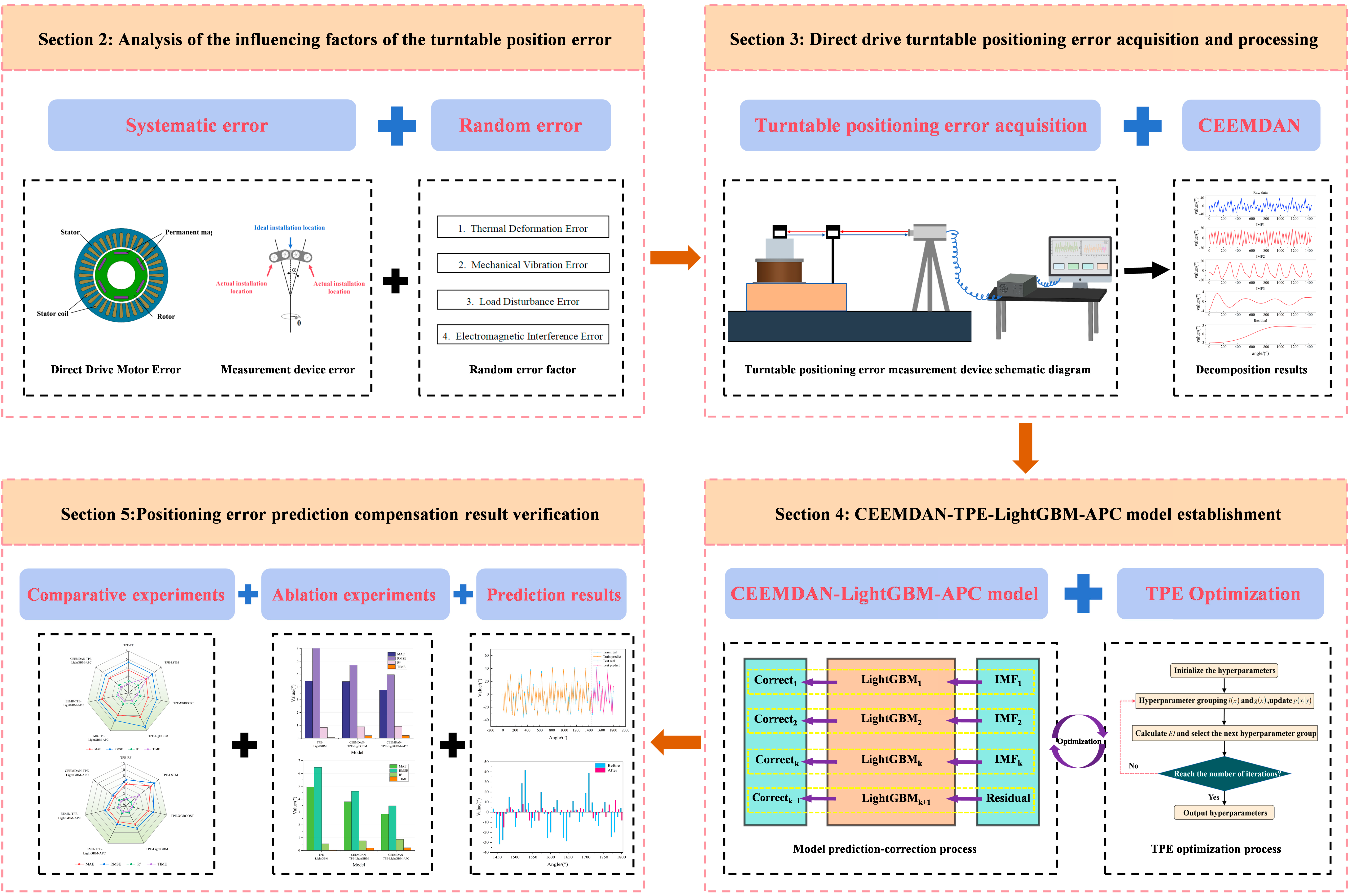

Dynamic Error Modeling and Predictive Compensation for Direct-Drive Turntables Based on CEEMDAN-TPE-LightGBM-APC Algorithm

Abstract

1. Introduction

2. Materials and Methods

2.1. Direct-Drive Turntable Positioning Error Mechanism Analysis

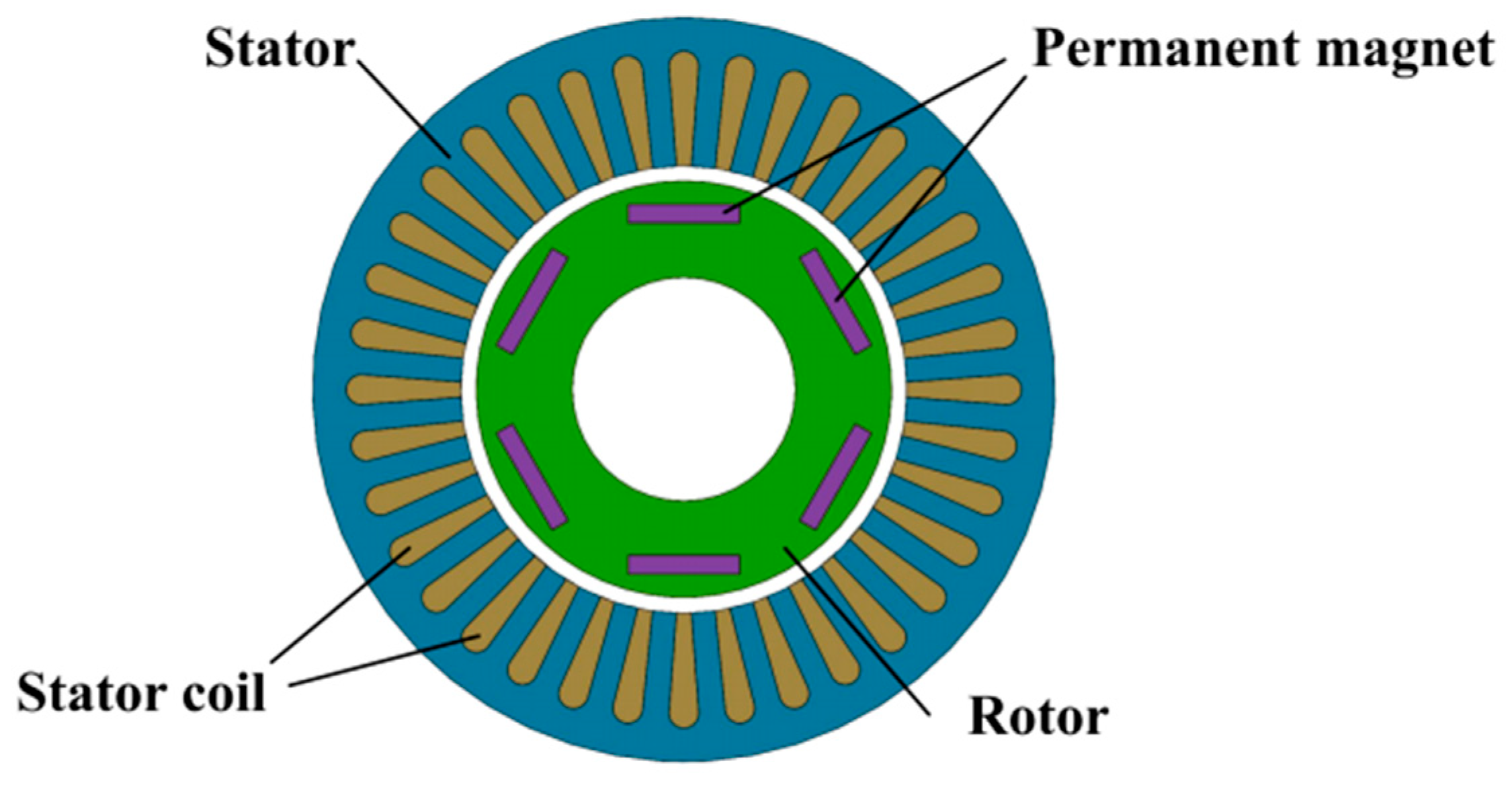

2.2. Direct-Drive Motor Positioning Error Factor Analysis

2.2.1. Direct-Drive Motor Structure

2.2.2. Analysis of Motor Torque Fluctuation

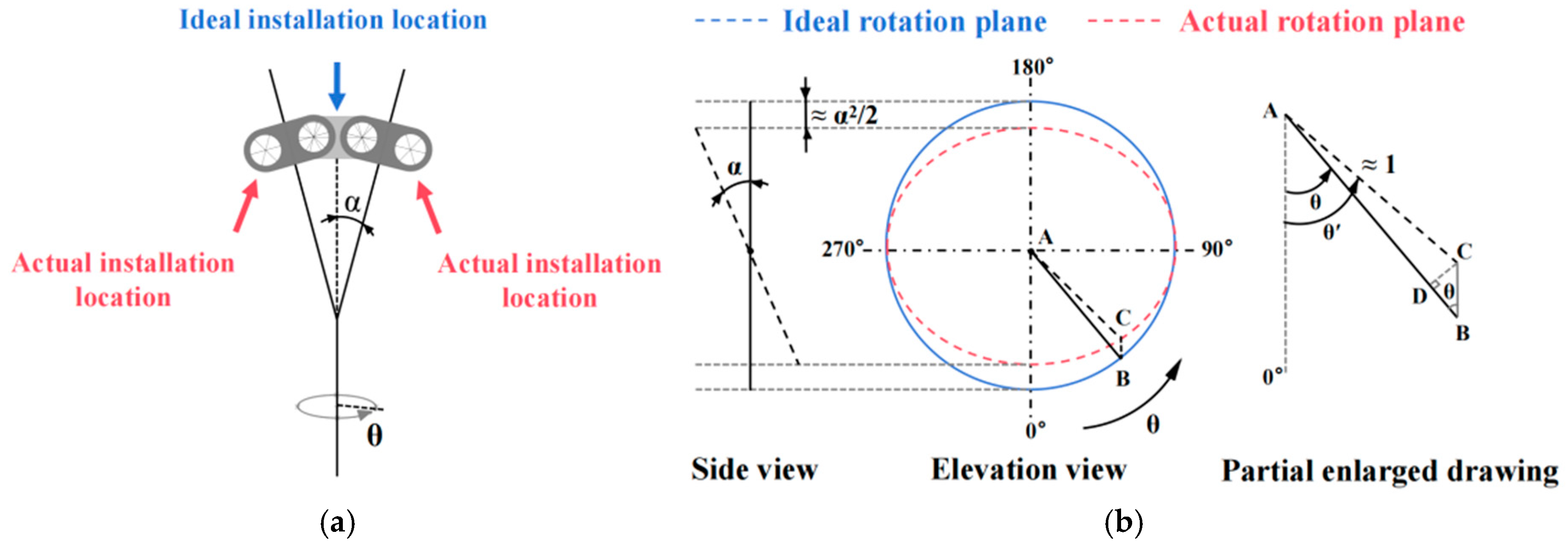

2.3. Measurement Device Installation Error Analysis

2.4. Random Error Factor Analysis

2.5. Algorithm Principle and Model Construction

2.5.1. CEEMDAN Decomposition and Reconstruction

2.5.2. LightGBM Algorithm

2.5.3. TPE Algorithm

2.5.4. Adaptive Prediction Correction Strategy

- (1)

- Define dynamic scaler

- (2)

- Predictive outlier detection

- (3)

- Corrective treatment of outliers

- (1)

- Inverse proportional design of the scaling factor: , which achieves an adaptive balance between error fluctuation and sensitivity.

- (2)

- EWMA-based smoothing correction: Effectively mitigates short-term anomaly effects while preserving long-term trends, thus preventing trajectory deviation caused by isolated anomalies.

- (3)

- Closed-loop feedback mechanism: Continuous optimization of parameters through error updating, forming a closed-loop self-adjusting prediction system of “prediction-correction-feedback”, so that the model continuously adapts to time-varying factors such as wear and tear of the equipment and temperature drift of the environment in long-term operation.

2.5.5. CEEMDAN-TPE-LightGBM-APC Fusion Modeling

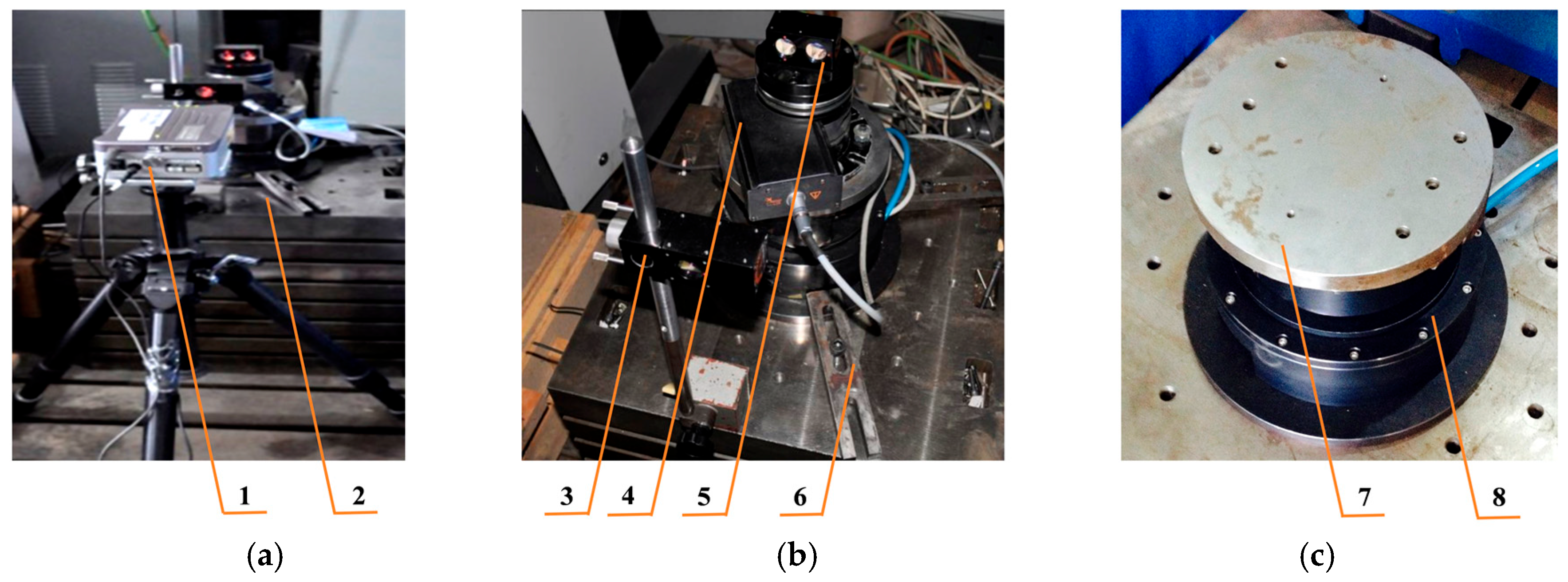

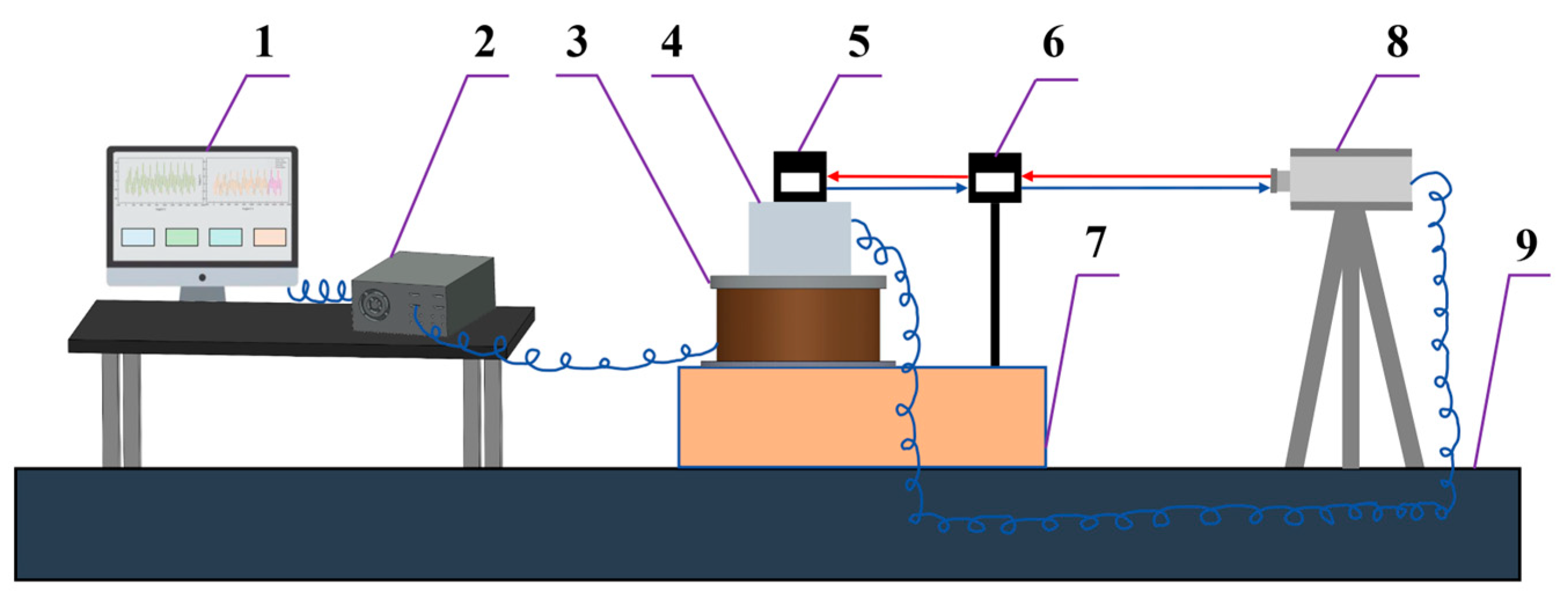

2.6. Positioning Error Experiment and Data Description

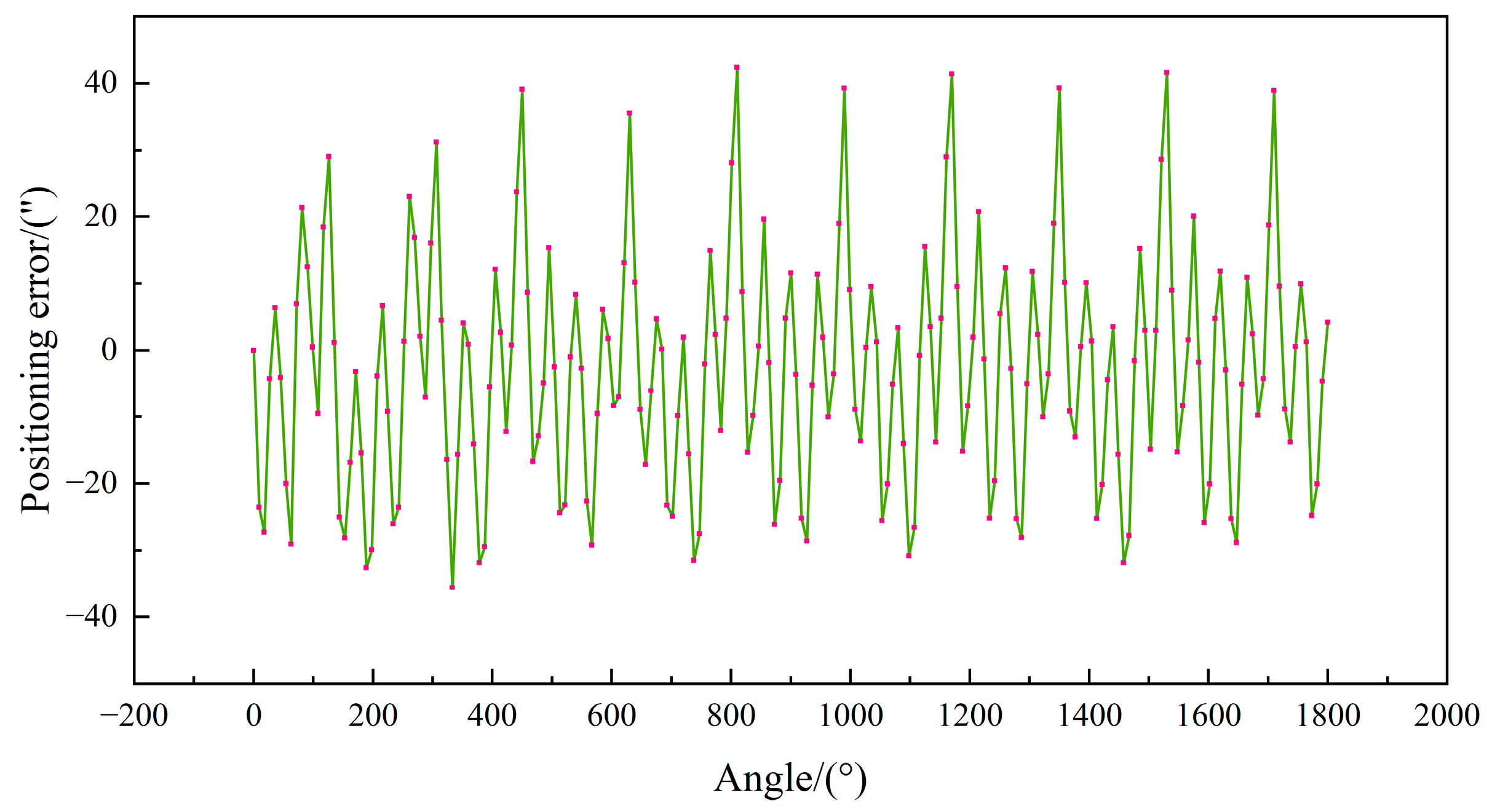

2.6.1. Positioning Error Measurement and Data Description

2.6.2. Dataset Construction and Partitioning

2.6.3. Indicators for Model Evaluation

3. Results

3.1. CEEMDAN Decomposition Results

3.2. Hyperparameter Optimization

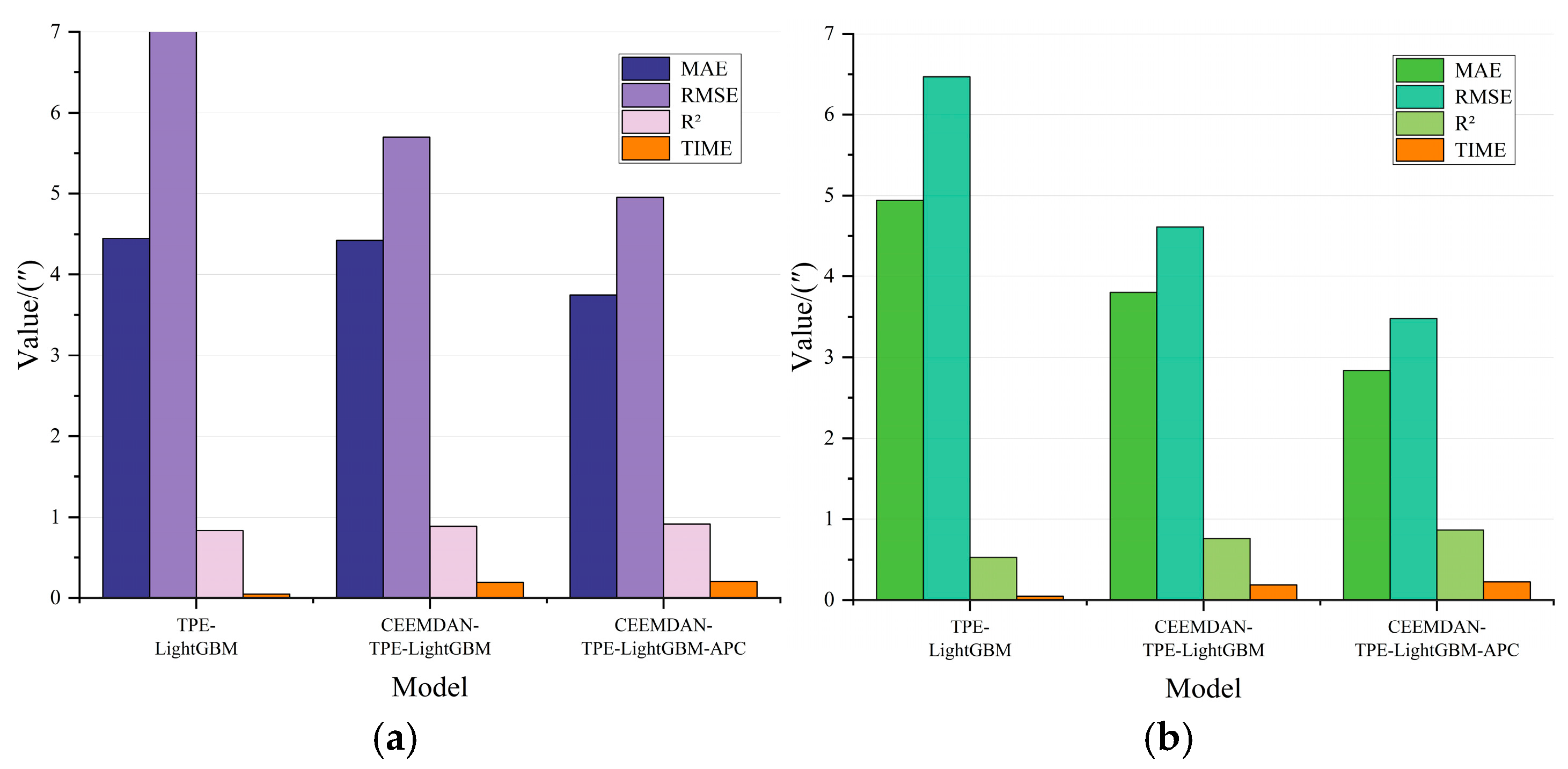

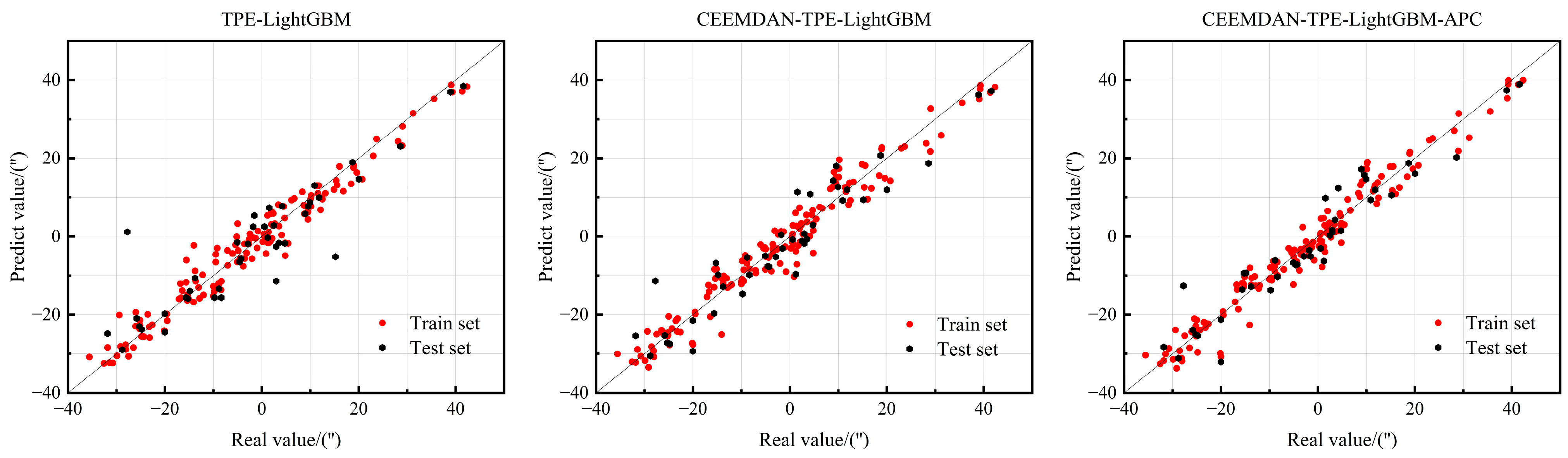

3.3. Model Ablation Experiment

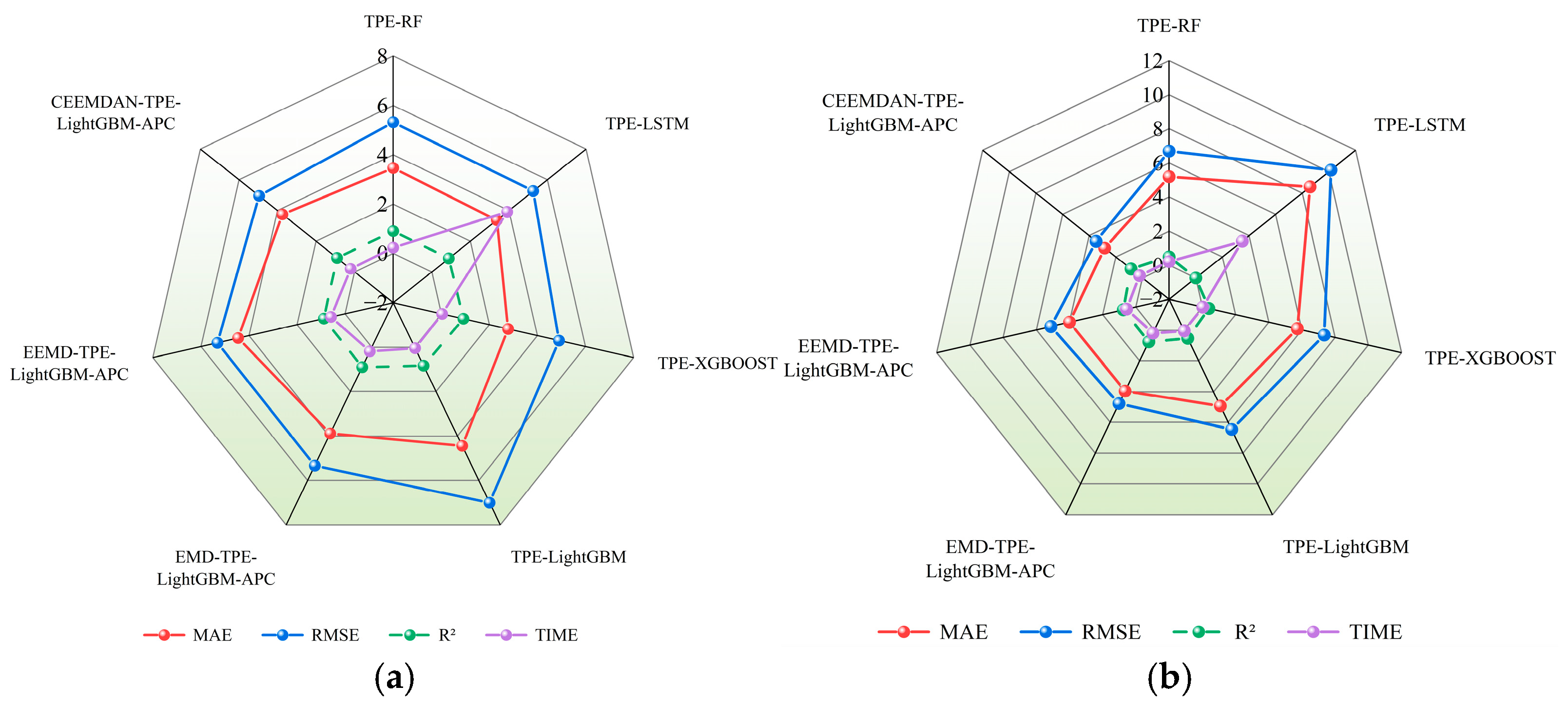

3.4. Model Comparison Experiments

3.5. Overall Model Prediction Results

4. Discussion

- (1)

- In the model ablation experiment, the effectiveness of TPE hyperparameter optimization, CEEMDAN signal decomposition, and APC adaptive prediction correction module is verified, respectively, and the overall prediction performance of the model is gradually improved.

- (2)

- In the model comparison experiments, six mainstream prediction and decomposition algorithms, namely, TPE-RF, TPE-LSTM, TPE-XGBOOST, TPE-LightGBM, EMD-TPE-LightGBM-APC, and EEMD-TPE-LightGBM-APC, are used to compare with the proposed model of this study, and verify the model of this study in terms of effectiveness and superiority in the application of turntable error prediction and compensation.

- (3)

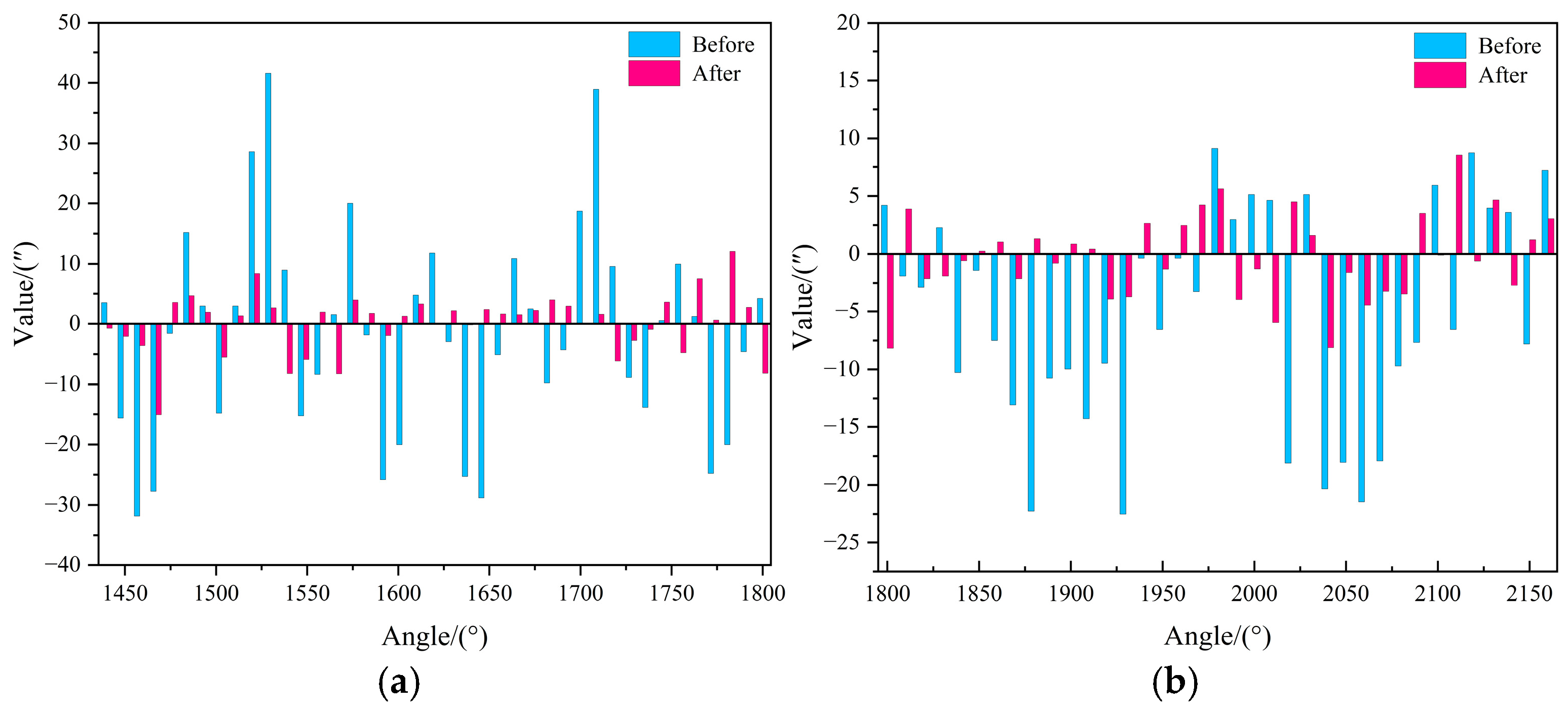

- Comparison of the effect before and after model prediction and compensation as shown in Table 4, after the model prediction and compensation of localization error, the localization accuracy is significantly improved, and the range of localization error on the test set (9° interval) is reduced from [−31.83″, 41.59″] to [−15.09″, 12.07″], and the standard deviation is reduced from 17.16″ to 4.95″, which is a decrease of 71.2%; Meanwhile, the range of turntable positioning error on the extrapolated test set (10° interval) is reduced from [−22.50″, 9.15″] to [−8.15″, 8.56″], and the standard deviation is reduced from 9.44″ to 3.68″, with a reduction of 61.0%, which proves the validity and reasonableness of the predictive compensation of turntable positioning error.

- (4)

- Compared with other studies, this study achieved a higher degree of error compensation, as shown in Table 5. This error compensation method has a better error compensation effect.

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Liu, W.; Li, F.; Jing, C.; Wan, Y.; Wang, X.; Helali, M. Research on torque fluctuation suppression method of linear motor based on magnetic field orientation control. Trans. Emerg. Telecommun. Technol. 2020, 31, e3916. [Google Scholar] [CrossRef]

- Bichan, M.; Jaen-Sola, P.; Gonzalez-Delgado, D.; Oterkus, E. On the Integrity of Large-Scale Direct-Drive Wind Turbine Electrical Generator Structures: An Integrated Design Methodology for Optimisation, Considering Thermal Loads and Novel Techniques. Machines 2024, 12, 277. [Google Scholar] [CrossRef]

- Zhang, X.; Cheng, Y.; Zhao, Z.; He, Y. Robust model predictive direct speed control for SPMSM drives based on full parameter disturbances and load observer. IEEE Trans. Power Electron. 2019, 35, 8361–8373. [Google Scholar] [CrossRef]

- Choi, B.K.; Kim, M.S.; Cho, S.Y.; Ahn, S.; Kim, J.S.; Yoo, J.; Jeon, M.Y. Compensation of Scanning Speed Instability in a Wavelength-Swept Laser for Dynamic Fiber Optic Sensors. IEEE Sens. J. 2024, 25, 2784–2790. [Google Scholar] [CrossRef]

- Ahmad, I.; Ikram, J.; Yousuf, M.; Badar, R.; Bukhari, S.S.H.; Ro, J.-S. Performance improvement of multi-rotor axial flux vernier permanent magnet machine by permanent magnet shaping. IEEE Access 2021, 9, 143188–143197. [Google Scholar] [CrossRef]

- Hassan, M.; Ge, X.; Woldegiorgis, A.T.; Mastoi, M.S.; Atif, R.; Shaikh, M.S.; Kumar, S. A look-up table-based model predictive torque control of IPMSM drives with duty cycle optimization. ISA Trans. 2023, 138, 670–686. [Google Scholar] [CrossRef]

- Zhang, S.; Zou, H.; Tang, M.; Kong, F.; Shao, W.; Hu, Z. Study on the friction characteristics of a self-lubricating linear compressor using vapor injection. Int. J. Refrig. 2025, 169, 294–307. [Google Scholar] [CrossRef]

- Yu, Y.; Dai, L.; Chen, M.-S.; Kong, L.-B.; Wang, C.-Q.; Xue, Z.-P. Calibration, compensation and accuracy analysis of circular grating used in single gimbal control moment gyroscope. Sensors 2020, 20, 1458. [Google Scholar] [CrossRef]

- Zhao, C.; Wan, Q.; Liang, L. Automatic compensation system for small absolute optical encoders. IEEE Sens. J. 2024, 24, 29778–29785. [Google Scholar] [CrossRef]

- Li, Y.-X.; Ren, S.-Q.; Liu, Q.-B.; Wang, C.-H. Error mechanism analysis and accuracy enhancement method for circular gratings angle-measuring system. Sens. Actuators A Phys. 2024, 370, 115227. [Google Scholar] [CrossRef]

- Lemma, B.D.; Pradabane, S. Control of PMSM drive using lookup table based compensated duty ratio optimized direct torque control (DTC). IEEE Access 2023, 11, 19863–19875. [Google Scholar] [CrossRef]

- Zhou, Y.; Zhu, W.; Shu, Y.; Huang, Y.; Zou, W.; Xue, Z. Analysis and application of real-time compensation of positioning precision of the turntable with a harmonic function. Metrol. Meas. Syst. 2022, 29, 553–571. [Google Scholar] [CrossRef]

- Zuo, Y.; Guo, L.; Liu, W.; Ding, J. Position error detection and compensation for far-field radar cross-section measurement. IEEE Antennas Wirel. Propag. Lett. 2021, 20, 1518–1522. [Google Scholar] [CrossRef]

- Wang, T.; Shi, J.; Sun, J.; Zhang, S. Position error decomposition and prediction of CNC machine tool under thermal–mechanical coupling loads. Int. J. Adv. Manuf. Technol. 2025, 137, 199–216. [Google Scholar] [CrossRef]

- Gao, Y.; Xu, J.; Zhao, Q.; Fang, L.; Cao, X. A calibration method for predicting and compensating the flexible positioning errors of a 7-DOF series compliant robot caused by end-effector’s gravity. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2024, 238, 2930–2953. [Google Scholar] [CrossRef]

- Han, Y.; Ma, H.; Wang, Y.; Shi, D.; Feng, Y.; Li, X.; Shi, Y.; Ding, X.; Zhang, W. Neural Network Robust Control Based on Computed Torque for Lower Limb Exoskeleton. Chin. J. Mech. Eng. 2024, 37, 37. [Google Scholar] [CrossRef]

- Ma, M.Y.; Huang, Y.C.; Wu, Y.T. A Morphing Point-to-Point Displacement Control Based on Long Short-Term Memory for a Coplanar XXY Stage. Sensors 2023, 23, 1938. [Google Scholar] [CrossRef]

- Dai, S.; Song, K.-F.; Wang, Y.-L.; Zhang, P.-J. Two-Dimensional Space Turntable Pitch Axis Trajectory Prediction Method Based on Sun Vector and CNN-LSTM Model. Appl. Sci. 2023, 13, 4939. [Google Scholar] [CrossRef]

- Xu, Q.; Ju, W.; Lin, Y.; Zhang, T. Research on Positioning Error Compensation of Rock Drilling Manipulator Based on ISBOA-BP Neural Network. Appl. Sci. 2024, 14, 8480. [Google Scholar] [CrossRef]

- Gui, H.; Liu, J.; Ma, C.; Li, M.; Wang, S. Mist-edge-fog-cloud computing system for geometric and thermal error prediction and compensation of worm gear machine tools based on ONT-GCN spatial–temporal model. Mech. Syst. Signal Process. 2023, 184, 109682. [Google Scholar] [CrossRef]

- Wu, C.Y.; Xiang, S.T.; Xiang, W.S. Thermal error modeling of rotary axis based on convolutional neural network. J. Manuf. Sci. Eng. 2021, 143, 051013. [Google Scholar]

- Gao, X.; Zhang, K.; Zhang, Z.; Wang, M.; Zan, T.; Gao, P. XGBoost-based thermal error prediction and compensation of ball screws. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2024, 238, 151–163. [Google Scholar] [CrossRef]

- Li, B.; Chen, G.; Si, Y.; Zhou, X.; Li, P.; Li, P.; Fadiji, T. GNSS/INS integration based on machine learning LightGBM model for vehicle navigation. Appl. Sci. 2022, 12, 5565. [Google Scholar] [CrossRef]

- Xie, F.; Zhang, W.; Shen, M.; Zhang, J. Multi-condition dynamic model control strategy of the direct drive motor of electric vehicles based on PIO–LightGBM algorithm. J. Power Electron. 2023, 23, 499–509. [Google Scholar] [CrossRef]

- Park, S.; Jung, S.; Jung, S.; Rho, S.; Hwang, E. Sliding window-based LightGBM model for electric load forecasting using anomaly repair. J. Supercomput. 2021, 77, 12857–12878. [Google Scholar] [CrossRef]

- Rui, Y.; Gong, Y.; Zhao, Y.; Luo, K.; Lu, W. Predicting Traffic Flow Parameters for Sustainable Highway Management: An Attention-Based EMD–BiLSTM Approach. Sustainability 2023, 16, 190. [Google Scholar] [CrossRef]

- Li, Y.; Ye, Y.; Xu, Y.; Li, L.; Chen, X.; Huang, J. Two-stage forecasting of TCN-GRU short-term load considering error compensation and real-time decomposition. Earth Sci. Inform. 2024, 17, 5347–5357. [Google Scholar] [CrossRef]

- Gu, A.; Wang, Z.; Yin, Z.; Zhou, M.; Li, S.; Xun, Q.; Dong, J. Empirical research for investment model based on VMD-LSTM. Math. Probl. Eng. 2022, 2022, 4185974. [Google Scholar] [CrossRef]

- Shen, K.; Zhao, D. An EMD-LSTM deep learning method for aircraft hydraulic system fault diagnosis under different environmental noises. Aerospace 2023, 10, 55. [Google Scholar] [CrossRef]

- Kartal, E.; Altunkaynak, A. Empirical-singular-wavelet based machine learning models for sea level forecasting in the bosphorus strait: A performance analysis. Ocean Model. 2024, 188, 102324. [Google Scholar] [CrossRef]

- Ahmadi, H.; Mastouri, R.; Jafarinia, R. On the capability of preprocessing techniques for suspended sediment load prediction using artificial intelligence methods. Hydrol. Sci. J. 2022, 67, 369–384. [Google Scholar] [CrossRef]

- Li, Z.; Chen, Z. Short-term load forecasting based on CEEMDAN-FE-ISSA-LightGBM model. Front. Energy Res. 2023, 11, 1111786. [Google Scholar] [CrossRef]

- Bucinskas, V.; Dzedzickis, A.; Sumanas, M.; Sutinys, E.; Petkevicius, S.; Butkiene, J.; Virzonis, D.; Morkvenaite-Vilkonciene, I. Improving industrial robot positioning accuracy to the microscale using machine learning method. Machines 2022, 10, 940. [Google Scholar] [CrossRef]

- Liu, Q.; Lu, H.; Yonezawa, H.; Yonezawa, A.; Kajiwara, I.; Jiang, T.; He, J. Geometric and dynamic error compensation of dual-drive machine tool based on mechanism-data hybrid method. Mech. Syst. Signal Process. 2025, 224, 112041. [Google Scholar] [CrossRef]

- Guan, Y.; Yang, J.; Tan, S.; Ding, H. A data-driven rolling optimization method for trajectory tracking error prediction of CNC machine tools. Sci. China Technol. Sci. 2025, 68, 1120301. [Google Scholar] [CrossRef]

- Liu, M.; Bao, R.; Li, S.; Yan, X.; Li, W. A Coupling Error Compensation Approach Concerning Constrained Space Coordinate Precision of a Heavy-Load Longitudinal and Transversal Swing Table. Appl. Sci. 2025, 15, 4693. [Google Scholar] [CrossRef]

- Liu, H.; Guo, Y.; Liu, J.; Niu, W. Dynamic Error Compensation for Ball Screw Feed Drive Systems Based on Prediction Model. Machines 2025, 13, 433. [Google Scholar] [CrossRef]

| Parameter Name | Search Scope | Final Parameter |

|---|---|---|

| learning_rate | 0.01~0.2 | 0.189 |

| max_depth | 1~5 | 4 |

| num_leaves | 20~100 | 83 |

| feature_fraction | 0.5~1 | 0.772 |

| bagging_fraction | 0.5~1 | 0.849 |

| bagging_freq | 1~5 | 2 |

| reg_alpha | 0~1 | 0.958 |

| reg_lambda | 0~1 | 0.532 |

| Model | Performance Metrics | |||||||

|---|---|---|---|---|---|---|---|---|

| Test Set (9°) | Extrapolation Test Set (10°) | |||||||

| MAE (″) | RMSE(″) | R² | TIME (s) | MAE (″) | RMSE(″) | R² | TIME (s) | |

| TPE-LightGBM | 4.4440 | 7.0053 | 0.8334 | 0.0477 | 4.9425 | 6.4693 | 0.5261 | 0.0469 |

| CEEMDAN-TPE-LightGBM | 4.4182 | 5.6978 | 0.8898 | 0.1966 | 3.8017 | 4.6113 | 0.7592 | 0.1847 |

| CEEMDAN-TPE-LightGBM-APC | 3.7491 | 4.9532 | 0.9167 | 0.2065 | 2.8386 | 3.4807 | 0.8628 | 0.2216 |

| Model | Performance Metrics | |||||||

|---|---|---|---|---|---|---|---|---|

| Test Set (9°) | Extrapolation Test Set (10°) | |||||||

| MAE (″) | RMSE(″) | R² | TIME (s) | MAE (″) | RMSE(″) | R² | TIME (s) | |

| TPE-RF | 3.4626 | 5.3175 | 0.9040 | 0.2324 | 5.1921 | 6.6712 | 0.4960 | 0.2131 |

| TPE-LSTM | 3.3701 | 5.2644 | 0.8830 | 3.9130 | 8.5916 | 9.1631 | 0.0003 | 3.5000 |

| TPE-XGBOOST | 2.7778 | 4.8977 | 0.9185 | 0.0322 | 5.7221 | 7.3458 | 0.3889 | 0.0242 |

| TPE-LightGBM | 4.4440 | 7.0053 | 0.8334 | 0.0477 | 4.9425 | 6.4693 | 0.5261 | 0.0469 |

| EMD-TPE-LightGBM-APC | 3.8851 | 5.3311 | 0.8990 | 0.1916 | 3.9564 | 4.7780 | 0.7523 | 0.1922 |

| EEMD-TPE-LightGBM-APC | 4.4521 | 5.3101 | 0.8822 | 0.5864 | 3.9962 | 5.1215 | 0.7612 | 0.5660 |

| CEEMDAN-TPE-LightGBM-APC | 3.7491 | 4.9532 | 0.9167 | 0.2065 | 2.8386 | 3.4807 | 0.8628 | 0.2216 |

| Performance Metrics | Effect Comparison | |||

|---|---|---|---|---|

| Before Compensation | After Compensation | Variation | ||

| Test set (9°) | Error range | [−31.83″, 41.59″] | [−15.09″, 12.07″] | — |

| Standard Deviation | 17.16″ | 4.95″ | ↓ 71.2% | |

| Extrapolation test set (10°) | Error range | [−22.50″, 9.15″] | [−8.15″, 8.56″] | — |

| Standard Deviation | 9.44″ | 3.68″ | ↓ 61.0% | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, M.; Ren, H.; Liu, S.; Feng, B.; Wei, J.; Ge, H.; Zhang, B. Dynamic Error Modeling and Predictive Compensation for Direct-Drive Turntables Based on CEEMDAN-TPE-LightGBM-APC Algorithm. Micromachines 2025, 16, 731. https://doi.org/10.3390/mi16070731

Yang M, Ren H, Liu S, Feng B, Wei J, Ge H, Zhang B. Dynamic Error Modeling and Predictive Compensation for Direct-Drive Turntables Based on CEEMDAN-TPE-LightGBM-APC Algorithm. Micromachines. 2025; 16(7):731. https://doi.org/10.3390/mi16070731

Chicago/Turabian StyleYang, Manzhi, Hao Ren, Shijia Liu, Bin Feng, Juan Wei, Hongyu Ge, and Bin Zhang. 2025. "Dynamic Error Modeling and Predictive Compensation for Direct-Drive Turntables Based on CEEMDAN-TPE-LightGBM-APC Algorithm" Micromachines 16, no. 7: 731. https://doi.org/10.3390/mi16070731

APA StyleYang, M., Ren, H., Liu, S., Feng, B., Wei, J., Ge, H., & Zhang, B. (2025). Dynamic Error Modeling and Predictive Compensation for Direct-Drive Turntables Based on CEEMDAN-TPE-LightGBM-APC Algorithm. Micromachines, 16(7), 731. https://doi.org/10.3390/mi16070731