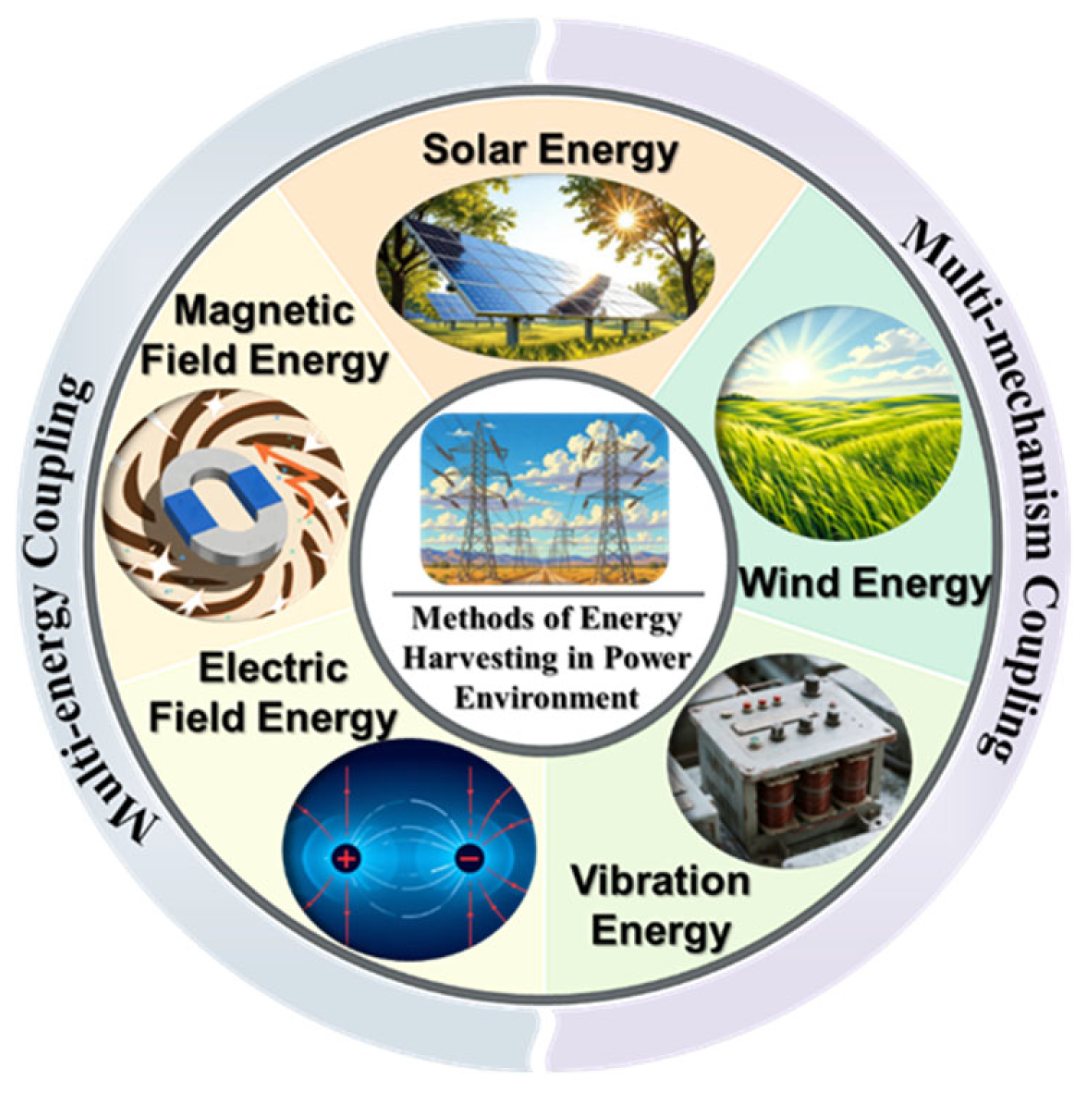

Advancements and Future Prospects of Energy Harvesting Technology in Power Systems

Abstract

1. Introduction

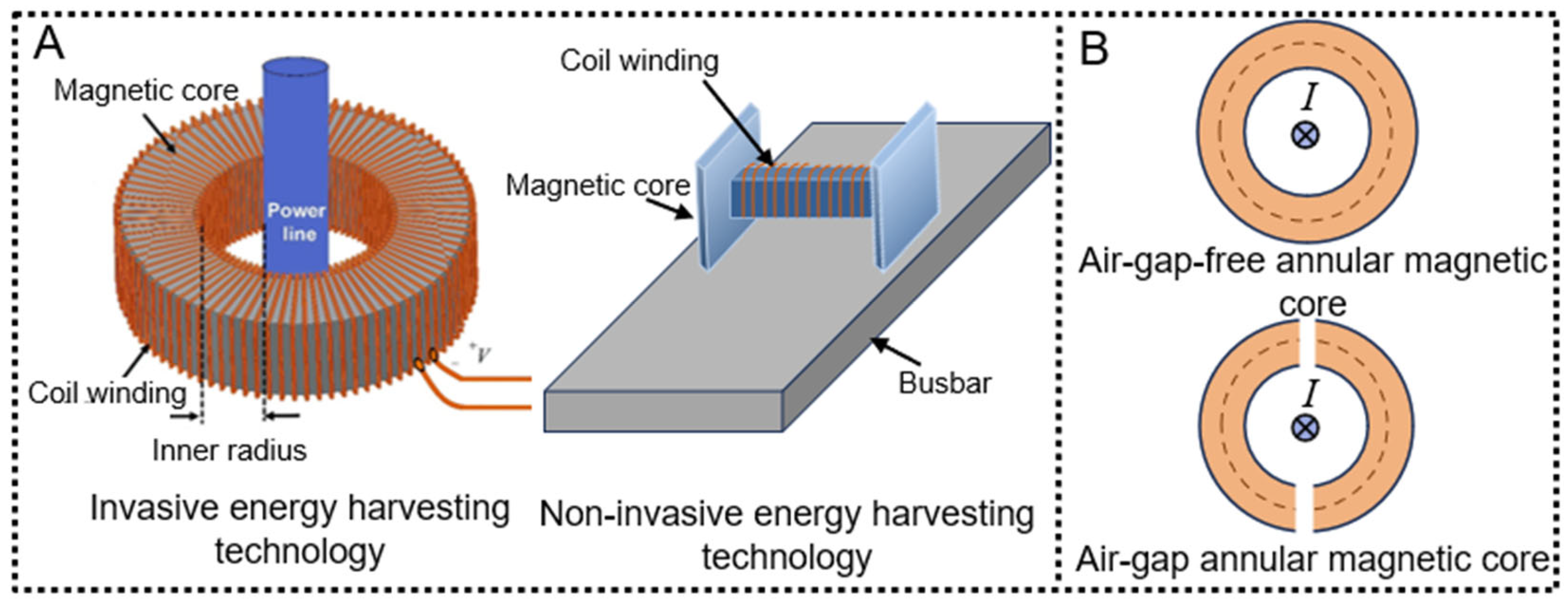

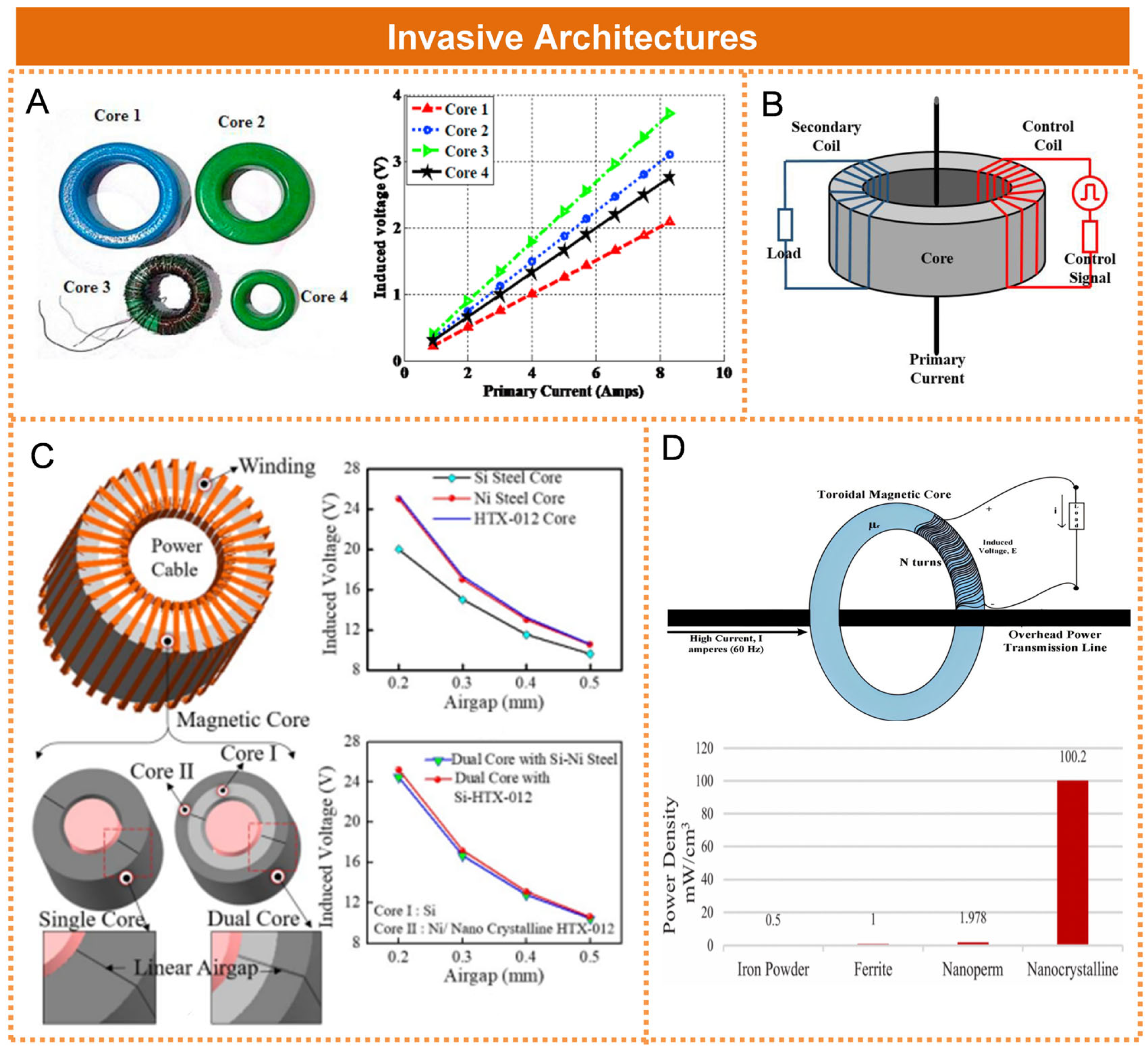

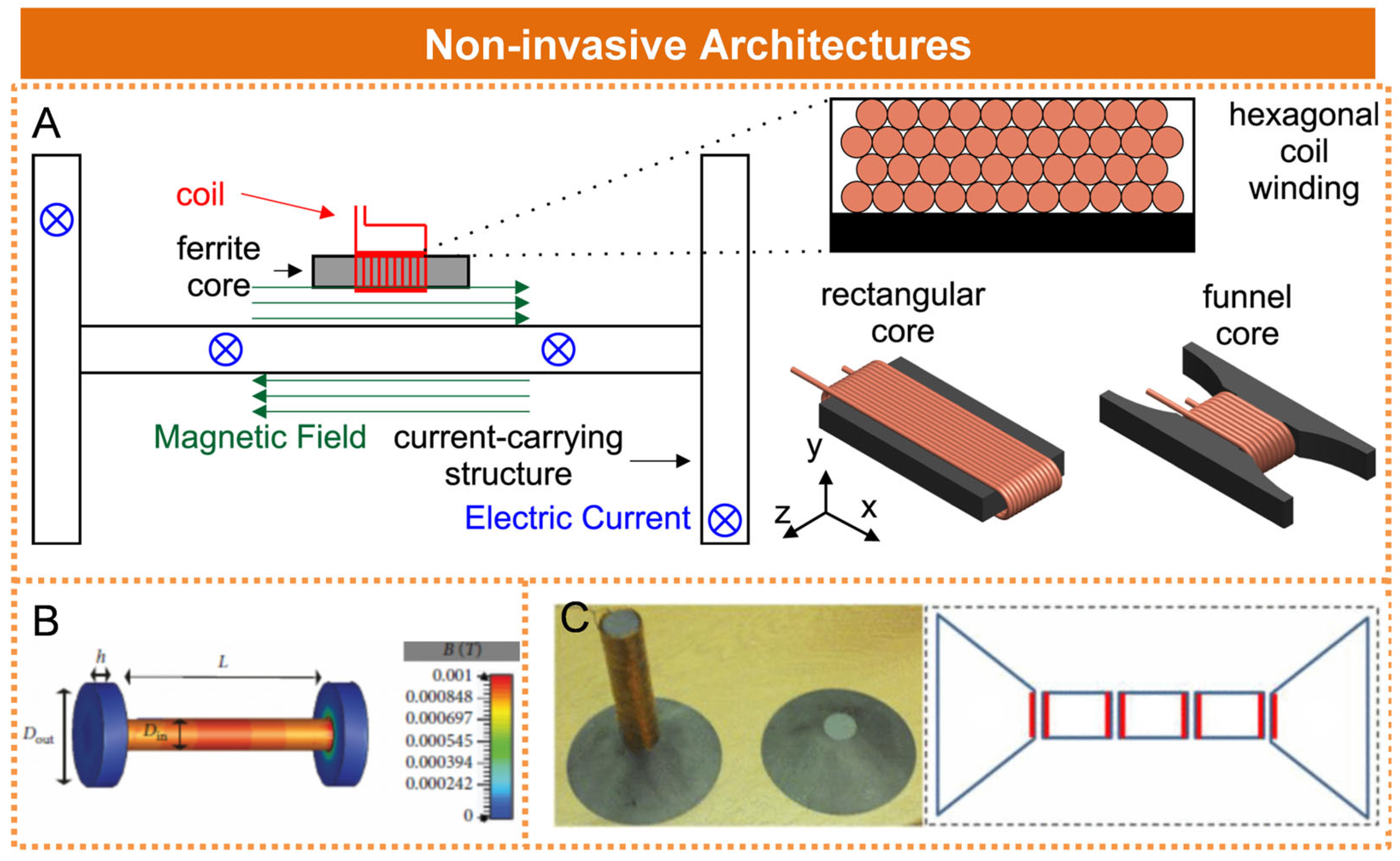

2. Magnetic Field Energy Harvesting Technology

2.1. Direct Magnetic Field Energy Harvesting Technology

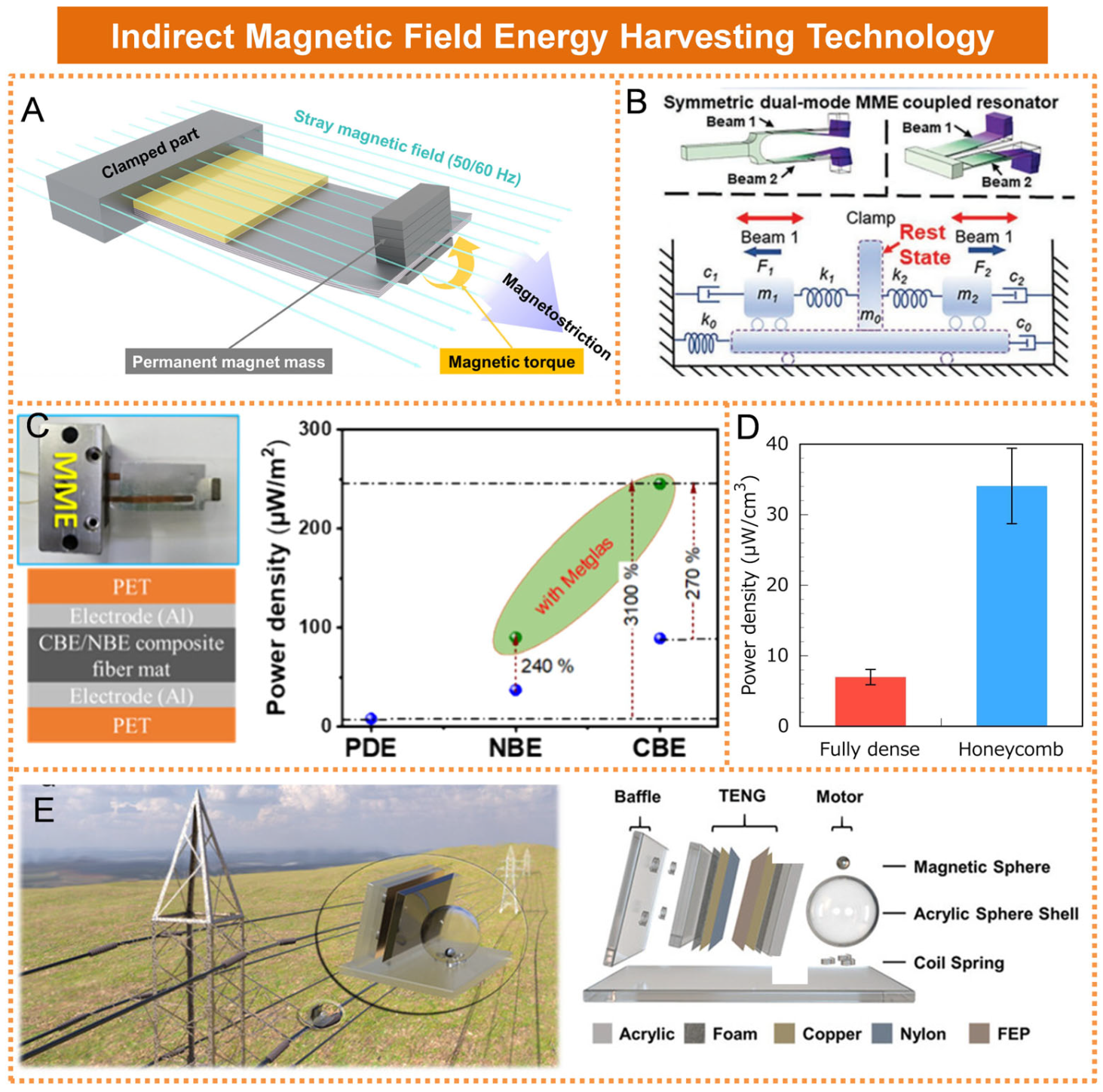

2.2. Indirect Magnetic Field Energy Harvesting Technology

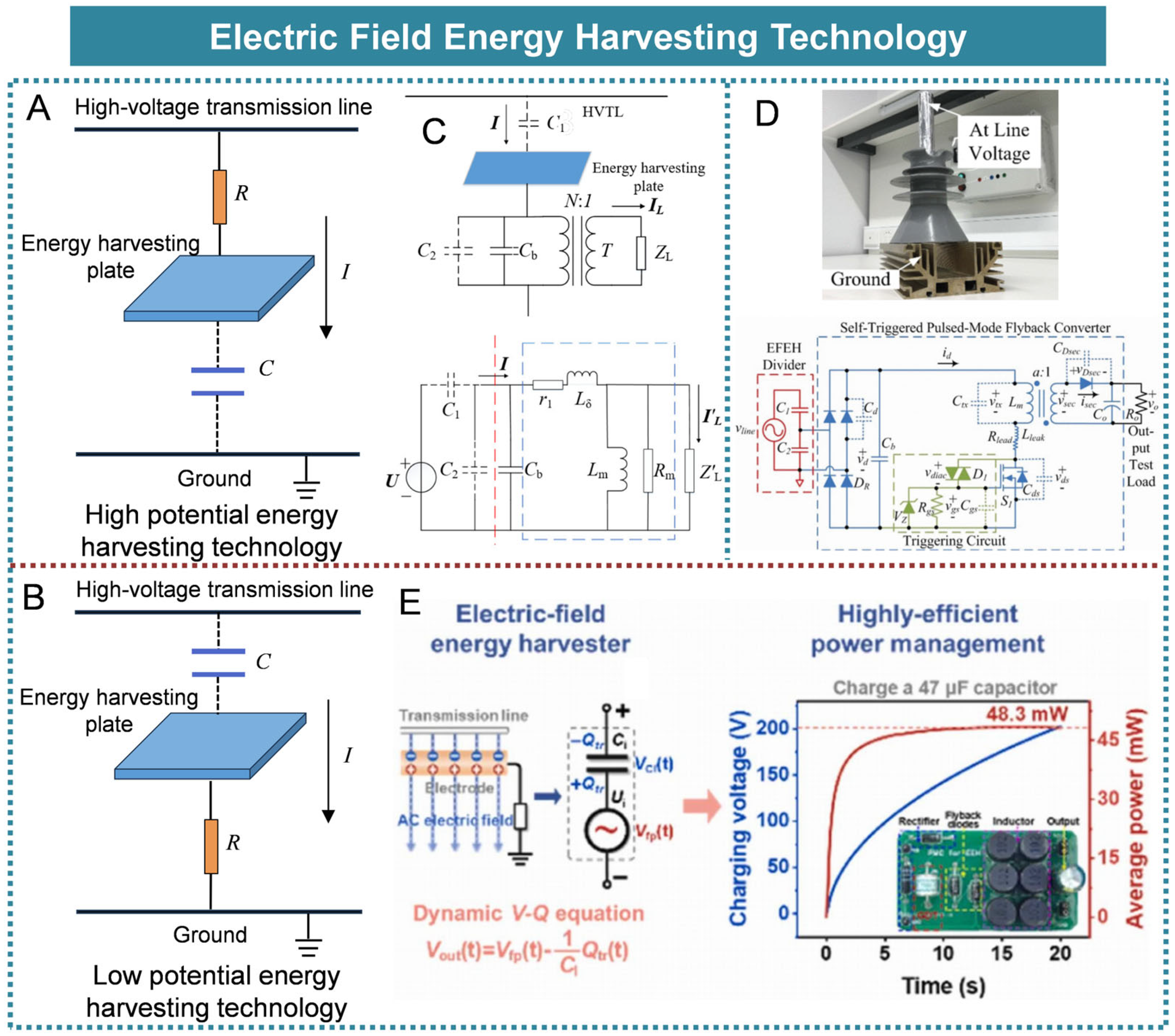

3. Electric Field Energy Harvesting Technology

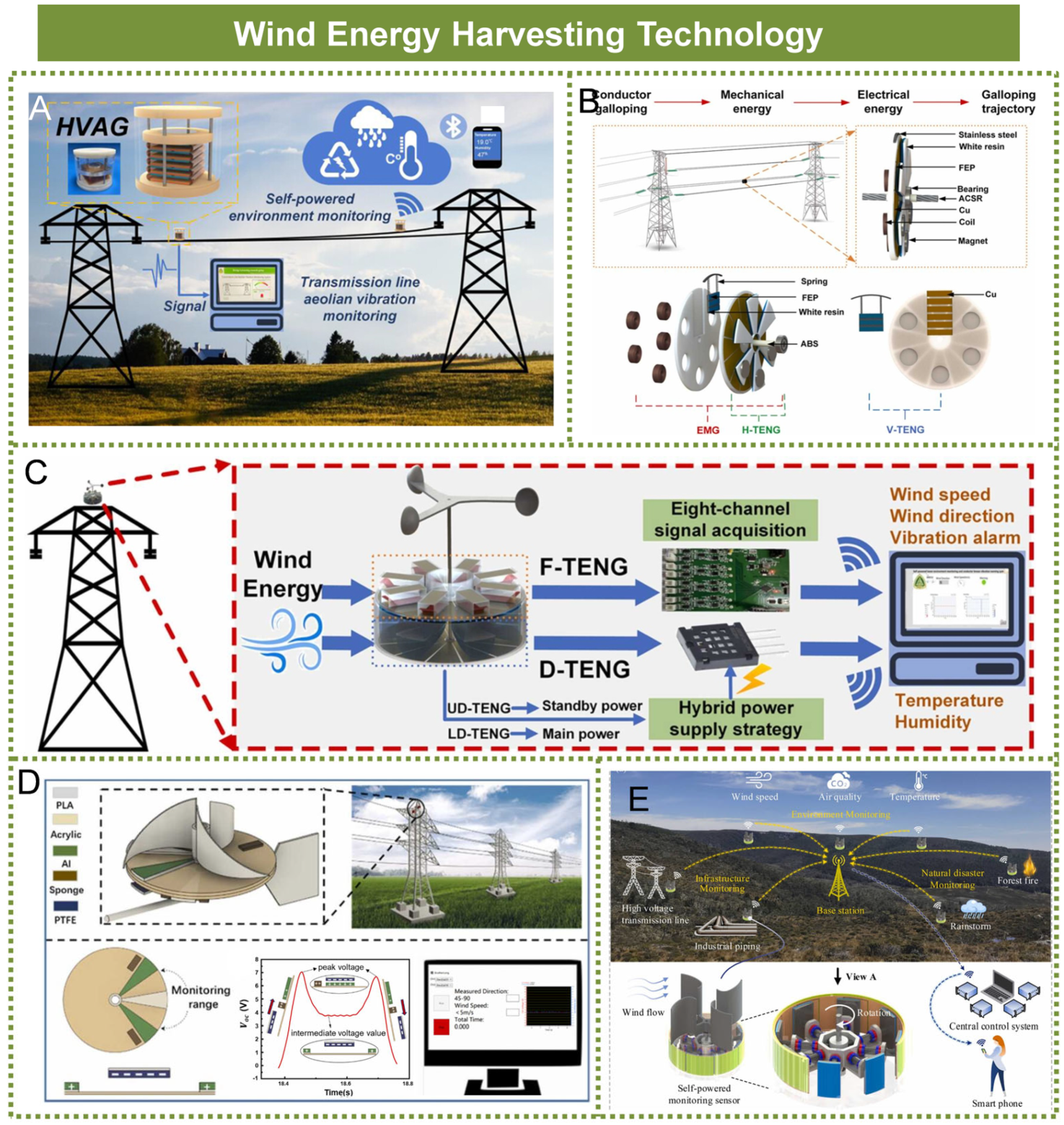

4. Wind Energy Harvesting Technology

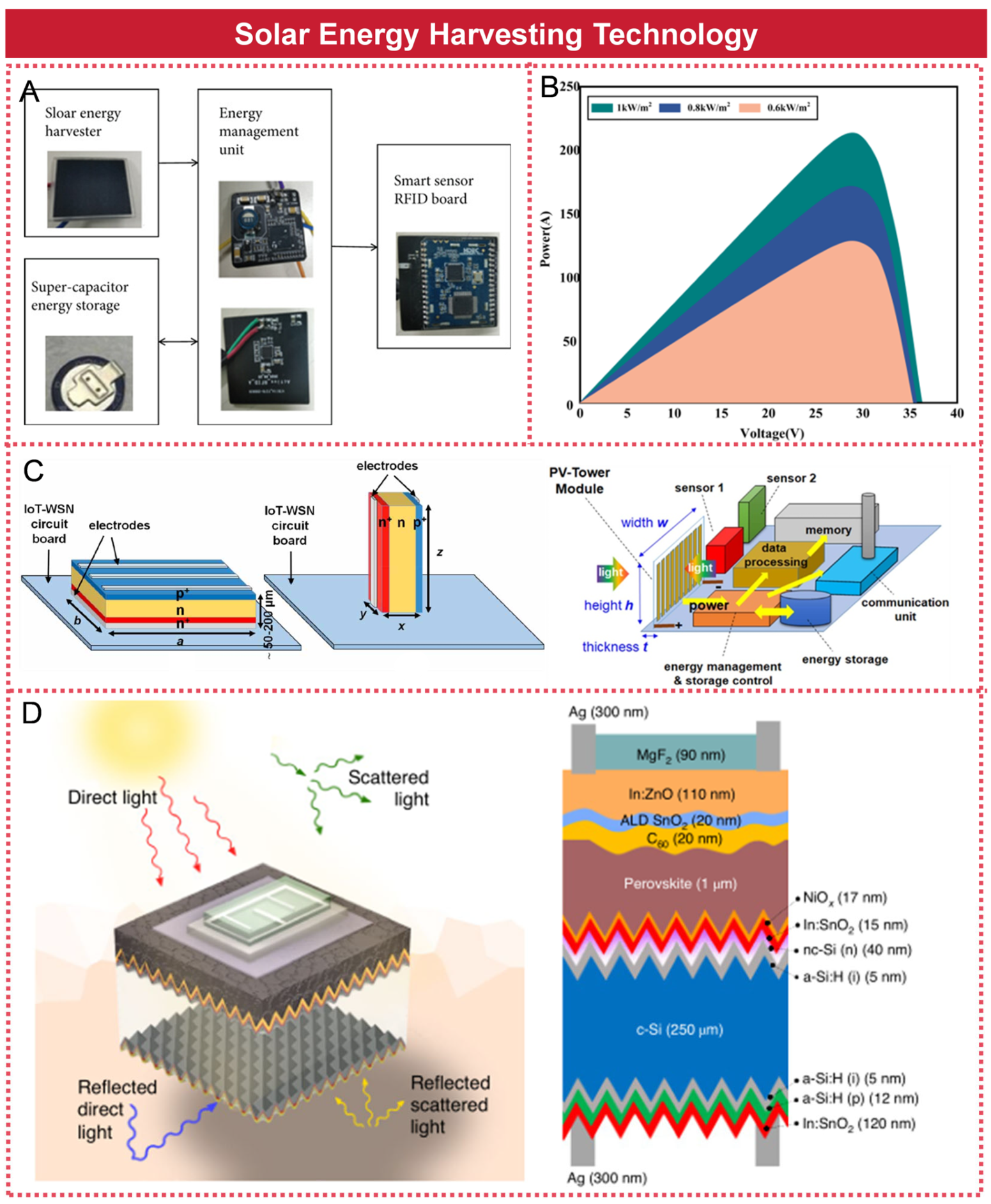

5. Solar Energy Harvesting Technology

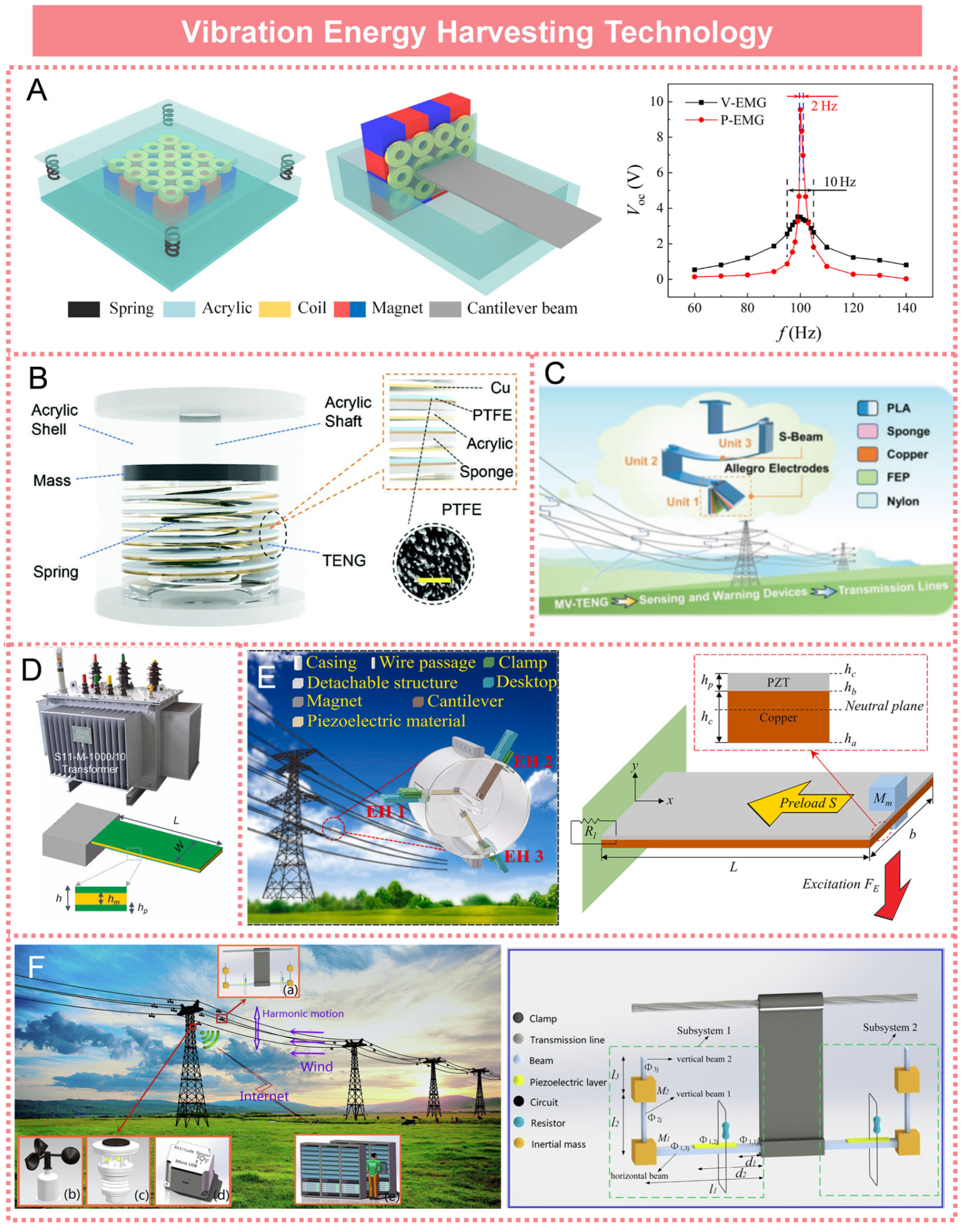

6. Vibration Energy Harvesting Technology

7. Multi-Energy Composite Technology

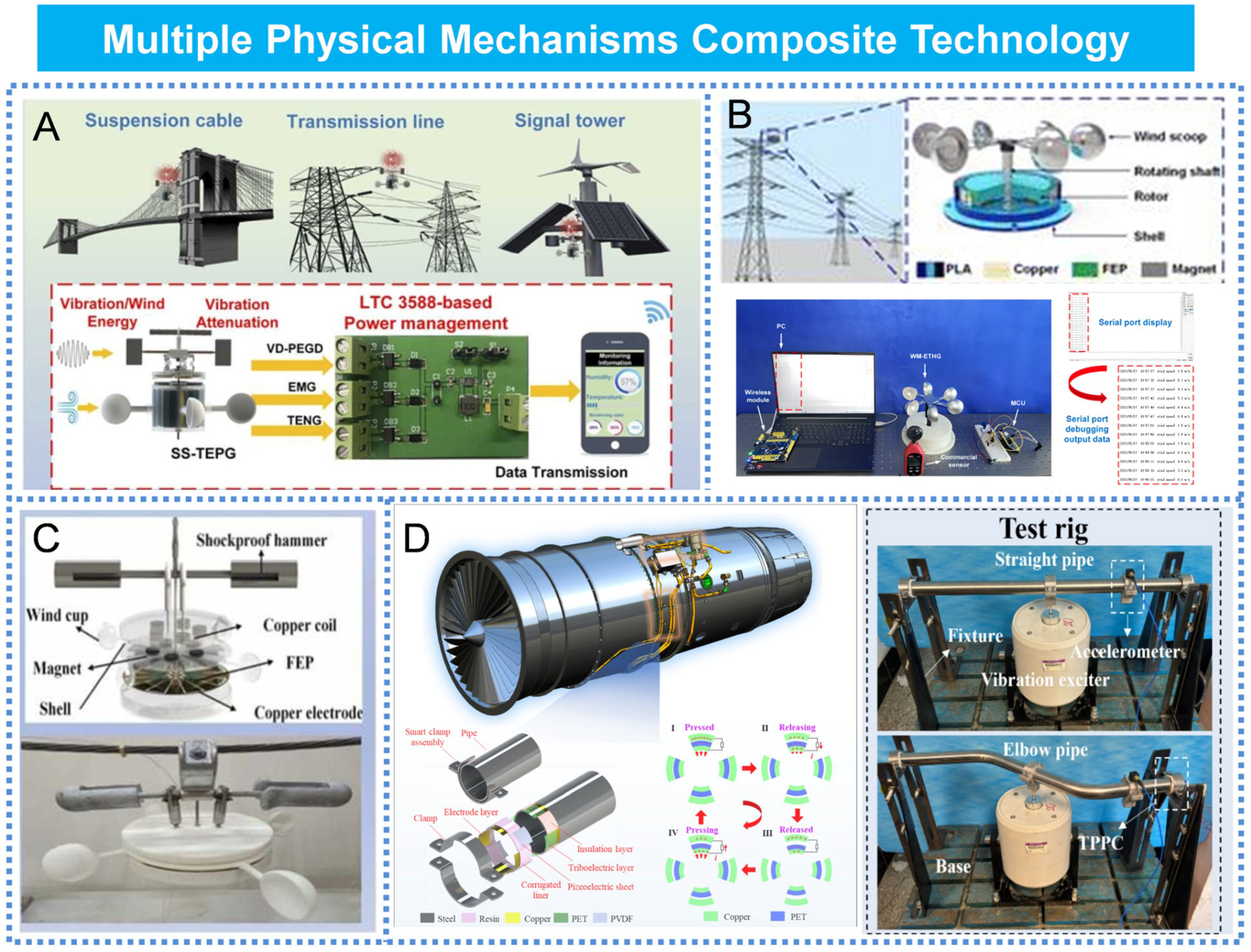

8. Multiple Physical Mechanisms Composite Technology

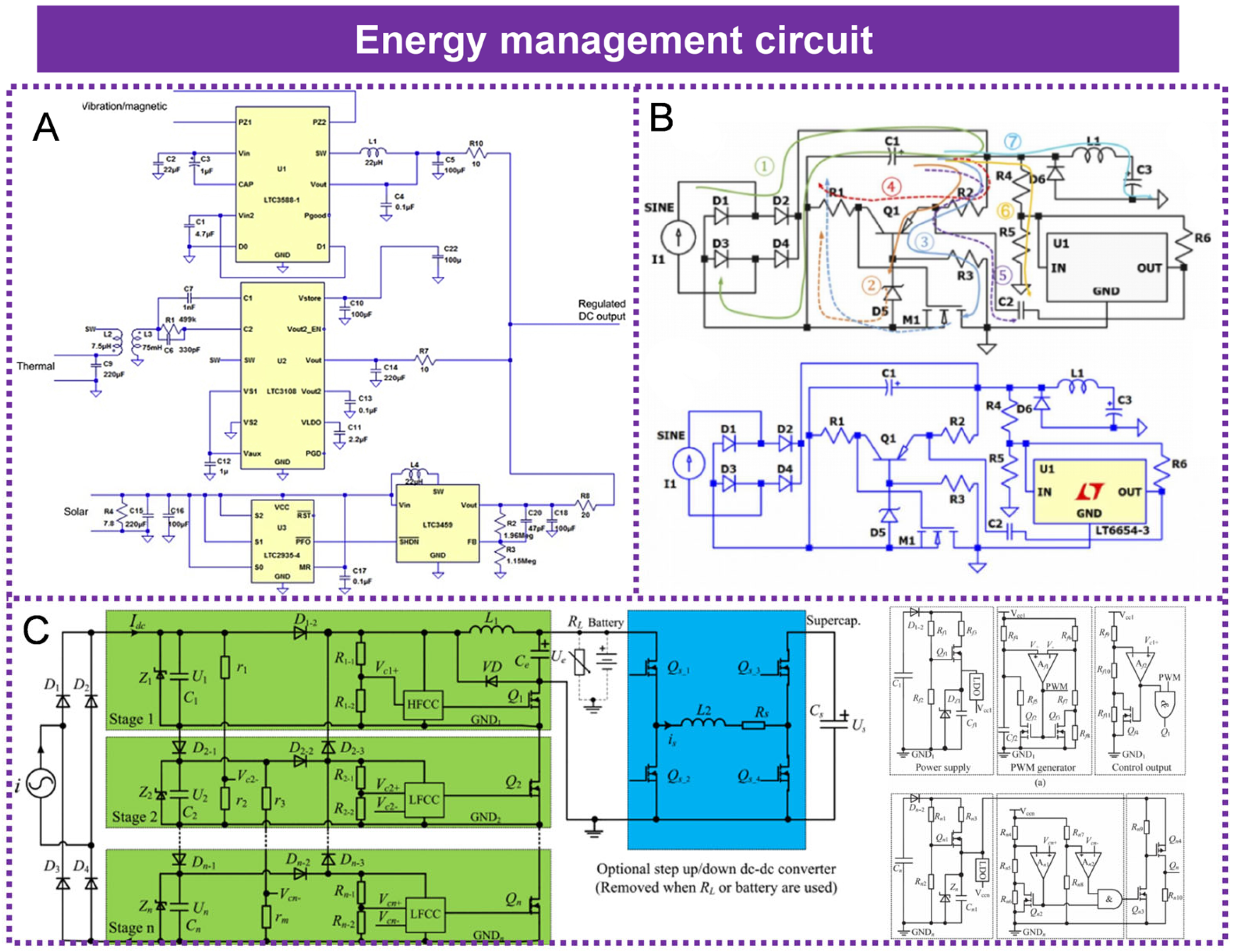

9. Energy Management Circuit

10. Summary and Outlook

- (1)

- Structural design is progressively evolving toward miniaturization and customization to better meet the on-site power supply requirements of electrical equipment.

- (2)

- From the perspective of energy diversification, the trend is shifting toward diversification, integration, and coupling, which can effectively enhance power generation capacity. This evolution is expected to drive significant growth in research related to multi-energy management.

- (3)

- The packaging technology of energy harvesters plays a critical role in ensuring their efficient and reliable performance under diverse environmental conditions, encompassing various design aspects such as mechanical support and protection against environmental degradation. Wang Fei et al. integrated silicon tip arrays into MEMS-based energy harvesters, thereby enabling charge restoration without compromising the integrity of the package [129]. This innovative approach effectively addresses challenges posed by harsh industrial environments, such as elevated humidity and temperature levels, and significantly improves the long-term operational stability of the devices. In the future, researchers should focus on innovations in materials, structures, and system integration to ensure that energy harvesting devices can operate stably over extended periods in harsh environments, thereby providing robust support for the deployment of self-powered sensors in specialized application scenarios.

- (4)

- The interface between energy harvesters and IoT platforms encompasses both hardware integration and data communication protocols, playing a critical role in ensuring that the collected environmental energy—such as solar, wind, or vibrational energy—is efficiently converted into electrical energy and seamlessly integrated into the IoT system. The hardware interface layer encompasses the physical connectivity of energy harvesting devices. In the future, energy harvesters should be directly integrated with the platform via standardized interfaces, such as RS-485, Modbus, or wireless communication protocols. Energy storage units are tasked with temporarily storing harvested energy and regulating its output through power management integrated circuits (ICs), thereby enabling plug-and-play functionality for connected devices. The interface of data communication protocols depends on standardized protocols (e.g., MQTT or LoRaWAN) for the transmission of real-time data. Future development trends emphasize the optimization of low-power communication protocols and the synergistic integration of multi-source energy solutions, aiming to enhance the robustness and interoperability of the interface.

- (5)

- Current standardization efforts primarily aim at improving energy harvesting efficiency and enhancing the adaptability of communication protocols to support distributed energy access. Future standardization work will concentrate on establishing engineering application standards, such as plug-and-play specifications, to ensure seamless integration of energy collection devices, sensors, and other equipment into the system platform, thereby supporting the intelligent development of the new power system.

Author Contributions

Funding

Conflicts of Interest

References

- Evans, D. The internet of things. how the next evolution of the internet is changing everything, whitepaper. Cisco Internet Bus. Solut. Group (IBSG) 2011, 1, 1–12. [Google Scholar]

- Elbouchikhi, E.; Zia, M.F.; Benbouzid, M.; El Hani, S. Overview of Signal Processing and Machine Learning for Smart Grid Condition Monitoring. Electronics 2021, 10, 2725. [Google Scholar] [CrossRef]

- Yilmaz, S.; Dener, M. Security with Wireless Sensor Networks in Smart Grids: A Review. Symmetry 2024, 16, 1295. [Google Scholar] [CrossRef]

- Ma, J.; Sun, H.; Chu, Z.; Zhao, J.; Yang, Z.; Liu, S.; Wen, J.; Qin, Y. Self-powered and self-calibrated sensing system for real-time environmental monitoring. Sci. Adv. 2025, 11, eadw3745. [Google Scholar] [CrossRef] [PubMed]

- Gholikhani, M.; Roshani, H.; Dessouky, S.; Papagiannakis, A.T. A critical review of roadway energy harvesting technologies. Appl. Energy 2020, 261, 114388. [Google Scholar] [CrossRef]

- Han, D.Y.; Song, C.K.; Lee, G.; Song, W.J.; Park, S. A Comprehensive Review of Battery-Integrated Energy Harvesting Systems. Adv. Mater. Technol. 2024, 9, 2302236. [Google Scholar] [CrossRef]

- Luo, H.; Yang, T.; Jing, X.; Cui, Y.; Qin, W. Environmental energy harvesting boosts self-powered sensing. Mater. Today Energy 2024, 40, 101502. [Google Scholar] [CrossRef]

- Zhang, D.; Zhou, L.; Wu, Y.; Yang, C.; Zhang, H. Triboelectric Nanogenerator for Self-Powered Gas Sensing. Small 2024, 20, 2406964. [Google Scholar] [CrossRef]

- Jiang, W.; Han, X.; Chen, L.; Bi, Q. Bursting vibration-based energy harvesting. Nonlinear Dyn. 2020, 100, 3043–3060. [Google Scholar] [CrossRef]

- Zhu, D. Advance Energy Harvesting Technologies. Energies 2022, 15, 2366. [Google Scholar] [CrossRef]

- Chong, Y.W.; Ismail, W.; Ko, K.; Lee, C.Y. Energy Harvesting For Wearable Devices: A Review. IEEE Sens. J. 2019, 19, 9047–9062. [Google Scholar] [CrossRef]

- Babayo, A.A.; Anisi, M.H.; Ali, I. A Review on energy management schemes in energy harvesting wireless sensor networks. Renew. Sustain. Energy Rev. 2017, 76, 1176–1184. [Google Scholar] [CrossRef]

- Luo, A.; Tan, Q.; Xu, W.; Huang, J.; Gu, S.; Guo, X.; Lee, C.; Fan, K.; Wang, F. A Comprehensive Review of Energy Harvesting From Kinetic Energy at Low Frequency. Adv. Mater. Technol. 2025, 10, 2401731. [Google Scholar] [CrossRef]

- Zhang, H.; Shen, Q.; Zheng, P.; Wang, H.; Zou, R.; Zhang, Z.; Pan, Y.; Zhi, J.Y.; Xiang, Z.R. Harvesting inertial energy and powering wearable devices: A review. Small Methods 2024, 8, 2300771. [Google Scholar] [CrossRef]

- Junior, O.A.; Maran, A.; Henao, N. A review of the development and applications of thermoelectric microgenerators for energy harvesting. Renew. Sustain. Energy Rev. 2018, 91, 376–393. [Google Scholar] [CrossRef]

- Espe, A.E.; Haugan, T.S.; Mathisen, G. Magnetic field energy harvesting in railway. IEEE T Power Electr. 2022, 37, 8659–8668. [Google Scholar] [CrossRef]

- Seo, D.; Kim, B.; Ha, M.; Han, S.; Yoon, S.; Cho, B. Energy harvesting with magneto-mechano-electric harvester for AC circular magnetic fields. Sens. Actuat. A-Phys. 2025, 387, 116422. [Google Scholar] [CrossRef]

- Riba, J.-R.; Arbat, R.; Ndong, Y.O.; Moreno-Eguilaz, M. Exploring the Limitations of Electric Field Energy Harvesting. Electronics 2023, 12, 3626. [Google Scholar] [CrossRef]

- Menéndez, O.; Villacrés, J.; Prado, A.; Vásconez, J.P.; Auat-Cheein, F. Assessment of Triboelectric Nanogenerators for Electric Field Energy Harvesting. Sensors 2024, 24, 2507. [Google Scholar] [CrossRef]

- Li, X.; Hu, G.; Guo, Z.; Wang, J.; Yang, Y.; Liang, J. Frequency up-conversion for vibration energy harvesting: A review. Symmetry 2022, 14, 631. [Google Scholar] [CrossRef]

- Qi, L.; Pan, H.; Pan, Y.; Luo, D.; Yan, J.; Zhang, Z. A review of vibration energy harvesting in rail transportation field. Iscience 2022, 25, 103849. [Google Scholar] [CrossRef]

- Zheng, X.; He, L.; Wang, S.; Liu, X.; Liu, R.; Cheng, G. A review of piezoelectric energy harvesters for harvesting wind energy. Sens. Actuat. A-Phys. 2023, 352, 114190. [Google Scholar] [CrossRef]

- Ali, A.; Ali, S.; Shaukat, H.; Khalid, E.; Behram, L.; Rani, H.; Altabey, W.A.; Kouritem, S.A.; Noori, M. Advancements in piezoelectric wind energy harvesting: A review. Results Eng. 2024, 21, 101777. [Google Scholar] [CrossRef]

- Satharasinghe, A.; Hughes-Riley, T.; Dias, T. A review of solar energy harvesting electronic textiles. Sensors 2020, 20, 5938. [Google Scholar] [CrossRef] [PubMed]

- Massiot, I.; Cattoni, A.; Collin, S. Progress and prospects for ultrathin solar cells. Nat. Energy 2020, 5, 959–972. [Google Scholar] [CrossRef]

- Yang, J.; Zhang, W.; Zou, L.; Wang, Y.; Sun, Y.; Feng, Y. Research on distribution and shielding of spatial magnetic field of a DC air core smoothing reactor. Energies 2019, 12, 937. [Google Scholar] [CrossRef]

- Liu, L.; Wen, X.; Shi, R.; Li, P.; Wen, Y.; Han, T. High-efficiency magnetic field energy harvesting from a three-core cable. Sens. Actuat. A-Phys. 2023, 360, 114501. [Google Scholar] [CrossRef]

- Tao, J.; Wang, Y.; Cheng, H.; Mai, R. Analysis and Design of Magnetic Field Energy Harvesting for Freight Train Sensors. IEEE Trans. Transp. Electrif. 2023, 10, 4503–4512. [Google Scholar] [CrossRef]

- Bhuiyan, R.H.; Dougal, R.A.; Ali, M. A miniature energy harvesting device for wireless sensors in electric power system. IEEE Sens. J. 2010, 10, 1249–1258. [Google Scholar] [CrossRef]

- Park, B.; Kim, D.; Park, J.; Kim, K.; Koo, J.; Park, H.; Ahn, S. Optimization design of toroidal core for magnetic energy harvesting near power line by considering saturation effect. AIP Adv. 2018, 8, 056728. [Google Scholar] [CrossRef]

- Gaikwad, A.; Kulkarni, S. Evaluation of dimensional effect on electromagnetic energy harvesting. Procedia Comput. Sci. 2018, 143, 58–65. [Google Scholar] [CrossRef]

- Zhuang, Y.; Xu, C.; Song, C.; Chen, A.; Lee, W.; Huang, Y.; Zhou, J. Improving current transformer-based energy extraction from AC power lines by manipulating magnetic field. IEEE Trans. Ind. Electron. 2019, 67, 9471–9479. [Google Scholar] [CrossRef]

- Paul, S.; Bashir, S.; Chang, J. Design of a novel electromagnetic energy harvester with dual core for deicing device of transmission lines. IEEE Trans. Magn. 2018, 55, 1–4. [Google Scholar] [CrossRef]

- Najafi, S.A.A.; Ali, A.A.; Sozer, Y.; De Abreu-Garcia, A. Energy harvesting from overhead transmission line magnetic fields. In Proceedings of the 2018 IEEE Energy Conversion Congress and Exposition (ECCE), Portland, OR, USA, 23–27 September 2018; pp. 7075–7082. [Google Scholar]

- Zhang, J.; Tian, X.; Li, J.; Yan, D. A novel electromagnetic energy harvester based on double-ring core for power line energy harvesting. J. Circuit. Syst. Comp. 2020, 29, 2050265. [Google Scholar] [CrossRef]

- Wright, S.W.; Kiziroglou, M.E.; Spasic, S.; Radosevic, N.; Yeatman, E.M. Inductive energy harvesting from current-carrying structures. IEEE Sens. Lett. 2019, 3, 1–4. [Google Scholar] [CrossRef]

- Wang, H.; Shi, G.; Han, C.; Monti, G. A free-standing electromagnetic energy harvester for condition monitoring in smart grid. Wirel. Power Transf. 2021, 2021, e7. [Google Scholar] [CrossRef]

- Yuan, S.; Huang, Y.; Zhou, J.; Xu, Q.; Song, C.; Thompson, P. Magnetic field energy harvesting under overhead power lines. IEEE T Power Electr. 2015, 30, 6191–6202. [Google Scholar] [CrossRef]

- Roscoe, N.M.; Judd, M.D. Harvesting energy from magnetic fields to power condition monitoring sensors. IEEE Sens. J. 2013, 13, 2263–2270. [Google Scholar] [CrossRef]

- Moghe, R.; Lambert, F.C.; Divan, D. Smart “stick-on” sensors for the smart grid. IEEE Trans. Smart Grid 2011, 3, 241–252. [Google Scholar] [CrossRef]

- Li, Q.; Zhang, L.; Zhang, C.; Tian, Y.; Fan, Y.; Li, B.; An, Z.; Li, D.; Wang, Z.L. Compact, robust, and regulated-output hybrid generators for magnetic energy harvesting and self-powered sensing applications in power transmission lines. Energ. Environ. Sci. 2024, 17, 2787–2799. [Google Scholar] [CrossRef]

- Tashiro, K.; Wakiwaka, H.; Inoue, S.-I.; Uchiyama, Y. Energy harvesting of magnetic power-line noise. IEEE Trans. Magn. 2011, 47, 4441–4444. [Google Scholar] [CrossRef]

- Muñoz-Gómez, A.-M.; Menéndez-Marín, M.; Ballestín-Fuertes, J.; Sanz-Osorio, J.-F. Single-Stage Power Converter for Magnetic Field Energy Harvesting to Achieve Self-Powered Smart Grid IoT Devices. Electronics 2025, 14, 415. [Google Scholar] [CrossRef]

- Wu, Z.; Wen, Y.; Li, P. A power supply of self-powered online monitoring systems for power cords. IEEE Trans. Energy Convers. 2013, 28, 921–928. [Google Scholar] [CrossRef]

- Yu, Y.; Cheng, Z.; Chang, J.; Mai, Z.; Wang, B.; Zhu, R.; Sun, M.; Dong, S.; Ci, P. Enhanced In-Plane Omnidirectional Energy Harvesting from Extremely Weak Magnetic Fields via Fourfold Symmetric Magneto-Mechano-Electric Coupling. Adv. Energy Mater. 2024, 14, 2402487. [Google Scholar] [CrossRef]

- He, X.; Xu, Y.; Wu, J.; Huang, H.; Liang, X.; Du, Y.; Qiao, J.; Li, Y.; Huang, H.; Ju, D.; et al. Enhanced Power Density by Resonant Frequency Optimization in Magneto-Mechano-Electric Generator for Multifunctional Wireless Sensor System. Small 2025, 21, 2412214. [Google Scholar] [CrossRef] [PubMed]

- Yu, Z.; Qiu, H.; Chu, Z.; Sun, Z.; Asl, M.J.P.; Li, F.; Dong, S. Significant output power enhancement in symmetric dual-mode magneto-mechano-electric coupled resonators. Adv. Energy Mater. 2022, 12, 2202306. [Google Scholar] [CrossRef]

- Pabba, D.P.; Kaarthik, J.; Ram, N.; Venkateswarlu, A. Harnessing the Induced Magnetostrictive Effect in Fully Flexible Fiber-Based Magnetoelectric Composites for Improved Stray Magnetic Energy Harvesting. ACS Appl. Electron. Mater. 2024, 6, 4783–4792. [Google Scholar] [CrossRef]

- Kurita, H.; Lohmuller, P.; Laheurte, P.; Nakajima, K.; Narita, F. Additive manufacturing and energy-harvesting performance of honeycomb-structured magnetostrictive Fe52–Co48 alloys. Addit. Manuf. 2022, 54, 102741. [Google Scholar] [CrossRef]

- Jin, X.; Yuan, Z.; Shi, Y.; Sun, Y.; Li, R.; Chen, J.; Wang, L.; Wu, Z.; Wang, Z.L. Triboelectric nanogenerator based on a rotational magnetic ball for harvesting transmission line magnetic energy. Adv. Funct. Mater. 2022, 32, 2108827. [Google Scholar] [CrossRef]

- Yuan, Z.; Wei, X.; Jin, X.; Sun, Y.; Wu, Z.; Wang, Z.L. Magnetic energy harvesting of transmission lines by the swinging triboelectric nanogenerator. Mater. Today Energy 2021, 22, 100848. [Google Scholar] [CrossRef]

- Yu, Z.; Yang, J.; Xu, L.; Chang, J.; Li, Z.; Yuan, X.; Dong, S. Giant tridimensional power responses in a T-shaped magneto–mechano–electric energy harvester. Energ. Environ. Sci 2024, 17, 1426–1435. [Google Scholar] [CrossRef]

- Sriramdas, R.; Kang, M.G.; Meng, M.; Kiani, M.; Ryu, J.; Sanghadasa, M.; Priya, S. Large power amplification in magneto-mechano-electric harvesters through distributed forcing. Adv. Energy Mater. 2020, 10, 1903689. [Google Scholar] [CrossRef]

- Chu, Z.; Sun, Z.; Wang, B.; Song, K.; Wang, J.; Gao, J.; Dong, S. Significantly enhanced power generation from extremely low-intensity magnetic field via a clamped-clamped magneto-mechano-electric generator. Adv. Energy Mater. 2022, 12, 2103345. [Google Scholar] [CrossRef]

- Chang, J.; Gao, X.; Peng, W.; Yu, Z.; Chu, Z.; Gao, J.; Liu, M.; Ci, P.; Dong, S. A dragonfly-wing-like energy harvester with enhanced magneto-mechano-electric coupling. Device 2023, 1, 100021. [Google Scholar] [CrossRef]

- Liu, J.; He, Z.; Mi, C.; Sha, Y.; Zhu, X.; Hao, H.; Chen, L.; Zuo, L. Enhancement of magnetoelectric coupling in laminate composites of textured Fe–Ga thin sheet and PZT. AIP Adv. 2024, 14, 015339. [Google Scholar] [CrossRef]

- Praveen, J.P.; Monaji, V.R.; Chandrakala, E.; Indla, S.; Subramanian, V.; Das, D. Enhanced magnetoelectric coupling in Ti and Ce substituted lead free CFO-BCZT laminate composites. J. Alloys Compd. 2018, 750, 392–400. [Google Scholar] [CrossRef]

- Ryu, J.; Kang, J.-E.; Zhou, Y.; Choi, S.-Y.; Yoon, W.-H.; Park, D.-S.; Choi, J.-J.; Hahn, B.-D.; Ahn, C.-W.; Kim, J.-W. Ubiquitous magneto-mechano-electric generator. Energ. Environ. Sci 2015, 8, 2402–2408. [Google Scholar] [CrossRef]

- Li, Z.; Mei, H.; Wang, L. A power supply technology for a low-power online monitoring sensor based on electric field induction. Sensors 2019, 19, 2169. [Google Scholar] [CrossRef]

- Rodriguez, J.C.; Holmes, D.G.; Mcgrath, B.; Wilkinson, R.H. A self-triggered pulsed-mode flyback converter for electric-field energy harvesting. IEEE J. Emerg. Sel. Top. Power Electron. 2017, 6, 377–386. [Google Scholar] [CrossRef]

- Hu, D.; Wang, Q.; Zheng, D.; Huang, X.; Wu, Z.; Wang, F.; Xu, S.; Chen, S. Highly efficient harvesting of electric-field energy from Maxwell’s displacement current by managing charge transfer. Nano Energy 2024, 131, 110197. [Google Scholar] [CrossRef]

- Zangl, H.; Bretterklieber, T.; Brasseur, G. A feasibility study on autonomous online condition monitoring of high-voltage overhead power lines. IEEE Trans. Instrum. Meas. 2009, 58, 1789–1796. [Google Scholar] [CrossRef]

- Zeng, X.; Yang, Z.; Wu, P.; Cao, L.; Luo, Y. Power source based on electric field energy harvesting for monitoring devices of high-voltage transmission line. IEEE Trans. Ind. Electron. 2020, 68, 7083–7092. [Google Scholar] [CrossRef]

- Zhang, J.; Li, P.; Wen, Y.; Zhang, F.; Yang, C. A management circuit with upconversion oscillation technology for electric-field energy harvesting. IEEE T Power Electr. 2015, 31, 5515–5523. [Google Scholar] [CrossRef]

- Moghe, R.; Iyer, A.R.; Lambert, F.C.; Divan, D. A low-cost electric field energy harvester for an MV/HV asset-monitoring smart sensor. IEEE Trans. Ind. Appl. 2014, 51, 1828–1836. [Google Scholar] [CrossRef]

- Zhou, L.; Liu, H.; Zuo, K.; Shang, K. Energy harvesting technology for AC overhead insulated transmission line based on electric field induction. High Volt. 2024, 9, 816–825. [Google Scholar] [CrossRef]

- Kang, S.; Kim, J.; Yang, S.; Yun, T.; Kim, H. Electric field energy harvesting under actual three-phase 765 kv power transmission lines for wireless sensor node. Electron. Lett. 2017, 53, 1135–1136. [Google Scholar] [CrossRef]

- Hu, D.; Huang, X.; Zheng, D.; Wu, Z.; Ding, C.; Wang, F.; Xu, S.; Chen, S. Hybrid nanogenerator for harvesting electric-field and vibration energy simultaneously via Maxwell’s displacement current. Nano Energy 2024, 119, 109077. [Google Scholar] [CrossRef]

- Zhou, J.; Zhang, J.; Xu, C.; Fang, L.; Wang, Y.; Zhuang, Y.; Jia, T.; Huang, Y.; Han, C. On the improvement of electric field energy harvesting from domestic power lines. AEU-Int. J. Electron. Commun. 2022, 155, 154349. [Google Scholar] [CrossRef]

- Gulati, M.; Parizi, F.S.; Whitmire, E.; Gupta, S.; Ram, S.S.; Singh, A.; Patel, S.N. CapHarvester: A stick-on capacitive energy harvester using stray electric field from AC power lines. Proc. ACM Interact. Mob. Wearable Ubiquitous Technol. 2018, 2, 1–20. [Google Scholar] [CrossRef]

- Khan, M.R.; Islam, M.A.; Rana, M.M.; Haque, T.; Joy, S.I.I. A Circuit Model for Energy Harvesting from Fringing Electric Fields for Mobile Wearable Device Applications. Energies 2021, 14, 7016. [Google Scholar] [CrossRef]

- Menéndez, O.; Romero, L.; Cheein, F.A. Serial switch only rectifier as a power conditioning circuit for electric field energy harvesting. Energies 2020, 13, 5279. [Google Scholar] [CrossRef]

- Menéndez, O.; Kouro, S.; Pérez, M.; Cheein, F.A. Mechatronized maximum power point tracking for electric field energy harvesting sensor. AEU-Int. J. Electron. Commun. 2019, 110, 152830. [Google Scholar] [CrossRef]

- Ren, Z.; Wu, L.; Pang, Y.; Zhang, W.; Yang, R. Strategies for effectively harvesting wind energy based on triboelectric nanogenerators. Nano Energy 2022, 100, 107522. [Google Scholar] [CrossRef]

- Li, Y.; Huang, M.; Tang, T.; Mei, M.; Zhao, H.; Zha, F.; Sun, L.; Liu, H. A High-Power Non-Contact Magnetic Conversion-Enhanced Wind Energy Harvester for Self-Powered IoT Nodes and Real-Time Wind Speed Sensing. Nano Energy 2025, 143, 111293. [Google Scholar] [CrossRef]

- Wang, Y.; Yang, E.; Chen, T.; Wang, J.; Hu, Z.; Mi, J.; Pan, X.; Xu, M. A novel humidity resisting and wind direction adapting flag-type triboelectric nanogenerator for wind energy harvesting and speed sensing. Nano Energy 2020, 78, 105279. [Google Scholar] [CrossRef]

- Dai, S.; Li, X.; Jiang, C.; Zhang, Q.; Peng, B.; Ping, J.; Ying, Y. Omnidirectional wind energy harvester for self-powered agro-environmental information sensing. Nano Energy 2022, 91, 106686. [Google Scholar] [CrossRef]

- Zhao, C.; Hu, G.; Yang, Y. A cantilever-type vibro-impact triboelectric energy harvester for wind energy harvesting. Mech. Syst. Signal Process. 2022, 177, 109185. [Google Scholar] [CrossRef]

- Zhang, J.; Fang, Z.; Shu, C.; Zhang, J.; Zhang, Q.; Li, C. A rotational piezoelectric energy harvester for efficient wind energy harvesting. Sens. Actuat. A-Phys. 2017, 262, 123–129. [Google Scholar] [CrossRef]

- Zhao, L.; Zou, H.; Yan, G.; Liu, F.; Tan, T.; Zhang, W.; Peng, Z.; Meng, G. A water-proof magnetically coupled piezoelectric-electromagnetic hybrid wind energy harvester. Appl. Energy 2019, 239, 735–746. [Google Scholar] [CrossRef]

- Gao, S.; Feng, S.; Wang, J.; Wu, H.; Chen, Y.; Zhang, J.; Li, Y.; Wang, R.; Luo, X.; Wei, H. Hybridized triboelectric-electromagnetic aeolian vibration generator as a self-powered system for efficient vibration energy harvesting and vibration online monitoring of transmission lines. ACS Appl. Mater. Interfaces 2023, 15, 34764–34778. [Google Scholar] [CrossRef]

- Gao, S.; Zeng, X.; Zhang, G.; Zhang, J.; Chen, Y.; Feng, S.; Lan, W.; Zhou, J.; Wang, Z.L. Triboelectric–electromagnetic hybridized module for energy harvesting of power transmission lines galloping and self-powered galloping state monitoring. Nano Energy 2022, 101, 107530. [Google Scholar] [CrossRef]

- Gao, S.; Zeng, X.; Chen, X.; Liao, T.; Wang, R.; Chen, Y.; Wei, H.; Luo, X.; Feng, S. Self-powered system for environment and aeolian vibration monitoring in the high-voltage transmission system by multi-directional wind-driven triboelectric nanogenerator. Nano Energy 2023, 117, 108911. [Google Scholar] [CrossRef]

- Tang, X.; Hou, W.; Zheng, Q.; Fang, L.; Zhu, R.; Zheng, L. Self-powered wind sensor based on triboelectric nanogenerator for detecting breeze vibration on electric transmission lines. Nano Energy 2022, 99, 107412. [Google Scholar] [CrossRef]

- Zou, H.; Zhao, L.; Wang, Q.; Gao, Q.; Yan, G.; Wei, K.; Zhang, W. A self-regulation strategy for triboelectric nanogenerator and self-powered wind-speed sensor. Nano Energy 2022, 95, 106990. [Google Scholar] [CrossRef]

- Sun, W.; Liu, Y.; Ma, L.; Zhang, R. Research on life extension method of transmission line intelligent sensing system based on environmental energy harvesting. J. Sens. 2021, 2021, 5542285. [Google Scholar] [CrossRef]

- Guo, B.; Li, Q.; Jiang, W.; Lu, K.; Cheng, H. A Deep Sensing System for Monitoring the Health Status of Transmission Line Equipment Based on Self-Powered Sensors. IEEE Sens. J. 2023, 23, 20834–20844. [Google Scholar] [CrossRef]

- Prakoso, A.B.; Wang, J.; Lu, C.; Wang, H. PV-Tower solar cell for small footprint photovoltaic energy harvesting for the internet of things application. Semicond. Sci. Technol. 2020, 35, 125014. [Google Scholar] [CrossRef]

- De Bastiani, M.; Mirabelli, A.J.; Hou, Y.; Gota, F.; Aydin, E.; Allen, T.G.; Troughton, J.; Subbiah, A.S.; Isikgor, F.H.; Liu, J. Efficient bifacial monolithic perovskite/silicon tandem solar cells via bandgap engineering. Nat. Energy 2021, 6, 167–175. [Google Scholar] [CrossRef]

- Liu, C.; Jing, X. Vibration energy harvesting with a nonlinear structure. Nonlinear Dyn. 2016, 84, 2079–2098. [Google Scholar] [CrossRef]

- Du, Y.; Deng, J.; Li, P.; Wen, Y. Energy transfer and redistribution: An approach for unifying vibrational energy harvesting and vibration attenuation. Nano Energy 2020, 78, 105245. [Google Scholar] [CrossRef]

- Li, Y.; Tao, K.; George, B.; Tan, Z. Harvesting vibration energy: Technologies and challenges. IEEE Ind. Electron. Mag. 2020, 15, 30–39. [Google Scholar] [CrossRef]

- Yang, T.; Zhou, S.; Fang, S.; Qin, W.; Inman, D.J. Nonlinear vibration energy harvesting and vibration suppression technologies: Designs, analysis, and applications. Appl. Phys. Rev. 2021, 8, 031317. [Google Scholar] [CrossRef]

- Xiang, Z.; Zhang, J.; Li, S.; Xie, S.; Liu, F.; Zhu, R.; He, D. Friction-induced vibration energy harvesting via a piezoelectric cantilever vibration energy collector. Tribol. Int. 2023, 189, 108933. [Google Scholar] [CrossRef]

- Liu, Q.; Qin, W.; Yang, T.; Deng, W.; Zhou, Z. Harvesting weak vibration energy by amplified inertial force and super-harmonic vibration. Energy 2023, 263, 125948. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, G.; Wang, W. A piezoelectric cantilever-beam-spring-pendulum oscillator for multi-directional vibration energy harvesting. Commun. Nonlinear Sci 2024, 138, 108199. [Google Scholar] [CrossRef]

- Deng, H.; Du, Y.; Wang, Z.; Ye, J.; Zhang, J.; Ma, M.; Zhong, X. Poly-stable energy harvesting based on synergetic multistable vibration. Commun. Phys. 2019, 2, 21. [Google Scholar] [CrossRef]

- Su, X.; Tong, C.; Pang, H.; Tomovic, M. Research on pendulum-type tunable vibration energy harvesting. Energy 2023, 278, 127866. [Google Scholar] [CrossRef]

- Xu, J.; Tat, T.; Zhao, X.; Xiao, X.; Zhou, Y.; Yin, J.; Chen, K.; Chen, J. Spherical magnetoelastic generator for multidirectional vibration energy harvesting. ACS Nano 2023, 17, 3865–3872. [Google Scholar] [CrossRef]

- Wei, C.; Jing, X. A comprehensive review on vibration energy harvesting: Modelling and realization. Renew. Sustain. Energy Rev. 2017, 74, 1–18. [Google Scholar] [CrossRef]

- Wang, W.; Yin, N.; Wu, Z.; Zhang, Z. Omnidirectional energy harvesting with 3D-TENG for vibration diagnosis. Chem. Eng. J. 2025, 509, 161022. [Google Scholar] [CrossRef]

- Xu, X.; Wu, Q.; Pang, Y.; Cao, Y.; Fang, Y.; Huang, G.; Cao, C. Multifunctional metamaterials for energy harvesting and vibration control. Adv. Funct. Mater. 2022, 32, 2107896. [Google Scholar] [CrossRef]

- Wang, X.; Yin, G.; Sun, T.; Xu, X.; Rasool, G.; Abbas, K. Mechanical vibration energy harvesting and vibration monitoring based on triboelectric nanogenerators. Energy Technol. 2024, 12, 2300931. [Google Scholar] [CrossRef]

- Liu, Z.; Zhao, C.; Hu, G.; Yang, Y. A multi-degree-of-freedom triboelectric energy harvester for dual-frequency vibration energy harvesting. Mech. Syst. Signal Process. 2023, 188, 109951. [Google Scholar] [CrossRef]

- Lv, P.; Fan, C.; Yang, A.; Yuan, H.; Chu, J.; Rong, M.; Wang, X. Research on vibration energy harvesting technology of power equipment based on alternating magnet array. High Volt. 2024, 9, 336–345. [Google Scholar] [CrossRef]

- Wu, H.; Wang, J.; Wu, Z.; Kang, S.; Wei, X.; Wang, H.; Luo, H.; Yang, L.; Liao, R.; Wang, Z.L. Multi-parameter optimized triboelectric nanogenerator based self-powered sensor network for broadband aeolian vibration online-monitoring of transmission lines. Adv. Energy Mater. 2022, 12, 2103654. [Google Scholar] [CrossRef]

- Zhang, X.; Yu, Y.; Xia, X.; Zhang, W.; Cheng, X.; Li, H.; Wang, Z.L.; Cheng, T. Multi-Mode Vibrational Triboelectric Nanogenerator for Broadband Energy Harvesting and Utilization in Smart Transmission Lines. Adv. Energy Mater. 2023, 13, 2302353. [Google Scholar] [CrossRef]

- Wang, F.; Zhou, M.; Wu, P.; Gao, L.; Chen, X.; Mu, X. Self-powered transformer intelligent wireless temperature monitoring system based on an ultra-low acceleration piezoelectric vibration energy harvester. Nano Energy 2023, 114, 108662. [Google Scholar] [CrossRef]

- Gu, S.; Xu, W.; Xi, K.; Luo, A.; Fan, K.; Wang, F. High-performance piezoelectric energy harvesting system with anti-interference capability for smart grid monitoring. Renew. Energy 2024, 221, 119742. [Google Scholar] [CrossRef]

- Nie, X.; Tan, T.; Yan, Z.; Yan, Z.; Zhang, W. Ultra-wideband piezoelectric energy harvester based on Stockbridge damper and its application in smart grid. Appl. Energy 2020, 267, 114898. [Google Scholar] [CrossRef]

- Hao, Z.; Liu, C.; Shao, T.; Ma, Z.; Lu, Y.; Wang, Y.; Sui, Z. Self-Powered Vibration Frequency Monitoring Device for the Grid Based on Triboelectric Nanogenerator and Micro Thermoelectric Generator. Adv. Sustain. Syst. 2024, 8, 2300561. [Google Scholar] [CrossRef]

- Huang, X.; Hu, D.; Wang, Q.; Wu, Z.; Wang, N.; Chen, Z.; Xu, S.; Chi, M.; Chen, S. Hybrid Nanogenerator Harvesting Electric-Field and Wind Energy for Self-Powered Sensors on High-Voltage Transmission Lines. Adv. Funct. Mater. 2025, 35, 2417400. [Google Scholar] [CrossRef]

- Feng, X.; Hao, Z.; Shao, T.; Ma, Z.; Lu, Y.; Wang, Y.; Liu, C. A hybrid energy harvesting approach for transmission lines based on triboelectric nanogenerator and micro thermoelectric generator. Nanotechnology 2024, 35, 345401. [Google Scholar] [CrossRef]

- Lu, Y.; Liu, C.; Wang, Y.; Hao, Z.; Chen, C.; Dong, B.; Zhou, X. A self-powered ice growth sensing system for transmission lines based on a triboelectric nanogenerator and a micro thermoelectric generator. Nanoscale 2025, 17, 11547–11563. [Google Scholar] [CrossRef]

- Wang, Q.; Hu, D.; Huang, X.; Chen, Z.; Yuan, Z.; Zhong, L.; Sun, Q.; Wang, F.; Xu, S.; Chen, S. Hybrid Triboelectric-Electromagnetic-Electric Field Energy Harvester for Simultaneous Wind and Electric Field Energy Capture in High-Voltage Transmission System. Adv. Energy Mater. 2025, 15, 2403931. [Google Scholar] [CrossRef]

- Ryu, H.; Yoon, H.-J.; Kim, S.-W. Energy harvesters: Hybrid energy harvesters: Toward sustainable energy harvesting. Adv. Mater. 2019, 31, 1970244. [Google Scholar] [CrossRef]

- Egbe, K.-J.I.; Nazar, A.M.; Jiao, P. Piezoelectric-triboelectric-electromagnetic hybrid rotational energy harvesters (H-REH). Int. J. Mech. Sci. 2022, 235, 107722. [Google Scholar] [CrossRef]

- He, L.; Han, Y.; Sun, L.; Wang, H.; Zhang, Z.; Cheng, G. A rotating piezoelectric-electromagnetic hybrid harvester for water flow energy. Energy Convers. Manag. 2023, 290, 117221. [Google Scholar] [CrossRef]

- Zhu, Y.; Zhang, Z.; Zhang, P.; Tan, Y. A magnetically coupled piezoelectric–electromagnetic low-frequency multidirection hybrid energy harvester. Micromachines 2022, 13, 761. [Google Scholar] [CrossRef]

- Tang, G.; Wang, Z.; Hu, X.; Wu, S.; Xu, B.; Li, Z.; Yan, X.; Xu, F.; Yuan, D.; Li, P. A non-resonant piezoelectric–electromagnetic–triboelectric hybrid energy harvester for low-frequency human motions. Nanomaterials 2022, 12, 1168. [Google Scholar] [CrossRef]

- Gao, S.; Wei, H.; Wang, J.; Luo, X.; Wang, R.; Chen, Y.; Xiang, M.; Chen, X.; Xie, H.; Feng, S. Self-powered system by a suspension structure-based triboelectric-electromagnetic-piezoelectric hybrid generator for unifying wind energy and vibration harvesting with vibration attenuation function. Nano Energy 2024, 122, 109323. [Google Scholar] [CrossRef]

- Zhao, J.; Han, L.; Xu, Z.; Zhang, Y.; Li, X.; Pei, Y.; Zheng, R.; Yu, X.; Jiang, C. Self-powered sensor for monitoring wind vibration on transmission lines based on an electromagnetic-triboelectric hybrid generator. Sustain. Energ. Fuels 2023, 7, 5147–5155. [Google Scholar] [CrossRef]

- Gao, S.; Luo, X.; Wei, H.; Wang, R.; Chen, X.; Zhang, J. Wind-driven suspended triboelectric-electromagnetic hybrid generator with vibration elimination for environmental monitoring in the high-voltage power transmission line. Nano Energy 2024, 128, 109831. [Google Scholar] [CrossRef]

- Zhu, Q.; Zhu, L.; Wang, Z.; Zhang, X.; Li, Q.; Han, Q.; Yang, Z.; Qin, Z. Hybrid triboelectric-piezoelectric nanogenerator assisted intelligent condition monitoring for aero-engine pipeline system. Chem. Eng. J. 2025, 519, 165121. [Google Scholar] [CrossRef]

- Yang, F.; Du, L.; Chen, W.; Li, J.; Wang, Y.; Wang, D. Hybrid energy harvesting for condition monitoring sensors in power grids. Energy 2017, 118, 435–445. [Google Scholar] [CrossRef]

- Zhou, K.; Wang, X.; Wang, L.; Duan, C.; Zhang, Y.; Zhao, L.; Maeda, R. Self-powered wireless sensing system with cylindrical high voltage side electric field energy harvesting by discharge circuit. Sens. Actuat. A-Phys. 2024, 380, 116047. [Google Scholar] [CrossRef]

- Cetinkaya, O.; Akan, O.B. Electric-Field Energy Harvesting in Wireless Networks. IEEE Wirel. Commun. 2017, 24, 34–41. [Google Scholar] [CrossRef]

- Riba, J.-R.; Moreno-Eguilaz, M.; Bogarra, S. Energy Harvesting Methods for Transmission Lines: A Comprehensive Review. Appl. Sci. 2022, 12, 10699. [Google Scholar] [CrossRef]

- Li, M.; Luo, A.; Luo, W.; Liu, X.; Wang, F. Electrostatic Vibration Energy Harvester With a Self-Rechargeable Electret. IEEE Electron. Device Lett. 2023, 44, 540–543. [Google Scholar] [CrossRef]

| Energy Form | Capture Mechanism |

|---|---|

| Magnetic Field Energy | Electromagnetic induction Magnetostriction material Machine construction |

| Electric Field Energy | High-potential region electrode Low-potential region electrode |

| Wind Energy | Electromagnetic induction Piezoelectric Triboelectric nanogenerator Multi-mechanism coupling |

| Solar Energy | Photovoltaic Technology |

| Vibration Energy | Piezoelectric Electromagnetic Triboelectric |

| Multi-energy Composite | Triboelectric–thermoelectric Triboelectric–electrostatic |

| Type | Frequency Range | Magnetic Field Strength/Conductor Current | Output Power | Power Density | Document |

|---|---|---|---|---|---|

| Standalone magnetic field energy harvesting | 50 Hz | 18 μT | 0.3 mW | 0.15 μW/cm3 | [39] |

| 50 Hz | 900 A | 116 mW | \ | [40] | |

| 50 Hz | 11 μT | 146.7 mW | 103 μW/cm3 | [38] | |

| 10 Hz–1 K Hz | 30 A | 0.36 mW | 106 μW/cm3 (36 μW/g) | [36] | |

| 50 Hz | 6.5 μT | 4.5 mW | 7.28 μW/cm3 | [37] | |

| 50 Hz | 100 A–800 A | 3.67 mW | 48.9 μW/cm3 | [41] | |

| Air-gap-free annular magnetic core | 60 Hz | 21.2 μT | 6.32 mW | 1.47μW/cm3 | [42] |

| 50 Hz | 10 A | 283 mW | 2.34 mW/cm3 | [32] | |

| 50 Hz | 8.3 A | 16.8 mW | \ | [31] | |

| 50 Hz | 60 A 600 A | 1.5 W 19.89 W | 1.04 W/cm3 | [43] | |

| Air-gap annular magnetic core | 50 Hz | 10 A | 63.72 mW | 22.01 mW/cm3 | [44] |

| 50–60 Hz | 909 A | \ | 0.68 mW/cm3 | [33] | |

| 60 Hz | 615 A | 55 W | 100.2 mW/cm3 | [34] | |

| 50 Hz | 78.6 mT | 32.78 mW | \ | [35] |

| Structure | Piezoelectric/Magnetostriction Material | Maximum Output Voltage | Maximum Output Power/ Power Density | Frequency of Collection | Document |

|---|---|---|---|---|---|

| Cantilever beam stacking structure | PZT-5H Ni | 40.3 V (1.8 Hz) | 0.87 mW | 50 Hz | [46] |

| Tuning fork structure | PZT-5H ST | 100 V (VPP) | 72 mW | 60 Hz | [47] |

| Cantilever beam laminated structure | PMN-PZT Metglas | 36.5 V (100 Hz 0.02 g) | 1.25 mW | 60 Hz | [53] |

| Clamp cantilever beam structure | PZT Copper | 1.775 V | 970 μW | 50 Hz | [54] |

| Imitating dragonfly structure | PZT TC4 | 45.5 V (VPP) | 4.45 mW | 50.5 Hz | [55] |

| - | PZT-5H Fe-Ga | 4.58 V | 897 μW | 50 Hz | [56] |

| - | CoFe2O4 NiFe2O4 | 12.2 V | 243 μW/m2 | 50 Hz | [48] |

| - | CTFO-BCZCT-CTFO | 800 mV/(cm Oe) | - | 954 Hz | [57] |

| - | PMN-PZT Ni | 9.52 V(Vpp) | 46.3 mW cm−3 Oe−2 | 60 Hz | [58] |

| - | Fe52–Co48 alloys | 150 mV | 34.0 µW·cm−3 | 293 Hz | [49] |

| Type | Voltage Level | Average Power | μW/μA | Document |

|---|---|---|---|---|

| High-potential energy harvesting technology | 150 kV | 370 mW | 413 μW/μA | [62] |

| 110 kV | 124 mW | 620 μW/μA | [63] | |

| 10 kV | 110 mW | 3.26 μW/μA | [64] | |

| 35 kV | 17 mW | \ | [65] | |

| 12.7 kV | 23.6 mW | 138.8 μW/μA | [60] | |

| 50 kV | 340 mW | 18.38 μW/μA | [59] | |

| 10 kV | 30.7 mW | 5.54μW/μA | [66] | |

| Low-potential energy harvesting technology | 765 kV | 0.17 mW | \ | [67] |

| 110 kV | 0.26 mW | 25.4 μW/μA | [68] | |

| 230 V | 367.5 μW | 105 μW/μA | [69] | |

| 110 V/230 V | 0.11–1.09 μW | \ | [70] | |

| 120 V | 2–2.5 µW | \ | [71] | |

| 230 V | 21.42 μW | 25 μW/μA | [72] | |

| 220 V | 0.6 μW | \ | [73] | |

| 110 kV | 48.3 mW | 956 μW/μA | [61] |

| Type | Strengths | Weaknesses |

|---|---|---|

| Magnetic field energy harvesting technology |

|

|

| Electric Field Energy Harvesting Technology |

|

|

| Wind Energy Harvesting Technology |

|

|

| Solar Energy Harvesting Technology |

|

|

| Vibration Energy Harvesting Technology |

|

|

| Type | Power Density | Applicable Environmental Parameters | Usage Scenarios | Document |

|---|---|---|---|---|

| Magnetic Field Energy Harvesting Technology | 1–200 mW/cm3 | 10–1000 Hz (frequency of magnetic field variation) |

| [38,39,47] |

| Electric Field Energy Harvesting Technology | 100–1000 μW/μA | 10–1000 kV (transmission line voltage) |

| [61,62,63] |

| Wind Energy Harvesting Technology | 10–200 mW/cm3 | 10–20 m/s (wind speed) |

| [83,84,85] |

| Solar Energy Harvesting Technology | <100 mW/cm2 | AM1.5 G |

| [86,88,89,127] |

| Vibration Energy Harvesting Technology | 10–200 μW/cm3 | 10–100 Hz (vibration frequency) |

| [105,107,108,128] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Du, H.; Lu, J.; Zhang, W.; Yang, G.; Zhang, W.; Xu, Z.; Wang, H.; Dai, K.; Gao, L. Advancements and Future Prospects of Energy Harvesting Technology in Power Systems. Micromachines 2025, 16, 964. https://doi.org/10.3390/mi16080964

Du H, Lu J, Zhang W, Yang G, Zhang W, Xu Z, Wang H, Dai K, Gao L. Advancements and Future Prospects of Energy Harvesting Technology in Power Systems. Micromachines. 2025; 16(8):964. https://doi.org/10.3390/mi16080964

Chicago/Turabian StyleDu, Haojie, Jiajing Lu, Wenye Zhang, Guang Yang, Wenzhuo Zhang, Zejun Xu, Huifeng Wang, Kejie Dai, and Lingxiao Gao. 2025. "Advancements and Future Prospects of Energy Harvesting Technology in Power Systems" Micromachines 16, no. 8: 964. https://doi.org/10.3390/mi16080964

APA StyleDu, H., Lu, J., Zhang, W., Yang, G., Zhang, W., Xu, Z., Wang, H., Dai, K., & Gao, L. (2025). Advancements and Future Prospects of Energy Harvesting Technology in Power Systems. Micromachines, 16(8), 964. https://doi.org/10.3390/mi16080964