PEDOT:PSS-MWCNT Nanocomposite Wire for Routing in Energy Harvesting Devices

Abstract

1. Introduction

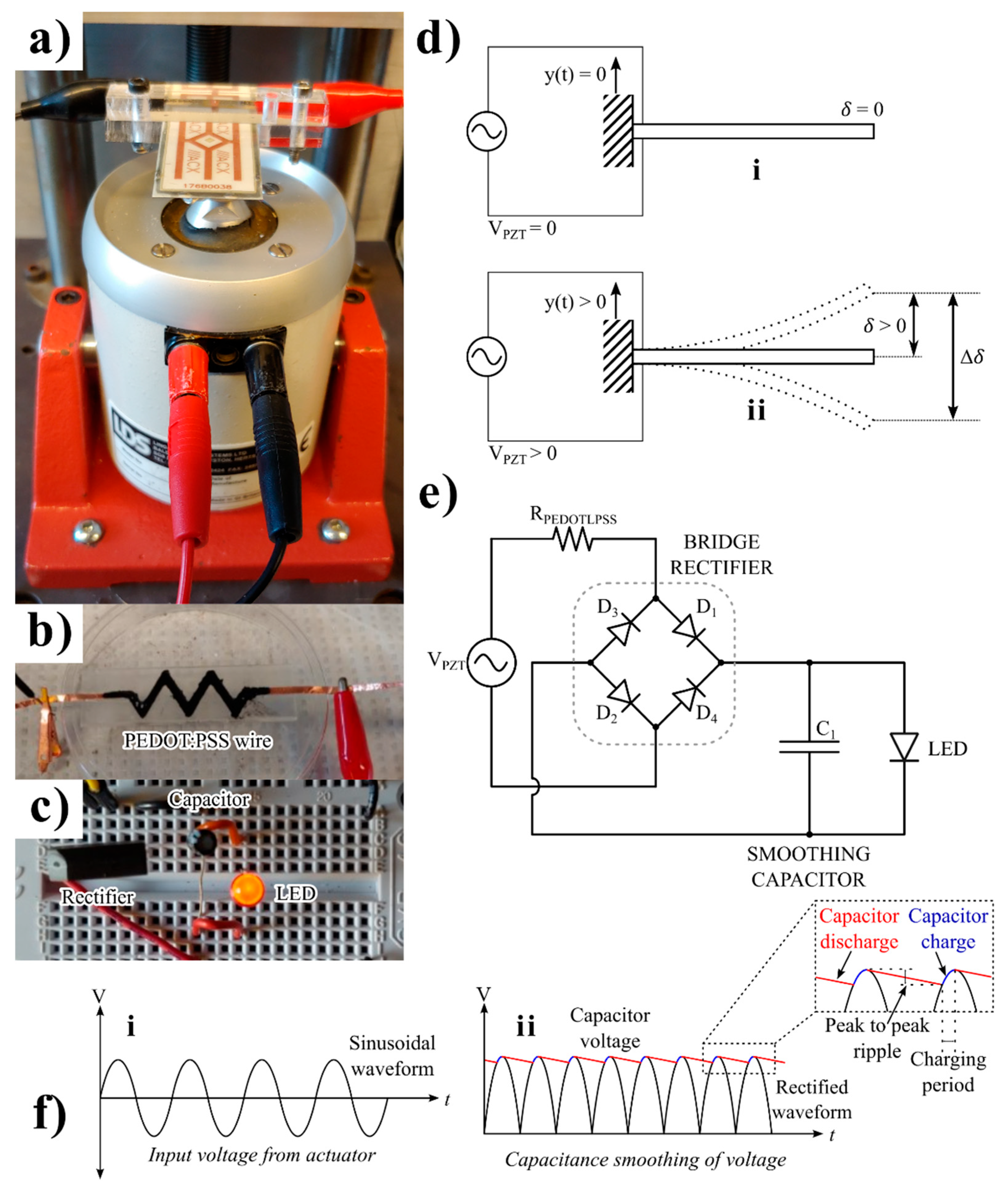

2. Methodology

2.1. PEDOT:PSS-MWCNT Composites

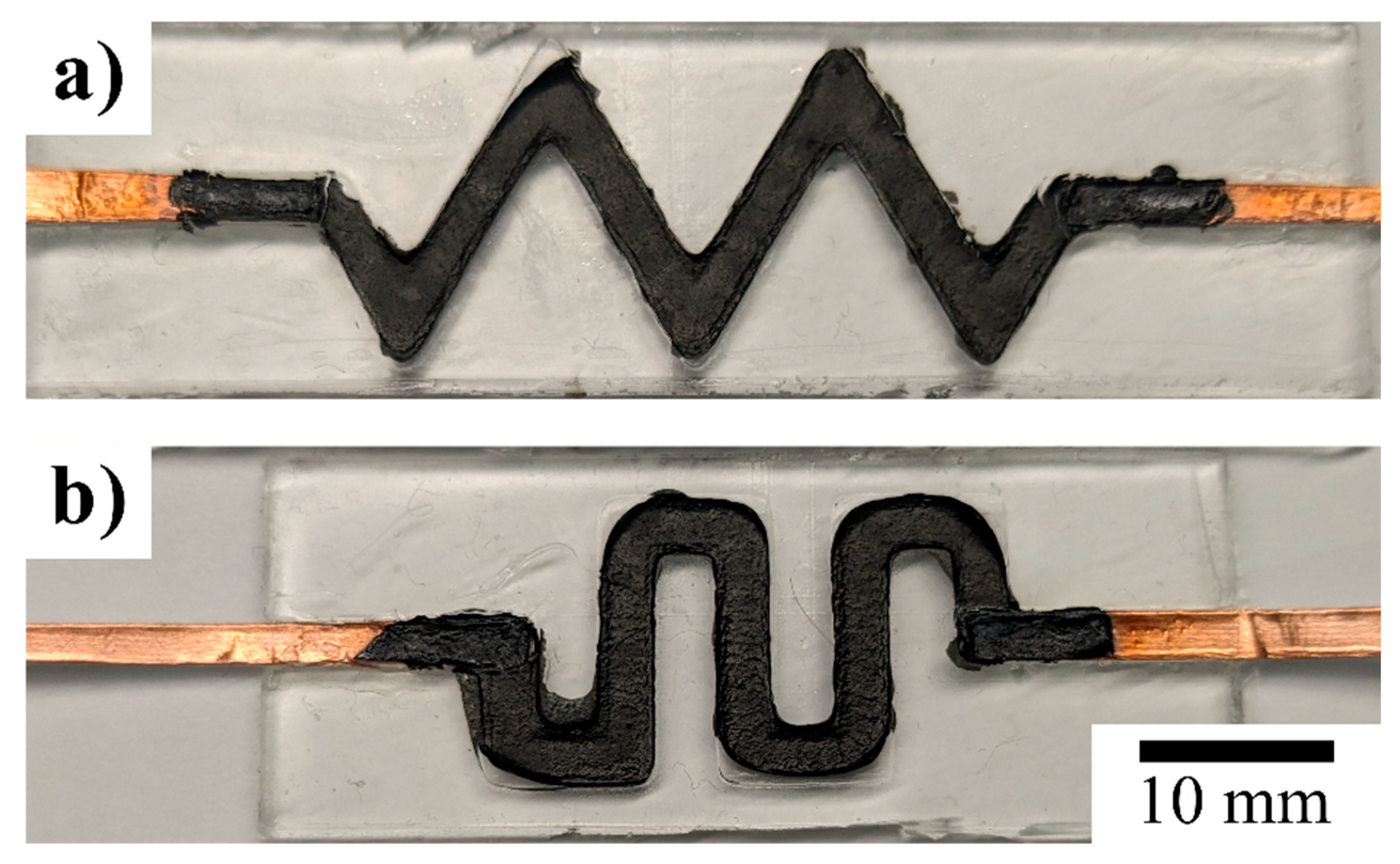

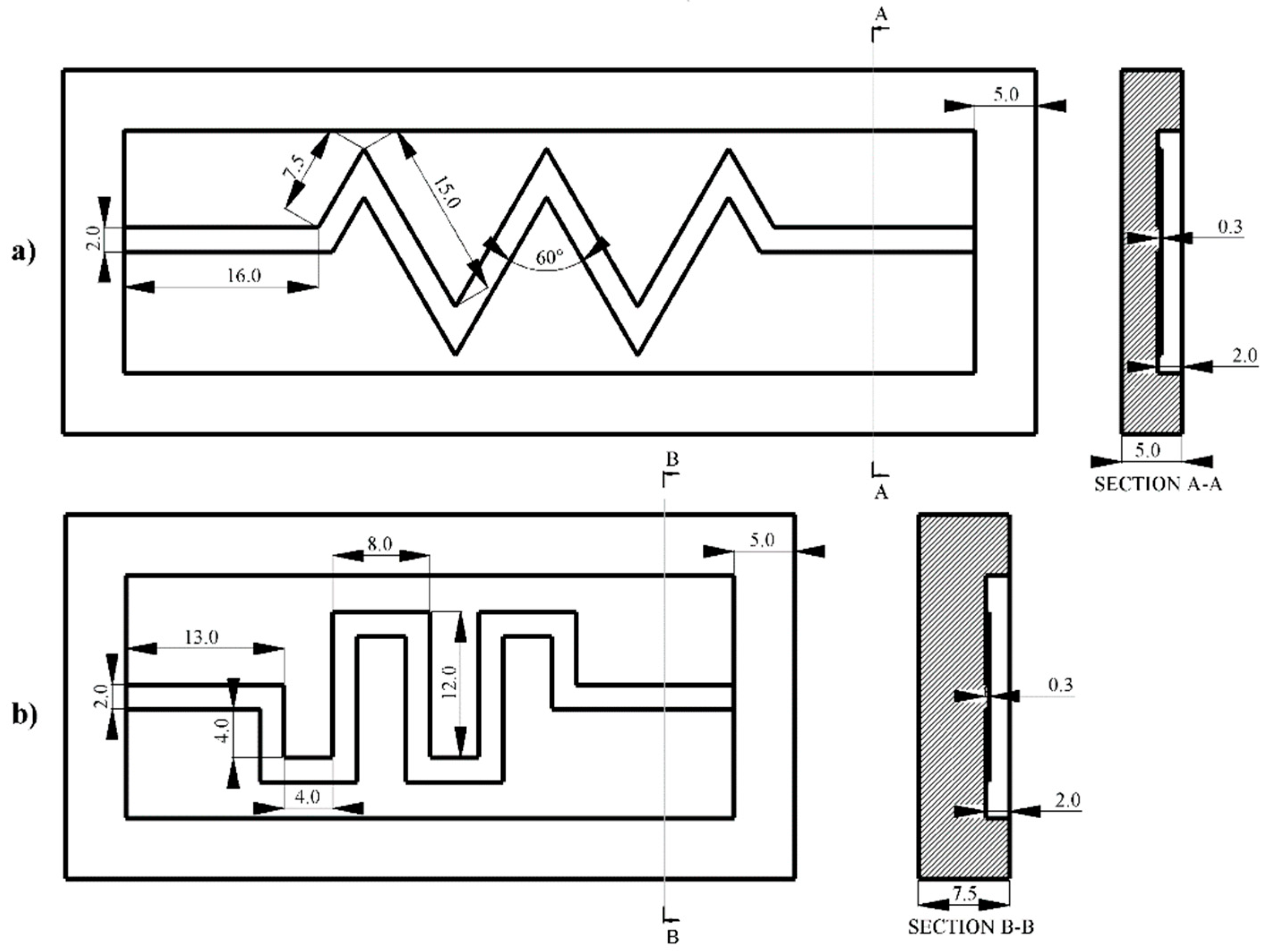

2.2. PDMS Molds

2.3. Experimental Set-Up

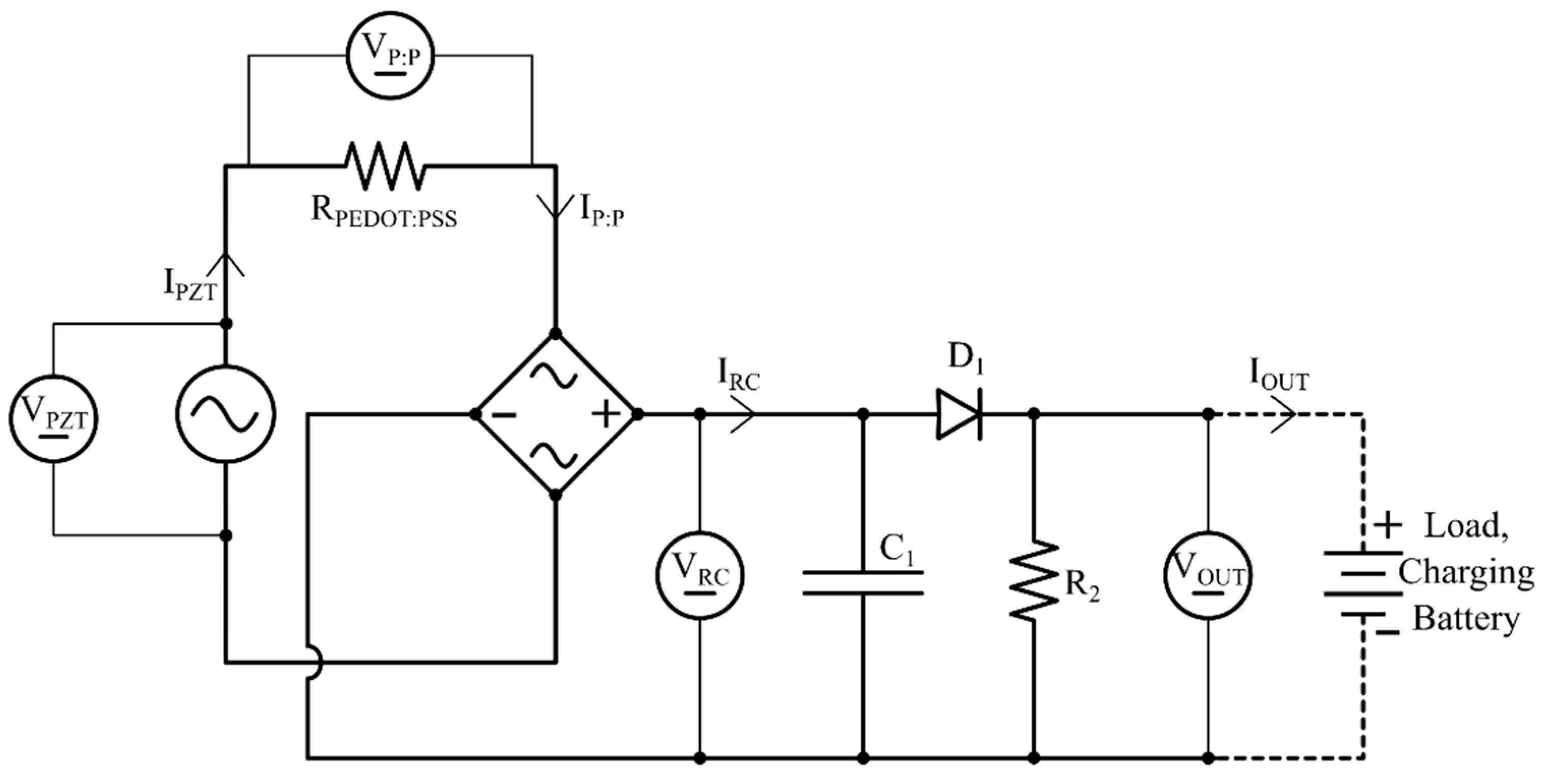

2.4. Electrical Measurements

Power and Efficiency Calculations

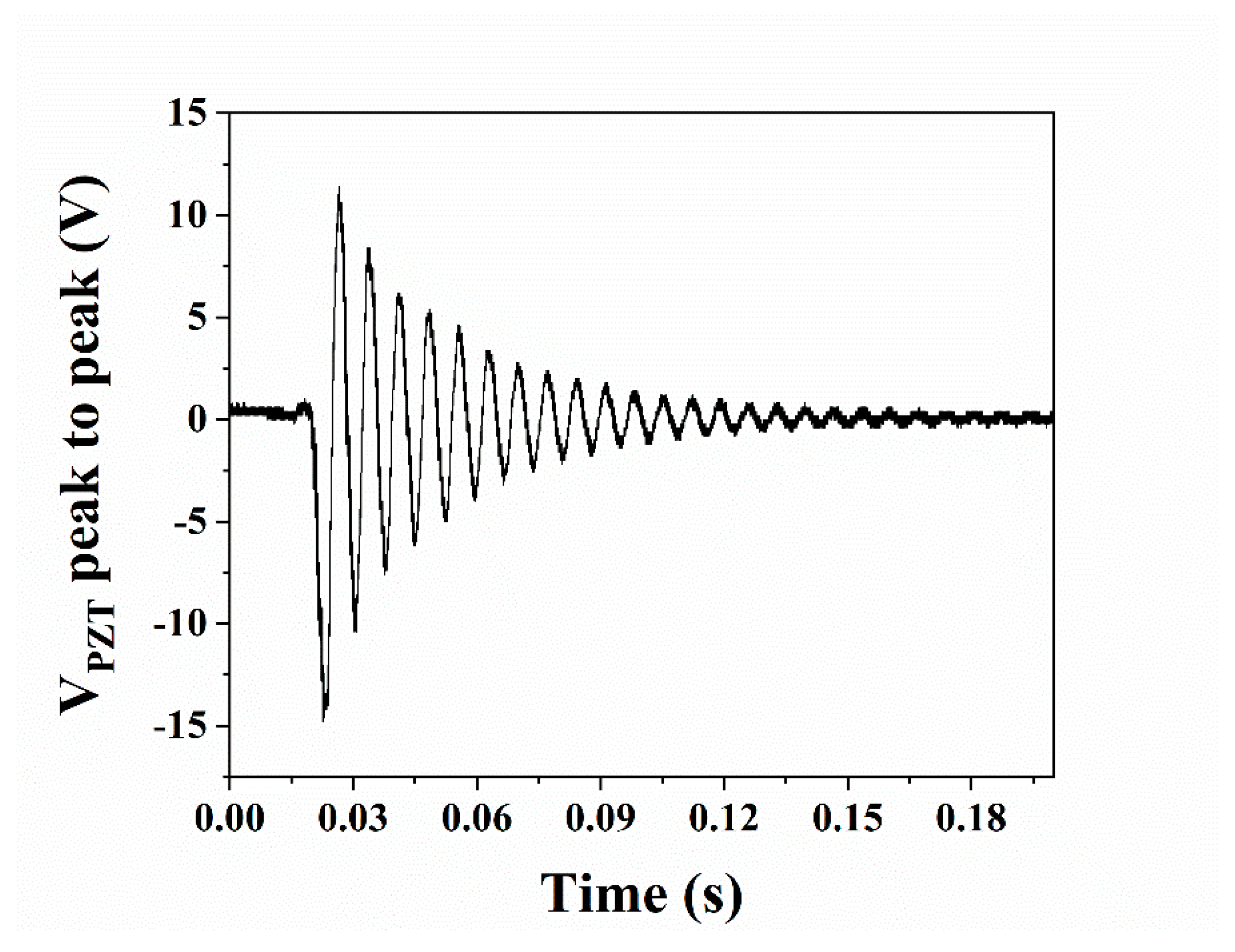

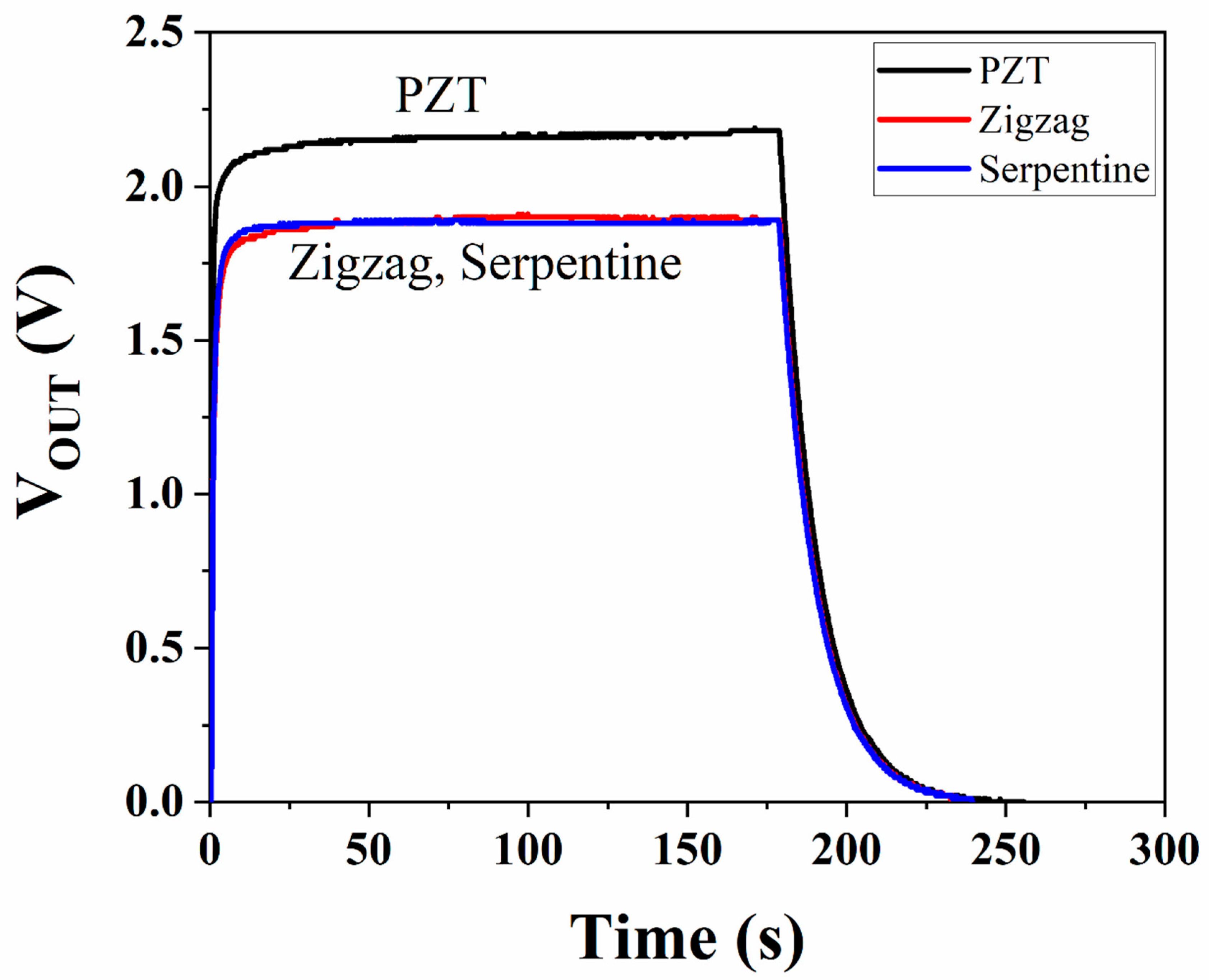

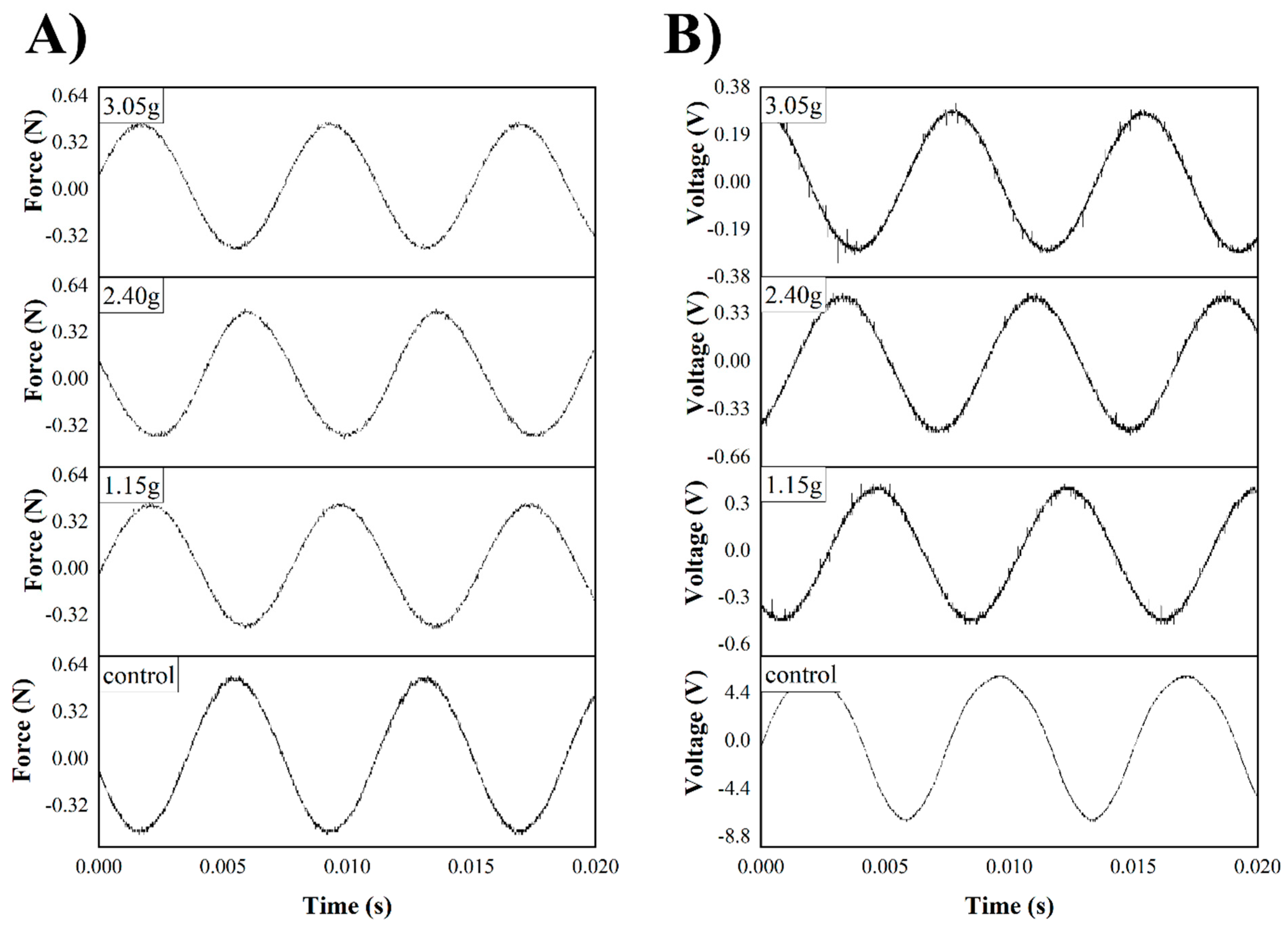

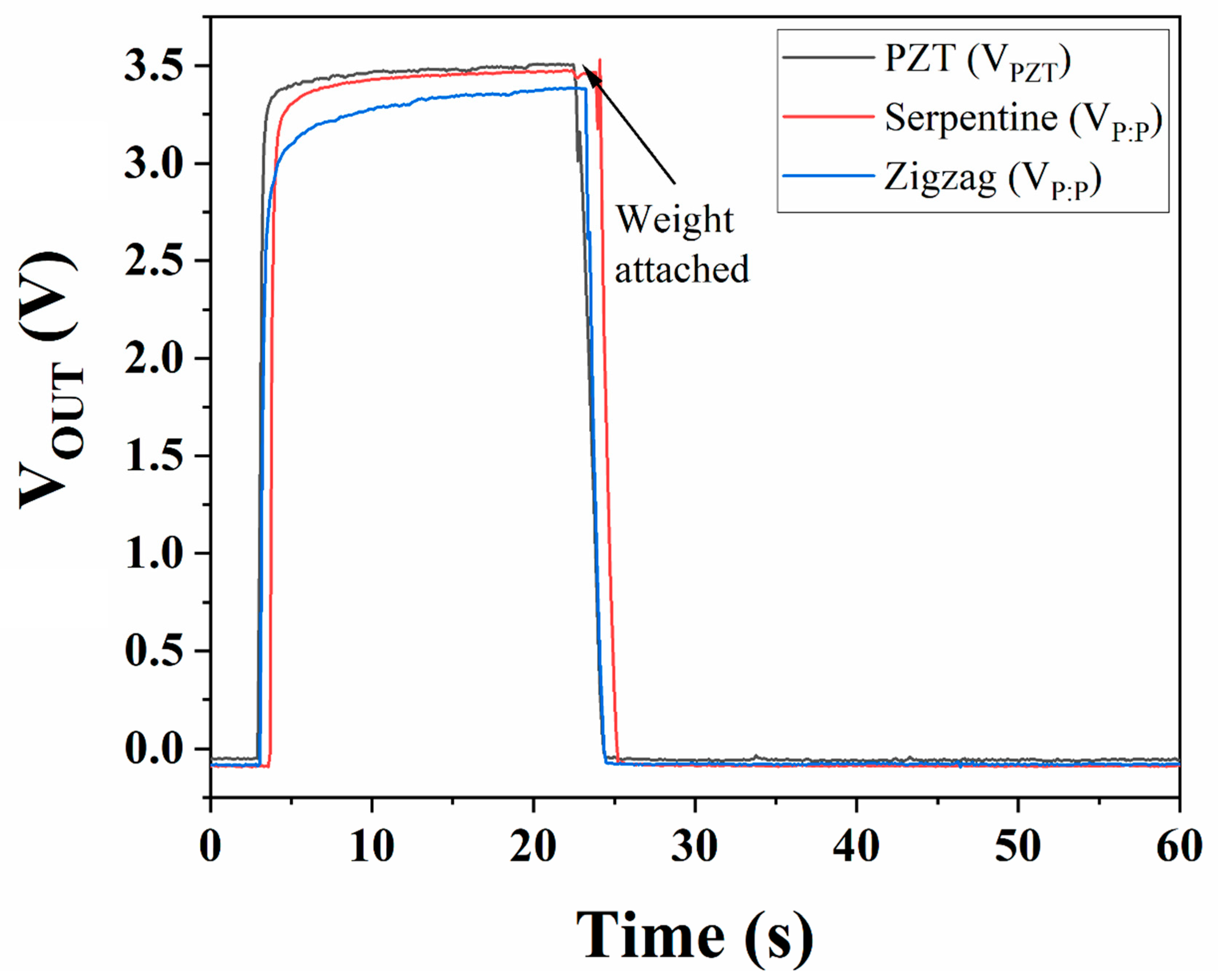

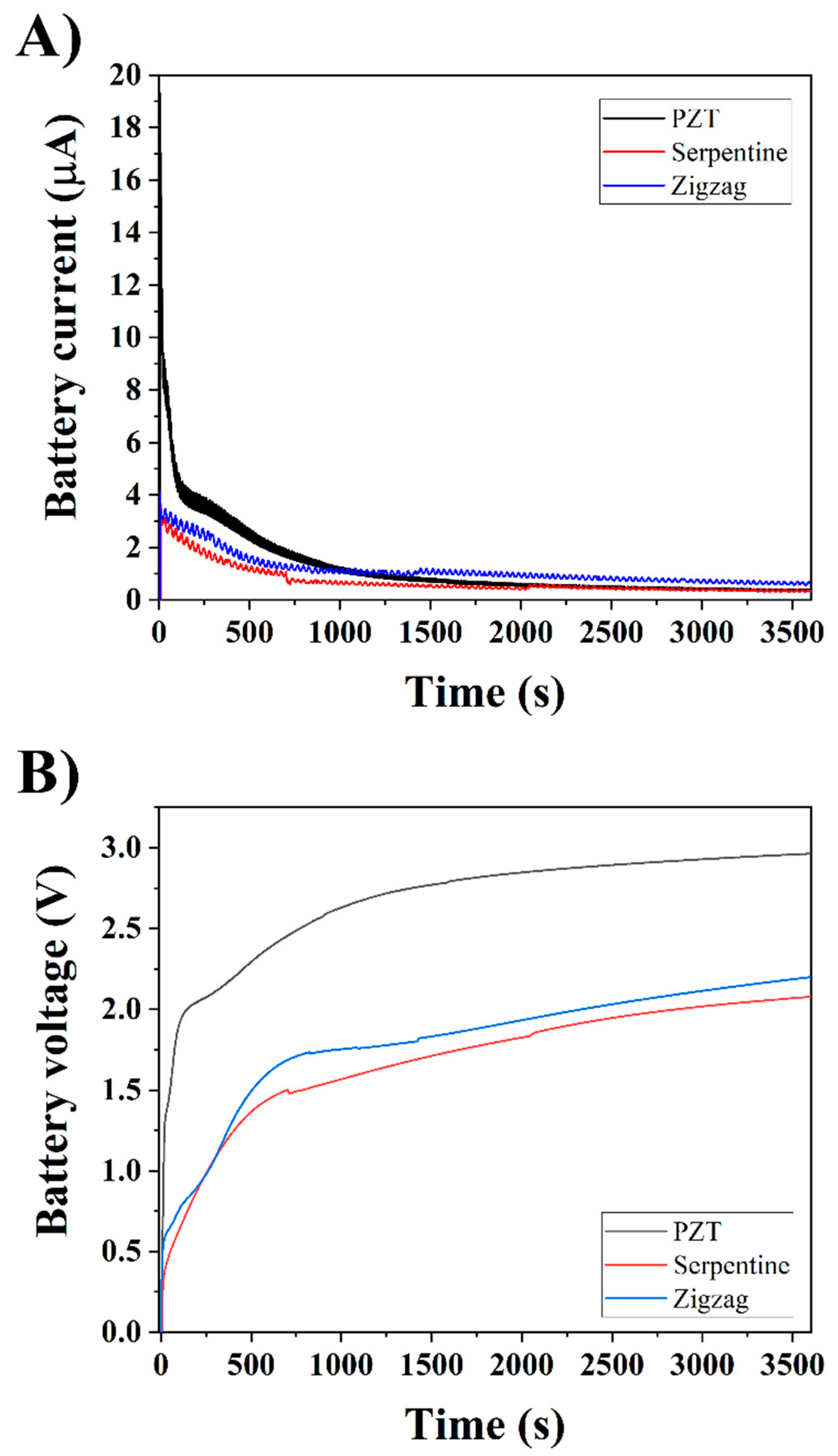

3. Results and Discussion

| 0 g | 1.15 g | 2.40 g | 3.05 g | |

|---|---|---|---|---|

| Shaker force (N) | 0.57 | 0.48 | 0.46 | 0.46 |

| Voltage, VPZT (V) | 6.00 | 0.49 | 0.45 | 0.32 |

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhao, R.; Guo, R.; Xu, X.; Liu, J. A Fast and Cost-Effective Transfer Printing of Liquid Metal Inks for Three-Dimensional Wiring in Flexible Electronics. ACS Appl. Mater. Interfaces 2020, 12, 36723–36730. [Google Scholar] [CrossRef] [PubMed]

- Gong, M.; Zhang, L.; Wan, P. Polymer nanocomposite meshes for flexible electronic devices. Prog. Polym. Sci. 2020, 107, 101279. [Google Scholar] [CrossRef]

- Gates, B.D. Flexible Electronics. Science 2009, 323, 1566–1567. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.; Dou, C.; Pal, L.; Hubbe, M. Review of Electrically Conductive Composites and Films Containing Cellulosic Fibers or Nanocellulose. Bioresources 2019, 14, 7494–7542. [Google Scholar] [CrossRef]

- Kaur, G.; Adhikari, R.; Cass, P.; Bown, M.; Gunatillake, P. Electrically conductive polymers and composites for biomedical applications. RSC Adv. 2015, 5, 37553–37567. [Google Scholar] [CrossRef]

- Huang, S.; Liu, Y.; Zhao, Y.; Ren, Z.; Guo, C.F. Flexible Electronics: Stretchable Electrodes and Their Future. Adv. Funct. Mater 2019, 29, 1805924. [Google Scholar] [CrossRef]

- Cochrane, C.; Koncar, V.; Lewandowski, M.; Dufour, C. Design and Development of a Flexible Strain Sensor for Textile Structures Based on a Conductive Polymer Composite. Sensors 2007, 7, 473–492. [Google Scholar] [CrossRef]

- Dan, L.; Elias, A.L. Flexible and Stretchable Temperature Sensors Fabricated Using Solution-Processable Conductive Polymer Composites. Adv. Healthc. Mater. 2020, 9, 2000380. [Google Scholar] [CrossRef]

- Sharma, S.; Hussain, S.; Singh, S.; Islam, S.S. MWCNT-conducting polymer composite based ammonia gas sensors: A new approach for complete recovery process. Sens. Actuators B Chem. 2014, 194, 213–219. [Google Scholar] [CrossRef]

- Latessa, G.; Brunetti, F.; Reale, A.; Saggio, G.; Di Carlo, A. Piezoresistive behaviour of flexible PEDOT:PSS based sensors. Sens. Actuators B Chem. 2009, 139, 304–309. [Google Scholar] [CrossRef]

- Aziz, S.B.; Abdullah, O.G.; Rasheed, M.A. A novel polymer composite with a small optical band gap: New approaches for photonics and optoelectronics. J. Appl. Polym. Sci. 2017, 134. [Google Scholar] [CrossRef]

- Kruželák, J.; Kvasničáková, A.; Hložeková, K.; Hudec, I. Progress in polymers and polymer composites used as efficient materials for EMI shielding. Nanoscale Adv. 2021, 3, 123–172. [Google Scholar] [CrossRef] [PubMed]

- Maruthi, N.; Faisal, M.; Raghavendra, N. Conducting polymer based composites as efficient EMI shielding materials: A comprehensive review and future prospects. Synth. Met. 2021, 272, 116664. [Google Scholar] [CrossRef]

- Song, P.; Liu, B.; Liang, C.; Ruan, K.; Qiu, H.; Ma, Z.; Guo, Y.; Gu, J. Lightweight, Flexible Cellulose-Derived Carbon Aerogel@Reduced Graphene Oxide/PDMS Composites with Outstanding EMI Shielding Performances and Excellent Thermal Conductivities. Nano-Micro Lett. 2021, 13, 91. [Google Scholar] [CrossRef]

- Sharma, D.; Bose, S. The journey of PDMS-based nanocomposites for EMI shielding applications: From bench to translational research. Mater. Adv. 2021, 2, 5580–5592. [Google Scholar] [CrossRef]

- Jia, H.; Kong, Q.-Q.; Liu, Z.; Wei, X.-X.; Li, X.-M.; Chen, J.-P.; Li, F.; Yang, X.; Sun, G.-H.; Chen, C.-M. 3D graphene/carbon nanotubes/polydimethylsiloxane composites as high-performance electromagnetic shielding material in X-band. Compos. Part A Appl. Sci. Manuf. 2020, 129, 105712. [Google Scholar] [CrossRef]

- Idumah, C.I.; Ezeani, E.O.; Nwuzor, I.C. A review: Advancements in conductive polymers nanocomposites. Polym. Plast. Technol. Mater. 2021, 60, 756–783. [Google Scholar] [CrossRef]

- Wang, Y.-F.; Sekine, T.; Takeda, Y.; Yokosawa, K.; Matsui, H.; Kumaki, D.; Shiba, T.; Nishikawa, T.; Tokito, S. Fully Printed PEDOT:PSS-based Temperature Sensor with High Humidity Stability for Wireless Healthcare Monitoring. Sci. Rep. 2020, 10, 2467. [Google Scholar] [CrossRef]

- Muckley, E.S.; Lynch, J.; Kumar, R.; Sumpter, B.; Ivanov, I.N. PEDOT:PSS/QCM-based multimodal humidity and pressure sensor. Sens. Actuators B Chem. 2016, 236, 91–98. [Google Scholar] [CrossRef]

- Zhang, X.; Yang, W.; Zhang, H.; Xie, M.; Duan, X. PEDOT:PSS: From conductive polymers to sensors. Nanotechnol. Precis. Eng. 2021, 4, 045004. [Google Scholar] [CrossRef]

- Panda, S.; Acharya, B. PDMS/MWCNT nanocomposites as capacitive pressure sensor and electromagnetic interference shielding materials. J. Mater. Sci. Mater. Electron. 2021, 32, 16215–16229. [Google Scholar] [CrossRef]

- Nallabothula, H.; Bhattacharjee, Y.; Samantara, L.; Bose, S. Processing-Mediated Different States of Dispersion of Multiwalled Carbon Nanotubes in PDMS Nanocomposites Influence EMI Shielding Performance. ACS Omega 2019, 4, 1781–1790. [Google Scholar] [CrossRef]

- Yen, C.-T.; Wu, F.-C.; Cheng, H.-L.; Sheu, H.-S.; Tang, F.-C.; Chou, W.-Y. Charge transfer highways in polymer solar cells embedded with imprinted PEDOT:PSS gratings. RSC Adv. 2014, 4, 58342–58348. [Google Scholar] [CrossRef]

- Wijeratne, K.; Ail, U.; Brooke, R.; Vagin, M.; Liu, X.; Fahlman, M.; Crispin, X. Bulk electronic transport impacts on electron transfer at conducting polymer electrode–electrolyte interfaces. Proc. Natl. Acad. Sci. USA 2018, 115, 11899–11904. [Google Scholar] [CrossRef] [PubMed]

- Das Neves, M.F.F.; Damasceno, J.P.V.; Holakoei, S.; Rocco, M.L.M.; Zarbin, A.J.G.; De Oliveira, C.K.B.Q.M.; Roman, L.S. Enhancement of conductivity and transmittance of graphene oxide/PEDOT:PSS electrodes and the evaluation of charge transfer dynamics. J. Appl. Phys. 2019, 126, 215107. [Google Scholar] [CrossRef]

- Li, J.; Liu, J.-C.; Gao, C. On the mechanism of conductivity enhancement in PEDOT/PSS film doped with multi-walled carbon nanotubes. J. Polym. Res. 2010, 17, 713–718. [Google Scholar] [CrossRef]

- Lee, H.-Y.; Kim, S.-K.; Lee, M.-R.; Peck, D.-H.; Kang, Y.C.; Kim, C.-S. Reduced mass transport resistance in polymer electrolyte membrane fuel cell by polyethylene glycol addition to catalyst ink. J. Hydrog. Energy 2019, 44, 354–361. [Google Scholar] [CrossRef]

- Ahmed, H.T.; Jalal, V.J.; Tahir, D.A.; Mohamad, A.H.; Abdullah, O.G. Effect of PEG as a plasticizer on the electrical and optical properties of polymer blend electrolyte MC-CH-LiBF4 based films. Results Phys. 2019, 15, 102735. [Google Scholar] [CrossRef]

- Ahmad Shahrim, N.; Ahmad, Z.; Azman, A.W.; Buys, Y.F.; Sarifuddin, N. Mechanisms for doped PEDOT:PSS electrical conductivity improvement. Mater. Adv. 2021, 2, 7118–7138. [Google Scholar] [CrossRef]

- Namkoong, G.; Younes, E.M.; Abdel-Fattah, T.M.; El-Maghraby, E.M.; Elsayed, A.H.; Abo Elazm, A.H. Aging process of PEDOT:PSS dispersion and robust recovery of aged PEDOT:PSS as a hole transport layer for organic solar cells. Org. Electron. 2015, 25, 237–244. [Google Scholar] [CrossRef]

- Raju, S.S.; Umapathy, M.; Uma, G. Cantilever piezoelectric energy harvester with multiple cavities. Smart Mater. Struct. 2015, 24, 115023. [Google Scholar] [CrossRef]

- Wang, X.; Niu, S.; Yi, F.; Yin, Y.; Hao, C.; Dai, K.; Zhang, Y.; You, Z.; Wang, Z.L. Harvesting Ambient Vibration Energy over a Wide Frequency Range for Self-Powered Electronics. ACS Nano 2017, 11, 1728–1735. [Google Scholar] [CrossRef] [PubMed]

- Zhou, S.; Cao, J.; Wang, W.; Liu, S.; Lin, J. Modeling and experimental verification of doubly nonlinear magnet-coupled piezoelectric energy harvesting from ambient vibration. Smart Mater. Struct. 2015, 24, 055008. [Google Scholar] [CrossRef]

- Hwang, G.-T.; Annapureddy, V.; Han, J.H.; Joe, D.J.; Baek, C.; Park, D.Y.; Kim, D.H.; Park, J.H.; Jeong, C.K.; Park, K.-I.; et al. Self-Powered Wireless Sensor Node Enabled by an Aerosol-Deposited PZT Flexible Energy Harvester. Adv. Energy Mater. 2016, 6, 1600237. [Google Scholar] [CrossRef]

- Ma, Y.; Ji, Q.; Chen, S.; Song, G. An experimental study of ultra-low power wireless sensor-based autonomous energy harvesting system. J. Renew. Sustain. Energy 2017, 9, 054702. [Google Scholar] [CrossRef]

- Xu, T.-B.; Siochi, E.J.; Kang, J.H.; Zuo, L.; Zhou, W.; Tang, X.; Jiang, X. Energy harvesting using a PZT ceramic multilayer stack. Smart Mater. Struct. 2013, 22, 065015. [Google Scholar] [CrossRef]

- Yuan, L.; Xiao, X.; Ding, T.; Zhong, J.; Zhang, X.; Shen, Y.; Hu, B.; Huang, Y.; Zhou, J.; Wang, Z.L. Paper-Based Supercapacitors for Self-Powered Nanosystems. Angew. Chem. Int. Ed. 2012, 51, 4934–4938. [Google Scholar] [CrossRef]

- Wang, W.; Cao, J.; Bowen, C.R.; Zhou, S.; Lin, J. Optimum resistance analysis and experimental verification of nonlinear piezoelectric energy harvesting from human motions. Energy 2017, 118, 221–230. [Google Scholar]

- Sun, X.; Wang, F.; Xu, J. Nonlinear Piezoelectric Structure for Ultralow-frequency Band Vibration Energy Harvesting with Magnetic Interaction. Int. J. Precis. Eng. Manuf.-Green Technol. 2019, 6, 671–679. [Google Scholar] [CrossRef]

- Atalay, T.; Köysal, Y.; Özdemir, A.E.; Özbaş, E. Evaluation of energy efficiency of thermoelectric generator with two-phase thermo-syphon heat pipes and nano-particle fluids. Int. J. Precis. Eng. Manuf.-Green Technol. 2018, 5, 5–12. [Google Scholar] [CrossRef]

- Kirihara, K.; Wei, Q.; Mukaida, M.; Ishida, T. Thermoelectric power generation using nonwoven fabric module impregnated with conducting polymer PEDOT:PSS. Synth. Met. 2017, 225, 41–48. [Google Scholar] [CrossRef]

- Wang, F.; Hansen, O. Electrostatic energy harvesting device with out-of-the-plane gap closing scheme. Sens. Actuators A Phys 2014, 211, 131–137. [Google Scholar] [CrossRef]

- Fan, F.-R.; Tian, Z.-Q.; Lin Wang, Z. Flexible triboelectric generator. Nano Energy 2012, 1, 328–334. [Google Scholar] [CrossRef]

- Richards, C.D.; Anderson, M.J.; Bahr, D.F.; Richards, R.F. Efficiency of energy conversion for devices containing a piezoelectric component. J. Micromech. Microeng. 2004, 14, 717. [Google Scholar] [CrossRef]

- Sodano, H.; Inman, D. A Review of Power Harvesting From Vibration Using Piezoelectric Materials. Shock. Vib. Dig. 2004, 36, 197–205. [Google Scholar] [CrossRef]

- Yuan, X.; Changgeng, S.; Yan, G.; Zhenghong, Z. Application review of dielectric electroactive polymers (DEAPs) and piezoelectric materials for vibration energy harvesting. J. Phys. Conf. Ser. 2016, 744, 012077. [Google Scholar] [CrossRef]

| RMS Voltage (V) | RMS Current (A) | Power (W) | |

|---|---|---|---|

| PZT, VPZT | 5.94 | 4.90 × 10−4 | 2.91 × 10−3 |

| Rectifier, VRC | 5.52 | 2.50 × 10−4 | 1.38 × 10−3 |

| RC network, Vout | 3.89 | 1.80 × 10−4 | 0.70 × 10−3 |

| RMS Voltage (V) | RMS Current (A) | Power (W) | |

|---|---|---|---|

| PZT, VPZT | 5.94 | 4.90 × 10−4 | 3.16 × 10−3 |

| PEDOT:PSS, VP:P | 5.52 | 4.60 × 10−4 | 2.92 × 10−3 |

| Rectifier, VRC | 5.86 | 2.50 × 10−4 | 1.47 × 10−3 |

| RC network, Vout | 4.12 | 1.80 × 10−4 | 0.74 × 10−3 |

| RMS Voltage (V) | RMS Current (A) | Power (W) | |

|---|---|---|---|

| PZT, VPZT | 6.55 | 5.10 × 10−4 | 3.34 × 10−3 |

| PEDOT:PSS, VP:P | 6.53 | 4.90 × 10−4 | 3.20 × 10−3 |

| Rectifier, VRC | 5.91 | 2.50 × 10−4 | 1.48 × 10−3 |

| RC network, Vout | 4.20 | 1.80 × 10−4 | 0.76 × 10−3 |

| Efficiency of Control | Efficiency with Zigzag Line | Efficiency with Serpentine Line | |

|---|---|---|---|

| PZT to PEDOT:PSS | n/a | 0.92 | 0.96 |

| PEDOT:PSS to rectifier | 0.47 * | 0.50 | 0.46 |

| Rectifier to RC network | 0.51 | 0.51 | 0.51 |

| Total efficiency | 0.24 | 0.23 | 0.23 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shafagh, S.H.; Deen, I.; Mamsapuram Panneerselvam, D.; Packirisamy, M. PEDOT:PSS-MWCNT Nanocomposite Wire for Routing in Energy Harvesting Devices. Micromachines 2025, 16, 382. https://doi.org/10.3390/mi16040382

Shafagh SH, Deen I, Mamsapuram Panneerselvam D, Packirisamy M. PEDOT:PSS-MWCNT Nanocomposite Wire for Routing in Energy Harvesting Devices. Micromachines. 2025; 16(4):382. https://doi.org/10.3390/mi16040382

Chicago/Turabian StyleShafagh, S. Haghgooye, Imran Deen, Dhilippan Mamsapuram Panneerselvam, and Muthukumaran Packirisamy. 2025. "PEDOT:PSS-MWCNT Nanocomposite Wire for Routing in Energy Harvesting Devices" Micromachines 16, no. 4: 382. https://doi.org/10.3390/mi16040382

APA StyleShafagh, S. H., Deen, I., Mamsapuram Panneerselvam, D., & Packirisamy, M. (2025). PEDOT:PSS-MWCNT Nanocomposite Wire for Routing in Energy Harvesting Devices. Micromachines, 16(4), 382. https://doi.org/10.3390/mi16040382