Electrothermal Failure Physics of GaN Schottky Diodes Under High-Temperature Forward Biasing

Abstract

1. Introduction

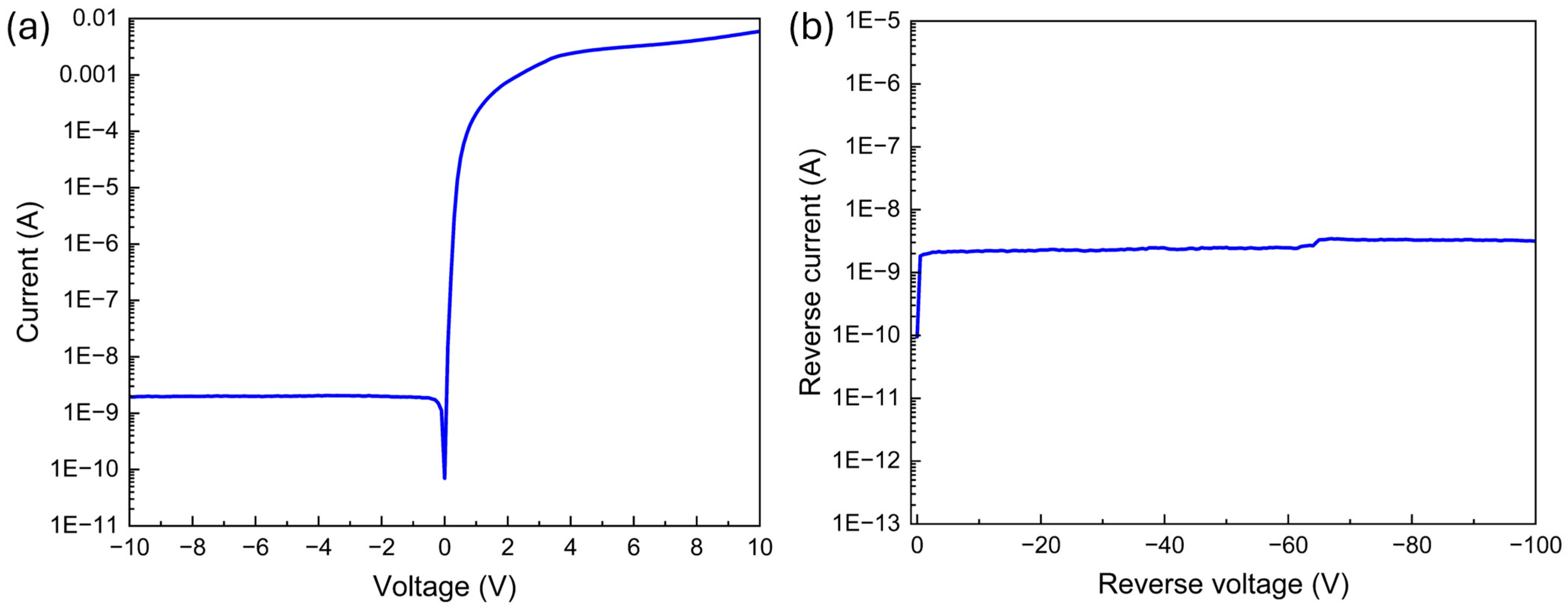

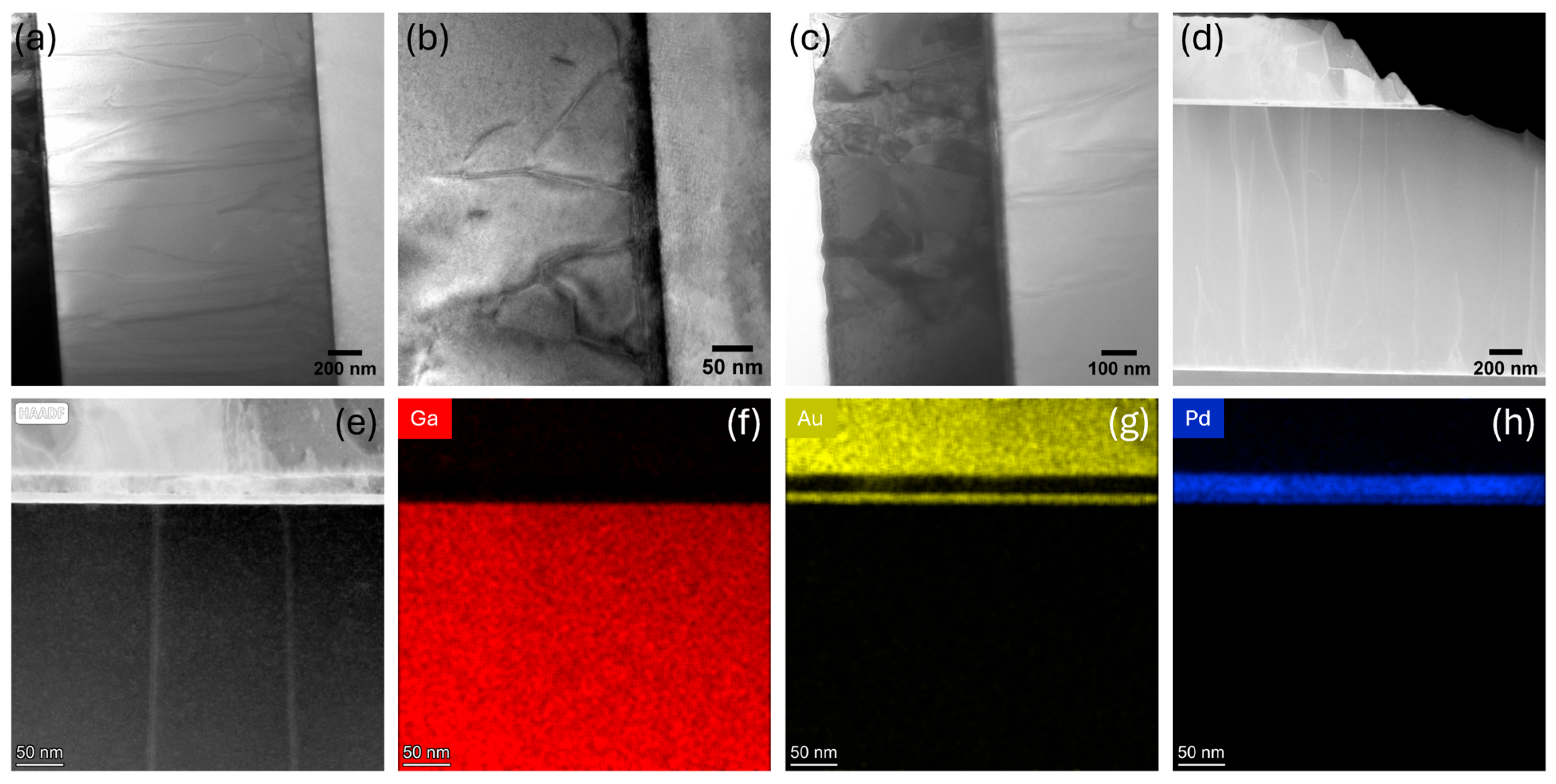

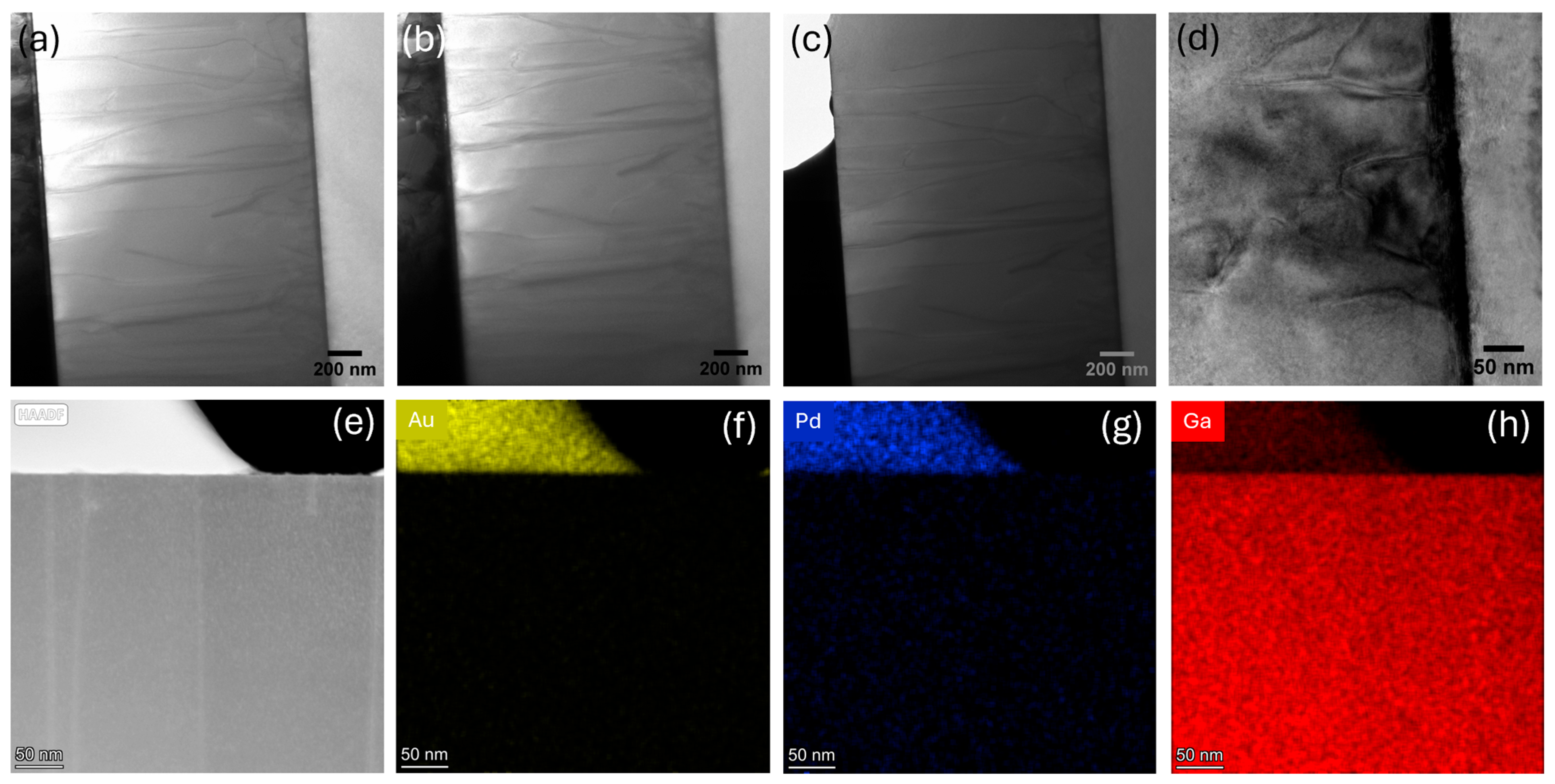

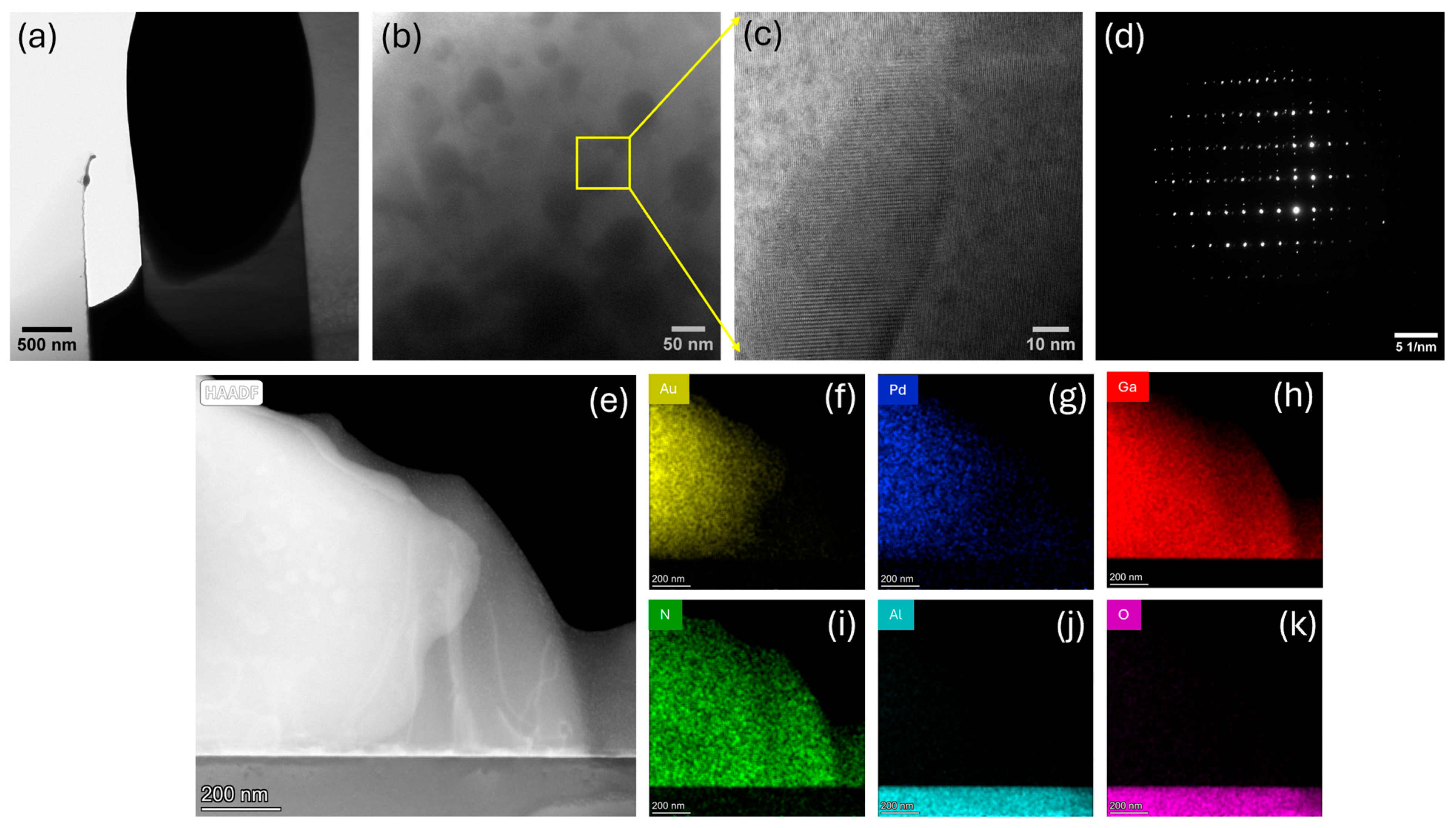

2. Materials and Methods

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Meneghini, M.; De Santi, C.; Abid, I.; Buffolo, M.; Cioni, M.; Khadar, R.A.; Nela, L.; Zagni, N.; Chini, A.; Medjdoub, F.; et al. GaN-based power devices: Physics; reliability; perspectives. J. Appl. Phys. 2021, 130, 181101. [Google Scholar] [CrossRef]

- Kozak, J.P.; Zhang, R.; Porter, M.; Song, Q.; Liu, J.; Wang, B.; Wang, R.; Saito, W.; Zhang, Y. Stability, Reliability, and Robustness of GaN Power Devices: A Review. IEEE Trans. Power Electron. 2023, 38, 8442–8471. [Google Scholar] [CrossRef]

- Islam, N.; Mohamed, M.F.; Khan, M.F.; Falina, S.; Kawarada, H.; Syamsul, M. Reliability, Applications and Challenges of GaN HEMT Technology for Modern Power Devices: A Review. Crystals 2022, 12, 1581. [Google Scholar] [CrossRef]

- Teo, K.H.; Zhang, Y.; Chowdhury, N.; Rakheja, S.; Ma, R.; Xie, Q.; Yagyu, E.; Yamanaka, K.; Li, K.; Palacios, T. Emerging GaN technologies for power, RF, digital, and quantum computing applications: Recent advances and prospects. J. Appl. Phys. 2021, 130, 160902. [Google Scholar] [CrossRef]

- Flack, T.J.; Pushpakaran, B.N.; Bayne, S.B. GaN Technology for Power Electronic Applications: A Review. J. Electron. Mater. 2016, 45, 2673–2682. [Google Scholar] [CrossRef]

- Pearton, S.J.; Aitkaliyeva, A.; Xian, M.; Ren, F.; Khachatrian, A.; Ildefonso, A.; Islam, Z.; Rasel, M.A.J.; Haque, A.; Polyakov, A.Y.; et al. Review—Radiation Damage in Wide and Ultra-Wide Bandgap Semiconductors. ECS J. Solid State Sci. Technol. 2021, 10, 055008. [Google Scholar] [CrossRef]

- Pearton, S.; Xia, X.; Ren, F.; Rasel, M.A.J.; Stepanoff, S.; Al-Mamun, N.; Haque, A.; Wolfe, D.E. Radiation damage in GaN/AlGaN and SiC electronic and photonic devices. J. Vac. Sci. Technol. B 2023, 41, 030802. [Google Scholar] [CrossRef]

- Jones, E.A.; Wang, F.F.; Costinett, D. Review of Commercial GaN Power Devices and GaN-Based Converter Design Challenges. IEEE J. Emerg. Sel. Top. Power Electron. 2016, 4, 707–719. [Google Scholar] [CrossRef]

- Zhong, Y.; Zhang, J.; Wu, S.; Jia, L.; Yang, X.; Liu, Y.; Zhang, Y.; Sun, Q. A review on the GaN-on-Si power electronic devices. Fundam. Res. 2022, 2, 462–475. [Google Scholar] [CrossRef] [PubMed]

- Buffolo, M.; Favero, D.; Marcuzzi, A.; Santi, C.D.; Meneghesso, G.; Zanoni, E.; Meneghini, M. Review and Outlook on GaN and SiC Power Devices: Industrial State-of-the-Art, Applications, and Perspectives. IEEE Trans. Electron Devices 2024, 71, 1344–1355. [Google Scholar] [CrossRef]

- Amano, H.; Baines, Y.; Beam, E.; Borga, M.; Bouchet, T.; Chalker, P.R.; Charles, M.; Chen, K.J.; Chowdhury, N.; Chu, R.; et al. The 2018 GaN power electronics roadmap. J. Phys. D Appl. Phys. 2018, 51, 163001. [Google Scholar] [CrossRef]

- Shao, Y.; Zhang, F.; He, Y.; Liu, P.; Sheng, B.; Lu, X.; Wang, Z.; Wang, X.; Li, Y.; Zheng, X.; et al. Research progress and prospect of GaN Schottky diodes. J. Phys. D Appl. Phys. 2024, 57, 093001. [Google Scholar] [CrossRef]

- Li, Y.; Pu, T.F.; Li, X.B.; Zhong, Y.R.; Yang, L.A.; Fujiwara, S.; Kitahata, H.; Ao, J.P. GaN Schottky Barrier Diode-Based Wideband and Medium-Power Microwave Rectifier for Wireless Power Transmission. IEEE Trans. Electron Devices 2020, 67, 4123–4129. [Google Scholar] [CrossRef]

- Wuerfl, J.; Bahat-Treidel, E.; Brunner, F.; Cho, E.; Hilt, O.; Ivo, P.; Knauer, A.; Kurpas, P.; Lossy, R.; Schulz, M.; et al. Reliability issues of GaN based high voltage power devices. Microelectron. Reliab. 2011, 51, 1710–1716. [Google Scholar] [CrossRef]

- Meneghini, M.; Rossetto, I.; Santi, C.D.; Rampazzo, F.; Tajalli, A.; Barbato, A.; Ruzzarin, M.; Borga, M.; Canato, E.; Zanoni, E.; et al. Reliability and failure analysis in power GaN-HEMTs: An overview. In Proceedings of the 2017 IEEE International Reliability Physics Symposium (IRPS), Monterey, California, USA, 2–6 April 2017; pp. 3B-2.1–3B-2.8. [Google Scholar]

- Zanoni, E.; Meneghini, M.; Meneghesso, G.; Rampazzo, F.; Marcon, D.; Zhan, V.G.; Chiocchetta, F.; Graff, A.; Altmann, F.; Simon-Najasek, M.; et al. Reliability Physics of GaN HEMT Microwave Devices: The Age of Scaling. In Proceedings of the 2020 IEEE International Reliability Physics Symposium (IRPS), Dallas, Texas, USA, 28 April–30 May 2020; pp. 1–10. [Google Scholar]

- Pearton, S.J.; Ren, F.; Zhang, A.P.; Lee, K.P. Fabrication and performance of GaN electronic devices. Mater. Sci. Eng. R Rep. 2000, 30, 55–212. [Google Scholar] [CrossRef]

- Paskova, T. Evans, GaN Substrates—Progress, Status, and Prospects. IEEE J. Sel. Top. Quantum Electron. 2009, 15, 1041–1052. [Google Scholar] [CrossRef]

- Zhang, D.; Cheng, X.; Ng, W.T.; Shen, L.; Zheng, L.; Wang, Q.; Qian, R.; Gu, Z.; Wu, D.; Zhou, W.; et al. Reliability Improvement of GaN Devices on Free-Standing GaN Substrates. IEEE Trans. Electron Devices 2018, 65, 3379–3387. [Google Scholar] [CrossRef]

- Wu, X.H.; Fini, P.; Tarsa, E.J.; Heying, B.; Keller, S.; Mishra, U.K.; DenBaars, S.P.; Speck, J.S. Dislocation generation in GaN heteroepitaxy. J. Cryst. Growth 1998, 189–190, 231–243. [Google Scholar] [CrossRef]

- Stabentheiner, M.; Diehle, P.; Hübner, S.; Lejoyeux, M.; Altmann, F.; Neumann, R.; Taylor, A.A.; Pogany, D.; Ostermaier, C. On the insignificance of dislocations in reverse bias degradation of lateral GaN-on-Si devices. J. Appl. Phys. 2024, 135, 025703. [Google Scholar] [CrossRef]

- Kuball, M.; Ťapajna, M.; Simms, R.J.T.; Faqir, M.; Mishra, U.K. AlGaN/GaN HEMT device reliability and degradation evolution: Importance of diffusion processes. Microelectron. Reliab. 2011, 51, 195–200. [Google Scholar] [CrossRef]

- Boughrara, N.; Benzarti, Z.; Khalfallah, A.; Evaristo, M.; Cavaleiro, A. Comparative study on the nanomechanical behavior and physical properties influenced by the epitaxial growth mechanisms of GaN thin films. Appl. Surf. Sci. 2022, 579, 152188. [Google Scholar] [CrossRef]

- Liliental-Weber, Z.; Ruvimov, S.; Kisielowski, C.H.; Chen, Y.; Swider, W.; Washburn, J.; Newman, N.; Gassmann, A.; Liu, X.; Schloss, L.; et al. Structural Defects in Heteroepitaxial and Homoepitaxial GaN. MRS Online Proc. Libr. 1995, 395, 351–362. [Google Scholar] [CrossRef]

- Liliental-Weber, Z. Structural defects in GaN revealed by transmission electron microscopy. Jpn. J. Appl. Phys. 2014, 53, 100205. [Google Scholar] [CrossRef]

- Setera, B.; Christou, A. Threading dislocations in GaN high-voltage switches. Microelectron. Reliab. 2021, 124, 114336. [Google Scholar] [CrossRef]

- Besendörfer, S.; Meissner, E.; Medjdoub, F.; Derluyn, J.; Friedrich, J.; Erlbacher, T. The impact of dislocations on AlGaN/GaN Schottky diodes and on gate failure of high electron mobility transistors. Sci. Rep. 2020, 10, 17252. [Google Scholar] [CrossRef]

- Hassan, A.; Savaria, Y.; Sawan, M.; Technology, G.I. An Ideal Candidate for High-Temperature Applications: A Review. IEEE Access 2018, 6, 78790–78802. [Google Scholar] [CrossRef]

- Cheney, D.J.; Douglas, E.A.; Liu, L.; Lo, C.F.; Xi, Y.Y.; Gila, B.P.; Ren, F.; Horton, D.; Law, M.E.; Smith, D.J.; et al. Reliability studies of AlGaN/GaN high electron mobility transistors. Semicond. Sci. Technol. 2013, 28, 074019. [Google Scholar] [CrossRef]

- Horng, R.H.; Chiang, C.C.; Hsiao, H.Y.; Zheng, X.; Wuu, D.S.; Lin, H.I. Improved thermal management of GaN/sapphire light-emitting diodes embedded in reflective heat spreaders. Appl. Phys. Lett. 2008, 93, 111907. [Google Scholar] [CrossRef]

- Jie, S.; Fatima, H.; Koudymov, A.; Chitnis, A.; Hu, X.; Wang, H.M.; Zhang, J.; Simin, G.; Yang, J.; Khan, M.A. Thermal management of AlGaN-GaN HFETs on sapphire using flip-chip bonding with epoxy underfill. IEEE Electron Device Lett. 2003, 24, 375–377. [Google Scholar]

- Kim, H. Vertical Schottky Contacts to Bulk GaN Single Crystals and Current Transport Mechanisms: A Review. J. Electron. Mater. 2021, 50, 6688–6707. [Google Scholar] [CrossRef]

- Chen, Y.Q.; Liao, X.Y.; Zeng, C.; Peng, C.; Liu, Y.; Li, R.G.; En, Y.F.; Huang, Y. Degradation mechanism of AlGaN/GaN HEMTs during high temperature operation stress. Semicond. Sci. Technol. 2018, 33, 015019. [Google Scholar] [CrossRef]

- Jung, H.; Behtash, R.; Thorpe, J.R.; Riepe, K.; Bourgeois, F.; Blanck, H.; Chuvilin, A.; Kaiser, U. Reliability behavior of GaN HEMTs related to Au diffusion at the Schottky interface. Physica Status Solidi 2009, 6 (Suppl. S2), S976–S979. [Google Scholar] [CrossRef]

- Monroy, E.; Calle, F.; Palacios, T.; Sánchez-Osorio, J.; Verdú, M.; Sánchez, F.J.; Montojo, M.T.; Omnès, F.; Bougrioua, Z.; Moerman, I.; et al. Reliability of Schottky Contacts on AlGaN. Physica Status Solidi 2001, 188, 367–370. [Google Scholar] [CrossRef]

- Barinov, A.; Casalis, L.; Gregoratti, L.; Kiskinova, M. Au/GaN interface: Initial stages of formation and temperature-induced effects. Phys. Rev. B 2001, 63, 085308. [Google Scholar] [CrossRef]

- Rasel, M.A.J.; Zhang, D.; Chen, A.; Thomas, M.; House, S.D.; Kuo, W.; Watt, J.; Islam, A.; Glavin, N.; Smyth, M.; et al. Temperature-induced degradation of GaN HEMT: An in situ heating study. J. Vac. Sci. Technol. B 2024, 42, 032209. [Google Scholar] [CrossRef]

- Al-Mamun, N.S.; Islam, A.; Glavin, N.; Haque, A.; Wolfe, D.E.; Ren, F.; Pearton, S. Synergistic effects of heating and biasing of AlGaN/GaN high electron mobility transistors: An in-situ transmission electron microscopy study. Microelectron. Reliab. 2024, 160, 115470. [Google Scholar] [CrossRef]

- Guo, J.D.; Pan, F.M.; Feng, M.S.; Guo, R.J.; Chou, P.F.; Chang, C.Y. Schottky contact and the thermal stability of Ni on n-type GaN. J. Appl. Phys. 1996, 80, 1623–1627. [Google Scholar] [CrossRef]

- Kim, C.C.; Seol, S.K.; Kim, J.K.; Lee, J.L.; Hwu, Y.; Ruterana, P.; Magaritondo, G.; Je, J.H. Metal/GaN reaction chemistry and their electrical properties. Physica Status Solidi 2004, 241, 2771–2774. [Google Scholar] [CrossRef]

- Puneetha, P.T.; Reddy, M.S.P.; Lee, Y.-W.; Jeong, S.-H.; Lokanadham, R.; Park, C.; Pradeep, A.G.; Reddy, V.R. Electrical and interface properties of PdAl/Au metal alloyed ohmic contacts on p-type GaN for high-temperature MEMS devices. J. Mater. Sci. Mater. Electron. 2017, 28, 16903–16909. [Google Scholar] [CrossRef]

- Cai, X.; Du, C.; Sun, Z.; Ye, R.; Liu, H.; Zhang, Y.; Duan, X.; Lu, H. Recent progress of physical failure analysis of GaN HEMTs. J. Semicond. 2021, 42, 051801. [Google Scholar] [CrossRef]

- Shankar, B.; Soni, A.; Shrivastava, M. Electro-Thermo-Mechanical Reliability of Recessed Barrier AlGaN/GaN Schottky Diodes Under Pulse Switching Conditions. IEEE Trans. Electron Devices 2020, 67, 2044–2051. [Google Scholar] [CrossRef]

- Mocanu, M.; Unger, C.; Pfost, M.; Waltereit, P.; Reiner, R. Thermal Stability and Failure Mechanism of Schottky Gate AlGaN/GaN HEMTs. IEEE Trans. Electron Devices 2017, 64, 848–855. [Google Scholar] [CrossRef]

- Park, S.Y.; Floresca, C.; Chowdhury, U.; Jimenez, J.L.; Lee, C.; Beam, E.; Saunier, P.; Balistreri, T.; Kim, M.J. Physical degradation of GaN HEMT devices under high drain bias reliability testing. Microelectron. Reliab. 2009, 49, 478–483. [Google Scholar] [CrossRef]

- Graff, A.; Simon-Najasek, M.; Poppitz, D.; Altmann, F. Physical failure analysis methods for wide band gap semiconductor devices. In Proceedings of the 2018 IEEE International Reliability Physics Symposium (IRPS), San Francisco, CA, USA, 11–15 May 2018; pp. 3B.2-1–3B.2-8. [Google Scholar]

- Huang, Y.; Yang, J.; Zhao, D.; Liu, Z.; Chen, P.; Liang, F.; Hou, Y. Degradation mechanism during catastrophic optical damage in 385 nm GaN-based ultraviolet laser diodes. Appl. Phys. Lett. 2024, 125, 171106. [Google Scholar] [CrossRef]

- Islam, Z.; Haque, A.; Glavin, N. Real-time visualization of GaN/AlGaN high electron mobility transistor failure at off-state. Appl. Phys. Lett. 2018, 113, 183102. [Google Scholar] [CrossRef]

- Islam, Z.; Paoletta, A.L.; Monterrosa, A.M.; Schuler, J.D.; Rupert, T.J.; Hattar, K.; Glavin, N.; Haque, A. Heavy ion irradiation effects on GaN/AlGaN high electron mobility transistor failure at off-state. Microelectron. Reliab. 2019, 102, 113493. [Google Scholar] [CrossRef]

- Islam, Z.; Haque, A.; Glavin, N.; Xian, M.; Ren, F.; Polyakov, A.Y.; Kochkova, A.; Tadjer, M.; Pearton, S.J. In Situ Transmission Electron Microscopy Observations of Forward Bias Degradation of Vertical Geometry β-Ga2O3 Rectifiers. ECS J. Solid State Sci. Technol. 2020, 9, 055008. [Google Scholar] [CrossRef]

- Islam, Z.; Glavin, N.; Haque, A. The Potential and Challenges of In Situ Microscopy of Electronic Devices and Materials, Wide Bandgap Semiconductor-Based Electronics; IOP Publishing: Bristol, UK, 2020; pp. 15-1–15-30. [Google Scholar]

- Wang, B.; Islam, Z.; Haque, A.; Chabak, K.; Snure, M.; Heller, E.; Glavin, N. In situ transmission electron microscopy of transistor operation and failure. Nanotechnology 2018, 29, 31LT01. [Google Scholar] [CrossRef]

- Kong, B.H.; Sun, Q.; Han, J.; Lee, I.-H.; Cho, H.K. Classification of stacking faults and dislocations observed in nonpolar a-plane GaN epilayers using transmission electron microscopy. Appl. Surf. Sci. 2012, 258, 2522–2528. [Google Scholar] [CrossRef]

- Potin, V.; Ruterana, P.; Nouet, G. HREM study of stacking faults in GaN layers grown over sapphire substrate. J. Phys. Condens. Matter 2000, 12, 10301. [Google Scholar] [CrossRef]

- Narita, T.; Kanechika, M.; Kojima, J.; Watanabe, H.; Kondo, T.; Uesugi, T.; Yamaguchi, S.; Kimoto, Y.; Tomita, K.; Nagasato, Y.; et al. Identification of type of threading dislocation causing reverse leakage in GaN p–n junctions after continuous forward current stress. Sci. Rep. 2022, 12, 1458. [Google Scholar] [CrossRef]

- Hamachi, T.; Tohei, T.; Hayashi, Y.; Imanishi, M.; Usami, S.; Mori, Y.; Sakai, A. Comprehensive analysis of current leakage at individual screw and mixed threading dislocations in freestanding GaN substrates. Sci. Rep. 2023, 13, 2436. [Google Scholar] [CrossRef] [PubMed]

- Arehart, A.R.; Moran, B.; Speck, J.S.; Mishra, U.K.; DenBaars, S.P.; Ringel, S.A. Effect of threading dislocation density on Ni/n-GaN Schottky diode I-V characteristics. J. Appl. Phys. 2006, 100, 023709. [Google Scholar] [CrossRef]

- Engelberg, E.Z.; Yashar, A.B.; Ashkenazy, Y.; Assaf, M.; Popov, I. Theory of electric field breakdown nucleation due to mobile dislocations. Phys. Rev. Accel. Beams 2019, 22, 083501. [Google Scholar] [CrossRef]

- Reiche, M.; Kittler, M.; Erfurth, W.; Pippel, E.; Sklarek, K.; Blumtritt, H.; Haehnel, A.; Uebensee, H. On the electronic properties of a single dislocation. J. Appl. Phys. 2014, 115, 194303. [Google Scholar] [CrossRef]

- Tarplee, M.C.; Madangarli, V.P.; Quinchun, Z.; Sudarshan, T.S. Design rules for field plate edge termination in SiC Schottky diodes. IEEE Trans. Electron Devices 2001, 48, 2659–2664. [Google Scholar] [CrossRef]

- Sabuktagin, S.; Yong-Tae, M.; Dogan, S.; Baski, A.A.; Morkoc, H. Observation of surface charging at the edge of a Schottky contact. IEEE Electron Device Lett. 2006, 27, 211–213. [Google Scholar] [CrossRef]

- Poate, J.M.; Turner, P.A.; DeBonte, W.J.; Yahalom, J. Thin-film interdiffusion. I. Au-Pd, Pd-Au, Ti-Pd, Ti-Au, Ti-Pd-Au, and Ti-Au-Pd. J. Appl. Phys. 1975, 46, 4275–4283. [Google Scholar] [CrossRef]

- Wang, Z.; Huang, Y.; Liu, C.T.; Li, J.; Wang, J. Atomic packing and size effect on the Hume-Rothery rule. Intermetallics 2019, 109, 139–144. [Google Scholar] [CrossRef]

- d’Heurle, F.M. Electromigration and failure in electronics: An introduction. Proc. IEEE 1971, 59, 1409–1418. [Google Scholar] [CrossRef]

- Yongkun, S.; Dmitry, V.; William, H.; Miles, B.; Scott, S.; Zachary, L. Out-diffusion of Pd as a potential degradation mechanism in GaN HEMTs with Ni-Pd-Au Schottky contacts. Proc. SPIE 2020, 11280, 157–166. [Google Scholar]

- Yongkun, S.; Dmitry, V.; William, H.; Scott, S.; Miles, B.; Zachary, L.; Neil, I. Out-diffusion of Pd as part of degradation mechanisms in RF AlGaN-GaN HEMTs with Ni-Pd-Au Schottky contacts: Part II. Proc. SPIE 2021, 11686, 147–156. [Google Scholar]

- Groh, R.; Gerey, G.; Bartha, L.; Pankove, J.I. On the thermal decomposition of GaN in vacuum. Physica Status Solidi 1974, 26, 353–357. [Google Scholar] [CrossRef]

- Thierry-Jebali, N.; Chiriac, R.; Brylinski, C. Evidence of Low Temperature Decomposition of GaN Hetero-Epitaxial Layers on C-Plane Sapphire Surface Characterized by Differential Scanning Calorimetry. Mater. Sci. Forum 2014, 778–780, 1185–1188. [Google Scholar] [CrossRef]

- Barinov, A.; Casalis, L.; Gregoratti, L.; Kiskinova, M. Stages of formation and thermal stability of a gold-n-GaN interface. J. Phys. D Appl. Phys. 2001, 34, 279. [Google Scholar] [CrossRef]

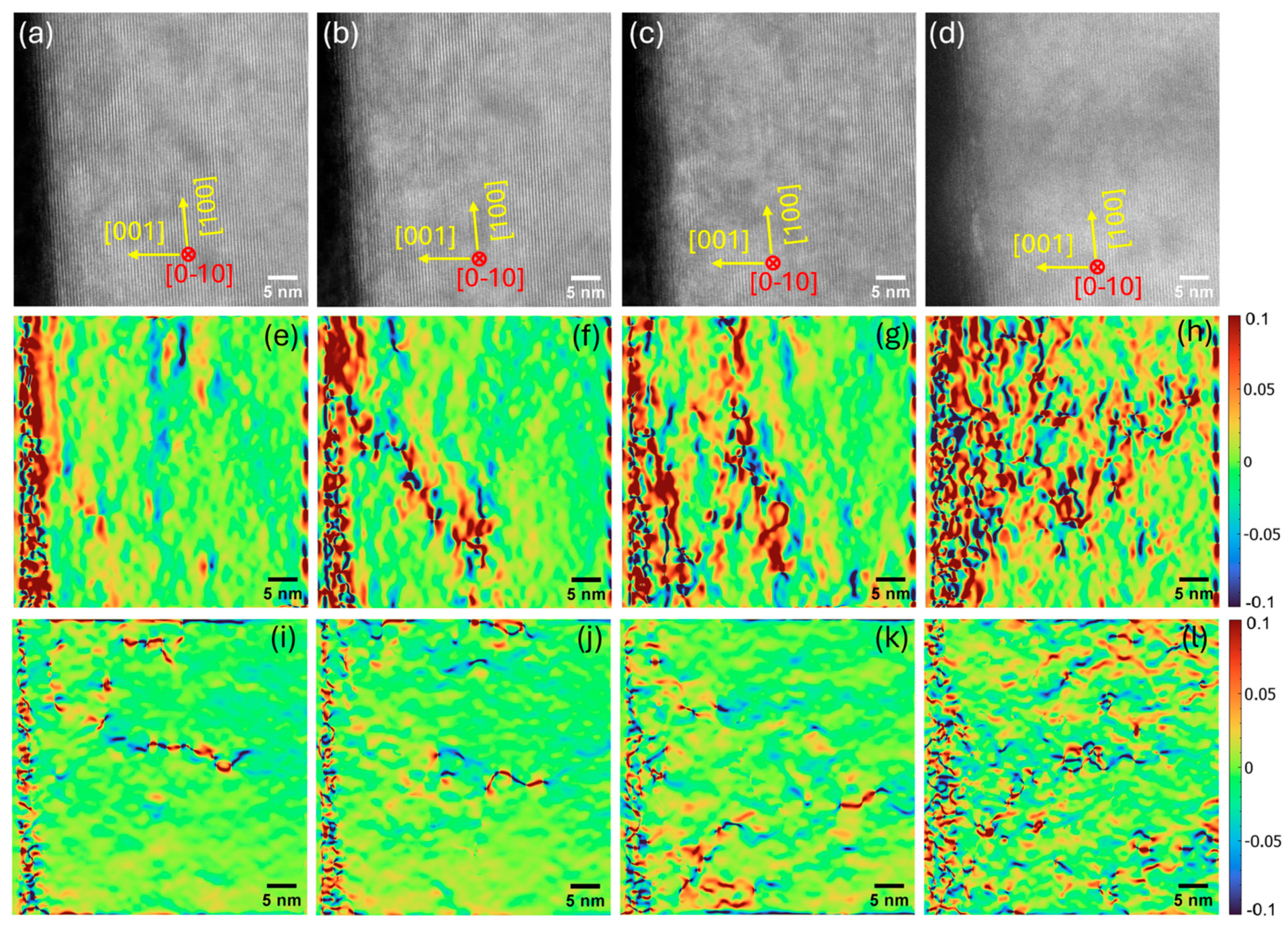

- Hÿtch, M.J. Geometric phase analysis of high resolution electron microscope images. Scanning Microsc 1997, 11, 53–66. [Google Scholar]

- Hÿtch, M.J.; Snoeck, E.; Kilaas, R. Quantitative measurement of displacement and strain fields from HREM micrographs. Ultramicroscopy 1998, 74, 131–146. [Google Scholar] [CrossRef]

| d-Spacing (nm) | |||||

|---|---|---|---|---|---|

| Lattice Planes | Pristine | 1 V, 45 °C | 2 V, 85 °C | 3 V, 185 °C | 4 V, 300 °C |

| [100] | 0.2972 | 0.2971 | 0.2960 | 0.2920 | 0.2956 |

| [101] | 0.2624 | 0.2623 | 0.2597 | 0.2577 | 0.2606 |

| [001] | 0.5599 | 0.5592 | 0.5522 | 0.5517 | 0.5566 |

| [−101] | 0.2626 | 0.2622 | 0.2621 | 0.2586 | 0.2615 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Al-Mamun, N.S.; Du, Y.; Song, J.; Chu, R.; Haque, A. Electrothermal Failure Physics of GaN Schottky Diodes Under High-Temperature Forward Biasing. Micromachines 2025, 16, 242. https://doi.org/10.3390/mi16030242

Al-Mamun NS, Du Y, Song J, Chu R, Haque A. Electrothermal Failure Physics of GaN Schottky Diodes Under High-Temperature Forward Biasing. Micromachines. 2025; 16(3):242. https://doi.org/10.3390/mi16030242

Chicago/Turabian StyleAl-Mamun, Nahid Sultan, Yuxin Du, Jianan Song, Rongming Chu, and Aman Haque. 2025. "Electrothermal Failure Physics of GaN Schottky Diodes Under High-Temperature Forward Biasing" Micromachines 16, no. 3: 242. https://doi.org/10.3390/mi16030242

APA StyleAl-Mamun, N. S., Du, Y., Song, J., Chu, R., & Haque, A. (2025). Electrothermal Failure Physics of GaN Schottky Diodes Under High-Temperature Forward Biasing. Micromachines, 16(3), 242. https://doi.org/10.3390/mi16030242