Optical Film with Microstructures to Regulate Viewing Angle of HUDs

Abstract

1. Introduction

2. Theoretical Design of Microstructures

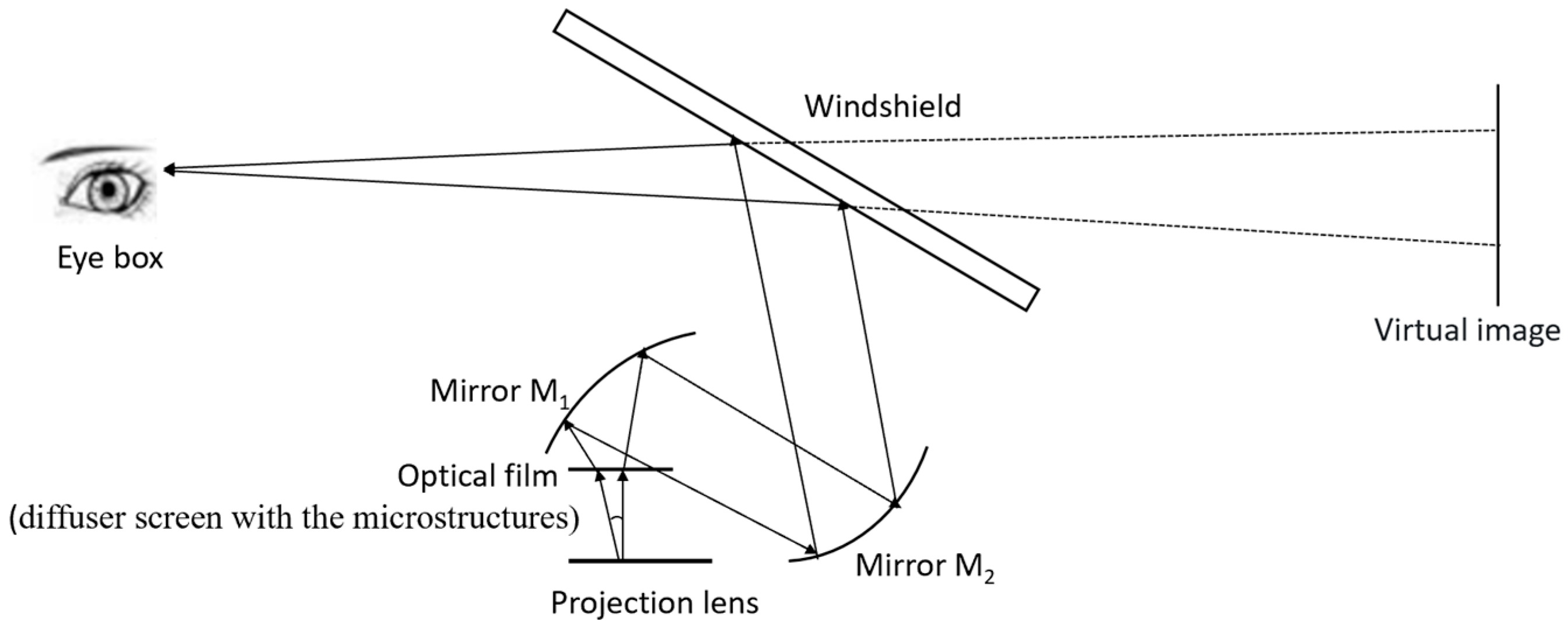

2.1. HUD Optical System

2.2. Microstructure Profile Design

3. Simulation Analysis and Discussion

4. Preparation and Experimental Testing

4.1. Preparation of Optical Film

4.2. Imaging Test

4.3. Viewing Angle Test

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Lv, Z.; Li, J.; Yang, Y.; Liu, J. 3D Head-Up Display with a Multiple Extended Depth of Field Based on Integral Imaging and Holographic Optical Elements. Opt. Express 2023, 31, 964–975. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Schroeter, R.; Rakotonirainy, A.; Kuo, J.; Lenné, M.G. Get Ready for Take-Overs: Using Head-Up Display for Drivers to Engage in Non–Driving-Related Tasks in Automated Vehicles. Hum. Factors 2023, 65, 1759–1775. [Google Scholar] [CrossRef] [PubMed]

- Cao, Y. Optimization Design of Optical Module for Vehicle Head-Up Display System. Master’s Thesis, Xi’an Technological University, Xi’an, China, 2022. [Google Scholar]

- Ren, J.W.; Chen, X.W.; Wang, B.; Cao, Y.; Sun, Y.H.; Li, X.Y.; Wu, S.J. Design of Dual-Light-Path Vehicle Head-Up Display Optical System Based on Single Light Engine. Acta Photonica Sin. 2023, 52, 249–258. [Google Scholar]

- Holden, K.L.; Boyer, J.L.; Ezer, N.; Holubec, K.; Sándor, A.; Stephens, J.P. Human Factors in Space Vehicle Design. Acta Astronaut. 2013, 92, 110–118. [Google Scholar] [CrossRef]

- Feng, Q.B.; Li, D.H.; Xiao, H.L. Surface Microstructure Design of Viewing Angle Deflection Film Based on Extended Light Source. Opt. Precis. Eng. 2021, 29, 1329–1336. [Google Scholar] [CrossRef]

- Feng, Q.B.; Yin, H.J.; Cheng, X.; Lv, G.Q. Surface Microstructure Design of Optical Film for Viewing Angle Deflection. Opt. Precis. Eng. 2016, 24, 1009–1014. [Google Scholar] [CrossRef]

- Tuo, C.F.; Lv, G.Q.; Xu, L.Y.; Feng, Q.B.; Wang, Z. Design of Microstructure Film for Improving Viewing Brightness of Vehicle Head-Up Display. Opt. Precis. Eng. 2021, 29, 1822–1831. [Google Scholar] [CrossRef]

- Zhang, Y.L.; Su, Z.P.; Pan, H.X.; Chen, X.T.; Zhang, Y.W. Optical Design and Tolerance Analysis of Free-Form Surface Vehicle Head-Up Display. Acta Photonica Sin. 2020, 49, 12–14. [Google Scholar]

- Ye, Y. Design and Optimization Research of Augmented Reality Head-Up Display System. Master’s Thesis, University of Electronic Science and Technology of China, Chengdu, China, 2024. [Google Scholar]

- Wang, R.; Jiang, L.; Song, Z.H. Design of an Integrated Vehicle Head-Up Display Optical System Based on Micro-Projection. Laser Optoelectron. Prog. 2018, 55, 424–430. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Feng, Q.; Li, X.; Chen, C.; Lv, G.; Wang, Z. Optical Film with Microstructures to Regulate Viewing Angle of HUDs. Micromachines 2025, 16, 714. https://doi.org/10.3390/mi16060714

Feng Q, Li X, Chen C, Lv G, Wang Z. Optical Film with Microstructures to Regulate Viewing Angle of HUDs. Micromachines. 2025; 16(6):714. https://doi.org/10.3390/mi16060714

Chicago/Turabian StyleFeng, Qibin, Xiangjun Li, Chunhui Chen, Guoqiang Lv, and Zi Wang. 2025. "Optical Film with Microstructures to Regulate Viewing Angle of HUDs" Micromachines 16, no. 6: 714. https://doi.org/10.3390/mi16060714

APA StyleFeng, Q., Li, X., Chen, C., Lv, G., & Wang, Z. (2025). Optical Film with Microstructures to Regulate Viewing Angle of HUDs. Micromachines, 16(6), 714. https://doi.org/10.3390/mi16060714