Time-Dependent Optothermal Performance Analysis of a Flexible RGB-W LED Light Engine

Abstract

1. Introduction

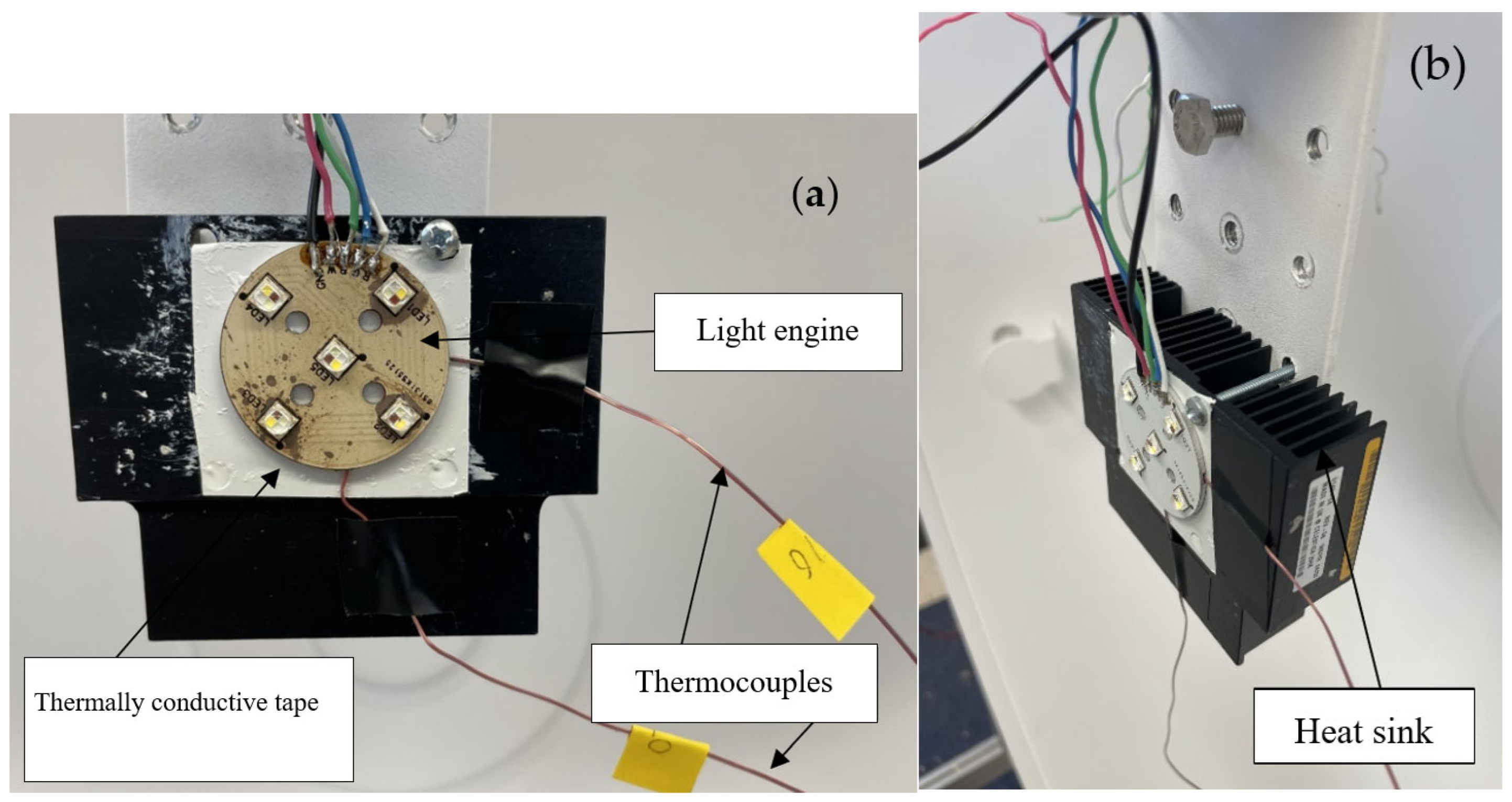

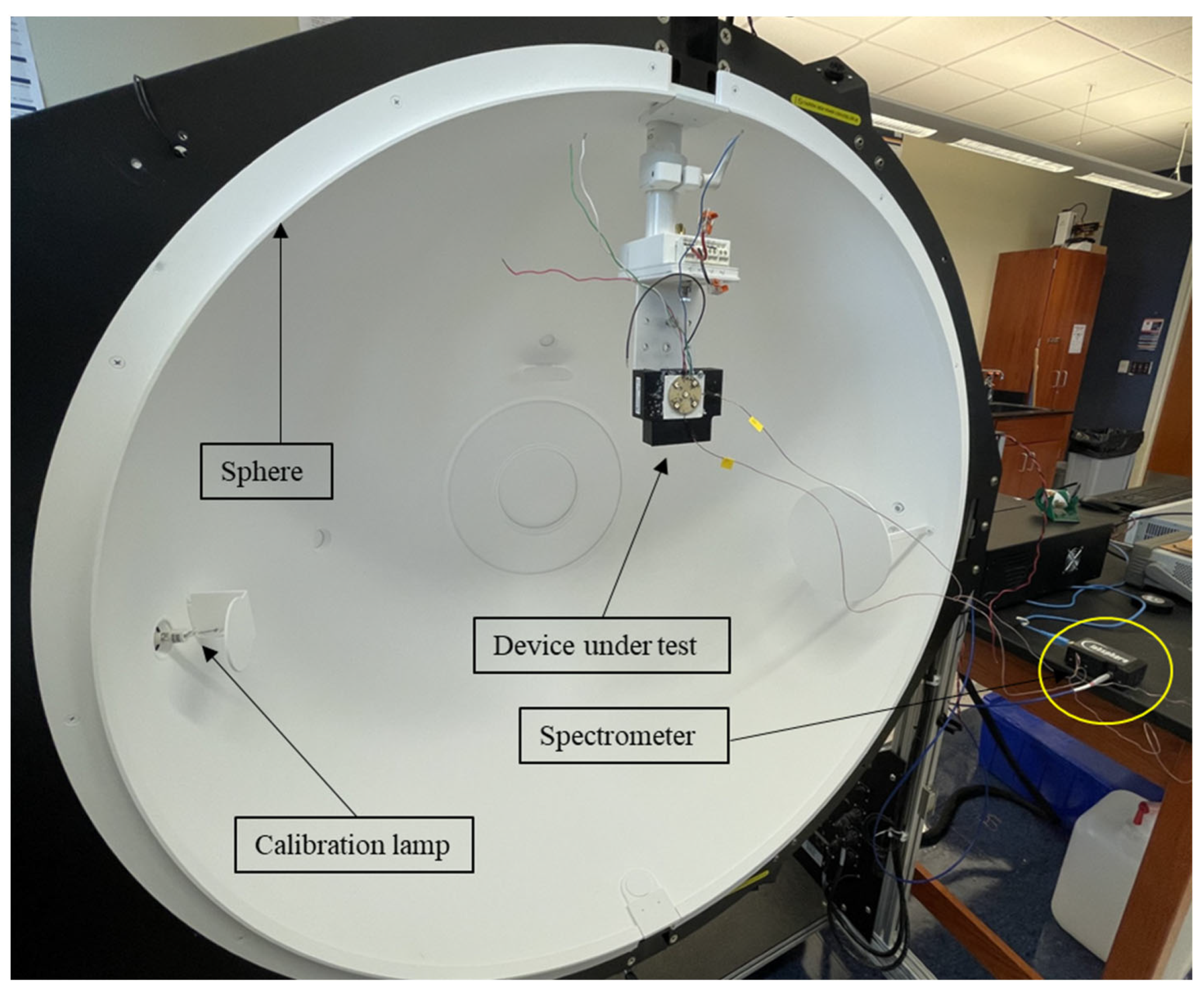

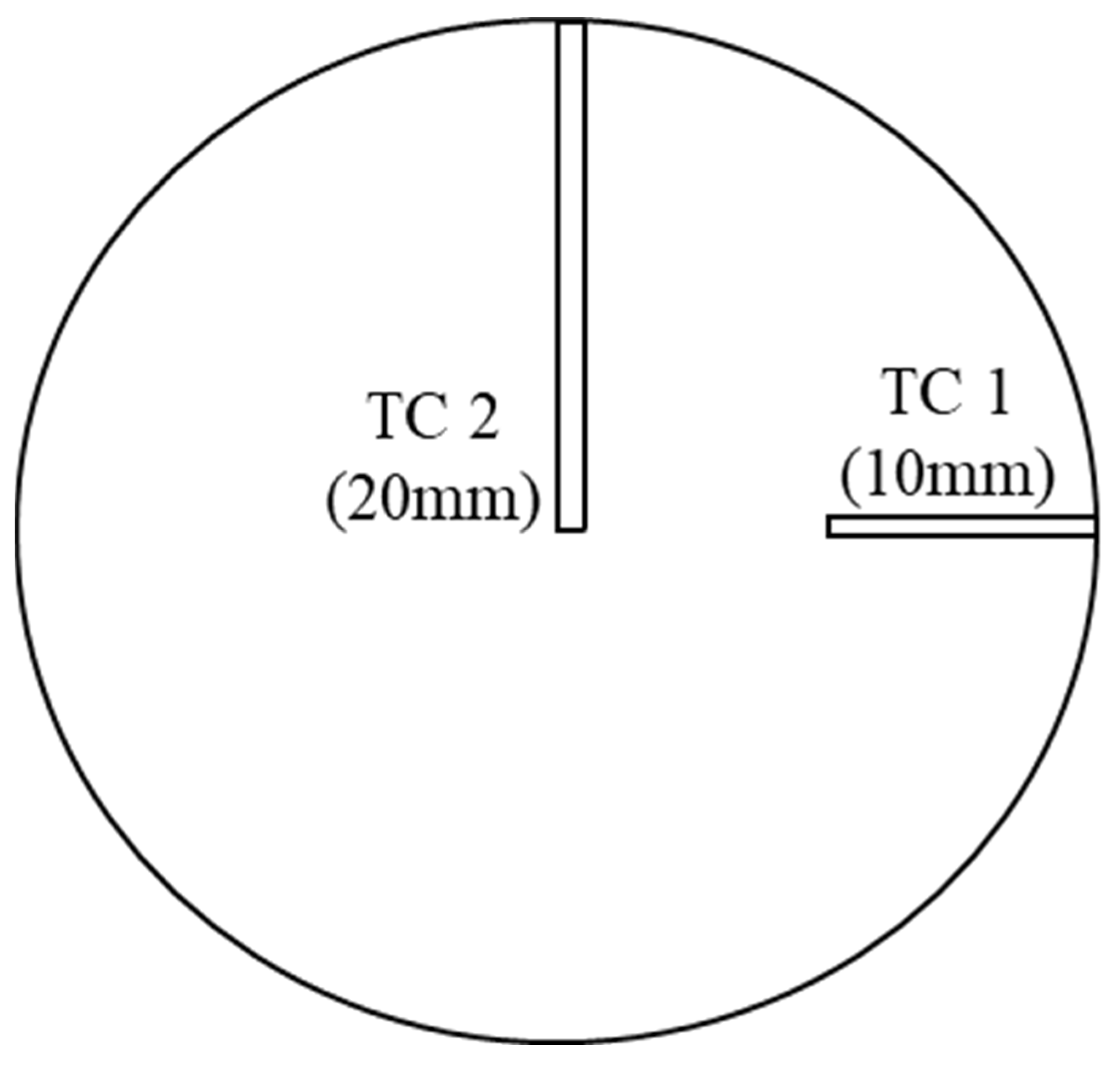

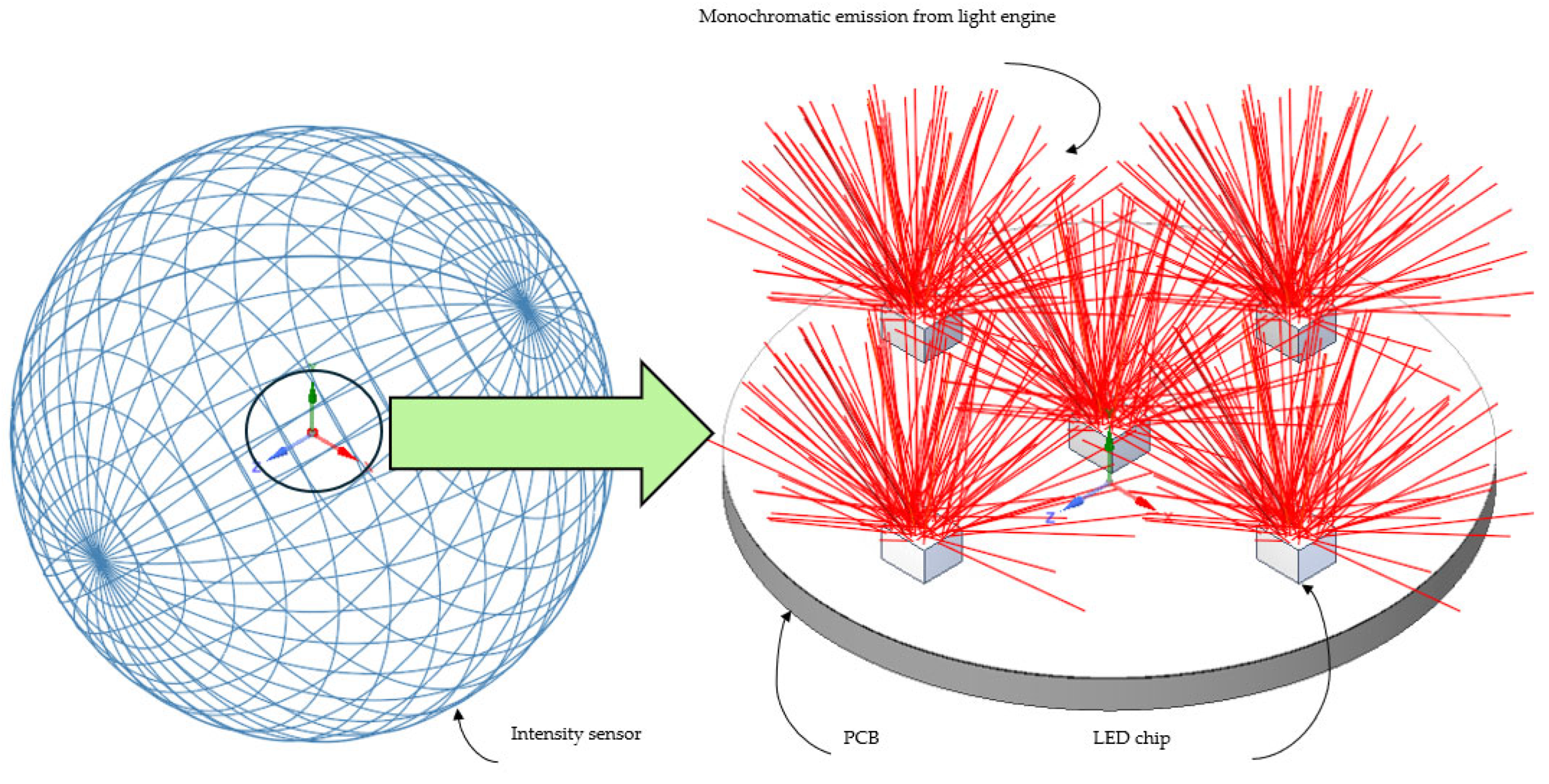

2. Experimental Study

3. Computational Models

4. Results and Discussions

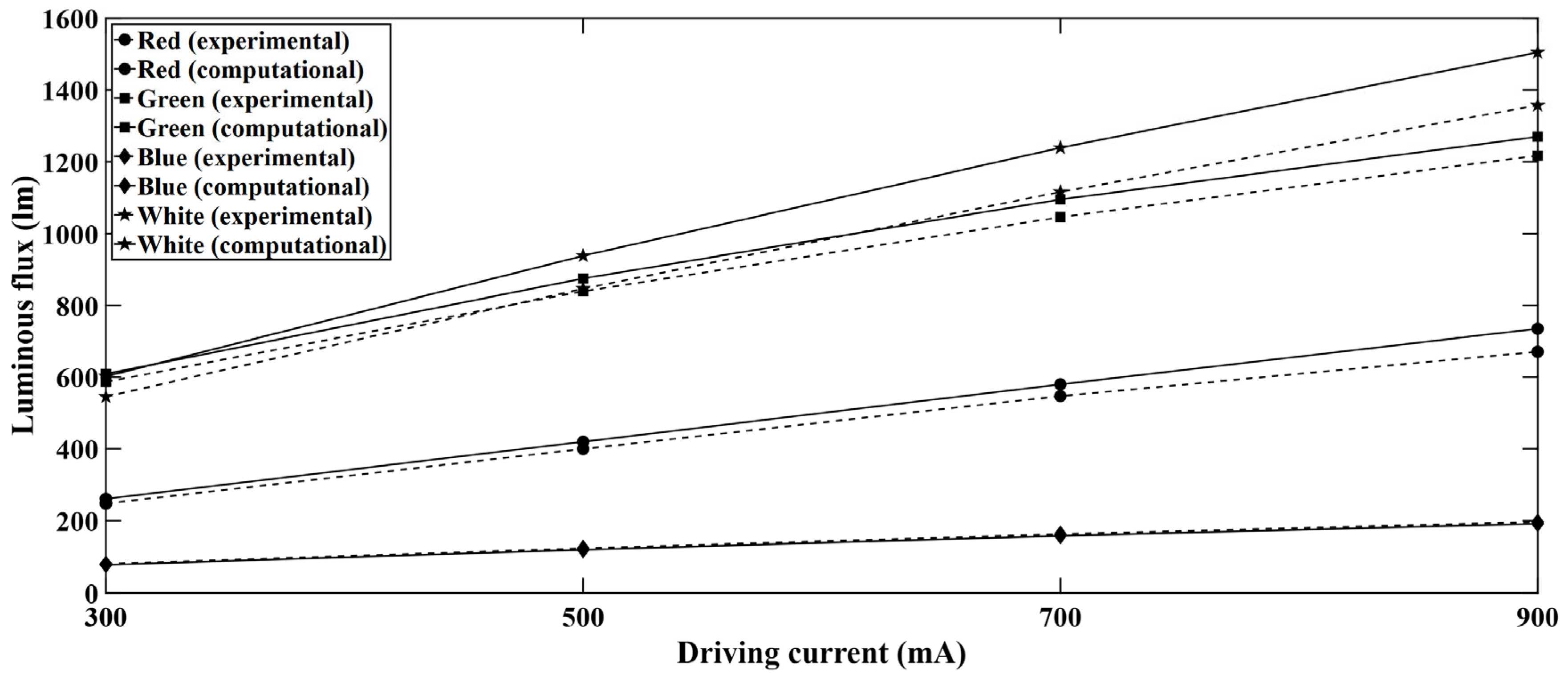

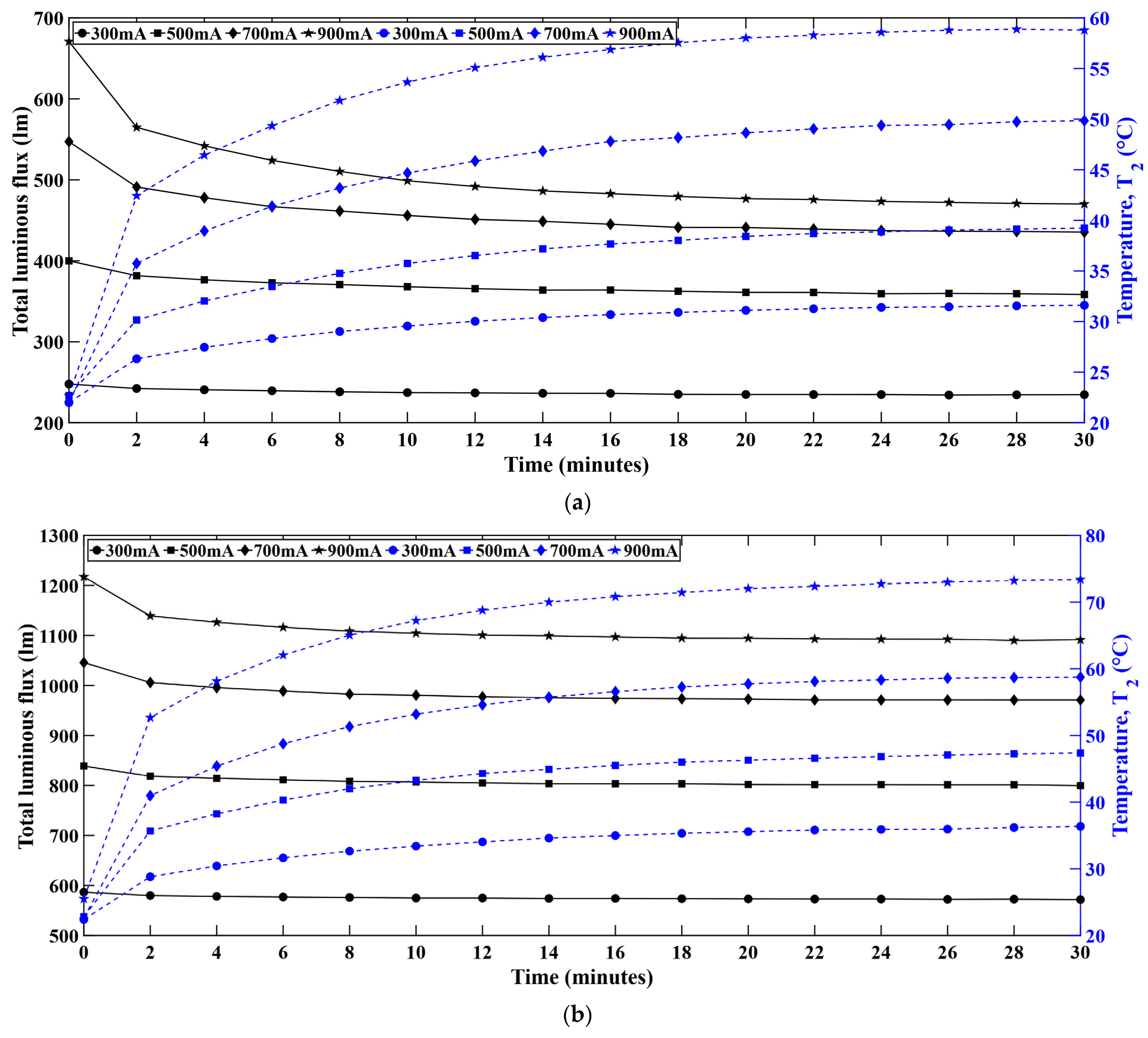

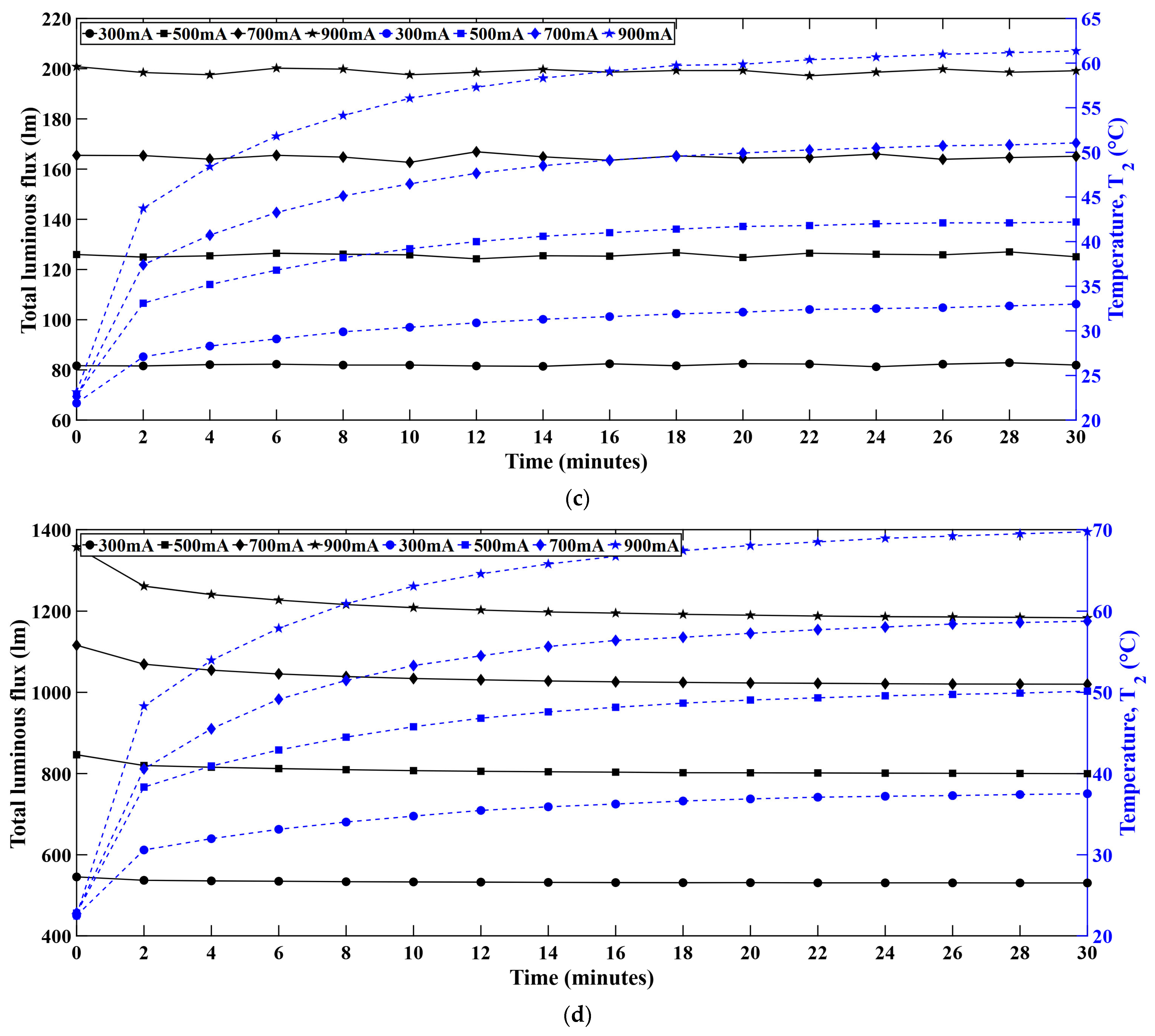

4.1. Total Luminous Flux Variation

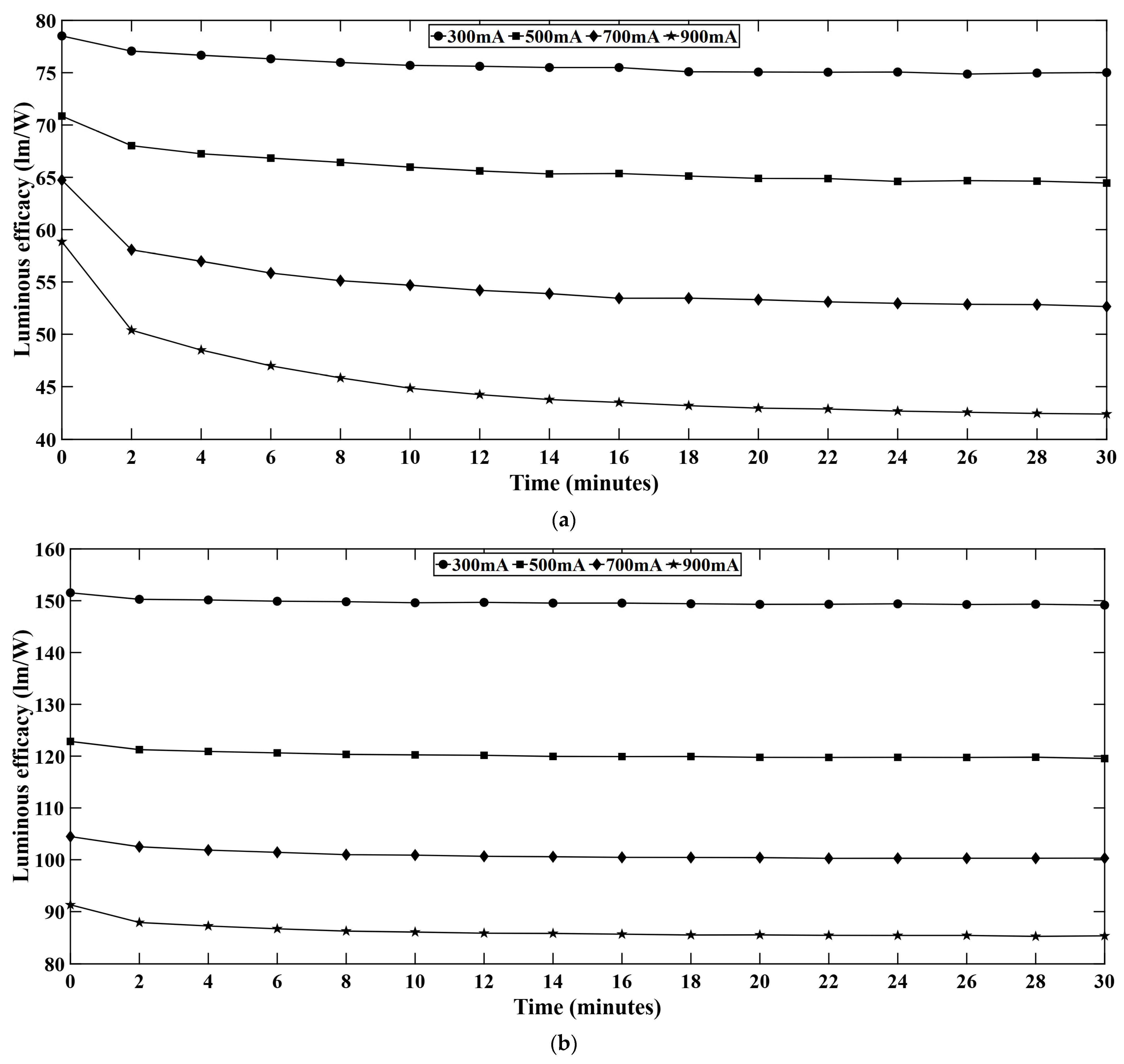

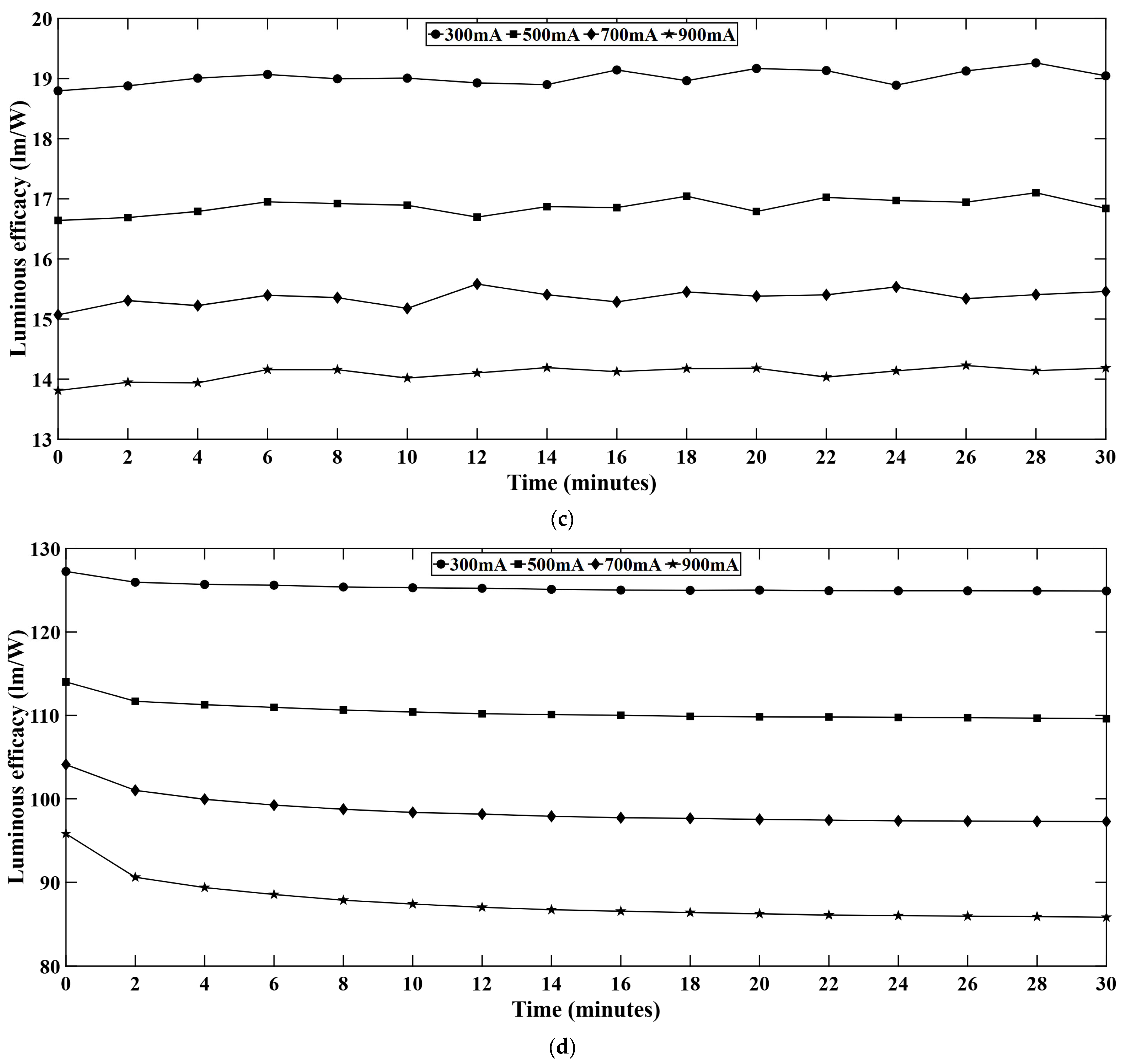

4.2. Variation of Luminous Efficacy

4.3. Correlated Color Temperature (CCT) Variation in White LED Series

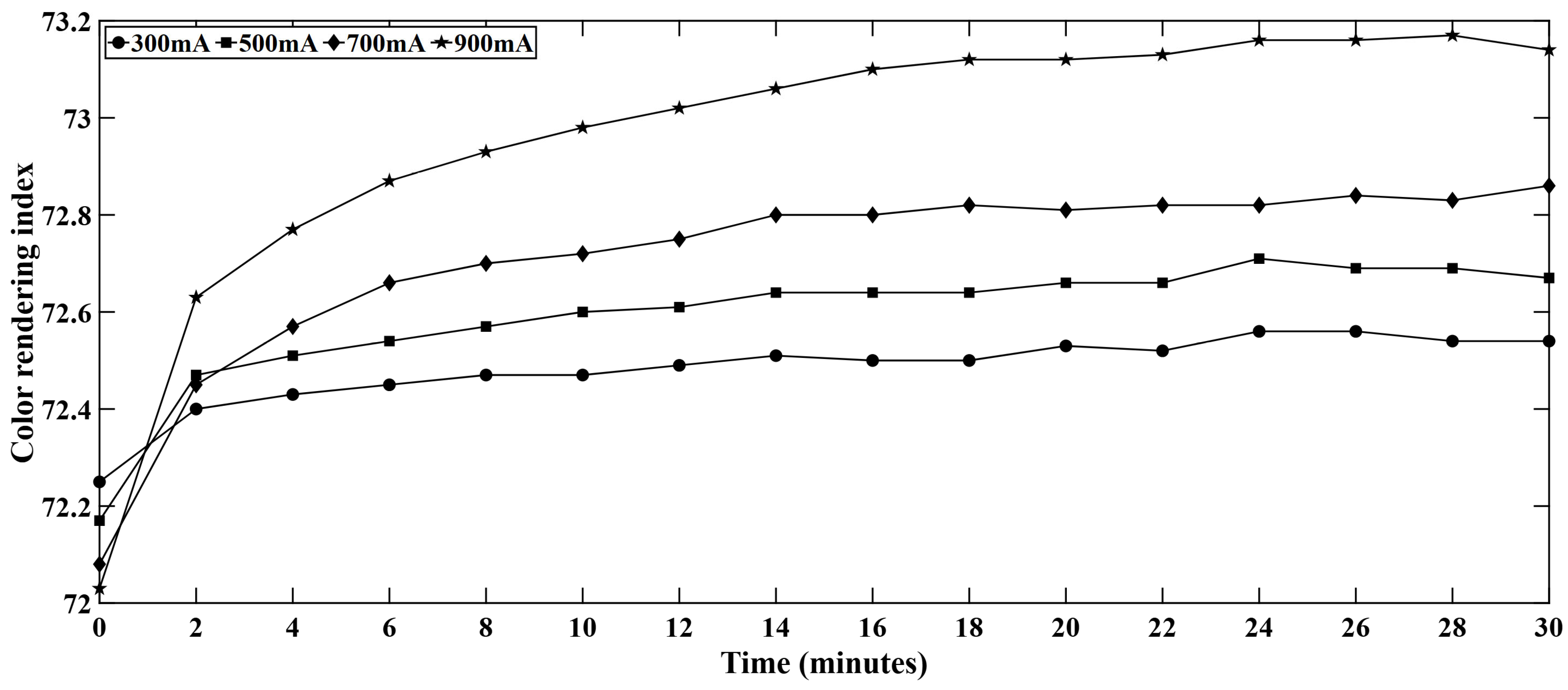

4.4. CRI Variation in White LED Series

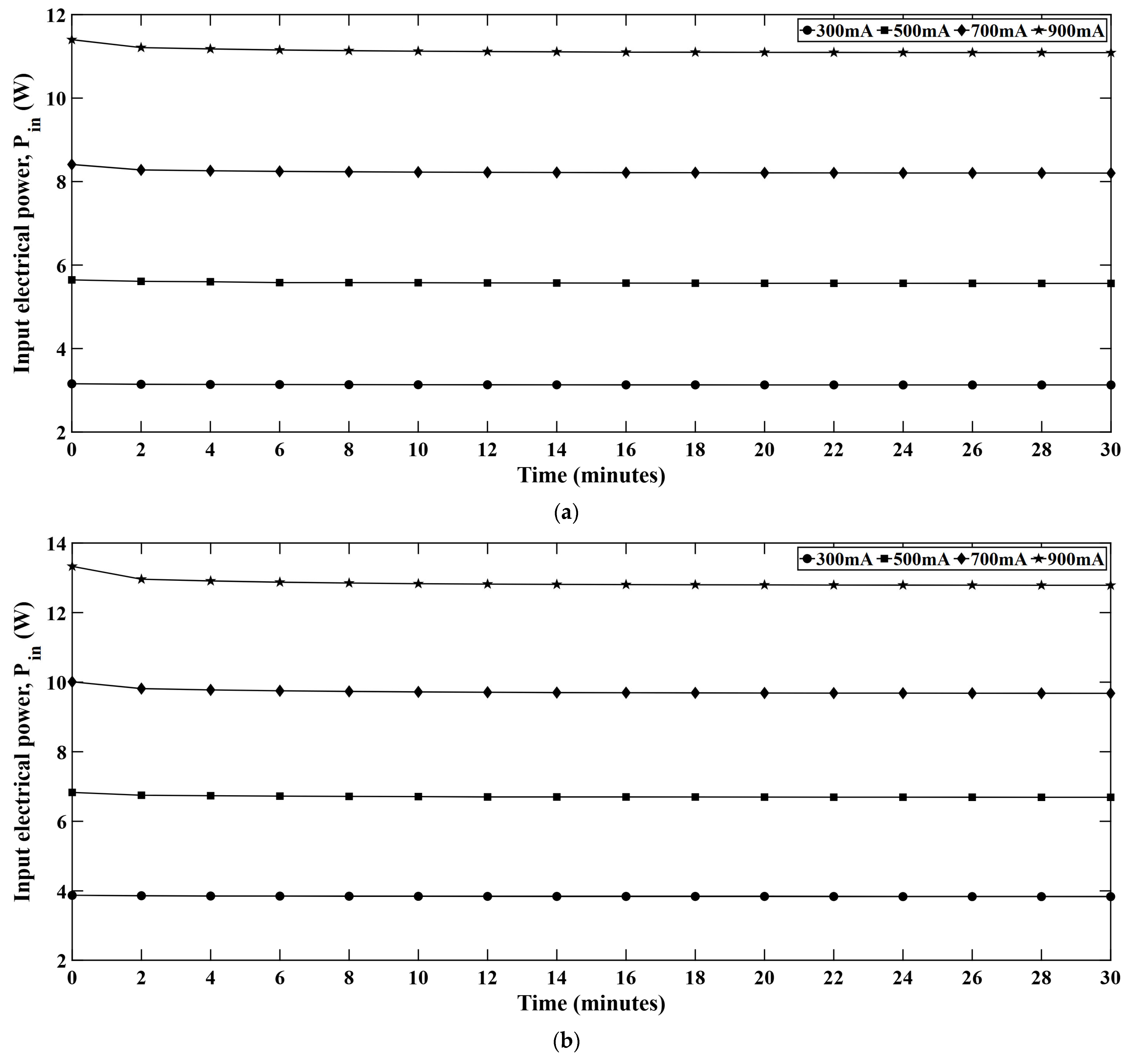

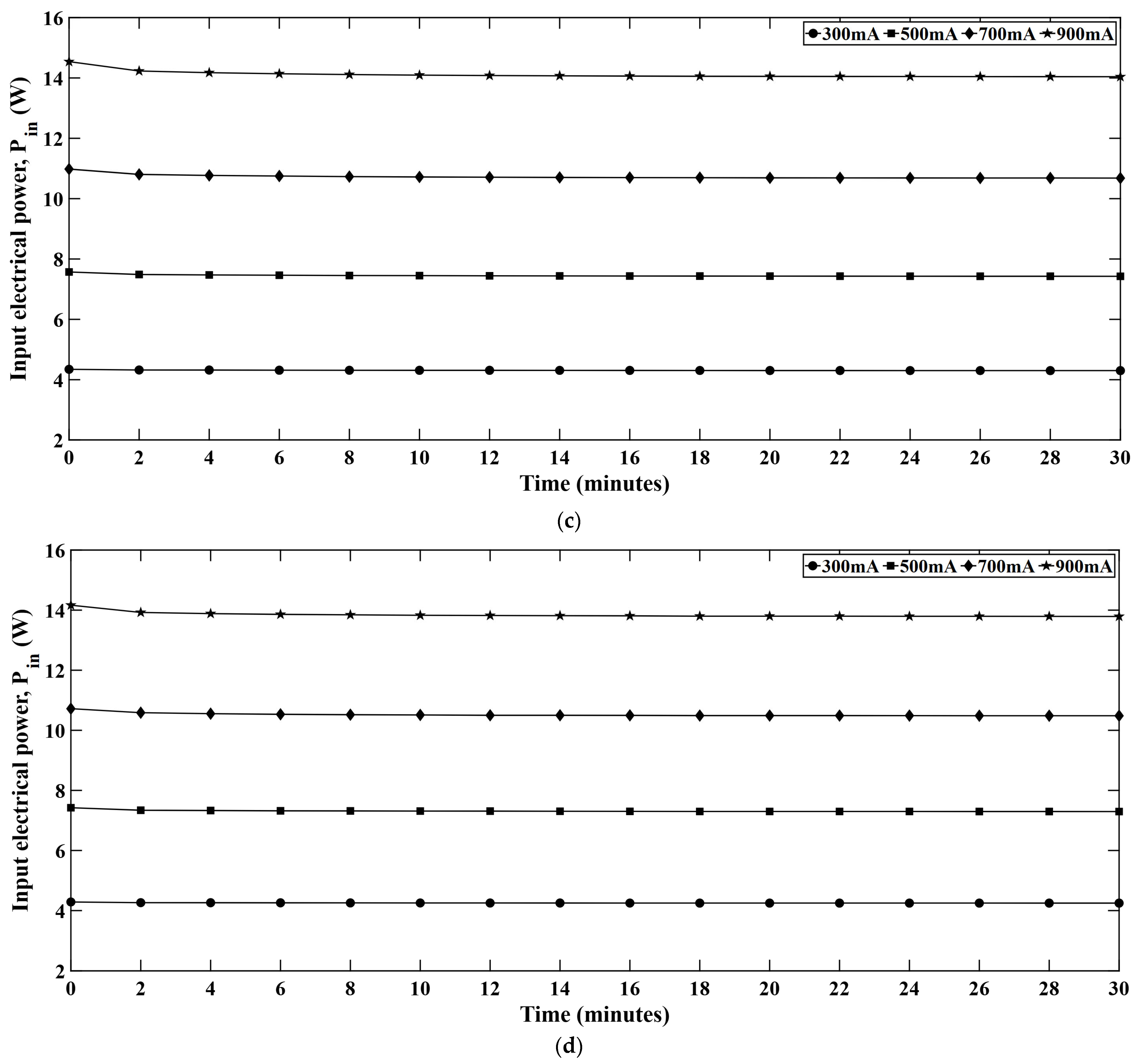

4.5. Input Electrical Power

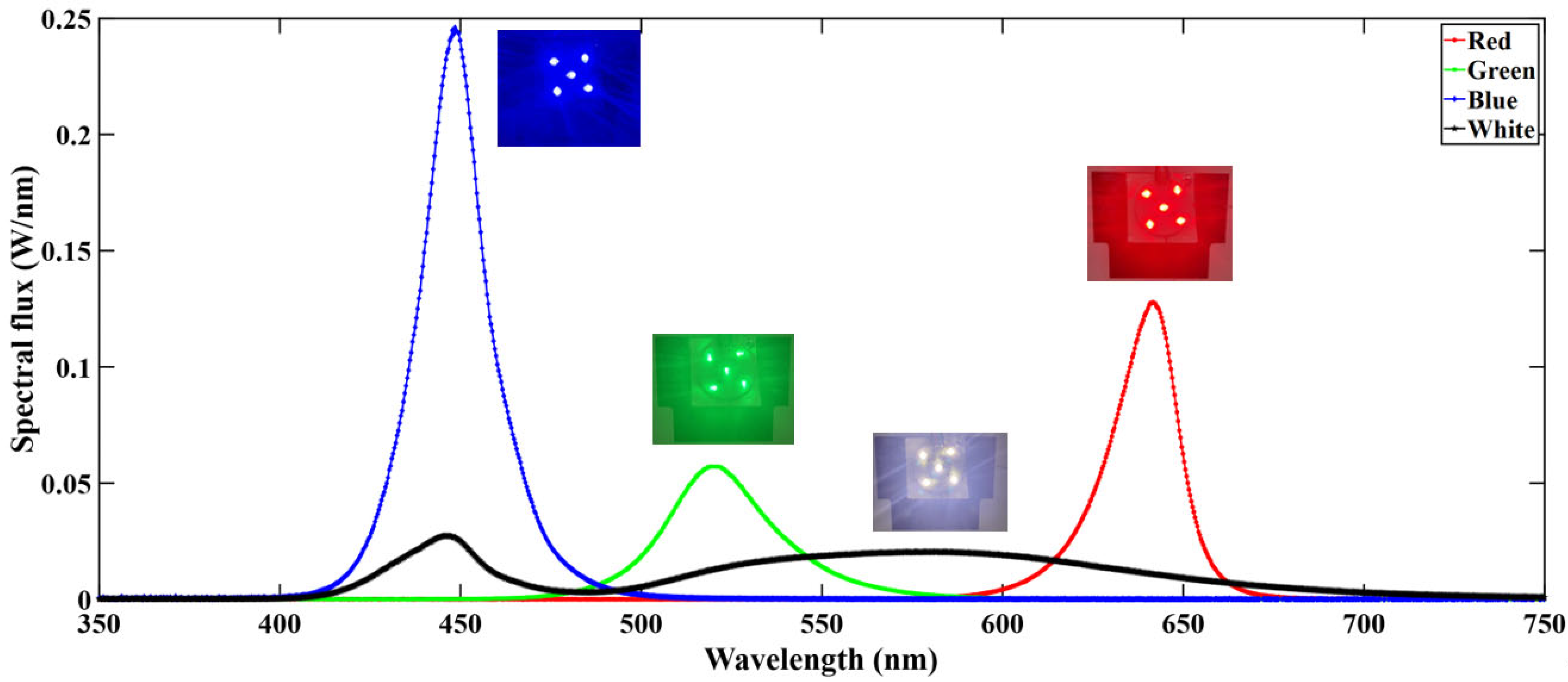

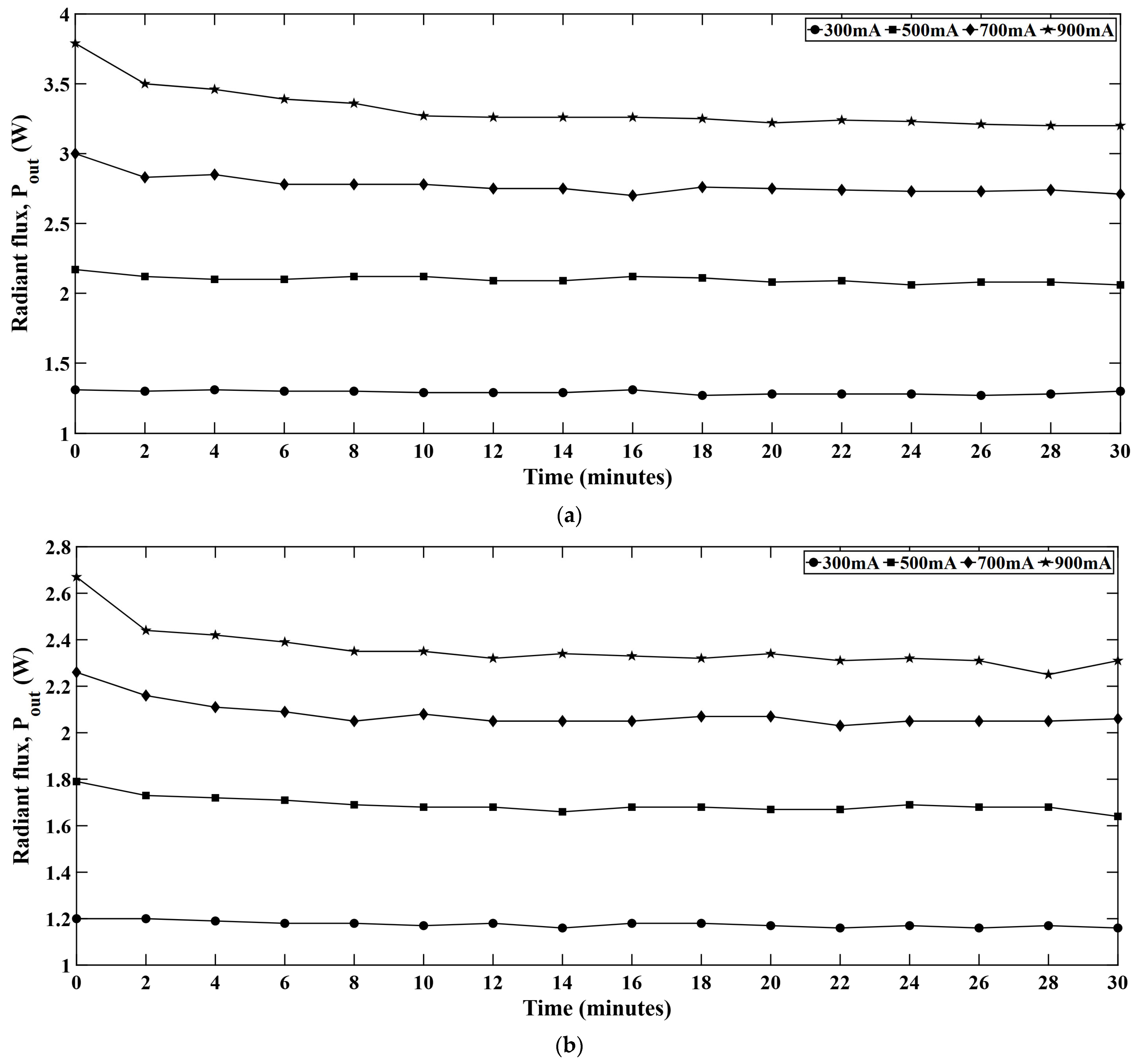

4.6. Radiant Flux

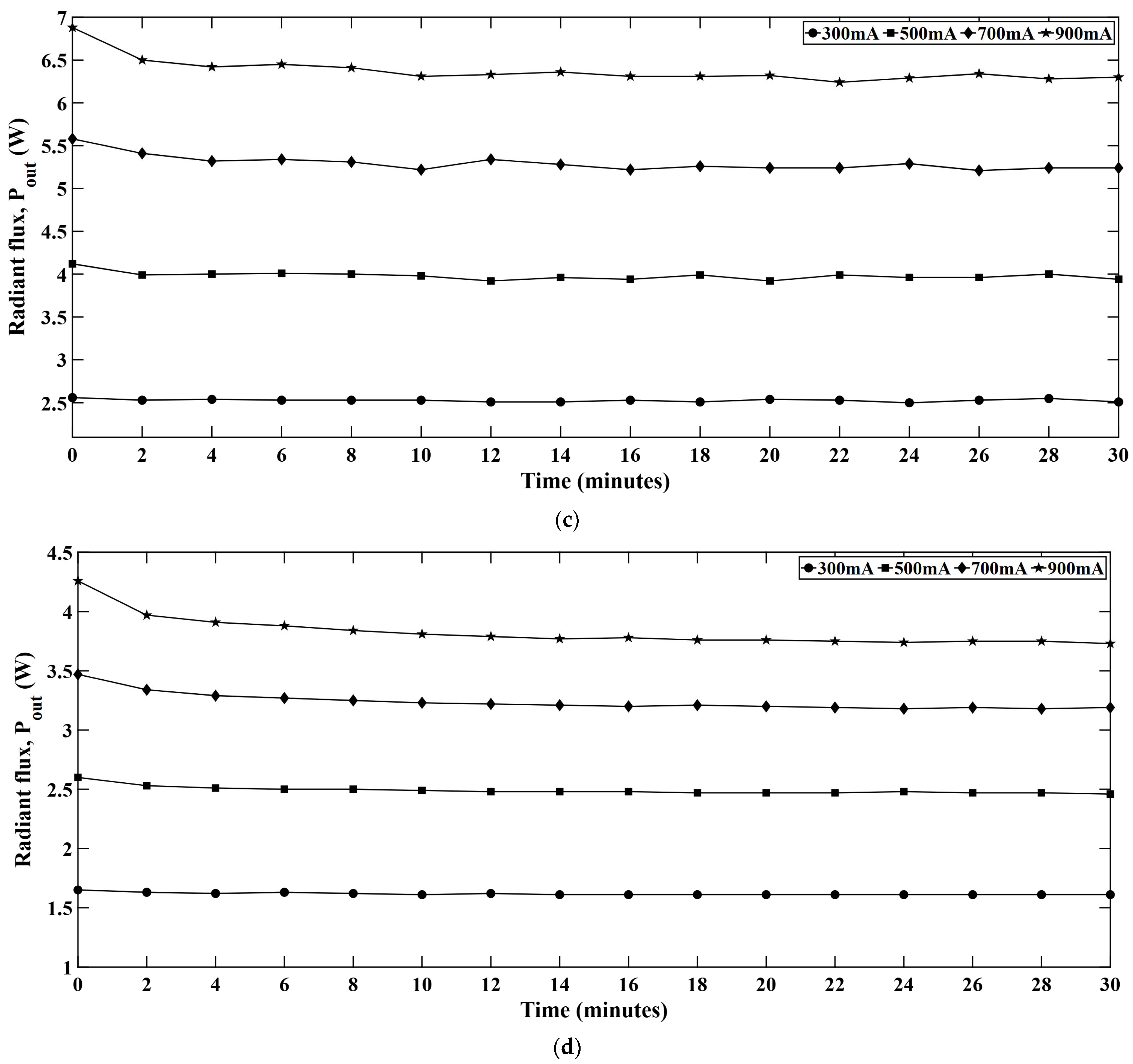

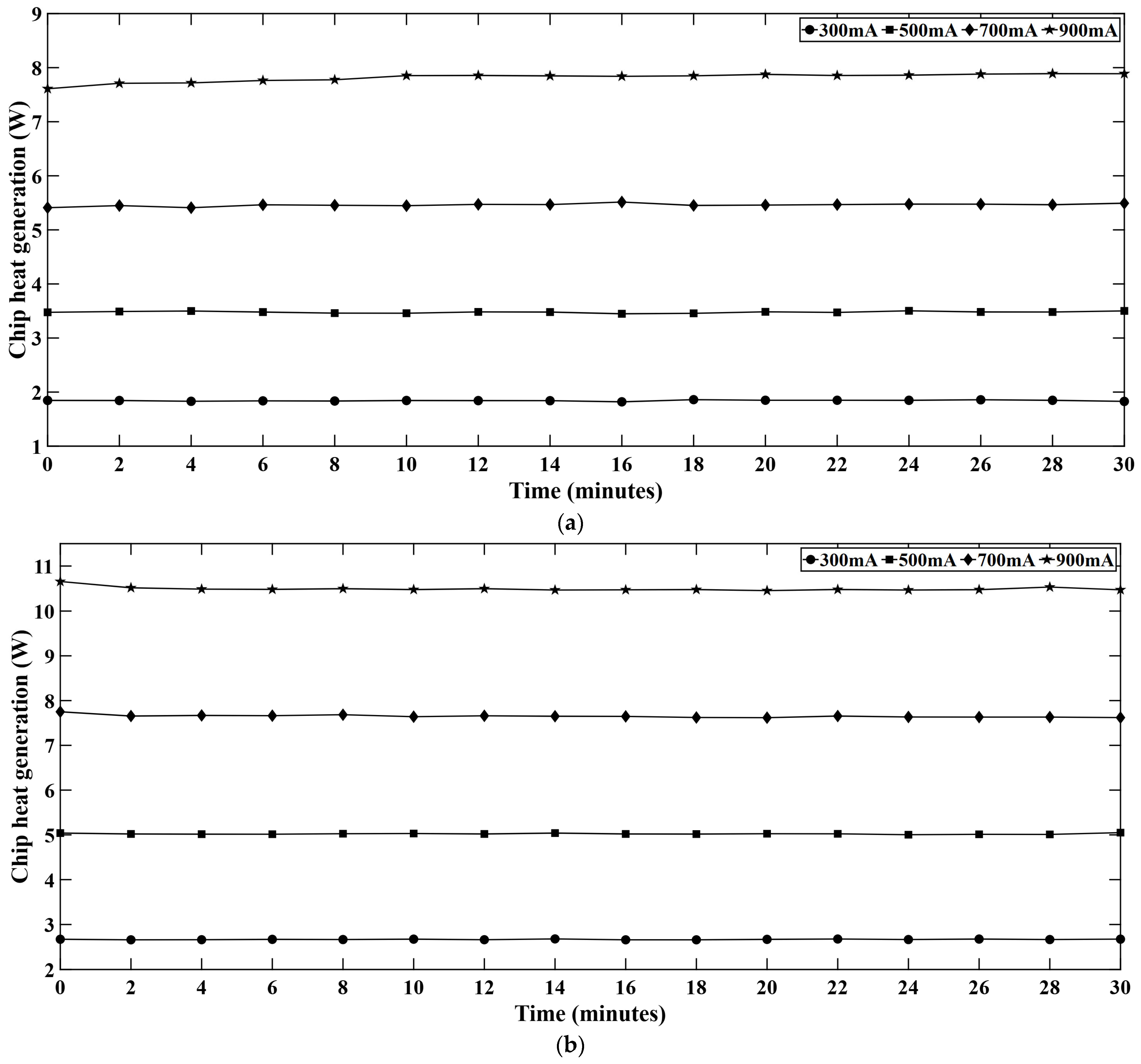

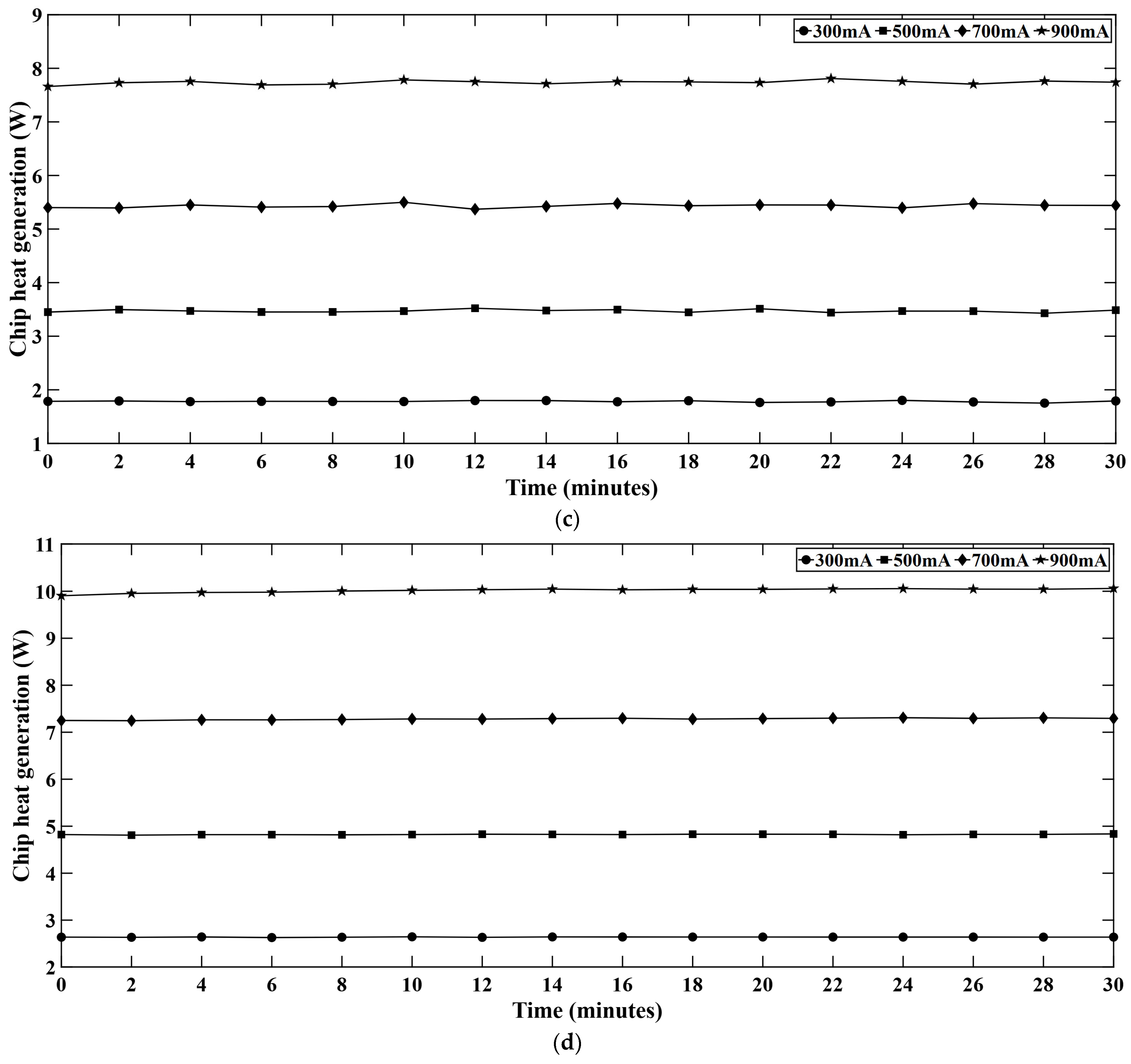

4.7. Chip Heat Generation Rate

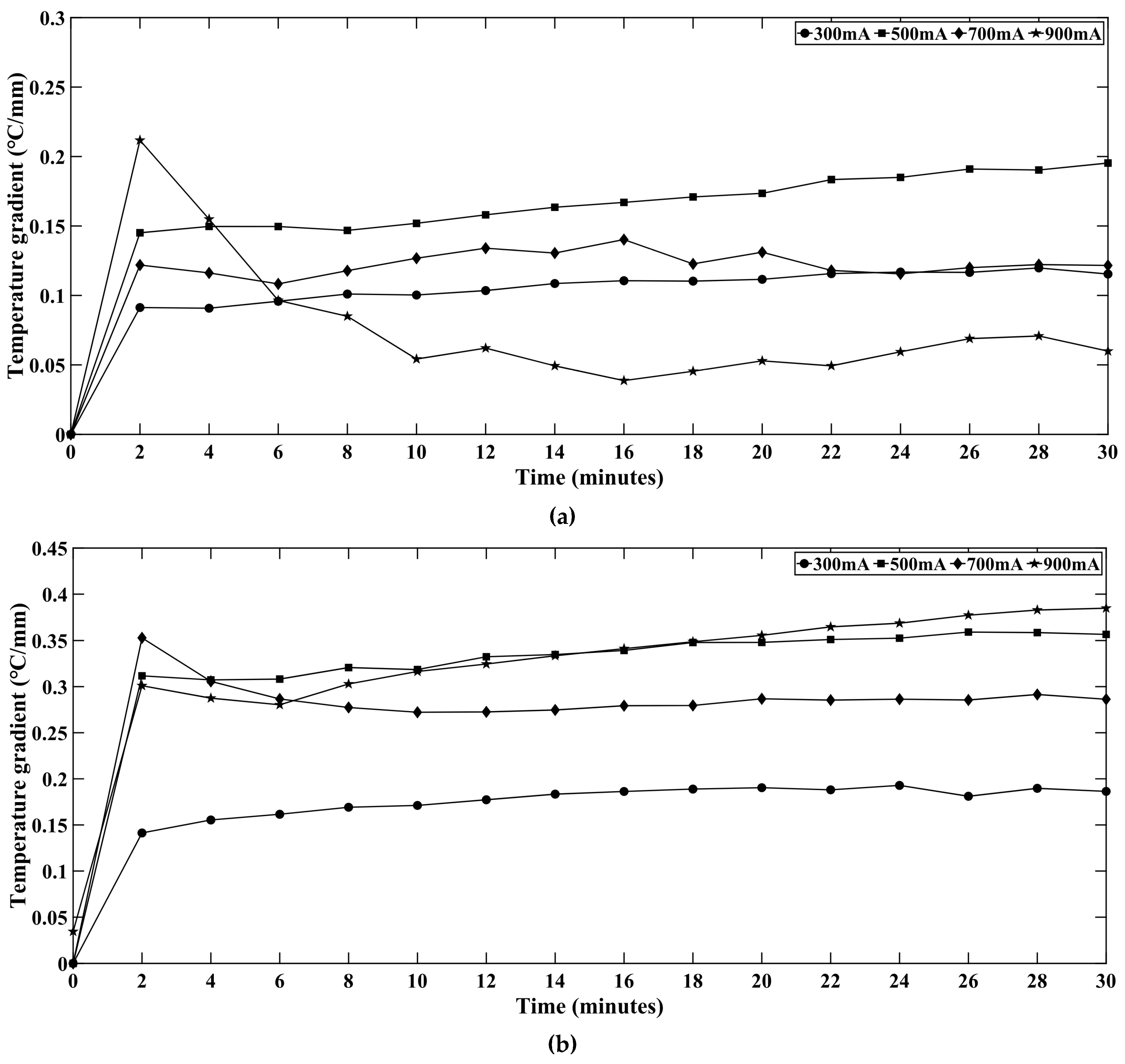

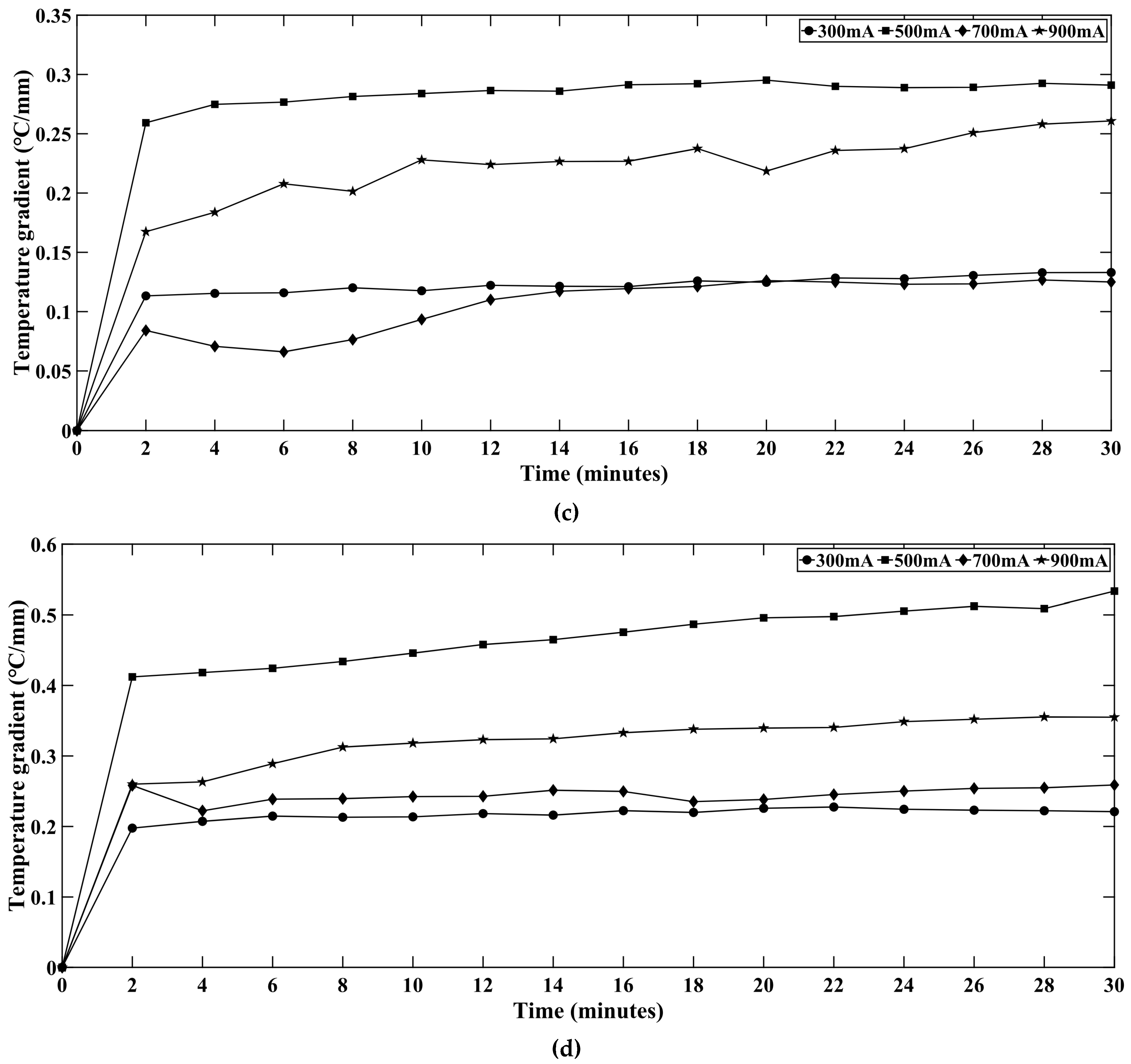

4.8. Temperature Variation at the Light Engine PCB

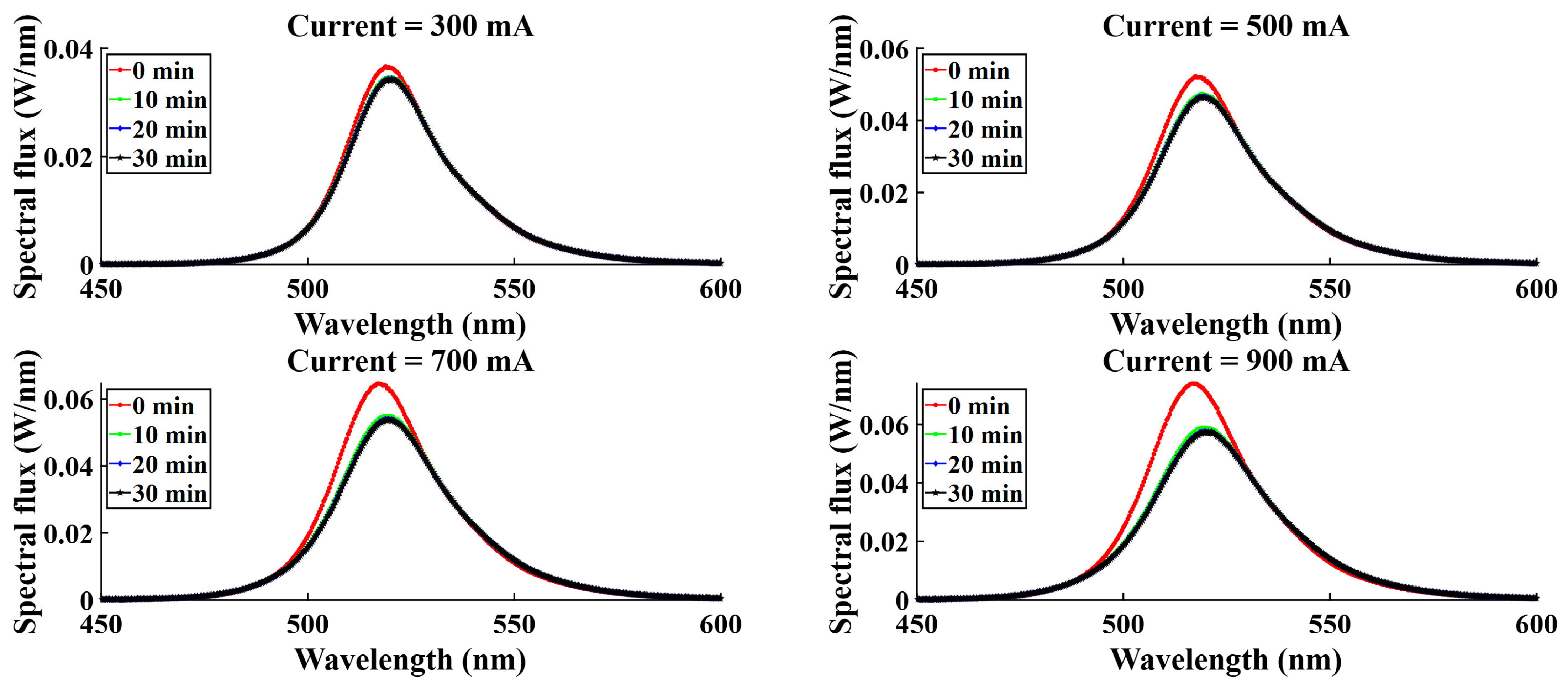

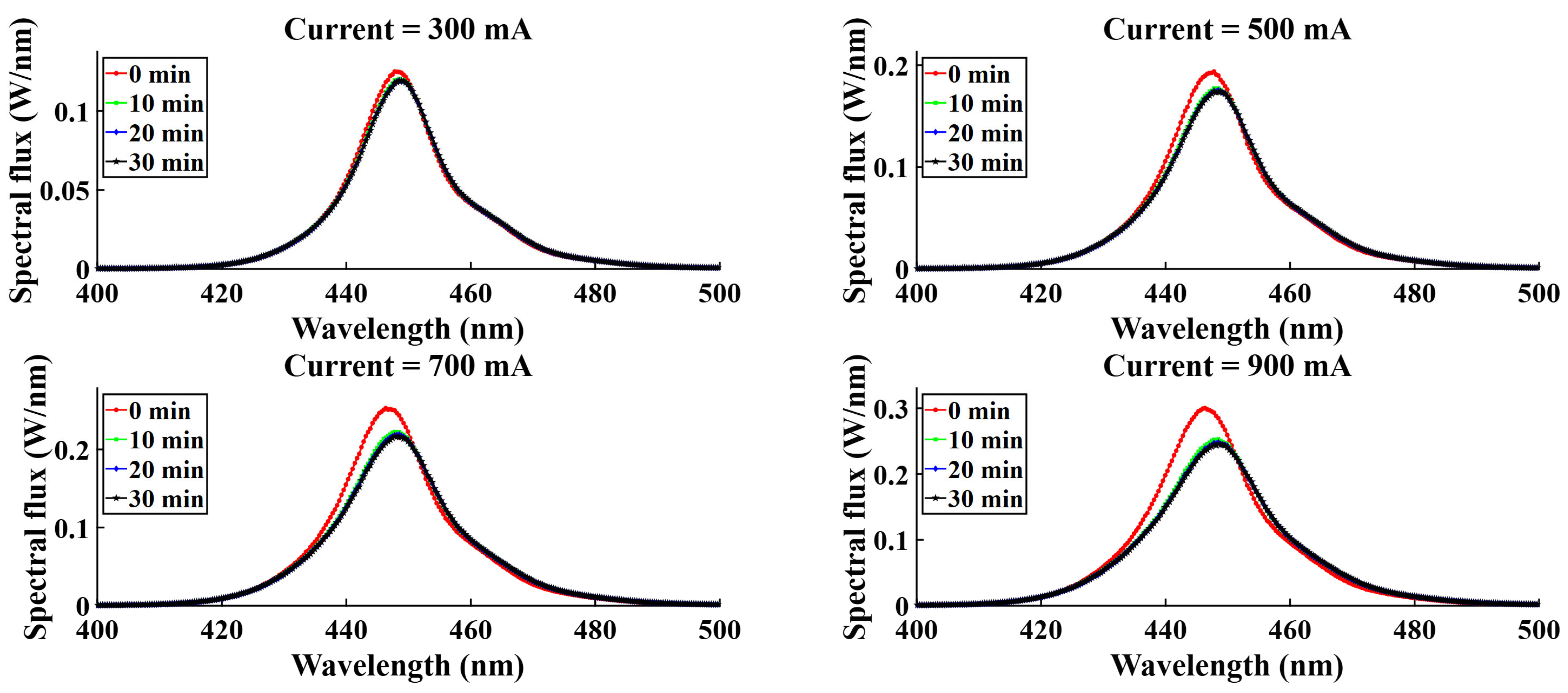

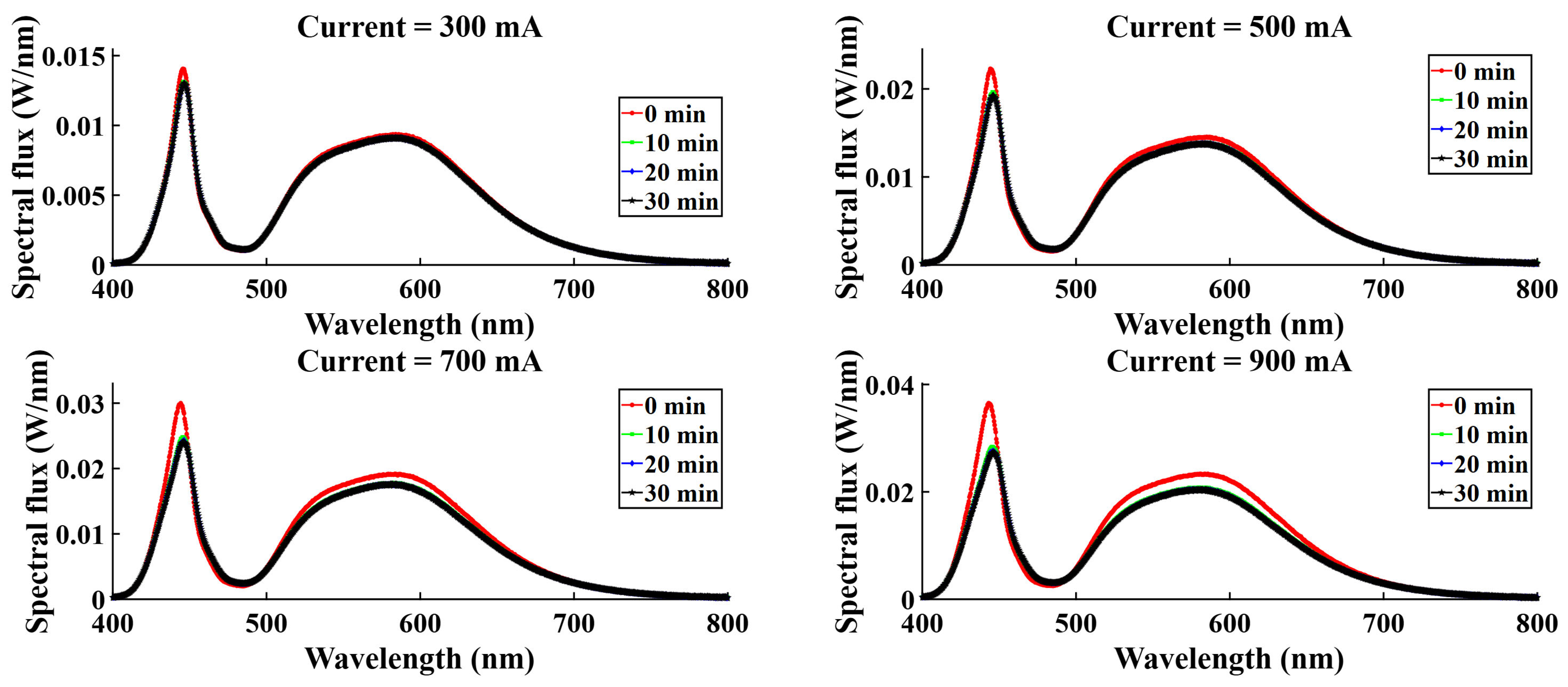

4.9. Spectral Flux Variation with Time at Different Current Levels

4.10. Experimental Uncertainty Analysis

5. Conclusions

- (a)

- Luminous flux decreases with time at any current level, and this is due to thermal degradation of the package while in operation. However, the B-LED series provides an almost constant luminous flux level throughout the operation time. That is because the B-LEDs are most efficient in converting electrical energy into photons and generating less heat. Also, having an operational time of only 30 min, there is no significant flux drop in the B-LEDs. However, in case of longer operation, B-LEDs also show a drop in luminous flux.

- (b)

- The luminous efficacy keeps falling as the driving current increases. Additionally, there are some temporal variations in the luminous efficacy. At higher current levels, the junction temperature increases, and the internal quantum efficiency reduces which results in low luminous efficacy. However, B-LEDs do not show any efficacy drop during the operational time. In fact, they showed some enhancement because of the high conversion efficiency and less current leakage of the InGaN based B-LEDs. Moreover, the efficiency droop is very low for B-LEDs which also contributes to the consistent luminous efficacy over a short operational time.

- (c)

- With time, the input electrical power decreases because the LEDs are driven at constant current and the forward voltage keeps falling when the system is in operation. This is because the LED chips heat up once turned on and the forward voltage drops compared to the initial cool condition.

- (d)

- B-LEDs show the maximum radiant flux because of having the highest conversion efficiency. On the other hand, G-LEDs produce the most heat as they show the least conversion efficiency. The efficiency droop for G-LEDs is around 47%, while B-LEDs show only 18% efficiency droop.

- (e)

- The temperature gradient at the PCB backside shows that temperature T2 is greater than T1. That is because thermocouple 2 is directly under the central chip while the other thermocouple is 10 mm away from the center. The temperature gradient remains high during the initial operation time and gradually reaches the steady state condition because of thermal spreading.

- (f)

- Spectral flux shows temporal variation for all color LEDs at any current level. Junction temperature rise, carrier leakage, phosphor degradation, etc. can be attributed to the potential causes of this spectral shift. For these reasons, the peak wavelength drops too.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| CEA | Controlled environment agriculture |

| CCT | Correlated color temperature |

| CRI | Color rendering index |

| IoT | Internet of things |

| IQE | Internal quantum efficiency |

| LED | Light emitting diode |

| LPW | Efficacy (lumen/watt) |

| PCB | Printed circuit board |

| RGB-W | Red, green, blue, white |

| TC | Thermocouple |

References

- Montoya, F.G.; Peña-García, A.; Juaidi, A.; Manzano-Agugliaro, F. Indoor Lighting Techniques: An Overview of Evolution and New Trends for Energy Saving. Energy Build. 2017, 140, 50–60. [Google Scholar] [CrossRef]

- Keerthana, S.; G. Indumathi, G. Indumathi. Revolutionizing Interior Spaces: A Comprehensive Analysis of LED Lighting for Illumination and Communication in Modern Architecture. Energy Build. 2025, 331, 115297. [Google Scholar] [CrossRef]

- Al Murad, M.; Razi, K.; Jeong, B.R.; Samy, P.M.A.; Muneer, S. Light Emitting Diodes (LEDs) as Agricultural Lighting: Impact and Its Potential on Improving Physiology, Flowering, and Secondary Metabolites of Crops. Sustainability 2021, 13, 1985. [Google Scholar] [CrossRef]

- Lozano-Castellanos, L.F.; Navas-Gracia, L.M.; Lozano-Castellanos, I.C.; Correa-Guimaraes, A. Technologies Applied to Artificial Lighting in Indoor Agriculture: A Review. Sustainability 2025, 17, 3196. [Google Scholar] [CrossRef]

- Yeh, N.; Chung, J.-P. High-Brightness LEDs—Energy Efficient Lighting Sources and Their Potential in Indoor Plant Cultivation. Renew. Sustain. Energy Rev. 2009, 13, 2175–2180. [Google Scholar] [CrossRef]

- Neo, D.C.J.; Ong, M.M.X.; Lee, Y.Y.; Teo, E.J.; Ong, Q.; Tanoto, H.; Xu, J.; Ong, K.S.; Suresh, V. Shaping and Tuning Lighting Conditions in Controlled Environment Agriculture: A Review. ACS Agric. Sci. Technol. 2022, 2, 3–16. [Google Scholar] [CrossRef]

- Lee, X.-H.; Chang, Y.-Y.; Sun, C.-C. Highly Energy-Efficient Agricultural Lighting by B+R LEDs with Beam Shaping Using Micro-Lens Diffuser. Opt. Commun. 2013, 291, 7–14. [Google Scholar]

- Boyce, P. Editorial: Exploring Human-Centric Lighting. Light. Res. Technol. 2016, 48, 101. [Google Scholar] [CrossRef]

- Madias, E.-N.D.; Christodoulou, K.; Androvitsaneas, V.P.; Skalkou, A.; Sotiropoulou, S.; Zervas, E.; Doulos, L.T. Τhe Effect of Artificial Lighting on Both Biophilic and Human-Centric Design. J. Build. Eng. 2023, 76, 107292. [Google Scholar] [CrossRef]

- Tuğçe Kazanasmaz, Z.; Büşra Köse, F.; Tayfur, G. Emerging Concept of Human Centric Lighting in Literature Review. In Proceedings of the 2022 IEEE International Conference on Environment and Electrical Engineering and 2022 IEEE Industrial and Commercial Power Systems Europe (EEEIC/I & CPS Europe), Prague, Czech Republic, 28 June–1 July 2022; pp. 1–6. [Google Scholar]

- Houser, K.W.; Esposito, T. Human-Centric Lighting: Foundational Considerations and a Five-Step Design Process. Front. Neurol. 2021, 12, 630553. [Google Scholar]

- Hou, L.; Wang, H.; Xu, M. A Review of RGB-LED Based Mixed-Color Illumination System for Machine Vision and Microscopy. Proc. SPIE 2016, 9684, 968439. [Google Scholar]

- Shlayan, N.; Venkat, R.; Ginobbi, P.; Mercier, G. A Novel RGBW Pixel for LED Displays. In Digital Scholarship—UNLV; University of Nevada Reno: Reno, NV, USA, 2008; pp. 407–411. [Google Scholar]

- Rybalochka, A.; Kornaga, V.; Kalustova, D.; Mukhin, V.; Kornaga, Y.; Zavgorodnii, V.; Valyukh, S. White Colour Hues in Displays and Lighting Systems Based on RGB and RGBW LEDs. Int. J. Image Graph. Signal Process. 2022, 14, 1–10. [Google Scholar] [CrossRef]

- Tanaka, M.; Horiuchi, T.; Tominaga, S. Color Control of a Lighting System Using RGBW LEDs. Proc. SPIE 2011, 7866, 78660W. [Google Scholar]

- Kalustova, D.; Kornaga, V.; Rybalochka, A.; Yu, Y.; Valyukh, S. Color Temperature Tunable RGBW Cluster with Optimize Color Rendering and Efficacy. Opt. Eng. 2023, 62, 045102. [Google Scholar] [CrossRef]

- Singh, P.; Tan, C.M. Degradation physics of high power LEDs in outdoor environment and the role of phosphor in the degradation process. Sci. Rep. 2016, 6, 24052. [Google Scholar] [CrossRef]

- Myland, P.; Herzog, A.; Babilon, S.; Van Driel, W.D.; Khanh, T.Q. LED degradation monitoring using a multi-channel spectral sensor. IEEE Access 2024, 12, 42295–42315. [Google Scholar] [CrossRef]

- Hamon, B.; van Driel, W.D. LED Degradation: From Component to System. Microelectron. Reliab. 2016, 64, 599–604. [Google Scholar] [CrossRef]

- Laird. Available online: https://www.laird.com/products/thermal-interface-materials/thermally-conductive-tape-and-adhesive/ttape-1000a (accessed on 29 July 2025).

- Arik, M.; Becker, C.A.; Weaver, S.E.; Petroski, J. Thermal management of LEDs: Package to system. In Third International Conference on Solid State Lighting; International Society for Optics and Photonics: San Diego, CA, USA, 2004; Volume 5187, pp. 64–75. [Google Scholar]

- Cengiz, C.; Azarifar, M.; Arik, M. Thermal and Optical Characterization of White and Blue Multi-Chip LED Light Engines. In Proceedings of the 2021 20th IEEE Intersociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems (iTherm), San Diego, CA, USA, 1–4 June 2021; pp. 285–293. [Google Scholar]

- ANSYS Inc. ANSYS SPEOS (Version 2024) [Computer software]. 2024. Available online: https://www.ansys.com/products/optics/ansys-speos (accessed on 22 August 2025).

- Setlur, A.A. Phosphors for LED-Based Solid-State Lighting. ECS Interface 2009, 18, 32–36. [Google Scholar] [CrossRef]

- Setlur, A.A.; Shiang, J.J.; Hannah, M.E.; Happek, U. Phosphor quenching in LED packages: Measurements, mechanisms, and paths forward. In Proceedings of the Ninth International Conference on Solid State Lighting, San Diego, CA, USA, 3–5 August 2009; Volume 7422, pp. 74–81. [Google Scholar]

- Setlur, A.; Brewster, M.; Garcia, F.; Hill, M.C.; Lyons, R.; Murphy, J.; Stecher, T.; Stoklosa, S.; Weaver, S.; Happek, U.; et al. Optimized Phosphors for Warm White LED Light Engines; General Electric Corporation: Niskayuna, NY, USA, 2012. [Google Scholar]

- Vos, J.J. Colorimetric and Photometric Properties of a 2° Fundamental Observer. Color Res. Appl. 1978, 3, 125–128. [Google Scholar] [CrossRef]

- Katsuyama, H.; Kikuchi, H. An Experimental Determination of the Maximum Spectral Luminous Efficacy of Radiation. Metrologia 1975, 11, 165–168. [Google Scholar] [CrossRef]

- Murphy, T.W. Maximum Spectral Luminous Efficacy of White Light. J. Appl. Phys. 2012, 111, 104909. [Google Scholar] [CrossRef]

- Onwukaeme, C.; Lee, B.; Ryu, H.Y. Temperature dependence of electron leakage current in InGaN blue light-emitting diode structures. Nanomaterials 2022, 12, 2405. [Google Scholar] [CrossRef]

- Park, J.H.; Cho, J.; Schubert, E.F.; Kim, J.K. The Effect of Imbalanced Carrier Transport on the Efficiency Droop in GaInN-Based Blue and Green Light-Emitting Diodes. Energies 2017, 10, 1277. [Google Scholar] [CrossRef]

- Ye, H.; Koh, S.W.; Yuan, C.; van Zeijl, H.; Gielen, A.W.J.; Lee, S.-W.R.; Zhang, G. Electrical–Thermal–Luminous–Chromatic Model of Phosphor-Converted White Light-Emitting Diodes. Appl. Therm. Eng. 2013, 63, 588–597. [Google Scholar] [CrossRef]

- Ryu, H.-Y.; Ryu, G.-H.; Lee, S.-H.; Kim, H.-J. Evaluation of the Internal Quantum Efficiency in Blue and Green Light-Emitting Diodes Using the Rate Equation Model. J. Korean Phys. Soc. 2013, 63, 180–184. [Google Scholar] [CrossRef]

- Piprek, J. Energy Efficiency Analysis of GaN-Based Blue Light Emitters. ECS J. Solid State Sci. Technol. 2019, 9, 015008. [Google Scholar] [CrossRef]

- Choi, D.-C.; Kim, Y.S.; Kim, K.-B.; Lee, S.-N. Spontaneous Emission Studies for Blue and Green InGaN-Based Light-Emitting Diodes and Laser Diodes. Photonics 2024, 11, 135. [Google Scholar] [CrossRef]

- Auf der Maur, M.; Pecchia, A.; Penazzi, G.; Rodrigues, W.; Di Carlo, A. Efficiency Drop in Green InGaN/GaN Light Emitting Diodes: The Role of Random Alloy Fluctuations. Phys. Rev. Lett. 2016, 116, 027401. [Google Scholar] [CrossRef] [PubMed]

| Color | Current (mA) | 300 | 500 | 700 | 900 | ||||

|---|---|---|---|---|---|---|---|---|---|

| Time (min.) | T1 (°C) | T2 (°C) | T1 (°C) | T2 (°C) | T1 (°C) | T2 (°C) | T1 (°C) | T2 (°C) | |

| Red | 0 2 4 6 8 10 12 14 16 18 20 22 24 26 28 30 | 22.1 25.4 26.6 27.4 28.0 28.6 29.0 29.3 29.6 29.8 30.0 30.1 30.2 30.3 30.4 30.5 | 22.0 26.3 27.5 28.3 29.0 29.6 30.0 30.4 30.7 30.9 31.1 31.3 31.4 31.5 31.6 31.6 | 22.8 28.7 30.5 32.0 33.3 34.2 34.9 35.5 36.0 36.3 36.7 36.9 37.0 37.1 37.2 37.3 | 22.7 30.2 32.0 33.5 34.8 35.7 36.5 37.2 37.7 38.0 38.4 38.7 38.9 39.0 39.1 39.2 | 22.1 35.2 38.2 40.5 42.4 44.0 45.1 46.1 46.9 47.5 48.0 48.4 48.7 48.8 49.1 49.2 | 22.0 35.7 38.9 41.4 43.2 44.7 45.9 46.8 47.8 48.2 48.6 49.0 49.4 49.5 49.7 49.8 | 22.8 40.3 44.9 48.4 51.0 53.1 54.5 55.6 56.5 57.1 57.5 57.8 58.0 58.1 58.2 58.2 | 22.7 42.4 46.4 49.3 51.8 53.7 55.1 56.1 56.9 57.6 58.0 58.3 58.6 58.8 58.9 58.8 |

| Green | 0 2 4 6 8 10 12 14 16 18 20 22 24 26 28 30 | 22.5 27.4 28.9 30.0 31.0 31.7 32.3 32.8 33.1 33.4 33.7 33.9 34.0 34.1 34.3 34.5 | 22.4 28.8 30.4 31.6 32.6 33.4 34.0 34.6 35.0 35.3 35.6 35.8 35.9 36.0 36.2 36.4 | 22.9 32.6 35.2 37.2 38.8 40.1 41.0 41.6 42.1 42.5 42.8 43.1 43.3 43.5 43.7 43.8 | 22.8 35.7 38.3 40.3 42.0 43.3 44.3 44.9 45.5 46.0 46.3 46.6 46.8 47.1 47.2 47.4 | 22.8 37.4 42.4 45.9 48.6 50.5 51.9 53.0 53.8 54.5 54.9 55.3 55.5 55.8 55.8 55.9 | 22.6 41.0 45.4 48.8 51.3 53.2 54.6 55.8 56.6 57.3 57.8 58.1 58.3 58.6 58.7 58.8 | 23.1 47.7 54.1 58.0 61.7 64.1 65.6 66.7 67.4 68.1 68.3 68.6 68.8 69.1 69.2 69.3 | 23.0 58.7 66.6 69.9 68.1 69.4 70.9 72.0 72.8 73.4 73.8 74.2 74.5 74.7 74.8 74.9 |

| Blue | 0 2 4 6 8 10 12 14 16 18 20 22 24 26 28 30 | 22.0 26.0 27.1 28.0 28.7 29.3 29.7 30.0 30.4 30.7 30.9 31.1 31.2 31.3 31.5 31.6 | 21.9 27.1 28.3 29.1 29.9 30.4 30.9 31.3 31.6 31.9 32.1 32.4 32.5 32.6 32.8 33.0 | 22.7 30.5 32.5 34.1 35.4 36.3 37.1 37.7 38.1 38.5 38.7 38.9 39.1 39.2 39.2 39.3 | 22.8 33.1 35.2 36.8 38.2 39.2 40.0 40.6 41.0 41.4 41.7 41.8 42.0 42.1 42.1 42.2 | 22.7 36.6 40.0 42.6 44.4 45.5 46.6 47.3 47.9 48.4 48.7 49.0 49.3 49.5 49.6 49.8 | 22.6 37.4 40.7 43.3 45.1 46.5 47.7 48.5 49.1 49.6 49.9 50.3 50.5 50.7 50.8 51.1 | 23.3 42.1 46.6 49.7 52.1 53.8 55.1 56.1 56.8 57.4 57.7 58.0 58.3 58.5 58.6 58.8 | 23.1 43.7 48.4 51.8 54.1 56.1 57.3 58.3 59.1 59.7 59.9 60.4 60.7 61.0 61.2 61.4 |

| White | 0 2 4 6 8 10 12 14 16 18 20 22 24 26 28 30 | 22.6 28.6 29.9 31.0 31.9 32.6 33.3 33.7 34.0 34.4 34.6 34.8 35.0 35.1 35.2 35.3 | 22.5 30.6 32.0 33.1 34.0 34.8 35.5 35.9 36.2 36.6 36.9 37.1 37.2 37.3 37.4 37.5 | 22.9 34.2 36.7 38.7 40.1 41.3 42.2 42.9 43.4 43.8 44.1 44.4 44.5 44.6 44.8 44.8 | 22.8 38.3 40.9 42.9 44.5 45.8 46.8 47.6 48.2 48.7 49.1 49.3 49.6 49.7 49.9 50.1 | 22.9 38.0 43.3 46.8 49.1 50.9 52.1 53.1 53.9 54.4 54.9 55.3 55.5 55.9 56.0 56.2 | 22.8 40.6 45.5 49.2 51.5 53.3 54.5 55.6 56.4 56.8 57.3 57.7 58.0 58.4 58.6 58.8 | 22.6 45.7 51.3 55.0 57.8 59.9 61.4 62.6 63.4 64.1 64.7 65.1 65.5 65.7 65.9 66.2 | 22.5 48.3 54.0 57.9 60.9 63.1 64.6 65.8 66.8 67.5 68.0 68.5 68.9 69.2 69.5 69.7 |

| Parameter | Parameter Type | Device | Model | Range | Accuracy | Maximum Uncertainty |

|---|---|---|---|---|---|---|

| Temperature (°C) | Measured | Thermocouple (T-type) | Omega 5TC-TT-T-30–36-ROHS | 0–150 | ±0.75% | 1 |

| DAQ | Agilent 34970A | −100 to 400 | ±1 | 4% | ||

| Voltage (V) | Measured | Power supply | Chroma 62012P-600-8 | 0–600 | 0.05% + 0.05%F.S. | 0.6 |

| Current (A) | Measured | Power supply | Chroma 62012P-600-8 | 0–8 | 0.1% + 0.1%F.S. | 0.016 |

| Input power (W) | Derived | Power supply | Chroma 62012P-600-8 | 0–1200 | - | 4.02 |

| Luminous flux (%) | Measured | Integrating sphere | Labsphere illumia plus 40″ base sphere | - | - | 1 |

| CCT (K) | Measured | Integrating sphere | Labsphere illumia plus 40″ base sphere | - | ±7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Islam, M.S.; Arik, M. Time-Dependent Optothermal Performance Analysis of a Flexible RGB-W LED Light Engine. Micromachines 2025, 16, 1007. https://doi.org/10.3390/mi16091007

Islam MS, Arik M. Time-Dependent Optothermal Performance Analysis of a Flexible RGB-W LED Light Engine. Micromachines. 2025; 16(9):1007. https://doi.org/10.3390/mi16091007

Chicago/Turabian StyleIslam, Md Shafiqul, and Mehmet Arik. 2025. "Time-Dependent Optothermal Performance Analysis of a Flexible RGB-W LED Light Engine" Micromachines 16, no. 9: 1007. https://doi.org/10.3390/mi16091007

APA StyleIslam, M. S., & Arik, M. (2025). Time-Dependent Optothermal Performance Analysis of a Flexible RGB-W LED Light Engine. Micromachines, 16(9), 1007. https://doi.org/10.3390/mi16091007