Structure and Temperature Dependence of Solder Layer and Electric Parameters in IGBT Modules

Abstract

1. Introduction

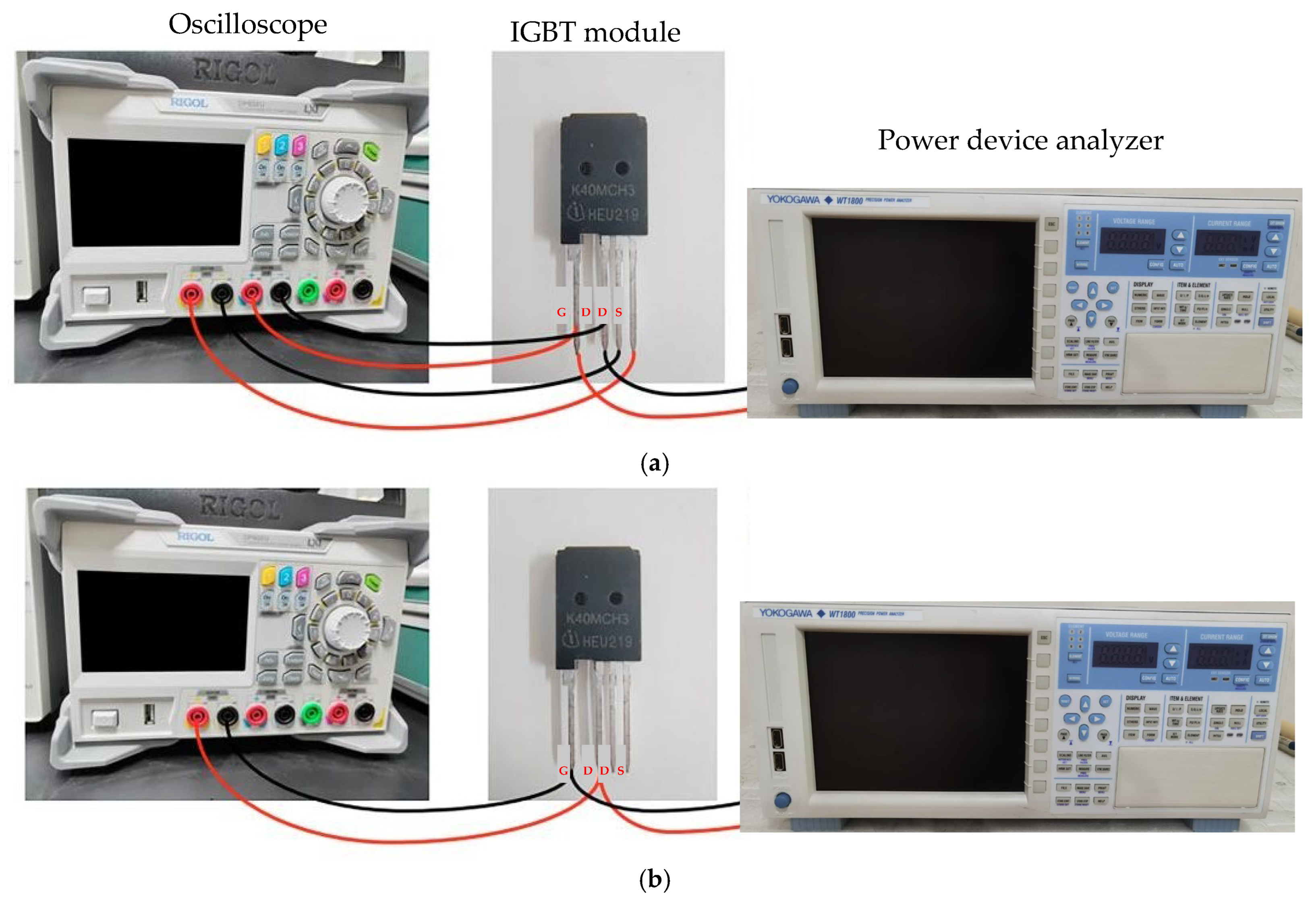

2. Experiment and Methods

2.1. Design of Thermal Fatigue Experiment

2.2. Metallographic Preparation Techniques and Microscopic Observation

3. High- and Low-Temperature Storage and Temperature Cycling Experiments with Discrete IGBTs

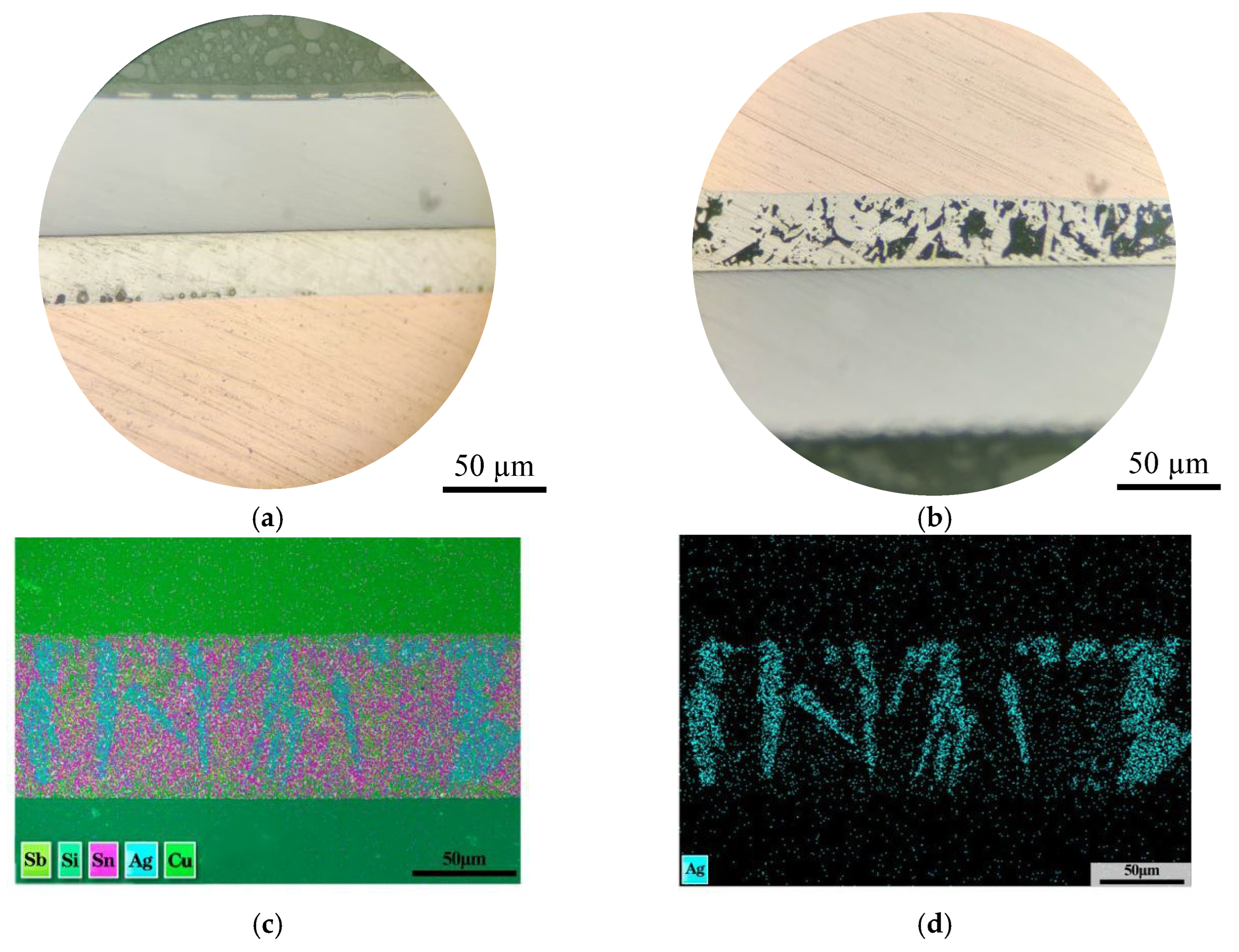

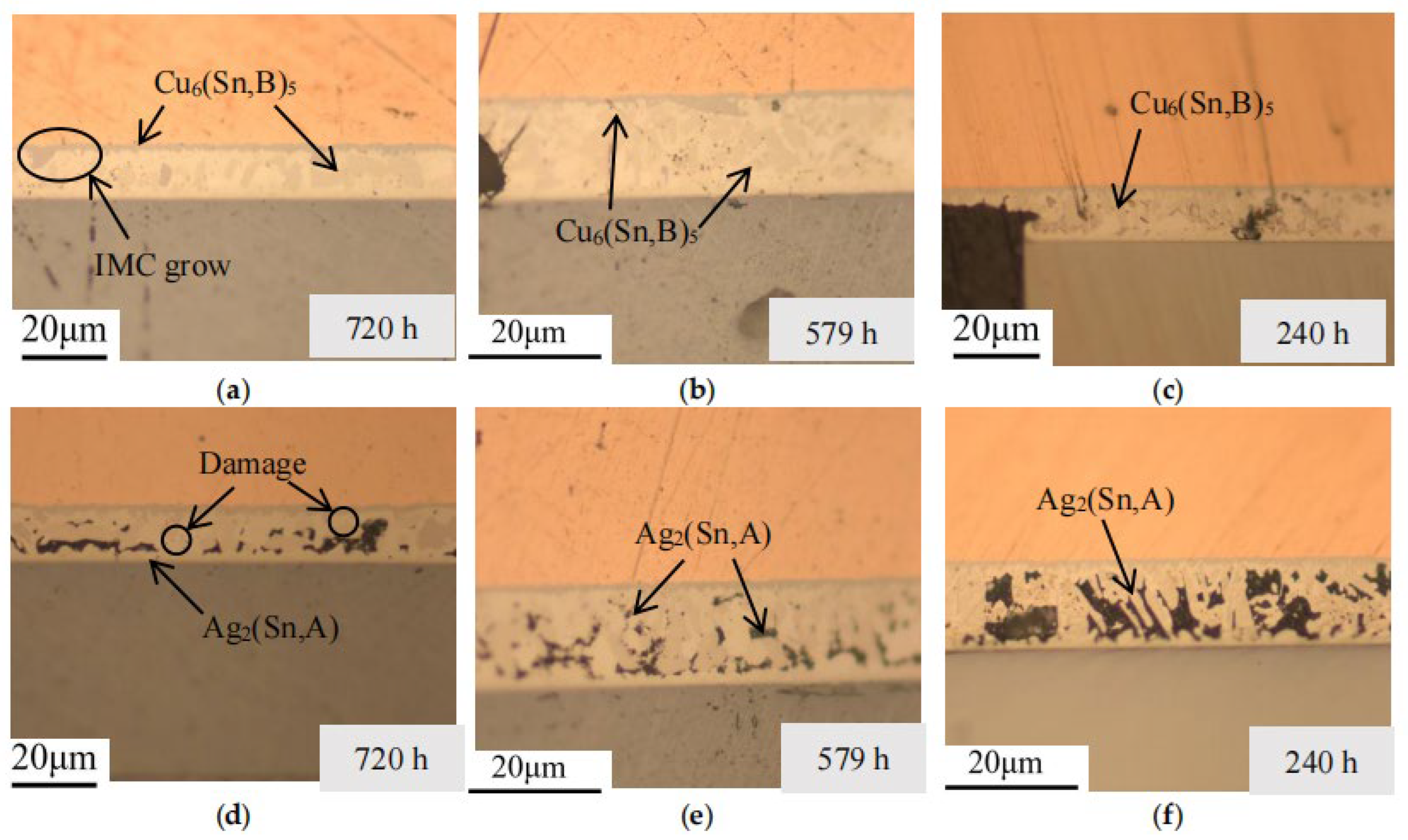

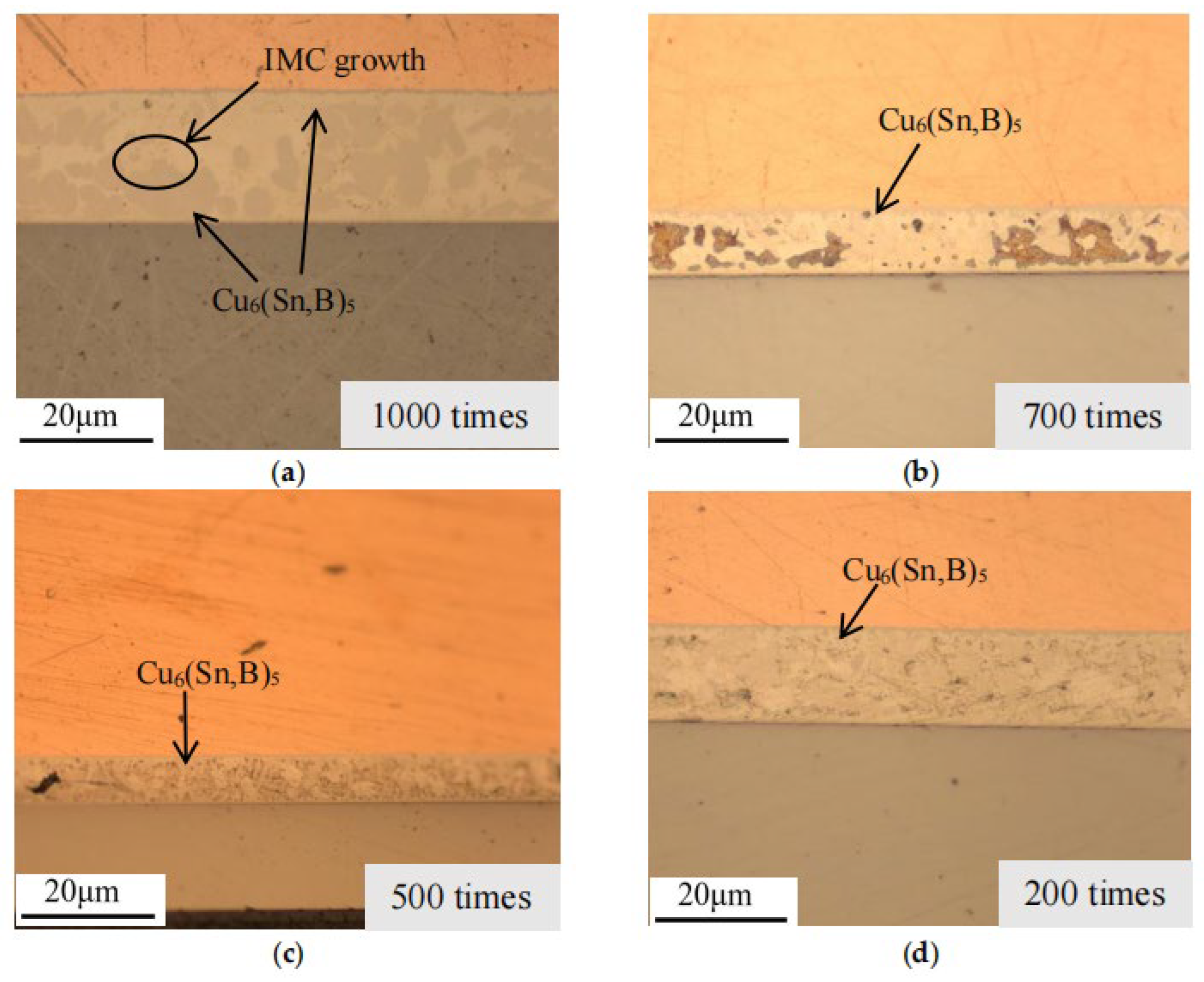

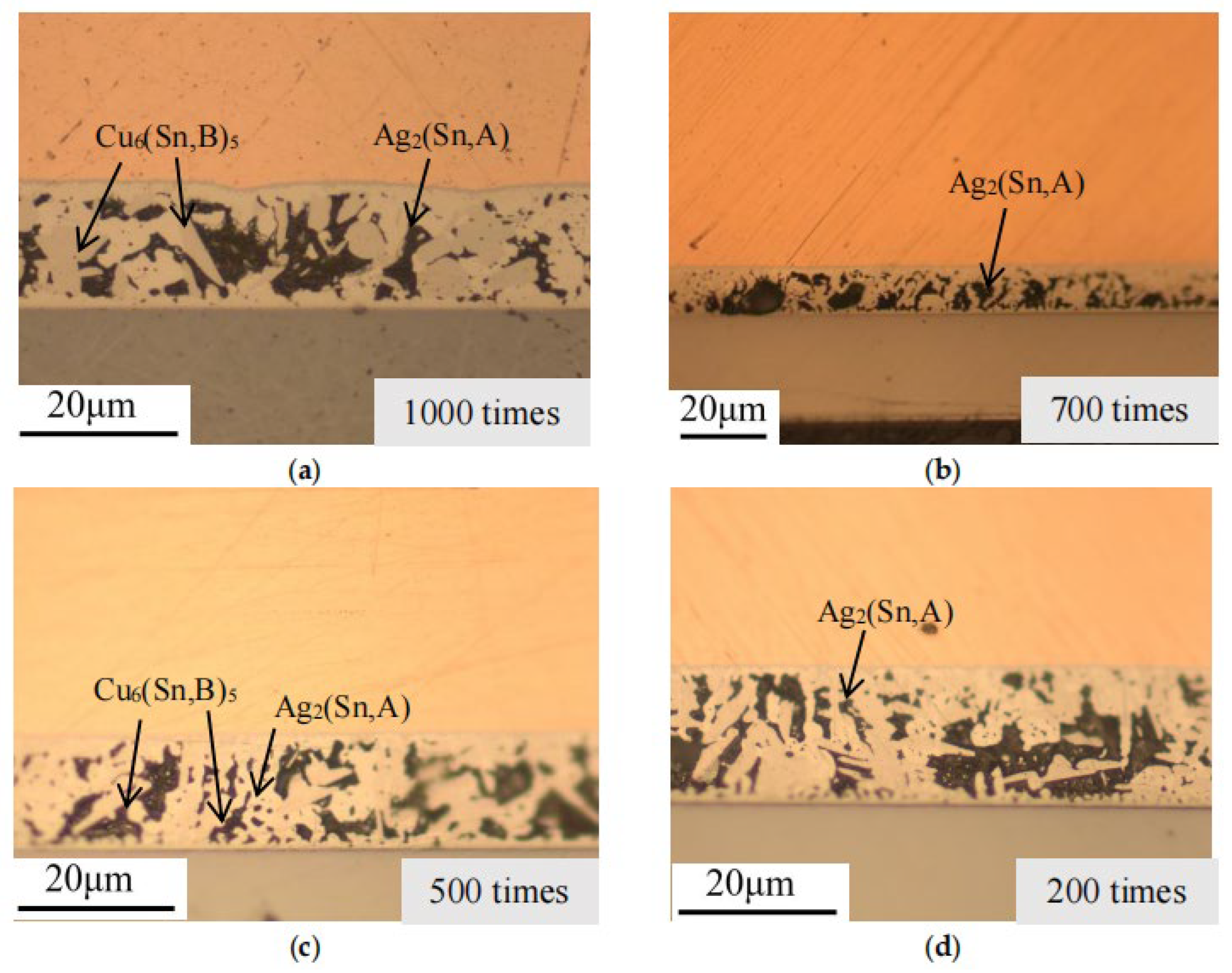

3.1. Microstructure Analysis of Solder Layer Aging

3.2. The Impact of Fatigue Testing on the Static Parameters of IGBT

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Liu, C. Advanced Pb-Free Interconnect Materials and Manufacture Processes to Enable High-Temperature Electronics Packaging. Ph.D. Thesis, Loughborough University, Loughborough, UK, 2022. [Google Scholar]

- Zhang, H.; Lee, N.-C. High Temperature Lead-Free Bonding Materials—The Need, the Potential Candidates and the Challenges. In Lead-Free Soldering Process Development and Reliability; Wiley: Hoboken, NJ, USA, 2020; pp. 155–189. [Google Scholar]

- Lutz, J.; Schlangenotto, H.; Scheuermann, U.; Doncker, R.D. Semiconductor Power Devices; Springer: Berlin/Heidelberg, Germany; Dordrecht, The Netherlands; London, UK; New York, NY, USA, 2011. [Google Scholar]

- Amro, R.; Lutz, J.; Rudzki, J.; Thoben, M.; Lindemann, A. Double-sided low-temperature joining technique for power cycling capability at high temperature. In Proceedings of the 2005 European Conference on Power Electronics and Applications, Dresden, Germany, 11–14 September 2005. [Google Scholar]

- Guth, K.; Siepe, D.; Görlich, J.; Torwesten, H.; Roth, R.; Hille, F.; Umbach, F. New assembly and interconnects beyond sintering methods. In Proceedings of the PCIM Europe International Exhibition & Conference for Power Electronics Intelligent Motion Power Quality, Nuremberg, Germany, 4–6 May 2010; pp. 232–237. [Google Scholar]

- Scheuermann, U.; Wiedl, P. Low temperature joining technology—A high reliability alternative to solder contacts. In Proceedings of the Workshop on Metal Ceramic Composites for Functional Applications, Wien, Austria, 4–6 June 1997; pp. 181–192. [Google Scholar]

- Scheuermann, U. Power module design for HV-IGBTs with extended reliability. In Proceedings of the PCIM Europe 39th International Power Conversion Conference, Nuremberg, Germany, 22–24 June 1999; pp. 49–54. [Google Scholar]

- Wu, X.; Yang, X.; Ye, J.; Liu, G. Novel Prognostics for IGBTs Using Wire-Bond Contact Degradation Model Considering On-Chip Temperature Distribution. IEEE Trans. Power Electron. 2025, 40, 4411–4424. [Google Scholar] [CrossRef]

- Wang, J.; Peng, J.; Cai, S.; Wang, X. The effect of solvents on thermal stability of solder pastes in reflow process. J. Mater. Sci. 2023, 58, 2347–2359. [Google Scholar] [CrossRef]

- Lee, S.; Yoo, K.S. Design of Experiments for Optimizing Silver–Graphene Composite as a Conductive Paste. Korean J. Chem. Eng. 2025, 1–12. [Google Scholar] [CrossRef]

- Ismail, N.; Jalar, A.; Abu Bakar, M.; Ismail, R.; Ibrahim, N.S. Effect of flux functional group for solder paste formulation towards soldering quality of SAC305/CNT/Cu. Solding Surf. Mt. Technol. 2020, 32, 157–164. [Google Scholar] [CrossRef]

- Huang, Z.; Dong, H.; Chen, B.; Tang, S.; Ma, Y.; Liu, W. Investigation of 1-hexanol base silver paste formula for low-temperature sintering. J. Mater. Sci. Mater. Electron. 2023, 34, 1816. [Google Scholar] [CrossRef]

- Zhao, S.; Tong, Y.; Wang, C.; Yao, E. Challenges and progress in packaging materials for power modules with high operation temperature: Review. J. Mater. Sci.-Mater. Electron. 2024, 35, 2237. [Google Scholar] [CrossRef]

- Vianco, P.T. A Review of Interface Microstructures in Electronic Packaging Applications: Brazing and Welding Technologies. JOM 2022, 74, 3557–3577. [Google Scholar] [CrossRef]

- Gao, W.; Guo, Q.; Peng, Y.; Ren, M.; Zhang, B.; Cai, S. Influence of Solder Layer Void on Thermal Stability for Power Semiconductor Device. In Proceedings of the 2019 20th International Conference on Electronic Packaging Technology (ICEPT), Hong Kong, China, 12–15 August 2019; pp. 1–4. [Google Scholar]

- Du, M.; Guo, Q.; Wang, H.; Ouyang, Z.; Wei, K. An Improved Cauer Model of IGBT Module: Inclusive Void Fraction in Solder Layer. IEEE Trans. Compon. Packag. Manuf. Technol. 2020, 10, 1401–1410. [Google Scholar] [CrossRef]

- Zhao, S.; Yang, X.; Wu, X.; Liu, G. Investigation on creep-fatigue interaction failure of die-attach solder layers in IGBTs under power cycling. IEEE Trans. Power Electron. 2025, 40, 7261–7274. [Google Scholar] [CrossRef]

- Li, L.; Du, X.; Chen, J.; Wu, Y. Thermal Fatigue Failure of Micro-Solder Joints in Electronic Packaging Devices: A Review. Materials 2024, 17, 2365. [Google Scholar] [CrossRef] [PubMed]

- Hernes, M.; D’Arco, S.; Antonopoulos, A.; Peftitsis, D. Failure analysis and lifetime assessment of IGBT power modules at low temperature stress cycles. IET Power Electron. 2021, 14, 1271–1283. [Google Scholar] [CrossRef]

- Abuelnaga, A.; Narimani, M.; Bahman, A.S. A Review on IGBT Module Failure Modes and Lifetime Testing. IEEE Access 2021, 9, 9643–9663. [Google Scholar] [CrossRef]

- Abueed, M.A. Effects of Creep and Fatigue on the Reliability of SnAgCu Solder Joints in Thermal Cycling. Ph.D. Thesis, Auburn University, Auburn, AL, USA, 2020. [Google Scholar]

- Alavi, O.; De Ceuninck, W.; Daenen, M. Impact of Solder Voids on IGBT Thermal Behavior: A Multi-Methodological Approach. Electronics 2024, 13, 2188. [Google Scholar] [CrossRef]

- Cui, H.; Zhou, M.; Yang, C.; Li, J.; Wang, C. Influence mechanism of solder aging and thermal network model optimization of multi-chip IGBT modules. Microelectron. Reliab. 2022, 139, 114827. [Google Scholar] [CrossRef]

- Qin, F.; Zhang, Y.; An, T.; Zhou, R. An Improved Thermal Network Model of Press-Pack IGBT Modules Considering Contact Surface Damage. IEEE Trans. Device Mater. Reliab. 2023, 23, 444–452. [Google Scholar] [CrossRef]

- Chen, J.; Liu, B.; Hu, M.; Huang, S.; Yu, S.; Wu, Y.; Yang, J. Study of the solder characteristics of IGBT modules based on thermal-mechanical coupling simulation. Materials 2023, 16, 3504. [Google Scholar] [CrossRef] [PubMed]

- GB/T 2423.22-2012; Environmental Testing—Part 2: Tests Methods—Test N: Change of Temperature. The Standardization Administration of the People’s Republic of China: Beijing, China, 2012. Available online: https://openstd.samr.gov.cn/bzgk/gb/newGbInfo?hcno=594F3D5E92C435D89F0F2444970C8E26 (accessed on 3 September 2025).

- Ismail, N.; Atiqah, A.; Jalar, A.; Bakar, M.A.; Rahim, R.A.A.; Ismail, A.G.; Hamzah, A.A.; Keng, L.K. A systematic literature review: The effects of surface roughness on the wettability and formation of intermetallic compound layers in lead-free solder joints. J. Manuf. Process. 2022, 83, 68–85. [Google Scholar] [CrossRef]

- Tu, C.; Xu, H.; Xiao, B.; Lu, J.; Guo, Q.; Long, L. Research on the Influence of Bond Wire Lift-Off Position on the Electro-Thermal Characteristics of IGBT. IEEE Trans. Electron Devices 2022, 69, 1271–1278. [Google Scholar] [CrossRef]

- Chen, J.; Deng, E.; Liu, P.; Yang, S.; Huang, Y. The Influence and Application of Bond Wires Failure on Electrothermal Characteristics of IGBT Module. IEEE Trans. Compon. Packag. Manuf. Technol. 2021, 11, 1426–1434. [Google Scholar] [CrossRef]

- Yang, Y.; Chen, J.; Liu, B.; Wu, Y. Simulation and assessment of thermal-thermal coupling of welding materials in IGBT. Micromachines 2024, 15, 1519. [Google Scholar] [CrossRef]

- Chen, J.; Chen, J.; Wang, H.; He, L.; Huang, B.; Dadbakhsh, S.; Bartolo, P. Fabrication and development of mechanical metamaterials via additive manufacturing for biomedical applications: A review. Int. J. Extrem. Manuf. 2025, 7, 012001. [Google Scholar] [CrossRef]

- Shi, Q.; Chen, J.; Chen, J.; Liu, Y.; Wang, H. Application of additively manufactured bone scaffold: A systematic review. Biofabrication 2024, 16, 022007. [Google Scholar] [CrossRef]

- Hu, M.; Zhi, S.; Chen, J.; Li, R.; Liu, B.; He, L.; Yang, H.; Wang, H. Restraint of intermetallic compound and improvement of mechanical performance of Ti/Al dissimilar alloy by rotary friction welding based on laser powder bed fusion. J. Manuf. Process. 2024, 131, 440–454. [Google Scholar] [CrossRef]

- Takeuchi, K.; Higurashi, E. Wafer Bonding of GaAs and SiC via Thin Au Film at Room Temperature. Micromachines 2025, 16, 439. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, J.; Wang, Y.; Fang, Y. Effect of Grain Structure and Ni/Au-UBM Layer on Electromigration-Induced Failure Mechanism in Sn-3.0Ag-0.5Cu Solder Joints. Micromachines 2022, 13, 953. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.; Liu, Y.; Yang, J.; He, L.; Tang, H.; Li, X. A review of development and applications of SiC power devices in packaging and interconnect technology. Solder. Surf. Mt. Technol. 2025; in press. [Google Scholar]

- Du, X.; Chen, J.; She, Y.; Liu, Y.; Yang, Y.; Yang, J.; Dong, S. Effect of process parameter optimization on morphology and mechanical properties of Ti6Al4V alloy produced by selective laser melting. Prog. Nat. Sci. Mater. Int. 2023, 33, 911–917. [Google Scholar] [CrossRef]

| High-temperature storage experiment | Number | Initial Value | 72 h | 96 h | 168 h | 240 h | 336 h | 579 h | 720 h |

| 2 | 1.52 | 1.52 | 1.54 | 1.55 | 1.55 | 1.62 | 1.64 | 1.71 | |

| 9 | 1.46 | 1.49 | 1.48 | 1.5 | 1.5 | 1.55 | 1.56 | - | |

| 10 | 1.5 | 1.52 | 1.54 | 1.56 | 1.56 | - | - | - | |

| Low-temperature storage experiment | Number | Initial value | 72 h | 96 h | 168 h | 240 h | 336 h | 579 h | 720 h |

| 4 | 1.53 | 1.54 | 1.52 | 1.56 | 1.57 | 1.6 | 1.6 | 1.63 | |

| 6 | 1.5 | 1.5 | 1.54 | 1.56 | 1.55 | 1.58 | 1.58 | - | |

| 8 | 1.48 | 1.5 | 1.48 | 1.51 | 1.52 | - | - | - | |

| Temperature cycling experiment | Number | Initial value | 50 times | 100 times | 200 times | 500 times | 700 times | 1000 times | |

| 1 | 1.46 | 1.5 | 1.55 | 1.52 | 1.56 | 1.59 | 1.64 | ||

| 3 | 1.5 | 1.5 | 1.54 | 1.53 | 1.58 | 1.6 | 1.62 | ||

| 5 | 1.52 | 1.5 | 1.53 | 1.54 | - | - | - | ||

| 7 | 1.48 | 1.52 | 1.53 | 1.52 | 1.58 | - | - | ||

| 11 | 1.5 | 1.54 | 1.58 | 1.56 | 1.6 | 1.61 | - |

| High-temperature storage experiment | Number | Initial Value | 72 h | 96 h | 168 h | 240 h | 336 h | 579 h | 720 h |

| 2 | 5.57 | 10.63 | 12.2 | 18.73 | 22.64 | 24.52 | 25.26 | 27.65 | |

| 9 | 3.31 | 11.24 | 15.16 | 19.86 | 20.85 | 23.03 | 25.86 | - | |

| 10 | 3.15 | 15.15 | 19.48 | 20.70 | 23.35 | - | - | - | |

| Low-temperature storage experiment | Number | Initial value | 72 h | 96 h | 168 h | 240 h | 336 h | 579 h | 720 h |

| 4 | 5.81 | 3.98 | 3.63 | 10.08 | 10.08 | 9.28 | 11.37 | 12.03 | |

| 6 | 8.49 | 9.75 | 7.08 | 5.32 | 6.09 | 4.87 | 5.89 | - | |

| 8 | 4.23 | 4.77 | 5.06 | 6.39 | 7.95 | - | - | - | |

| Temperature cycling experiment | Number | Initial value | 50 times | 100 times | 200 times | 500 times | 700 times | 1000 times | |

| 1 | 15.42 | 18.95 | 21.52 | 23.54 | 25.04 | 26.78 | 29.37 | ||

| 3 | 14.78 | 19.43 | 20.16 | 23.16 | 26.57 | 28.85 | 30 | ||

| 5 | 9.83 | 12.49 | 17.88 | 19.82 | - | - | - | ||

| 7 | 5.44 | 9.57 | 13.55 | 16.89 | 21.43 | - | - | ||

| 11 | 12.05 | 15.22 | 17.63 | 21.93 | 24.97 | 27.49 | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, J.; Liu, Y.; Liu, B.; Wu, Y. Structure and Temperature Dependence of Solder Layer and Electric Parameters in IGBT Modules. Micromachines 2025, 16, 1023. https://doi.org/10.3390/mi16091023

Chen J, Liu Y, Liu B, Wu Y. Structure and Temperature Dependence of Solder Layer and Electric Parameters in IGBT Modules. Micromachines. 2025; 16(9):1023. https://doi.org/10.3390/mi16091023

Chicago/Turabian StyleChen, Jibing, Yanfeng Liu, Bowen Liu, and Yiping Wu. 2025. "Structure and Temperature Dependence of Solder Layer and Electric Parameters in IGBT Modules" Micromachines 16, no. 9: 1023. https://doi.org/10.3390/mi16091023

APA StyleChen, J., Liu, Y., Liu, B., & Wu, Y. (2025). Structure and Temperature Dependence of Solder Layer and Electric Parameters in IGBT Modules. Micromachines, 16(9), 1023. https://doi.org/10.3390/mi16091023