3. Results

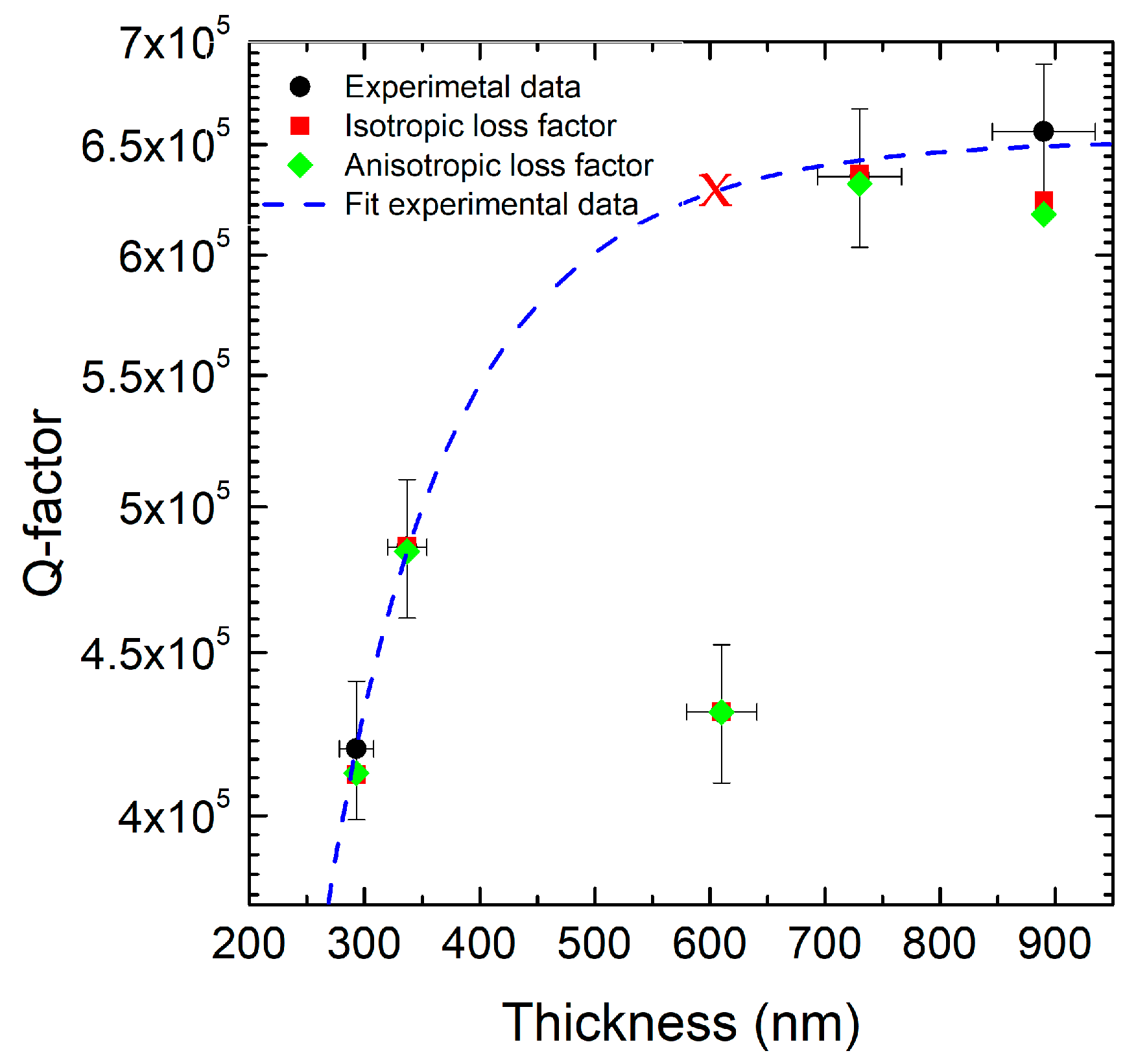

The Q-Factor increases significantly with increasing thickness, especially between 500 and 700 nm (

Figure 2). Beyond 700 nm, the Q-Factor stabilizes or shows a slight decrease. Using both models of isotropic and anisotropic dumping, it is possible to fit the experimental data with good accuracy. But, using this fitting, it is not possible to obtain with the same accuracy the resonance frequency for the different film thicknesses. The experimental values (black circles) range from ~4.05 × 10

5 at 300 nm to ~6.60 × 10

5 at 870 nm. The anisotropic loss factor model (green diamonds) shows excellent agreement, with errors below ±5.5% across all thicknesses. The isotropic model (red squares) deviates by up to +1.7% at 600 nm and has reduced accuracy in thicker films. These results quantitatively confirm that the anisotropic damping model more closely reproduces the measured energy dissipation behavior, particularly in the upper thickness range. The Q-Factor of the value at 610 nanometers deviates from the fit of the experimental values (lower by about 30%) due to the residual stress (in

Figure 2, the red cross indicates the expected value around

).

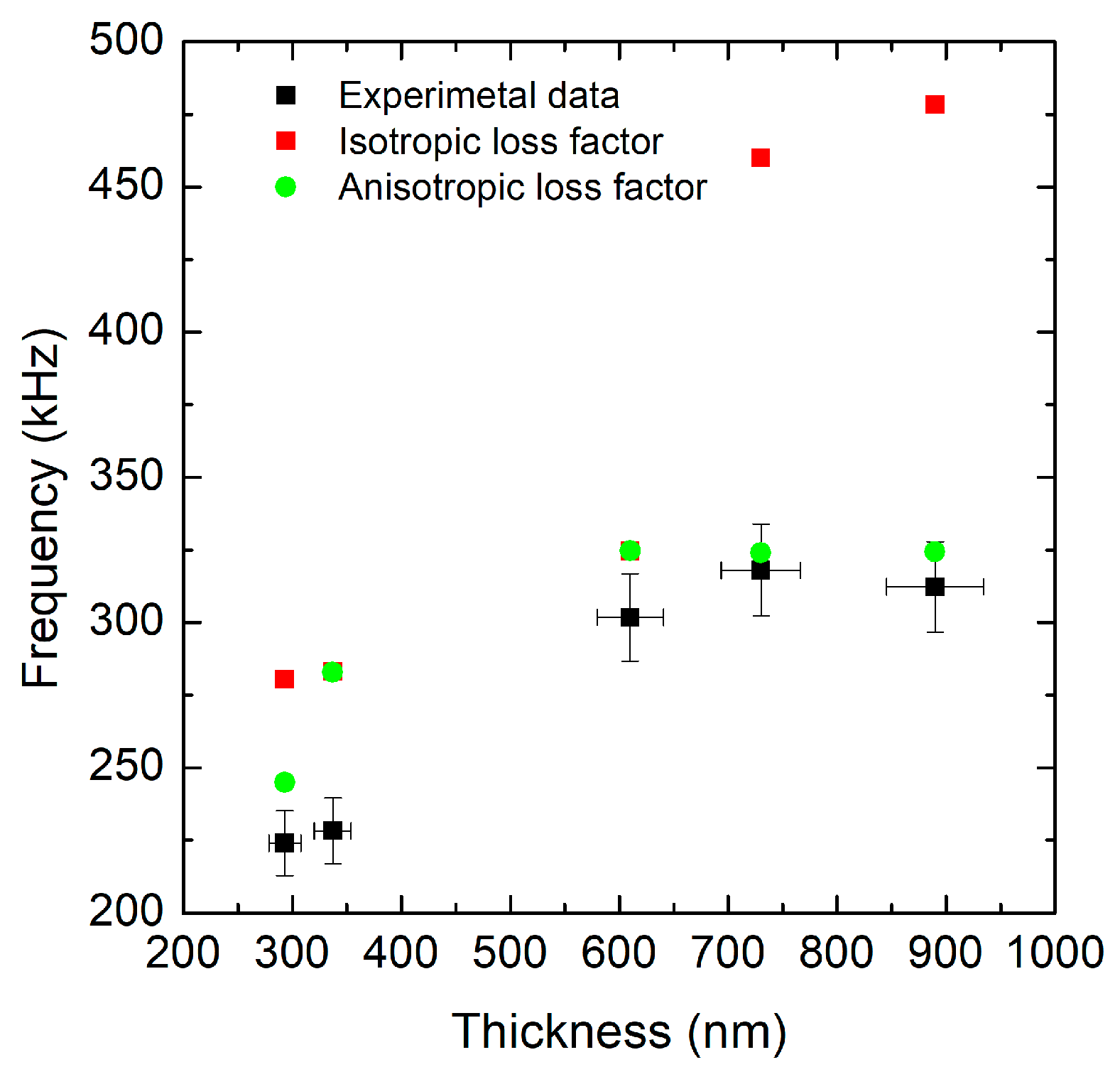

In fact, the experimental data show an increase in frequency with thickness up to around 700 nm, followed by a slight decrease (

Figure 3). The isotropic loss factor simulation overestimates the frequency for thinner films but significantly overestimates it for thicknesses above 600 nm, showing a sharp increase not observed experimentally. In contrast, the anisotropic loss factor simulation closely follows the experimental trend across the entire thickness range, with a larger estimate of the resonance frequency only for the thinner layers. The agreement between experimental data and the anisotropic model is clearly better than with the isotropic one. This suggests that the material exhibits anisotropic behavior and that including anisotropy in the loss factor is crucial for accurately predicting eigenfrequencies. The isotropic simulation lacks key directional mechanical effects or damping mechanisms, which likely become significant at higher thicknesses—hence the large overestimation above 600 nm. The drop in the experimental frequency after 700 nm might be due to additional real-world effects not captured by the simulations, such as tension changes in mechanical properties (i.e., density, Young’s modulus) and geometric effects (i.e., increased bending influence at greater thicknesses). The isotropic model systematically overestimates the frequency, with errors of up to +50%, while the anisotropic model shows a better fit with the experimental data.

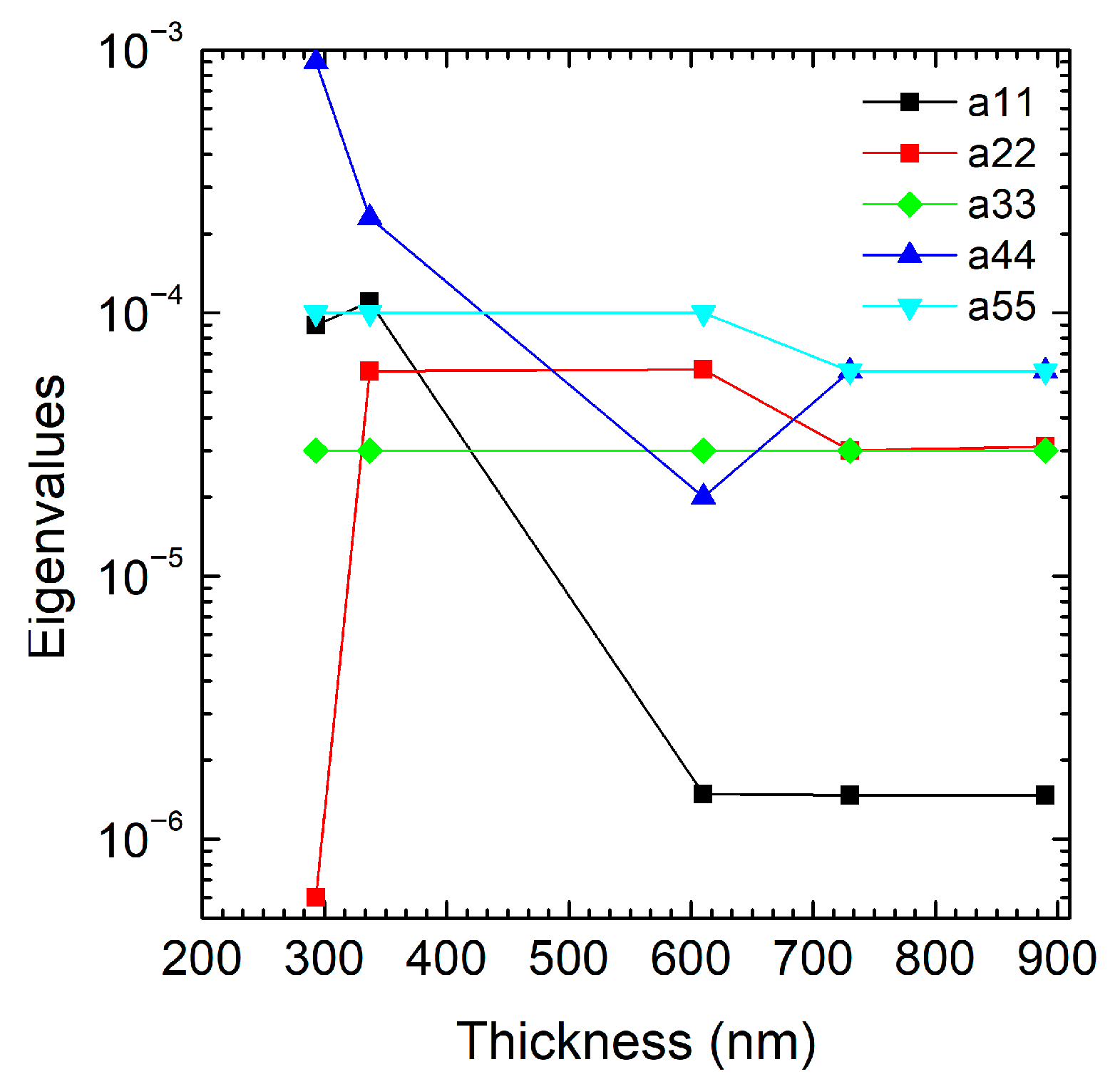

The loss factor matrix (

) describes how damping losses vary along different material directions. The eigenvalues (a

11, a

22, a

33, a

44, a

55) represent the principal damping values along the main anisotropy axes. Specifically, a

11, a

22, and a

33 correspond to the x, y, and z directions, respectively, while a

44 and a

55 are associated with the shear damping in the yz and

xz planes. A summary of the eigenvalues, their associated directions, and the corresponding damping mechanisms is reported in

Table 2. In

Figure 4, a comparison between these eigenvalues shows how direction dependent the damping is (i.e.,

>>

>>

indicates strong damping along few directions). If the plot shows similar eigenvalues (

≈

≈

), the material is nearly isotropic in damping. If they differ significantly (i.e.,

>

,

), the material is highly anisotropic, with losses dominated along one direction (e.g., fibers in a composite). In our case,

(black line) starts with relatively high values (~1.0 × 10

−4), peaking around 400 nm; after 400 nm, the value drops sharply to nearly 0 and remains negligible for thicknesses above 600 nm, indicating that losses along direction

x are suppressed as the thickness increases.

The damping along x is dominant in thinner films because under these conditions, the longitudinal direction is the main site of deformation and dissipation. For thicker films, the stiffness along x increases, which means less deformation and dissipation. The red line, , sharply increases for the lower thickness, and above 300 nm it almost remains constant (~). The sharp growth for observed above 300 nm may signal a new regime, where losses in the y direction are increased, while for higher thickness the anisotropic losses are lower. The transverse direction is a thickness-dependent threshold, participating in dissipation when the flexural modes also involve the y axis. The green line, , remains nearly constant over the entire thickness range (~2.5 × 10−5), suggesting low sensitivity to thickness variations above 300 nm. Furthermore, is the most stable, which could suggest that losses in direction z are less sensitive to thickness and generally minimal. The dissipation in the z direction is marginal. The blue line, , decreases, reaching a minimum at 600 nm, and, after a slight increase, it stays constant. It then shows shear damping in the yz plane, which is initially significant, and then a slight decrease in thicker films due to the vibration modes’ shift from torsion/shear to pure bending. For the cyan line, , no great variation in value can be observed in the entire range of film thickness; in the xz plane, the shear damping is thickness independent. The significant reduction in the coefficients, particularly , indicates lower anisotropic losses in the system, contributing to increased efficiency (higher Q-Factor).

In many practical applications, the inclusion of damping in eigenfrequency analyses is primarily aimed at estimating the attenuation levels of resonant modes. Although the effect of damping on the mode shapes and eigenfrequencies is often marginal, its accurate implementation is essential for predicting the performance of structures under dynamic loading conditions. The use of a matrix of anisotropic loss factors is particularly advantageous when dealing with systems in which energy dissipation is strongly dependent on material orientation during the propagation of elastic waves; this phenomenon is closely related to the attenuation tensor or the viscosity tensor, which represents the imaginary part of the complex elastic modulus. Compared to the Joffe model [

11], this is a micromechanical approach used to predict the effective elastic properties of composite materials. The model considers the contributions of the fibers and matrix phases, including their volume fractions and orientations, which represents the real part of the elastic modulus. Below, Voigt notation was used to simplify symmetric tensors (like stress/strain) into vectors/matrices as

where

C and η

are

= real part = conservative elastic matrix and

imaginary part = attenuation tensor matrix.

Compared to the Joffe model—which focuses on micromechanical predictions of effective elastic properties based on fiber–matrix interactions—the anisotropic damping model used in this study directly incorporates directional energy dissipation through a 6 × 6 loss factor matrix. While the Joffe model captures the real part of the elastic modulus, our approach targets the imaginary part, which governs attenuation and damping. This distinction allows for more accurate modeling of vibrational decay and resonance behavior in 3C-SiC structures. The anisotropic damping matrix shares conceptual similarities with the viscosity tensor model, often used in wave propagation studies. However, our implementation in COMSOL enables direct integration into FEM simulations, offering better control over directional damping and improved correlation with experimental data. The directional damping captured by the anisotropic model aligns with the known anisotropic stiffness of 3C-SiC, as reported by Thomsen [

7] and Yang et al. [

8]. The propagation of elastic waves in such materials is governed not only by stiffness tensors but also by attenuation tensors. Our model bridges this gap by incorporating both elastic and dissipative anisotropy, enabling more realistic simulation of wave behavior in MEMS resonators.

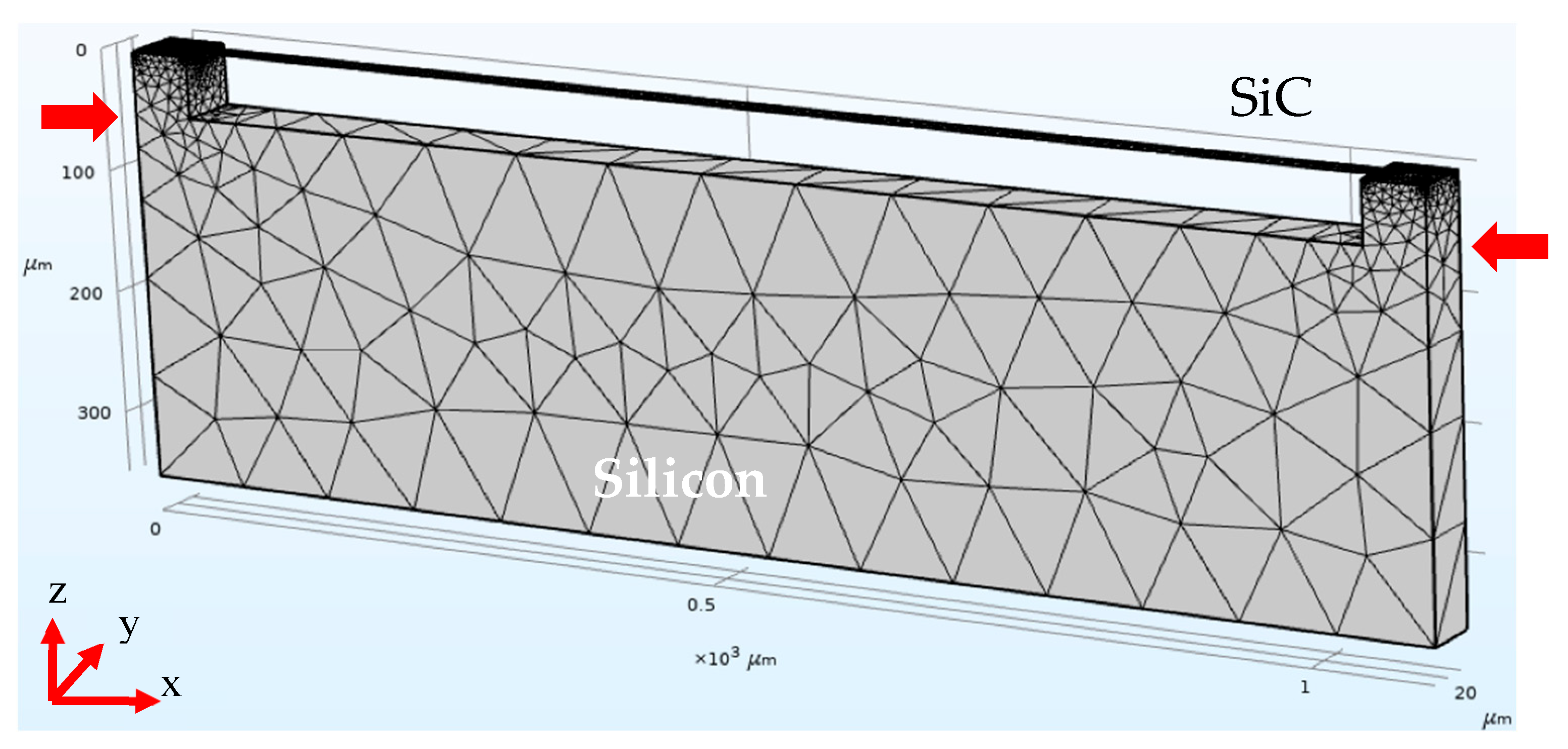

By applying compressive forces to the bridge and then producing a compressive strain in the structures, it is possible to simulate the decrease of the resonance frequency for the different samples. From these simulations, in

Figure 5a, it is possible to observe that the bridges that have the highest resonance frequency (

) and the highest tensile intrinsic stress are less sensitive to the compressive forces and produce the lowest deformation of the bridges. Instead, the thinner bridges, which are also those ones with the lowest tensile stress, show a larger deformation under the same compressive forces.

The frequency decreases as compressive strain increases. Thicker beams show higher initial resonance frequencies and lower sensitivity to compressive strain. Thinner beams show greater frequency shifts, indicating higher mechanical compliance and lower intrinsic tensile stress. The plot in

Figure 5b shows how the strain varies as a function of frequency under the application of tensile forces. Both

and

samples’ configurations [

6] show a strong strain response to tensile forces, which is even more pronounced than under compressive forces. The

shows the highest strain among all, suggesting strong mechanical resonance or greater tensile compliance at that frequency. The

,

, and

series respond weakly under tension, with very small strain magnitudes. The overall strain under tensile loading is higher than in the compressive case for the same configurations (

and

), indicating that the material or the structure is more compliant or deformable when pulled than when compressed [

12]. The frequency increases with tensile strain and the response is more pronounced than in compression, suggesting that the material is more compliant in tension. The percentage errors between simulated and experimental values for each sample are summarized in

Table 3. All values are within ±7%, indicating very good agreement. The anisotropic model used in the simulation appears to accurately capture the strain sensitivity trends across all samples.

The percentage errors between simulated and experimental values are all within ±7%, indicating very good agreement. The anisotropic model used in simulation appears to accurately capture the strain sensitivity trends across all samples.

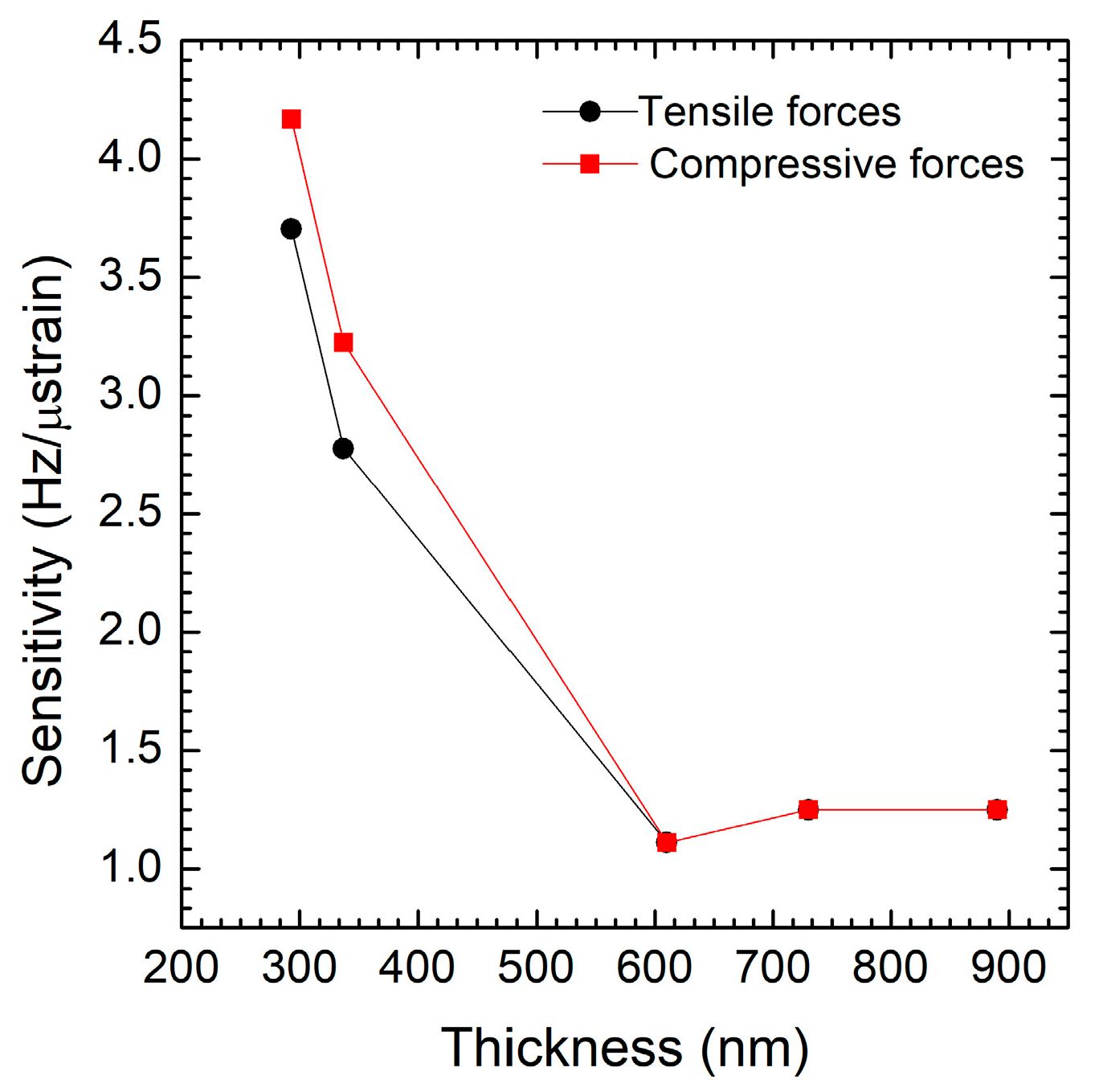

The graph in

Figure 6 shows how the strain sensitivity of the double-clamped beam (expressed in Hz/µstrain) varies as a function of thickness under both compressive (black line) and tensile forces (red line). The strain sensitivity decreases with thickness (up to ~650 nm) for both compressive and tensile forces. This suggests that thinner structures or those with lower residual stress are more sensitive to both types of forces up to this point. Both curves reach a minimum sensitivity at around 650 nm. This indicates that very thin layers with low intrinsic residual stress have the highest strain sensitivity. Tensile sensitivity is consistently higher than compressive sensitivity for each thickness. This means the structure is more responsive to stretching than compression, possibly due to the material characteristics of the tensile strain. The anisotropic model used in the simulation appears to accurately capture the strain sensitivity trends across all samples.

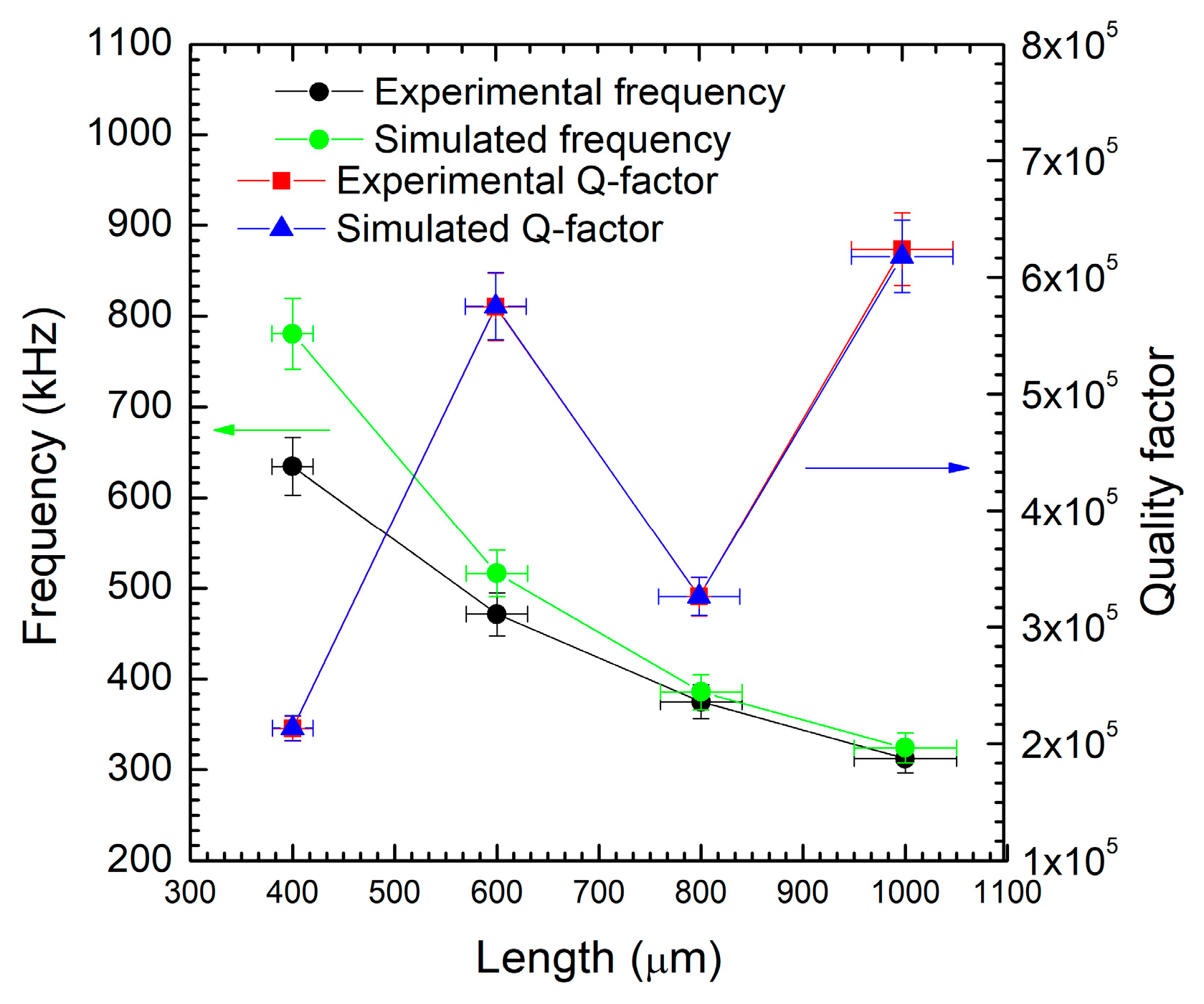

In

Figure 7, we have shown that for a fixed thickness of 890 nm (

), both experimental and simulated frequencies (black and light green, respectively) decrease as length increases. This trend aligns with typical mechanical resonance behavior, where longer structures resonate at lower frequencies. Simulated frequencies are consistently higher than the experimental ones, which may result from ideal conditions assumed in the simulations (i.e., no damping, perfect material properties). The study and the consideration of defect density have already been reported in previous work [

3] in which a bilayer model was developed. The 3C-SiC film can be considered a double layer with rich defect density near the interface film/substrate and a high-quality layer above the rich defect, with a reduction of them but not a total elimination. The experimental Q-Factor values (red line) have small fluctuations across most lengths, and the simulated Q-Factor curve (blue line) follows a similar trend because it has been fitted on the experimental values. This suggests that 600 nm is an optimal length for maximizing the Q-Factor, which is crucial for sensing performance and energy efficiency in resonant systems. But, a discrepancy between the simulation and the experiment can be found; while trends are similar, simulated values for frequency are generally higher than the experimental ones.

This discrepancy may arise due to real-world losses (i.e., air damping, fabrication imperfections) not accounted for in the simulations. The figure shows a clear inverse relationship between length and frequency and highlights 600 µm as the optimal length for high Q-Factor performance, both experimentally and in simulations. Despite some quantitative differences, simulation and experimental results are qualitatively consistent, reinforcing the validity of the model and the usefulness of this length for device optimization.

In

Figure 8, for both compressive and tensile forces, strain sensitivity decreases as the length increases for a fixed thickness of 890 nm. This trend suggests that shorter structures are more sensitive to external mechanical loading. In a comparison between compressive and tensile forces, the compressive force sensitivity is slightly higher than compressive force sensitivity across all lengths, which is especially notable at intermediate values (e.g., ~700–800 µm). This may indicate that the device responds more effectively (in terms of frequency change) under compressive loading. The figure demonstrates that device length is a key factor influencing frequency-based sensitivity, with shorter devices offering higher sensitivity. Additionally, the system appears to be slightly more responsive under compressive stress, although the difference is relatively small. This information can be useful when optimizing device geometry for strain sensing applications where high frequency sensitivity is critical.