.org/10.3390/mi17010014