Wettability, Tribology, Degradation, and Topography of Laser-Textured Surfaces of Biopolymers

Abstract

1. Introduction

- An amorphous thermoplastic polymer with a high transparency to visible light is called polycarbonate (PC) [21]. The first people to conduct LST on PC, specifically on PC/PMMA blends, were Viville et al. The purpose of this study was to assess the chemical and physical changes made to the surfaces after the laser treatment. For this purpose, a KrF excimer laser was used to emit a UV laser beam with a pulse length of 30 ns. UV light was shown to be capable of producing chemical changes and micropatterns on PC/PMMA mix surfaces [21,22]. This substance is suitable for use in biomedical applications. PC has been employed as a biomaterial in a variety of applications, from heart surgery to renal dialysis.

- By using a UV laser, polytetrafluoroethylene (PTFE) was altered. The procedure was carried out by Ahad et al. in a nitrogen-rich setting. A precisely regulated surface patterning was the outcome of the treatment [23].

- A CO2 laser was also used to texture nylon 6.6 to improve its biocompatibility. The biological investigations showed that the nylon’s cell survival was impacted by the surface alteration when employing this laser wavelength. Surfaces treated with CO2 lasers showed enhanced cell proliferation [24].

2. Materials and Methods

2.1. Samples Preparation

2.2. Laser Surface Texturing (LST)

3. Results and Discussions

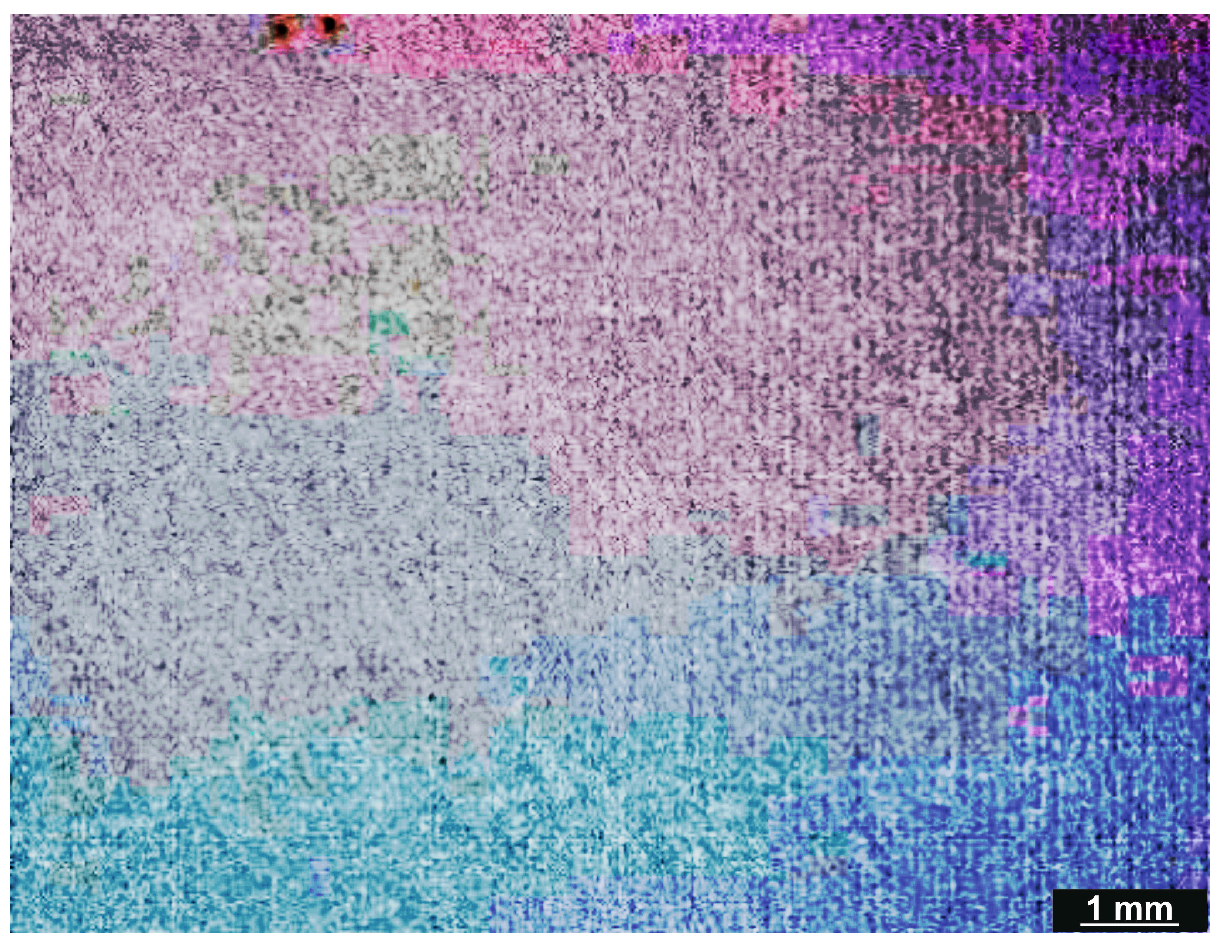

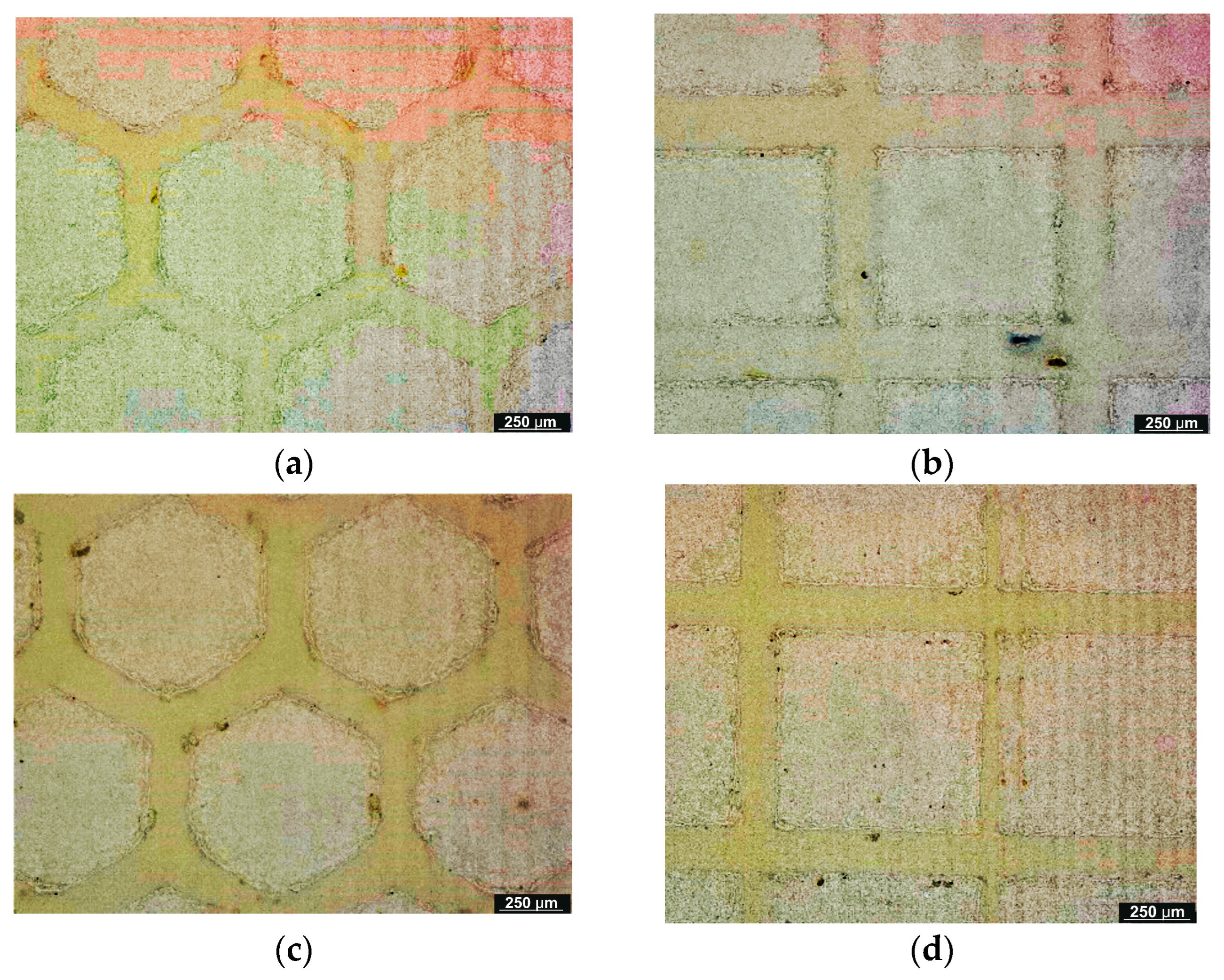

3.1. Microscopic Observation

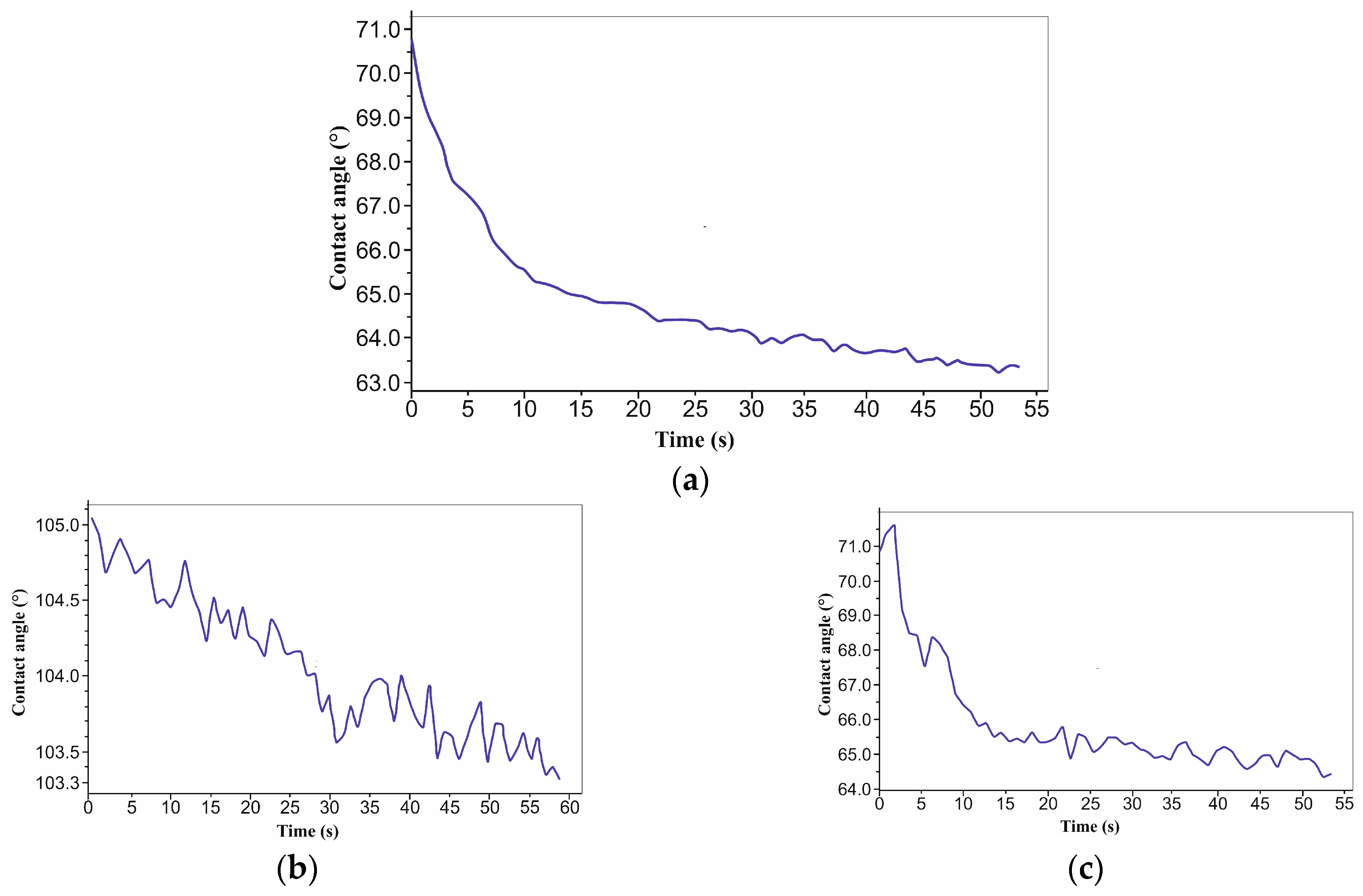

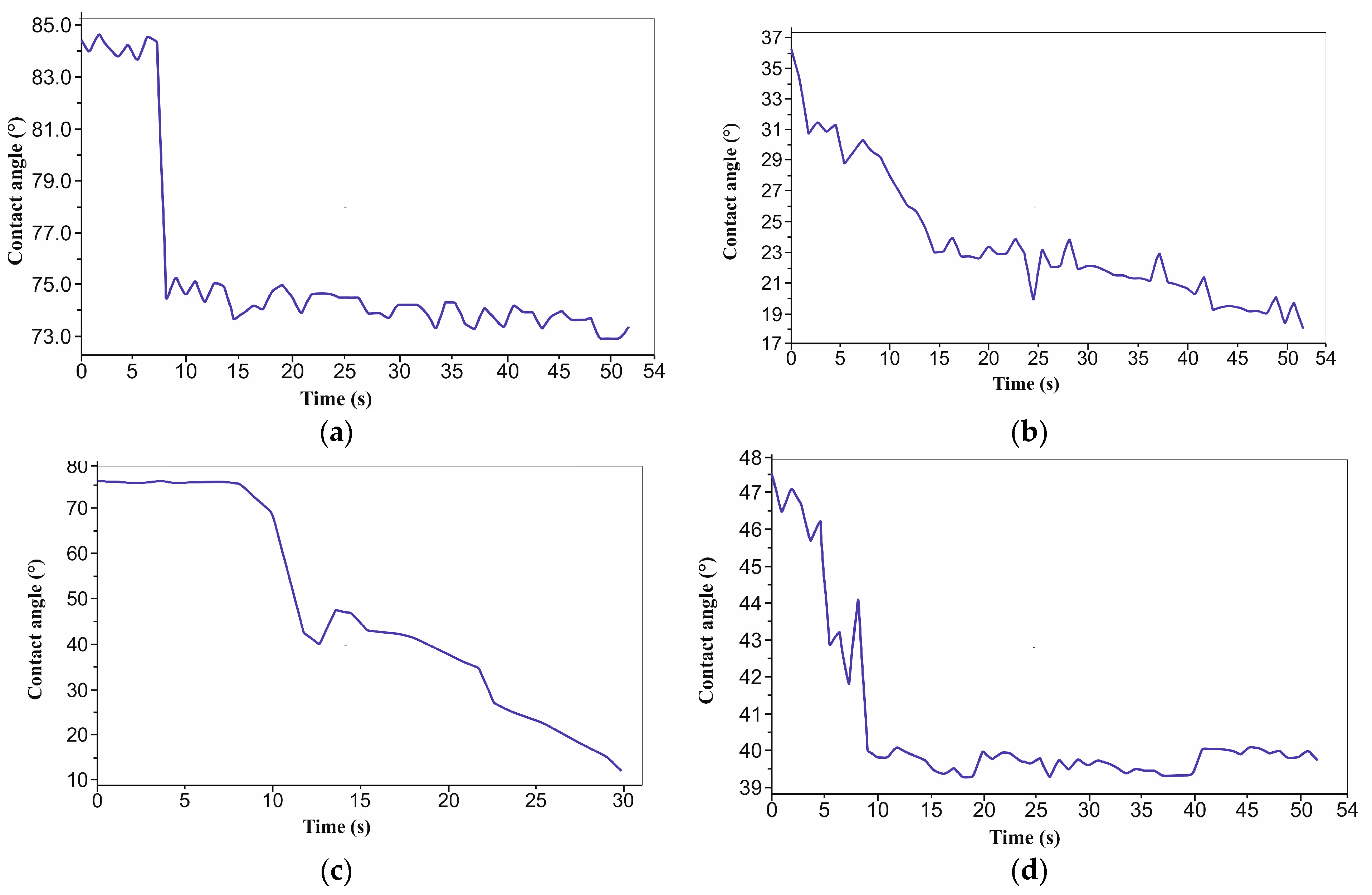

3.2. Wettability Test

3.3. Wear Test

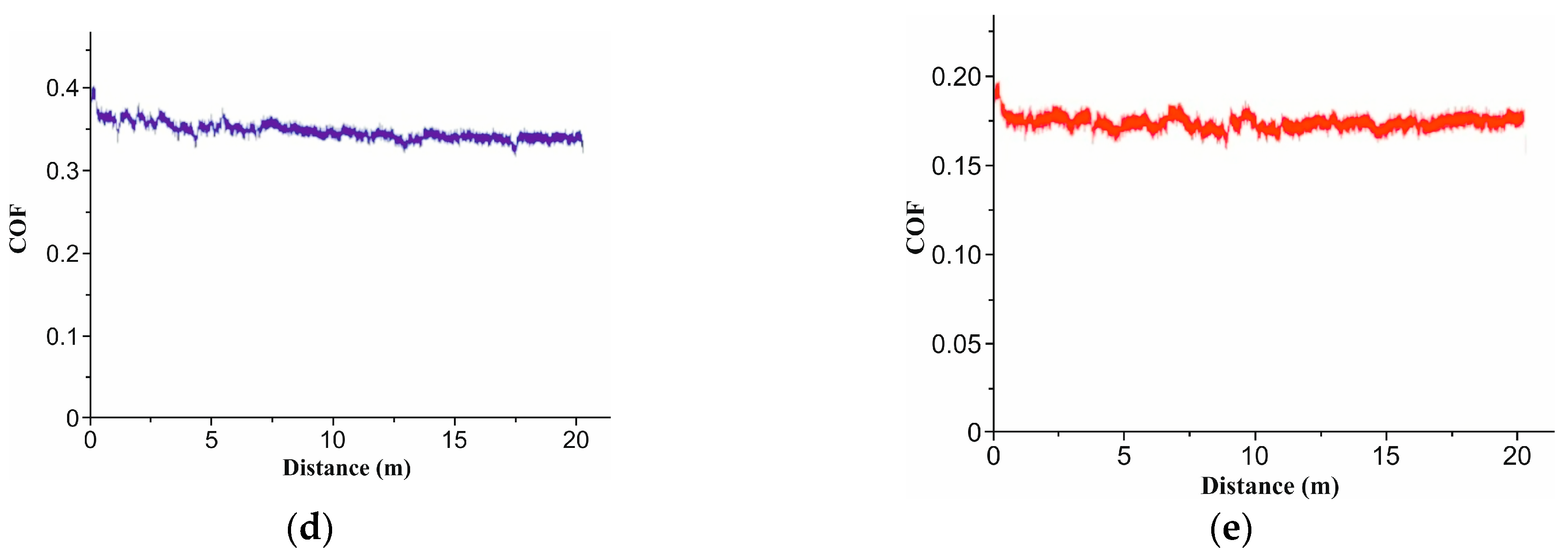

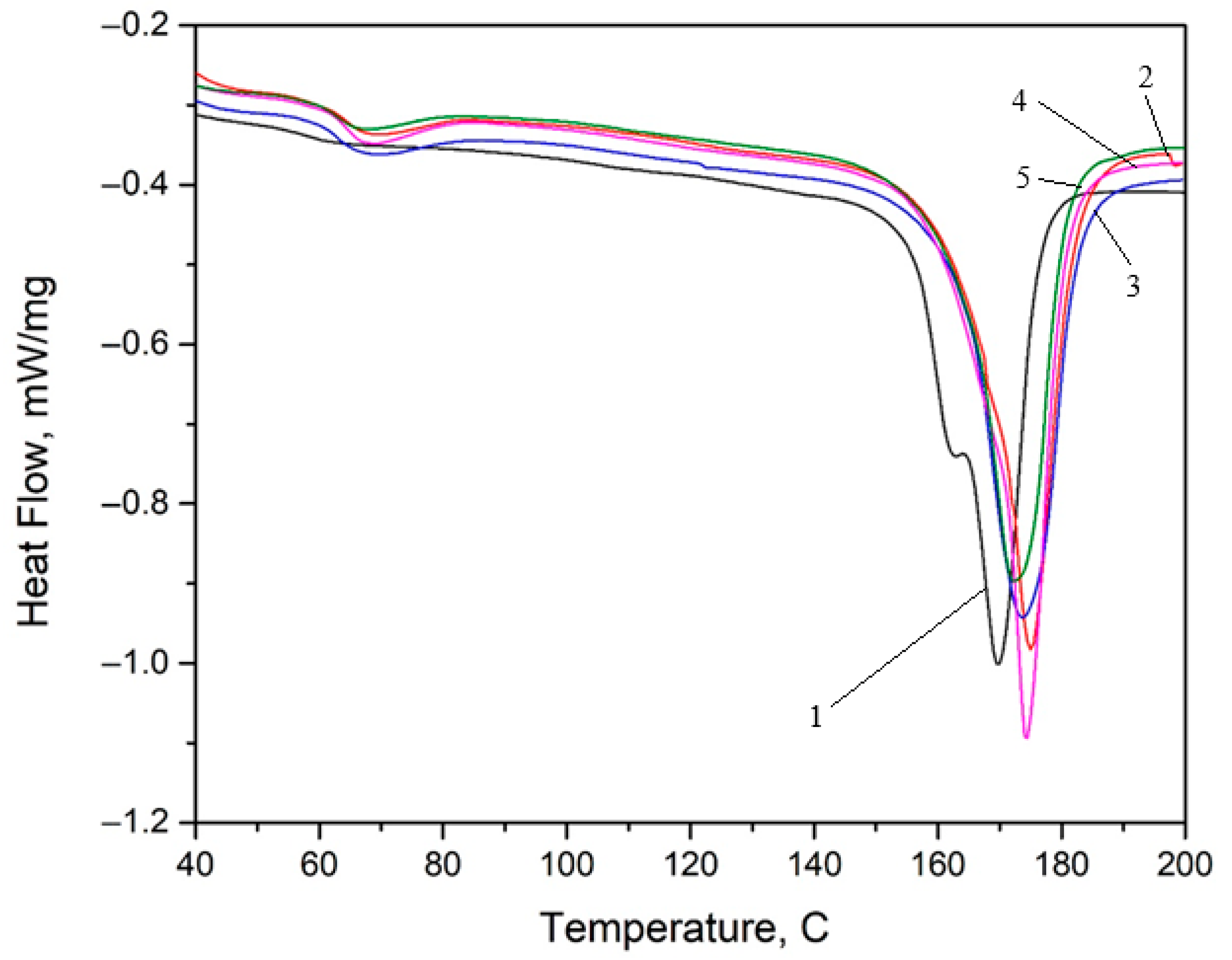

3.4. DSC Analysis

3.5. Degradation Test

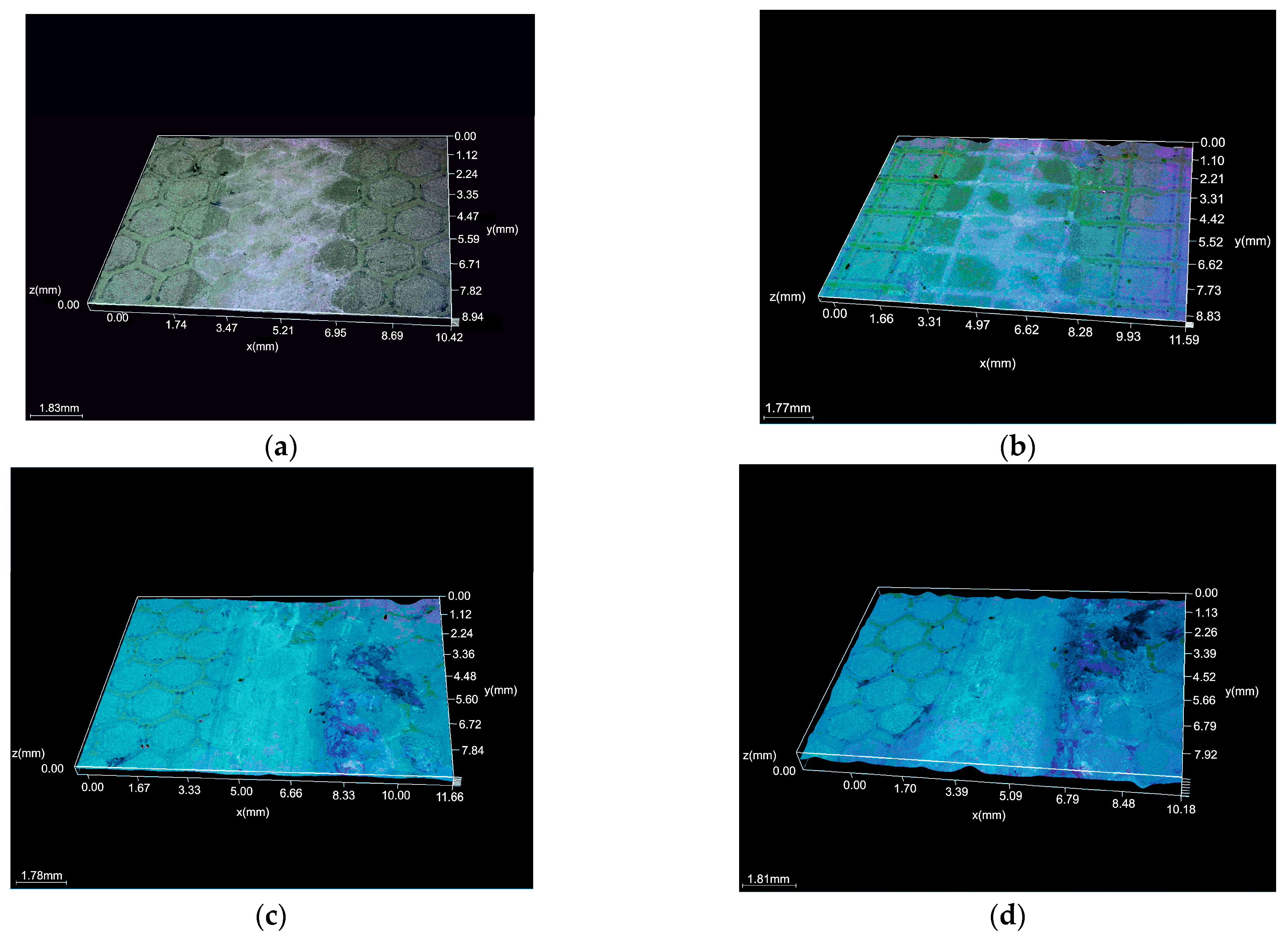

3.6. Topography

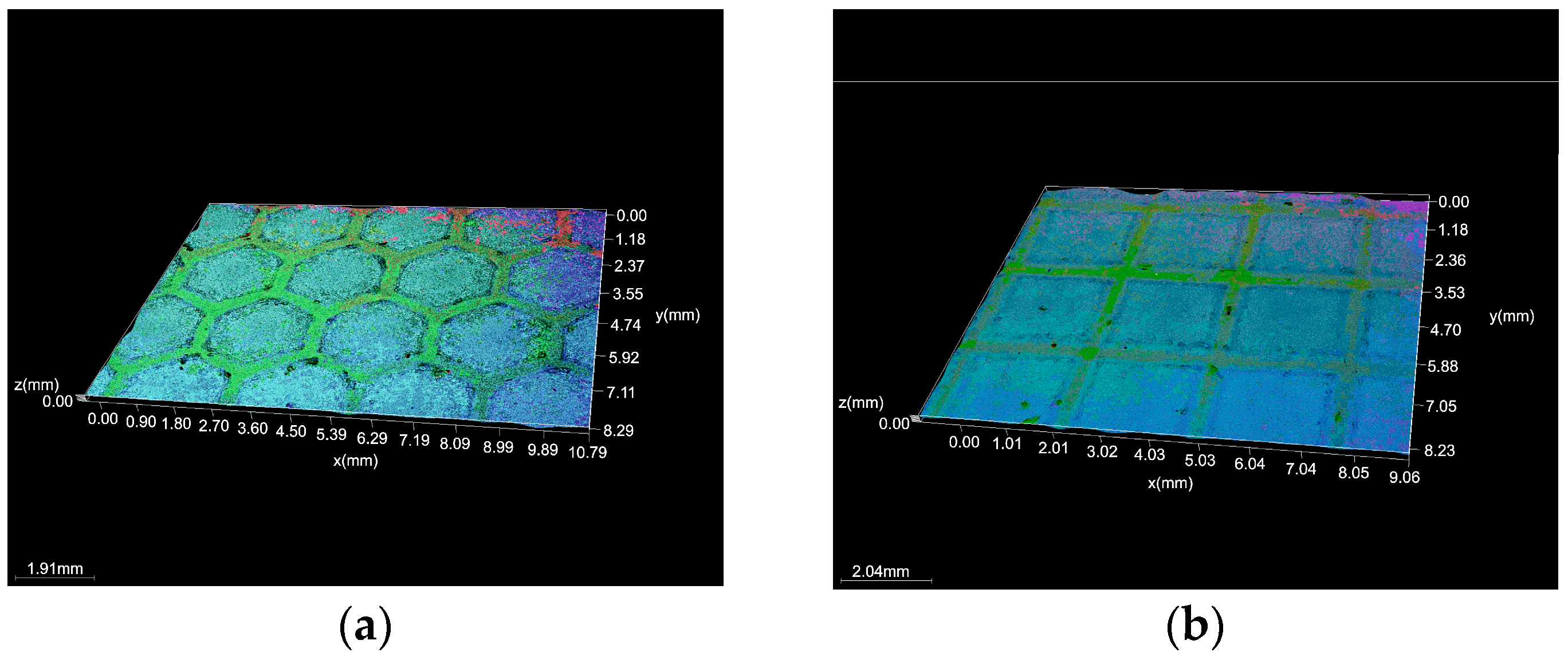

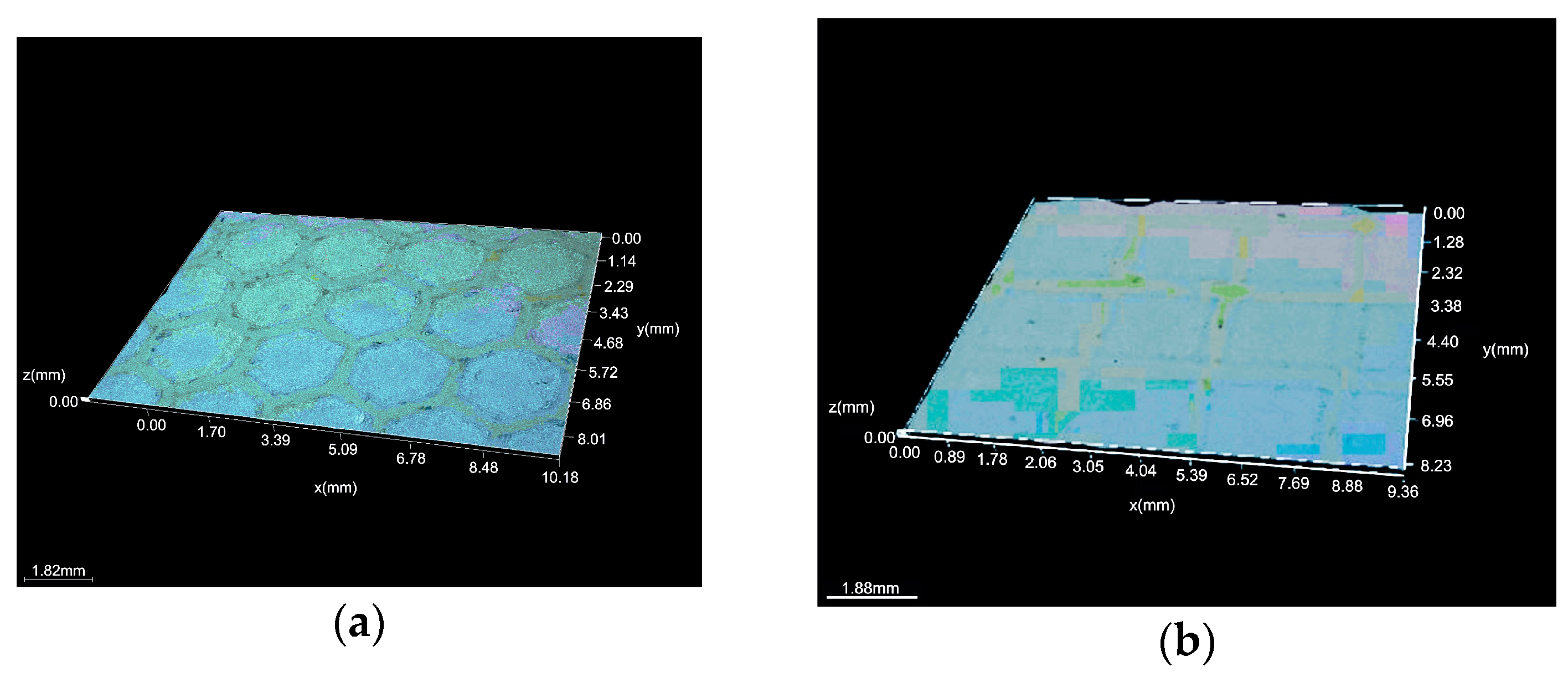

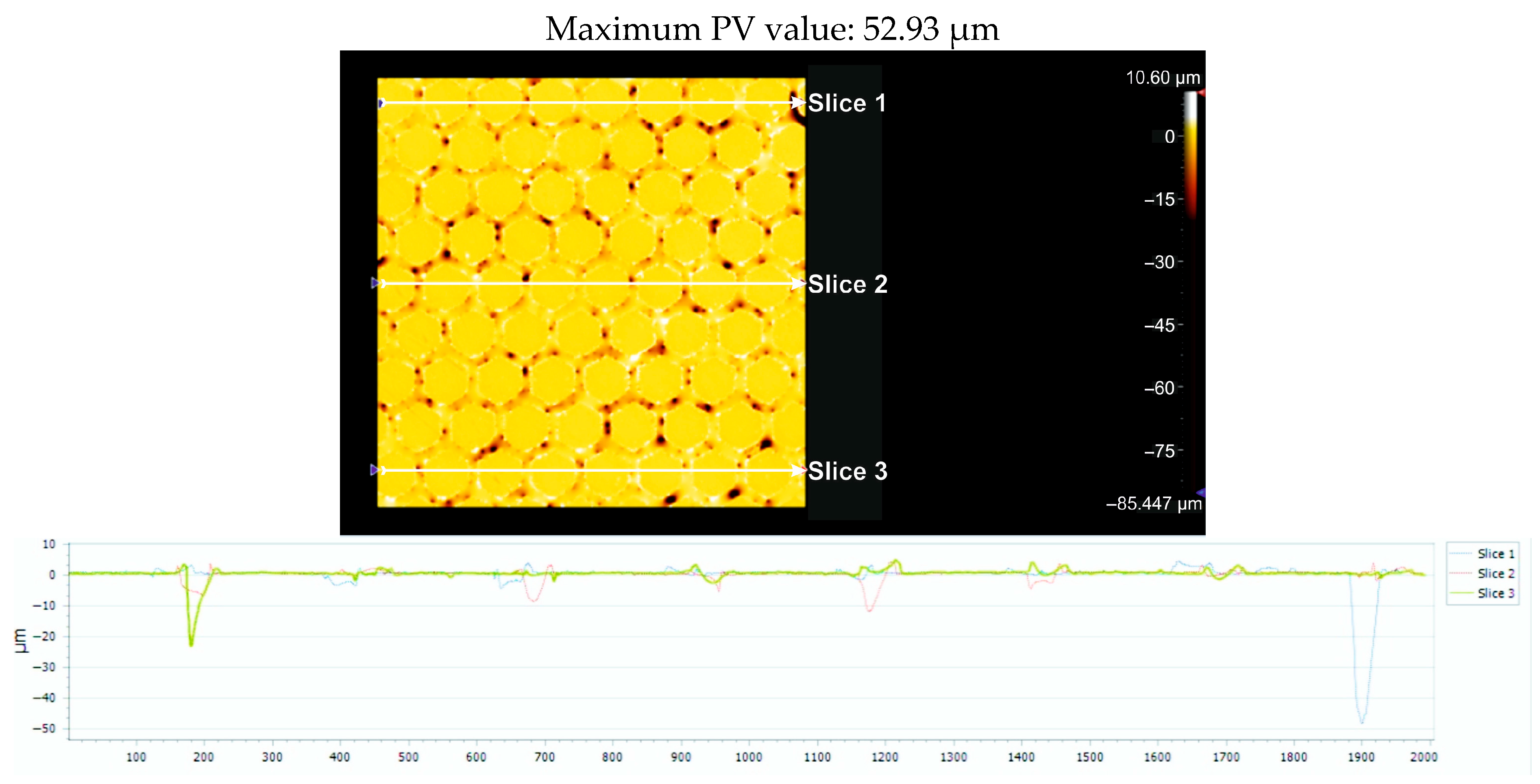

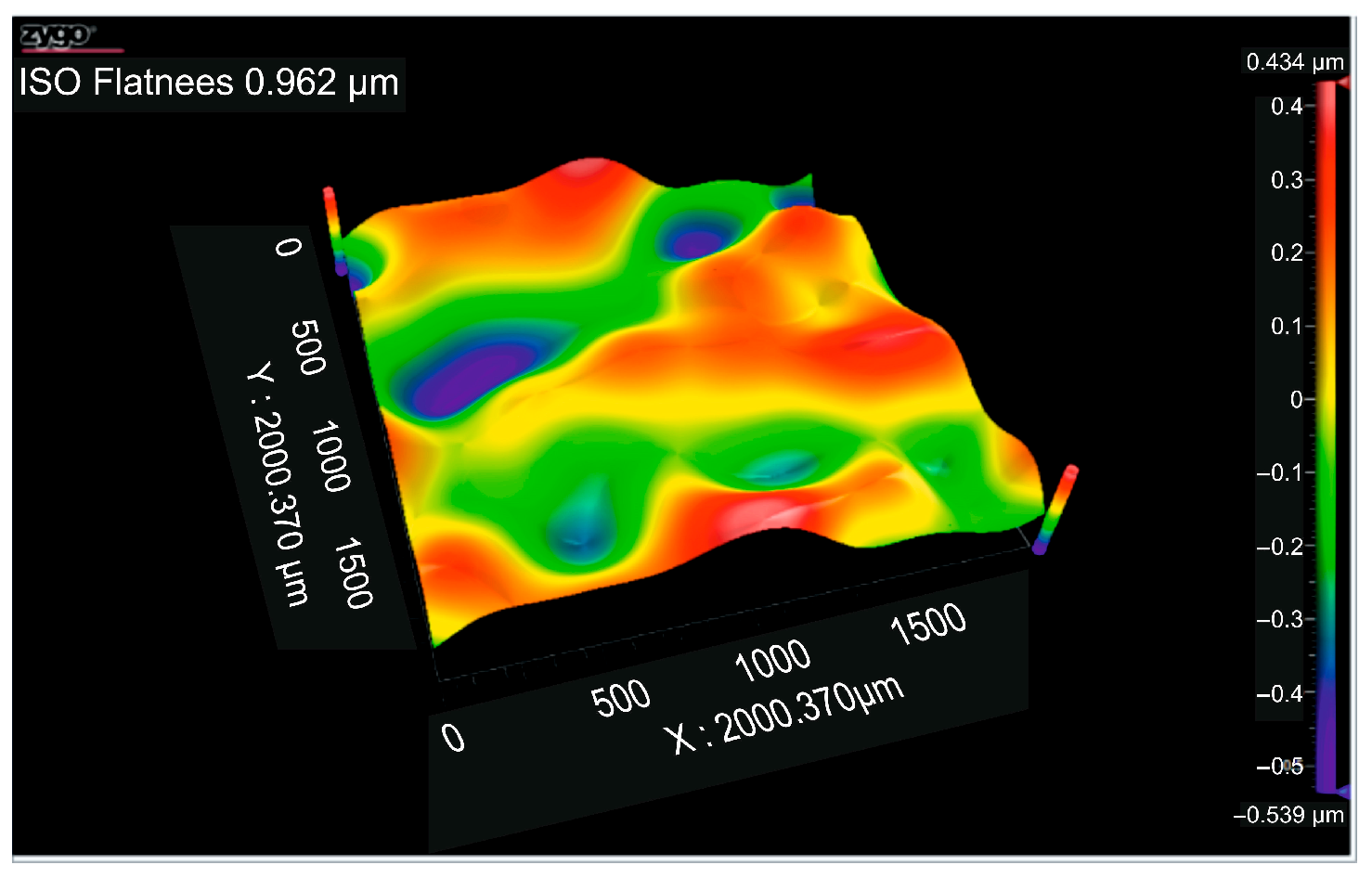

3.6.1. Topographic Analysis of Hexagonal Texture

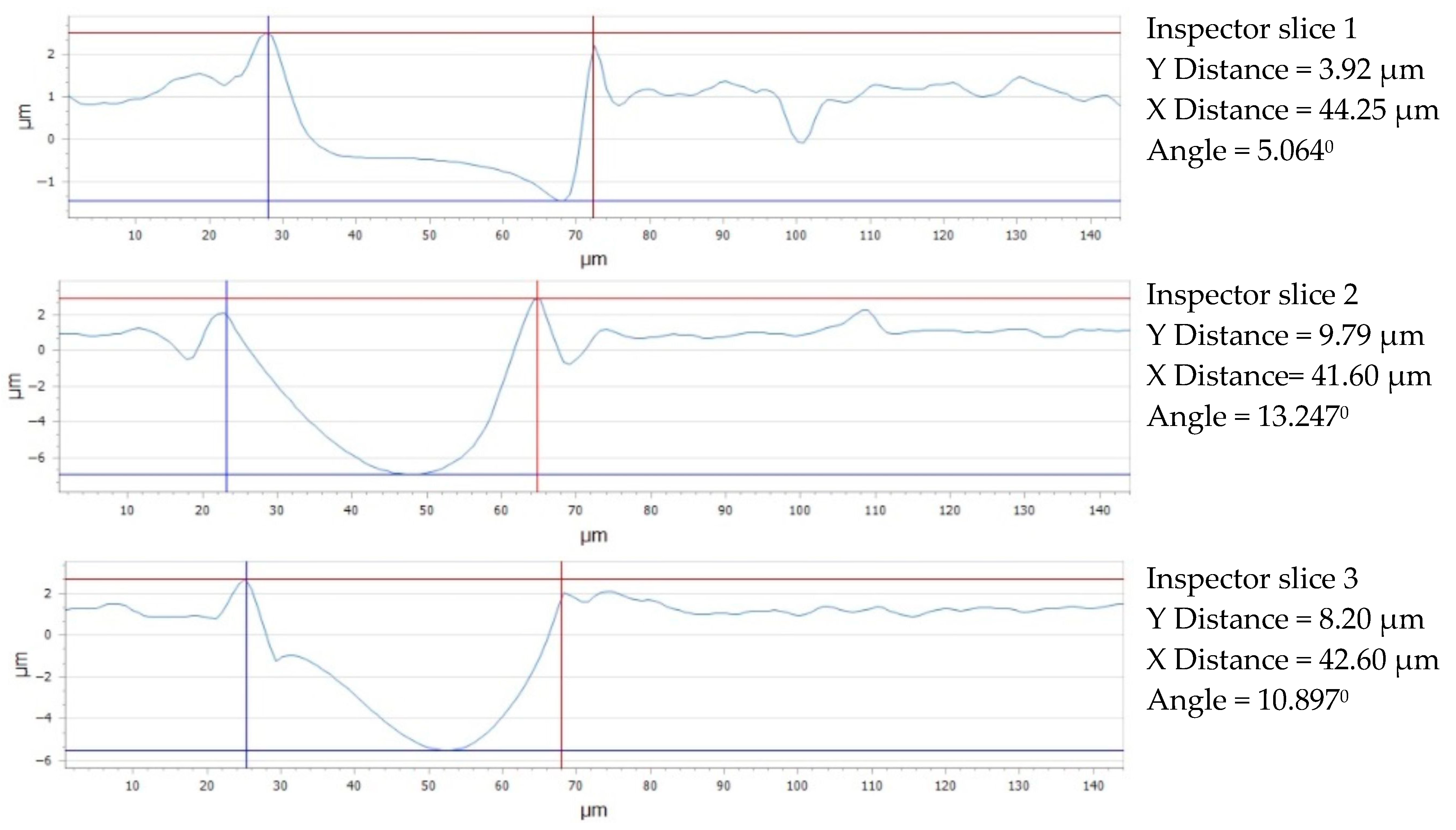

Topographic Analysis of Surfaces with 4x_H

Topographic Analysis of Surfaces with 6x_H

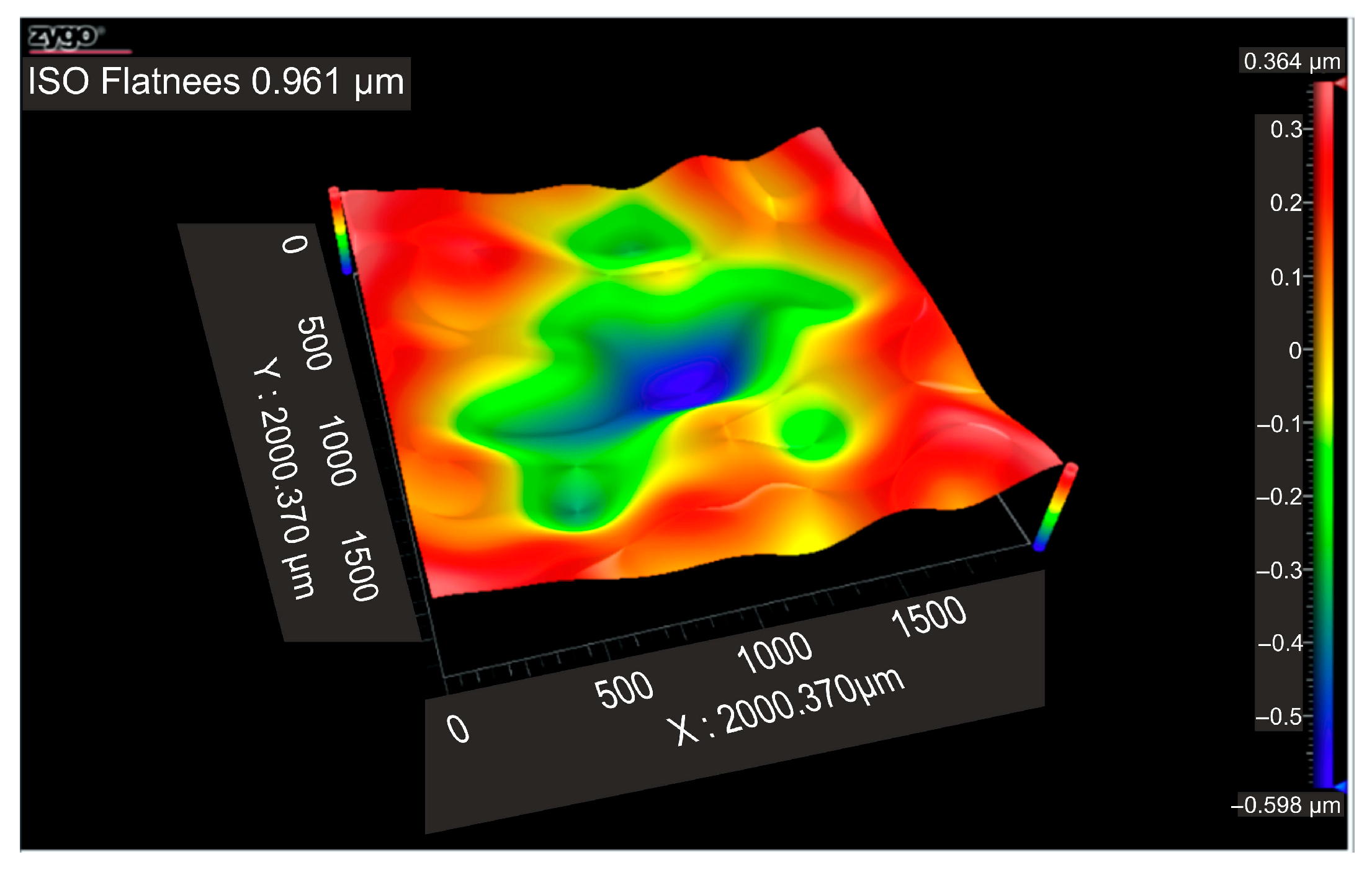

3.6.2. Topographic Analysis of Square Texture

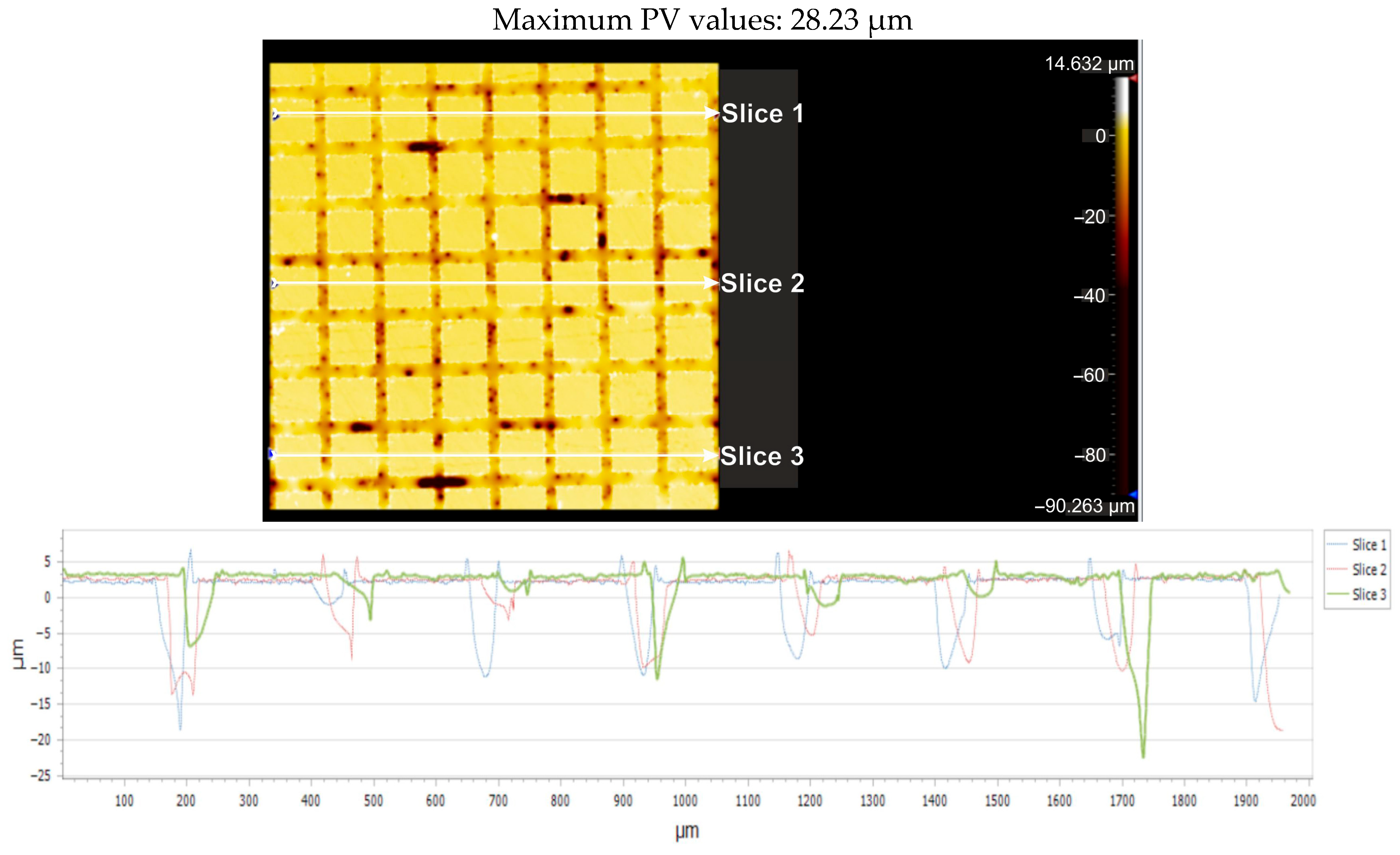

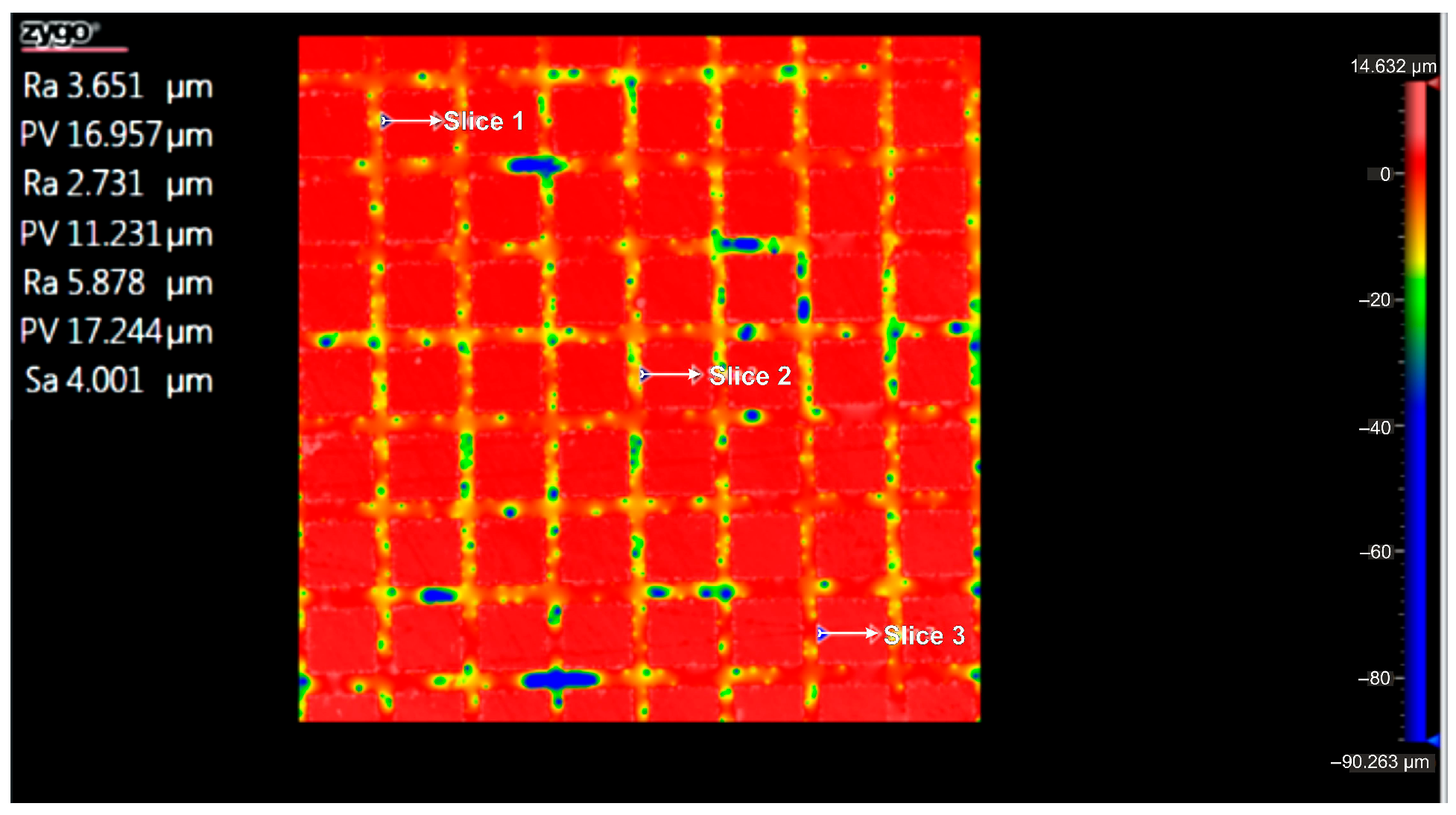

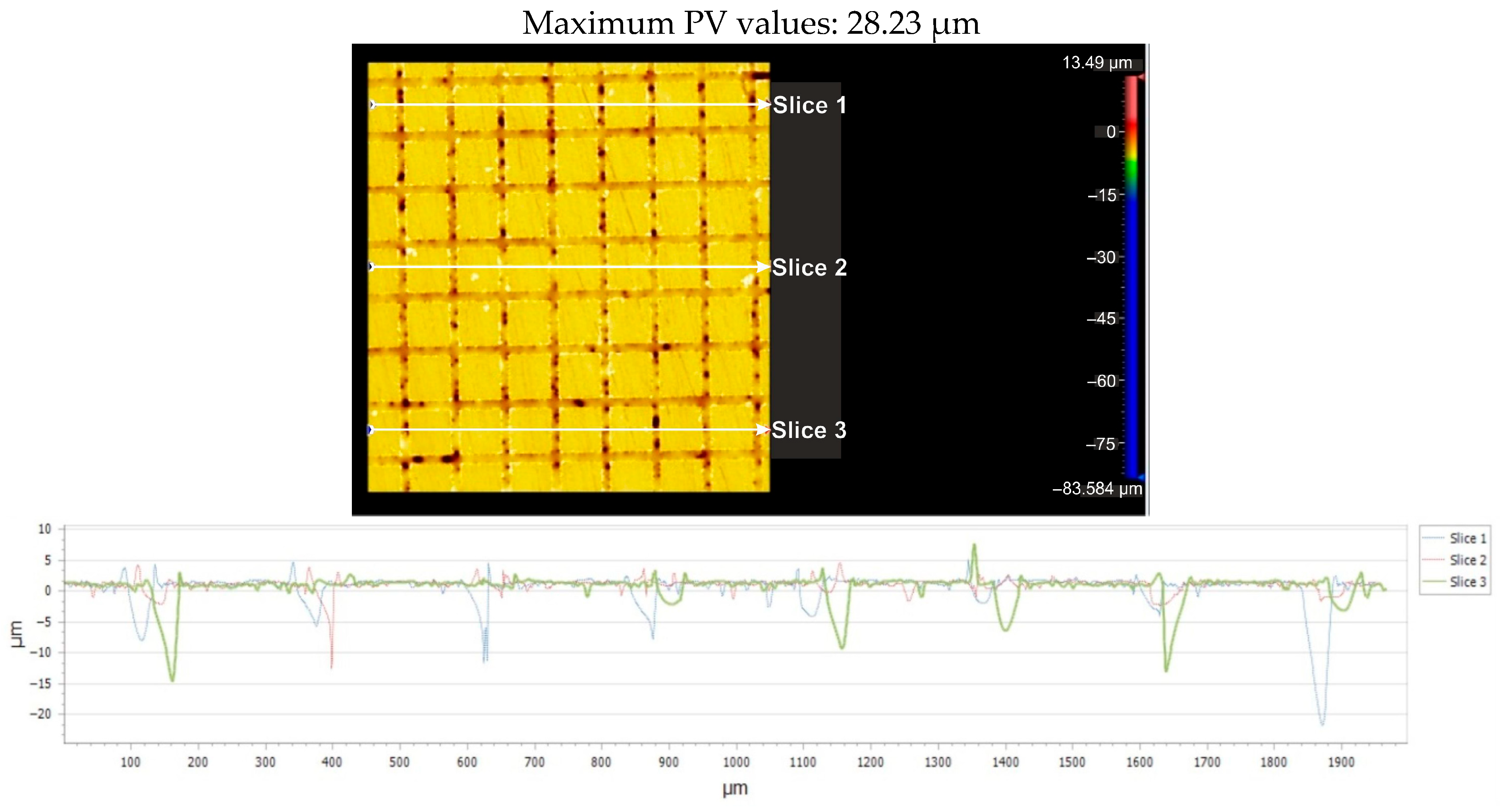

Topographic Analysis of Surfaces with 4x_S

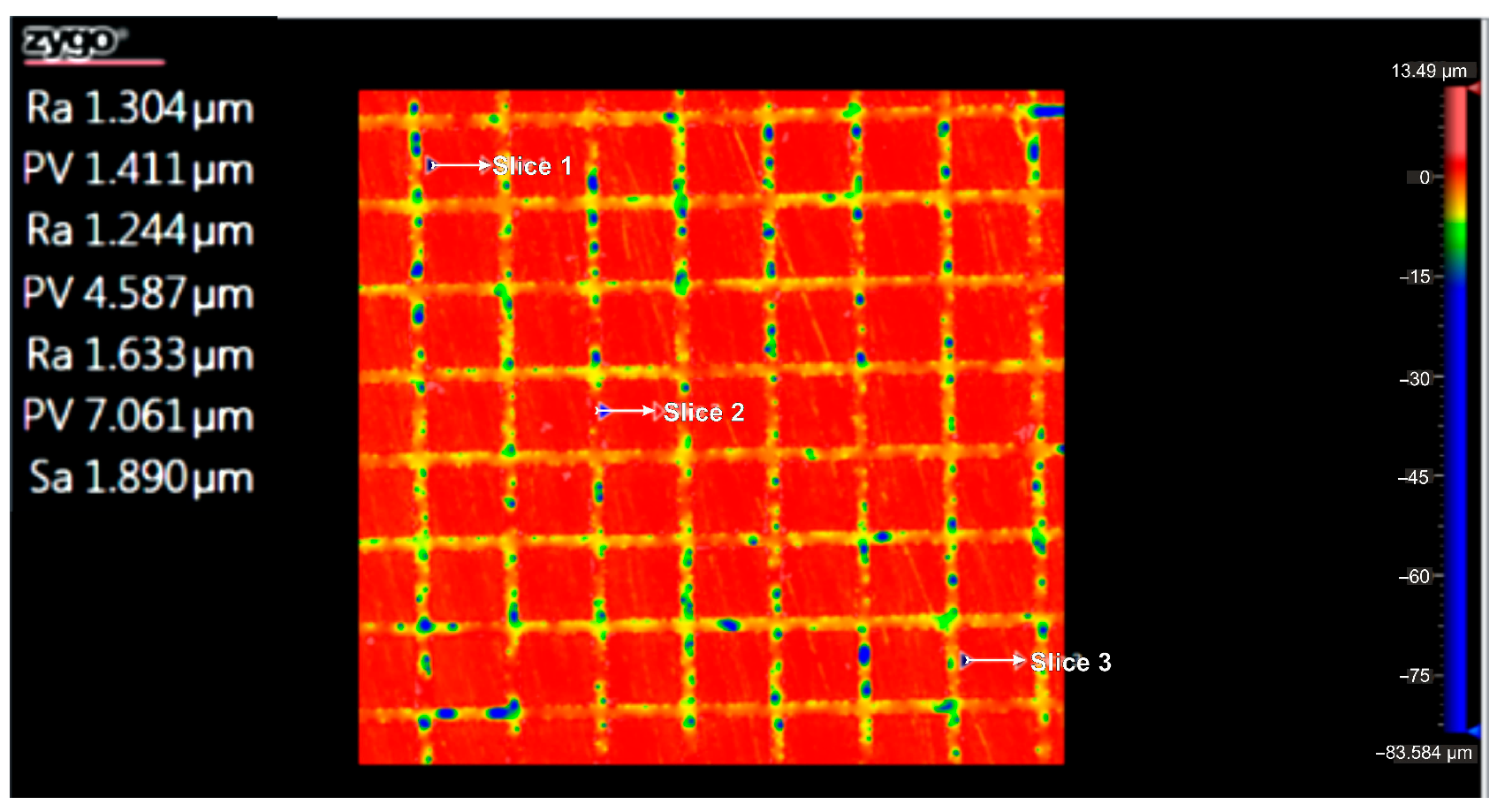

Topographic Analysis of Surfaces with 6x_S

3.6.3. Comparison of Hexagonal and Square Geometry at Four and Six Passes

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Riveiro, A.; Maçon, A.L.; del Val, J.; Comesaña, R.; Pou, J. Laser surface texturing of polymers for biomedical applications. Front. Phys. 2018, 6, 16. [Google Scholar] [CrossRef]

- Li, D.; Chen, X.; Guo, C.; Tao, J.; Tian, C.; Deng, Y.; Zhang, W. Micro surface texturing of alumina ceramic with nano-second laser. Procedia Eng. 2017, 174, 370–376. [Google Scholar] [CrossRef]

- Xing, Y.; Deng, J.; Feng, X.; Yu, S. Effect of laser surface texturing on Si3N4/TiC ceramic sliding against steel under dry friction. Mater. Design (1980–2015) 2013, 52, 34–45. [Google Scholar] [CrossRef]

- Šugár, P.; Šugárová, J.; Frnčík, M. Laser surface texturing of tool steel: Textured surfaces quality evaluation. Open Eng. 2016, 6, 90–97. [Google Scholar] [CrossRef]

- Tripathi, K.; Gyawali, G.; Joshi, B.; Amanov, A.; Wohn, S. Improved tribological behavior of grey cast Iron Under low and high viscous lubricants by laser surface texturing. Mater. Perform. Charact. 2017, 6, 24–41. [Google Scholar] [CrossRef]

- Ezhilmaran, V.; Vasa, N.J.; Vijayaraghavan, L. Investigation on generation of laser assisted dimples on piston ring surface and influence of dimple parameters on friction. Surf. Coat. Technol. 2018, 335, 314–326. [Google Scholar] [CrossRef]

- Liang, L.; Yuan, J.; Li, X.; Yang, F.; Jiang, L. Wear behavior of the micro-grooved texture on WC-Ni3Al cermet prepared by laser surface texturing. Int. J. Refract. Met. Hard Mater. 2018, 72, 211–222. [Google Scholar] [CrossRef]

- Shivakoti, I.; Kibria, G.; Cep, R.; Pradhan, B.B.; Sharma, A. Laser Surface Texturing for Biomedical Applications: A Review. Coatings 2021, 11, 124. [Google Scholar] [CrossRef]

- White, N.; Eder, K.; Byrnes, J.; Cairney, J.; McCarroll, I.E. Laser ablation sample preparation for atom probe tomography and transmission electron microscopy. Ultramicroscopy 2021, 220, 113161. [Google Scholar] [CrossRef]

- Tomanik, M.; Kobielarz, M.; Filipiak, J.; Szymonowicz, M.; Rusak, A.; Mroczkowska, K.; Antończak, A.; Pezowicz, C. Laser Texturing as a Way of Influencing the Micromechanical and Biological Properties of the Poly (L-Lactide) Surface. Materials 2020, 13, 3786. [Google Scholar] [CrossRef] [PubMed]

- Riveiro, A.; Soto, R.; Del Val, J.; Comesaña, R.; Boutinguiza, M.; Quintero, F.; Lusquiños, F.; Pou, J. Texturing of polypro-pylene (PP) with nanosecond lasers. Appl. Surf. Sci. 2016, 374, 379–386. [Google Scholar] [CrossRef]

- Mirzadeh, H.; Katbab, A.; Burford, R. CO2-laser graft copolymerization of HEMA and NVP onto ethylene-propylene rubber (EPR) as biomaterial-(III). Radiat. Phys. Chem. 1995, 46, 859–862. [Google Scholar] [CrossRef]

- Koufaki, N.; Ranella, A.; Aifantis, K.E.; Barberoglou, M.; Psycharakis, S.; Fotakis, C.; Stratakis, E. Controlling cell adhesion via replication of laser micro/nano-textured surfaces on polymers. Biofabrication 2011, 3, 045004. [Google Scholar] [CrossRef] [PubMed]

- Yeong, W.Y.; Yu, H.; Lim, K.P.; Ng, K.L.; Boey, Y.C.; Subbu, V.S.; Tan, L.P. Multiscale topological guidance for cell alignment via direct laser writing on biodegradable polymer. Tissue Eng. Part C Methods 2010, 16, 1011–1021. [Google Scholar] [CrossRef]

- Waugh, D.; Lawrence, J. Laser Surface Processing of Polymers for Biomedical Applications. In Laser-Assisted Fabrication of Materials; Springer: Berlin/Heidelberg, Germany, 2013; pp. 275–318. [Google Scholar]

- Jagur-Grodzinski, J. Polymers for tissue engineering, medical devices, and regenerative medicine. Concise general review of recent studies. Polym. Adv. Technol. 2006, 17, 395–418. [Google Scholar] [CrossRef]

- Kohane, D.S.; Langer, R. Polymeric biomaterials in tissue engineering. Pediatr. Res. 2008, 63, 487–491. [Google Scholar] [CrossRef] [PubMed]

- Teo, A.J.; Mishra, A.; Park, I.; Kim, Y.-J.; Park, W.-T.; Yoon, Y.-J. Polymeric biomaterials for medical implants and devices. ACS Biomater. Sci. Eng. 2016, 2, 454–472. [Google Scholar] [CrossRef] [PubMed]

- Lorusso, A.; Nassisi, V.; Paladini, F.; Torrisi, L.; Visco, A.M.; Campo, N. Comparison of the laser effects induced on ul-tra-high-molecular-weight polyethylene. Radiat. Eff. Defects Solids. 2008, 163, 435–440. [Google Scholar] [CrossRef]

- Riveiro, A.; Soto, R.; del Val, J.; Comesaña, R.; Boutinguiza, M.; Quintero, F.; Lusquiños, F.; Pou, J. Laser surface modification of ul-tra-high-molecular-weight polyethylene (UHMWPE) for biomedical applications. Appl. Surf. Sci. 2014, 302, 236–242. [Google Scholar] [CrossRef]

- Ahad, I.; Budner, B.; Korczyc, B.; Fiedorowicz, H.; Bartnik, A.; Kostecki, J.; Burdyńska, S.; Brabazon, D. Polycarbonate polymer surface modification by extreme ultraviolet (EUV) radiation. Acta Phys. Pol. A 2014, 125, 924–928. [Google Scholar] [CrossRef]

- Viville, P.; Beauvois, S.; Lambin, G.; Lazzaroni, R.; Bre´das, J.; Kolev, K.; Laude, L. Excimer laser-induced surface modifications of biocompatible polymer blends. Appl. Surf. Sci. 1996, 96–98, 558–562. [Google Scholar] [CrossRef]

- Ahad, I.U.; Butruk, B.; Ayele, M.; Budner, B.; Bartnik, A.; Fiedorowicz, H.; Ciach, T.; Brabazon, D. Extreme ultraviolet (EUV) surface modification of polytetrafluoroethylene (PTFE) for control of biocompatibility. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2015, 364, 98–107. [Google Scholar] [CrossRef]

- Waugh, D.; Lawrence, J.; Morgan, D.; Thomas, C. Interaction of CO2 laser-modified nylon with osteoblast cells in relation to wettability. Mater. Sci. Eng. C 2009, 29, 2514–2524. [Google Scholar] [CrossRef]

- Yasaka, K.; Koseki, Y.; Yoshinaka, K.; Miyake, K. Effects of Surface Texture on Soft-Materials for Medical Applications. Tribol. Online 2016, 11, 288–297. [Google Scholar] [CrossRef]

- Ikeuchi, K.; Takii, T.; Norikane, H.; Tomita, N.; Ohsumi, T.; Uyama, Y.; Ikada, Y. Water Lubrication of Polyure-thane Grafted with Dimethylacrylamide for Medical Use. Wear 1993, 161, 179–185. [Google Scholar] [CrossRef]

- Evangelista, I.; Wencel, D.; Beguin, S.; Zhang, N.; Gilchrist, M.D. Influence of Surface Texturing on the Dry Tribological Properties of Polymers in Medical Devices. Polymers 2023, 15, 2858. [Google Scholar] [CrossRef] [PubMed]

- Affatato, S.; Brando, D. Introduction to Wear Phenomena of Orthopaedic Implants. In Wear of Orthopaedic Implants and Artificial Joints; Woodhead Publishing: Sawston, UK, 2013; pp. 3–26. [Google Scholar]

- Ching, H.A.; Choudhury, D.; Nine, J.; Abu Osman, N.A. Effects of surface coating on reducing friction and wear of or-thopaedic implants. Sci. Technol. Adv. Mater. 2014, 15, 014402. [Google Scholar] [CrossRef] [PubMed]

- Howard, J.J. Balancing innovation and medical device regulation: The case of modern metal-on-metal hip replacements. Med. Devices. Evi. Res. 2016, 9, 267–275. [Google Scholar] [CrossRef]

- Bialas, O.; Lis, M.; Wozniak, A.; Adamiak, M. Laser Superficial Fusion of Gold Nanoparticles with PEEK Polymer for Car-diovascular Application. Materials 2021, 14, 971. [Google Scholar] [CrossRef]

- Available online: https://www.tecnaro.de/en/arboblend-arbofill-arboform/verarbeitung/ (accessed on 12 September 2022).

- Nedelcu, D.; Comaneci, R. Microstructure, mechanical properties and technology of samples obtained by injection from arboblend V2 nature. Indian J. Eng. Mater. Sci. 2014, 21, 272–276. [Google Scholar]

- Mazurchevici, S.-N.; Vaideanu, D.; Rapp, D.; Varganici, C.-D.; Cărăușu, C.; Boca, M.; Nedelcu, D. Dynamic mechanical analysis and thermal expansion of lignin-based biopolymers. Polymers 2021, 13, 2953. [Google Scholar] [CrossRef] [PubMed]

- Mazurchevici, S.-N.; Motaș, J.G.; Diaconu, M.; Lisa, G.; Lohan, N.M.; Glod, M.; Nedelcu, D. Nanocomposite biopolymer arboblend V2 nature AgNPs. Polymers 2021, 13, 2932. [Google Scholar] [CrossRef] [PubMed]

- Mazurchevici, S.-N.; Bialas, O.; Mindru, T.D.; Adamiak, M.; Nedelcu, D. Characterization of Arboblend V2 Nature Textured Surfaces Obtained by Injection Molding. Polymers 2023, 15, 406. [Google Scholar] [CrossRef] [PubMed]

| Software | Cimita software |

| Laser | Diode-pumped solid state |

| Cut speed | 1 [mm/s] |

| Cut passes | 4 and 6 passes |

| Power | 48 [mW] |

| Pulsation frequency | 400 [Hz] |

| Wavelength | 355 [nm] |

| Pulse width | 6 [ps] |

| No | Test Name | Equipment/Parameters/Investigations |

|---|---|---|

| 1 | Microscopic observation | Leica DVM6 digital microscope (DM)/ geometric structure of the surfaces, wear tracks. |

| 2 | Wettability test | Biolin Scientific Attension Theta Flex strain gauge/2 µL drops of distilled water measurement liquid were applied; three contact angle measurements as a function of time (60 s) were conducted; measurements were taken at 25 °C/contact angle (Δ) and surface wettability. |

| 3 | Wear test | CSM tribometer (CSM Instruments, Needham, MA, USA)/ball-on-plate method was used; a 6 mm-diameter Al2O3 ceramic ball was used; 4 N typical loads; sliding speed 1.2 cm/s, frequency 1 Hz, constant length of 6 mm/friction coefficient. |

| 4 | DSC analysis | The NETZSCH calorimeter type DSC 200 F3 Maia, with a temperature accuracy of 0.1 K, 276 sensitivities below 1 μW, and an enthalpy accuracy below 1% was used. Calibration was performed with Hg, Bi, In, Sn, and Zn according to standards. Heating was performed between RT and 180 °C for all samples using a heating rate of 10 °C/min. Sample fragments weighing less than 30 mg were cut and investigated under an Ar-protective atmosphere. The resulting DSC thermographs, comprising heat flow variations with temperature, were evaluated using the Proteus software v.6.1. |

| 5 | Degradation test | WKL 100/40—Weiss climate chamber/T↓–T = −5 °C wt = 1 h, aging: T = −5 °C, t = 3 h, T↑–T = 50 °C. HD = 90%. t =1 h, aging T = 50 °C. HD = 90%. t = 3 h/degradation. |

| 6 | Topography | Zegage-type profilometer with non-contact optical measurement technology/10× magnification; 0.815 µm lateral resolution and a 0.83/0.83 mm field of view (FOV). |

| Arboblend V2 Nature | Arboblend V2 Nature 4 Texturing Passes | Arboblend V2 Nature 6 Texturing Passes | |||||||

|---|---|---|---|---|---|---|---|---|---|

| No of Samples | Contact Angle (°) | Texturing Type | No of Samples | Contact Angle (°) | Texturing Type | No of Samples | Contact Angle (°) | ||

| Average | Average | ||||||||

| 1 | 63 | Hexagon | 1 | 65 | 62 ± 2 | Hexagon | 1 | 30 | 30 ± 8 |

| 2 | 61 | 2 | 62 | 2 | 40 | ||||

| 3 | 64 | 3 | 60 | 3 | 20 | ||||

| Average | 63 ± 1 | Square | 1 | 103 | 98 ± 4 | Square | 1 | 73 | 68 ± 5 |

| 2 | 92 | 2 | 61 | ||||||

| 3 | 98 | 3 | 70 | ||||||

| Sample | Ts gt | Tmid gt | Ti gt | Tf gt | ΔCp | Ts | T50 | Tf | ΔH/m |

|---|---|---|---|---|---|---|---|---|---|

| [°C] | [°C] | [°C] | [°C] | [J/(g·K)] | [°C] | [°C] | [°C] | [kJ/kg] | |

| Base material | 64 | 66.6 | 65.8 | 67.8 | 0.397 | 156.2 | 169.8 | 1761 | −43.39 |

| 4xH | 60.6 | 64.1 | 62.8 | 65.9 | 0.147 | 165.4 | 172.4 | 180.4 | −40.43 |

| 4xS | 62.1 | 65.4 | 64.5 | 67.3 | 0.241 | 169.7 | 174.2 | 180.3 | −46.69 |

| 6xH | 60.6 | 64.5 | 62.8 | 66.7 | 0.207 | 164.5 | 173.6 | 182.4 | −44.51 |

| 6xS | 62.4 | 66.3 | 64.6 | 67.7 | 0.141 | 168.3 | 175.1 | 181.9 | −44.15 |

| Material | Weight (g) | Difference | ||

|---|---|---|---|---|

| Before Texturing | After Texturing | |||

| Arboblend V2 Nature | 4 texturing passes | 38.785 | 38.845 | +0.06 |

| 6 texturing passes | 37.840 | 37.903 | +0.063 | |

| No.crt. | Reference Line | PV (µm) | RMS (µm) |

|---|---|---|---|

| 1 | Slice 1 | 52.93 | 5.13 |

| 2 | Slice 2 | 16.39 | 1.81 |

| 3 | Slice 3 | 28.45 | 1.96 |

| 4 | Mean | 32.59 | 2.97 |

| Nr.crt. | Reference Line | PV (µm) | RMS (µm) |

|---|---|---|---|

| 1 | Slice 1 | 21.75 | 2.281 |

| 2 | Slice 2 | 13.41 | 1.553 |

| 3 | Slice 3 | 34.36 | 2.776 |

| 4 | Mean | 23.17 | 2.203 |

| 5 | Standard deviation | 10.54 | 0.615 |

| 6 | Range | 20.94 | 1.223 |

| 7 | 3 Sigma | 31.64 | 1.846 |

| Nr.crt. | Reference Line | PV (µm) | RMS (µm) |

|---|---|---|---|

| 1 | Slice 1 | 25.27 | 3.818 |

| 2 | Slice 2 | 24.95 | 4.124 |

| 3 | Slice 3 | 28.23 | 3.630 |

| 4 | Mean | 26.15 | 3.857 |

| 5 | Standard deviation | 1.80 | 0.249 |

| 6 | Range | 3.27 | 0.494 |

| 7 | 3 Sigma | 5.42 | 0.748 |

| Nr.crt. | Reference Line | PV (µm) | RMS (µm) |

|---|---|---|---|

| 1 | Slice 1 | 26.56 | 2.812 |

| 2 | Slice 2 | 16.59 | 1.463 |

| 3 | Slice 3 | 22.27 | 2.326 |

| 4 | Mean | 21.81 | 2.200 |

| 5 | Standard deviation | 5.00 | 0.683 |

| 6 | Range | 9.97 | 1.349 |

| 7 | 3 Sigma | 15.01 | 2.051 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ciofu, C.-D.; Rusu, P.-D.; Adamiak, M.; Bialas, O.; Tampu, C.; Kyratsis, P.; Tzotzis, A.; Mazurchevici, S.-N.; Nedelcu, A.; Jiang, Z.; et al. Wettability, Tribology, Degradation, and Topography of Laser-Textured Surfaces of Biopolymers. Micromachines 2025, 16, 1009. https://doi.org/10.3390/mi16091009

Ciofu C-D, Rusu P-D, Adamiak M, Bialas O, Tampu C, Kyratsis P, Tzotzis A, Mazurchevici S-N, Nedelcu A, Jiang Z, et al. Wettability, Tribology, Degradation, and Topography of Laser-Textured Surfaces of Biopolymers. Micromachines. 2025; 16(9):1009. https://doi.org/10.3390/mi16091009

Chicago/Turabian StyleCiofu, Ciprian-Dumitru, Petronela-Daniela Rusu (Ostahie), Marcin Adamiak, Oktawian Bialas, Catalin Tampu, Panagiotis Kyratsis, Anastasios Tzotzis, Simona-Nicoleta Mazurchevici, Alexandra Nedelcu, Zhengyi Jiang, and et al. 2025. "Wettability, Tribology, Degradation, and Topography of Laser-Textured Surfaces of Biopolymers" Micromachines 16, no. 9: 1009. https://doi.org/10.3390/mi16091009

APA StyleCiofu, C.-D., Rusu, P.-D., Adamiak, M., Bialas, O., Tampu, C., Kyratsis, P., Tzotzis, A., Mazurchevici, S.-N., Nedelcu, A., Jiang, Z., Mindru, D., & Nedelcu, D. (2025). Wettability, Tribology, Degradation, and Topography of Laser-Textured Surfaces of Biopolymers. Micromachines, 16(9), 1009. https://doi.org/10.3390/mi16091009