Experimental Investigation of Al2O3 Nano-Powder-Mixed Dielectric in EDM-Assisted Micro-Milling

Abstract

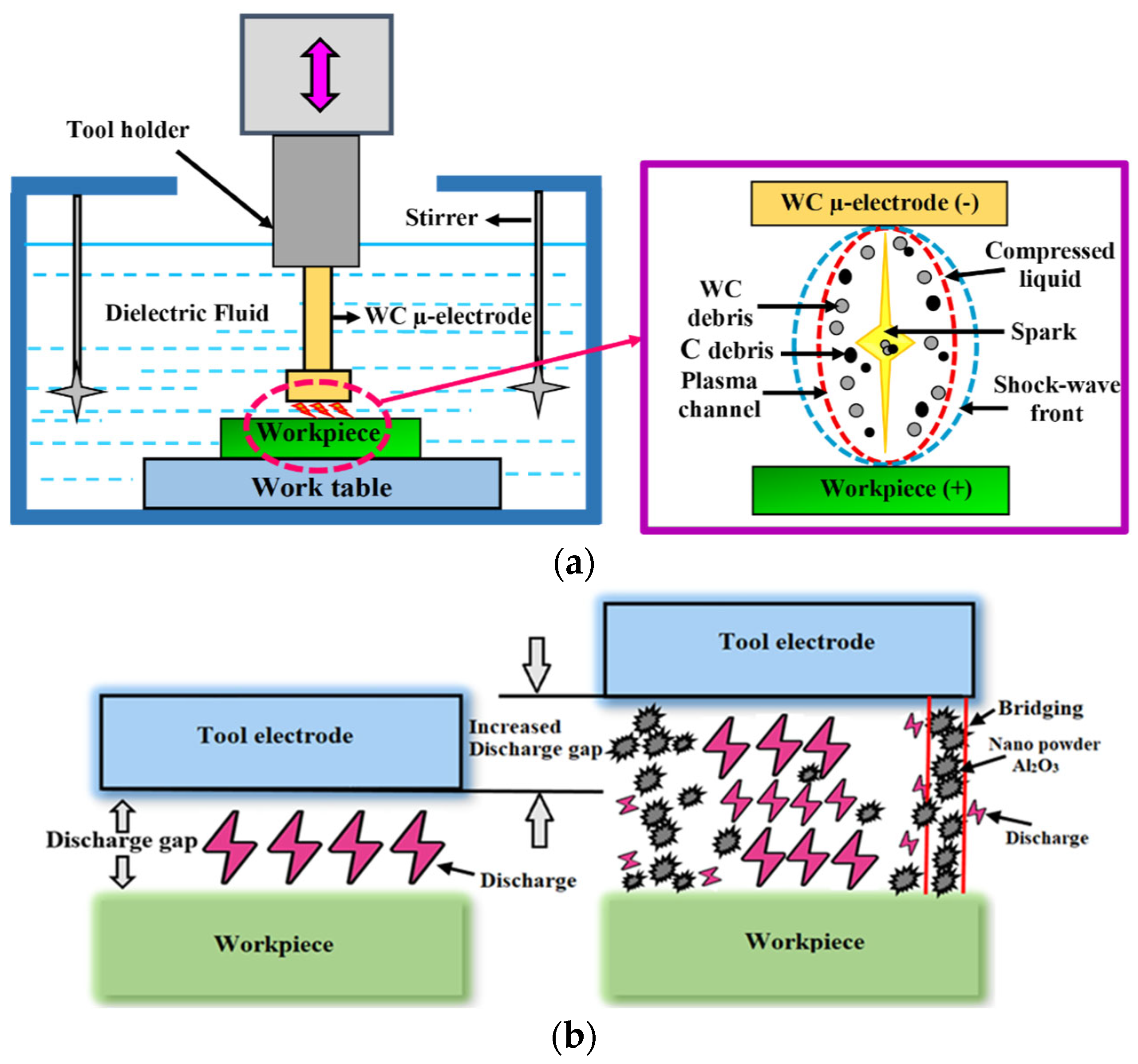

1. Introduction

2. Materials and Methods

2.1. Electrode and Workpiece Material

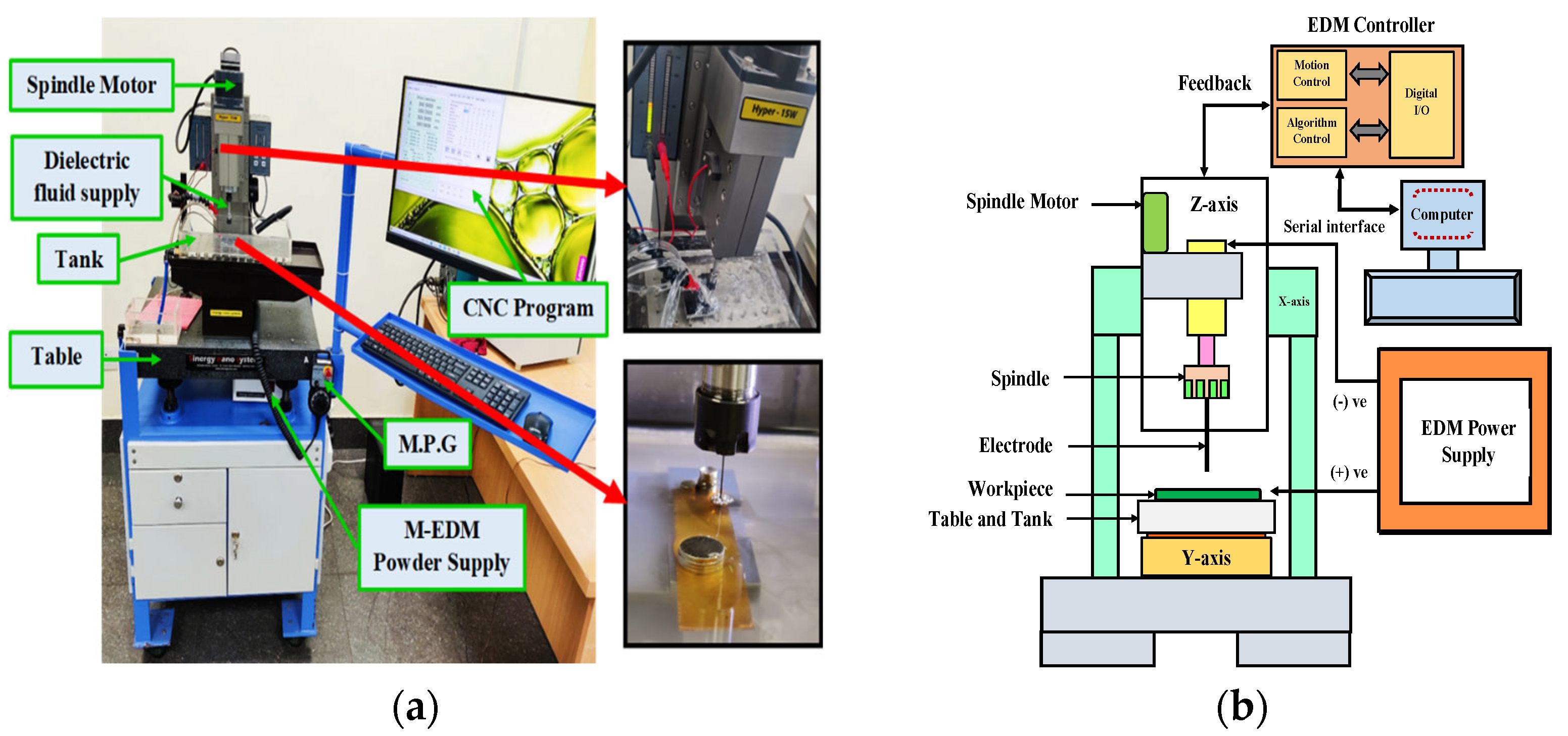

2.2. Experimental Setup

2.3. Machining Parameters

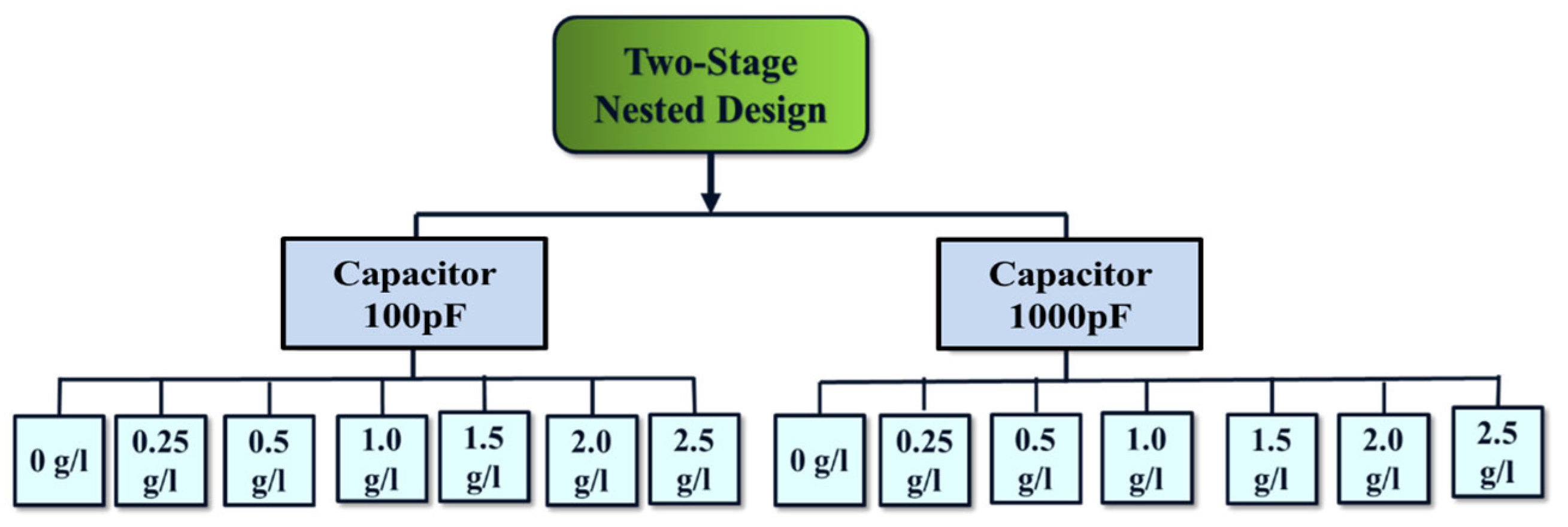

2.4. Design of Experiments

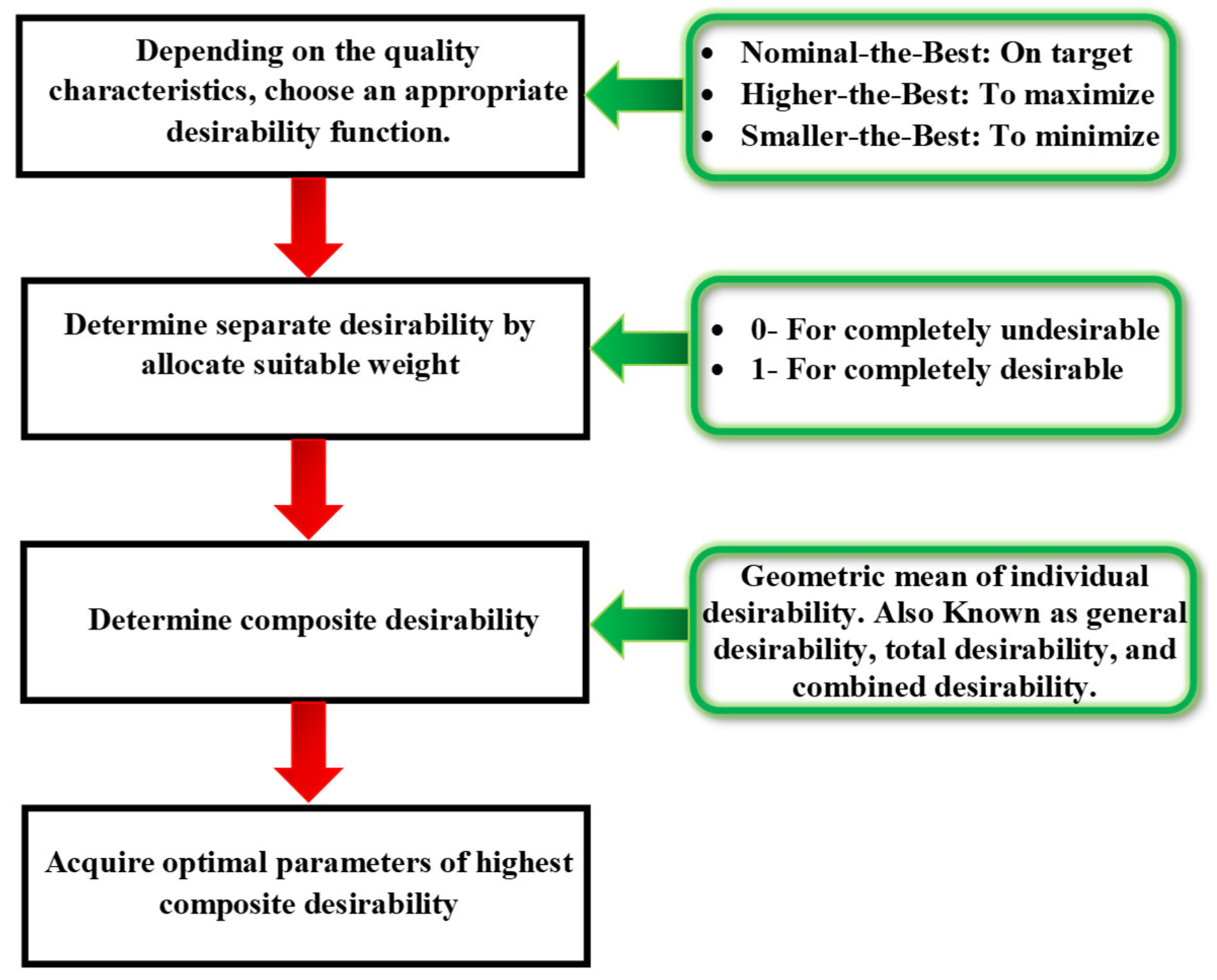

2.5. Desirability Function Analysis (DFA)

2.6. Estimation of MRR and TWR, Micro-Channel Width, and Depth

3. Results

3.1. Two-Stage Nested Analysis

3.2. Analysis of MRR

3.3. Analysis of Tool Wear Rate (TWR)

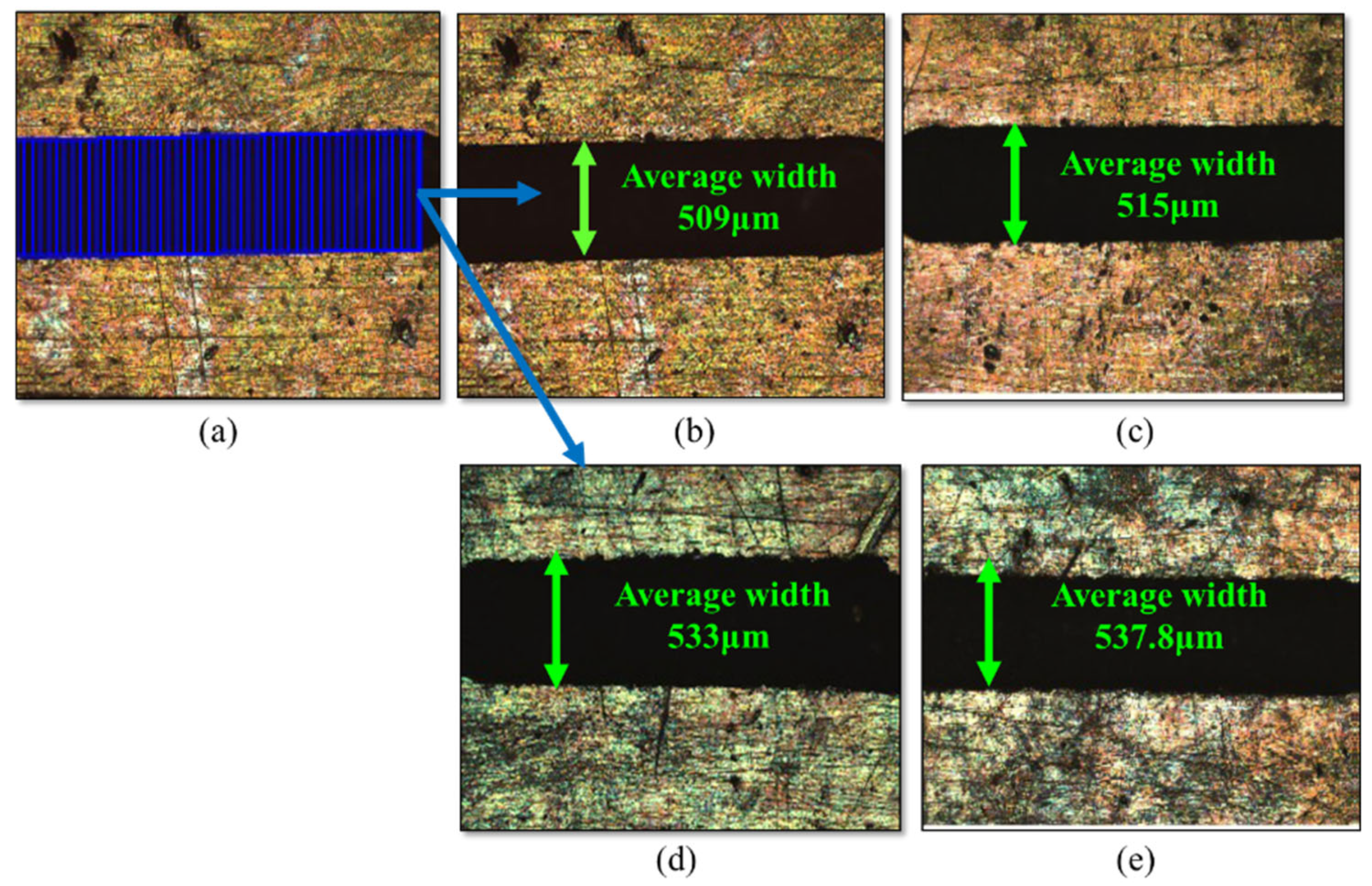

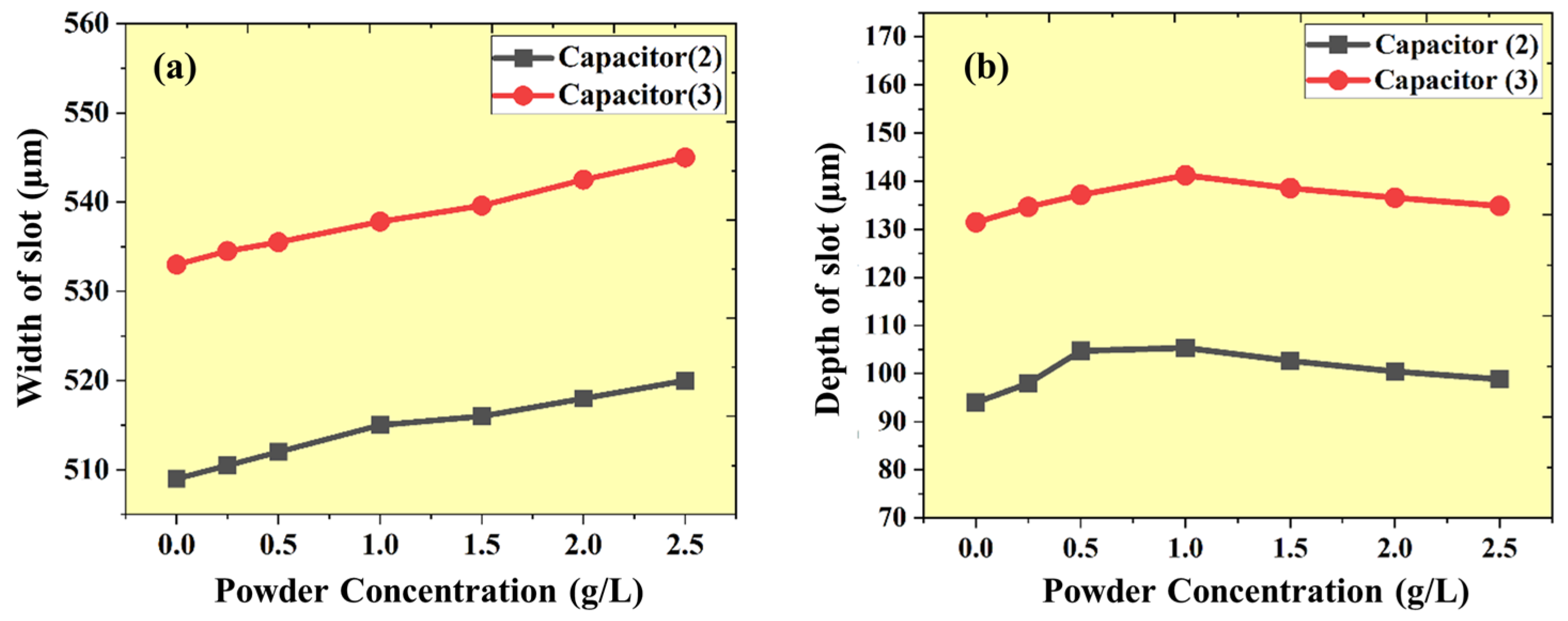

3.4. Performance Analysis of Width of Machining

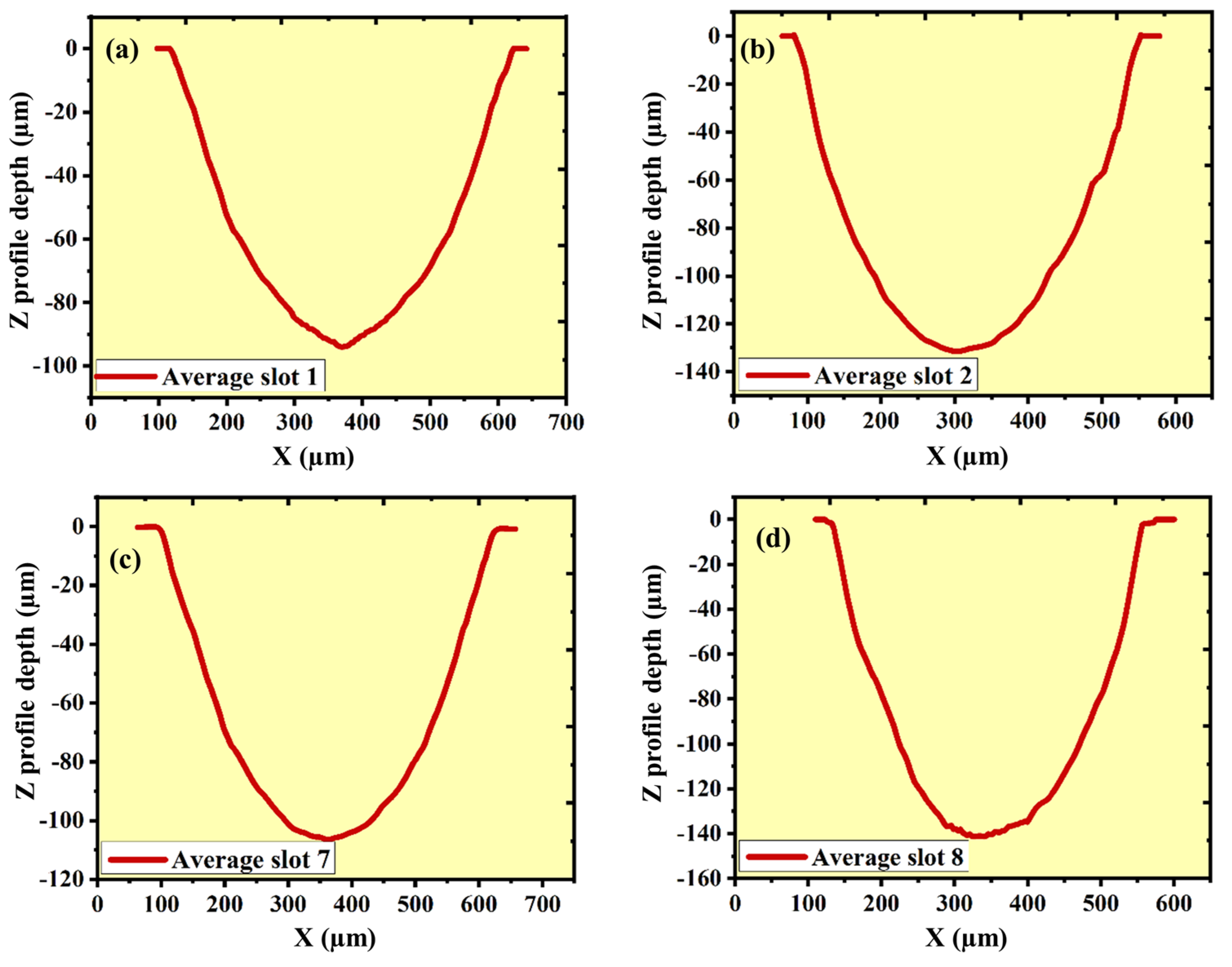

3.5. Performance Analysis of Depth of Machining

3.6. Implementation of DFA

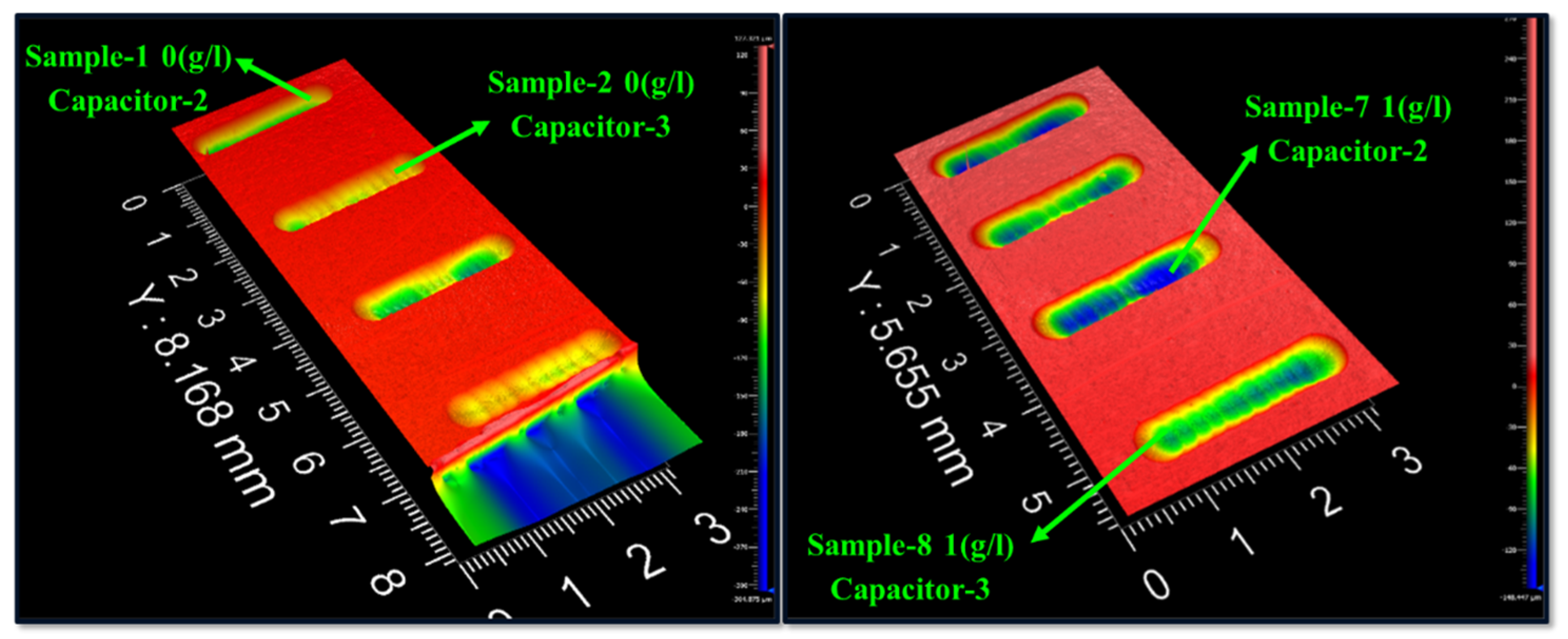

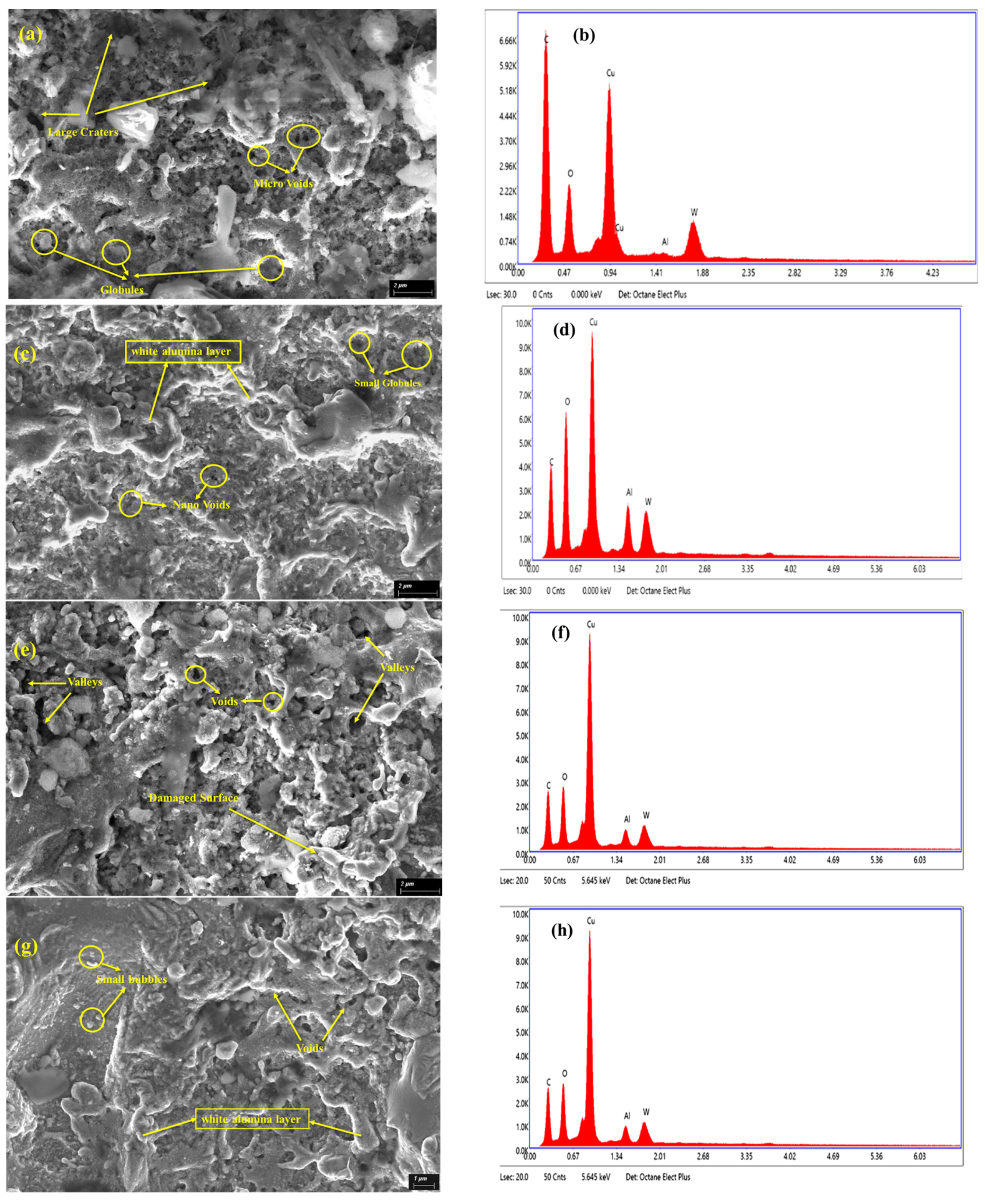

3.7. Effect of Powder Concentration and Energy Levels on Machined Surfaces

4. Conclusions

- The nano-powder shows different behaviors at different capacitance levels. At low capacitance, it enhances gap voltage and flushing. On the other side, at high capacitance, it enhances energy distribution.

- The nano-powder also improves the machining performances in terms of MRR, which increased by 50.5% (100 pF) and 8.7% (1000 pF); TWR was reduced by 4.2% (100 pF) and 3.3% (1000 pF), the width increased by 0.4% (100 pF) and 0.3% (1000 pF), and the depth increased by 12% (100 pF) and 7.4% (1000 pF).

- The nano-powder optimum concentration depends on the energy levels at which the desired objective is achieved. At low capacitance, it is 0.8 g/L, and at high capacitance, it is about 1.0 g/L. Excess concentrations act like non-energized debris, which degraded the machining performance.

- At low capacitance (100 pF), the machined surface was coated with a mass (debris + nano-powder), which enhanced the surface quality of the material. But, at high capacitance (1000 pF), the surface deposition is low, and the dimensional accuracy is high.

- As per the desirability (maximum MRR, targeted depth, minimum TWR, and width), 1.0 g/L of nano-powder concentration showed the best performance at a low capacitance level (100 pF).

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| Pc | Powder concentration [g/L] |

| V | Voltage [volts] |

| ρ | Density [gm/mm3] |

| wi and wf | Initial and final weights [gram] |

| MRR | Material removal rate [mm3/s] |

| PC | Percentage contribution [%] |

| TWR | Tool wear rate [mm3/s] |

| mm | Millimeter |

| nm | Nanometer |

| pF | Pico faraday |

| μm | Micrometer |

| μm/s | Micrometer per second |

| μ-EDM | Micro-electrical discharge machining |

| ANOVA | Analysis of variance |

| Adj. MS | Adjusted mean squares |

| CDi | Composite desirability |

| DOF | Degree of freedom |

| DI | Deionized |

| EDM | Electrical discharge machining |

| DFA | Desirability function analysis |

| EDX | Energy dispersive X-ray |

| g/L | Gram per liter |

| MEMS | Micro-electromechanical systems |

| NPMEDM | Nano-powder mixed electric discharge machine |

| PM μ-EDM | Powder-mixed micro-electrical discharge machining |

| Seq. SS | Sequential sum of squares |

| SEM | Scanning electron microscope |

References

- Vázquez, E.; Rodríguez, C.A.; Elías-Zúñiga, A.; Ciurana, J. An Experimental Analysis of Process Parameters to Manufacture Metallic Micro-Channels by Micro-Milling. Int. J. Adv. Manuf. Technol. 2010, 51, 945–955. [Google Scholar] [CrossRef]

- Shirguppikar, S.S.; Patil, M.S. Experimental Investigation on Micro-Electro Discharge Machining Process Using Tungsten Carbide and Titanium Nitride-Coated Micro-Tool Electrode for Machining of Ti-6Al-4V. Adv. Mater. Process. Technol. 2020, 8, 187–204. [Google Scholar] [CrossRef]

- Nagrale, M.S.; Mastud, S. Optimisation and Experimental Investigation of Material Removal Rate and Tool Wear Rate of Micro Electro Discharge Machining (MEDM) of Hastelloy C276 Optimisation and Experimental Investigation of Material Removal Rate and Tool Wear Rate of Micro Electr. Adv. Mater. Process. Technol. 2022, 8, 3582–3596. [Google Scholar] [CrossRef]

- Yadav, S.; Sisodia, N.; Agarwal, D.; Singh, R.K.; Sharma, A.K. Performance Analysis of Powder-Assisted Micro-Drilling Operation Using Micro-EDM. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2024, 238, 7627–7639. [Google Scholar] [CrossRef]

- Chen, S.; Lian, M.; Wu, X.; Lei, J.; Zhao, H.; Peng, T.; Luo, F. Study on the Micro-EDM Processing Characteristics of Ti-6Al-4V Alloy with Different Electrode Materials. Int. J. Adv. Manuf. Technol. 2021, 116, 3369–3376. [Google Scholar] [CrossRef]

- Tamang, S.K.; Natarajan, N.; Chandrasekaran, M. Optimization of EDM Process in Machining Micro Holes for Improvement of Hole Quality. J. Braz. Soc. Mech. Sci. Eng. 2017, 39, 1277–1287. [Google Scholar] [CrossRef]

- Yadav, S.; Kumar, V.; Misra, J.P.; Singh, R.K.; Upadhyay, V. Surface Modification by Electrical Discharge Machining: A Systematic Literature Review and Bibliometric Analysis. Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng. 2023. [Google Scholar] [CrossRef]

- Gong, S.; Wang, H.; Tian, C.; Wang, Z.; Wang, Y. Micro Electrical Discharge Milling of a Monocrystalline Silicon Complex Micro-Cavity. Mater. Manuf. Process. 2022, 37, 681–692. [Google Scholar] [CrossRef]

- Unune, D.R.; Mali, H.S. Dimensional Accuracy and Surface Quality of Micro-Channels with Low-Frequency Vibration Assistance in Micro-Electro-Discharge Milling. Adv. Mater. Process. Technol. 2020, 8, 863–874. [Google Scholar] [CrossRef]

- Sivaprakasam, P.; Udaya Prakash, J.; Hariharan, P.; Gowri, S. Micro-Electric Discharge Machining (Micro-EDM) of Aluminium Alloy and Aluminium Matrix Composites—A Review. Adv. Mater. Process. Technol. 2022, 8, 1699–1714. [Google Scholar] [CrossRef]

- Jahan, M.P.; Rahman, M.; Wong, Y.S. A Review on the Conventional and Micro-Electrodischarge Machining of Tungsten Carbide. Int. J. Mach. Tools Manuf. 2011, 51, 837–858. [Google Scholar] [CrossRef]

- Agarwal, D.; Yadav, S.; Singh, R.K.; Sharma, A.K. An Investigation on the Effect of Alumina Nano Powder Mixed Dielectric Oil on EDM-Assisted Precision Micro-Drilling Operation. Proc. Inst. Mech. Eng. Part. E J. Process Mech. Eng. 2024. [Google Scholar] [CrossRef]

- Karthikeyan, G.; Ramkumar, J.; Dhamodaran, S.; Aravindan, S. Micro Electric Discharge Milling Process Performance: An Experimental Investigation. Int. J. Mach. Tools Manuf. 2010, 50, 718–727. [Google Scholar] [CrossRef]

- Prakash, S.; Kumar, S. Fabrication of Microchannels: A Review. Proc. Inst. Mech. Eng. B J. Eng. Manuf. 2015, 229, 1273–1288. [Google Scholar] [CrossRef]

- Ishfaq, K.; Naveed, R.; Asad, M.; Mudassar, M. Analyzing Laminated Electrode(s) Performance for the EDM of Microchannel(s) in Al (6061). Int. J. Adv. Manuf. Technol. 2022, 123, 2941–2958. [Google Scholar] [CrossRef]

- Dutta, S.; Sarma, D.K.; Dutta, H. Investigation of Performance Characteristics amid Nano Powder Mixed Electrical Discharge Micro-Milling on Hastelloy C 276. Mach. Sci. Technol. 2023, 27, 610–652. [Google Scholar] [CrossRef]

- Hourmand, M.; Sarhan, A.A.D.; Sayuti, M. Micro-Electrode Fabrication Processes for Micro-EDM Drilling and Milling: A State-of-the-Art Review. Int. J. Adv. Manuf. Technol. 2017, 91, 1023–1056. [Google Scholar] [CrossRef]

- Kumar, D.; Singh, N.K.; Bajpai, V. Recent Trends, Opportunities and Other Aspects of Micro-EDM for Advanced Manufacturing: A Comprehensive Review. J. Braz. Soc. Mech. Sci. Eng. 2020, 42, 222. [Google Scholar] [CrossRef]

- Karthikeyan, G.; Garg, A.K.; Ramkumar, J.; Dhamodaran, S. A Microscopic Investigation of Machining Behavior in ΜeD-Milling Process. J. Manuf. Process 2012, 14, 297–306. [Google Scholar] [CrossRef]

- Jahan, M.P.; Rahman, M.; Wong, Y.S. Modelling and Experimental Investigation on the Effect of Nanopowder-Mixed Dielectric in Micro-Electrodischarge Machining of Tungsten Carbide. Proc. Inst. Mech. Eng. B J. Eng. Manuf. 2010, 224, 1725–1739. [Google Scholar] [CrossRef]

- Agarwal, D.; Yadav, S.; Singh, R.K.; Sharma, A.K. To Investigate the Effect of Discharge Energy and Addition of Nano-Powder on Processing of Micro Slots Using EDM Assisted µ-Milling Operation. Mater. Manuf. Process. 2024, 40, 80–94. [Google Scholar] [CrossRef]

- Gattu, S.D.; Yan, J. Micro Electrical Discharge Machining of Ultrafine Particle Type Tungsten Carbide Using Dielectrics Mixed with Various Powders. Micromachines 2022, 13, 998. [Google Scholar] [CrossRef]

- Abdudeen, A.; Qudeiri, J.E.A.; Kareem, A.; Ahammed, T.; Ziout, A. Recent Advances and Perceptive Insights into Powder-Mixed Dielectric Fluid of EDM. Micromachines 2020, 11, 754. [Google Scholar] [CrossRef] [PubMed]

- Prihandana, G.S.; Mahardika, M.; Sriani, T. Micromachining in Powder-Mixed Micro Electrical Discharge Machining. Appl. Sci. 2020, 10, 3795. [Google Scholar] [CrossRef]

- Gul, I.A.; Abdul-Rani, A.M.; Al-Amin, M.; Garba, E. Elucidating Powder-Mixed Electric Discharge Machining Process, Applicability, Trends and Futuristic Perspectives. Machines 2023, 11, 381. [Google Scholar] [CrossRef]

- Elumalai, B.; Gowri, S.; Hariharan, P.; Arun Pillai, K.V. Experimental Investigations on ΜeD Milling of Inconel 718 with Nano SiC Abrasive Mixed Dielectric. Mater. Res. 2022, 25, e20210468. [Google Scholar] [CrossRef]

- Tiwary, A.P.; Pradhan, B.B.; Bhattacharyya, B. Influence of Various Metal Powder Mixed Dielectric on Micro-EDM Characteristics of Ti-6Al-4V. Mater. Manuf. Process. 2019, 34, 1103–1119. [Google Scholar] [CrossRef]

- Arun Pillai, K.V.; Hariharan, P.; Krishna Murthy, R. Micro ED Milling of Ti-6Al-4V with SiC Nano Powder Mixed Dielectrics at Different Ranges of Discharge Energy. Silicon 2021, 13, 1827–1837. [Google Scholar] [CrossRef]

- Chow, H.M.; Yang, L.D.; Lin, C.T.; Chen, Y.F. The Use of SiC Powder in Water as Dielectric for Micro-Slit EDM Machining. J. Mater. Process Technol. 2008, 195, 160–170. [Google Scholar] [CrossRef]

- Kumar, A.; Mandal, A.; Dixit, A.R.; Das, A.K. Performance Evaluation of Al2O3 Nano Powder Mixed Dielectric for Electric Discharge Machining of Inconel 825. Mater. Manuf. Process. 2018, 33, 986–995. [Google Scholar] [CrossRef]

- Tan, P.C.; Yeo, S.H.; Tan, Y.V. Effects of Nanopowder Additives in Micro-Electrical Discharge Machining. Int. J. Precis. Eng. Manuf. 2008, 9, 22–26. [Google Scholar]

- Prihandana, G.S.; Sriani, T.; Prihandana, K.; Prihandana, Y.; Mahardika, M.; Hamdi, M.; Mitsui, K. Study on the Effect of Nano and Micro MoS2 Powder in Micro-Electrical Discharge Machining. Adv. Mat. Res. 2011, 264–265, 1450–1455. [Google Scholar] [CrossRef]

- Sivaprakasam, P.; Hariharan, P. Surface Characteristics of Nano Powder Mixed Micro-Wire Electrical Discharge Machining on Inconel Alloy. Mater. Today Proc. 2021, 38, 494–498. [Google Scholar] [CrossRef]

- Mohanty, S.; Mishra, A.; Nanda, B.K.; Routara, B.C. Multi-Objective Parametric Optimization of Nano Powder Mixed Electrical Discharge Machining of AlSiCp Using Response Surface Methodology and Particle Swarm Optimization. Alex. Eng. J. 2018, 57, 609–619. [Google Scholar] [CrossRef]

- Elumalai, B.; Gowri, S.; Hariharan, P.; Arun Pillai, K.V. The Effect of Discharge Energy and Nano Al2O3on ΜED Milling of Inconel 718. Surf. Topogr. 2021, 9, 045017. [Google Scholar] [CrossRef]

- Kuriachen, B.; Mathew, J. Effect of Powder Mixed Dielectric on Material Removal and Surface Modification in Microelectric Discharge Machining of Ti-6Al-4V. Mater. Manuf. Process. 2016, 31, 439–446. [Google Scholar] [CrossRef]

- Kumar, A.; Mandal, A.; Dixit, A.R.; Das, A.K.; Kumar, S.; Ranjan, R. Comparison in the Performance of EDM and NPMEDM Using Al 2 O 3 Nanopowder as an Impurity in DI Water Dielectric. Int. J. Adv. Manuf. Technol. 2019, 100, 1327–1339. [Google Scholar] [CrossRef]

- Pillai, K.V.A.; Hariharan, P.; Jafferson, J.M. ΜED Milling of Ti-6Al-4V Using Cryogenic-Treated Wc Tool and Nano-Graphene Powder-Mixed Dielectricat Different Discharge Energy Regimes. Int. J. Adv. Manuf. Technol. 2019, 102, 2721–2743. [Google Scholar] [CrossRef]

- Jeavudeen, S.; Jailani, H.S.; Murugan, M. Powder Additives Influence on Dielectric Strength of EDM Fluid and Material Removal. Int. J. Mach. Mach. Mater. 2020, 22, 47–61. [Google Scholar] [CrossRef]

- Abdul-Rani, A.M.; Nanimina, A.M.; Ginta, T.L.; Razak, M.A. Machined Surface Quality in Nano Aluminum Mixed Electrical Discharge Machining. Procedia Manuf. 2017, 7, 510–517. [Google Scholar] [CrossRef]

- Sahu, D.R.; Mandal, A. Critical Analysis of Surface Integrity Parameters and Dimensional Accuracy in Powder-Mixed EDM. Mater. Manuf. Process. 2020, 35, 430–441. [Google Scholar] [CrossRef]

- Jahan, M.P.; Rahman, M.; Wong, Y.S. Study on the Nano-Powder-Mixed Sinking and Milling Micro-EDM of WC-Co. Int. J. Adv. Manuf. Technol. 2011, 53, 167–180. [Google Scholar] [CrossRef]

- Sahu, D.R.; Kumar, A.; Roy, B.K.; Mandal, A. Parametric Investigation into Alumina Nanopowder Mixed EDM of Inconel 825 Alloy Using RSM; Springer: Singapore, 2019; ISBN 9789811364129. [Google Scholar]

- Chaudhari, R.; Shah, Y.; Khanna, S.; Patel, V.K.; Vora, J.; Pimenov, D.Y.; Giasin, K. Experimental Investigations and Effect of Nano-Powder-Mixed EDM Variables on Performance Measures of Nitinol SMA. Materials 2022, 15, 7392. [Google Scholar] [CrossRef] [PubMed]

- Devarajaiah, D.; Muthumari, C. Evaluation of Power Consumption and MRR in WEDM of Ti–6Al–4V Alloy and Its Simultaneous Optimization for Sustainable Production. J. Braz. Soc. Mech. Sci. Eng. 2018, 40, 400. [Google Scholar] [CrossRef]

- Derringer, G.; Suich, R. Simultaneous Optimization of Several Response Variables. J. Qual. Technol. 1980, 12, 214–219. [Google Scholar] [CrossRef]

| Properties | Workpiece (Cu) | Electrode (WC) |

|---|---|---|

| Composition (wt.%) | Pure Cu | 90% W |

| Density (g/cm3; at 25°C) | 8.96 | 15.63 |

| Melting Point (°C) | 1083 | 2870 |

| Thermal Conductivity [W/mK] | 401 | 110 |

| Thermal Expansion Coefficient (K−1; 0–100 °C) | 16–16.7 × 10−6 | 4.5–6.0 × 10−6 |

| Electrical Resistivity (Ωm) | 1.72 × 10−8 | 65 × 10−6 |

| Size | Thickness: 2 mm | Diameter: 500 µm |

| Hardness (HV) | 100 | 1300 |

| Tensile Strength (MPa) | 210 | 344 |

| Features | Specifications |

|---|---|

| Machine Movement (mm) | Maximum Movement: 135 × 65 × 65 |

| Travel Accuracy (µm) | Precision: 5, Recurrence: 2 |

| Energy Level (pF) | 0, 33, 100, 1000, 10,000 |

| Voltage (V) | 24 to 200 |

| Feed (µm/s) | 5 to 15 |

| Polarity | Forward and Reverse |

| Working Condition | S.I Unit | Description |

|---|---|---|

| Voltage | V | 115 |

| Energy Level (Capacitance) | pF | 2 (100), 3 (1000) |

| Powder Specification | Nm | Al2O3, Shape—Spherical, Size—25 |

| Powder Concentration | g/L | 0, 0.25, 0.5, 1.0, 1.5, 2.0, 2.5 |

| Tool Travel Speed | µm/s | 8 |

| Length of Slot/Channel | mm | 2.5 |

| Depth of Slot/Channel | µm | 110 |

| Dielectric Fluid | - | Micro-EDM oil |

| Polarity | - | Reverse; Workpiece [Cathode(−ve)], Tool [Anode(+ve)] |

| Exp. No. | Capacitor | Powder Concentration (g/L) | Width of Micro-Channel (µm) | Depth of Micro-Channel (µm) | TWR (mm3/min) | MRR (mm3/min) |

|---|---|---|---|---|---|---|

| 1. | 2 | 0 | 509 | 94 | 0.00017 | 0.00063 |

| 2. | 3 | 0 | 533 | 131.45 | 0.00085 | 0.00230 |

| 3. | 2 | 0.25 | 510.5 | 98 | 0.00016 | 0.00095 |

| 4. | 3 | 0.25 | 534.5 | 134.64 | 0.00083 | 0.0025 |

| 5. | 2 | 0.5 | 512 | 104.74 | 0.00020 | 0.0012 |

| 6. | 3 | 0.5 | 535.5 | 137.135 | 0.00081 | 0.0027 |

| 7. | 2 | 1.0 | 515 | 105.35 | 0.00021 | 0.0014 |

| 8. | 3 | 1.0 | 537.8 | 141.25 | 0.00079 | 0.0030 |

| 9. | 2 | 1.5 | 516 | 102.65 | 0.00023 | 0.0012 |

| 10. | 3 | 1.5 | 539.6 | 138.546 | 0.00082 | 0.0028 |

| 11. | 2 | 2.0 | 518 | 100.45 | 0.00023 | 0.0001 |

| 12. | 3 | 2.0 | 542.5 | 136.564 | 0.00083 | 0.0027 |

| 13. | 2 | 2.5 | 520 | 98.85 | 0.00020 | 0.0001 |

| 14. | 3 | 2.5 | 545 | 134.854 | 0.00084 | 0.0025 |

| Control Parameter’s | DOF | Seq. SS | Adj. MS | F-Value | %PC | Remarks |

|---|---|---|---|---|---|---|

| NESTED ANOVA for MRR | ||||||

| Powder Concentration (A) | 1 | 1 × 10−6 | 1.3 × 10−6 | 0.87 | 6.77 | |

| Capacitor (B) (Within Powder Concentration) | 12 | 1.8 × 10−5 | 1.5 × 10−6 | 637.74 | 93.06 | Significant |

| Error | 14 | 0.00 | 0.00 | |||

| Total | 27 | 2.0 × 10−5 | ||||

| NESTED ANOVA for TWR | ||||||

| Powder Concentration (A) | 1 | 4.4 × 10−9 | 4.4 × 10−9 | 1.92 × 10−2 | 0.16 | |

| Capacitor (B) (Within Powder Concentration) | 12 | 2.73 × 10−6 | 2.28 × 10−7 | 1.05 × 104 | 99.83 | Significant |

| Error | 14 | 3.0 × 10−10 | 2.0 × 10−11 | |||

| Total | 27 | 2.74 × 10−6 | ||||

| NESTED ANOVA for Width | ||||||

| Powder Concentration (A) | 1 | 416.42 | 416.42 | 1.24 | 9.36 | |

| Capacitor (B) (Within Powder Concentration) | 12 | 4030.05 | 335.84 | 1741.38 | 90.6 | Significant |

| Error | 14 | 2.70 | 0.19 | |||

| Total | 27 | 4449.17 | ||||

| NESTED ANOVA for Depth | ||||||

| Powder Concentration (A) | 1 | 337.68 | 337.68 | 0.45 | 3.63 | |

| Capacitor (B) (Within Powder Concentration) | 12 | 8967.95 | 747.33 | 1.51 × 104 | 96.4 | Significant |

| Error | 14 | 0.69 | 0.05 | |||

| Total | 27 | 9306.32 | ||||

| Expt. No | Capacitor | Powder Conc. (g/L) | Desirability Index | Composite Desirability (CDi) | Rank | |||

|---|---|---|---|---|---|---|---|---|

| Width | TWR | MRR | Depth | |||||

| 1 | 2 | 0 | 1 | 0.99745 | 0 | 0 | 0 | 12 |

| 2 | 3 | 0 | 0.75984 | 0 | 0.91612 | 1.23690 | 0 | 12 |

| 3 | 2 | 0.25 | 0.98942 | 1 | 0.60536 | 0.70711 | 0.80671 | 6 |

| 4 | 3 | 0.25 | 0.73490 | 0.41292 | 0.94243 | 1.26243 | 0.77515 | 9 |

| 5 | 2 | 0.5 | 0.97848 | 0.98552 | 0.69983 | 0.90515 | 0.88406 | 2 |

| 6 | 3 | 0.5 | 0.71673 | 0.47492 | 0.96080 | 1.28138 | 0.80459 | 7 |

| 7 | 2 | 1 | 0.95544 | 0.98054 | 0.75465 | 0.91774 | 0.89750 | 1 |

| 8 | 3 | 1 | 0.66874 | 0.53884 | 1 | 1.31090 | 0.82903 | 4 |

| 9 | 2 | 1.5 | 0.94738 | 0.97432 | 0.68389 | 0.8575 | 0.85775 | 3 |

| 10 | 3 | 1.5 | 0.62233 | 0.45697 | 0.97818 | 1.29173 | 0.77424 | 10 |

| 11 | 2 | 2 | 0.93061 | 0.97234 | 0.61916 | 0.796819 | 0.817404 | 5 |

| 12 | 3 | 2 | 0.51335 | 0.40218 | 0.96670 | 1.277117 | 0.71054 | 11 |

| 13 | 2 | 2.5 | 0.91287 | 0.98589 | 0.56888 | 0.74200 | 0.78508 | 8 |

| 14 | 3 | 2.5 | 0 | 0.37076 | 0.94243 | 1.26409 | 0 | 12 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yadav, S.; Agarwal, D.; Sharma, A.K.; Singh, R.K.; Chauhan, S.; Mohanty, S. Experimental Investigation of Al2O3 Nano-Powder-Mixed Dielectric in EDM-Assisted Micro-Milling. Micromachines 2025, 16, 725. https://doi.org/10.3390/mi16070725

Yadav S, Agarwal D, Sharma AK, Singh RK, Chauhan S, Mohanty S. Experimental Investigation of Al2O3 Nano-Powder-Mixed Dielectric in EDM-Assisted Micro-Milling. Micromachines. 2025; 16(7):725. https://doi.org/10.3390/mi16070725

Chicago/Turabian StyleYadav, Sharad, Deepak Agarwal, Anuj Kumar Sharma, Rabesh Kumar Singh, Saurabh Chauhan, and Shalini Mohanty. 2025. "Experimental Investigation of Al2O3 Nano-Powder-Mixed Dielectric in EDM-Assisted Micro-Milling" Micromachines 16, no. 7: 725. https://doi.org/10.3390/mi16070725

APA StyleYadav, S., Agarwal, D., Sharma, A. K., Singh, R. K., Chauhan, S., & Mohanty, S. (2025). Experimental Investigation of Al2O3 Nano-Powder-Mixed Dielectric in EDM-Assisted Micro-Milling. Micromachines, 16(7), 725. https://doi.org/10.3390/mi16070725