Applications of Dry Film Photoresist in Micromachining: A Review

Abstract

1. Introduction

2. Structure and Lithography Mechanism of DFR

2.1. Structure and Types

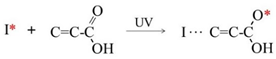

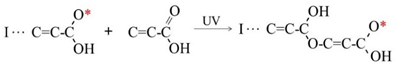

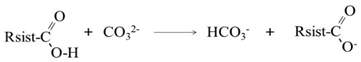

2.2. Lithography Mechanism

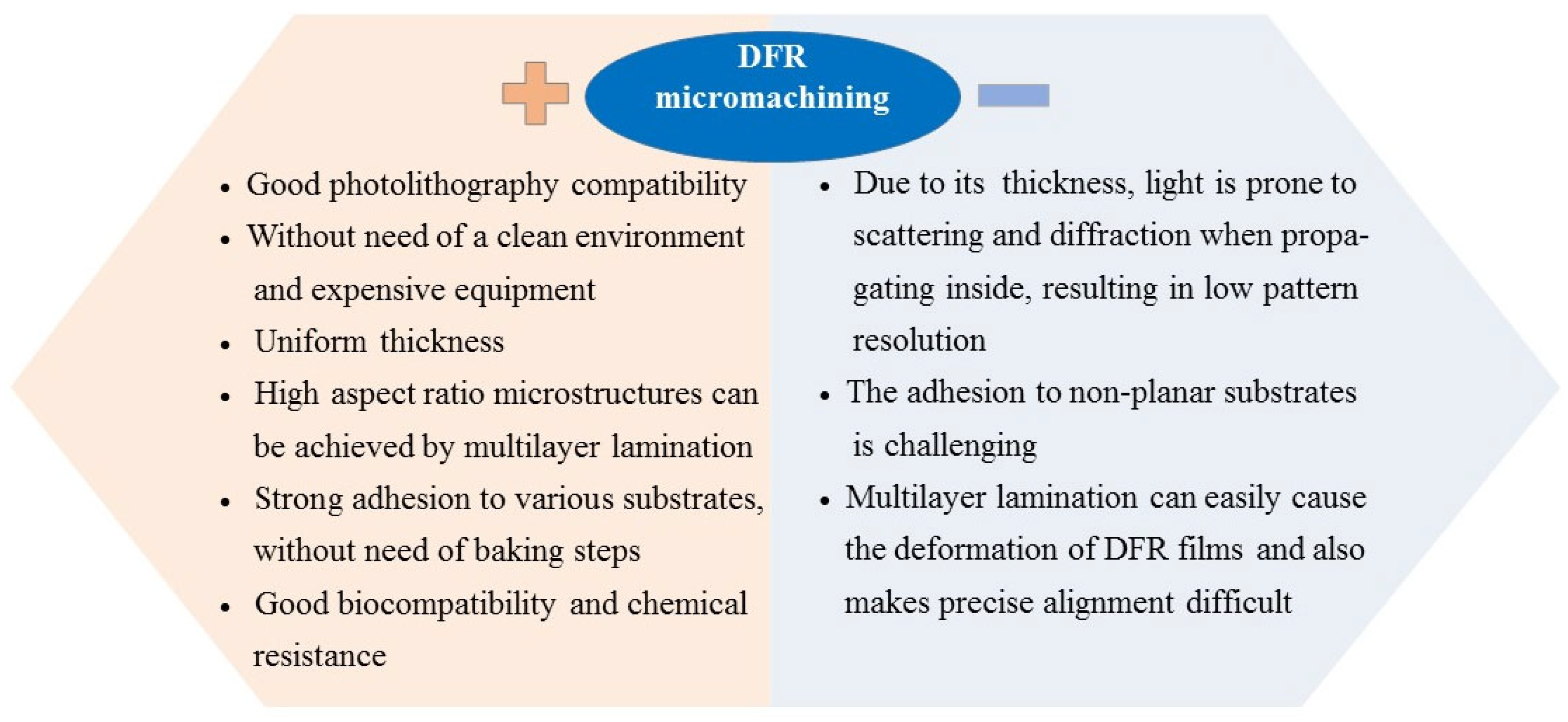

2.3. Characteristics of Micromachining Based on DFR

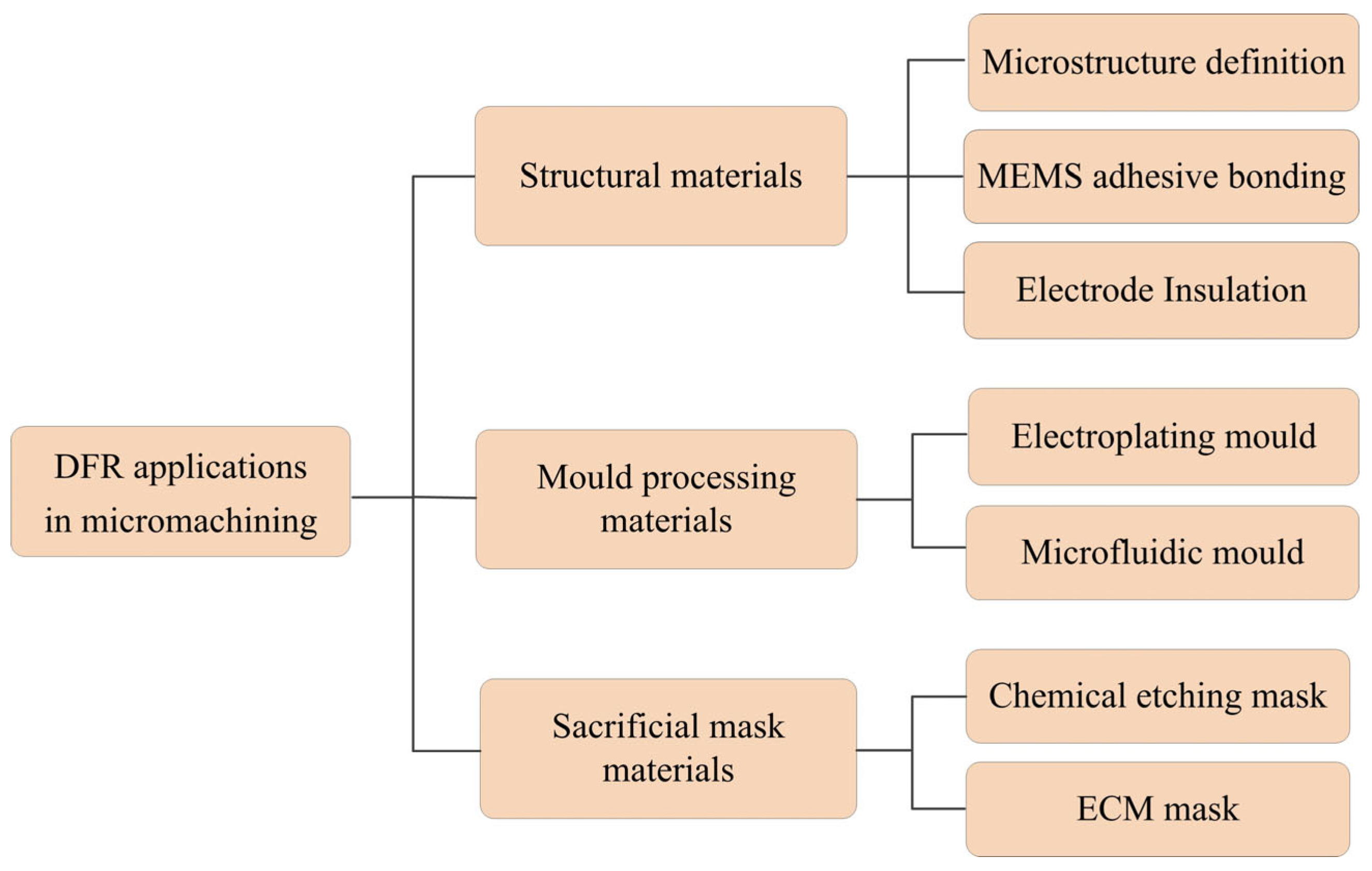

3. Broad Classification of DFR Applications in Micromachining

4. Applications of DFR as Structural Materials

4.1. Microstructure Definition

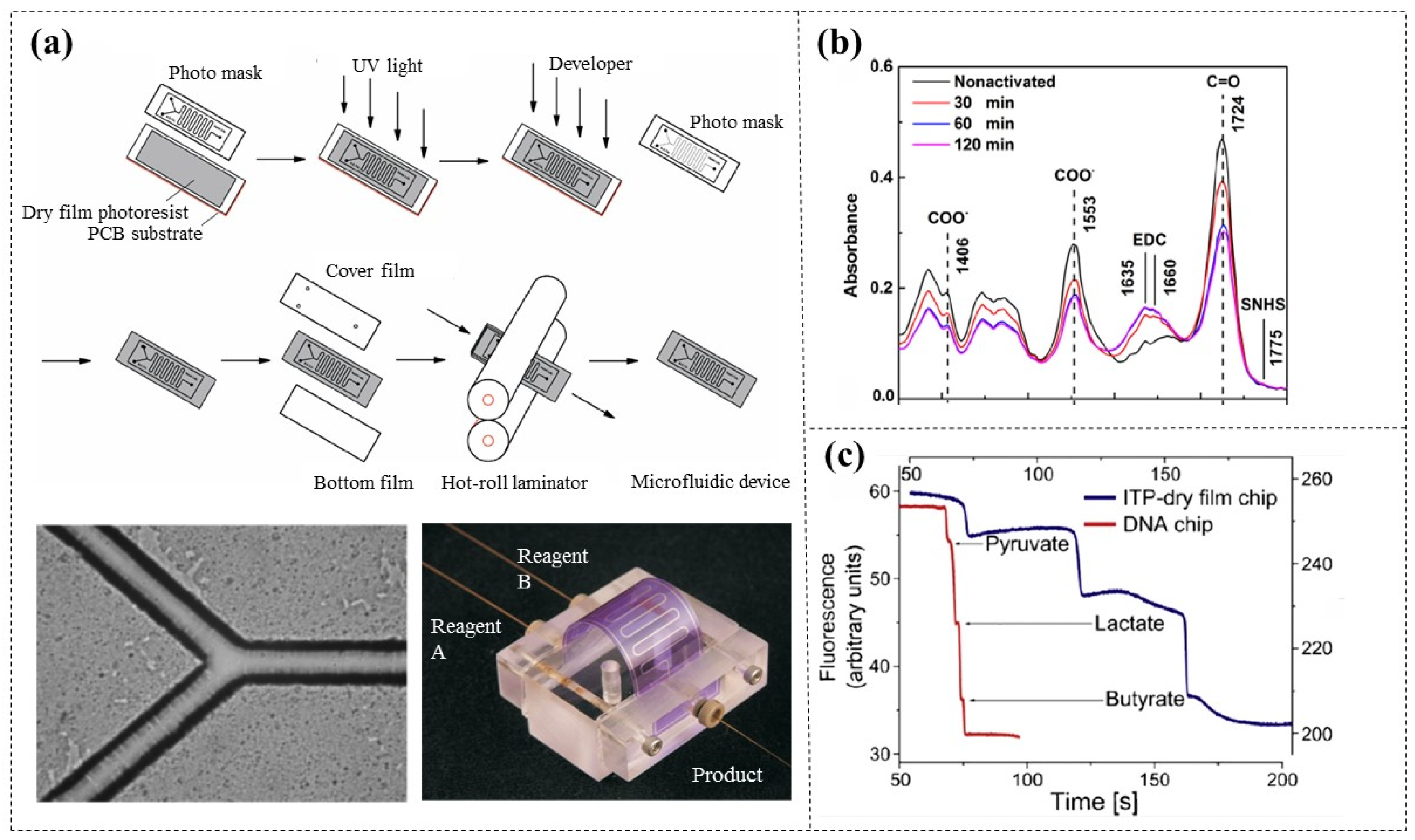

4.1.1. Microfluidic Chip Definition

4.1.2. Microcantilever Fabrication

4.1.3. Waveguide Component Construction

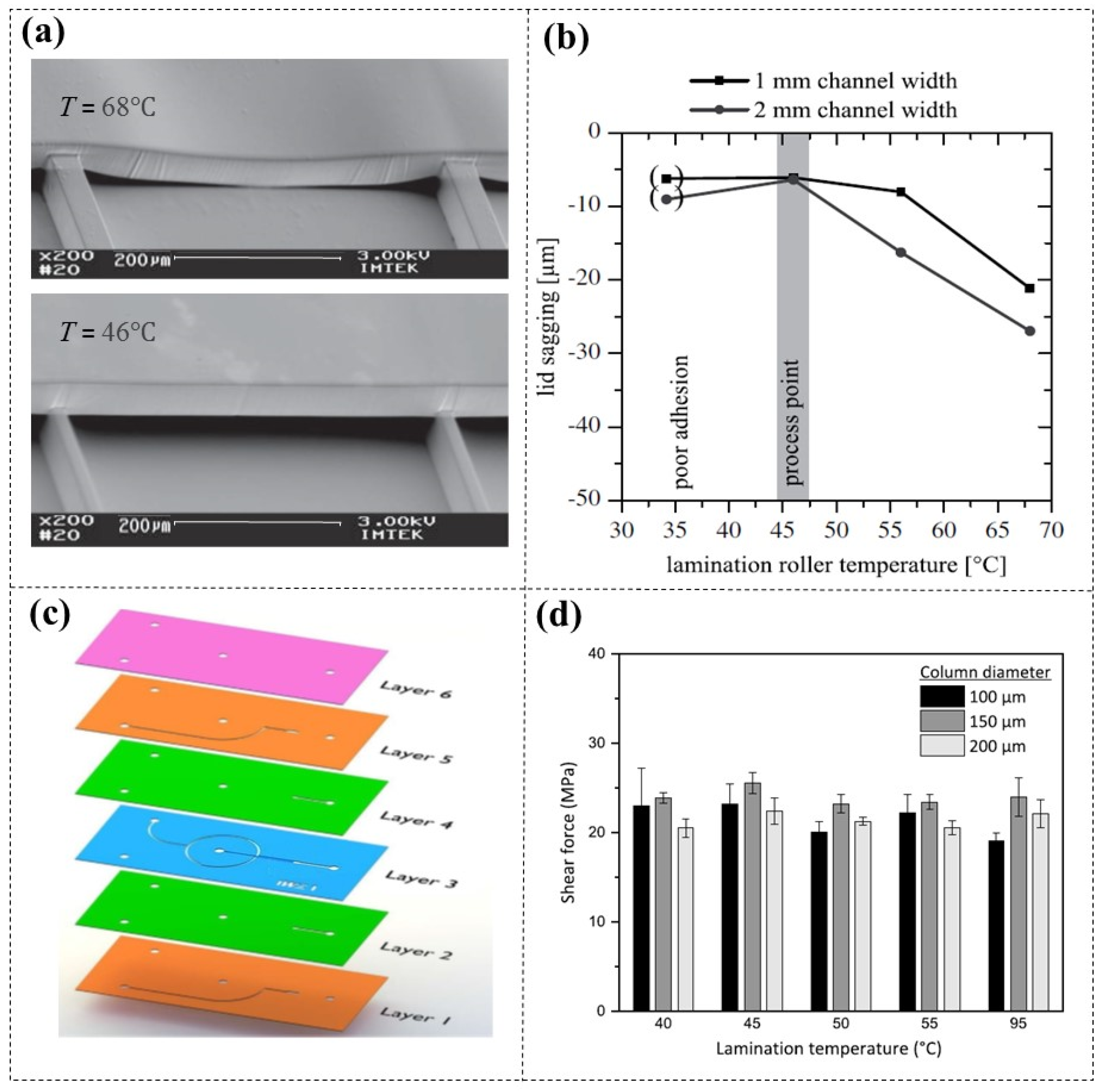

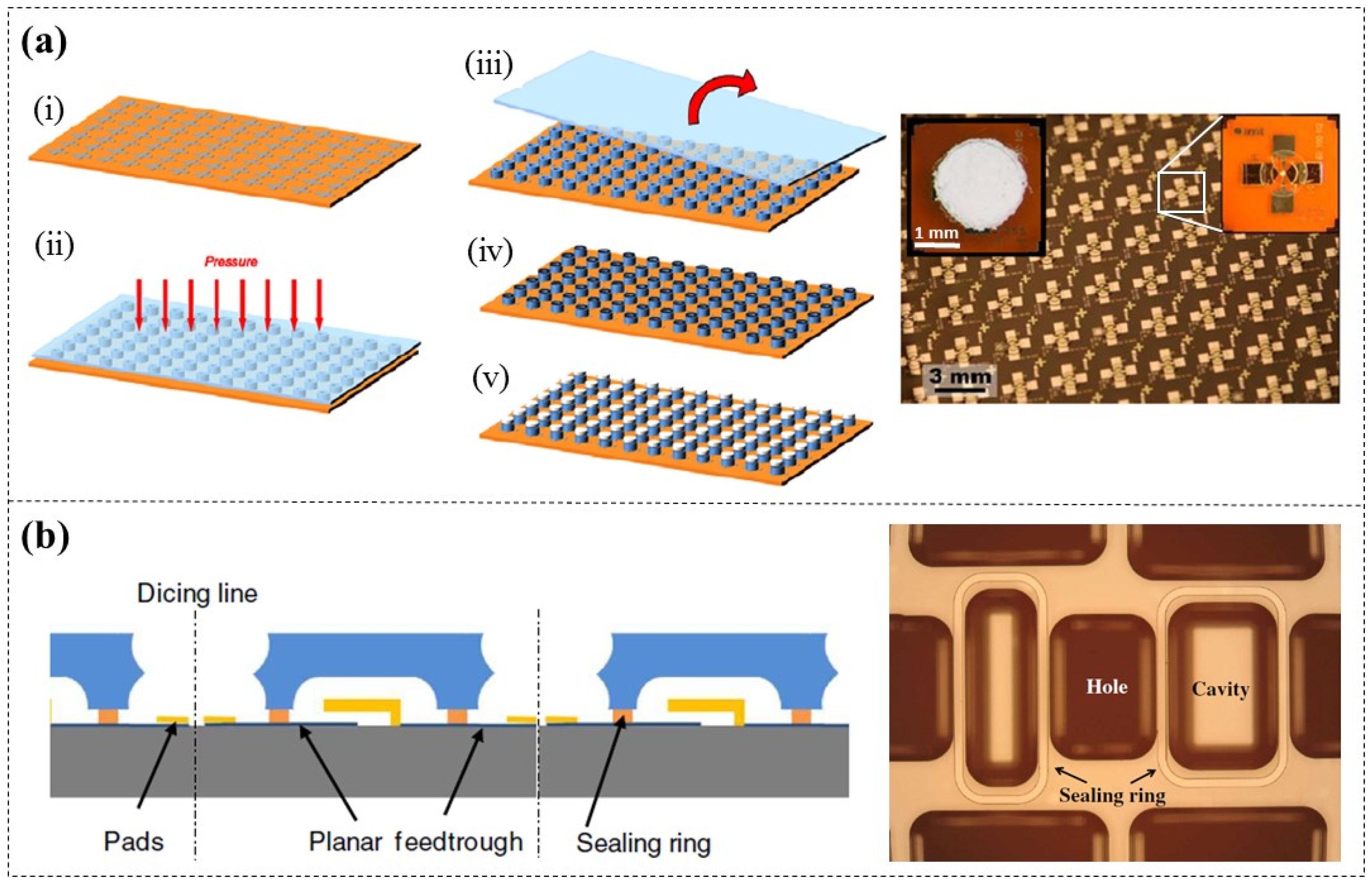

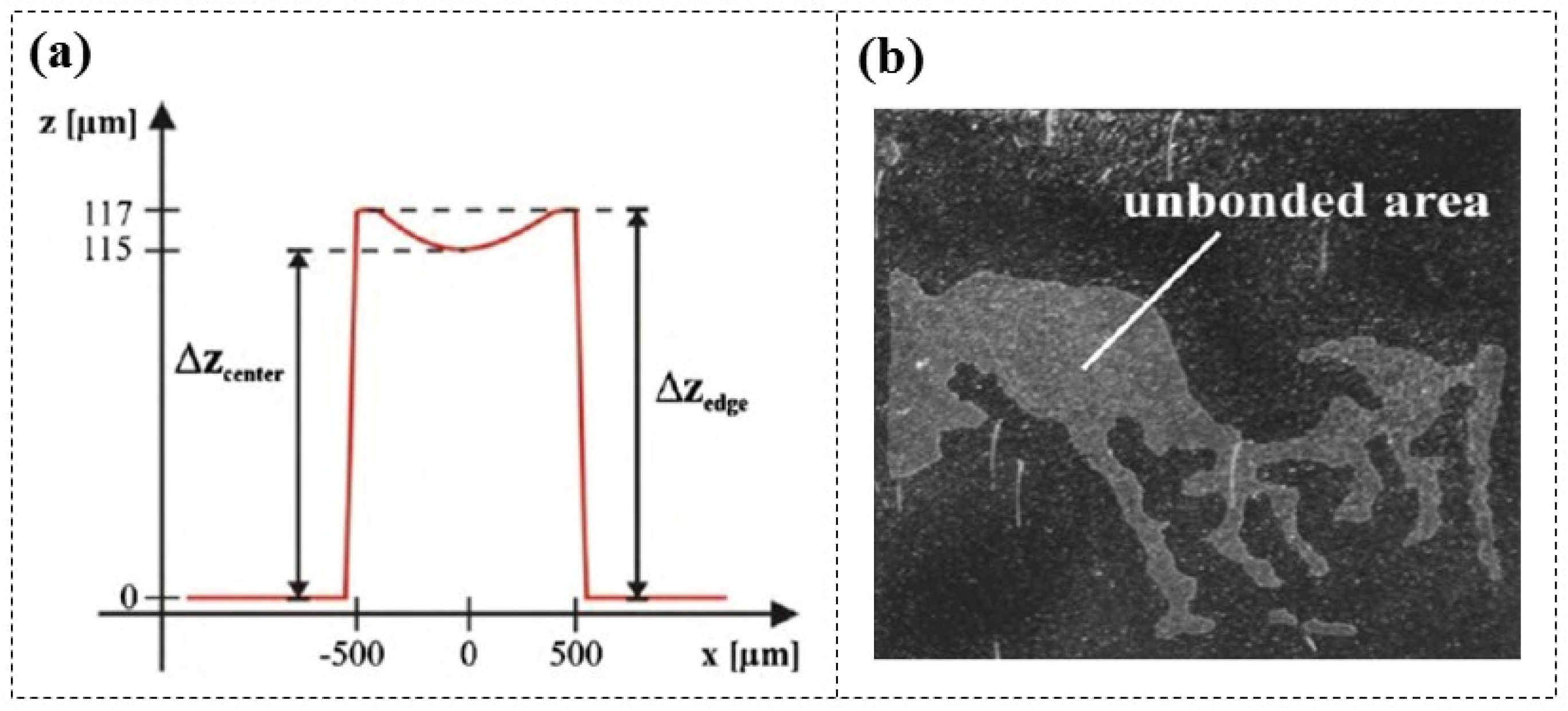

4.2. MEMS Adhesive Encapsulation

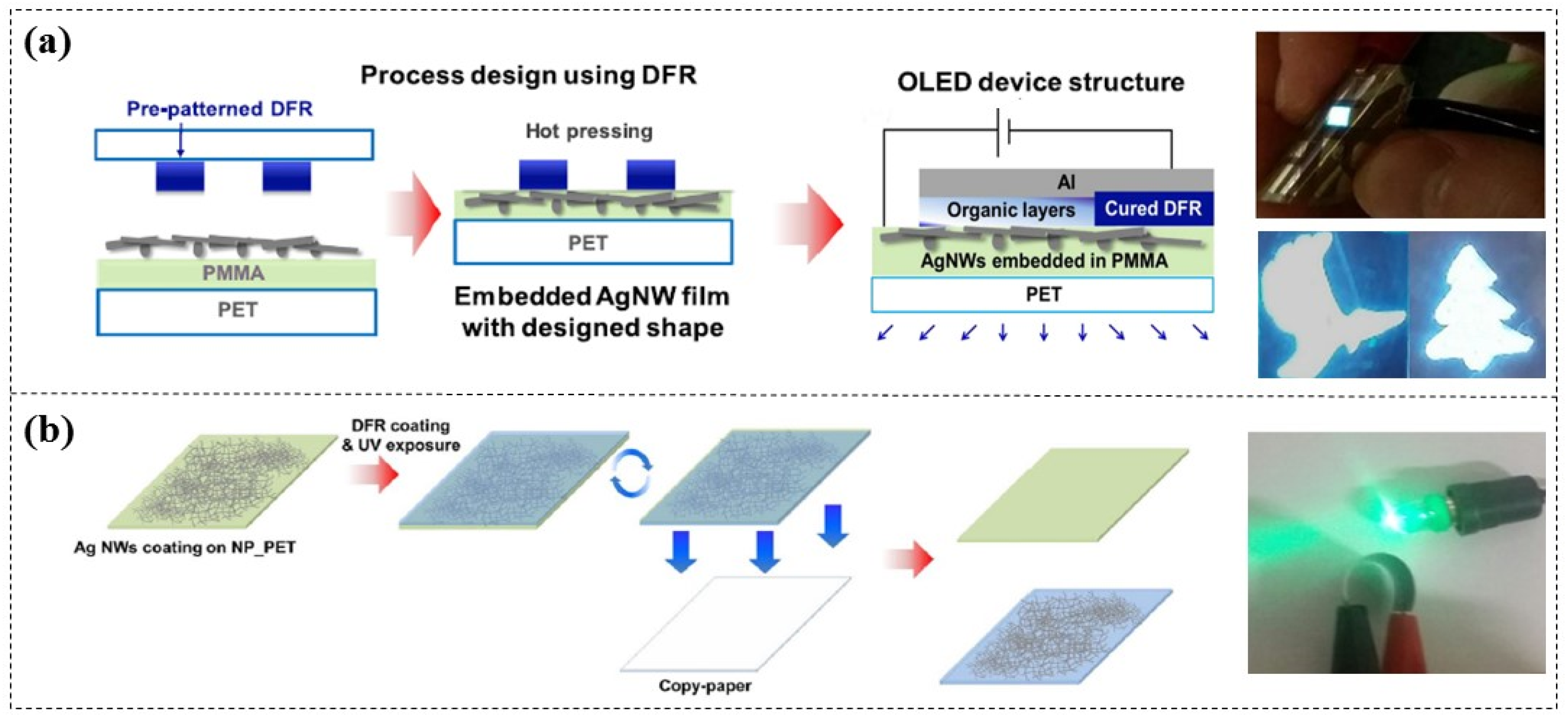

4.3. Flexible Electrode Insulation

5. Applications of DFR as Mould Processing Materials

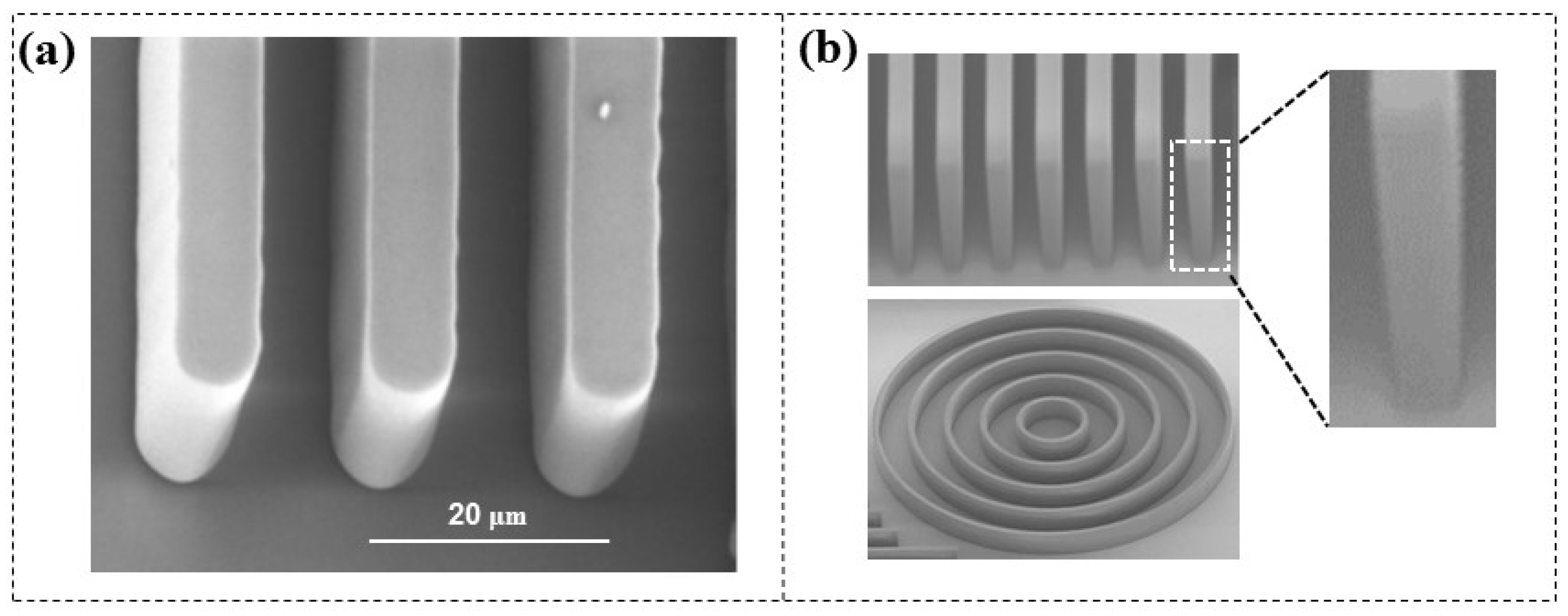

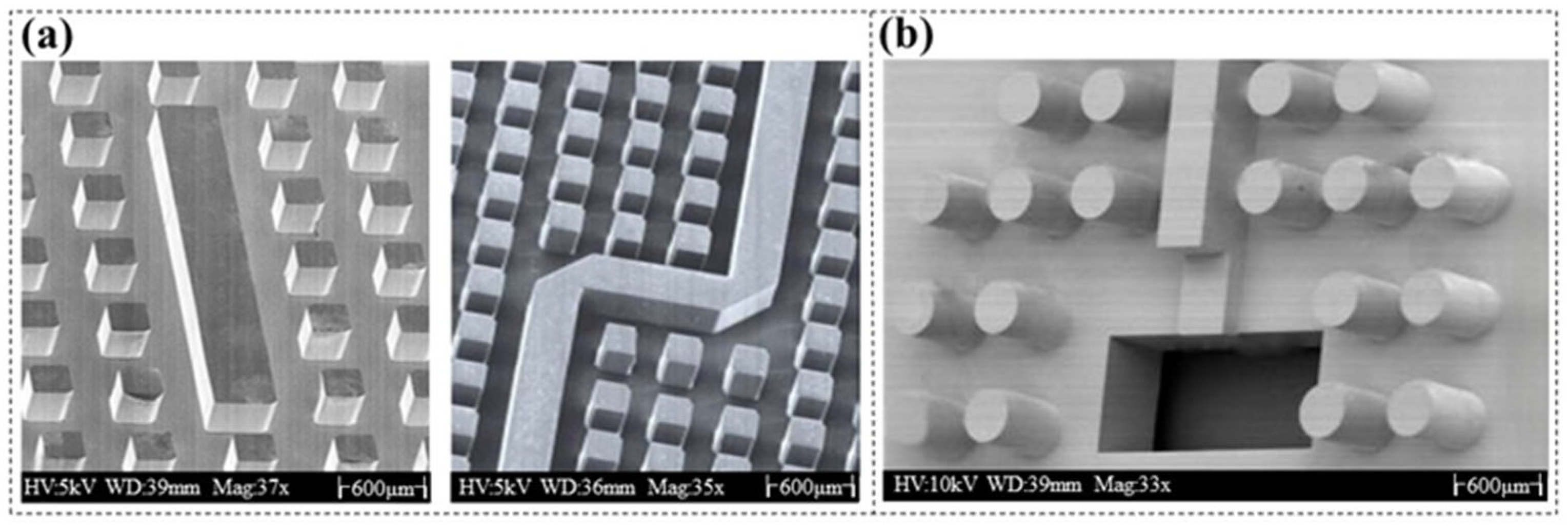

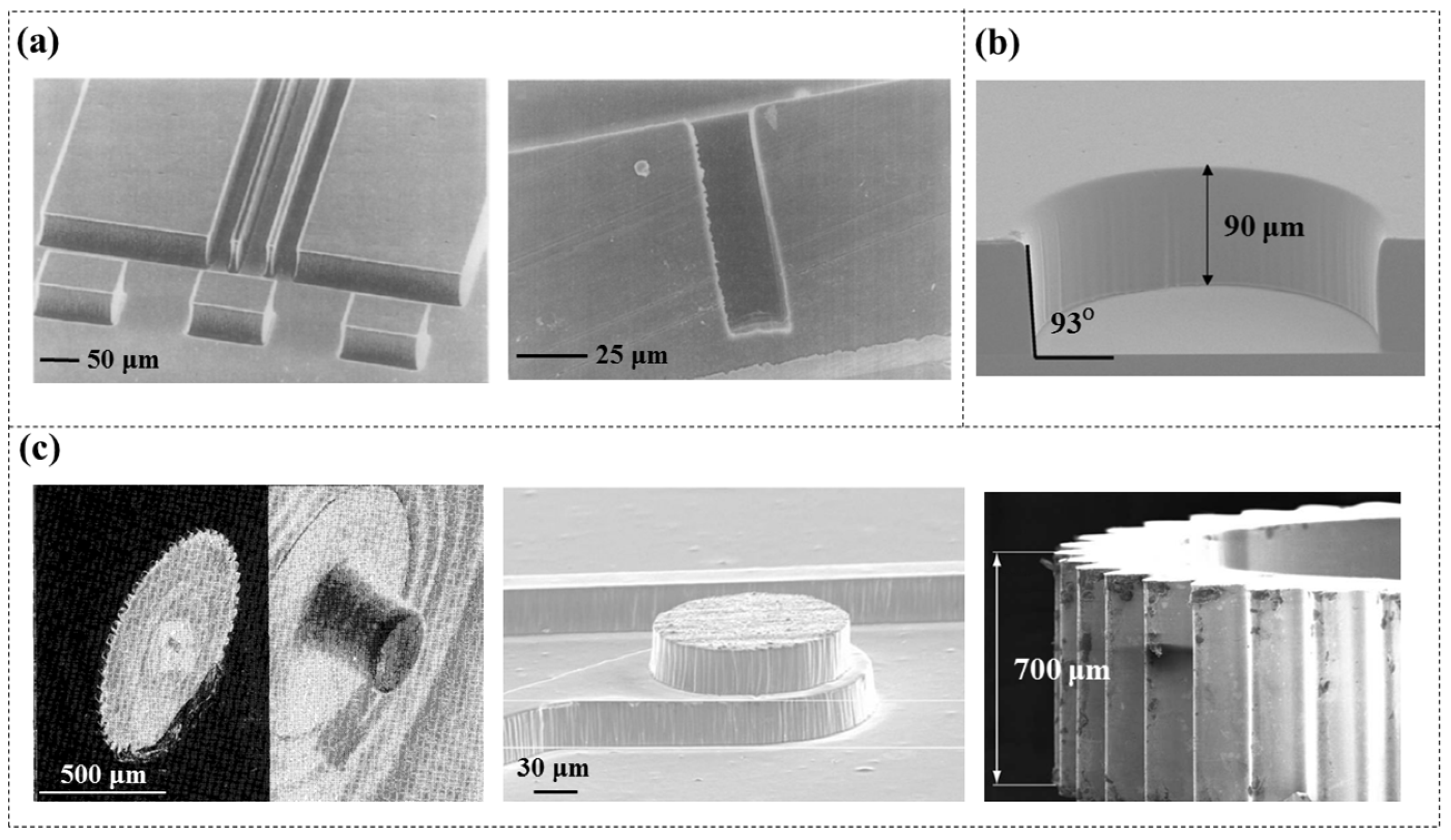

5.1. Metal Electroplating Moulds

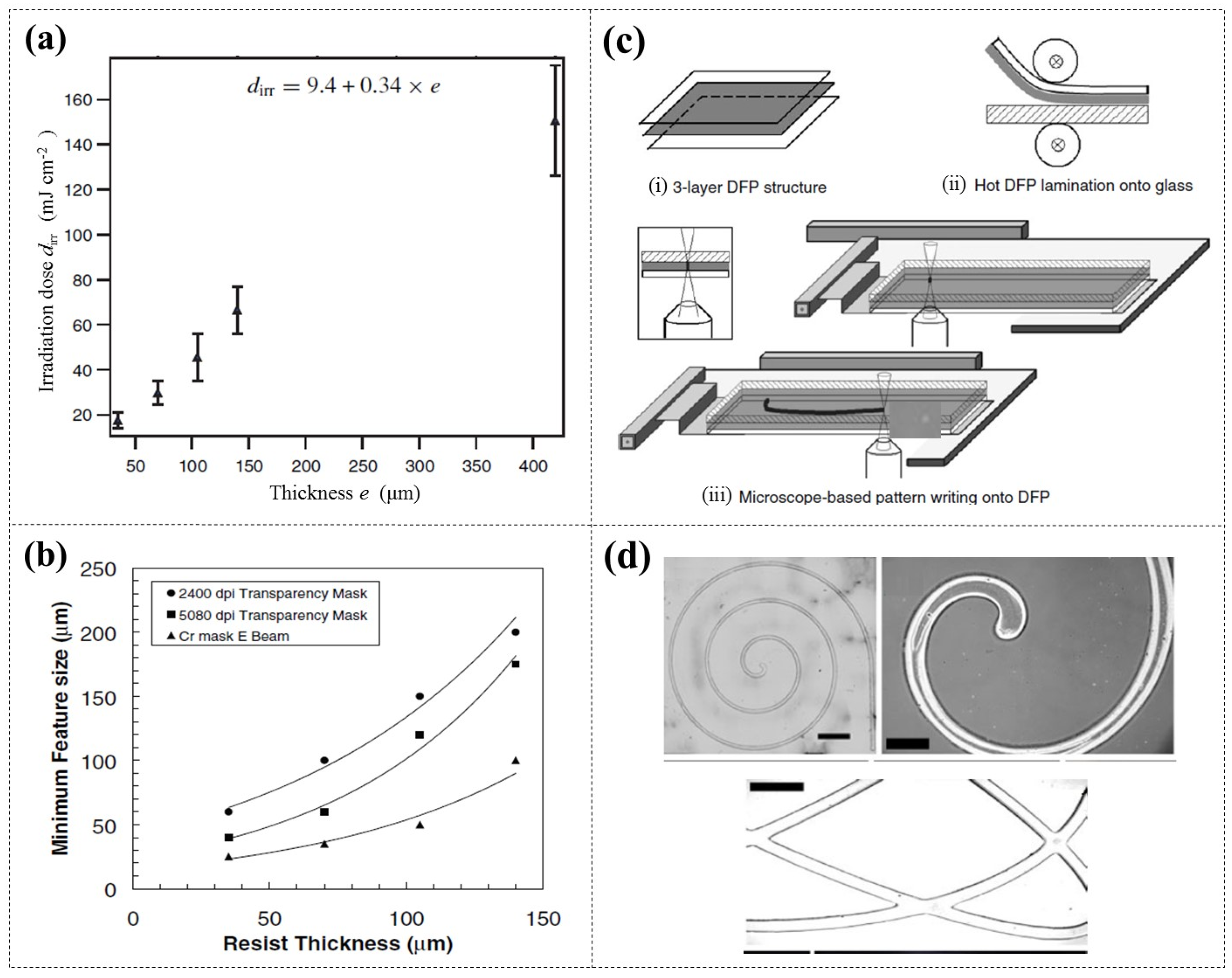

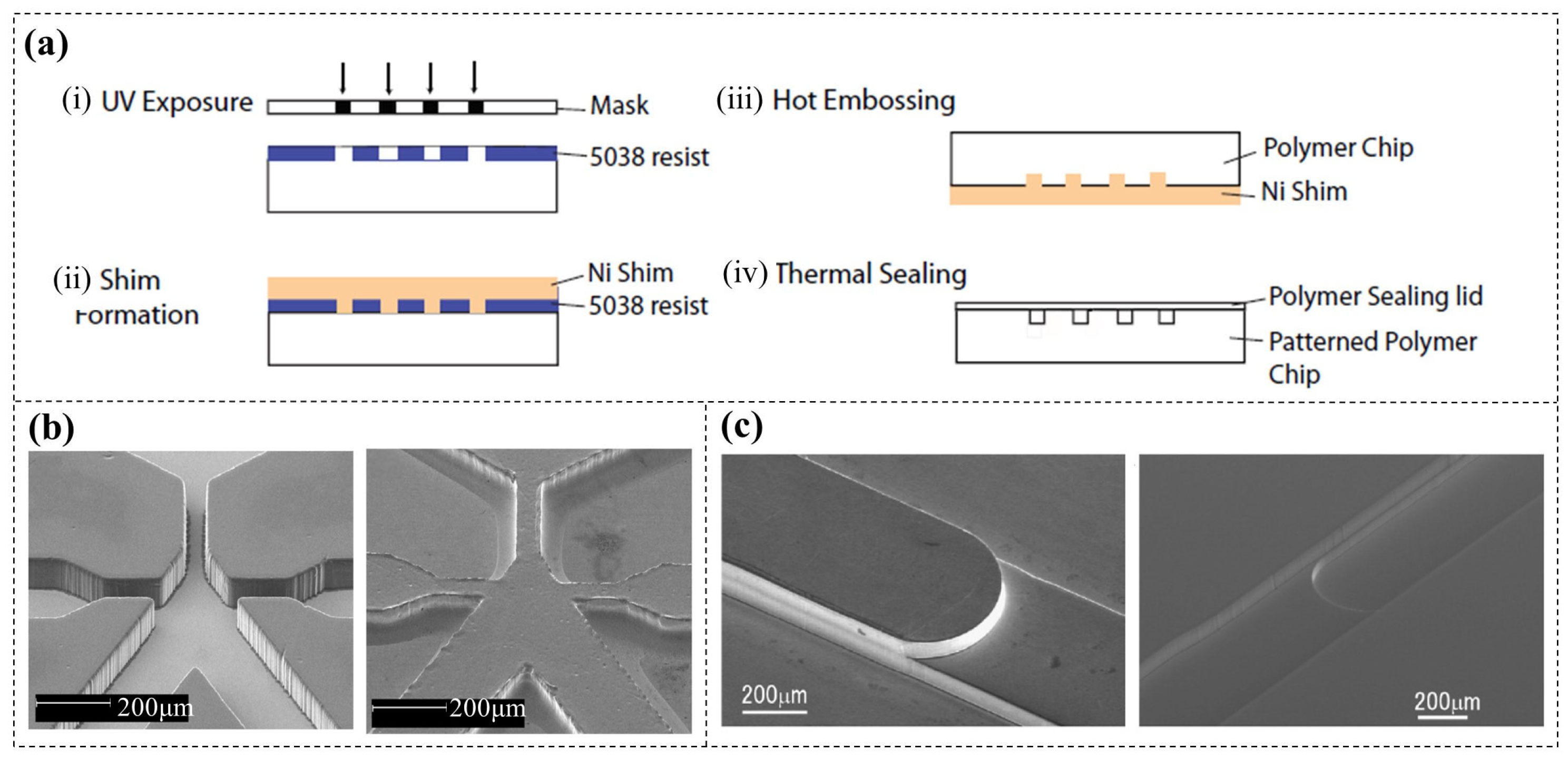

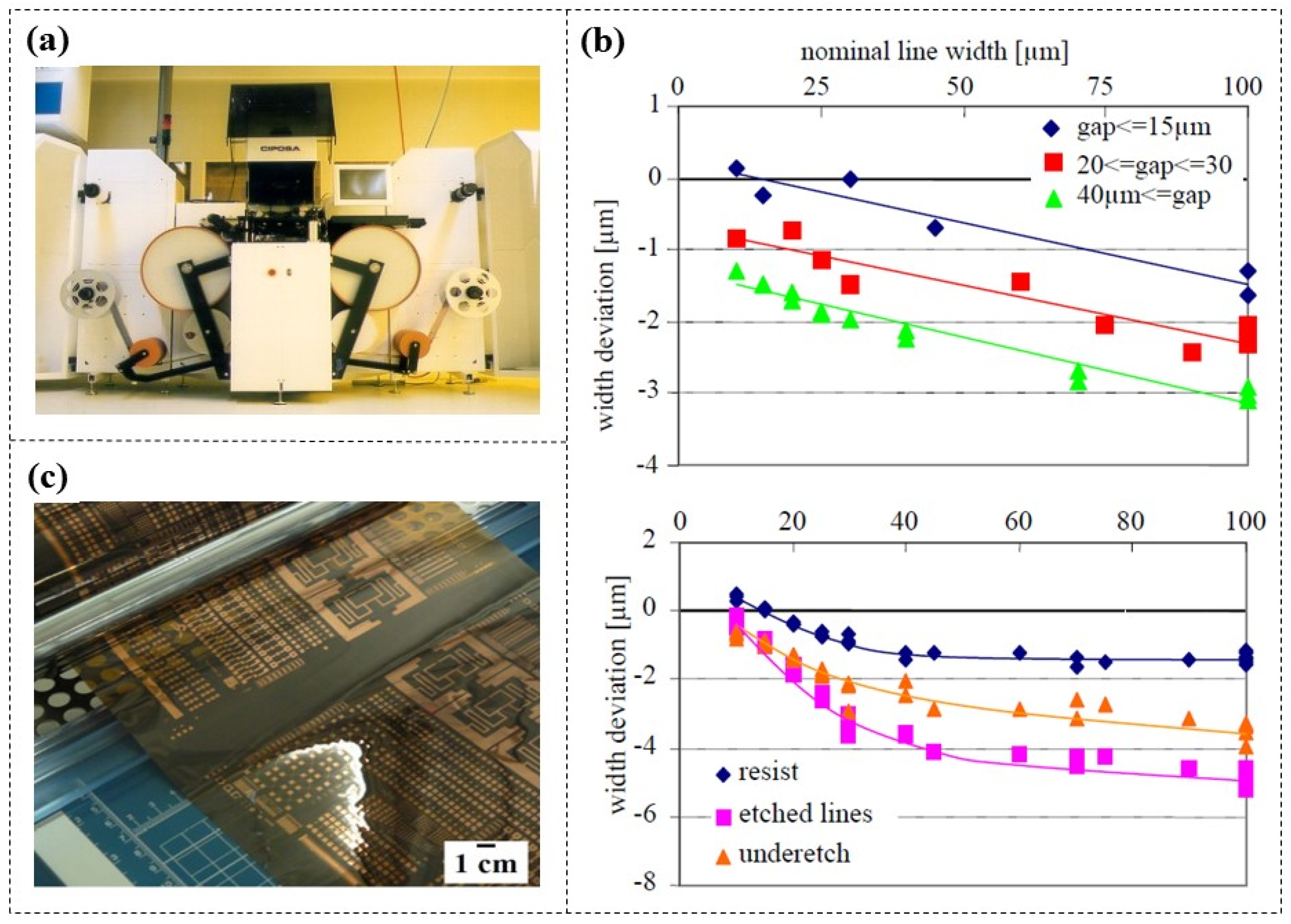

5.2. Microfluidic Moulds

6. Applications of DFR as Sacrificial Mask Materials

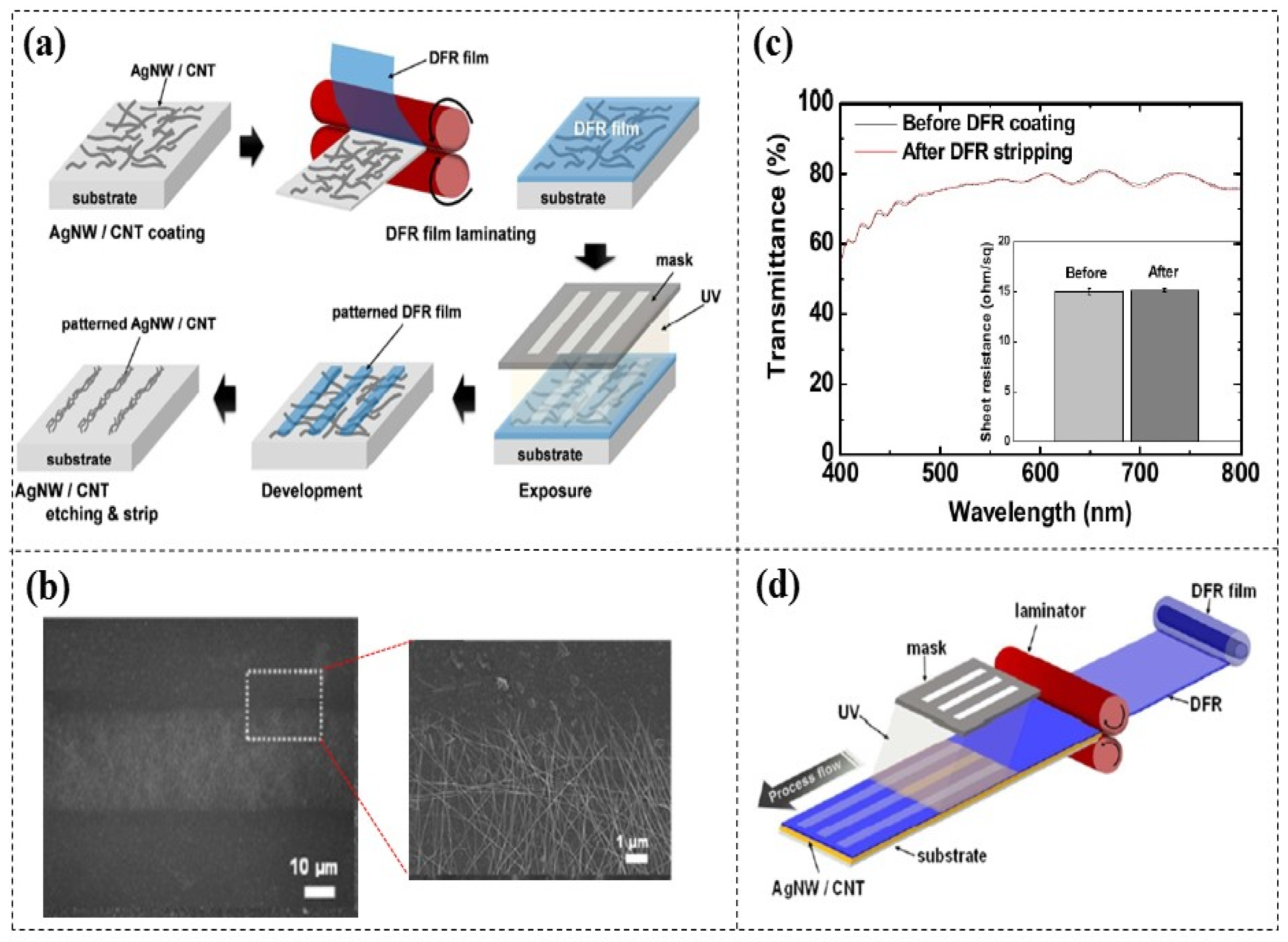

6.1. Sacrificial Masks for Chemical Etching

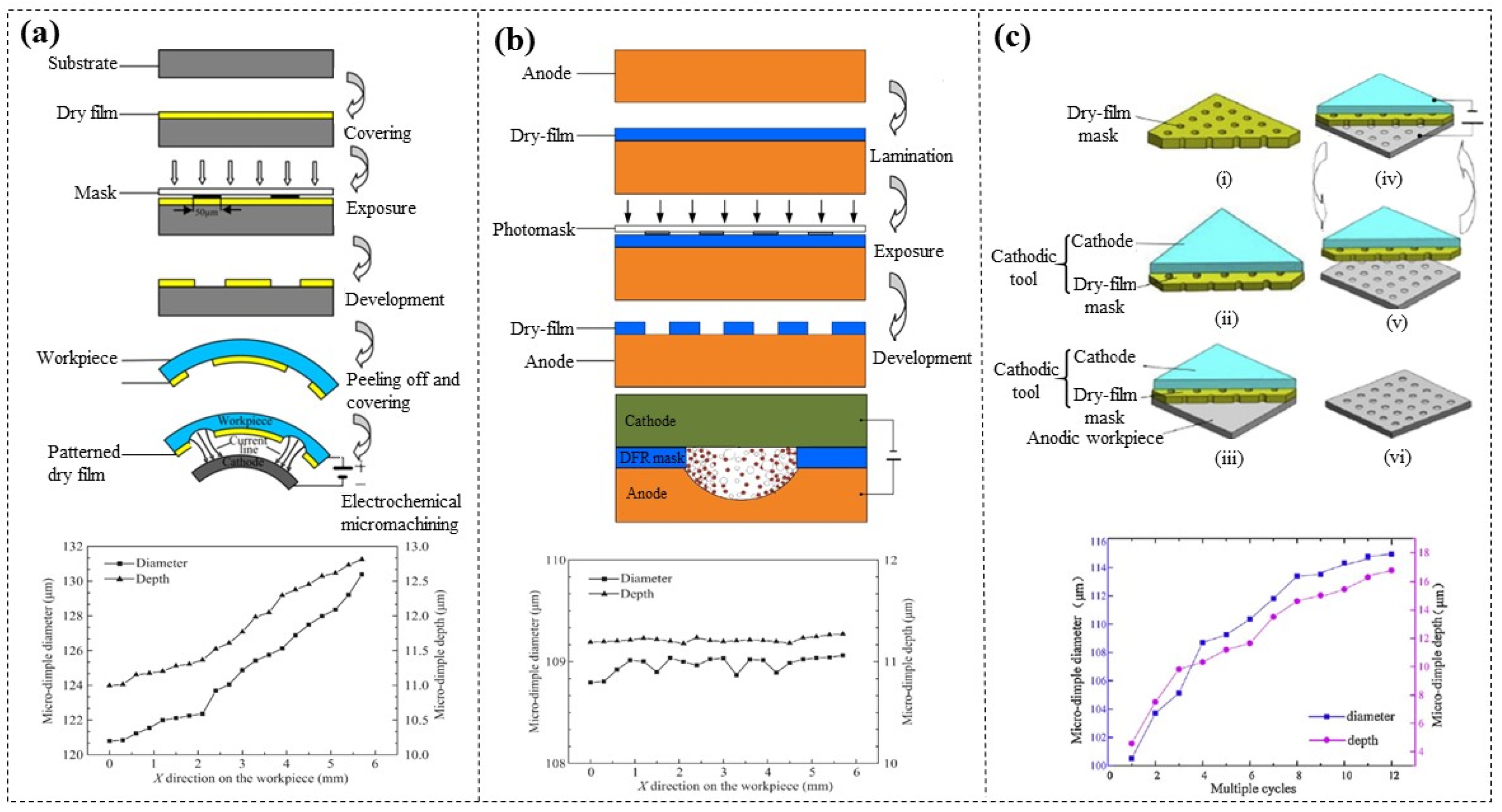

6.2. Sacrificial Masks for Electrochemical Micromachining (EMM)

7. Conclusions and Discussion

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Shufu, J.; Ya, W.U.; Wei, Z. Research progress of photosensitive dry film related technologies. J. Technol. 2023, 23, 38–42. [Google Scholar]

- Zhang, M.; Li, S. Low-cost and facile implementation of microfluidic colour-changing devices using dry film photoresist-based moulds. J. Exp. Nanosci. 2018, 13, 221–230. [Google Scholar] [CrossRef]

- Kukharenka, E.; Farooqui, M.M.; Grigore, L.; Kraft, M.; Hollinshead, N. Electroplating moulds using dry film thick negative photoresist. J. Micromech. Microeng. 2003, 13, S67–S74. [Google Scholar] [CrossRef]

- Shaw, J.M.; Gelorme, J.D.; LaBianca, N.C.; Conley, W.E.; Holmes, S.J. Negative photoresists for optical lithography. IBM J. Res. Dev. 1997, 41, 81–94. [Google Scholar] [CrossRef]

- Tsai, Y.; Yang, S.; Lee, H.; Jen, H.; Hsieh, Y. Fabrication of a flexible and disposable microreactor using a dry film photoresist. J. Chin. Chem. Soc. 2006, 53, 683–688. [Google Scholar] [CrossRef]

- Jung, M.Y.; Jang, W.I.; Choi, C.A.; Lee, M.R.; Jun, C.H.; Kim, Y.T. Novel lithography process for extreme deep trench by using laminated negative dry film resist. In Proceedings of the 17th IEEE International Conference on Micro Electro Mechanical Systems (MEMS), Maastricht, The Netherlands, 25–29 January 2004; pp. 685–688. [Google Scholar]

- Garland, S.P.; Murphy, T.M.; Pan, T. Print-to-pattern dry film photoresist lithography. J. Micromech. Microeng. 2014, 24, 057002. [Google Scholar] [CrossRef]

- Jillek, W.; Yung, W.K.C. Embedded components in printed circuit boards: A processing technology review. Int. J. Adv. Manuf. Technol. 2005, 25, 350–360. [Google Scholar] [CrossRef]

- Bruch, R.; Kling, A.; Urban, G.A.; Dincer, C. Dry film photoresist-based electrochemical microfluidic biosensor platform: Device fabrication, on-chip assay preparation, and system operation. J. Vis. Exp. 2017, 127, 56105. [Google Scholar]

- Bahadur, B.; Sampica, J.D.; Tchon, J.L.; Butterfield, A. Direct dry film optical bonding-A low-cost, robust, and scalable display lamination technology. J. Soc. Inf. Display 2011, 19, 732–740. [Google Scholar] [CrossRef]

- Hwang, B.; Matteini, P. Review on dry film photoresist-based patterning of Ag nanowire flexible electrodes for wearable electronics. Fash. Text. 2022, 9, 27. [Google Scholar] [CrossRef]

- Wang, Q.; Chen, L.; Bi, X.; Dong, X.; Xie, J.; Feng, B.; Duan, H. Dry film photoresist enabled sustainable large-area manufacturing for flexible electronics. ACS Appl. Mater. Interfaces 2025, 17, 49976–49985. [Google Scholar] [CrossRef] [PubMed]

- Pfeiffer, F.; Felix, N.M.; Neuber, C.; Ober, C.K.; Schmidt, H.W. Physical vapor deposition of molecular glass photoresists: A new route to chemically amplified patterning. Adv. Funct. Mater. 2007, 17, 2336–2342. [Google Scholar] [CrossRef]

- Hernández, R.; Zaragoza, J.B.; Jiménez-Pérez, J.; Orea, A.C.; Correa-Pacheco, Z. Study of photosensitive dry films absorption for printed circuit boards by photoacoustic technique. Int. J. Thermophys. 2017, 38, 114. [Google Scholar] [CrossRef]

- Cao, Y.; Yang, Z. Comparative analysis of positive photoresist and negative photoresist in nanoimprint lithography technology. Mater. Res. Dev. 2024, 4, 57–62. [Google Scholar]

- Zeng, W.; Wang, B.; Chang, H.; Olegovich, L.V. Precise detection of the low-quality cooking oil by monodisperse droplet generation in a flow-focusing microdroplet generator. Anal. Chim. Acta 2025, 1363, 344143. [Google Scholar] [CrossRef]

- Dewangan, P.; Purohit, S.; Sahu, V.; Vardhan, R.V.; Peddigari, M.; Pal, P. Fabrication of the microfluidic channels in silicon wafers using isotropic wet etching method: The impact of the composition of HNA solution on etching. Microsyst. Technol. 2025, 31, 63–73. [Google Scholar] [CrossRef]

- Golvari, P.; Kuebler, S.M. Fabrication of functional microdevices in SU-8 by multi-photon lithography. Micromachines 2021, 12, 472. [Google Scholar] [CrossRef]

- Horak, J.; Dincer, C.; Bakirci, H.; Urban, G. A disposable dry film photoresist-based microcapillaryimmunosensor chip for rapid detection of Epstein-Barr virus infection. Sens. Actuators B-Chem. 2014, 191, 813–820. [Google Scholar] [CrossRef]

- Smejkal, P.; Breadmore, M.C.; Guijt, R.M.; Foret, F.; Bek, F.; Macka, M. Analytical isotachophoresis of lactate in human serum using dry film photoresist microfluidic chips compatible with a commercially available field-deployable instrument platform. Anal. Chim. Acta 2013, 803, 135–142. [Google Scholar] [CrossRef]

- Temiz, Y.; Lovchik, R.D.; Delamarche, E. Capillary-driven microfluidic chips for miniaturized immunoassays: Patterning capture antibodies using microcontact printing and dry-film resists. In Microchip Diagnostics: Methods and Protocols; Springer: New York, NY, USA, 2017; pp. 34–46. [Google Scholar]

- Vulto, P.; Glade, N.; Altomare, L.; Bablet, J.; Del Tin, L.; Medoro, G.; Chartier, I.; Manaresi, N.; Tartagni, M.; Guerrieri, R. Microfluidic channel fabrication in dry film resist for production and prototyping of hybrid chips. Lab Chip 2005, 5, 158–162. [Google Scholar] [CrossRef]

- Azizy, R.; Otto, H.; König, J.; Schreier, D.; Weigel, C.; Cierpka, C.; Strehle, S. A microfluidic magnetohydrodynamic pump based on a thermally bonded composite of glass and dry film photoresist. Micro Nano Eng. 2023, 18, 100173. [Google Scholar] [CrossRef]

- Anderson, J.R.; Chiu, D.T.; Jackman, R.J.; Cherniavskaya, O.; McDonald, J.C.; Wu, H.; Whitesides, S.H.; Whitesides, G.M. Fabrication of topologically complex three-dimensional microfluidic systems in PDMS by rapid prototyping. Anal. Chem. 2000, 72, 3158–3164. [Google Scholar] [CrossRef] [PubMed]

- Zhang, M.; Wu, J.; Wang, L.; Xiao, K.; Wen, W. A simple method for fabricating multi-layer PDMS structures for 3D microfluidic chips. Lab Chip 2010, 10, 1199–1203. [Google Scholar] [CrossRef] [PubMed]

- Masrie, M.; Majlis, B.Y.; Yunas, J. Fabrication of multilayer-PDMS based microfluidic device for bio-particles concentration detection. Bio-Med. Mater. Eng. 2014, 24, 1951–1958. [Google Scholar] [CrossRef] [PubMed]

- Agirregabiria, M.; Blanco, F.J.; Berganzo, J.; Arroyo, M.T.; Fullaondo, A.; Mayora, K.; Ruano-Lopez, J.M. Fabrication of SU-8 multilayer microstructures based on successive CMOS compatible adhesive bonding and releasing steps. Lab Chip 2005, 5, 545–552. [Google Scholar] [CrossRef]

- Lee, J.B.; Choi, K.H.; Yoo, K. Innovative SU-8 lithography techniques and their applications. Micromachines 2014, 6, 1–18. [Google Scholar] [CrossRef]

- Stöhr, U.; Vulto, P.; Hoppe, P.; Urban, G.; Reinecke, H. High-resolution permanent photoresist laminate for microsystem applications. J. Micro/Nanolithography MEMS MOEMS 2008, 7, 033009. [Google Scholar] [CrossRef]

- Courson, R.; Cargou, S.; Conédéra, V.; Fouet, M.; Blatché, M.C.; Serpentini, C.L.; Gué, A.M. Low-cost multilevel microchannel lab on chip: DF-1000 series dry film photoresist as a promising enabler. RSC Adv. 2014, 4, 54847–54853. [Google Scholar] [CrossRef]

- Bruch, R.; Chatelle, C.; Kling, A.; Rebmann, B.; Wirth, S.; Schumann, S.; Weber, W.; Dincer, C.; Urban, G. Clinical on-site monitoring of ß-lactam antibiotics for a personalized antibiotherapy. Sci. Rep. 2017, 7, 3127. [Google Scholar] [CrossRef]

- Roos, M.M.; Winkler, A.; Nilsen, M.; Menzel, S.B.; Strehle, S. Towards green 3D-microfabrication of Bio-MEMS devices using ADEX dry film photoresists. Int. J. Precis. Eng. Manuf.-Green Technol. 2022, 9, 43–57. [Google Scholar] [CrossRef]

- Meier, R.C.; Badilita, V.; Brunne, J.; Wallrabe, U.; Korvink, J.G. Complex three-dimensional high aspect ratio microfluidic network manufactured in combined PerMX dry-resist and SU-8 technology. Biomicrofluidics 2011, 5, 034111. [Google Scholar] [CrossRef]

- Vásquez Quintero, A.; Briand, D.; De Rooij, N.F. Effect of low-temperature processing on dry film photoresist properties for flexible electronics. J. Polym. Sci. Pol. Phys. 2013, 51, 668–679. [Google Scholar] [CrossRef]

- Wangler, N.; Gutzweiler, L.; Kalkandjiev, K.; Müller, C.; Mayenfels, F.; Reinecke, H.; Zengerle, R.; Paust, N. High-resolution permanent photoresist laminate TMMF for sealed microfluidic structures in biological applications. J. Micromech. Microeng. 2011, 21, 095009. [Google Scholar] [CrossRef]

- McCreedy, T. Rapid prototyping of glass and PDMS microstructures for micro total analytical systems and micro chemical reactors by microfabrication in the general laboratory. Anal. Chim. Acta 2001, 427, 39–43. [Google Scholar] [CrossRef]

- Cao, Y.; Floehr, J.; Ingebrandt, S.; Schnakenberg, U. Dry film resist laminated microfluidic system for electrical impedance measurements. Micromachines 2021, 12, 632. [Google Scholar] [CrossRef]

- El Hasni, A.; Pfirrmann, S.; Kolander, A.; Yacoub-George, E.; König, M.; Landesberger, C.; Voigt, A.; Grützner, G.; Schnakenberg, U. Six-layer lamination of a new dry film negative-tone photoresist for fabricating complex 3D microfluidic devices. Microfluid. Nanofluid. 2017, 21, 41. [Google Scholar] [CrossRef]

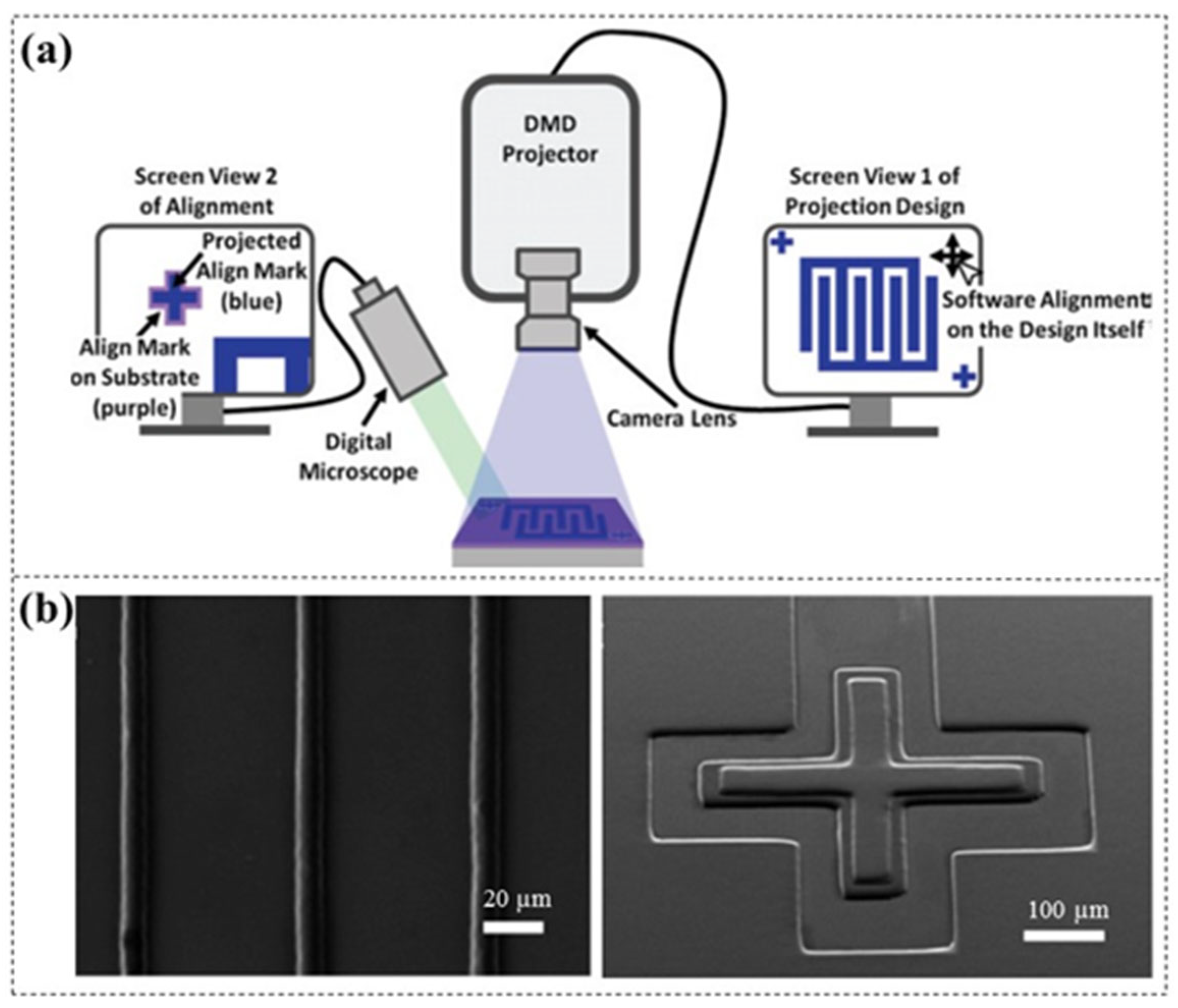

- Zhao, S.; Cong, H.; Pan, T. Direct projection on dry-film photoresist (DP 2): Do-it-yourself three-dimensional polymer microfluidics. Lab Chip 2009, 9, 1128–1132. [Google Scholar] [CrossRef]

- Narayanan, N.; Saldanha, A.; Gale, B.K. A microfabricated electrical SPLITT system. Lab Chip 2006, 6, 105–114. [Google Scholar] [CrossRef]

- Lang, H.P.; Hegner, M.; Gerber, C. Nanomechanical cantilever array sensors. In Springer Handbook of Nanotechnology; Springer: Berlin/Heidelberg, Germany, 2007; pp. 457–485. [Google Scholar]

- Abgrall, P.; Charlot, S.; Fulcrand, R.; Paul, L.; Boukabache, A.; Gué, A.M. Low-stress fabrication of 3D polymer free standing structures using lamination of photosensitive films. Microsyst. Technol. 2008, 14, 1205–1214. [Google Scholar] [CrossRef]

- Sečianska, K.; Šoltýs, J.; Cambel, V. Study of magnetic micro-ellipses by cantilever sensor. Acta Phys. Pol. A 2017, 131, 833–835. [Google Scholar] [CrossRef]

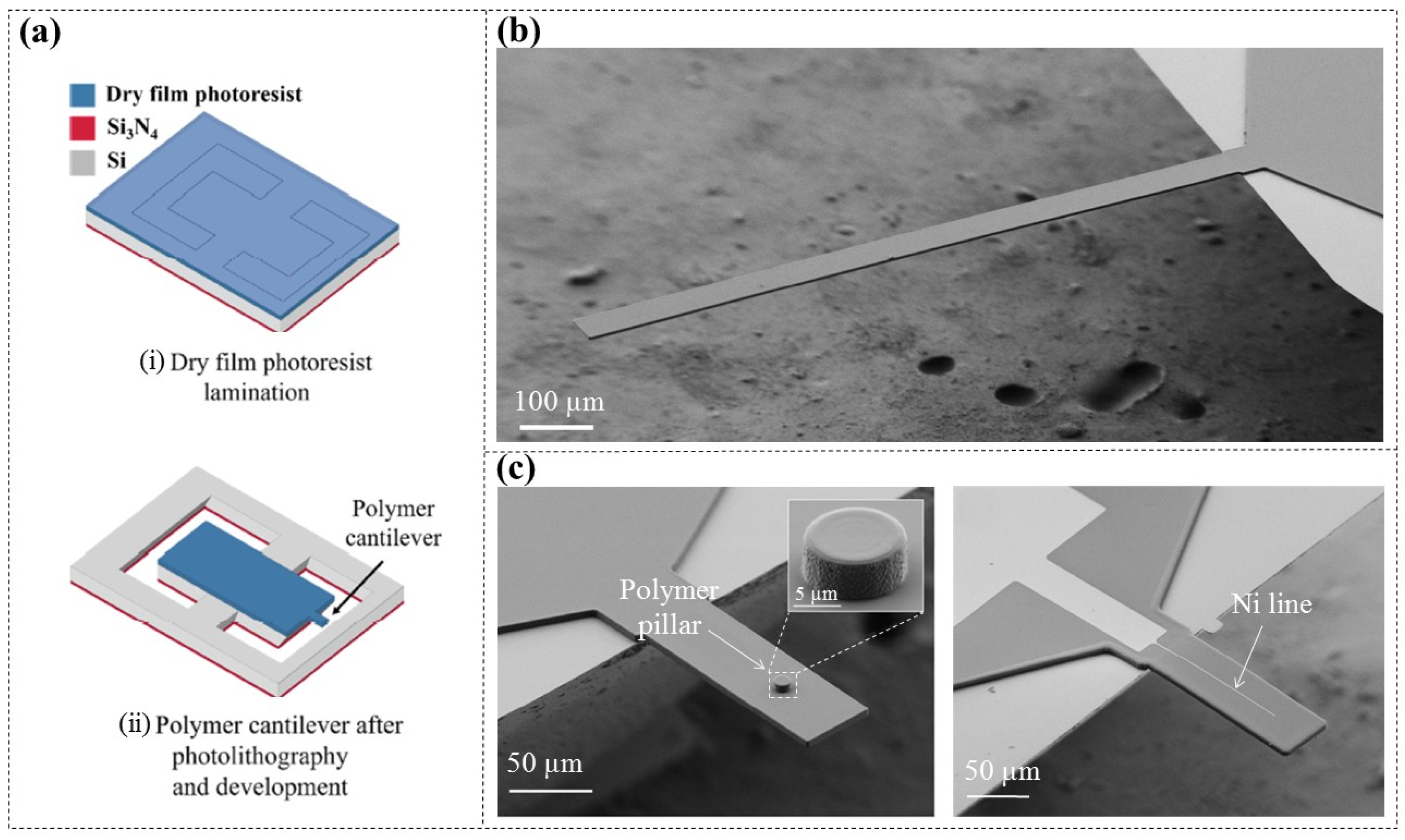

- Nilsen, M.; Dannberg, O.; Fröhlich, T.; Strehle, S. Direct polymer microcantilever fabrication from free-standing dry film photoresists. J. Micromech. Microeng. 2020, 30, 095012. [Google Scholar] [CrossRef]

- Xu, J.; Bertke, M.; Li, X.; Mu, H.; Zhou, H.; Yu, F.; Hamdana, G.; Schmidt, A.; Bremers, H.; Peiner, E. Fabrication of ZnOnanorods and Chitosan@ ZnOnanorods on MEMS piezoresistive self-actuating silicon microcantilever for humidity sensing. Sens. Actuators B-Chem. 2018, 273, 276–287. [Google Scholar] [CrossRef]

- Hofer, M.; Ivanov, T.; Rudek, M.; Kopiec, D.; Guliyev, E.; Gotszalk, T.P.; Rangelow, I.W. Fabrication of self-actuated piezoresistive thermal probes. Microelectron. Eng. 2015, 145, 32–37. [Google Scholar] [CrossRef]

- Gaitas, A.; French, P. Piezo-thermal probe array for high throughput applications. Sens. Actuators A-Phys. 2012, 186, 125–129. [Google Scholar] [CrossRef][Green Version]

- Rahiminejad, S.; Zaman, A.; Pucci, E.; Raza, H.; Vassilev, V.; Haasl, S.; Lundgren, P.; Kildal, P.S.; Enoksson, P. Micromachined ridge gap waveguide and resonator for millimeter-wave applications. Sens. Actuators A-Phys. 2012, 186, 264–269. [Google Scholar] [CrossRef]

- Gomez-Torrent, A.; Garcia-Vigueras, M.; Le Coq, L.; Mahmoud, A.; Ettorre, M.; Sauleau, R.; Oberhammer, J. A low-profile and high-gain frequency beam steering subterahertz antenna enabled by silicon micromachining. IEEE Trans. Antennas Propag. 2019, 68, 672–682. [Google Scholar] [CrossRef]

- Rahiminejad, S.; Pucci, E.; Haasl, S.; Enoksson, P. SU8 ridge-gap waveguide resonator. Int. J. Microw. Wirel. Technol. 2014, 6, 459–465. [Google Scholar] [CrossRef]

- Ryu, M.; Ng, S.H.; Anand, V.; Lundgaard, S.; Hu, J.; Katkus, T.; Appadoo, D.; Vilagosh, Z.; Wood, A.W.; Juodkazis, S.; et al. Attenuated total reflection at THz wavelengths: Peculiarities of total internal reflection and polariscopy. Preprints 2021, 11, 7632. [Google Scholar]

- Saleem, A.; Rahiminejad, S.; Desmaris, V.; Enoksson, P. Carbon nanotubes as base material for fabrication of gap waveguide components. Sens. Actuators A-Phys. 2015, 224, 163–168. [Google Scholar] [CrossRef]

- Farjana, S.; Ghaderi, M.; Rahiminejad, S.; Haasl, S.; Enoksson, P. Dry film photoresist-based microfabrication: A new method to fabricate millimeter-wave waveguide components. Micromachines 2021, 12, 260. [Google Scholar] [CrossRef]

- Farjana, S.; Ghaderi, M.; Zaman, A.U.; Rahiminejad, S.; Lundgren, P.; Enoksson, P. Low-loss gap waveguide transmission line and transitions at 220–320 GHz using dry film micromachining. IEEE Trans. Compon. Packag. Manuf. Technol. 2021, 11, 2012–2021. [Google Scholar] [CrossRef]

- Farjana, S.; Alfonso, E.; Lundgren, P.; Vassilev, V.; Enoksson, P.; Zaman, A.U. Multilayer dry film photoresist fabrication of a robust> 100 GHZ gap waveguide slot array antenna. IEEE Access 2023, 11, 43630–43638. [Google Scholar] [CrossRef]

- Shen, Y.; Gallagher, M.; Immonen, M.; Johnson, R.; Joo, J.; Kondoh, M.; Neely, M.; Ryley, J.; Saraue, E.; Senk, D.; et al. Polymer waveguides for co-packaged optics. In Proceedings of the IEEE 74th Electronic Components and Technology Conference (ECTC), Denver, CO, USA, 28–31 May 2024; pp. 1683–1686. [Google Scholar]

- Chartier, I.; Sudor, J.; Fouillet, Y.; Sarrut, N.; Bory, C.; Gruss, A. Fabrication of a hybrid plastic-silicon microfluidic device for high-throughput genotyping. In Proceedings of the Microfluidics, BioMEMS, and Medical Microsystems, San Jose, CA, USA, 27–29 January 2003; pp. 208–219. [Google Scholar]

- Wang, Y.R.; Chen, H.W.; He, Q.H.; Soper, S.A. A high-performance polycarbonate electrophoresis microchip with integrated three-electrode system for end-channel amperometric detection. Electrophoresis 2008, 29, 1881–1888. [Google Scholar] [CrossRef] [PubMed]

- Dang, F.; Shinohara, S.; Tabata, O.; Yamaoka, Y.; Kurokawa, M.; Shinohara, Y.; Ishikawa, M.; Baba, Y. Replica multichannel polymer chips with a network of sacrificial channels sealed by adhesive printing method. Lab Chip 2005, 5, 472–478. [Google Scholar] [CrossRef] [PubMed]

- Hromada, L.P.; Nablo, B.J.; Kasianowicz, J.J.; Gaitan, M.A.; DeVoe, D.L. Single molecule measurements within individual mem-brane-bound ion channels using a polymer-based bilayer lipidmembrane chip. Lab Chip 2008, 8, 602–608. [Google Scholar] [CrossRef]

- Amanat, N.; James, N.J.; MsKenzie, D.R. Welding methods for joining thermo-plastic polymers for the hermetic enclosure of medical devices. Med. Eng. Phys. 2010, 32, 690–699. [Google Scholar] [CrossRef]

- Courbat, J.; Briand, D.; De Rooij, N.F. Reversed processing of dry photoresist: Application to the encapsulation of chemical sensors. Procedia Eng. 2010, 5, 335–338. [Google Scholar] [CrossRef][Green Version]

- Giacomozzi, F.; Mulloni, V.; Colpo, S.; Faes, A.; Sordo, G.; Girardi, S. RF-MEMS packaging by using quartz caps and epoxy polymers. Microsyst. Technol. 2015, 21, 1941–1948. [Google Scholar] [CrossRef]

- Baumgartner, T.; Hauck, K.; Töpper, M.; Manessis, D.; Ehrmann, O.; Lang, K.D.; Liebsch, W.; Ehlin, M.; Itabashi, T. Dry film photo resists and polymers-the low cost option for standard and 3-D wafer level packaging. In Proceedings of the 11th International Conference on Electronic Packaging Technology & High Density Packaging, Xi’an, China, 16–19 August 2010; pp. 50–54. [Google Scholar]

- Giacomozzi, F.; Mulloni, V.; Resta, G.; Margesin, B. MEMS packaging by using dry film resist. In Proceedings of the XVIII AISEM Annual Conference, Trento, Italy, 3–5 February 2015; pp. 1–4. [Google Scholar]

- Cai, J.; Zhou, Q.; Zhang, M.; Wu, S.Y.; Yu, D.; Liu, Q.H. Development of glass-based micro-patterned dry film bonding for mm-W device integration. IEEE Electron Device Lett. 2023, 44, 1873–1876. [Google Scholar] [CrossRef]

- Vulto, P.; Huesgen, T.; Albrecht, B.; Urban, G.A. A full-wafer fabrication process for glass microfluidic chips with integrated electroplated electrodes by direct bonding of dry film resist. J. Micromech. Microeng. 2009, 19, 077001. [Google Scholar] [CrossRef]

- Huesgen, T.; Lenk, G.; Albrecht, B.; Vulto, P.; Lemke, T.; Woias, P. Optimization and characterization of wafer-level adhesive bonding with patterned dry-film photoresist for 3D MEMS integration. Sens. Actuators A-Phys. 2010, 162, 137–144. [Google Scholar] [CrossRef]

- Blanco, F.J.; Agirregabiria, M.; Garcia, J.; Berganzo, J.; Tijero, M.; Arroyo, M.T.; Ruano, J.M.; Aramburu, I.; Mayora, K. Novel three-dimensional embedded SU-8 microchannels fabricated using a low temperature full wafer adhesive bonding. J. Micromech. Microeng. 2004, 14, 1047–1056. [Google Scholar] [CrossRef]

- El Fissi, L.; Vandormael, D.; Francis, L.A. Direct assembly of cyclic olefin copolymer microfluidic devices helped by dry photoresist. Sens. Actuators A-Phys. 2015, 223, 76–83. [Google Scholar] [CrossRef]

- Wu, H.; Huang, B.; Zare, R.N. Construction of microfluidic chips using polydimethylsiloxane for adhesive bonding. Lab Chip 2005, 5, 1393–1398. [Google Scholar] [CrossRef] [PubMed]

- Borók, A.; Laboda, K.; Bonyár, A. PDMS bonding technologies for microfluidic applications: A review. Biosensors 2021, 11, 292. [Google Scholar] [CrossRef]

- Jiang, B.; Guo, H.; Chen, D.; Zhou, M. Microscale investigation on the wettability and bonding mechanism of oxygen plasma-treated PDMS microfluidic chip. Appl. Surf. Sci. 2022, 574, 151704. [Google Scholar] [CrossRef]

- Shen, C.; Mokkapati, V.; Santagata, F.; Bossche, A.; Sarro, P. Low temperature encapsulation of nanochannels with water inside. In Proceedings of the 16th International Solid-State Sensors, Actuators and Microsystems Conference, Beijing, China, 5–9 June 2011; pp. 854–857. [Google Scholar]

- Sierros, K.A.; Morris, N.J.; Ramji, K.; Cairns, D.R. Stress–corrosion cracking of indium tin oxide coated polyethylene terephthalate for flexible optoelectronic devices. Thin Solid Films 2009, 517, 2590–2595. [Google Scholar] [CrossRef]

- Fang, Y.; Wu, Z.; Li, J.; Jiang, F.; Zhang, K.; Zhang, Y.; Zhou, Y.; Zhou, J.; Hu, B. High-performance hazy silver nanowire transparent electrodes through diameter tailoring for semitransparent photovoltaics. Adv. Funct. Mater. 2018, 28, 1705409. [Google Scholar] [CrossRef]

- Hu, L.; Kim, H.S.; Lee, J.Y.; Peumans, P.; Cui, Y. Scalable coating and properties of transparent, flexible, silver nanowire electrodes. ACS Nano 2010, 4, 2955–2963. [Google Scholar] [CrossRef]

- Lee, M.; Ko, Y.; Min, B.K.; Jun, Y. Silver nanowire top electrodes in flexible perovskite solar cells using titanium metal as substrate. ChemSusChem 2016, 9, 31–35. [Google Scholar] [CrossRef]

- Amicucci, C.; Ha, H.; Matteini, P.; Hwang, B. Facile fabrication of silver-nanowire-based chips using dry-film photoresist for wearable optical detection. Fash. Text. 2022, 9, 20. [Google Scholar] [CrossRef]

- Kim, S.; Kim, B.; Cho, S.M.; Lee, H.J.; Hwang, B. Etchant-free patterning of silver nanowire transparent electrode using dry-film photoresists for organic light-emitting diodes. Mater. Lett. 2017, 209, 433–436. [Google Scholar] [CrossRef]

- Kim, S.; Hwang, B. Ag nanowire electrode with patterned dry film photoresist insulator for flexible organic light-emitting diode with various designs. Mater. Des. 2018, 160, 572–577. [Google Scholar] [CrossRef]

- Kim, S.; Eom, T.Y.; Cho, M.; Song, K.Y.; An, C.H.; Lee, H.J.; Hwang, B. Simple transfer of Ag nanowires by dry film photoresist for paper-based flexible electronics. Mater. Lett. 2017, 199, 196–199. [Google Scholar] [CrossRef]

- Weltin, A.; Kieninger, J.; Enderle, B.; Gellner, A.K.; Fritsch, B.; Urban, G.A. Polymer-based, flexible glutamate and lactate microsensors for in vivo applications. Biosens. Bioelectron. 2014, 61, 192–199. [Google Scholar] [CrossRef]

- Ezoe, Y.; Mitsuishi, I.; Takagi, U.; Koshiishi, M.; Mitsuda, K.; Yamasaki, N.Y.; Ohashi, T.; Kato, F.; Sugiyama, S.; Riveros, R.E.; et al. Ultra light-weight and high-resolution X-ray mirrors using DRIE and X-ray LIGA techniques for space X-ray telescopes. Microsyst. Technol. 2010, 16, 1633–1641. [Google Scholar] [CrossRef]

- Son, S.J.; Cho, Y.S.; Choi, C.J. Advanced micromanufacturing for high-precision microbearing by nanopowder metallurgy and LIGA processing. Rev. Adv. Mater. Sci. 2011, 28, 190–195. [Google Scholar]

- Schröter, T.J.; Koch, F.; Meyer, P.; Baumann, M.; Münch, D.; Kunka, D.; Engelhardt, S.; Zuber, M.; Baumbach, T.; Mohr, J. Large area gratings by x-ray LIGA dynamic exposure for x-ray phase-contrast imaging. J. Micro/Nanolithography MEMS MOEMS 2017, 16, 013501. [Google Scholar] [CrossRef]

- Zhu, J.; Holmes, A.; Arnold, J.; Lawes, R.; Prewett, P. Laminated dry film resist for microengineering applications. Microelectron. Eng. 1996, 30, 365–368. [Google Scholar] [CrossRef]

- Lorenz, H.; Paratte, L.; Luthier, R.; de Rooij, N.F.; Renaud, P. Low-cost technology for multilayer electroplated parts using laminated dry film resist. Sens. Actuators A-Phys. 1996, 53, 364–368. [Google Scholar] [CrossRef]

- Wangler, N.; Beck, S.; Ahrens, G.; Voigt, A.; Grützner, G.; Müller, C.; Reinecke, H. Ultra thick epoxy-based dry-film resist for high aspect ratios. Microelectron. Eng. 2012, 97, 92–95. [Google Scholar] [CrossRef]

- Esch, M.B.; Kapur, S.; Irizarry, G.; Genova, V. Influence of master fabrication techniques on the characteristics of embossed microfluidic channels. Lab Chip 2003, 3, 121–127. [Google Scholar] [CrossRef] [PubMed]

- Martinez-Duarte, R.; Madou, M. SU-8 photolithography and its impact on microfluidics. In Microfluidics and Nanofluidics Handbook; CRC Press: Boca Raton, FL, USA, 2011; pp. 231–268. [Google Scholar]

- Scott, S.M.; Ali, Z. Fabrication methods for microfluidic devices: An overview. Micromachines 2021, 12, 319. [Google Scholar] [CrossRef] [PubMed]

- Stephan, K.; Pittet, P.; Renaud, L.; Kleimann, P.; Morin, P.; Ouaini, N.; Ferrigno, R. Fast prototyping using a dry film photoresist: Microfabrication of soft-lithography masters for microfluidic structures. J. Micromech. Microeng. 2007, 17, N69–N74. [Google Scholar] [CrossRef]

- Leech, P.; Wu, N.; Zhu, Y. Application of dry film resist in the fabrication of microfluidic chips for droplet generation. J. Micromech. Microeng. 2009, 19, 065019. [Google Scholar] [CrossRef]

- Leigh, S.Y.; Tattu, A.; Mitchell, J.S.; Entcheva, E. M: Microscope-based masklessmicropatterning with dry film photoresist. Biomed. Microdevices 2011, 13, 375–381. [Google Scholar] [CrossRef]

- Cho, H.; Hashimoto, T.; Wong, E.; Hori, Y.; Wood, L.B.; Zhao, L.; Haigis, K.M.; Hyman, B.T.; Irimia, D. Microfluidic chemotaxis platform for differentiating the roles of soluble and bound amyloid-β on microglial accumulation. Sci. Rep. 2013, 3, 1823. [Google Scholar] [CrossRef]

- Park, J.; Wetzel, I.; Marriott, I.; Dréau, D.; D’Avanzo, C.; Kim, D.Y.; Tanzi, R.E.; Cho, H. A 3D human triculture system modeling neurodegeneration and neuroinflammation in Alzheimer’s disease. Nat. Neurosci. 2018, 21, 941–951. [Google Scholar] [CrossRef]

- Choi, S.; Song, S.; Choi, C.; Park, J.K. Sheathless focusing of microbeads and blood cells based on hydrophoresis. Small 2008, 4, 634–641. [Google Scholar] [CrossRef]

- Koucherian, N.E.; Yan, S.; Hui, E.E. Fabrication of multilayer molds by dry film photoresist. Micromachines 2022, 13, 1583. [Google Scholar] [CrossRef]

- Ito, T.; Kaneko, S.; Suzuki, K. Fabrication of column chip made of PMMA for μFIA. Talanta 2011, 85, 707–712. [Google Scholar] [CrossRef]

- Nathanson, H.C.; Newell, W.E.; Wickstrom, R.A.; Davis, J.R. The resonant gate transistor. IEEE Trans. Electron Dev. 1967, 14, 117–133. [Google Scholar] [CrossRef]

- Toda, N.; Togasaki, K.; Yoshihara, K.; Kaguchi, Y.; Mochizuki, A.; Funai, K.; Iwashita, K. Development of a Novel Negative-Tone Dry Film Resist with PVA Layer for Wiring with 1.5/1.5 µm Line/Space. J. Photopolym. Sci. Technol. 2025, 38, 79–84. [Google Scholar] [CrossRef]

- Cho, S.H.; Lu, H.M.; Cauller, L.; Romero-Ortega, M.I.; Lee, J.B.; Hughes, G.A. Biocompatible SU-8-based microprobes for recording neural spike signals from regenerated peripheral nerve fibers. Sens. J. IEEE 2008, 8, 1830–1836. [Google Scholar] [CrossRef]

- Jeon, J.; Jang, M.; Ye, S.; Kim, T.; Kim, S.C.; Won, S.O.; Kim, S.K. Metastable rutile TiO2 growth on non-lattice-matched substrates via a sacrificial layer strategy. Small 2025, 21, 2502409. [Google Scholar] [CrossRef] [PubMed]

- Strohhöfer, C.; Klink, G.; Feil, M.; Drost, A.; Bollmann, D.; Hemmetzberger, D.; Bock, K. Roll-to-roll microfabrication of polymer microsystems. Meas. Control 2007, 40, 80–83. [Google Scholar] [CrossRef]

- Kamyshny, A.; Magdassi, S. Conductive nanomaterials for printed electronics. Small 2014, 10, 3515–3535. [Google Scholar] [CrossRef] [PubMed]

- Yang, M.; Zhao, Y.; Li, J.; Tang, W.; Pan, H.; Chen, J.; Sun, F. Accurate flexible printed circuit (FPC) position identification using haptic information in industrial robotic mobile phone assembly. IEEE Trans. Ind. Electron. 2024, 71, 16143–16152. [Google Scholar] [CrossRef]

- Yuan, W.; Wu, X.; Gu, W.; Lin, J.; Cui, Z. Printed stretchable circuit on soft elastic substrate for wearable application. J. Semicond. 2018, 39, 232–237. [Google Scholar] [CrossRef]

- Drost, A.; Klink, G.; Feil, M.; Bock, K. Studies of fine pitch patterning by reel-to-reel processes for flexible electronic systems. In Proceedings of the International Symposium on Advanced Packaging Materials: Processes, Properties and Interfaces, Irvine, CA, USA, 16–18 March 2005; pp. 130–135. [Google Scholar]

- Temiz, Y.; Guiducci, C.; Leblebici, Y. Post-CMOS processing and 3-D integration based on dry-film lithography. IEEE Trans. Compon. Packag. Manuf. Technol. 2013, 3, 1458–1466. [Google Scholar] [CrossRef]

- Palavesam, N.; Marin, S.; Hemmetzberger, D.; Landesberger, C.; Bock, K.; Kutter, C. Roll-to-roll processing of film substrates for hybrid integrated flexible electronics. Flex. Print. Electron. 2018, 3, 014002. [Google Scholar] [CrossRef]

- Zhou, Y.; Feng, B.; Chen, L.; Fan, F.; Ji, Z.; Duan, H. Wafer-recyclable, eco-friendly, and multiscale dry transfer printing by transferable photoresist for flexible epidermal electronics. ACS Appl. Mater. Interfaces 2024, 16, 13525–13533. [Google Scholar] [CrossRef] [PubMed]

- An, C.H.; Kim, S.; Lee, H.J.; Hwang, B. Facile patterning using dry film photo-resists for flexible electronics: Ag nanowire networks and carbon nanotube networks. J. Mater. Chem. C 2017, 5, 4804–4809. [Google Scholar] [CrossRef]

- Bhattacharya, S.; Chaudhary, K.; Ramkumar, J.; Srivastava, K.V. Selective etching of ITO-PET using a dry film photoresist for large area metamaterial fabrication. J. Mater. Chem. C 2024, 12, 19266–19273. [Google Scholar] [CrossRef]

- Coltro, W.K.T.; Piccin, E.; da Silva, J.A.F.; do Lago, C.L.; Carrilho, E. A toner-mediated lithographic technology for rapid prototyping of glass microchannels. Lab Chip 2007, 7, 931–934. [Google Scholar] [CrossRef]

- Qu, N.S.; Chen, X.L.; Li, H.; Zhu, D. Fabrication of PDMS microthrough-holes for electrochemical micromachining. Int. J. Adv. Manuf. Technol. 2014, 72, 487–494. [Google Scholar] [CrossRef]

- Chen, Q.; Li, G.; Jin, Q.H.; Zhao, J.L.; Ren, Q.S.; Xu, Y.S. A rapid and low-cost procedure for fabrication of glass microfluidic devices. J. Microelectromech. Syst. 2007, 16, 1193–1200. [Google Scholar] [CrossRef]

- Gorissen, B.; Van Hoof, C.; Reynaerts, D.; De Volder, M. SU8 etch mask for patterning PDMS and its application to flexible fluidic microactuators. Microsyst. Nanoeng. 2016, 2, 16045. [Google Scholar] [CrossRef]

- Zhang, L.; Wang, W.; Ju, X.J.; Xie, R.; Liu, Z.; Chu, L.Y. Fabrication of glass-based microfluidic devices with dry film photoresists as pattern transfer masks for wet etching. RSC Adv. 2015, 5, 5638–5646. [Google Scholar] [CrossRef]

- Zhang, H.; Ding, B.; Chen, T. A high efficiency industrial polysilicon solar cell with a honeycomb-like surface fabricated by wet etching using a photoresist mask. Appl. Surf. Sci. 2016, 387, 1265–1273. [Google Scholar] [CrossRef]

- Zhang, H.; Ding, B.; Xiang, Y.; Chen, T. A continuous, single-face wet texturing process for industrial multicrystalline silicon solar cells using a surfactant treated photoresist mask. Sol. Energ. Mat. Sol. C 2018, 180, 173–183. [Google Scholar] [CrossRef]

- Kikuchi, K.; Tsuchitani, S.; Miwa, M.; Asaka, K. Formation of patterned electrode in Ionic polymer-metal composite using dry film photoresist. IEEJ Trans. Electr. Electron. Eng. 2008, 3, 452–454. [Google Scholar] [CrossRef]

- Bhattacharyya, B.; Doloi, B.; Sridhar, P.S. Electrochemical micro-machining: New possibilities for micro-manufacturing. J. Mater. Process. Technol. 2001, 113, 301–305. [Google Scholar] [CrossRef]

- Munda, J.; Bhattacharyya, B. Investigation into electrochemical micromachining (EMM) through response surface methodology based approach. Int. J. Adv. Manuf. Technol. 2008, 35, 821–832. [Google Scholar] [CrossRef]

- Nouraei, S.; Roy, S. Electrochemical process for micropattern transfer without photolithography: A modeling analysis. J. Electrochem. Soc. 2008, 155, D97–D103. [Google Scholar] [CrossRef]

- Madore, C.; Piotrowski, O.; Landolt, D. Through-mask electrochemical micromachining of titanium. J. Electrochem. Soc. 2019, 146, 2526–2532. [Google Scholar] [CrossRef]

- Kumar, A.; Alok, A.; Das, M. Surface texturing by electrochemical micromachining: A review. Mater. Sci. Eng. Conf. Ser. 2020, 804, 012011. [Google Scholar] [CrossRef]

- Hao, X.; Wang, L.; Wang, Q.; Guo, F.; Tang, Y.; Ding, Y.; Lu, B. Surface micro-texturing of metallic cylindrical surface with proximity rolling-exposure lithography and electrochemical micromachining. Appl. Surf. Sci. 2011, 257, 8906–8911. [Google Scholar] [CrossRef]

- Qu, N.; Chen, X.; Li, H.; Zeng, Y. Electrochemical micromachining of micro-dimple arrays on cylindrical inner surfaces using a dry-film photoresist. Chin. J. Aeronaut. 2014, 27, 1030–1036. [Google Scholar] [CrossRef]

- Zhang, X.; Qu, N.; Chen, X. Sandwich-like electrochemical micromachining of micro-dimples. Surf. Coat. Technol. 2016, 302, 438–447. [Google Scholar] [CrossRef]

- Qu, N.; Zhang, X.; Chen, X.; Li, H.; Zhu, D. Modified microscale pattern transfer without photolithography of substrates. J. Mater. Process. Technol. 2015, 218, 71–79. [Google Scholar] [CrossRef]

| Features | Positive DFR | Negative DFR |

|---|---|---|

| Lithography pattern |  |  |

| Thermal stability | Easy to soften at high temperature, storage at 2~8 °C. | High thermal resistance, suitable for hot pressing, storage at 5~20 °C. |

| Adhesion | Common adhesion performance, suitable for smooth surfaces. | Good adhesion performance, also applicable for rough surfaces. |

| Exposure principle | Photodecomposition reaction. | Cross-linking reaction. |

| Developer solution | 0.1~0.4% (w/w) C4H13NO/KOH solution. | 1~2% (w/w) Na2CO3 solution/C6H12O3/C8H10 |

| Resolution | Achievable at the nanoscale | Typically >=10 μm, due to swelling deformation during development. |

| Corrosion resistance | Poor | Good |

| Cost | High | Low |

| Application fields | Ultrafine structure micromachining, such as logic chips and memory devices, etc. | Standard structure micromachining, such as packaging, MEMS devices, and PCB manufacturing, etc. |

| Materials | First Resonance (GHz) | Unloaded Quality (Q) | Loss (dB/m) | Ref. |

|---|---|---|---|---|

| Second Resonance (GHz) | ||||

| Si | 234 | 642 | 0.033 | [48] |

| 284 | 628 | 0.043 | ||

| SU-8 | 234 | 319 | 0.067 | [50] |

| 284 | 628 | 0.041 | ||

| CNT | 234 | 274 | 0.079 | [52] |

| 284 | 518 | 0.051 | ||

| DFR | 234.6 | 656 | 0.032 | [53] |

| 284 | 786 | 0.033 |

| Photoresist | SU-8 | DFR |

|---|---|---|

| Clean environment and with expensive equipment | Necessary | Unnecessary |

| Substrate flatness | Only suitable for coating on flat surfaces | Suitable for laminating on both curved and uneven surfaces |

| Lamination temperature | >=95 °C | 50~85 °C (the required temperature gradually decreases from the first layer) |

| Processing time | Coating and baking are necessary and these processes will take about 30 min | Coating and baking are not needed, and the lamination will take about 3~5 min |

| Uniformity of thickness | Non-uniform thickness | Uniform thickness |

| Pattern resolution | <=1 μm | >=10 μm |

| Aspect ratio | Up to 10 | <=7 (Free-standing structure) <=5 (Channel structure) |

| Large area processing | Not suitable due to significant edge effects | Suitable |

| Solvent waste | More than 95% of the photoresist solvent is wasted | No waste |

| Current Progress | Key Technological Challenges | Future Opportunities |

|---|---|---|

|

|

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, M.; Meng, F.; Li, X.; Zeng, W. Applications of Dry Film Photoresist in Micromachining: A Review. Micromachines 2025, 16, 1258. https://doi.org/10.3390/mi16111258

Zhang M, Meng F, Li X, Zeng W. Applications of Dry Film Photoresist in Micromachining: A Review. Micromachines. 2025; 16(11):1258. https://doi.org/10.3390/mi16111258

Chicago/Turabian StyleZhang, Min, Funa Meng, Xiaoping Li, and Wen Zeng. 2025. "Applications of Dry Film Photoresist in Micromachining: A Review" Micromachines 16, no. 11: 1258. https://doi.org/10.3390/mi16111258

APA StyleZhang, M., Meng, F., Li, X., & Zeng, W. (2025). Applications of Dry Film Photoresist in Micromachining: A Review. Micromachines, 16(11), 1258. https://doi.org/10.3390/mi16111258