Optimising (Al,Ga) (As,Bi) Quantum Well Laser Structures for Reflectance Mode Pulse Oximetry

Abstract

1. Introduction

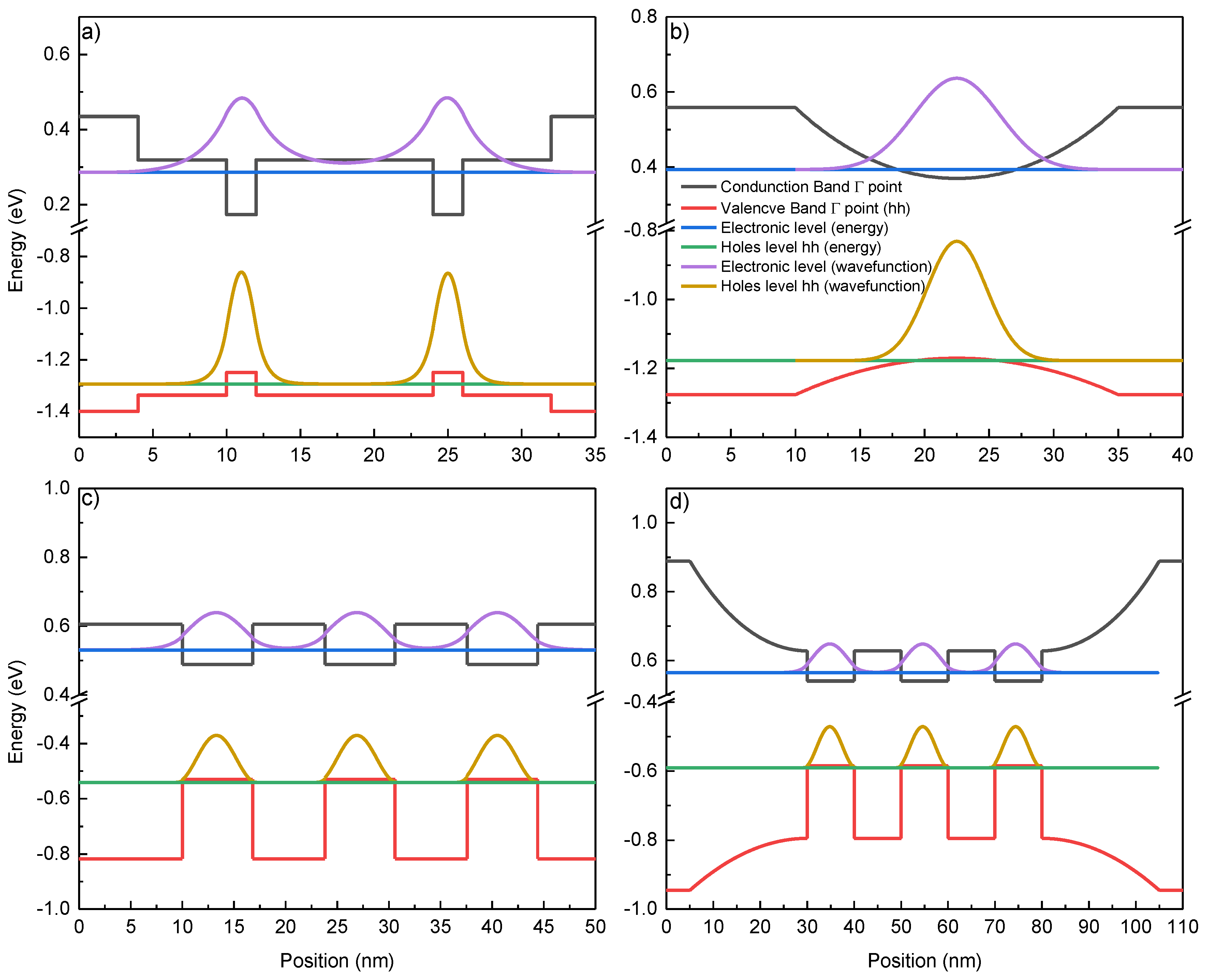

2. Structure Modeling and Growth

3. Processing and Characterization

4. Results and Discussion

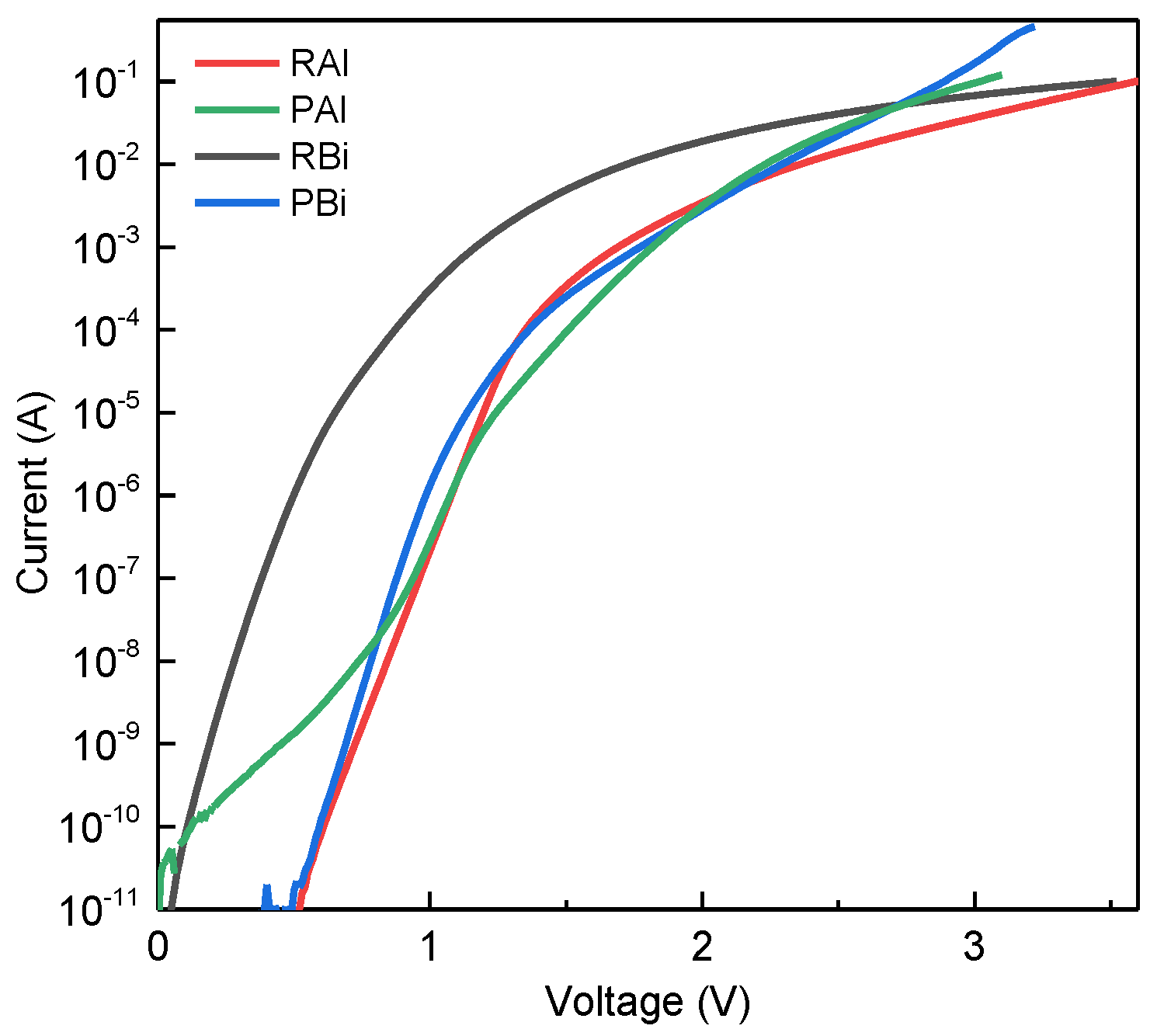

4.1. I-V Characteristics

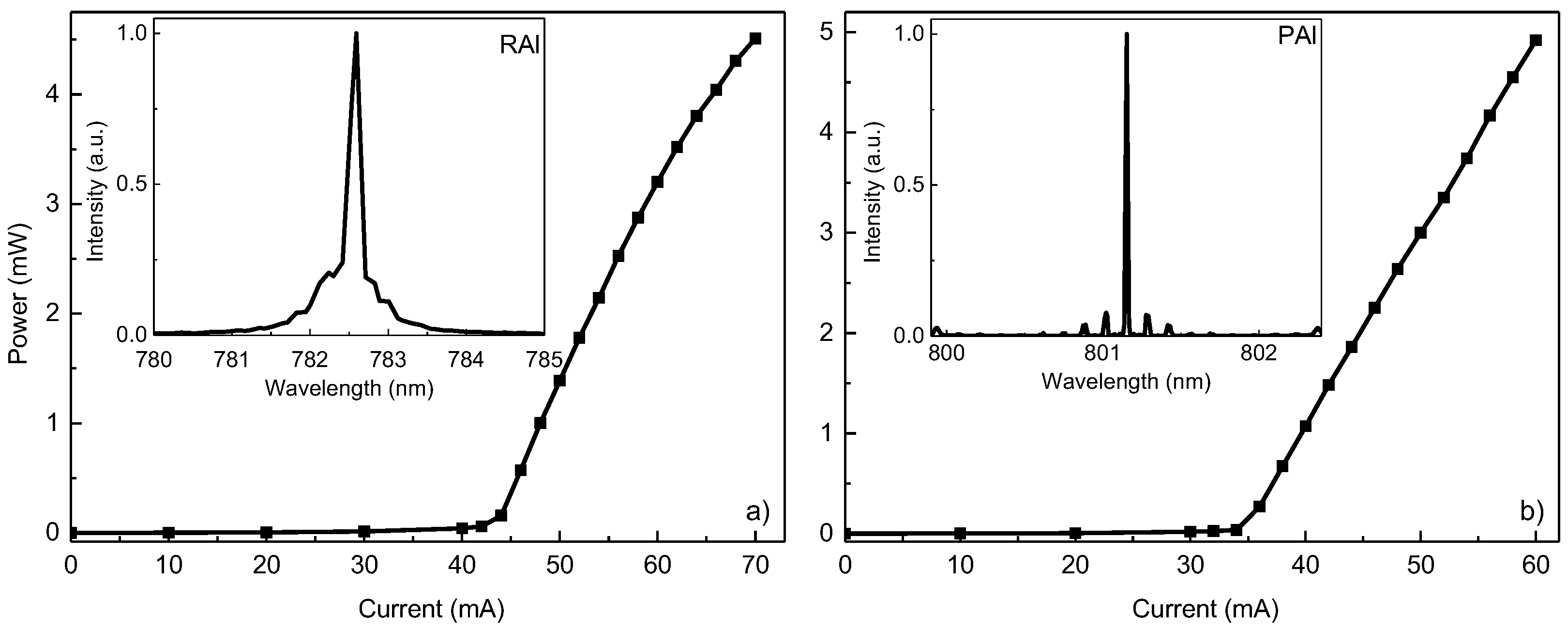

4.2. Light Output Characteristics

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Sinex, J.E. Pulse oximetry: Principles and limitations. Am. J. Emerg. Med. 1999, 17, 59–67. [Google Scholar] [CrossRef] [PubMed]

- Yossef Hay, O.; Cohen, M.; Nitzan, I.; Kasirer, Y.; Shahroor-Karni, S.; Yitzhaky, Y.; Engelberg, S.; Nitzan, M. Pulse oximetry with two infrared wavelengths without calibration in extracted arterial blood. Sensors 2018, 18, 3457. [Google Scholar] [CrossRef] [PubMed]

- Francoeur, S.; Seong, M.J.; Mascarenhas, A.; Tixier, S.; Adamcyk, M.; Tiedje, T. Band gap of GaAs1-xBix, 0<x<3.6%. Appl. Phys. Lett. 2003, 82, 3874–3876. [Google Scholar] [CrossRef]

- Alberi, K.; Dubon, O.D.; Walukiewicz, W.; Yu, K.M.; Bertulis, K.; Krotkus, A. Valence band anticrossing in GaAs1-xBix. Appl. Phys. Lett. 2007, 91, 051909. [Google Scholar] [CrossRef]

- Oe, K.; Okamoto, H. New semiconductor alloy GaAs1-xBix grown by metal organic vapor phase epitaxy. Jpn. J. Appl. Phys. 1998, 37, L1283. [Google Scholar] [CrossRef]

- Tominaga, Y.; Oe, K.; Yoshimoto, M. Low temperature dependence of oscillation wavelength in GaAs1-xBix Laser by photo-pumping. Appl. Phys. Express 2010, 3, 062201. [Google Scholar] [CrossRef]

- Wu, X.; Pan, W.; Zhang, Z.; Li, Y.; Cao, C.; Liu, J.; Zhang, L.; Song, Y.; Ou, H.; Wang, S. 1.142 μm GaAsBi/GaAs quantum well lasers grown by molecular beam epitaxy. ACS Photonics 2017, 4, 1322–1326. [Google Scholar] [CrossRef]

- Ludewig, P.; Knaub, N.; Hossain, N.; Reinhard, S.; Nattermann, L.; Marko, I.P.; Jin, S.R.; Hild, K.; Chatterjee, S.; Stolz, W.; et al. Electrical injection Ga(AsBi)/(AlGa)As single quantum well laser. Appl. Phys. Lett. 2013, 102, 242115. [Google Scholar] [CrossRef]

- Butkutė, R.; Geižutis, A.; Pačebutas, V.; Čechavičius, B.; Bukauskas, V.; Kundrotas, R.; Ludewig, P.; Volz, K.; Krotkus, A. Multi-quantum well Ga(AsBi)/GaAs laser diodes with more than 6% of bismuth. Electron. Lett. 2014, 50, 1155–1157. [Google Scholar] [CrossRef]

- Marko, I.P.; Ludewig, P.; Bushell, Z.L.; Jin, S.R.; Hild, K.; Batool, Z.; Reinhard, S.; Nattermann, L.; Stolz, W.; Volz, K.; et al. Physical properties and optimization of GaBiAs/(Al)GaAs based near-infrared laser diodes grown by MOVPE with up to 4.4% Bi. J. Phys. D Appl. Phys. 2014, 47, 345103. [Google Scholar] [CrossRef]

- Fuyuki, T.; Yoshida, K.; Yoshioka, R.; Yoshimoto, M. Electrically pumped room-temperature operation of GaAs1-xBix laser diodes with low-temperature dependence of oscillation wavelength. Appl. Phys. Express 2014, 7, 082101. [Google Scholar] [CrossRef]

- Armalytė, S.; Glemža, J.; Jonkus, V.; Pralgauskaitė, S.; Matukas, J.; Pūkienė, S.; Zelioli, A.; Dudutienė, E.; Naujokaitis, A.; Bičiūnas, A.; et al. Low-frequency noise characteristics of (Al, Ga)As and Ga(As, Bi) quantum well structures for NIR laser diodes. Sensors 2023, 23, 2282. [Google Scholar] [CrossRef] [PubMed]

- Luna, E.; Puustinen, J.; Hilska, J.; Guina, M. Detection of BiGa hetero-antisites at Ga(As,Bi)/(Al,Ga)As interfaces. J. Appl. Phys. 2024, 135, 125303. [Google Scholar] [CrossRef]

- Beyer, A.; Knaub, N.; Rosenow, P.; Jandieri, K.; Ludewig, P.; Bannow, L.; Koch, S.W.; Tonner, R.; Volz, K. Local Bi ordering in MOVPE grown Ga(As,Bi) investigated by high resolution scanning transmission electron microscopy. Appl. Mater. Today 2017, 6, 22–28. [Google Scholar] [CrossRef]

- Gelczuk, Ł.; Kopaczek, J.; Rockett, T.B.O.; Richards, R.D.; Kudrawiec, R. Deep-level defects in n-type GaAsBi alloys grown by molecular beam epitaxy at low temperature and their influence on optical properties. Sci. Rep. 2017, 7, 12824. [Google Scholar] [CrossRef]

- Glemža, J.; Špokas, A.; Zelioli, A.; Kamarauskas, M.; Bičiūnas, A.; Čechavičius, B.; Spigulis, J.; Chiu, Y.J.; Pralgauskaitė, S.; Matukas, J.; et al. Quality evaluation of NIR laser diodes for medical application using low-frequency noise characterization. Infrared Phys. Technol. 2025, 147, 105794. [Google Scholar] [CrossRef]

- Puustinen, J.; Hilska, J.; Guina, M. Analysis of GaAsBi growth regimes in high resolution with respect to As/Ga ratio using stationary MBE growth. J. Cryst. Growth 2019, 511, 33–41. [Google Scholar] [CrossRef]

- Richards, R.D.; Bastiman, F.; Hunter, C.J.; Mendes, D.F.; Mohmad, A.R.; Roberts, J.S.; David, J.P.R. Molecular beam epitaxy growth of GaAsBi using As2 and As4. J. Cryst. Growth 2014, 390, 120–124. [Google Scholar] [CrossRef]

- Rockett, T.B.O.; Richards, R.D.; Gu, Y.; Harun, F.; Liu, Y.; Zhou, Z.; David, J.P.R. Influence of growth conditions on the structural and opto-electronic quality of GaAsBi. J. Cryst. Growth 2017, 477, 139–143. [Google Scholar] [CrossRef]

- Pūkienė, S.; Karaliūnas, M.; Jasinskas, A.; Dudutienė, E.; Čechavičius, B.; Devenson, J.; Butkutė, R.; Udal, A.; Valušis, G. Enhancement of photoluminescence of GaAsBi quantum wells by parabolic design of AlGaAs barriers. Nanotechnology 2019, 30, 455001. [Google Scholar] [CrossRef]

- Andreani, L.C.; Pasquarello, A.; Bassani, F. Hole subbands in strained GaAs - Ga1-xAlxAs quantum wells: Exact solution of the effective-mass equation. Phys. Rev. B Condens. Matter 1987, 36, 5887–5894. [Google Scholar] [CrossRef]

- Mahtab, M.; Synowicki, R.; Bahrami-Yekta, V.; Bannow, L.C.; Koch, S.W.; Lewis, R.B.; Tiedje, T. Complex dielectric function of GaAs1-xBix as a function of Bi content. Phys. Rev. Mater. 2019, 3, 054601. [Google Scholar] [CrossRef]

- Ferhat, M.; Zaoui, A. Structural and electronic properties of III-V bismuth compounds. Phys. Rev. B Condens. Matter Mater. Phys. 2006, 73, 115107. [Google Scholar] [CrossRef]

- Janotti, A.; Wei, S.H.; Zhang, S.B. Theoretical study of the effects of isovalent coalloying of Bi and N in GaAs. Phys. Rev. B Condens. Matter 2002, 65. [Google Scholar] [CrossRef]

- Karpus, V.; Norkus, R.; Butkutė, R.; Stanionytė, S.; Čechavičius, B.; Krotkus, A. THz-excitation spectroscopy technique for band-offset determination. Opt. Express 2018, 26, 33807–33817. [Google Scholar] [CrossRef] [PubMed]

- Ludewig, P.; Knaub, N.; Stolz, W.; Volz, K. MOVPE growth of Ga(AsBi)/GaAs multi quantum well structures. J. Cryst. Growth 2013, 370, 186–190. [Google Scholar] [CrossRef]

- Hu, Z.; Nomoto, K.; Song, B.; Zhu, M.; Qi, M.; Pan, M.; Gao, X.; Protasenko, V.; Jena, D.; Xing, H.G. Near unity ideality factor and Shockley-Read-Hall lifetime in GaN-on-GaN p-n diodes with avalanche breakdown. Appl. Phys. Lett. 2015, 107, 243501. [Google Scholar] [CrossRef]

- Song, Y.; Lv, Z.; Bai, J.; Niu, S.; Wu, Z.; Qin, L.; Chen, Y.; Liang, L.; Lei, Y.; Jia, P.; et al. Processes of the reliability and degradation mechanism of high-power semiconductor lasers. Crystals 2022, 12, 765. [Google Scholar] [CrossRef]

- Jiménez, J. Laser diode reliability: Crystal defects and degradation modes. C. R. Phys. 2003, 4, 663–673. [Google Scholar] [CrossRef]

| Laser Diode | RAl | PAl | RBi | PBi |

|---|---|---|---|---|

| QW type | RQW | PGBs | RQW | RQW in PGBs |

| No of QW | 2 | 1 | 3 | 3 |

| QW composition | (Al, Ga)As | GaAsBi | ||

| QW thickness, nm | 2 | 25 | 6.8 | 10 |

| Parabolic grading | - | Al0.30 ↔ Al0.09 | - | Al0.30 ↔ Al0.00 |

| Barrier composition | Al0.15Ga0.85As | - | GaAs | GaAs |

| Outer/inner barrier thickness, nm | 5/10 | - | -/7 | -/10 |

| Spacer composition | Al0.30Ga0.70As | Al0.30Ga0.70As | GaAs | - |

| Spacer thickness, nm | 200 | 200 | 25 | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Špokas, A.; Zelioli, A.; Bičiūnas, A.; Čechavičius, B.; Glemža, J.; Pralgauskaitė, S.; Kamarauskas, M.; Bukauskas, V.; Spigulis, J.; Chiu, Y.-J.; et al. Optimising (Al,Ga) (As,Bi) Quantum Well Laser Structures for Reflectance Mode Pulse Oximetry. Micromachines 2025, 16, 506. https://doi.org/10.3390/mi16050506

Špokas A, Zelioli A, Bičiūnas A, Čechavičius B, Glemža J, Pralgauskaitė S, Kamarauskas M, Bukauskas V, Spigulis J, Chiu Y-J, et al. Optimising (Al,Ga) (As,Bi) Quantum Well Laser Structures for Reflectance Mode Pulse Oximetry. Micromachines. 2025; 16(5):506. https://doi.org/10.3390/mi16050506

Chicago/Turabian StyleŠpokas, Aivaras, Andrea Zelioli, Andrius Bičiūnas, Bronislovas Čechavičius, Justinas Glemža, Sandra Pralgauskaitė, Mindaugas Kamarauskas, Virginijus Bukauskas, Janis Spigulis, Yi-Jen Chiu, and et al. 2025. "Optimising (Al,Ga) (As,Bi) Quantum Well Laser Structures for Reflectance Mode Pulse Oximetry" Micromachines 16, no. 5: 506. https://doi.org/10.3390/mi16050506

APA StyleŠpokas, A., Zelioli, A., Bičiūnas, A., Čechavičius, B., Glemža, J., Pralgauskaitė, S., Kamarauskas, M., Bukauskas, V., Spigulis, J., Chiu, Y.-J., Matukas, J., & Butkutė, R. (2025). Optimising (Al,Ga) (As,Bi) Quantum Well Laser Structures for Reflectance Mode Pulse Oximetry. Micromachines, 16(5), 506. https://doi.org/10.3390/mi16050506