Multiphysics Measurement Method for Supercapacitors State of Health Determination

Abstract

1. Introduction

2. Materials and Methods

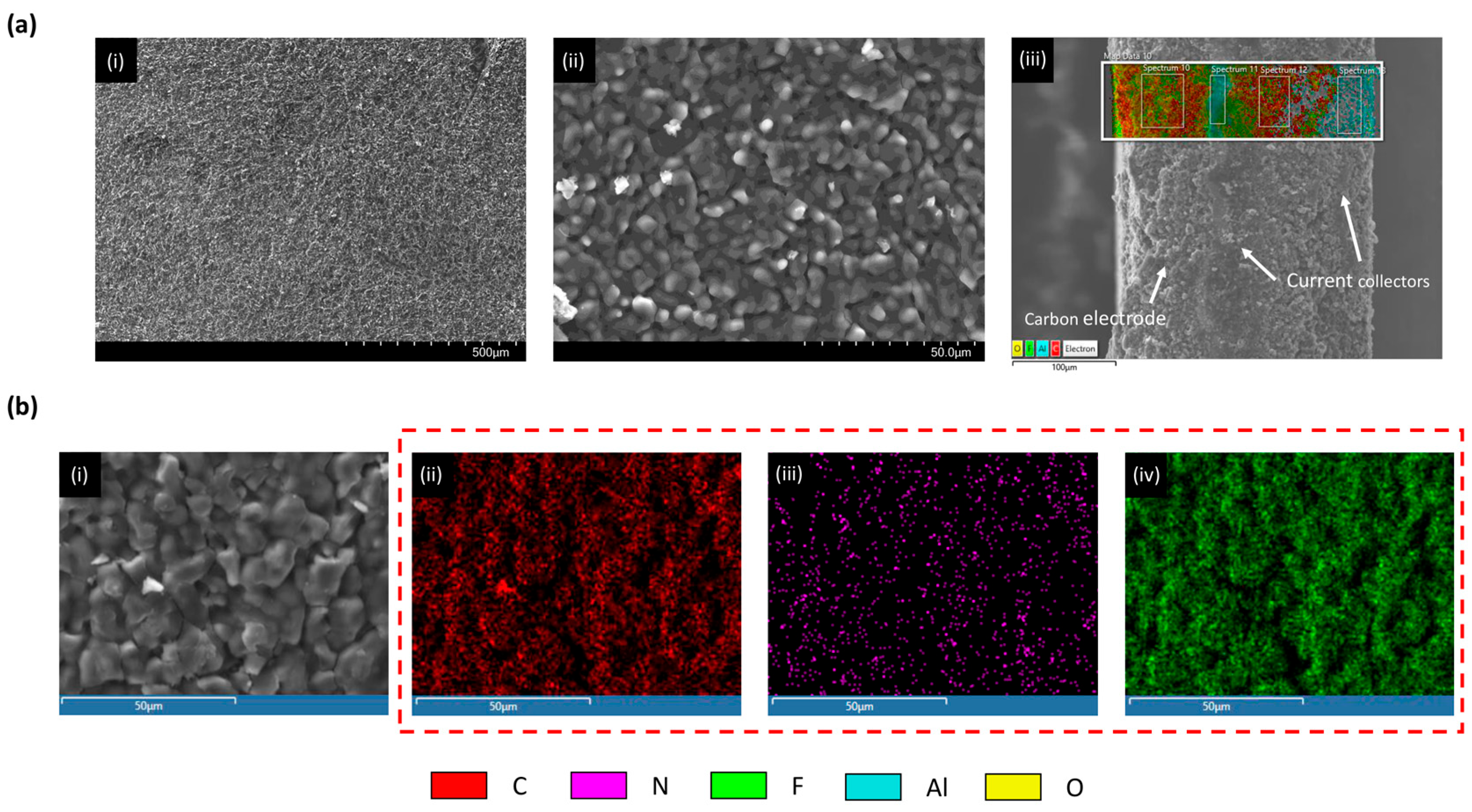

2.1. Materials Selection

2.2. Methods of Characterization

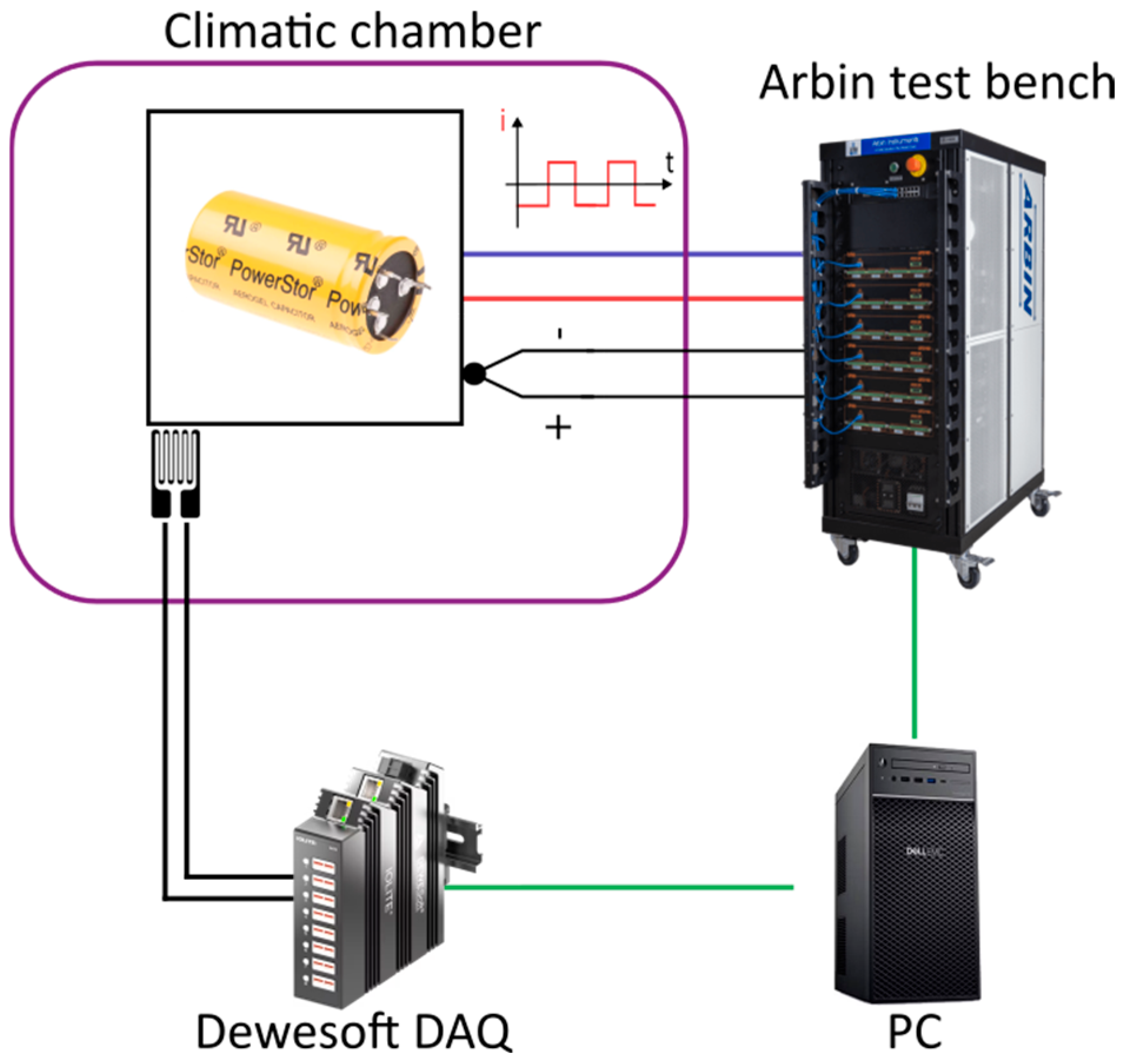

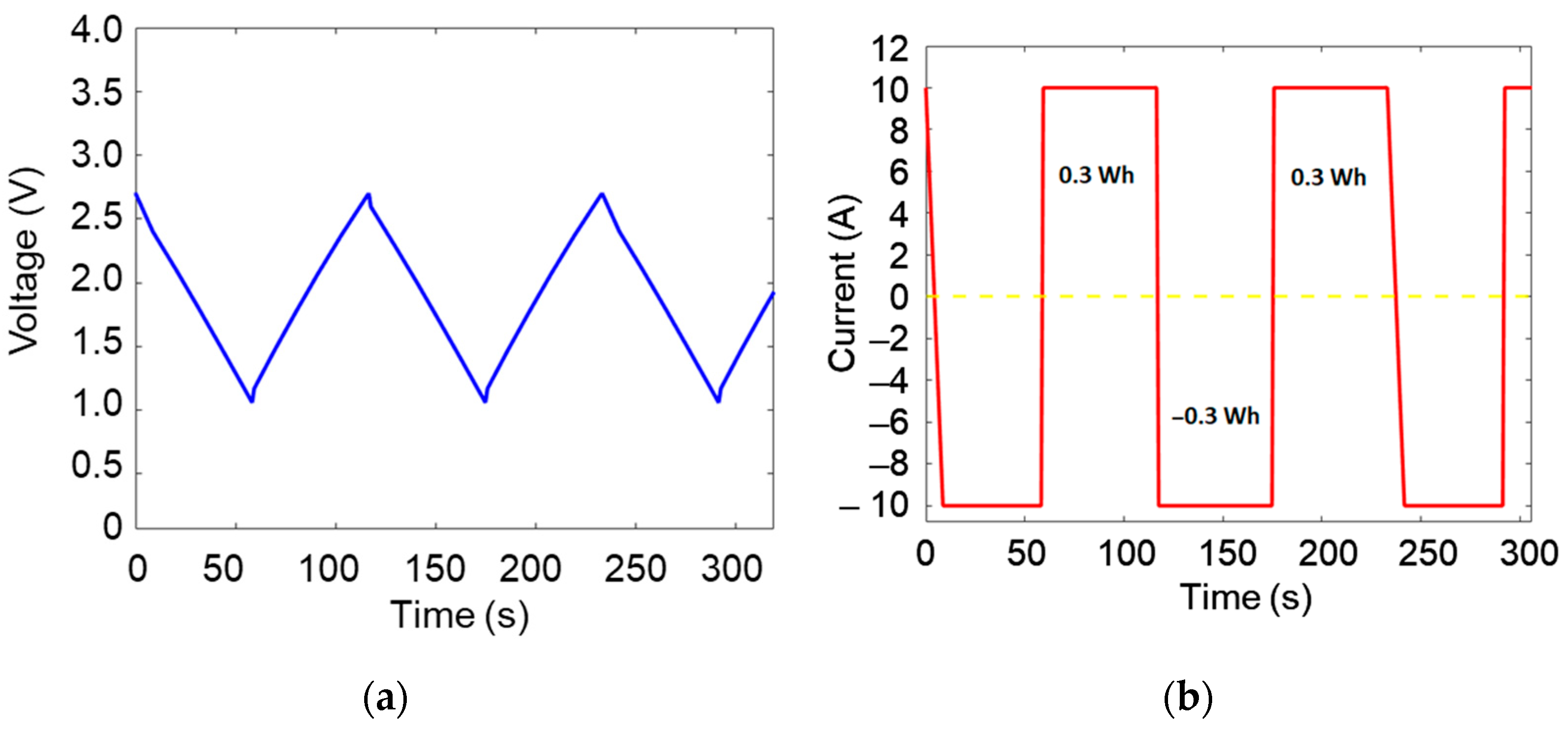

2.2.1. Ageing Setup

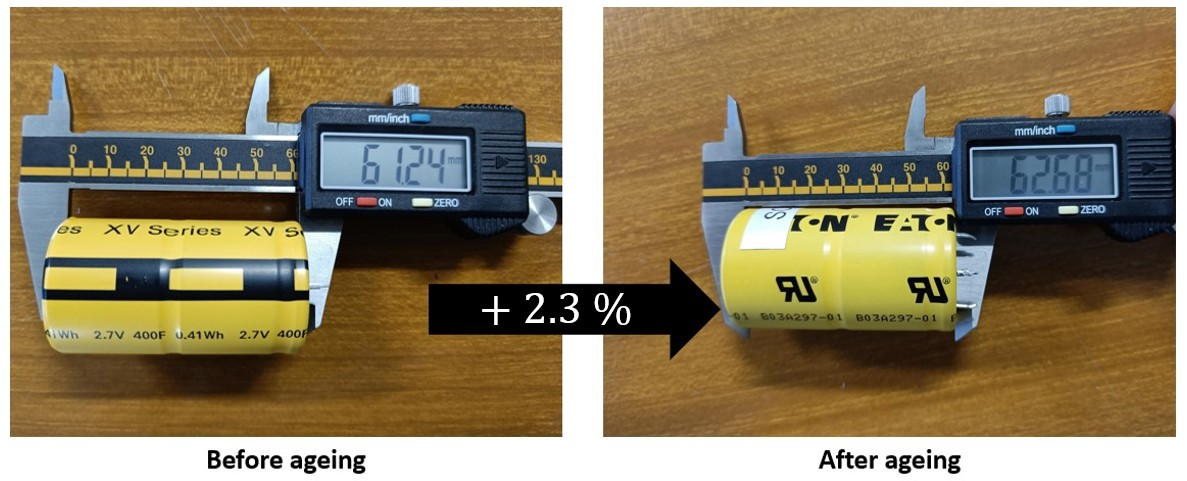

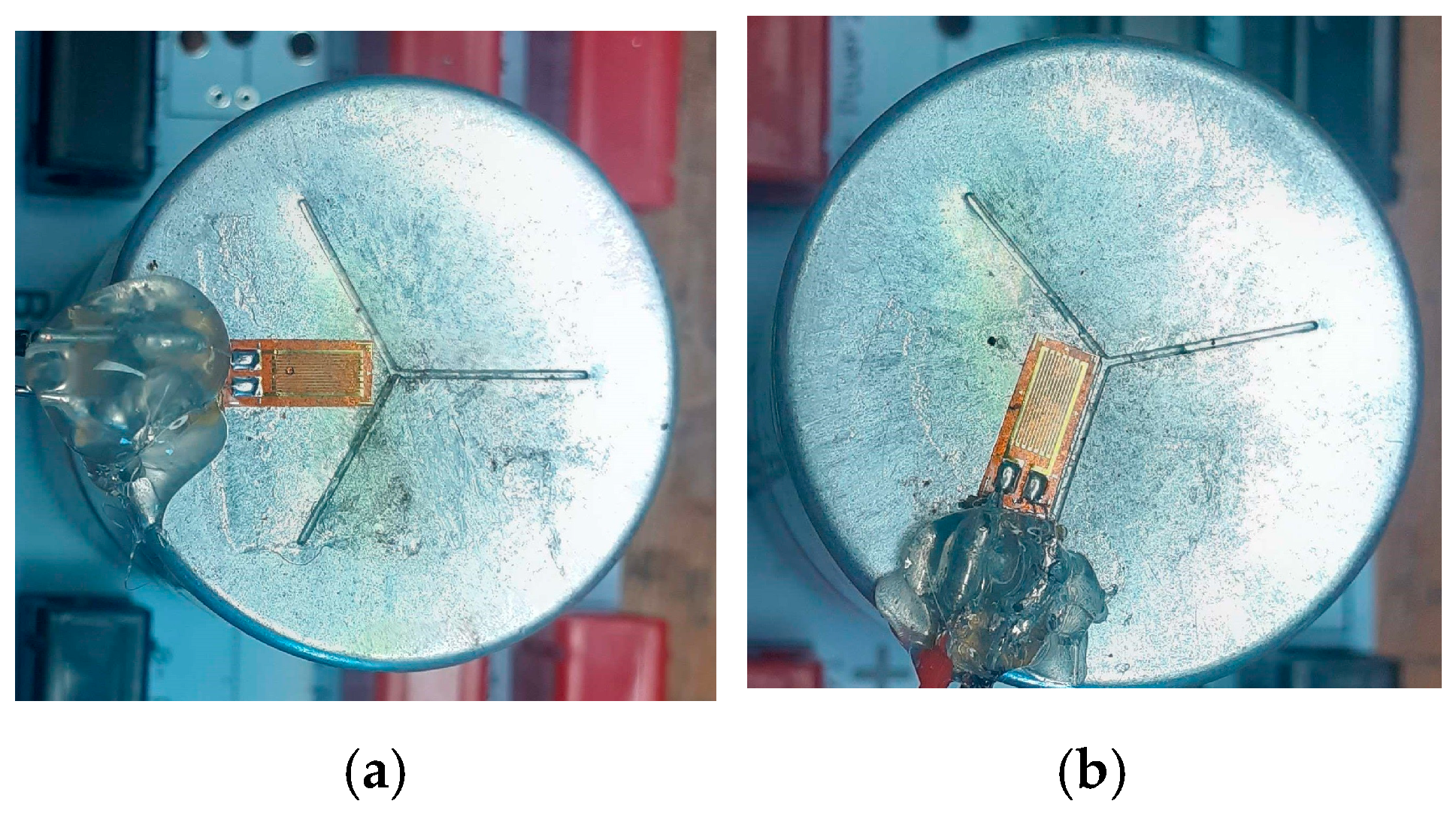

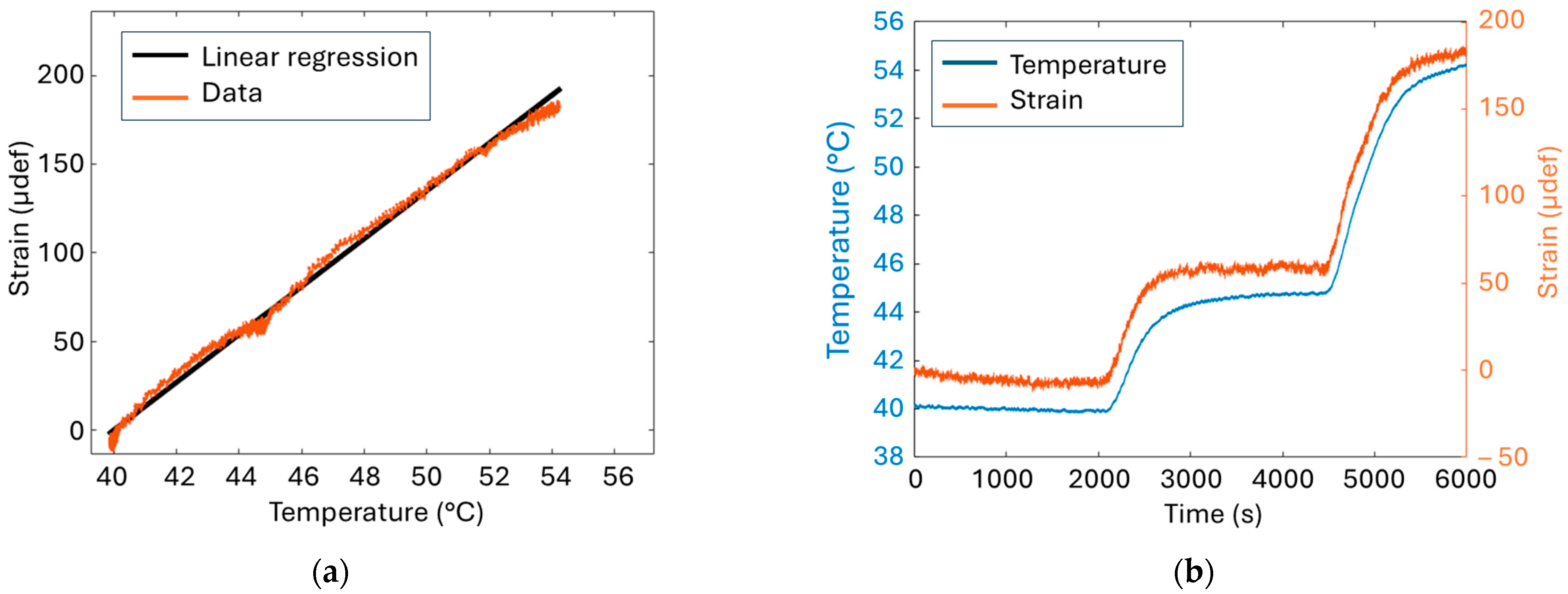

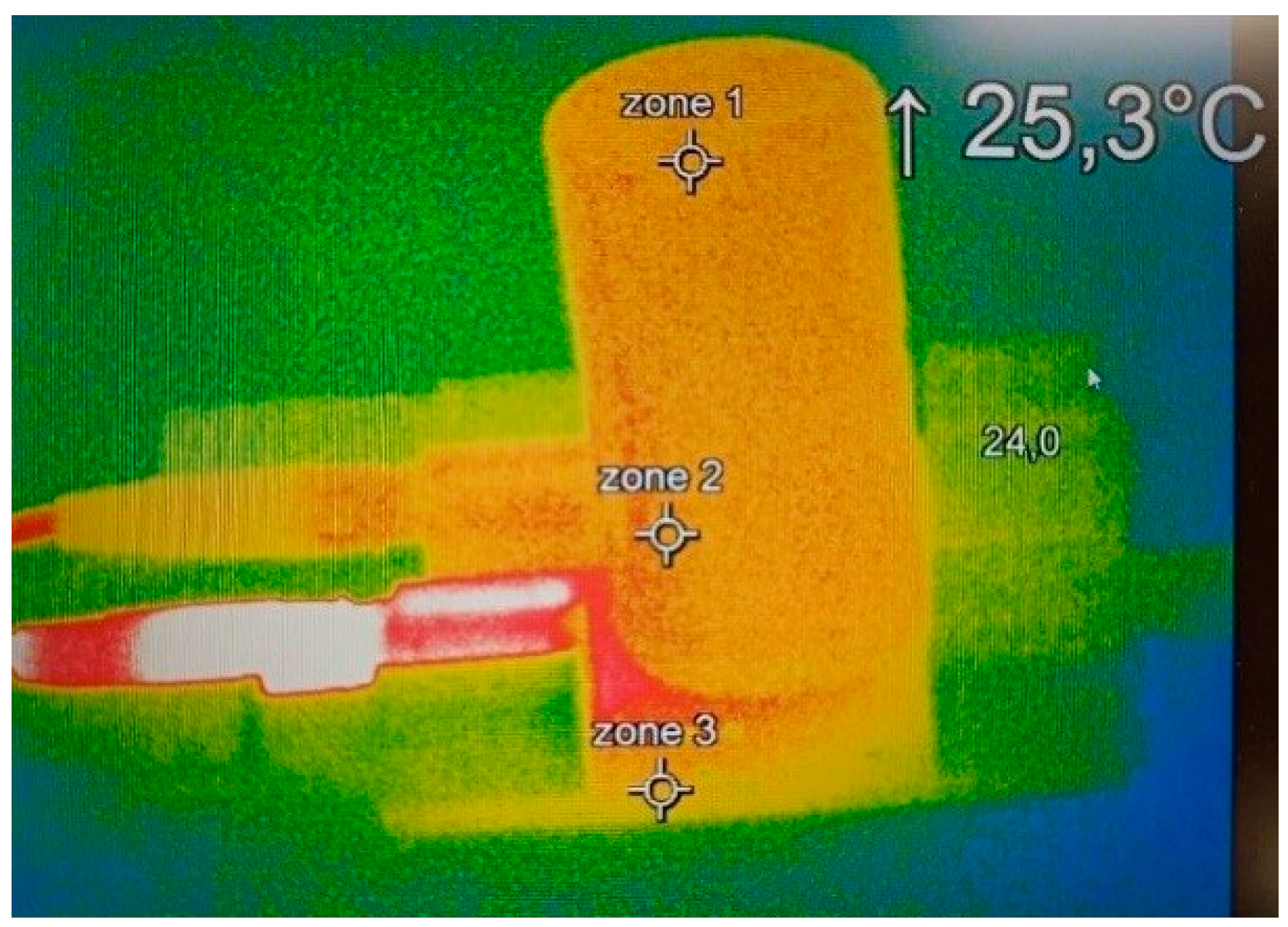

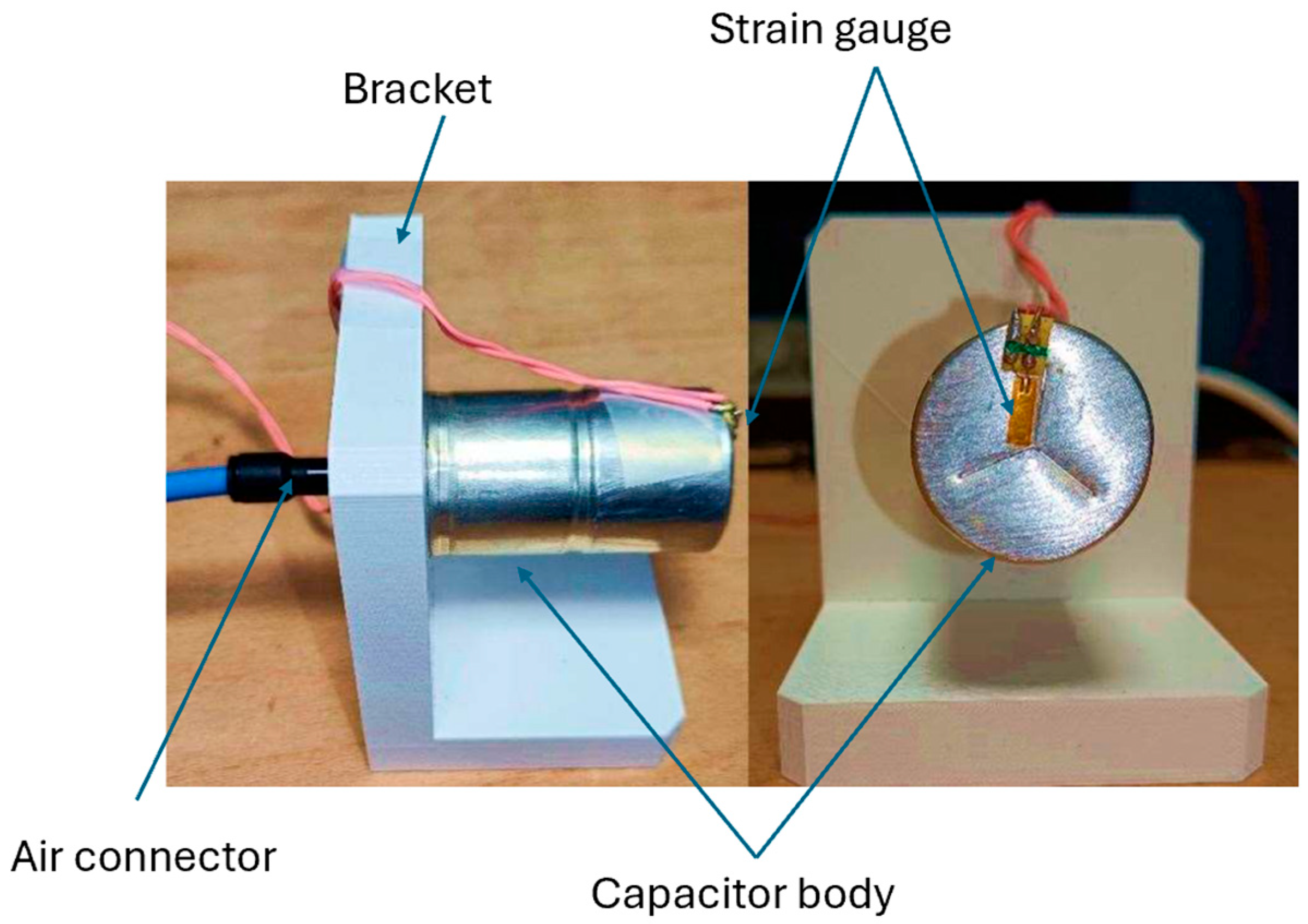

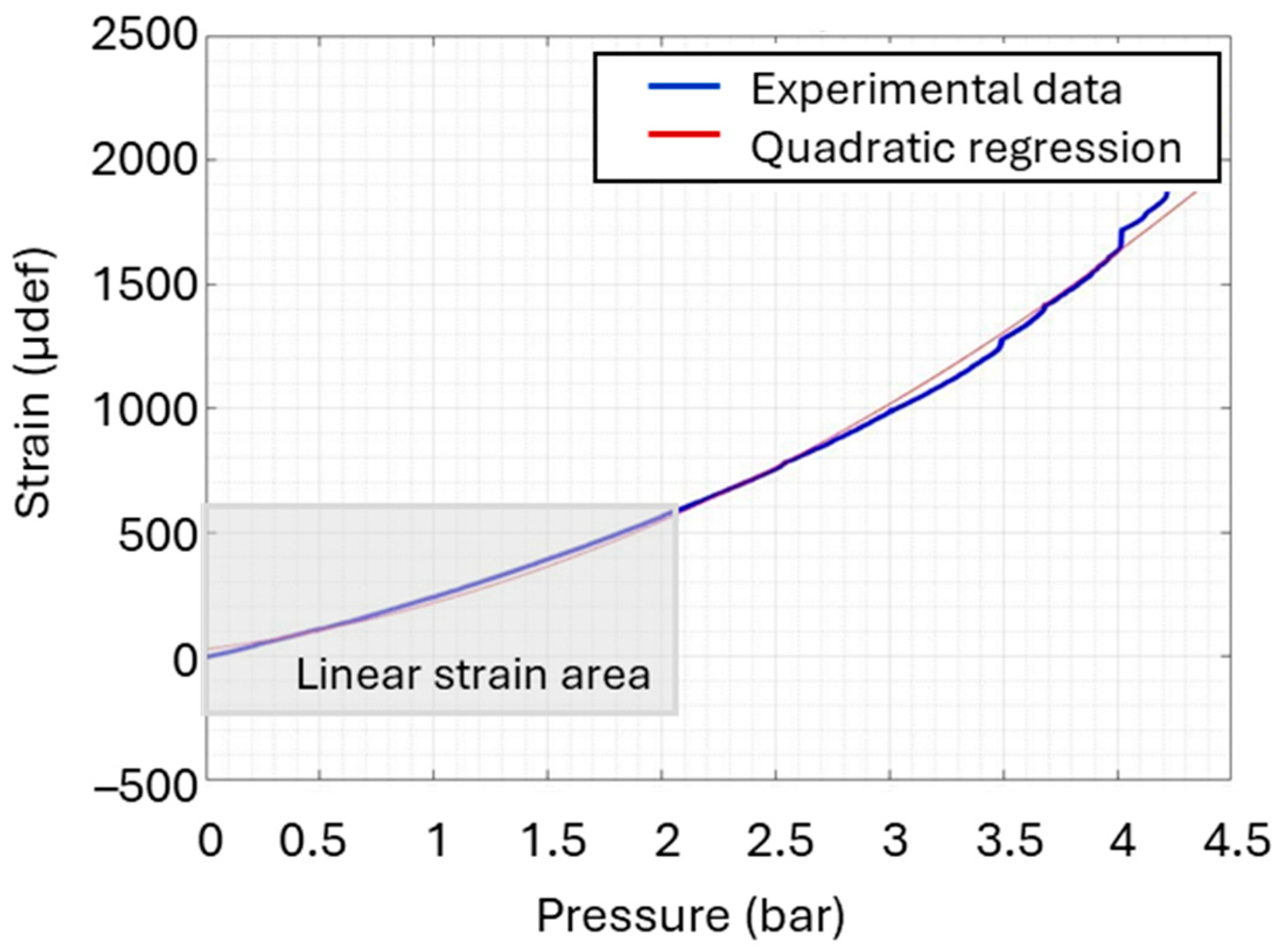

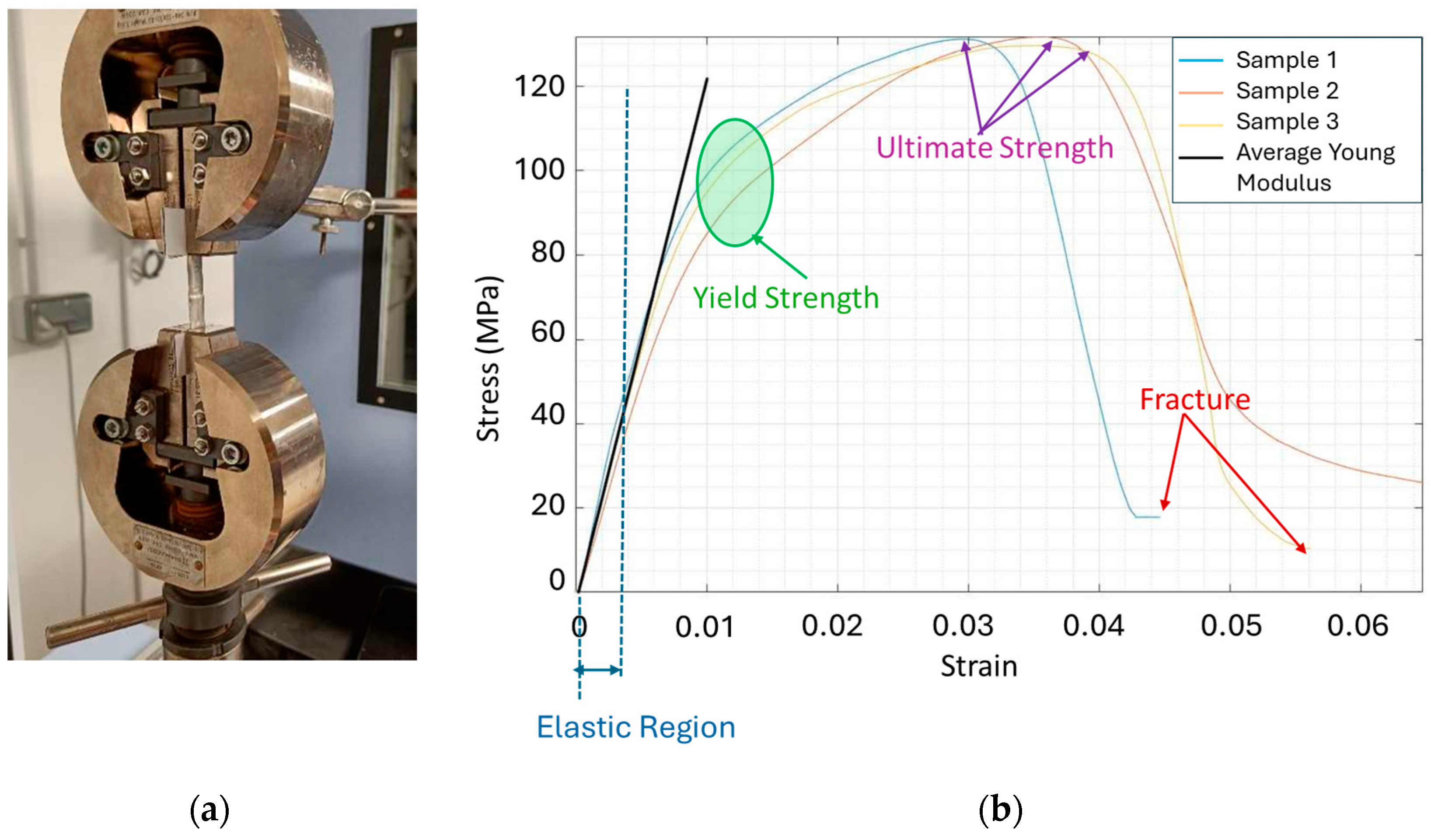

2.2.2. Strain Measurement

3. Results and Discussions

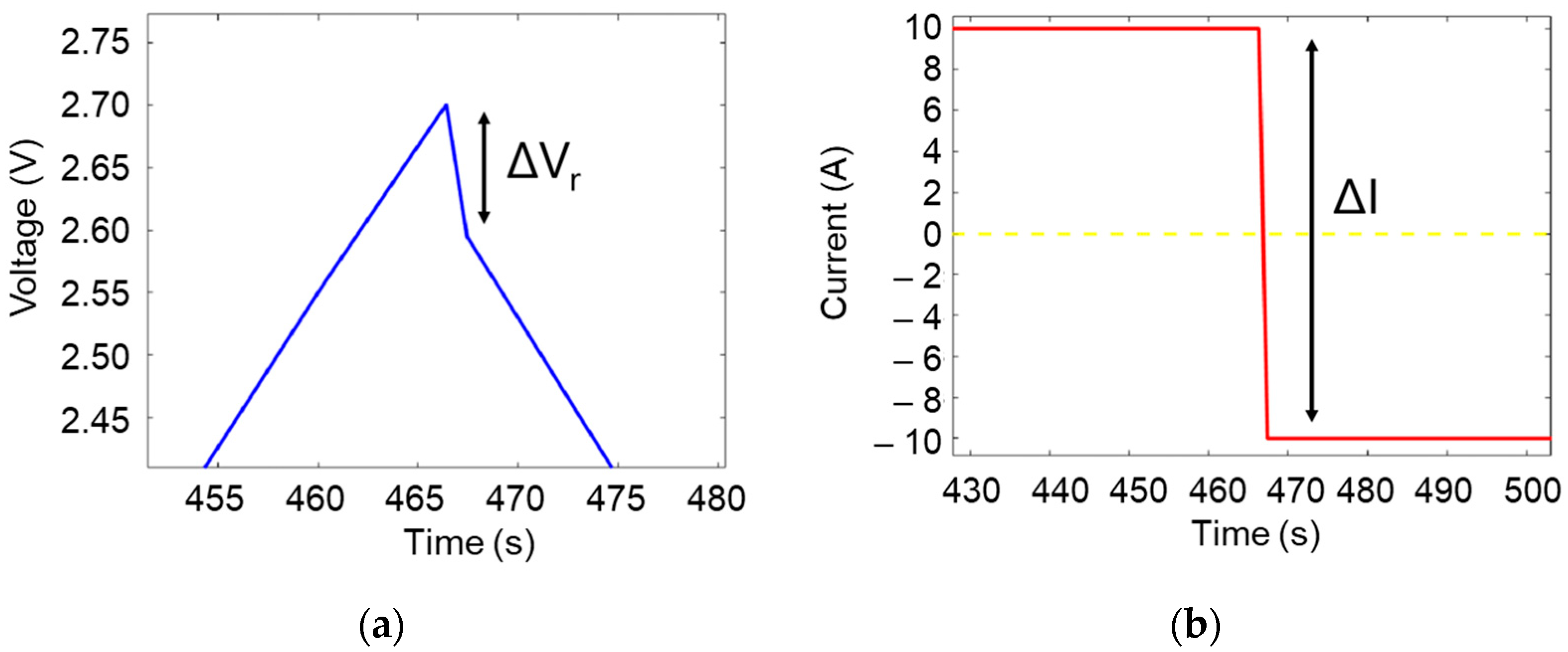

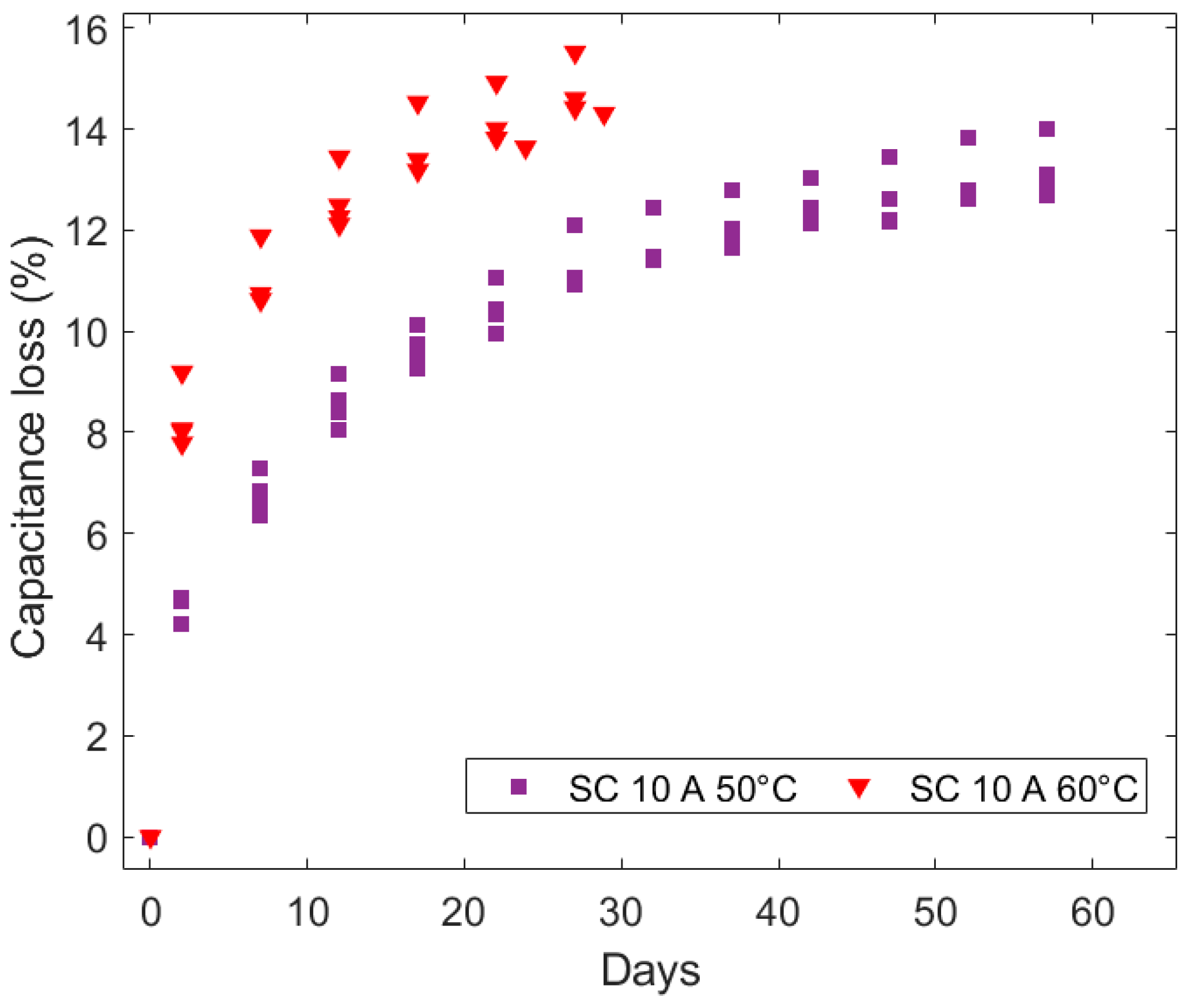

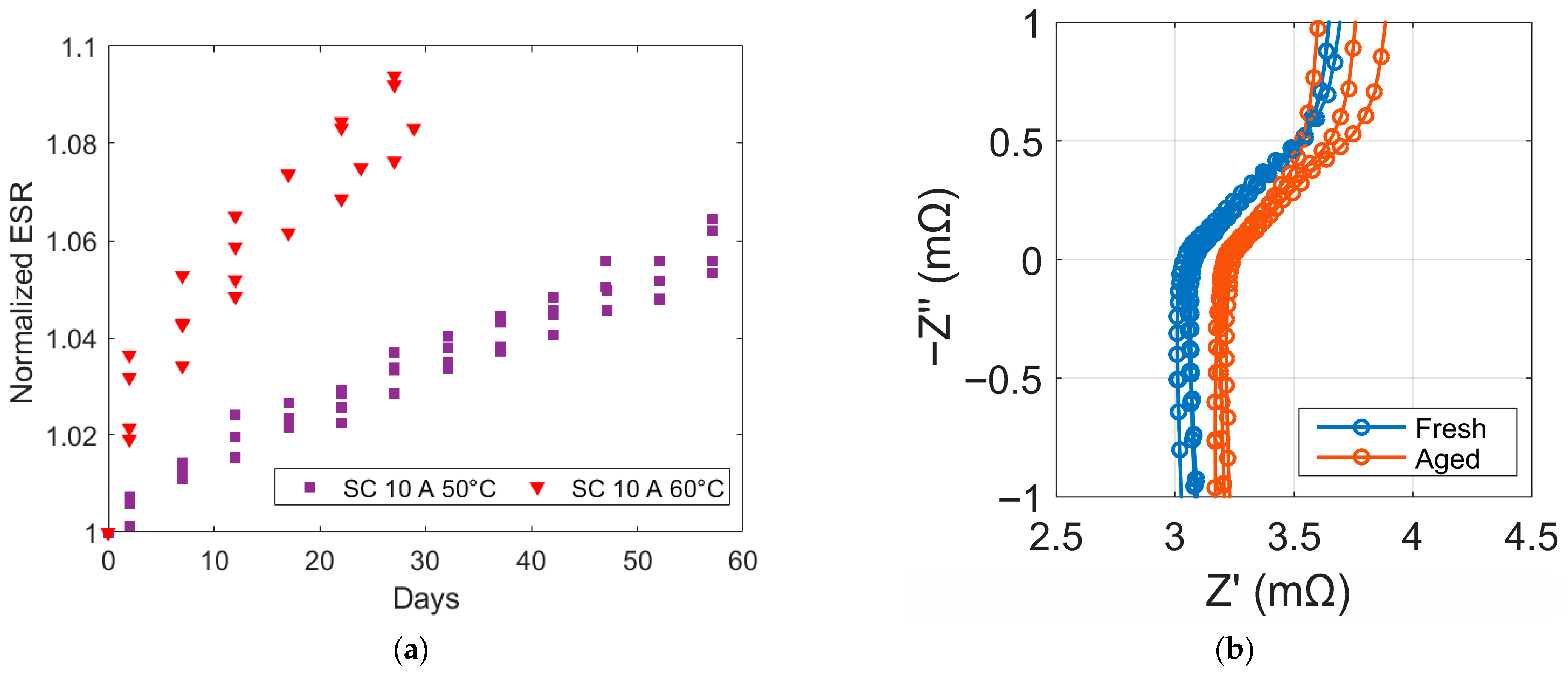

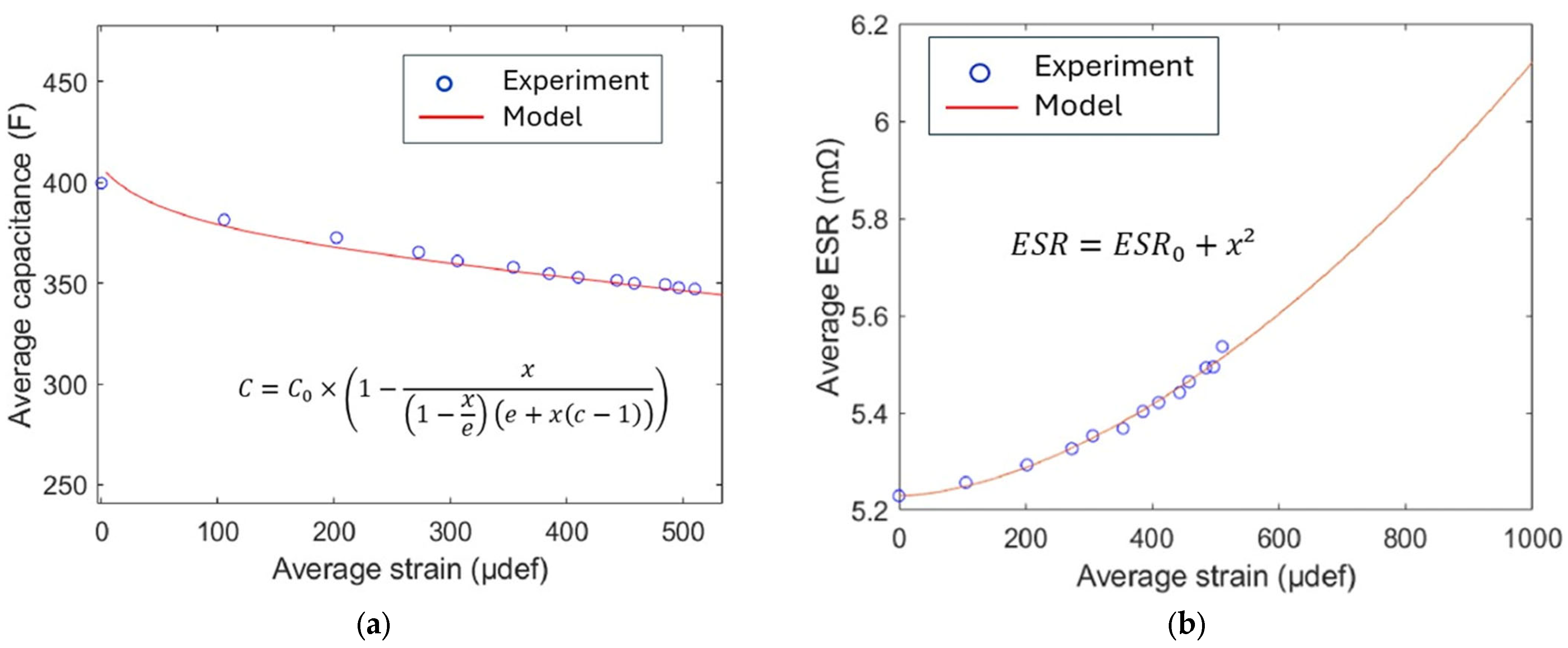

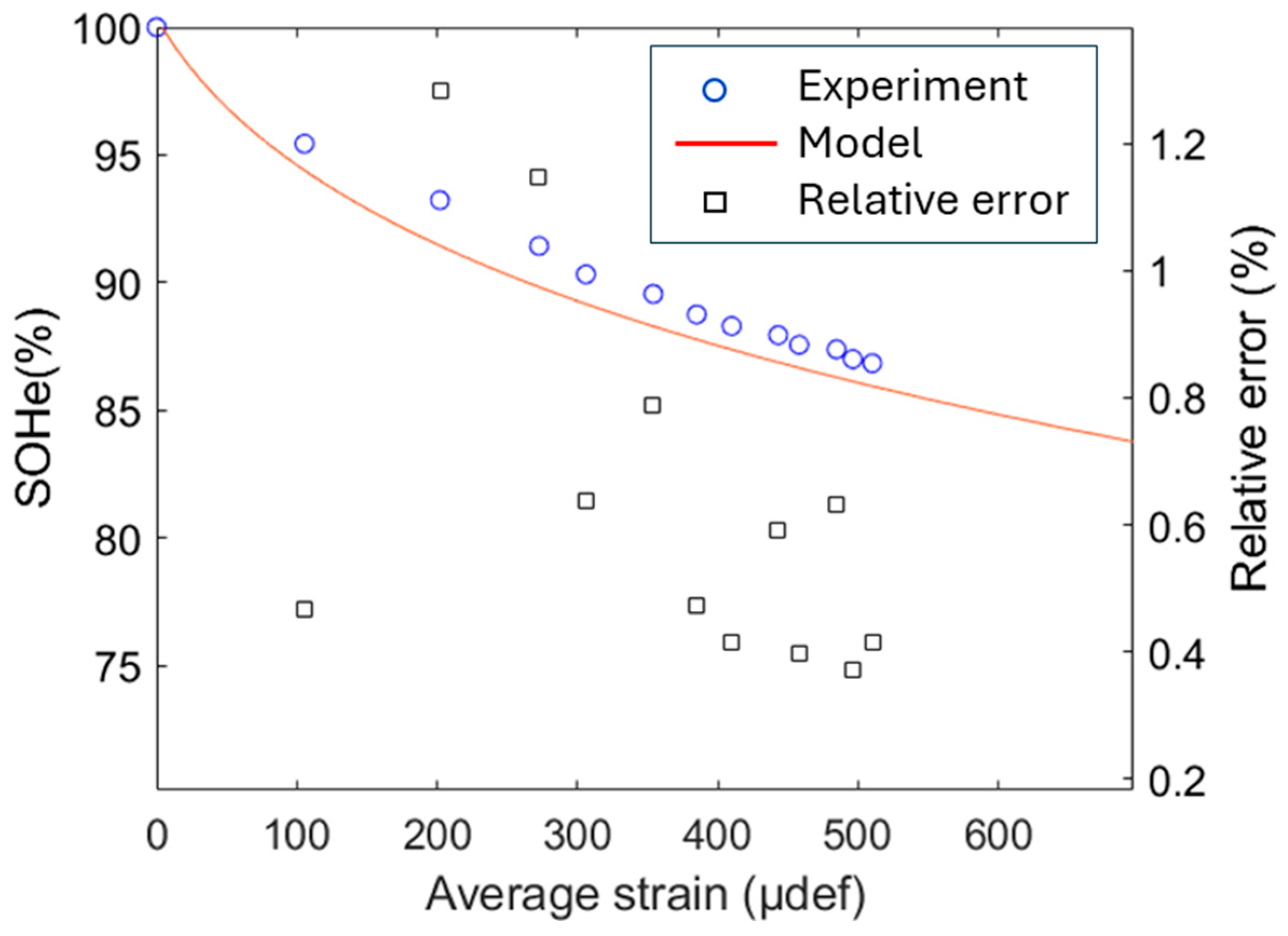

3.1. Ageing of Electric Properties

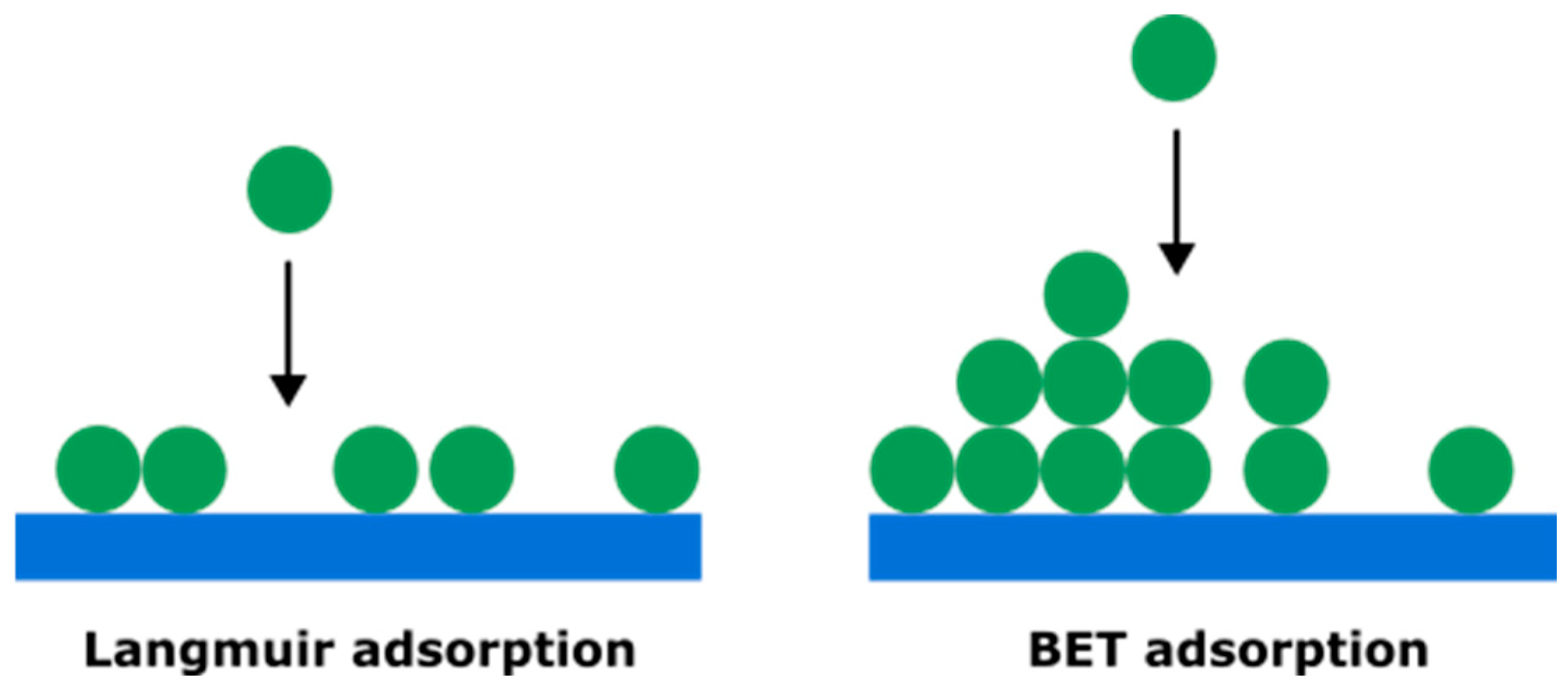

3.2. Analytical Modelling Based on Strain and Pressure Measurements

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Nyamathulla, S.; Dhanamjayulu, C. A Review of Battery Energy Storage Systems and Advanced Battery Management System for Different Applications: Challenges and Recommendations. J. Energy Storage 2024, 86, 111179. [Google Scholar] [CrossRef]

- Lemian, D.; Bode, F. Battery-Supercapacitor Energy Storage Systems for Electrical Vehicles: A Review. Energies 2022, 15, 5683. [Google Scholar] [CrossRef]

- Zakertabrizi, M.; Bozorgmehrian, F.; Jeong, M.; Hosseini, E.; Ponce, V.; Fallahi, H.; Bahadorikhalili, S.; Nasrabadi, H.; Jarrahbashi, D.; Castaneda, H.; et al. Patterned Nanostructures on Cathodes: A Pathway to Stronger, High-Energy, High-Power Li-Ion Batteries. ACS Nano 2025, 19, 38970–38980. [Google Scholar] [CrossRef]

- Zhang, C.; Mao, Y.; Li, K.; Liu, Y.; Xu, Z.; Pang, K.; Cai, S.; Fan, L.; Gao, C. High Power and Energy Density Graphene Phase Change Composite Materials for Efficient Thermal Management of Li-Ion Batteries. Energy Storage Mater. 2025, 75, 104003. [Google Scholar] [CrossRef]

- Zhang, B.; Wang, X.; Wang, S.; Li, Y.; Chen, L.; Jiao, H.; Yu, Z.; Tu, J. High-Energy-Density Lithium Manganese Iron Phosphate for Lithium-Ion Batteries: Progresses, Challenges, and Prospects. J. Energy Chem. 2025, 100, 1–17. [Google Scholar] [CrossRef]

- Chaari, R. Evaluation et Modélisation du Vieillissement des Supercondensateurs Pour des Applications Véhicules Hybrides. Doctoral Thesis, Université Bordeaux-I, Talence, France, 2013. Available online: http://www.theses.fr/2013BOR14828/document (accessed on 11 July 2013).

- Hologne-Carpentier, M.; Mogniotte, J.-F.; Le, M.-Q.; Allard, B.; Clerc, G.; Cottinet, P.-J. A Multi-Physics Approach to Condition Monitoring of SiC Power Module. Microelectron. Eng. 2021, 250, 111633. [Google Scholar] [CrossRef]

- German, R.; Sari, A.; Venet, P.; Zitouni, Y.; Briat, O.; Vinassa, J.-M. Ageing Law for Supercapacitors Floating Ageing. In Proceedings of the 2014 IEEE 23rd International Symposium on Industrial Electronics (ISIE), Istanbul, Turkey, 1–4 June 2014; IEEE: New York, NY, USA, 2014; pp. 1773–1777. [Google Scholar] [CrossRef]

- Shili, S.; Sari, A.; Hijazi, A.; Venet, P. Online Lithium-Ion Batteries Health Monitoring Using Balancing Circuits. In Proceedings of the IEEE International Conference on Industrial Technology (ICIT), Toronto, ON, Canada, 22–25 March 2017; IEEE: New York, NY, USA, 2017; pp. 484–488. [Google Scholar] [CrossRef]

- Kim, T.; Qiao, W.; Qu, L. Online SOC and SOH Estimation for Multicell Lithium-Ion Batteries Based on an Adaptive Hybrid Battery Model and Sliding-Mode Observer. In Proceedings of the 2013 IEEE Energy Conversion Congress and Exposition, Denver, CO, USA, 15–19 September 2013; IEEE: New York, NY, USA, 2013; pp. 292–298. [Google Scholar] [CrossRef]

- Prakasha, G.; Santosh Kumar, S.; Sunil Kumar, K.N.; Darshan, A.B.; Venkatesha, G. Electric Vehicle Battery Power Management System Analysis. In Proceedings of the 2022 International Interdisciplinary Humanitarian Conference for Sustainability (IIHC), Bengaluru, India, 18–19 November 2022; IEEE: New York, NY, USA; pp. 1179–1183. [Google Scholar] [CrossRef]

- Zhang, M.; Liu, Y.; Li, D.; Cui, X.; Wang, L.; Li, L.; Wang, K. Electrochemical Impedance Spectroscopy: A New Chapter in the Fast and Accurate Estimation of the State of Health for Lithium-Ion Batteries. Energies 2023, 16, 1599. [Google Scholar] [CrossRef]

- Vadhva, P.; Hu, J.; Johnson, M.J.; Stocker, R.; Braglia, M.; Brett, D.J.L.; Rettie, A.J.E. Electrochemical Impedance Spectroscopy for All-Solid-State Batteries: Theory, Methods and Future Outlook. ChemElectroChem 2021, 8, 1930–1947. [Google Scholar] [CrossRef]

- Kulkarni, C.S.; Mehta, M.R.; Khasin, M.; Lawson, J. A Prognostics Framework for Battery Health Monitoring Integrated With Thermal Modeling. In AIAA AVIATION FORUM AND ASCEND 2024; AIAA Aviation Forum and ASCEND co-located Conference Proceedings; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2024. [Google Scholar] [CrossRef]

- Pan, Y.; Xu, K.; Wang, R.; Wang, H.; Chen, G.; Wang, K. Lithium-Ion Battery Condition Monitoring: A Frontier in Acoustic Sensing Technology. Energies 2025, 18, 1068. [Google Scholar] [CrossRef]

- Suti, A.; Budinger, M.; Di Rito, G.; Reysset, A. Development and HIL Validation of Observer-Based Monitoring Algorithms of Battery Packs for eVTOL UAV Applications. Appl. Energy 2025, 401, 126637. [Google Scholar] [CrossRef]

- Gadsden, S.A.; Al-Shabi, M.; Habibi, S.R. Estimation Strategies for the Condition Monitoring of a Battery System in a Hybrid Electric Vehicle. Int. Sch. Res. Not. 2011, 2011, 120351. [Google Scholar] [CrossRef]

- Koseoglou, M.; Tsioumas, E.; Papagiannis, D.; Jabbour, N.; Mademlis, C. A Novel On-Board Electrochemical Impedance Spectroscopy System for Real-Time Battery Impedance Estimation. IEEE Trans. Power Electron. 2021, 36, 10776–10787. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, L.; Li, D.; Wang, K. State-of-Health Estimation of Lithium-Ion Batteries Based on Electrochemical Impedance Spectroscopy: A Review. Prot. Control Mod. Power Syst. 2023, 8, 1–17. [Google Scholar] [CrossRef]

- Bothe, A.; Balducci, A. Thermal Analysis of Electrical Double Layer Capacitors: Present Status and Remaining Challenges. J. Power Sources 2022, 548, 232090. [Google Scholar] [CrossRef]

- Pameté, E.; Köps, L.; Kreth, F.A.; Pohlmann, S.; Varzi, A.; Brousse, T.; Balducci, A.; Presser, V. The Many Deaths of Supercapacitors: Degradation, Aging, and Performance Fading. Adv. Energy Mater. 2023, 13, 2301008. [Google Scholar] [CrossRef]

- Vignesh, V.; Subramani, K.; Sathish, M.; Navamathavan, R. In Smart Supercapacitors; Hussain, C.M., Ahamed, M.B., Eds.; Chapter 15—Design and Fabrication of Supercapacitors. Elsevier: Amsterdam, The Netherlands, 2023; pp. 361–404. [Google Scholar] [CrossRef]

- Zeng, X.; Berecibar, M. Emerging Sensor Technologies and Physics-Guided Methods for Monitoring Automotive Lithium-Based Batteries. Commun. Eng. 2025, 4, 44. [Google Scholar] [CrossRef]

- Sun, N.; Rong, Q.; Wu, J.; Huang, L.; Passerini, S.; Li, H.; Wang, H.; Chen, J.; Huang, Y.; Liu, Z.; et al. Fully Printable Integrated Multifunctional Sensor Arrays for Intelligent Lithium-Ion Batteries. Nat. Commun. 2025, 16, 7361. [Google Scholar] [CrossRef]

- Le, M.Q.; Capsal, J.-F.; Lallart, M.; Hebrard, Y.; Van Der Ham, A.; Reffe, N.; Geynet, L.; Cottinet, P.-J. Review on Energy Harvesting for Structural Health Monitoring in Aeronautical Applications. Prog. Aerosp. Sci. 2015, 79, 147–157. [Google Scholar] [CrossRef]

- Ogunleye, R.O.; Rusnáková, S.; Javořík, J.; Žaludek, M.; Kotlánová, B. Advanced Sensors and Sensing Systems for Structural Health Monitoring in Aerospace Composites. Adv. Eng. Mater. 2024, 26, 2401745. [Google Scholar] [CrossRef]

- Das, S.; Saha, P. A Review of Some Advanced Sensors Used for Health Diagnosis of Civil Engineering Structures. Measurement 2018, 129, 68–90. [Google Scholar] [CrossRef]

- Yoon, J.; Lee, J.; Kim, G.; Ryu, S.; Park, J. Deep Neural Network-Based Structural Health Monitoring Technique for Real-Time Crack Detection and Localization Using Strain Gauge Sensors. Sci. Rep. 2022, 12, 20204. [Google Scholar] [CrossRef]

- Aditama, V.; Dewi, S.M.; Wibowo, A.; Wijaya, M.N. Real-Time Structural Health Monitoring (SHM) Using Strain Gauge Arduino Sensor at Reinfocement Concrete under Static and Impact Loading. AIP Conf. Proc. 2024, 3077, 050046. [Google Scholar] [CrossRef]

- Bergmayr, T.; Winklberger, M.; Kralovec, C.; Schagerl, M. Structural Health Monitoring of Aerospace Sandwich Structures via Strain Measurements along Zero-Strain Trajectories. Eng. Fail. Anal. 2021, 126, 105454. [Google Scholar] [CrossRef]

- Dissanayake, K.; Kularatna-Abeywardana, D. A Review of Supercapacitors: Materials, Technology, Challenges, and Renewable Energy Applications. J. Energy Storage 2024, 96, 112563. [Google Scholar] [CrossRef]

- Gunasekaran, P.; Cuesta, A. Double-Layer Structure and Cation-Dependent Solvent Decomposition in Acetonitrile-Based Electrolytes. J. Solid State Electrochem. 2025, 29, 2213–2224. [Google Scholar] [CrossRef]

- Available online: https://www.eaton.com/content/dam/eaton/products/electronic-components/resources/data-sheet/eaton-xv%20supercapacitor-cylindrical-snap-in-data-sheet.pdf (accessed on 13 October 2025).

- Stadler, R.; Maurer, A. Methods for Durability Testing and Lifetime Estimation of Thermal Interface Materials in Batteries. Batteries 2019, 5, 34. [Google Scholar] [CrossRef]

- INTERNATIONAL ELECTROTECHNICAL COMMISSION. Edition 3.0 2022-10. Available online: https://cdn.standards.iteh.ai/samples/104071/4839e4c1f4864d6f96b7698d18427fa7/IEC-62391-1-2022.pdf (accessed on 13 October 2025).

- Available online: https://www.powerelectronictips.com/supercapacitor-specifications-and-iec-en-62391-1/ (accessed on 13 October 2025).

- Adel, M.Y.; Mohammed, O.B.; Younis, A.T. Estimation of Equivalent Series Resistance (ESR) of Supercapacitors Using Charging/Discharging Kinetics. ChemistryOpen 2025, 14, e202400444. [Google Scholar] [CrossRef]

- Barsoukov, E.; Macdonald, J.R. Impedance Spectroscopy: Theory, Experiment, and Applications; John Wiley & Sons: Hoboken, NJ, USA, 2005. [Google Scholar]

- Cuervo-Reyes, E.; Scheller, C.P.; Held, M.; Sennhauser, U. A Unifying View of the Constant-Phase-Element and Its Role as an Aging Indicator for Li-Ion Batteries. J. Electrochem. Soc. 2015, 162, A1585. [Google Scholar] [CrossRef]

- Wei, L.; Wu, M.; Yan, M.; Liu, S.; Cao, Q.; Wang, H. A Review on Electrothermal Modeling of Supercapacitors for Energy Storage Applications. IEEE J. Emerg. Sel. Top. Power Electron. 2019, 7, 1677–1690. [Google Scholar] [CrossRef]

- Escher, I.; Hahn, M.; Ferrero, G.A.; Adelhelm, P. A Practical Guide for Using Electrochemical Dilatometry as Operando Tool in Battery and Supercapacitor Research. Energy Technol. 2022, 10, 2101120. [Google Scholar] [CrossRef]

- Rouquerol, J.; Llewellyn, P.; Rouquerol, F. Is the Bet Equation Applicable to Microporous Adsorbents? In Studies in Surface Science and Catalysis; Elsevier: Amsterdam, The Netherlands, 2007; Volume 160, pp. 49–56. [Google Scholar] [CrossRef]

- Bobbin, M.P.; Sharlin, S.; Feyzishendi, P.; Dang, A.H.; Wraback, C.M.; Josephson, T.R. Formalizing Chemical Physics Using the Lean Theorem Prover. Digit. Discov. 2024, 3, 264–280. [Google Scholar] [CrossRef]

- Dormant, L.M.; Adamson, A.W. Application of the BET Equation to Heterogeneous Surfaces. J. Colloid Interface Sci. 1972, 38, 285–289. [Google Scholar] [CrossRef]

- Kost, R.; Kreth, F.A.; Balducci, A. Post-Mortem Gas Chromatography-Mass Spectrometry Analysis of Aging Processes in Acetonitrile-based Supercapacitors. ChemElectroChem 2024, 11, e202300823. [Google Scholar] [CrossRef]

- Mukhopadhyay, S.C.; Ihara, I. Sensors and Technologies for Structural Health Monitoring: A Review. In New Developments in Sensing Technology for Structural Health Monitoring; Springer: Berlin/Heidelberg, Germany. [CrossRef]

- Naseri, F.; Karimi, S.; Farjah, E.; Schaltz, E. Supercapacitor Management System: A Comprehensive Review of Modeling, Estimation, Balancing, and Protection Techniques. Renew. Sustain. Energy Rev. 2022, 155, 111913. [Google Scholar] [CrossRef]

- Bhaduri, A. Mechanical Properties and Working of Metals and Alloys; Springer Series in Materials Science; Springer: Singapore, 2018; Volume 264. [Google Scholar] [CrossRef]

- Soualhi, A.; Makdessi, M.; German, R.; Echeverría, F.R.; Razik, H.; Sari, A.; Venet, P.; Clerc, G. Heath Monitoring of Capacitors and Supercapacitors Using the Neo-Fuzzy Neural Approach. IEEE Trans. Ind. Inform. 2018, 14, 24–34. [Google Scholar] [CrossRef]

- Mazloomian, K.; Lancaster, H.J.; Howard, C.A.; Shearing, P.R.; Miller, T.S. Supercapacitor Degradation: Understanding Mechanisms of Cycling-Induced Deterioration and Failure of a Pseudocapacitor. Batter. Supercaps 2023, 6, e202300214. [Google Scholar] [CrossRef]

- Spielbauer, M.; Soellner, J.; Berg, P.; Koch, K.; Keil, P.; Rosenmüller, C.; Bohlen, O.; Jossen, A. Experimental Investigation of the Impact of Mechanical Deformation on Aging, Safety and Electrical Behavior of 18650 Lithium-Ion Battery Cells. J. Energy Storage 2022, 55, 105564. [Google Scholar] [CrossRef]

- ISO 12405-4:2018 Electrically Propelled Road Vehicles—Test Specification for Lithium-Ion Traction Battery Packs and Systems. Part 4: Performance Testing. Available online: https://www.iso.org/standard/71407.html (accessed on 13 October 2025).

- Penna, J.A.M.; Nascimento, C.L.; Rodrigues, L.R. Health monitoring and remaining useful life estimation of lithium-ion aero-nautical batteries. In Proceedings of the 2012 IEEE Aerospace Conference, Big Sky, MT, USA, 3–10 March 2012. [Google Scholar] [CrossRef]

| Eaton XV3560-2R7407-R | |

| Nominal Capacitance | 400 F |

| Rated Voltage (Vr) | 2.7 V |

| Maximum continuous current | 26 A |

| Peak current | 220 A |

| Operating temperature | −40 °C to +65 °C |

| Initial ESR | 3.2 mΩ |

| Stored energy (E) | 0.41 Wh |

| Max power | 570 W |

| Length | 63 mm |

| Diameter | 35 mm |

| Typical mass | 72 g |

| Cycle life 1 | 500,000 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Doucet, T.; Mogniotte, J.-F.; Amiot, R.; Hijazi, A.; Venet, P.; Le, M.-Q.; Cottinet, P.-J. Multiphysics Measurement Method for Supercapacitors State of Health Determination. Micromachines 2025, 16, 1295. https://doi.org/10.3390/mi16111295

Doucet T, Mogniotte J-F, Amiot R, Hijazi A, Venet P, Le M-Q, Cottinet P-J. Multiphysics Measurement Method for Supercapacitors State of Health Determination. Micromachines. 2025; 16(11):1295. https://doi.org/10.3390/mi16111295

Chicago/Turabian StyleDoucet, Thomas, Jean-François Mogniotte, Raphaël Amiot, Alaa Hijazi, Pascal Venet, Minh-Quyen Le, and Pierre-Jean Cottinet. 2025. "Multiphysics Measurement Method for Supercapacitors State of Health Determination" Micromachines 16, no. 11: 1295. https://doi.org/10.3390/mi16111295

APA StyleDoucet, T., Mogniotte, J.-F., Amiot, R., Hijazi, A., Venet, P., Le, M.-Q., & Cottinet, P.-J. (2025). Multiphysics Measurement Method for Supercapacitors State of Health Determination. Micromachines, 16(11), 1295. https://doi.org/10.3390/mi16111295