Development, Design, and Electrical Performance Simulation of Novel Through-Type 3D Semi Spherical Electrode Detector Based on SOI Substrate

Abstract

1. Introduction

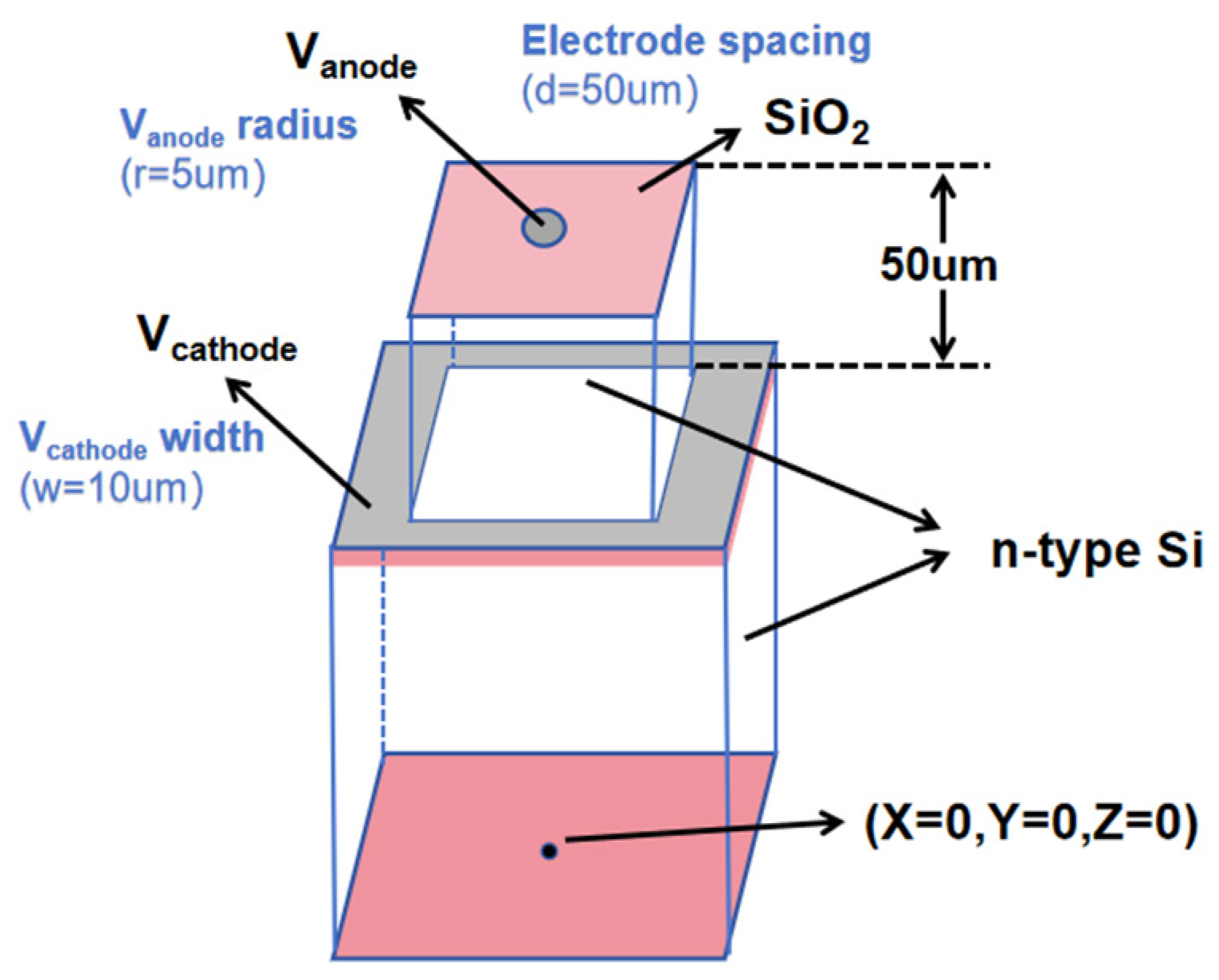

2. Three-Dimensional Semi Spherical Electrode Detector Based on SOI Substrate

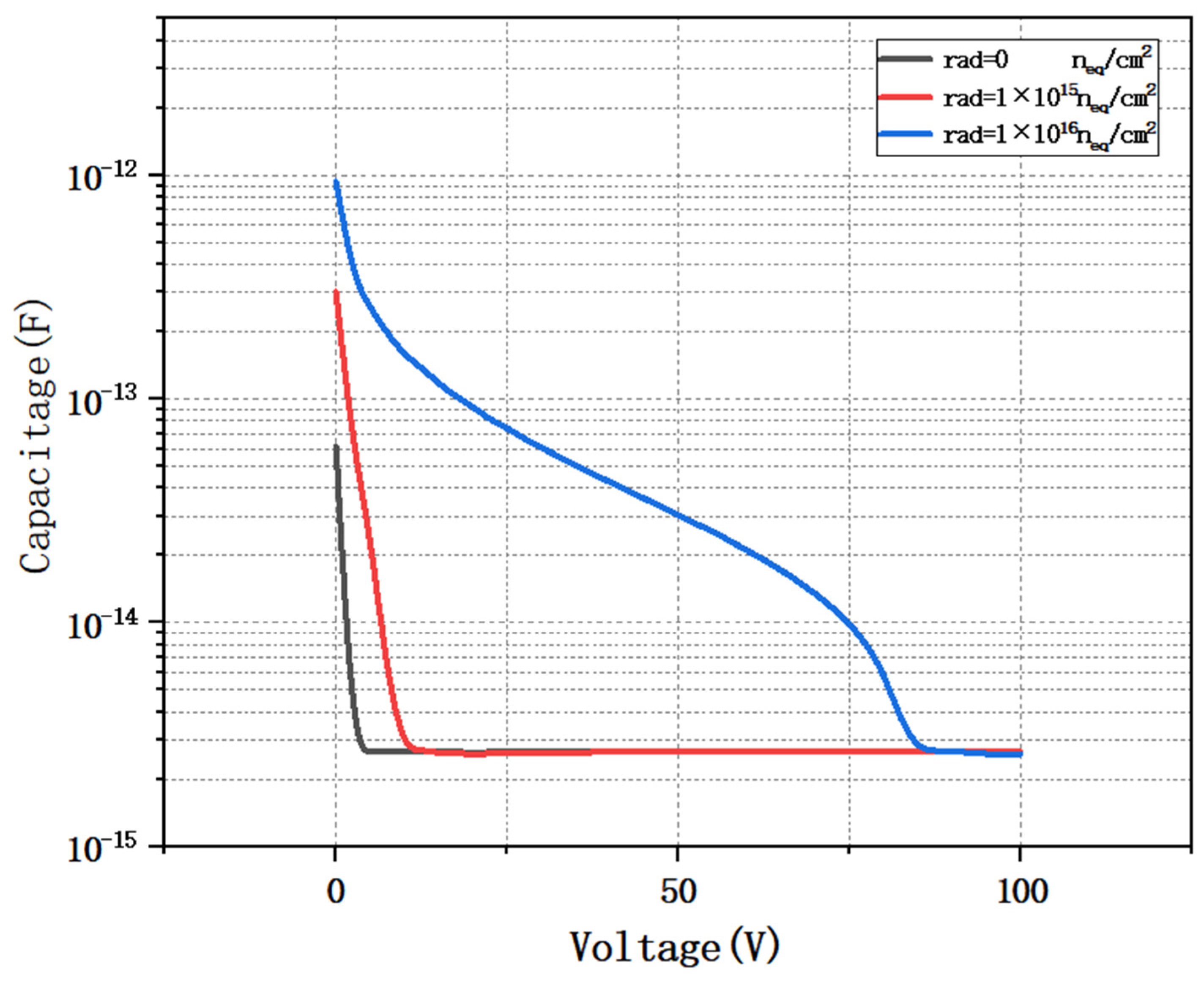

3. Electrical Characteristics

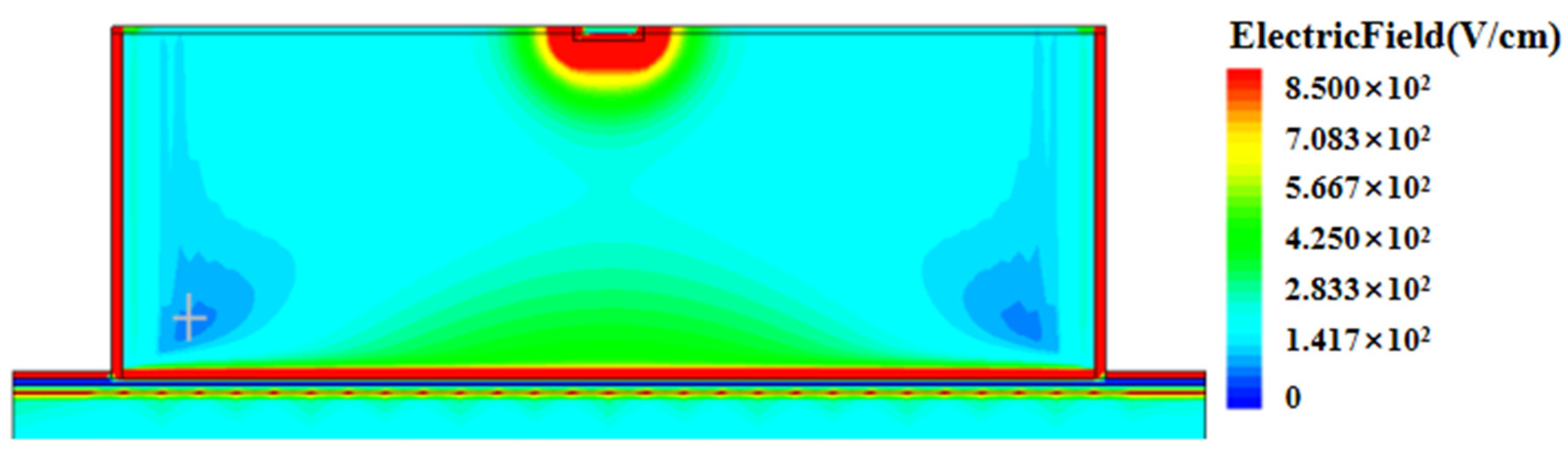

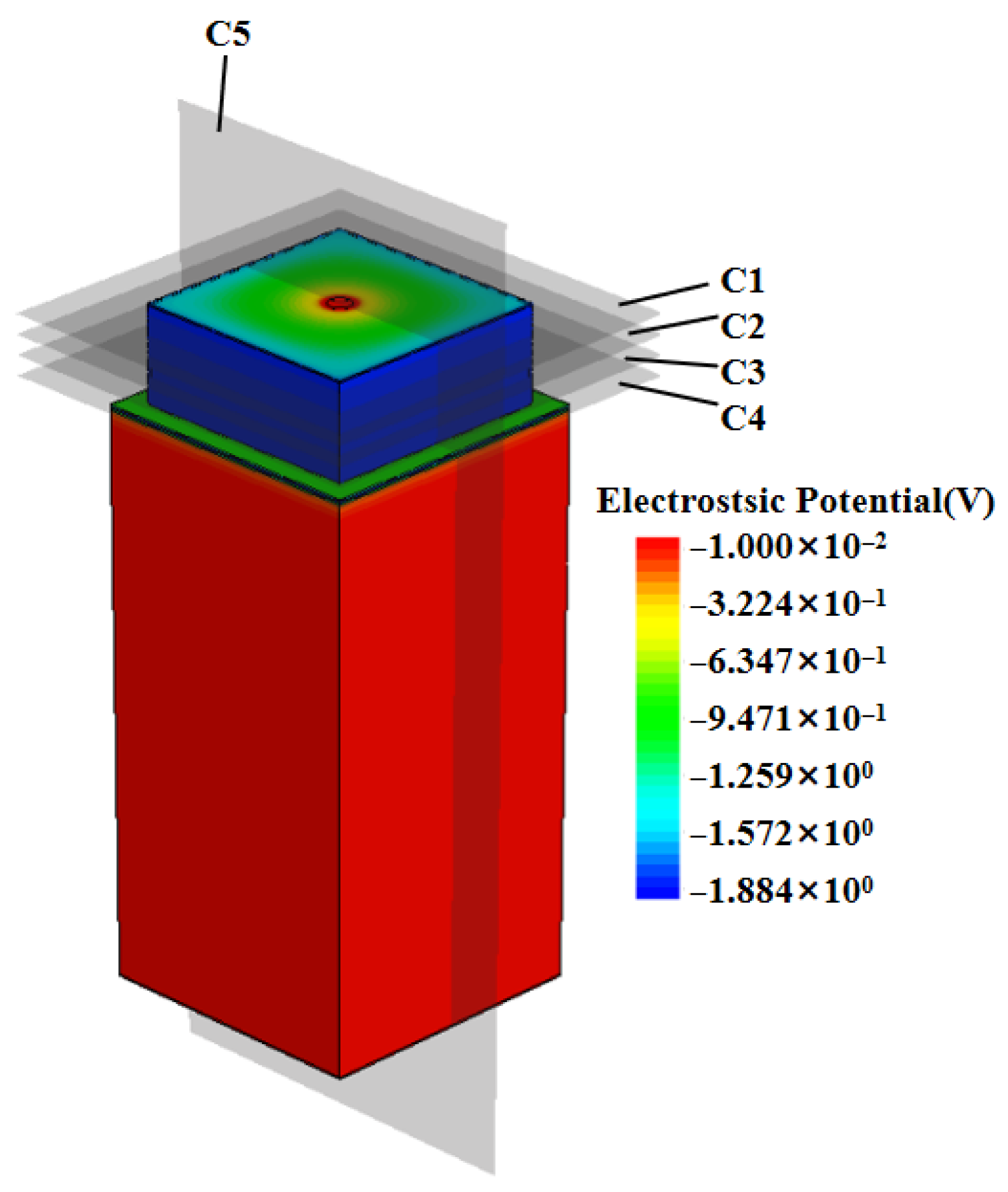

3.1. Analysis of Electric Field Characteristics

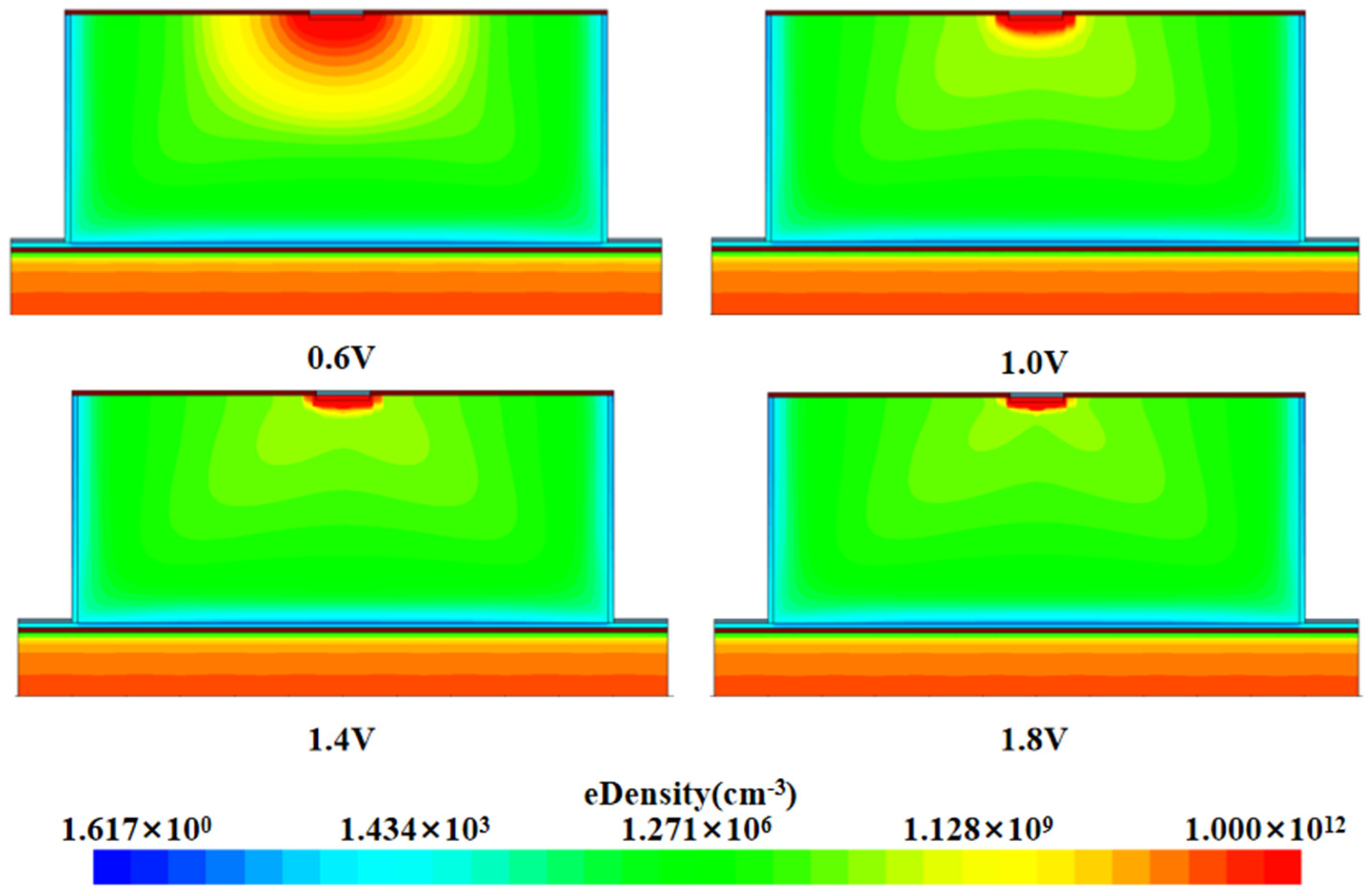

3.2. Analysis of Electron Concentration Inside Detector

3.3. Analysis of Electron Concentration Characteristics

3.4. Analysis of Transient Induced Current in Detectors and Estimation of Charge Collection Efficiency After Irradiation

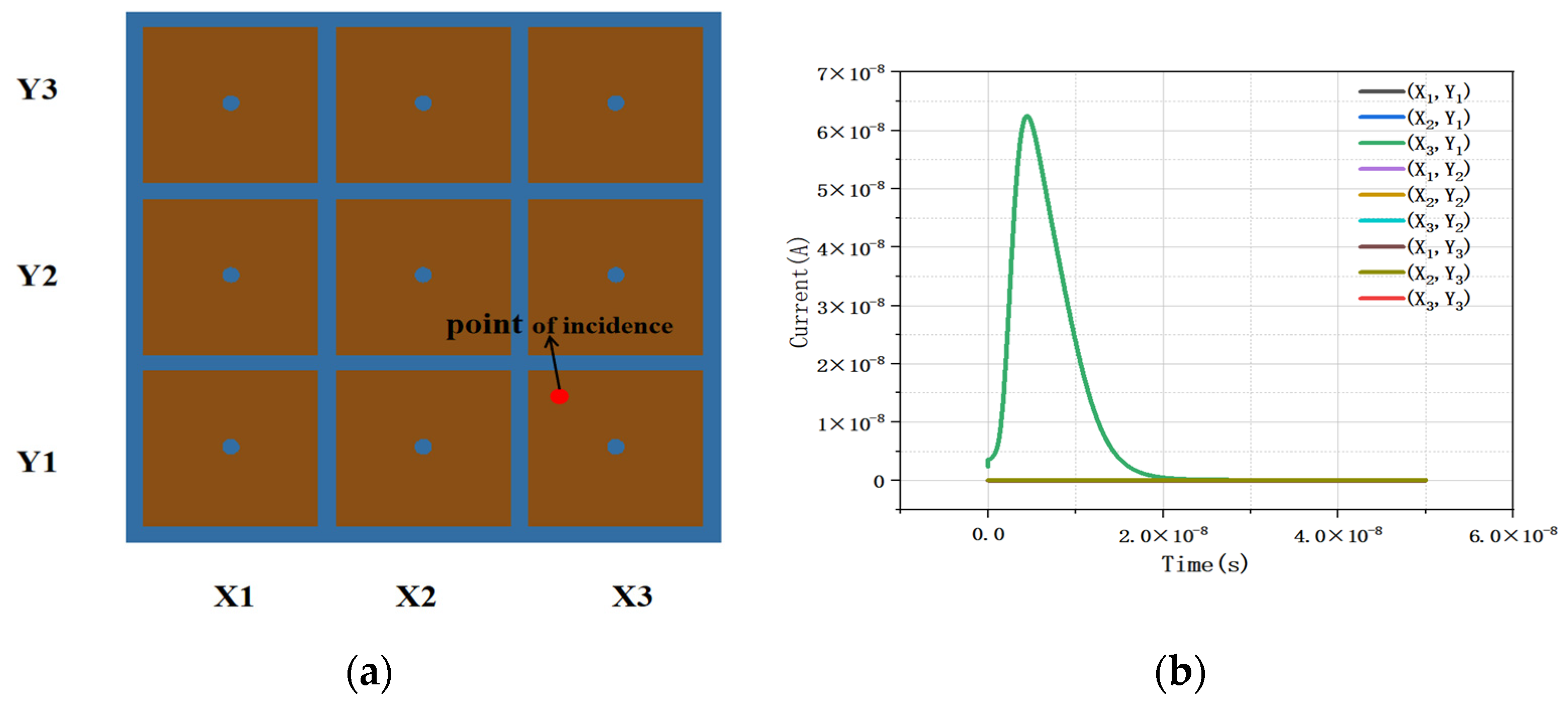

3.5. Analysis of Transient Induced Current in Detectors

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- He, R.; Niu, X.-Y.; Wang, Y.; Liang, H.-W.; Liu, H.-B.; Tian, Y.; Zhang, H.-L.; Zou, C.-J.; Liu, Z.-Y.; Zhang, Y.-L.; et al. Advances in nuclear detection and readout techniques. Nucl. Sci. Tech. 2023, 34, 205. [Google Scholar] [CrossRef]

- Moser, H.-G. Silicon detector systems in high energy physics. Prog. Part. Nucl. Phys. 2009, 63, 186–237. [Google Scholar] [CrossRef]

- Jiang, W.; Chalich, Y.; Deen, M.J. Sensors for positron emission tomography applications. Sensors 2019, 19, 5019. [Google Scholar] [CrossRef]

- Badalà, A.; La Cognata, M.; Nania, R.; Osipenko, M.; Piantelli, S.; Turrisi, R.; Barion, L.; Capra, S.; Carbone, D.; Carnesecchi, F.; et al. Trends in particle and nuclei identification techniques in nuclear physics experiments. La Riv. Nuovo C 2022, 45, 189–276. [Google Scholar] [CrossRef]

- Härkönen, J.; Ott, J.; Gädda, A.; Bezak, M.; Brücken, E.; Tuovinen, E.; Bharthuar, S.; Luukka, P.; Tuominen, E. Processing and interconnections of finely segmented semiconductor pixel detectors for applications in particle physics and photon detection. Front. Phys. 2021, 9, 601730. [Google Scholar] [CrossRef]

- Osadchii, S.M.; Petukhov, A.A.; Dunin, V.B. X-ray Absorption Spectroscopy Analysis of Heavy Metals by Means of a Silicon Detector. J. Surf. Investig. X-Ray Synchrotron Neutron Tech. 2019, 13, 683–689. [Google Scholar] [CrossRef]

- Martin, C.B.; ATLAS Pixel Collaboration. Operational experience and performance with the ATLAS Pixel Detector. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrom. Detect. Assoc. Equip. 2019, 924, 293–296. [Google Scholar] [CrossRef]

- Hugging, F. The ATLAS pixel detector. IEEE Trans. Nucl. Sci. 2006, 53, 1732–1736. [Google Scholar] [CrossRef]

- Della Negra, M.; Jenni, P.; Virdee, T.S. Journey in the search for the Higgs boson: The ATLAS and CMS experiments at the Large Hadron Collider. Science 2012, 338, 1560–1568. [Google Scholar] [CrossRef]

- Alam, M.S.; Ciocio, A.; Einsweiler, K.; Emes, J.; Gilchriese, M.; Joshi, A.; Kleinfelder, S.; Marchesini, R.; McCormack, F.; Milgrome, O.; et al. The ATLAS silicon pixel sensors. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrom. Detect. Assoc. Equip. 2001, 456, 217–232. [Google Scholar] [CrossRef]

- Stapnes, S. Detector challenges at the LHC. Nature 2007, 448, 290–296. [Google Scholar] [CrossRef] [PubMed]

- Weber, W.A.; Czernin, J.; Anderson, C.J.; Badawi, R.D.; Barthel, H.; Bengel, F.; Bodei, L.; Buvat, I.; DiCarli, M.; Graham, M.M.; et al. The future of nuclear medicine, molecular imaging, and theranostics. J. Nucl. Med. 2020, 61 (Suppl. S2), 263S–272S. [Google Scholar] [CrossRef] [PubMed]

- Enlow, E.; Abbaszadeh, S. State-of-the-art challenges and emerging technologies in radiation detection for nuclear medicine imaging: A review. Front. Phys. 2023, 11, 1106546. [Google Scholar] [CrossRef]

- Lange, J. Recent progress on 3D silicon detectors. arXiv 2015, arXiv:1511.02080. [Google Scholar] [CrossRef]

- Parker, S.I.; Kenney, C.J.; Segal, J. 3D—A proposed new architecture for solid-state radiation detectors. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrom. Detect. Assoc. Equip. 1997, 395, 328–343. [Google Scholar] [CrossRef]

- Kenney, C.; Parker, S.; Segal, J.; Storment, C. Silicon detectors with 3-D electrode arrays: fabrication and initial test results. IEEE Trans. Nucl. Sci. 1999, 46, 1224–1236. [Google Scholar] [CrossRef]

- DaVia, C.; Hasi, J.; Kenney, C.; Kok, A.; Parker, S. 3D silicon detectors—Status and applications. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrom. Detect. Assoc. Equip. 2005, 549, 122–125. [Google Scholar] [CrossRef]

- Li, Z. New detectors with novel electrode configurations for applications in sLHC and photon sciences. In Proceedings of the Fifteenth Workshop of CERN RD50, Geneva, Switzerland, 16–18 November 2009; CERN: Geneva, Switzerland, 2009. [Google Scholar]

- Kenney, C.; Segal, J.; Westbrook, E.; Parker, S.; Hasi, J.; Da Via, C.; Watts, S.; Morse, J. Active-edge planar radiation sensors. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrom. Detect. Assoc. Equip. 2006, 565, 272–277. [Google Scholar] [CrossRef]

- Li, Z. New BNL 3D-Trench electrode Si detectors for radiation hard detectors for sLHC and for X-ray applications. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrom. Detect. Assoc. Equip. 2011, 658, 90–97. [Google Scholar] [CrossRef]

- Kalliopuska, J.; Eränen, S.; Virolainen, T. Alternative fabrication process for edgeless detectors on 6 in. wafers. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrom. Detect. Assoc. Equip. 2011, 633, S50–S54. [Google Scholar] [CrossRef]

- Kalliopuska, J.; Tlustos, L.; Eränen, S.; Virolainen, T. Characterization of edgeless pixel detectors coupled to Medipix2 readout chip. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrom. Detect. Assoc. Equip. 2011, 648, S32–S36. [Google Scholar] [CrossRef]

- Wu, X.; Kalliopuska, J.; Eränen, S.; Virolainen, T. Recent advances in processing and characterization of edgeless detectors. J. Instrum. 2012, 7, C02001. [Google Scholar] [CrossRef]

- Forcolin, G.; Boscardin, M.; Ficorella, F.; Lai, A.; Loi, A.; Mendicino, R.; Ronchin, S.; Betta, G.-F.D. 3D trenched-electrode pixel sensors: Design, technology and initial results. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrom. Detect. Assoc. Equip. 2020, 981, 164437. [Google Scholar] [CrossRef]

- Ye, J.; Loi, A.; Lai, A.; Betta, G.-F.D. Design and simulation of modified 3D-trench electrode sensors. J. Instrum. 2023, 18, C11021. [Google Scholar] [CrossRef]

- Liu, M.; Li, X.; Cheng, W.; Li, Z.; Li, Z. Radiation hardness property of ultra-fast 3D-Trench Electrode silicon detector on N-type substrate. Micromachines 2021, 12, 1400. [Google Scholar] [CrossRef]

- Zhu, X.; Li, Z.; Liu, Z.; Long, T.; Zhao, J.; Li, X.; Liu, M.; Wang, M. A Novel Polysilicon-Fill-Strengthened Etch-Through 3D Trench Electrode Detector: Fabrication Methods and Electrical Property Simulations. Micromachines 2025, 16, 912. [Google Scholar] [CrossRef]

- Liu, M.; Lu, S.; Li, Z. Theoretical bases of hypothetical sphere-electrode detectors and practical near-sphere-electrode (semisphere-electrode and near-semisphere-electrode) detectors. J. Phys. D Appl. Phys. 2020, 54, 045101. [Google Scholar] [CrossRef]

- Li, Z. Radiation damage effects in Si materials and detectors and rad-hard Si detectors for SLHC. J. Instrum. 2009, 4, P03011. [Google Scholar] [CrossRef]

- Lindström, G.; Ahmed, M.; Albergo, S.; Allport, P.; Anderson, D.; Andricek, L.; Angarano, M.; Augelli, V.; Bacchetta, N.; Bartalini, P.; et al. Radiation hard silicon detectors—Developments by the RD48 (ROSE) collaboration. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrom. Detect. Assoc. Equip. 2001, 466, 308–326. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Z.; Long, T.; Li, Z.; Zhu, X.; Zhao, J.; Li, X.; Liu, M.; Wang, M. Development, Design, and Electrical Performance Simulation of Novel Through-Type 3D Semi Spherical Electrode Detector Based on SOI Substrate. Micromachines 2025, 16, 1006. https://doi.org/10.3390/mi16091006

Liu Z, Long T, Li Z, Zhu X, Zhao J, Li X, Liu M, Wang M. Development, Design, and Electrical Performance Simulation of Novel Through-Type 3D Semi Spherical Electrode Detector Based on SOI Substrate. Micromachines. 2025; 16(9):1006. https://doi.org/10.3390/mi16091006

Chicago/Turabian StyleLiu, Zhiyu, Tao Long, Zheng Li, Xuran Zhu, Jun Zhao, Xinqing Li, Manwen Liu, and Meishan Wang. 2025. "Development, Design, and Electrical Performance Simulation of Novel Through-Type 3D Semi Spherical Electrode Detector Based on SOI Substrate" Micromachines 16, no. 9: 1006. https://doi.org/10.3390/mi16091006

APA StyleLiu, Z., Long, T., Li, Z., Zhu, X., Zhao, J., Li, X., Liu, M., & Wang, M. (2025). Development, Design, and Electrical Performance Simulation of Novel Through-Type 3D Semi Spherical Electrode Detector Based on SOI Substrate. Micromachines, 16(9), 1006. https://doi.org/10.3390/mi16091006