SAW-Based Hydrogen Sensing: Mechanisms, Design Strategies, and Future Prospects

Abstract

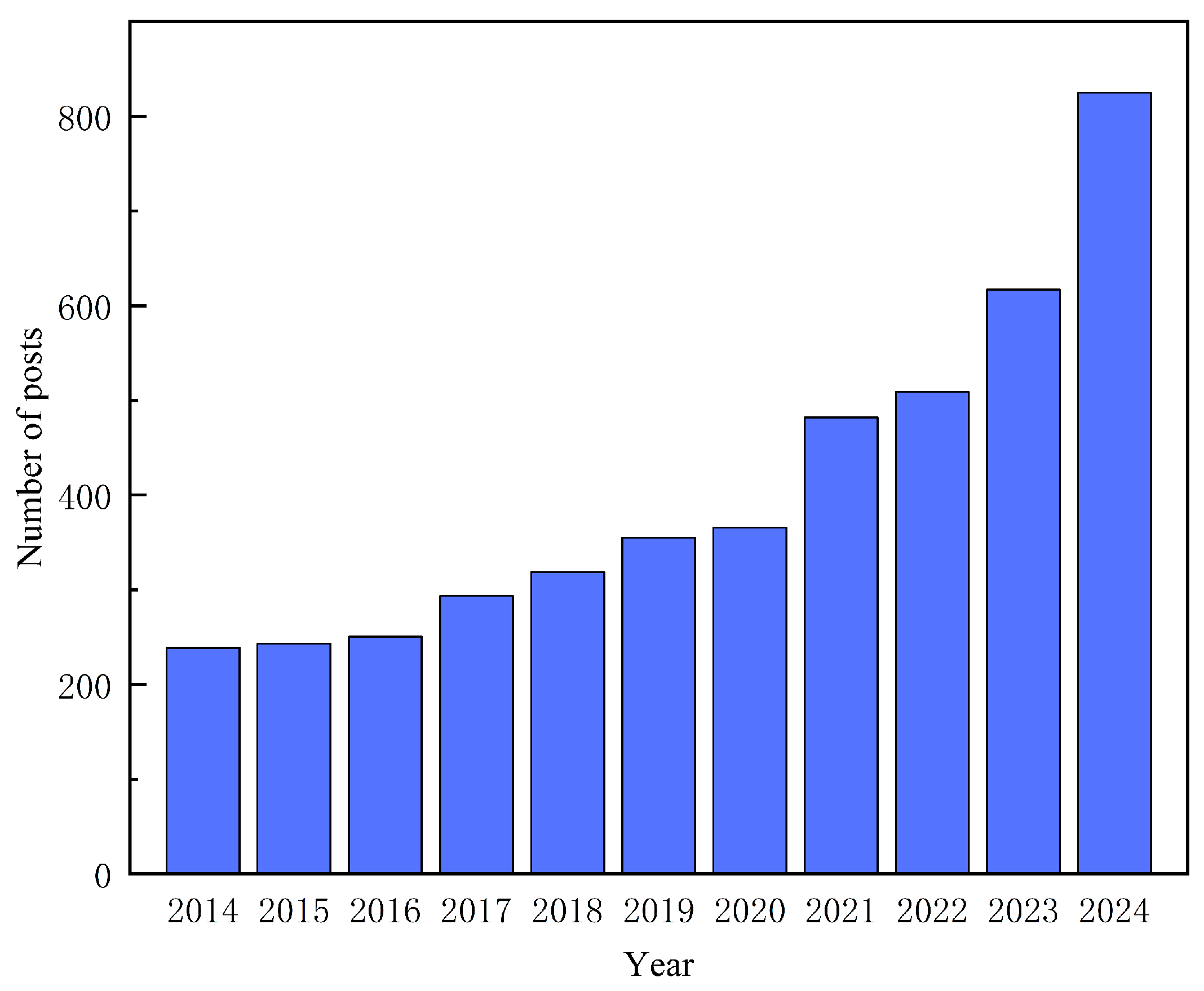

1. Introduction

2. Overview of Hydrogen-Sensing Technologies

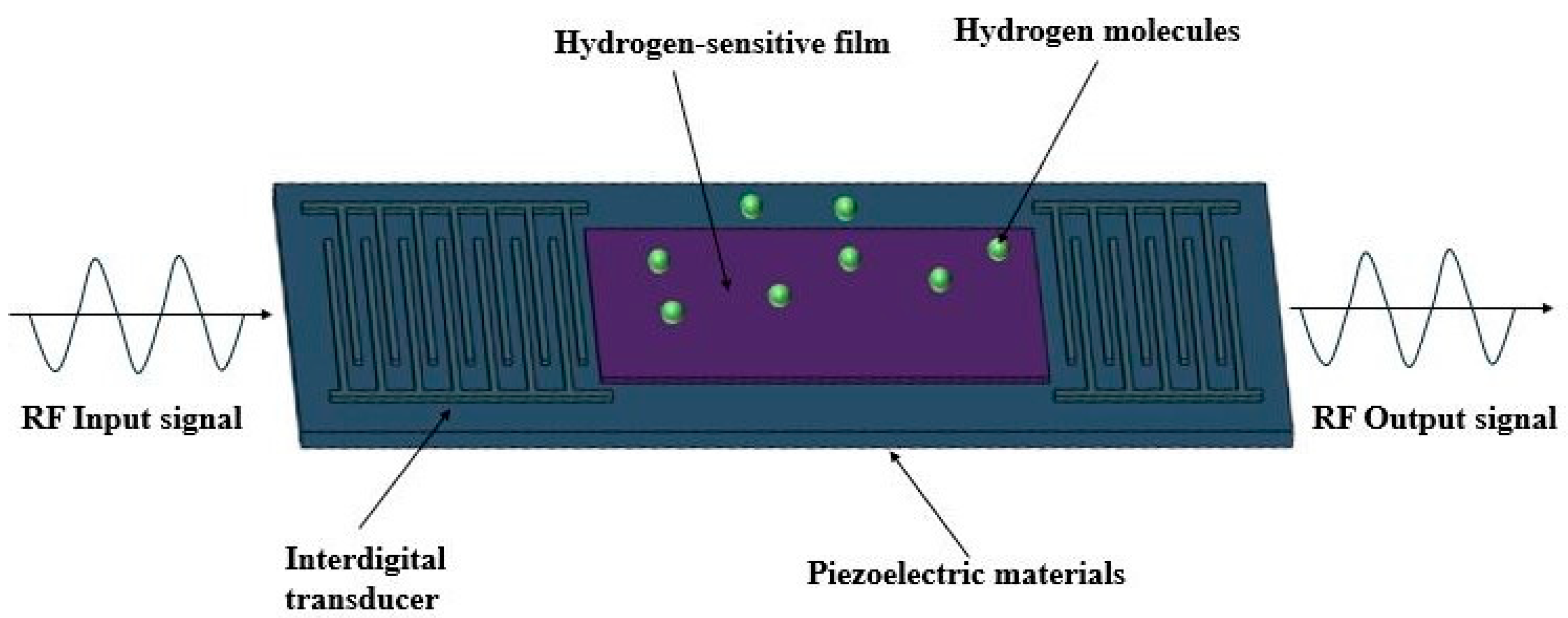

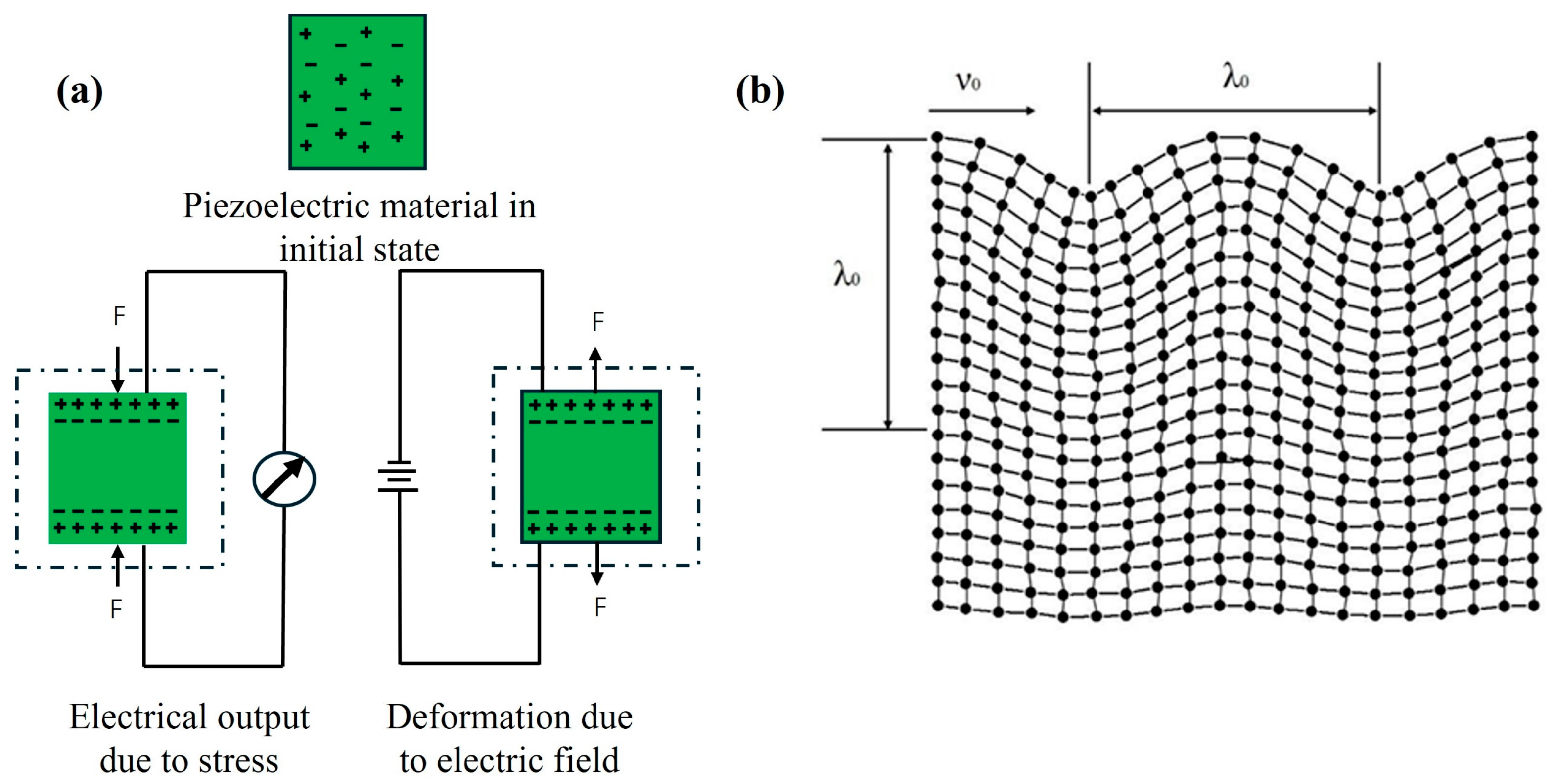

3. Response Mechanism of SAW Hydrogen Sensors

| Piezoelectric Materials | v0 (m/s) | K2 (%) | TCF (ppm/°C) | cm (cm2/g/MHz) | ce (cm2s/g) | CS (pF/cm) | Ref. |

|---|---|---|---|---|---|---|---|

| 64° Y-X LiNbO3 | 4742 | 11.3 | −70 | - | - | - | [45] |

| 128° Y-X LiNbO3 | 3997 | 5.6 | −75 | - | - | 5.0 | [45] |

| 36°Y-X LINbO3 | 4212 | 4.7 | −35 | - | - | - | [45] |

| Y-Z LiNbO3 | 3488 | 4.8 | −94 | 0.55 | 1.73 × 10−7 | 4.6 | [45,46,47] |

| Y-Z LiTaO3 | 3230 | 0.74 | - | - | - | - | [47] |

| ST quartz | 3158 | 0.14 | 0 | 1.28 | 3.86 × 10−7 | 0.55 | [45,46] |

| Y-X quartz | 3159.3 | 0.23 | 19 | 1.35 | 4.16 × 10−7 | 0.55 | [45,47] |

| AIN | 5800 | 1.5–1.7 | −19 to −25 | - | - | 2.12 | [48] |

| ZnO | 2720 | 3.2 | −40 to −60 | - | - | - | [48] |

| GaN | 4130 | 0.13 | - | - | - | - | [49] |

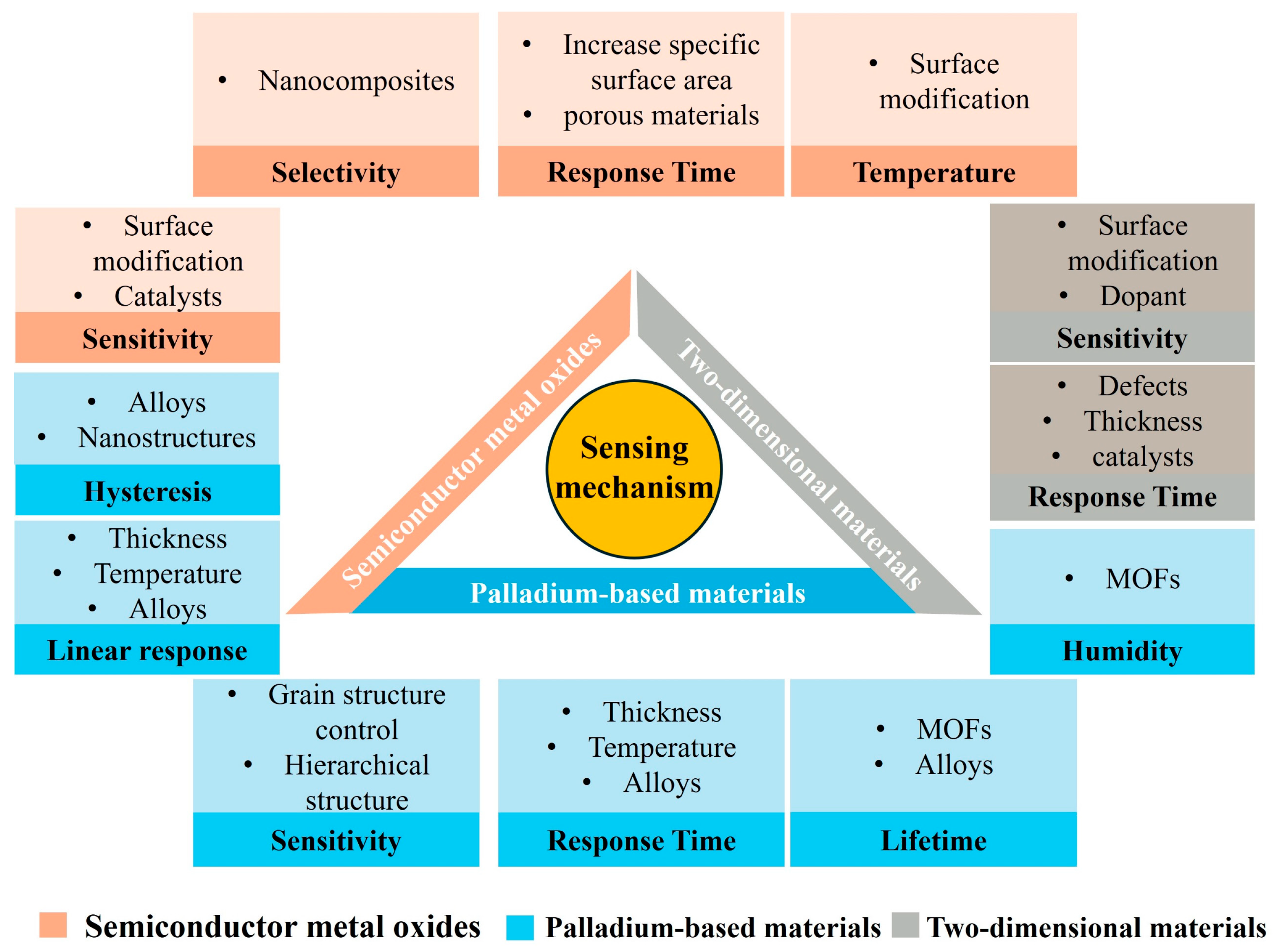

4. Design Strategy for SAW Hydrogen Sensors

4.1. Hydrogen-Sensitive Film

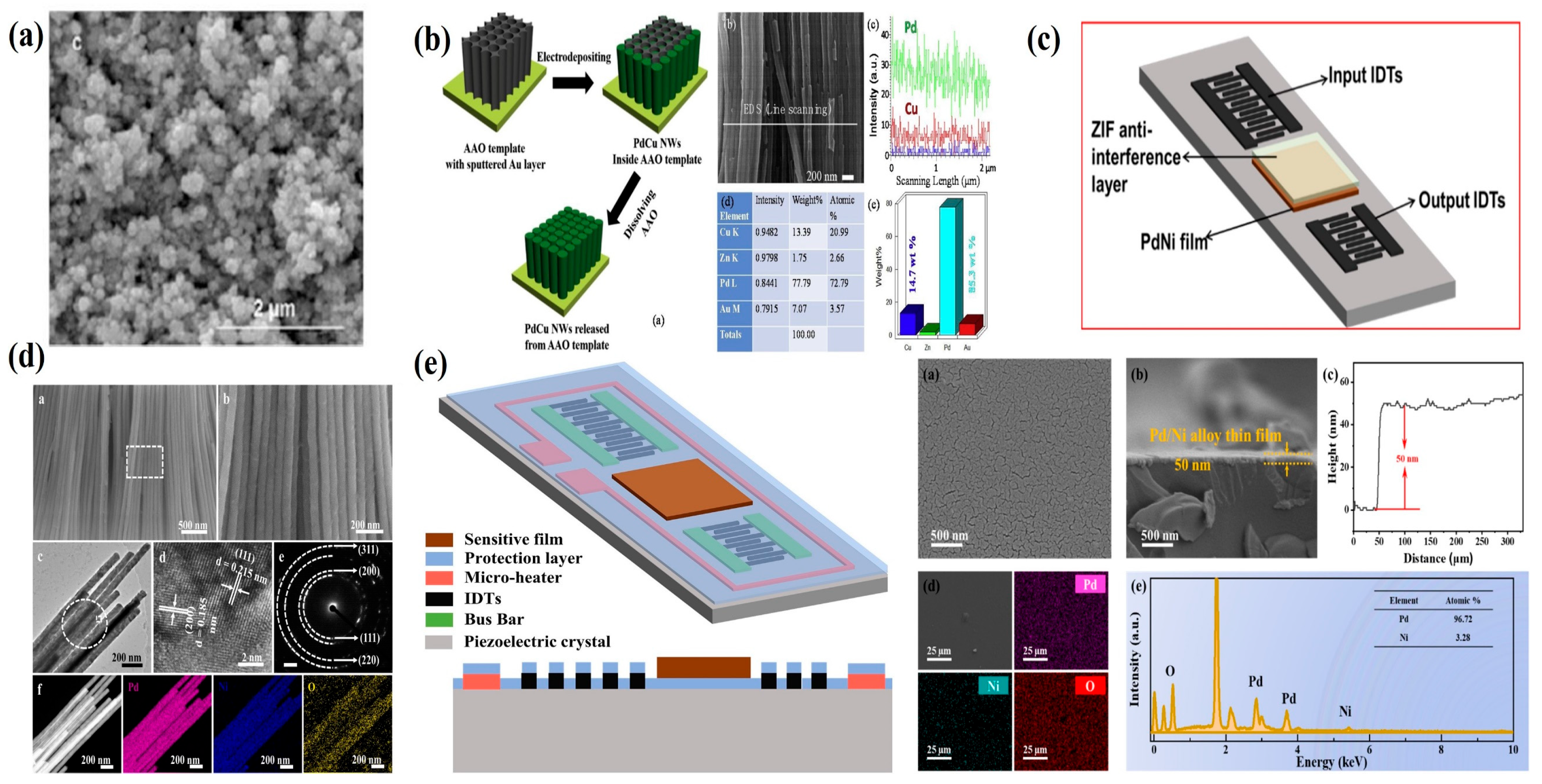

4.1.1. Palladium-Based Thin Film

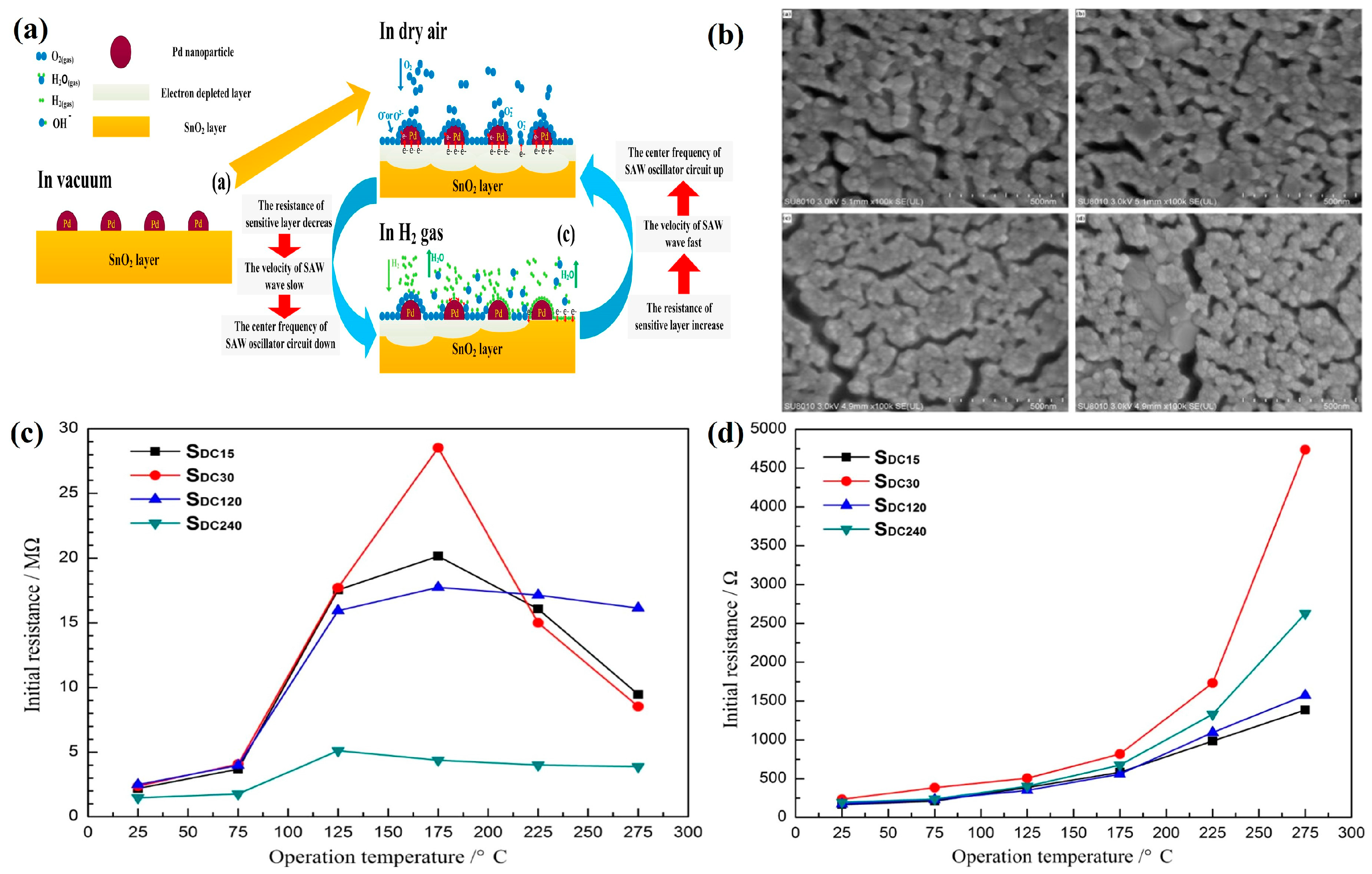

4.1.2. Semiconductor Metal Oxides

4.1.3. Other Hydrogen-Sensitive Materials

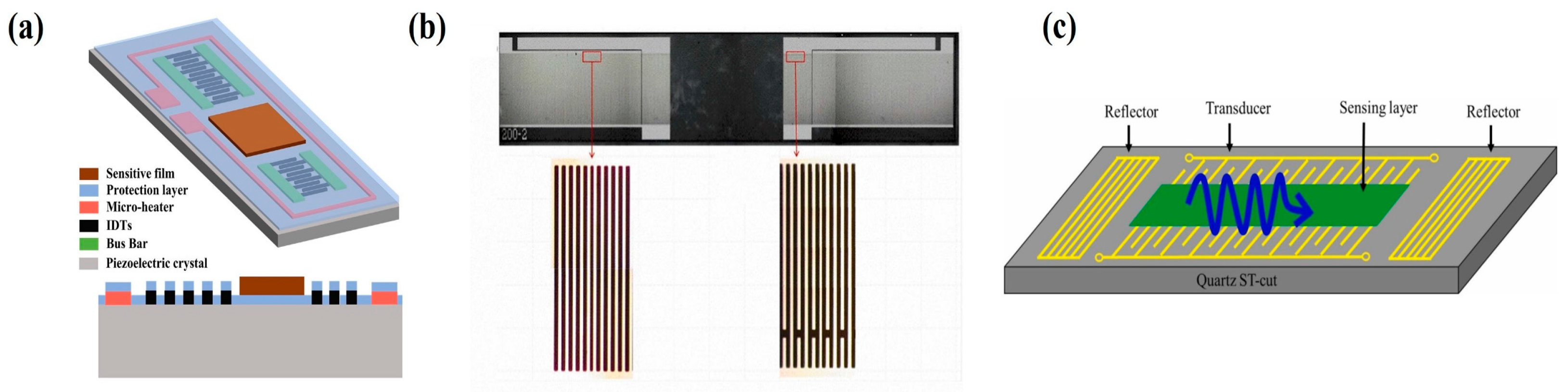

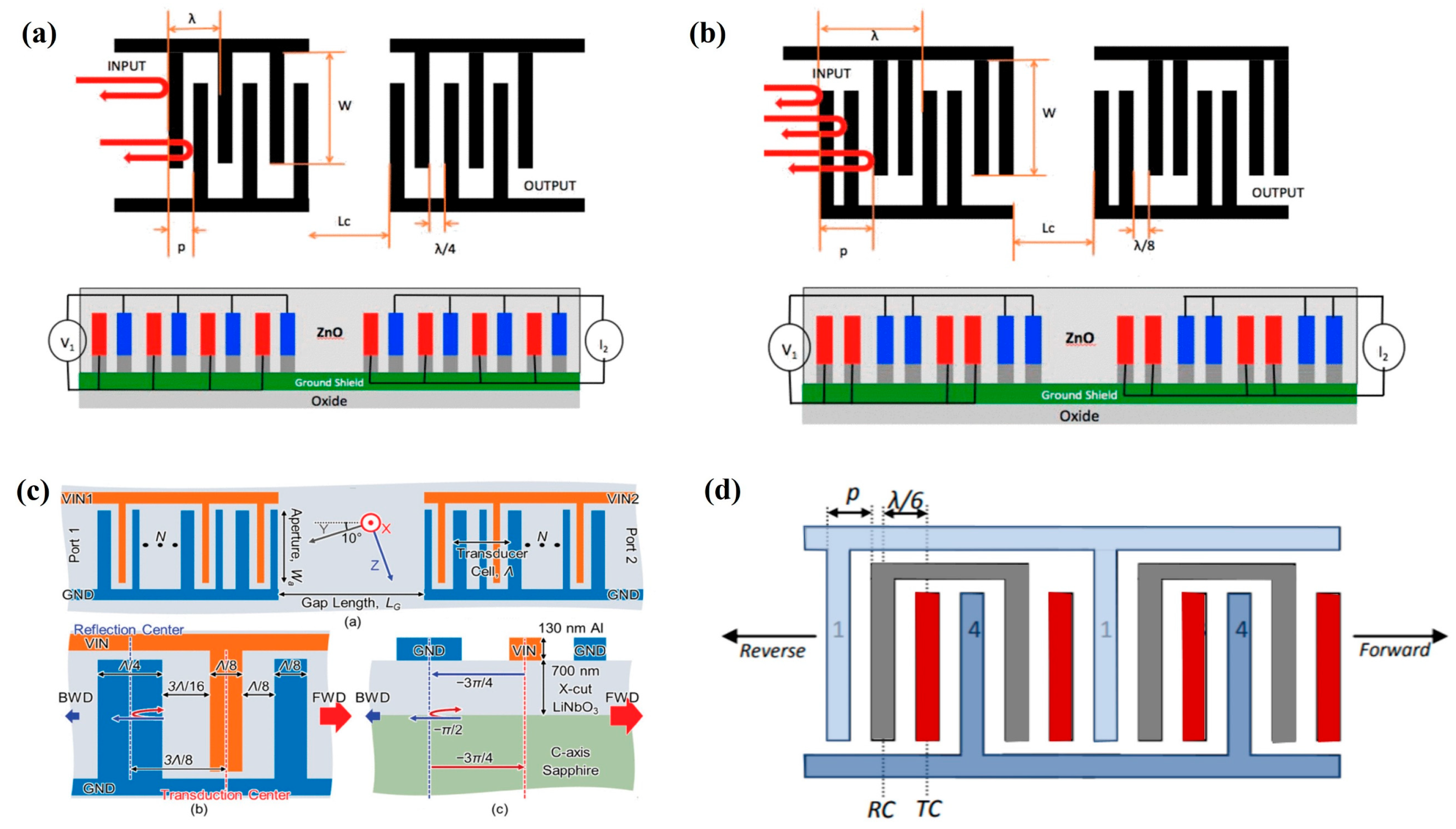

4.2. Design of Interdigital Transducer

4.2.1. Material Selection and Interdigital Transducer Structure

4.2.2. Configuration of Interdigital Transducer

5. Simulation and Modeling of SAW Device

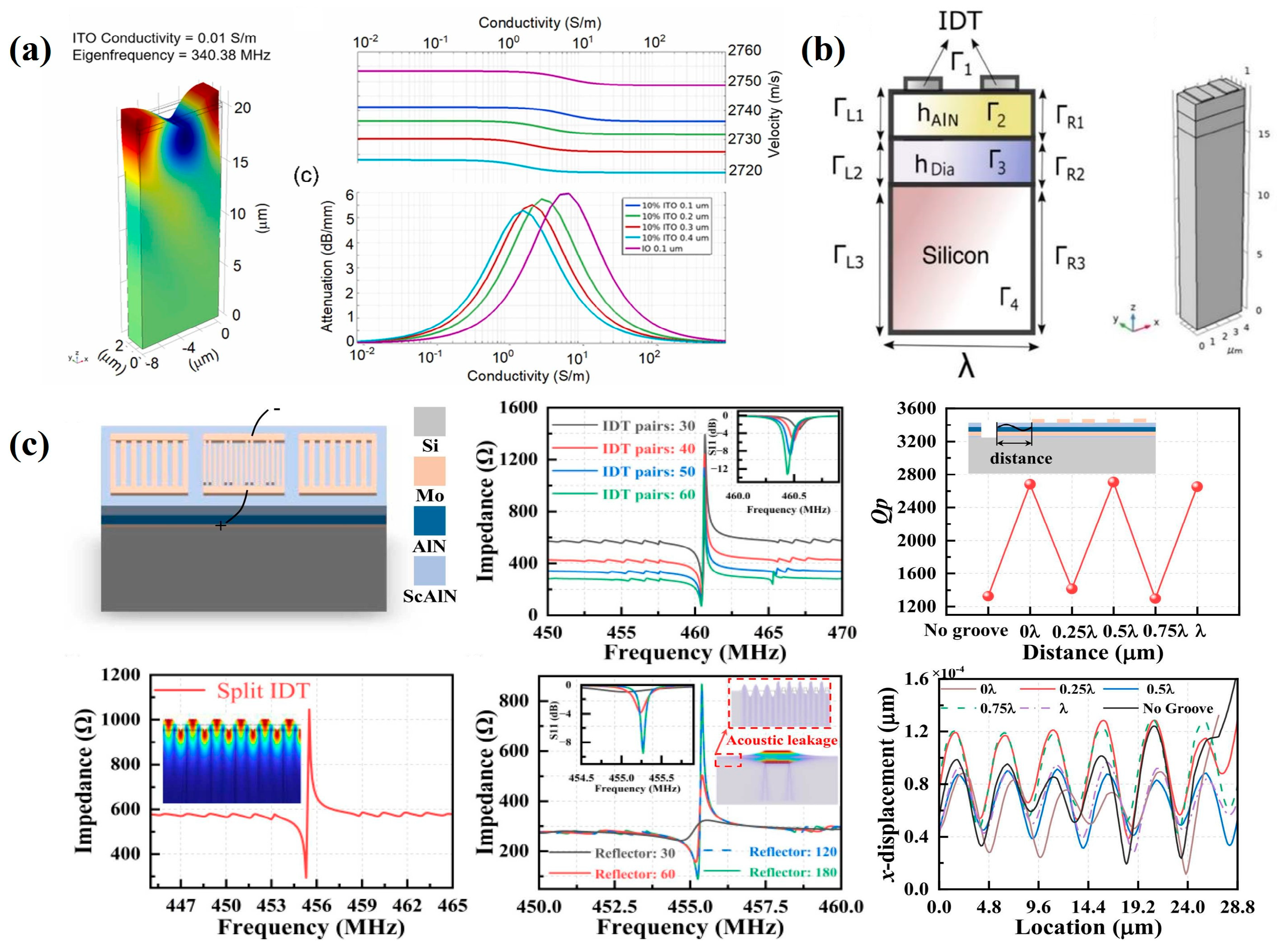

5.1. FEM Method

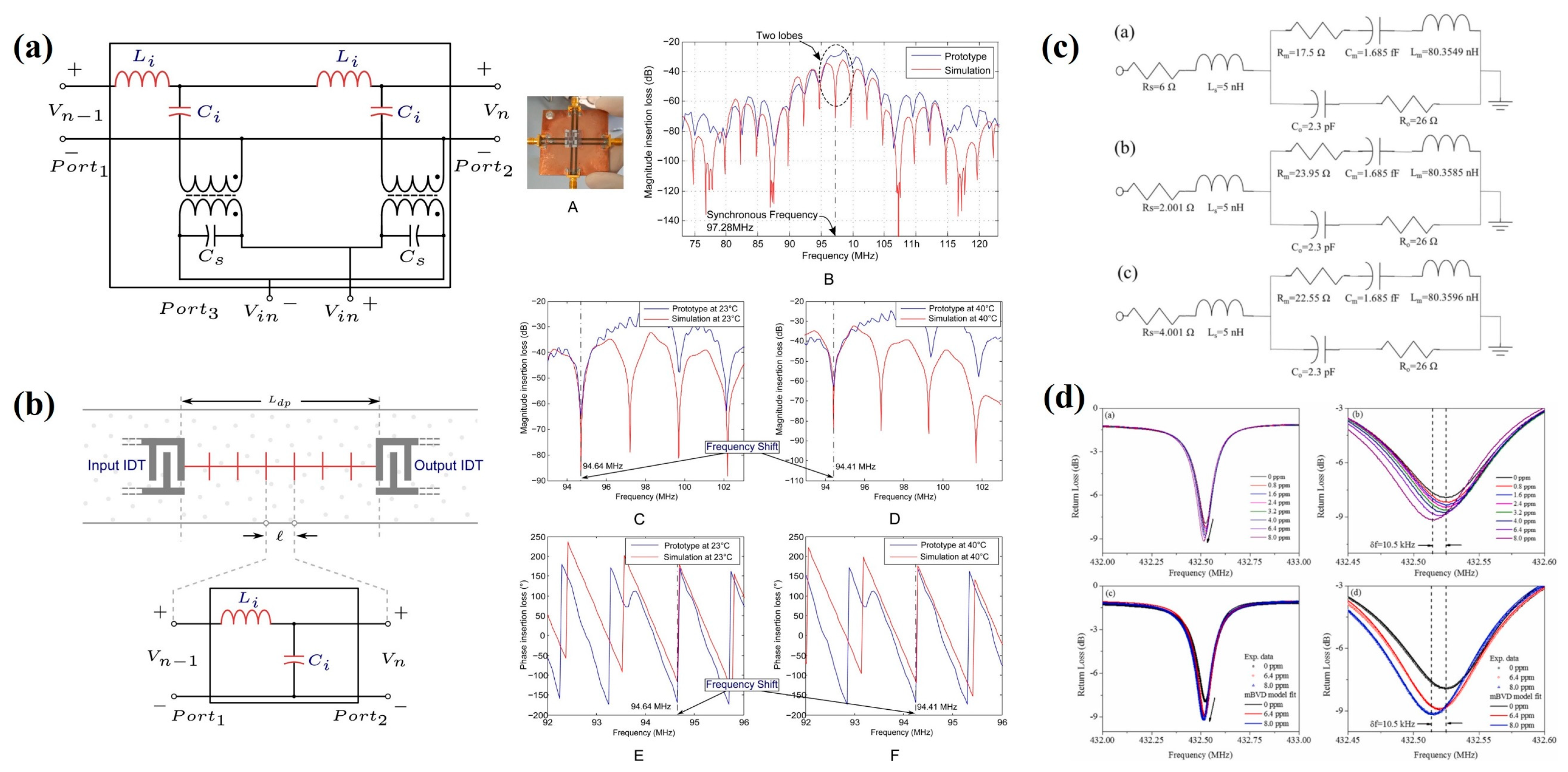

5.2. Equivalent Circuit Model

6. Fabrication Method of SAW Devices

7. Read Circuit

7.1. Differential Oscillation Circuit

7.2. Phase Detection Circuit

8. Challenges Faced by SAW Hydrogen Sensors

- (1)

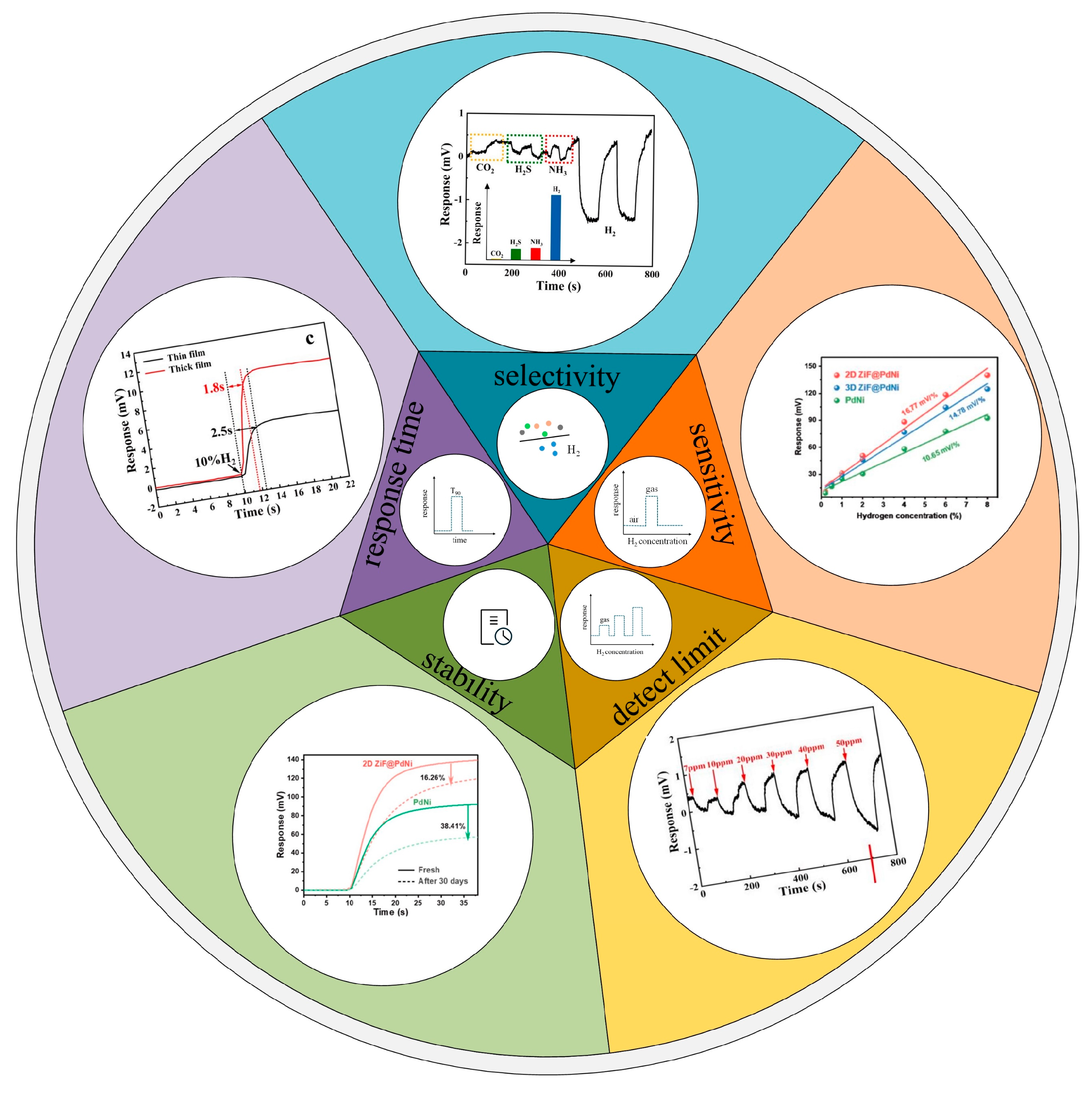

- Long-term stability and selectivity: While SAW sensors themselves exhibit excellent stability, the failure mechanisms of hydrogen-sensitive materials during operation require further investigation. Material degradation, oxidation, and poisoning are the primary factors leading to response deterioration. In addition, various types of cross-sensitivity remain unresolved. Recent studies have shown that the molecular sieving properties of MOF or polymer coatings offer an effective strategy to enhance the long-term stability of hydrogen-sensitive materials.

- (2)

- Response/recovery time: Material innovation plays a decisive role in significantly shortening the response and recovery times of SAW hydrogen sensors. The introduction of nanostructures, alloying strategies, and catalytic modifications can substantially increase the specific surface area and the number of active adsorption sites for hydrogen molecules, thereby accelerating reaction kinetics. Additionally, effective surface treatments and structural-level wavelength optimization have been shown to further improve response performance. Recent reports indicate that SAW hydrogen sensors can achieve response times of less than 2 s. However, this performance still falls short of the stringent requirements specified by international standards such as ISO for certain applications. Furthermore, as most hydrogen sensors are currently tested in nitrogen atmospheres, further studies are needed to develop high-performance sensors capable of reliable operation in ambient air.

- (3)

- Sensitivity: According to the response mechanism of SAW devices, the sensitivity of a sensor primarily depends on the structural parameters and thickness of the sensitive film, as well as the device’s operating frequency. However, current SAW hydrogen sensors still fall short of achieving ppb-level sensitivity, largely because their operating frequencies are limited to the MHz range. Although epitaxial waveguides have been reported to confine acoustic energy on the surface of the piezoelectric layer and thereby improve sensitivity, their practical application remains constrained by fabrication complexity and the coupling of multiple acoustic modes. Consequently, future research should focus on elucidating the influence of thin-film structures on the response mechanism of SAW devices and exploring the feasibility of GHz-level SAW architectures, with the goal of achieving breakthroughs in sensitivity and detection limits to ultimately approach ppb-level performance.

- (4)

- Interference resistance: To enhance the sensor’s performance in high-temperature and high-humidity environments, appropriate compensation measures are essential. Temperature compensation is mainly achieved through two methods: material selection—such as using ST-X quartz substrates with a near-zero TCF—and structural design, like differential detection. In humid conditions, competitive adsorption of water molecules can compromise baseline stability. Future research could focus on innovative packaging materials or real-time algorithmic compensation within the signal processing framework [126].

- (5)

- Limit of Detection (LOD): The LOD of a sensor is typically evaluated based on the system’s baseline noise and the sensor’s sensitivity. Achieving breakthroughs in LOD requires simultaneously reducing system noise and enhancing sensitivity, which depends not only on the design of high-performance SAW chips but also on their integration with low-noise readout circuits. Compared with conventional differential oscillator circuits, phase-detection circuits can circumvent the noise amplification caused by oscillator gain limitations, thereby enabling lower baseline noise and higher resolution. This approach provides a feasible pathway for SAW hydrogen sensors to achieve ppb-level detection limits.

9. Conclusions

Funding

Data Availability Statement

Conflicts of Interest

References

- Rasul, M.G.; Hazrat, M.A.; Sattar, M.A.; Jahirul, M.I.; Shearer, M.J. The future of hydrogen: Challenges on production, storage and applications. Energy Convers. Manag. 2022, 272, 116326. [Google Scholar] [CrossRef]

- Yue, M.; Lambert, H.; Pahon, E.; Roche, R.; Jemei, S.; Hissel, D. Hydrogen energy systems: A critical review of technologies, applications, trends and challenges. Renew. Sustain. Energy Rev. 2021, 146, 111180. [Google Scholar] [CrossRef]

- Zhang, L.; Ji, L.; Yao, Z.; Yan, N.; Sun, Z.; Yang, X.; Zhu, X.; Hu, S.; Chen, L. Facile synthesized Fe nanosheets as superior active catalyst for hydrogen storage in MgH2. Int. J. Hydrogen Energy 2019, 44, 21955–21964. [Google Scholar] [CrossRef]

- Jiang, N.; Zhang, M.; Brika, S.K.; Teymu, Z.A.; Feng, B. Green finance for sustainable hydrogen transport: Assessing economic feasibility of sustainable supply chains. Int. J. Hydrogen Energy 2025, 145, 815–831. [Google Scholar] [CrossRef]

- Rayleigh, L. On Waves Propagated along the Plane Surface of an Elastic Solid. Proc. Lond. Math. Soc. 1885, s1–s17, 4–11. [Google Scholar] [CrossRef]

- White, R.M.; Voltmer, F.W. Direct Piezoelectric Coupling To Surface Elastic Waves. Appl. Phys. Lett. 1965, 7, 314–316. [Google Scholar] [CrossRef]

- Su, R.; Fu, S.; Xu, H.; Lu, Z.; Liu, P.; Xiao, B.; Wang, R.; Zeng, F.; Song, C.; Wang, W.; et al. 5.9 GHz Longitudinal Leaky SAW Filter With FBW of 9.2% and IL of 1.8 dB Using LN/Quartz Structure. IEEE Microw. Wirel. Technol. Lett. 2023, 33, 1434–1437. [Google Scholar] [CrossRef]

- Wilson, W.C.; Malocha, D.C.; Kozlovski, N.; Gallagher, D.R.; Fisher, B.; Pavlina, J.; Saldanha, N.; Puccio, D.; Atkinson, G.M. Orthogonal Frequency Coded SAW Sensors for Aerospace SHM Applications. IEEE Sens. J. 2009, 9, 1546–1556. [Google Scholar] [CrossRef]

- Mandal, D.; Bovender, T.; Geil, R.D.; Sahoo, D.; Banerjee, S. Surface acoustic waves (SAW) sensor for the active detection of Microcystin-LR (Cyanobacteria). Sens. Bio-Sens. Res. 2025, 47, 100724. [Google Scholar] [CrossRef]

- ISO 26142:2010; Hydrogen Detection Apparatus—Stationary Applications. International Organization for Standardization: Geneva, Switzerland, 2010.

- Cho, W.; Kim, T.; Shin, H. Thermal conductivity detector (TCD)-type gas sensor based on a batch-fabricated 1D nanoheater for ultra-low power consumption. Sens. Actuators B Chem. 2022, 371, 132541. [Google Scholar] [CrossRef]

- Harumoto, T.; Shi, J.; Nakamura, Y.; Fujiki, H. Enhanced hydrogen gas detectability of sweep heating thin-wire thermal conductivity detector. Sens. Actuators A Phys. 2023, 358, 114446. [Google Scholar] [CrossRef]

- Berndt, D.; Muggli, J.; Wittwer, F.; Langer, C.; Heinrich, S.; Knittel, T.; Schreiner, R. MEMS-based thermal conductivity sensor for hydrogen gas detection in automotive applications. Sens. Actuators A Phys. 2020, 305, 111670. [Google Scholar] [CrossRef]

- Wang, J.; Dai, J.; Hu, W.; Zhang, F.; Yang, M. Improved performance of fiber-optic hydrogen sensor of porous Pt/WO3 based on ZIF-8. Int. J. Hydrogen Energy 2024, 51, 909–916. [Google Scholar] [CrossRef]

- Zhou, X.; Ma, F.; Ling, H.; Yu, B.; Peng, W.; Yu, Q. A compact hydrogen sensor based on the fiber-optic Fabry-Perot interferometer. Opt. Laser Technol. 2020, 124, 105995. [Google Scholar] [CrossRef]

- Verhoeff, D.J.; Schreuders, H.; Bannenberg, L.J. Tantalum-palladium alloy based optical micro-mirror hydrogen sensor. Sens. Actuators B Chem. 2025, 428, 137229. [Google Scholar] [CrossRef]

- Abdalwareth, A.; Flachenecker, G.; Angelmahr, M.; Schade, W. Optical fiber evanescent hydrogen sensor based on palladium nanoparticles coated Bragg gratings. Sens. Actuators A Phys. 2023, 361, 114594. [Google Scholar] [CrossRef]

- Zhi, Z.; Gao, W.; Yang, J.; Geng, C.; Yang, B.; Tian, C.; Fan, S.; Li, H.; Li, J.; Hua, Z. Amperometric hydrogen gas sensor based on Pt/C/Nafion electrode and ionic electrolyte. Sens. Actuators B Chem. 2022, 367, 132137. [Google Scholar] [CrossRef]

- Seleka, W.M.; Phasha, M.M.; Kganyakgo, L.K.; Makwakwa, D.; Makhado, E. Preparation of a conductive hydrogel based on carrageenan, polyvinyl alcohol, and polypyrrole as a potential room temperature electrochemical hydrogen gas sensor. Microchem. J. 2025, 214, 114091. [Google Scholar] [CrossRef]

- Wang, C.; Yang, J.; Li, J.; Luo, C.; Xu, X.; Qian, F. Solid-state electrochemical hydrogen sensors: A review. Int. J. Hydrogen Energy 2023, 48, 31377–31391. [Google Scholar] [CrossRef]

- Zheng, C.; Yi, G.; Gao, Y. An Electrochemical Sensor for Measuring Hydrogen Permeation Behavior in Atmospheric Environment. Int. J. Electrochem. Sci. 2012, 7, 9518–9525. [Google Scholar] [CrossRef]

- Jiao, Y.; Chen, W.; Zhang, Q.; Pei, Z.; Feng, L.; Cao, P. High sensitivity resistive hydrogen sensor using palladium–vanadium bilayer composite thin film structure. Int. J. Hydrogen Energy 2025, 136, 332–338. [Google Scholar] [CrossRef]

- Gong, J.; Wang, Z.; Tang, Y.; Sun, J.; Wei, X.; Zhang, Q.; Tian, G.; Wang, H. MEMS-based resistive hydrogen sensor with high performance using a palladium-gold alloy thin film. J. Alloys Compd. 2023, 930, 167398. [Google Scholar] [CrossRef]

- Lo, C.; Tan, S.-W.; Wei, C.-Y.; Tsai, J.-H.; Lour, W.-S. Sensing properties of resistive-type hydrogen sensors with a Pd–SiO2 thin-film mixture. Int. J. Hydrogen Energy 2013, 38, 313–318. [Google Scholar] [CrossRef]

- Guo, Y.; Yuan, Z.; Liang, J.; Shan, C.; He, M.; Zhang, D.; Duan, Z.; Wang, M.; Liu, A.; Jiang, Y.; et al. Mechanistic modeling and experimental demonstration of Pd-catalyzed dual-gate TeSeO FET hydrogen sensors. Sens. Actuators B Chem. 2026, 447, 138779. [Google Scholar] [CrossRef]

- Yan, G.; Xiao, S. A review on H2 sensors based on FET. Chin. J. Anal. Chem. 2024, 52, 100401. [Google Scholar] [CrossRef]

- Lim, C.; Wang, W.; Yang, S.; Lee, K. Development of SAW-based multi-gas sensor for simultaneous detection of CO2 and NO2. Sens. Actuators B Chem. 2011, 154, 9–16. [Google Scholar] [CrossRef]

- Aslam, M.Z.; Zhang, H.; Good, M.; Guo, Y.; Larche, M. A multimodal lithium niobate-based SAW gas sensor for accurate detection of carbon dioxide at elevated temperature. Ultrasonics 2024, 138, 107198. [Google Scholar] [CrossRef]

- Arsat, R.; Yu, X.F.; Li, Y.X.; Wlodarski, W.; Kalantar-zadeh, K. Hydrogen gas sensor based on highly ordered polyaniline nanofibers. Sens. Actuators B Chem. 2009, 137, 529–532. [Google Scholar] [CrossRef]

- Lee, K.; Wang, W.; Kim, T.; Yang, S. A novel 440 MHz wireless SAW microsensor integrated with pressure–temperature sensors and ID tag. J. Micromech. Microeng. 2007, 17, 515. [Google Scholar] [CrossRef]

- Singh, G.; Kim, S.; Lee, K. Development of a highly sensitive and portable particulate matter SAW sensor and interface electronics. Sens. Actuators A Phys. 2022, 343, 113641. [Google Scholar] [CrossRef]

- Wang, W.; Xue, X.; Fan, S.; Liu, M.; Liang, Y.; Lu, M. Development of a wireless and passive temperature-compensated SAW strain sensor. Sens. Actuators A Phys. 2020, 308, 112015. [Google Scholar] [CrossRef]

- Luo, W.; Fu, Q.; Deng, J.; Yan, G.; Zhou, D.; Gong, S.; Hu, Y. An integrated passive impedance-loaded SAW sensor. Sens. Actuators B Chem. 2013, 187, 215–220. [Google Scholar] [CrossRef]

- Zou, L.; McLeod, C.; Bahmanyar, M.R. Wireless Interrogation of Implantable SAW Sensors. IEEE Trans. Biomed. Eng. 2020, 67, 1409–1417. [Google Scholar] [CrossRef]

- Yang, Q.; Cui, B.; Jin, J.; Cheng, L.; Xue, X.; Yin, Y.; Wang, W. Review of Surface Acoustic Wave-Based Gas Sensors. Sens. Int. 2025, 7, 100348. [Google Scholar] [CrossRef]

- Wang, L.; Song, J.; Yu, C. Recent progress on mass-sensitive gas sensors for environmental and industrial applications. Measurement 2025, 249, 117039. [Google Scholar] [CrossRef]

- Raj, V.B.; Singh, H.; Nimal, A.T.; Sharma, M.U.; Gupta, V. Oxide thin films (ZnO, TeO2, SnO2, and TiO2) based surface acoustic wave (SAW) E-nose for the detection of chemical warfare agents. Sens. Actuators B Chem. 2013, 178, 636–647. [Google Scholar] [CrossRef]

- Jakubik, W.; Wrotniak, J.; Powroźnik, P. Theoretical analysis of a surface acoustic wave gas sensor mechanism using electrical conductive bi-layer nanostructures. Sens. Actuators B Chem. 2018, 262, 947–952. [Google Scholar] [CrossRef]

- Jakubik, W. Elemental theory of a SAW gas sensor based on electrical conductivity changes in bi-layer nanostructures. Sens. Actuators B Chem. 2014, 203, 511–516. [Google Scholar] [CrossRef]

- Jakubik, W.P. Hydrogen gas-sensing with bilayer structures of WO3 and Pd in SAW and electric systems. Thin Solid Film. 2009, 517, 6188–6191. [Google Scholar] [CrossRef]

- Kumar, R.; Mandal, N.; Mitra, D.; Sarkar, R. Design and Analysis of SAW Sensor Using Different Substrate for DCM Gas Detection. In Proceedings of the 2024 17th International Conference on Sensing Technology (ICST), Sydney, Australia, 9–11 December 2024; pp. 1–6. [Google Scholar]

- Wang, C.; Fan, L.; Zhang, S.y.; Li, Z.; Yang, Y.t. Investigations of Rayleigh wave hydrogen sensors. In Proceedings of the 2008 Symposium on Piezoelectricity, Acoustic Waves, and Device Applications, Nanjing, China, 5–8 December 2008; pp. 504–508. [Google Scholar]

- Wang, S.-H.; Shen, C.-Y.; Huang, H.-M.; Shih, Y.-C. Rayleigh surface acoustic wave sensor for ppb-level nitric oxide gas sensing. Sens. Actuators A Phys. 2014, 216, 237–242. [Google Scholar] [CrossRef]

- Jiang, J. Design and Investigation of a High-Performance Quartz-Based SAW Temperature Sensor. Micromachines 2024, 15, 1349. [Google Scholar] [CrossRef]

- Ou, H.-C. Design of Low-Loss One-Pole Synchronous Lithium Niobate Surface Acoustic Wave Resonators for Sensing Applications. Ph.D. Thesis, The George Washington University, Washington, DC, USA, 2010. [Google Scholar]

- Ricco, A.J.; Martin, S.J. Thin metal film characterization and chemical sensors: Monitoring electronic conductivity, mass loading and mechanical properties with surface acoustic wave devices. Thin Solid Film. 1991, 206, 94–101. [Google Scholar] [CrossRef]

- Cui, B.; Ren, Z.; Wang, W.; Cheng, L.; Gao, X.; Huang, L.; Hu, A.; Hu, F.; Jin, J. Review of surface acoustic wave-based hydrogen sensor. Sens. Actuators Rep. 2024, 7, 100197. [Google Scholar] [CrossRef]

- Aslam, M.Z.; Zhang, H.; Sreejith, V.S.; Naghdi, M.; Ju, S. Advances in the surface acoustic wave sensors for industrial applications: Potentials, challenges, and future directions: A review. Measurement 2023, 222, 113657. [Google Scholar] [CrossRef]

- Mandal, D.; Banerjee, S. Surface Acoustic Wave (SAW) Sensors: Physics, Materials, and Applications. Sensors 2022, 22, 820. [Google Scholar] [CrossRef] [PubMed]

- Phan, D.-T.; Chung, G.-S. Surface acoustic wave hydrogen sensors based on ZnO nanoparticles incorporated with a Pt catalyst. Sens. Actuators B Chem. 2012, 161, 341–348. [Google Scholar] [CrossRef]

- Rýger, I.; Vanko, G.; Lalinský, T.; Haščík, Š.; Benčúrová, A.; Nemec, P.; Andok, R.; Tomáška, M. GaN/SiC based surface acoustic wave structures for hydrogen sensors with enhanced sensitivity. Sens. Actuators A Phys. 2015, 227, 55–62. [Google Scholar] [CrossRef]

- Sun, C.; Mikhaylov, R.; Yang, X.; Zhang, X.; Feng, K.; Zheng, T.; Fu, Y.-Q.; Yang, X. Enhanced integrated acoustofluidics with printed circuit board electrodes attached to piezoelectric film coated substrate. Ultrasonics 2025, 147, 107531. [Google Scholar] [CrossRef]

- Zu, H.; Liu, M.; Li, Z.; Li, T.; San, H. Optimal preparation of AlN thin films on sapphire substrate and its effective validation in SAW resonators. Vacuum 2025, 237, 114182. [Google Scholar] [CrossRef]

- Qu, Y.; Chen, X.; Liu, Y.; Wang, S.; Gu, X.; Wei, M.; Huang, X.; Liu, Z.; Ding, J.; Wen, Z.; et al. Novel AlN/ScAlN composite film SAW for achieving highly sensitive temperature sensors. Sens. Actuators A Phys. 2025, 381, 116079. [Google Scholar] [CrossRef]

- Aslam, M.Z.; Jeoti, V.; Karuppanan, S.; Pandian, M.S.; Ferrer, E.M.; Suresh, K. Surface acoustic wave modes characteristics of CMOS compatible SiO2/AlN/SiO2/Si multilayer structure with embedded electrodes. Sens. Actuators A Phys. 2020, 313, 112202. [Google Scholar] [CrossRef]

- Bartoli, F.; Moutaouekkil, M.; Streque, J.; Pigeat, P.; Hage-Ali, S.; Boulet, P.; Jahed, H.M.; Elmazria, O.; Zhgoon, S.; Bartoli, F.; et al. Theoretical and experimental study of ScAlN/Sapphire structure based SAW sensor. In Proceedings of the 2017 IEEE SENSORS, Glasgow, UK, 29 October–1 November 2017; pp. 1–3. [Google Scholar]

- Maouhoub, S.; Aoura, Y.; Mir, A. FEM simulation of Rayleigh waves for SAW devices based on ZnO/AlN/Si. Microelectron. Eng. 2015, 136, 22–25. [Google Scholar] [CrossRef]

- Viespe, C.; Grigoriu, C. SAW sensor based on highly sensitive nanoporous palladium thin film for hydrogen detection. Microelectron. Eng. 2013, 108, 218–221. [Google Scholar] [CrossRef]

- Jakubik, W.; Urbańczyk, M.; Maciak, E.; Krzywiecki, M. Bi-layer nanostructures of CuPc and Pd in SAW and resistance hydrogen sensor. Procedia Eng. 2011, 25, 252–255. [Google Scholar] [CrossRef][Green Version]

- Cui, B.; Jin, J.; Cheng, L.; Xue, X.; Liang, Y.; Wang, W. Enhanced response speed of SAW based hydrogen sensor employing a micro-heater. Int. J. Hydrogen Energy 2023, 48, 17339–17348. [Google Scholar] [CrossRef]

- Wang, X.; Du, L.; Cheng, L.; Zhai, S.; Zhang, C.; Wang, W.; Liang, Y.; Yang, D.; Chen, Q.; Lei, G. Pd/Ni nanowire film coated SAW hydrogen sensor with fast response. Sens. Actuators B Chem. 2022, 351, 130952. [Google Scholar] [CrossRef]

- Wang, W.; Liu, X.; Mei, S.; Jia, Y.; Liu, M.; Xue, X.; Yang, D. Development of a Pd/Cu nanowires coated SAW hydrogen gas sensor with fast response and recovery. Sens. Actuators B Chem. 2019, 287, 157–164. [Google Scholar] [CrossRef]

- Wang, X.; Du, L.; Cheng, L.; Zhai, S.; Zhang, C.; Wang, W.; Liang, Y.; Yang, D.; Chen, Q.; Lei, G. SAW sensor employing Pd/Ni nanowire for super-fast hydrogen detection at room temperature. Results Chem. 2022, 4, 100327. [Google Scholar] [CrossRef]

- Yang, L.; Yin, C.; Zhang, Z.; Zhou, J.; Xu, H. The investigation of hydrogen gas sensing properties of SAW gas sensor based on palladium surface modified SnO2 thin film. Mater. Sci. Semicond. Process. 2017, 60, 16–28. [Google Scholar] [CrossRef]

- Rýger, I.; Vanko, G.; Lalinský, T.; Haščík, Š.; Nemec, P.; Benčúrová, A.; Tomáška, M. The GaN/SiC Heterostructure-based Hydrogen SAW Sensor Operating in GHz Range. Procedia Eng. 2014, 87, 260–263. [Google Scholar] [CrossRef][Green Version]

- Wang, C.; Wang, Y.; Zhang, S.-y.; Fan, L.; Shui, X.-J. Characteristics of SAW hydrogen sensors based on InOx/128°YX-LiNbO3 structures at room temperature. Sens. Actuators B Chem. 2012, 173, 710–715. [Google Scholar] [CrossRef]

- Sadek, A.Z.; Wlodarski, W.; Shin, K.; Kaner, R.B.; Kalantar-zadeh, K. A polyaniline/WO3 nanofiber composite-based ZnO/64° YX LiNbO3 SAW hydrogen gas sensor. Synth. Met. 2008, 158, 29–32. [Google Scholar] [CrossRef]

- Jin, J.; Cui, B.; Cheng, L.; Xue, X.; Hu, A.; Liang, Y.; Wang, W. Dimensionality regulation of ZIF anti-interference layer for high-selectivity and fast-response hydrogen sensing. Int. J. Hydrogen Energy 2024, 50, 903–911. [Google Scholar] [CrossRef]

- Vanotti, M.; Blondeau-Patissier, V.; Moutarlier, V.; Ballandras, S. Analysis of palladium and yttrium–palladium alloy layers used for hydrogen detection with SAW device. Sens. Actuators B Chem. 2015, 217, 30–35. [Google Scholar] [CrossRef]

- Devkota, J.; Mao, E.; Greve, D.W.; Ohodnicki, P.R.; Baltrus, J. A surface acoustic wave hydrogen sensor with tin doped indium oxide layers for intermediate temperatures. Sens. Actuators B Chem. 2022, 354, 131229. [Google Scholar] [CrossRef]

- Marcu, A.; Viespe, C. Laser-grown ZnO nanowires for room-temperature SAW-sensor applications. Sens. Actuators B Chem. 2015, 208, 1–6. [Google Scholar] [CrossRef]

- Vizireanu, S.; Constantinoiu, I.; Satulu, V.; Stoica, S.D.; Viespe, C. High-Sensitivity H2 and CH4 SAW Sensors with Carbon Nanowalls and Improvement in Their Performance after Plasma Treatment. Chemosensors 2023, 11, 566. [Google Scholar] [CrossRef]

- Viespe, C.; Miu, D. Surface Acoustic Wave Sensor with Pd/ZnO Bilayer Structure for Room Temperature Hydrogen Detection. Sensors 2017, 17, 1529. [Google Scholar] [CrossRef]

- Ha, N.H.; Nam, N.H.; Dung, D.D.; Phuong, N.H.; Thach, P.D.; Hong, H.S. Hydrogen Gas Sensing Using Palladium-Graphene Nanocomposite Material Based on Surface Acoustic Wave. J. Nanomater. 2017, 2017, 9057250. [Google Scholar] [CrossRef]

- Kowalska, E.; Czerwosz, E.; Diduszko, R.; Kaminska, A.; Danila, M. Influence of PdHx formation ability on hydrogen sensing properties of palladium-carbonaceous films. Sens. Actuators A Phys. 2013, 203, 434–440. [Google Scholar] [CrossRef]

- Kerroum, I.; Fall, M.E.; Reinhardt, A.; Domingue, F. Hydrogen effect on density and Young‘s modulus of thin films in acoustic sensors. Sens. Actuators B Chem. 2016, 223, 520–526. [Google Scholar] [CrossRef]

- Cui, B.; Jin, J.; Hu, A.; Ren, Z.; Liang, Y.; Wang, W.; Cheng, L. Multiphysics coupled sensing mechanism of Pd/Ni alloy thin-film coated SAW hydrogen sensor. Smart Mater. Struct. 2024, 33, 055009. [Google Scholar] [CrossRef]

- Lim, Y.; Lee, Y.; Heo, J.-I.; Shin, H. Highly sensitive hydrogen gas sensor based on a suspended palladium/carbon nanowire fabricated via batch microfabrication processes. Sens. Actuators B Chem. 2015, 210, 218–224. [Google Scholar] [CrossRef]

- Bi, S.; Tan, D.; Fang, C.; Peng, Y.; Zeng, L.; Wang, Y.; Sun, N.; Zhang, Z.; Sun, H.; Jiang, C.; et al. High-performance palladium nanotube network as fast, high-resolution, and wide range hydrogen detector in atmosphere. Sens. Actuators B Chem. 2024, 404, 135307. [Google Scholar] [CrossRef]

- Gupta, D.; Dutta, D.; Kumar, M.; Barman, P.B.; Sarkar, C.K.; Basu, S.; Hazra, S.K. A low temperature hydrogen sensor based on palladium nanoparticles. Sens. Actuators B Chem. 2014, 196, 215–222. [Google Scholar] [CrossRef]

- Sil, D.; Hines, J.; Udeoyo, U.; Borguet, E. Palladium Nanoparticle-Based Surface Acoustic Wave Hydrogen Sensor. ACS Appl. Mater. Interfaces 2015, 7, 5709–5714. [Google Scholar] [CrossRef] [PubMed]

- Deepti; Kumar, H.; Tripathi, A.; Dey, A.B.; Gupta, M.; Krishna, R.; Avasthi, D.K. Improved hydrogen sensing behaviour in ion-irradiated Pd-Au alloy thin films. Sens. Actuators B Chem. 2019, 301, 127006. [Google Scholar] [CrossRef]

- Liu, G.; Peng, L.; Yan, D.; Shu, L.; Fan, L.; Wu, W.; Wang, X. Highly durable PdNi alloy gradient film hydrogen sensor. Int. J. Hydrogen Energy 2025, 116, 497–506. [Google Scholar] [CrossRef]

- Eadi, S.B.; Oh, J.S.; Kim, C.; Sim, G.; Kim, K.; Kim, H.Y.; Kim, J.J.; Do, H.R.; Chu, S.-I.; Jung, S.H.; et al. Improved hydrogen gas sensing performance of Pd–Ni alloy thin films. Int. J. Hydrogen Energy 2023, 48, 12534–12539. [Google Scholar] [CrossRef]

- Lee, E.; Lee, J.M.; Lee, E.; Noh, J.-S.; Joe, J.H.; Jung, B.; Lee, W. Hydrogen gas sensing performance of Pd–Ni alloy thin films. Thin Solid Film. 2010, 519, 880–884. [Google Scholar] [CrossRef]

- Jin, J.; Cui, B.; Zhou, L.; Cheng, L.; Xue, X.; Hu, A.; Liang, Y.; Wang, W. Influence of the Pd Oxidation State in PdNi Thin Films on Surface Acoustic Wave Hydrogen Sensing Performance. ACS Sens. 2024, 9, 2395–2401. [Google Scholar] [CrossRef]

- Li, Y.; Xiao, A.-S.; Zou, B.; Zhang, H.-X.; Yan, K.-L.; Lin, Y. Advances of metal–organic frameworks for gas sensing. Polyhedron 2018, 154, 83–97. [Google Scholar] [CrossRef]

- Liu, Q.; Yao, J.; Wang, Y.; Sun, Y.; Ding, G. Temperature dependent response/recovery characteristics of Pd/Ni thin film based hydrogen sensor. Sens. Actuators B Chem. 2019, 290, 544–550. [Google Scholar] [CrossRef]

- Jiao, Y.; Chen, W.; Zhang, Q.; Pei, Z.; Feng, L.; Cao, P. Grain structure regulation: A novel approach to enhance the sensitivity and baseline stability of palladium thin film resistive hydrogen sensors. Int. J. Hydrogen Energy 2025, 143, 276–285. [Google Scholar] [CrossRef]

- Cui, B.; Jin, J.; Ren, Z.; Hu, A.; Liang, Y.; Wang, W.; Cheng, L. Performance enhancement of SAW based hydrogen sensor employing Pd/Ni alloy thin film. In Proceedings of the 2023 International Congress on Ultrasonics, ICU, Beijing, China, 18–21 September 2023. [Google Scholar]

- Xing, Q.; Chen, X.; Cai, Y.; Zhang, M. Oxygen-defect rich SnO2-based homogenous composites for fast response and recovery hydrogen sensor. Sens. Actuators B Chem. 2024, 419, 136407. [Google Scholar] [CrossRef]

- Yang, S.; Jiang, C.; Wei, S.-h. Gas sensing in 2D materials. Appl. Phys. Rev. 2017, 4, 021304. [Google Scholar] [CrossRef]

- Zhou, J.; Wang, C.; Zhang, X.; Jiang, L.; Wu, R. Advances in two-dimensional layered materials for gas sensing. Mater. Sci. Eng. R Rep. 2024, 161, 100872. [Google Scholar] [CrossRef]

- Chen, Q.; Zhang, Y.; Tang, M.; Wang, Z.; Zhang, D. A fast response hydrogen sensor based on the heterojunction of MXene and SnO2 nanosheets for lithium-ion battery failure detection. Sens. Actuators B Chem. 2024, 405, 135229. [Google Scholar] [CrossRef]

- Wu, J.; Guo, Y.; Wang, Y.; Zhu, H.; Zhang, X. Ti3C2 MXene-derived sodium titanate nanoribbons for conductometric hydrogen gas sensors. Sens. Actuators B Chem. 2022, 361, 131693. [Google Scholar] [CrossRef]

- Kumar, N.; Jasani, J.; Sonvane, Y.; Korvink, J.G.; Sharma, A.; Sharma, B. Unfolding the hydrogen gas sensing mechanism across 2D Pnictogen/graphene heterostructure sensors. Sens. Actuators B Chem. 2024, 399, 134807. [Google Scholar] [CrossRef]

- Evro, S.; Jain, I.P. MXenes for hydrogen energy systems: Advances in production, storage, fuel cells, and safety applications. Int. J. Hydrogen Energy 2025, 145, 147–168. [Google Scholar] [CrossRef]

- Li, L.; Peng, B.; Wang, Y.; Wang, B.; Huang, H.; Zhang, W.; Zhu, J.; Liao, L. A novel design method for SAW temperature sensor with monotonic and linear frequency-temperature behavior in wide temperature range. Sens. Actuators A Phys. 2020, 307, 111982. [Google Scholar] [CrossRef]

- Zhao, C.; Geng, W.; Qiao, X.; Xue, F.; He, J.; Xue, G.; Liu, Y.; Wei, H.; Bi, K.; Li, Y.; et al. Anti-irradiation SAW temperature sensor based on 128° YX LiNbO3 single crystal. Sens. Actuators A Phys. 2022, 333, 113230. [Google Scholar] [CrossRef]

- Miqueleti, S.A.; Costa-Félix, R.P.B.; Cernicchiaro, G. Acoustic impedance measurement method using spherical waves. Measurement 2024, 225, 113921. [Google Scholar] [CrossRef]

- Che, J.; Wang, J.; Qiao, C.; Xia, Y.; Ou, K.; Zhou, J.; Ni, Y.; Zhang, W.; Han, Y.; Zu, X.; et al. Si-Cu nanocomposite as an effective sensing layer for H2S based on quartz surface acoustic wave sensors. Sens. Actuators A Phys. 2023, 353, 114225. [Google Scholar] [CrossRef]

- Singh, J.; Gupta, S.K.; Vinita. Room temperature operating formaldehyde sensor based on n-type ZnO functionalized surface acoustic wave resonator. Sens. Actuators A Phys. 2024, 365, 114818. [Google Scholar] [CrossRef]

- Ralib, A.A.M.; Nordin, A.N.; Hashim, U. Finite element modeling of SAW resonator in CMOS technology for single and double interdigitated electrode (IDT) structure. In Proceedings of the RSM 2013 IEEE Regional Symposium on Micro and Nanoelectronics, Daerah Langkawi, Malaysia, 25–27 September 2013; pp. 1–4. [Google Scholar]

- Lu, R.; Yang, Y.; Hassanien, A.E.; Gong, S. Gigahertz Low-Loss and High Power Handling Acoustic Delay Lines Using Thin-Film Lithium-Niobate-on-Sapphire. IEEE Trans. Microw. Theory Tech. 2021, 69, 3246–3254. [Google Scholar] [CrossRef]

- Kondoh, J.; Okiyama, Y.; Mikuni, S.; Matsui, Y.; Nara, M.; Mori, T.; Yatsuda, H. Development of a Shear Horizontal Surface Acoustic Wave Sensor System for Liquids with a Floating Electrode Unidirectional Transducer. Jpn. J. Appl. Phys. 2008, 47, 4065. [Google Scholar] [CrossRef]

- Zhai, J.X.; Chen, C. Low-loss Floating Electrode Unidirectional Transducer for SAW Sensor. Acoust. Phys. 2019, 65, 178–184. [Google Scholar] [CrossRef]

- Wen, W.; Shitang, H.; Shunzhou, L.; Minghua, L.; Yong, P. Enhanced sensitivity of SAW gas sensor coated molecularly imprinted polymer incorporating high frequency stability oscillator. Sens. Actuators B Chem. 2007, 125, 422–427. [Google Scholar] [CrossRef]

- Nie, W.; Wang, F.; Kong, D.; Yang, Z.; Han, Y.; Han, X.; Shan, X.; Lin, X.; Chen, G.; Dun, H.; et al. Gigahertz Low-Loss Surface Acoustic Wave Devices Based on ScAlN/Si Structures. J. Electron. Mater. 2023, 52, 7763–7774. [Google Scholar] [CrossRef]

- Wu, M.; Liu, X.; Wang, R.; Lin, X.; Liu, Y. A high-performance surface acoustic wave sensing technique. Rev. Sci. Instrum. 2024, 95, 054903. [Google Scholar] [CrossRef]

- Ramakrishnan, N.; Namdeo, A.K.; Nemade, H.B.; Palathinkal, R.P. Simplified Model for FEM Simulation of SAW Delay Line Sensor. Procedia Eng. 2012, 41, 1022–1027. [Google Scholar] [CrossRef]

- Kannan, T. Finite Element Analysis of Surface Acoustic Wave Resonators. Modal Harmon. Anal. 2006. [Google Scholar]

- Atashbar, M.Z.; Bazuin, B.J.; Simpeh, M.; Krishnamurthy, S. 3D FE simulation of H2 SAW gas sensor. Sens. Actuators B Chem. 2005, 111–112, 213–218. [Google Scholar] [CrossRef]

- Maouhoub, S.; Aoura, Y.; Mir, A. FEM simulation of AlN thin layers on diamond substrates for high frequency SAW devices. Diam. Relat. Mater. 2016, 62, 7–13. [Google Scholar] [CrossRef]

- Abu Waar, Z.; Moustafa, M. Design and Analysis of SAW Gas Sensor Utilizing AIN/Diamond/Si Multilayered Structure for VOCs Detection. J. Electron. Mater. 2024, 53, 5255–5264. [Google Scholar] [CrossRef]

- Harathi, N.; Kavitha, S.; Sarkar, A. ZnO nanostructured 2D layered SAW based hydrogen gas sensor with enhanced sensitivity. Mater. Today Proc. 2020, 33, 2621–2625. [Google Scholar] [CrossRef]

- Rajput, P.; Kumar, J.; Mittal, U.; Nimal, A.T.; Arsenin, A.V.; Volkov, V.S.; Mishra, P. Sensitivity enhancement analysis of frequency tuned-SAW resonator with temperature for sensor applications. Sens. Bio-Sens. Res. 2022, 37, 100509. [Google Scholar] [CrossRef]

- Andersen, B.D.; Cavin, M.; Belkerdid, M.A.; Malocha, D.C. Sensitivity analysis of one port and two port BAW and SAW resonator model parameters. In Proceedings of the IEEE 48th Annual Symposium on Frequency Control, Boston, MA, USA, 1–3 June 1994; pp. 308–314. [Google Scholar]

- Skeie, H. Development and Evaluation of an Equivalent Circuit Model for Acoustic Surface Wave Transducers. In Proceedings of the 1971 2nd European Microwave Conference, Stockholm, Sweden, 23–28 August 1971; pp. 1–4. [Google Scholar]

- Perez-Cortes, L.; Hernandez-Rodriguez, C.; Mazingue, T.; Lomello-Tafin, M. Functionality of Surface Acoustic Wave (SAW) transducer for palladium–platinum-based hydrogen sensor. Sens. Actuators A Phys. 2016, 251, 35–41. [Google Scholar] [CrossRef]

- Kent, C.K.; Ramakrishnan, N.; Kesuma, H.P. Advancements in One-Port Surface Acoustic Wave (SAW) Resonators for Sensing Applications: A Review. IEEE Sens. J. 2024, 24, 17337–17352. [Google Scholar] [CrossRef]

- Cheng, C.; Liu, Y.; Li, X.; Yang, J.; Tong, T.; Ke, Q. The strain transfer characteristics of SAW strain sensors and their impact on the sensor performance. Sens. Actuators A Phys. 2025, 389, 116575. [Google Scholar] [CrossRef]

- Durdaut, P.; Kittmann, A.; Rubiola, E.; Friedt, J.M.; Quandt, E.; Knöchel, R.; Höft, M. Noise Analysis and Comparison of Phase- and Frequency-Detecting Readout Systems: Application to SAW Delay Line Magnetic Field Sensor. IEEE Sens. J. 2019, 19, 8000–8008. [Google Scholar] [CrossRef]

- Fahim; Mainuddin; Mittal, U.; Kumar, J.; Nimal, A.T.; Sharma, M.U. Single chip readout electronics for SAW based gas sensor systems. In Proceedings of the 2017 IEEE SENSORS, Glasgow, UK, 29 October–1 November 2017; pp. 1–3. [Google Scholar]

- Nie, W.; Pan, Y.; Hu, S.; Jiang, Z.; Fan, X.; Luo, J.; Tao, R.; Fu, C. Implementation and comparative analysis of surface acoustic wave sensor readout circuit architectures: Delay-line versus resonator configurations. Appl. Acoust. 2025, 240, 110907. [Google Scholar] [CrossRef]

- Fu, C.; Hu, S.; Jiang, Z.; Nie, W.; Fan, X.; Tao, R.; Luo, J. High-linearity surface acoustic wave delay line sensors: A comprehensive strategy for triple transition echo elimination. J. Acoust. Soc. Am. 2025, 157, 2498–2504. [Google Scholar] [CrossRef]

- Ren, Z.; Cui, B.; Cheng, L.; Jin, J.; Liang, Y.; Xue, X.; Wang, W. Temperature and Humidity Effects on SAW Hydrogen Sensor and Compensation Method. IEEE Sens. J. 2024, 24, 22317–22325. [Google Scholar] [CrossRef]

| Project | Detection Range | LOD | Response (t90)/Recovery Time (t10) | Accuracy | Ambient Temperature (°C) | Ambient Humidity (RH%) | Ambient Pressure (kPa) |

|---|---|---|---|---|---|---|---|

| Stationary | 0.01–10 vol% | <0.01–0.05 vol% | <30 s/60 s | ±10%F.S. | −20–60 | 15–95 | 80–120 |

| Automobile | 0.01–10 vol% | <0.01–0.2 vol%H2 | <1–3 s/30 s | ±5–10%F.S. | −40–105 | 5–95 | 80–120 |

| Sensitive Film | Range | LOD | Sensitivity | Response Time | Recovery Time | Operating Temperature | Ref. |

|---|---|---|---|---|---|---|---|

| Nanoporous Pd | 0.008–2% | 48 ppm | 0.31 Hz/ppm | 15–44 s | 34 s | - | [58] |

| Pd-CuPC | 0.5–4% | - | 0.1048 Hz/ppm | - | - | 38 °C | [59] |

| Pd/Ni | 0.2–10% | 15 ppm | 0.181 mv/% | <2 s | <7 s | 75 °C | [60] |

| Pd/Ni NWs | 0.3–3.5% | 7 ppm | 1.65 mv/% | <2 s | <4 s | RT | [61] |

| Pd/Cu NWs | 0.1–4.5% | 7 ppm | 1.5 kHz/% | <4 s | <4 s | RT | [62] |

| Pd/Ni NWs | 1–3% | - | 0.92 mv/% | <2 s | RT | [63] | |

| Pd-SnO2 | 0.01–0.2% | - | 115.9 kHz to 2000 ppm | 1 s | 583 s | 175 °C | [64] |

| Pd (GaN/SiC) | 0.002–0.1% | 20 ppm | 60 kHz to 1000 ppm | 15 s | 5 min | RT | [51,65] |

| Pt/InOx | 0.04–0.68% | - | 23.63 kHz to 2000 ppm | - | - | RT | [66] |

| Polyaniline/WO3 | 1–4% | - | - | - | - | - | [67] |

| PdNi/ZIF-8 | 0.2–8% | 5 ppm | 16.77 mv/% | - | - | RT | [68] |

| Pd-Y | 0.5–2% | - | - | - | - | - | [69] |

| ITO | 5–100% | - | 0.0018 rad/vol% | - | - | 350 °C | [70] |

| ZnO NWs | 0.2–2% | 2253 ppm | 0.062 Hz/ppm | - | - | RT | [71] |

| Carbon Nanowalls | 0.02–0.1% | 7.79 ppm | 9.4 Hz/ppm | - | - | RT | [72] |

| Pd/ZnO | 0.2–2% | 59 ppm | 0.51 Hz/ppm | 12 s–16 s | - | RT | [73] |

| Pd/Gr | 0.25–1% | - | 30 kHz to 1% | - | - | RT | [74] |

| Performance Parameters | Al | Au | Cu | Mo | W |

|---|---|---|---|---|---|

| Adhesion | Robust | Poor | Robust | Robust | Good |

| Density (g/cm3) | 2.7 | 19.32 | 8.96 | 10.28 | 19.25 |

| Maximum operating temperature (°C) | 250 | 300 | 250 | 500 | 600 |

| Resistivity (μΩ/cm) | 2.65 | 2.2 | 1.7 | 5.34 | 5.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, S.; Chai, J.; Gao, L.; Wang, R.; Zhang, Z.; Ren, Z.; Xu, H.; Lan, Y.; Ma, K.; Li, M. SAW-Based Hydrogen Sensing: Mechanisms, Design Strategies, and Future Prospects. Micromachines 2025, 16, 1227. https://doi.org/10.3390/mi16111227

Chen S, Chai J, Gao L, Wang R, Zhang Z, Ren Z, Xu H, Lan Y, Ma K, Li M. SAW-Based Hydrogen Sensing: Mechanisms, Design Strategies, and Future Prospects. Micromachines. 2025; 16(11):1227. https://doi.org/10.3390/mi16111227

Chicago/Turabian StyleChen, Shengzhuo, Jin Chai, Libo Gao, Rongjie Wang, Zhonggang Zhang, Ziming Ren, Hongyan Xu, Yihui Lan, Kezhen Ma, and Meng Li. 2025. "SAW-Based Hydrogen Sensing: Mechanisms, Design Strategies, and Future Prospects" Micromachines 16, no. 11: 1227. https://doi.org/10.3390/mi16111227

APA StyleChen, S., Chai, J., Gao, L., Wang, R., Zhang, Z., Ren, Z., Xu, H., Lan, Y., Ma, K., & Li, M. (2025). SAW-Based Hydrogen Sensing: Mechanisms, Design Strategies, and Future Prospects. Micromachines, 16(11), 1227. https://doi.org/10.3390/mi16111227