Wearable Flexible Wireless Pressure Sensor Based on Poly(vinyl alcohol)/Carbon Nanotube/MXene Composite for Health Monitoring

Abstract

1. Introduction

2. Materials and Methods

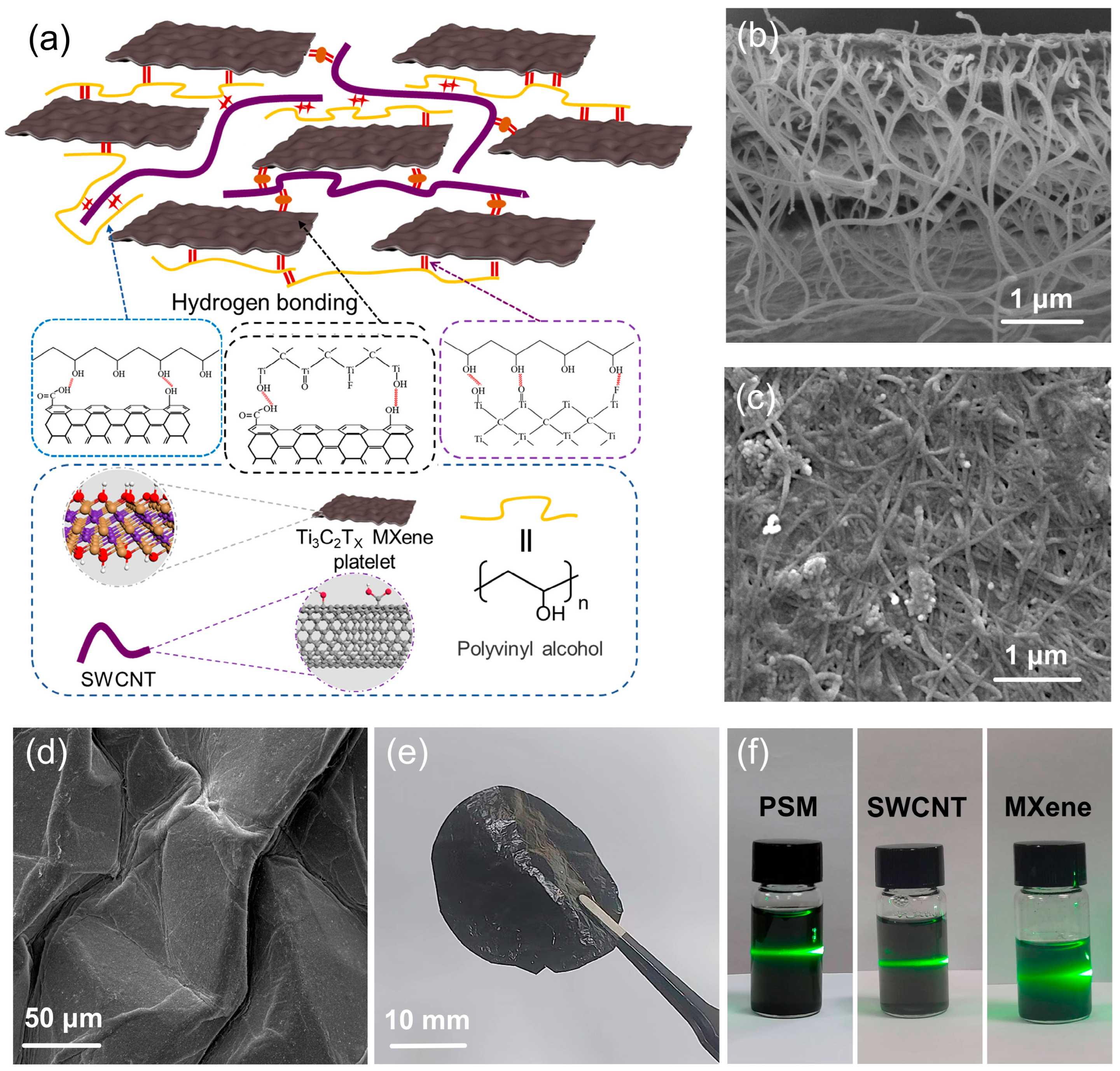

2.1. PVA/SWCNT/MXene Composite Film Fabrication

2.2. Pressure Sensor Fabrication

2.3. Pressure Sensor Performance

3. Results and Discussion

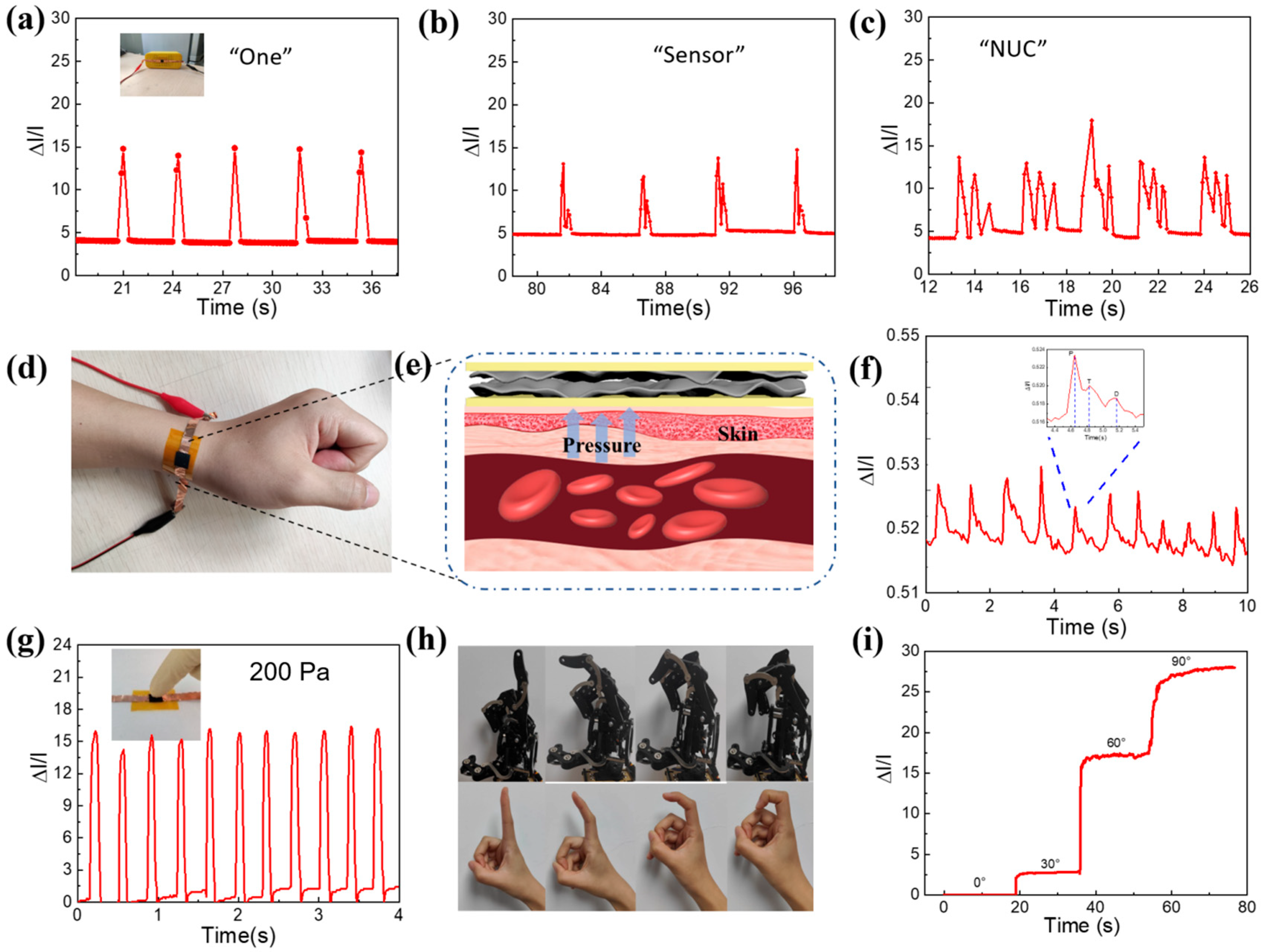

3.1. Film Performance Test

3.2. Neural Network Classifier Trained for Joint Motion Recognition

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| ADC | Analog-to-digital converter |

| PVA | Poly(vinyl alcohol) |

| SWCNTs | Single-walled carbon nanotubes |

| PSM | PVA/SWCNT/MXene |

| SEM | Scanning electron microscopy |

| XPS | X-ray photoelectron spectroscopy |

| SVM | Support vector machine |

| PI | Polyimide |

References

- Yang, R.; Dutta, A.; Li, B.; Tiwari, N.; Zhang, W.; Niu, Z.; Gao, Y.; Erdely, D.; Xin, X.; Li, T.; et al. Iontronic pressure sensor with high sensitivity over ultra-broad linear range enabled by laser-induced gradient micro-pyramids. Nat. Commun. 2023, 14, 2907. [Google Scholar] [CrossRef]

- Xia, H.; Wang, L.; Zhang, H.; Wang, Z.; Zhu, L.; Cai, H.; Ma, Y.; Yang, Z.; Zhang, D. MXene/PPy@PDMS sponge-based flexible pressure sensor for human posture recognition with the assistance of a convolutional neural network in deep learning. Microsyst. Nanoeng. 2023, 9, 155. [Google Scholar] [CrossRef]

- Lee, J.; So, H. 3D-printing-assisted flexible pressure sensor with a concentric circle pattern and high sensitivity for health monitoring. Microsyst. Nanoeng. 2023, 9, 44. [Google Scholar] [CrossRef]

- Wang, M.; Lin, Z.; Ma, S.; Yu, Y.; Chen, B.; Liang, Y.; Ren, L. Composite Flexible Sensor Based on Bionic Microstructure to Simultaneously Monitor Pressure and Strain. Adv. Healthc. Mater. 2023, 12, 2301005. [Google Scholar] [CrossRef] [PubMed]

- Pan, W.; Wang, Y.; Ouyang, G.; Ren, M.; Cao, M. High-Sensitivity and Low-Cost Wearable Flexible Pressure Sensor Based on MOFs. ACS Appl. Electron. Mater. 2023, 5, 3851–3858. [Google Scholar] [CrossRef]

- Zhu, H.; Luo, H.; Cai, M.; Song, J. A Multifunctional Flexible Tactile Sensor Based on Resistive Effect for Simultaneous Sensing of Pressure and Temperature. Adv. Sci. 2024, 11, e2307693. [Google Scholar] [CrossRef]

- Yang, C.; Wang, W.; Zhang, D.; Du, C.; Zhang, H.; Xia, H. High-Sensitivity Wearable Flexible Pressure Sensor Based on MXene and Polyaniline for Human Motion Detection. ACS Appl. Polym. Mater. 2023, 5, 10386–10394. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, D.; Wang, D.; Xu, Z.; Zhang, H.; Chen, X.; Wang, Z.; Xia, H.; Cai, H. Efficient Fabrication of TPU/MXene/Tungsten Disulfide Fibers with Ultra-Fast Response for Human Respiratory Pattern Recognition and Disease Diagnosis via Deep Learning. ACS Appl. Mater. Interfaces 2023, 15, 37946–37956. [Google Scholar] [CrossRef]

- Yang, J.; Liu, L.; Zhang, D.; Zhang, H.; Ma, J.; Zheng, J.; Wang, C. Dual-Stage Surficial Microstructure to Enhance the Sensitivity of MXene Pressure Sensors for Human Physiological Signal Acquisition. ACS Appl. Mater. Interfaces 2024, 16, 1096–1106. [Google Scholar] [CrossRef]

- Chen, J.; Xia, X.; Yan, X.; Wang, W.; Yang, X.; Pang, J.; Qiu, R.; Wu, S. Machine Learning-Enhanced Biomass Pressure Sensor with Embedded Wrinkle Structures Created by Surface Buckling. ACS Appl. Mater. Interfaces 2023, 15, 46440–46448. [Google Scholar] [CrossRef] [PubMed]

- Du, Y.; Lu, W.; Liu, Y.; Yu, R.; Wu, P.; Kong, J. MXene-based pressure sensor with ultrahigh sensitivity in a small pressure range for voiceless speaking and abnormal writing recognition. Adv. Compos. Hybrid Ma. 2024, 7, 24. [Google Scholar] [CrossRef]

- Gao, X.; Yuan, L.; Xue, C.; Zhang, X.; Meng, X.; Li, X. Bubbles-Induced Porous Structure-Based Flexible Piezoresistive Sensors for Speech Recognition. ACS Appl. Mater. Interfaces 2024, 16, 9532–9543. [Google Scholar] [CrossRef] [PubMed]

- Cao, Y.; Guo, Y.; Chen, Z.; Yang, W.; Li, K.; He, X.; Li, J. Highly sensitive self-powered pressure and strain sensor based on crumpled MXene film for wireless human motion detection. Nano Energy 2022, 92, 106689. [Google Scholar] [CrossRef]

- Cai, Y.; Shen, J.; Ge, G.; Zhang, Y.; Jin, W.; Huang, W.; Shao, J.; Yang, J.; Dong, X. Stretchable Ti3C2Tx MXene/Carbon Nanotube Composite Based Strain Sensor with Ultrahigh Sensitivity and Tunable Sensing Range. ACS Nano 2018, 12, 56–62. [Google Scholar] [CrossRef]

- Ershad, F.; Thukral, A.; Yue, J.; Comeaux, P.; Lu, Y.; Shim, H.; Sim, K.; Kim, N.-I.; Rao, Z.; Guevara, R.; et al. Ultra-conformal drawn-on-skin electronics for multifunctional motion artifact-free sensing and point-of-care treatment. Nat. Commun. 2020, 11, 3823. [Google Scholar] [CrossRef]

- Gao, J.; Wang, H.; Gao, Z.; Gui, H.; Wang, Y.; Tang, J.; Huang, L. Preparation and performance study of high-sensitivity flexible pressure sensors based on MXene/PVDF@ZIF-8 composite membranes. Appl. Surf. Sci. 2025, 681, 161626. [Google Scholar] [CrossRef]

- Pu, J.-H.; Zhao, X.; Zha, X.-J.; Bai, L.; Ke, K.; Bao, R.-Y.; Liu, Z.-Y.; Yang, M.-B.; Yang, W. Multilayer structured AgNW/WPU-MXene fiber strain sensors with ultrahigh sensitivity and a wide operating range for wearable monitoring and healthcare. J. Mater. Chem. A 2019, 7, 15913–15923. [Google Scholar] [CrossRef]

- Zhang, L.; Zhang, S.; Wang, C.; Zhou, Q.; Zhang, H.; Pan, G.-B. Highly Sensitive Capacitive Flexible Pressure Sensor Based on a High-Permittivity MXene Nanocomposite and 3D Network Electrode for Wearable Electronics. ACS Sens. 2021, 6, 2630–2641. [Google Scholar] [CrossRef]

- Xiao, Y.; Duan, Y.; Li, N.; Wu, L.; Meng, B.; Tan, F.; Lou, Y.; Wang, H.; Zhang, W.; Peng, Z. Multilayer Double-Sided Microstructured Flexible Iontronic Pressure Sensor with a Record-wide Linear Working Range. ACS Sens. 2021, 6, 1785–1795. [Google Scholar] [CrossRef] [PubMed]

- Xu, J.; Wang, H.; Ma, T.; Wu, Y.; Xue, R.; Cui, H.; Wu, X.; Wang, Y.; Huang, X.; Yao, W. A graphite nanoplatelet-based highly sensitive flexible strain sensor. Carbon 2020, 166, 316–327. [Google Scholar] [CrossRef]

- Liu, H.; Wang, L.; Lin, G.; Feng, Y. Recent progress in the fabrication of flexible materials for wearable sensors. Biomater. Sci. 2022, 10, 614–632. [Google Scholar] [CrossRef]

- Yu, Z.; Cai, G.; Tong, P.; Tang, D. Saw-Toothed Microstructure-Based Flexible Pressure Sensor as the Signal Readout for Point-of-Care Immunoassay. ACS Sens. 2019, 4, 2272–2276. [Google Scholar] [CrossRef]

- Shirhatti, V.; Nuthalapati, S.; Kedambaimoole, V.; Kumar, S.; Nayak, M.M.; Rajanna, K. Multifunctional Graphene Sensor Ensemble as a Smart Biomonitoring Fashion Accessory. ACS Sens. 2021, 6, 4325–4337. [Google Scholar] [CrossRef]

- Wei, H.; Kong, D.; Li, T.; Xue, Q.; Wang, S.; Cui, D.; Huang, Y.; Wang, L.; Hu, S.; Wan, T.; et al. Solution-Processable Conductive Composite Hydrogels with Multiple Synergetic Networks toward Wearable Pressure/Strain Sensors. ACS Sens. 2021, 6, 2938–2951. [Google Scholar] [CrossRef]

- Zang, Y.; Zhang, F.; Di, C.-A.; Zhu, D. Advances of flexible pressure sensors toward artificial intelligence and health care applications. Mater. Horiz. 2015, 2, 140–156. [Google Scholar] [CrossRef]

- Zhou, J.; Chen, H.; Zhou, P.; Peng, Q.; Guo, Q.; Wang, J.; Xu, Y.; You, M.; Weng, M. Ti3C2Tx MXene Nanosheet-Functionalized Leathers for Versatile Wearable Electronics. ACS Appl. Nano Mater. 2023, 6, 18150–18164. [Google Scholar] [CrossRef]

- Wang, D.; Wang, L.; Lou, Z.; Zheng, Y.; Wang, K.; Zhao, L.; Han, W.; Jiang, K.; Shen, G. Biomimetic, biocompatible and robust silk Fibroin-MXene film with stable 3D cross-link structure for flexible pressure sensors. Nano Energy 2020, 78, 105252. [Google Scholar] [CrossRef]

- Liu, N.; Li, Q.; Wan, H.; Chang, L.; Wang, H.; Fang, J.; Ding, T.; Wen, Q.; Zhou, L.; Xiao, X. High-temperature stability in air of Ti3C2Tx MXene-based composite with extracted bentonite. Nat. Commun. 2022, 13, 5551. [Google Scholar] [CrossRef] [PubMed]

- Lai, Q.; Zhao, X.; Sun, Q.; Tang, Z.; Tang, X.; Roy, V.A.L. Emerging MXene-Based Flexible Tactile Sensors for Health Monitoring and Haptic Perception. Small 2023, 19, 2300283. [Google Scholar] [CrossRef] [PubMed]

- Enyashin, A.N.; Ivanovskii, A.L. Structural and Electronic Properties and Stability of MXenes Ti2C and Ti3C2 Functionalized by Methoxy Groups. J. Phys. Chem. C 2013, 117, 13637–13643. [Google Scholar] [CrossRef]

- Lipatov, A.; Alhabeb, M.; Lukatskaya, M.R.; Boson, A.; Gogotsi, Y.; Sinitskii, A. Effect of Synthesis on Quality, Electronic Properties and Environmental Stability of Individual Monolayer Ti3C2 MXene Flakes. Adv. Electron. Mater. 2016, 2, 1600255. [Google Scholar] [CrossRef]

- Yang, H.; Li, J.; Xiao, X.; Wang, J.; Li, Y.; Li, K.; Li, Z.; Yang, H.; Wang, Q.; Yang, J.; et al. Topographic design in wearable MXene sensors with in-sensor machine learning for full-body avatar reconstruction. Nat. Commun. 2022, 13, 5311. [Google Scholar] [CrossRef]

- Sun, Z.; Zhu, M.; Shan, X.; Lee, C. Augmented tactile-perception and haptic-feedback rings as human-machine interfaces aiming for immersive interactions. Nat. Commun. 2022, 13, 5224. [Google Scholar] [CrossRef]

- Kim, K.K.; Ha, I.; Kim, M.; Choi, J.; Won, P.; Jo, S.; Ko, S.H. A deep-learned skin sensor decoding the epicentral human motions. Nat. Commun. 2020, 11, 2149. [Google Scholar] [CrossRef] [PubMed]

- Lu, Y.; Tian, H.; Cheng, J.; Zhu, F.; Liu, B.; Wei, S.; Ji, L.; Wang, Z.L. Decoding lip language using triboelectric sensors with deep learning. Nat. Commun. 2022, 13, 1401. [Google Scholar] [CrossRef] [PubMed]

- Shi, L.; Li, Z.; Chen, M.; Qin, Y.; Jiang, Y.; Wu, L. Quantum effect-based flexible and transparent pressure sensors with ultrahigh sensitivity and sensing density. Nat. Commun. 2020, 11, 3529. [Google Scholar] [CrossRef]

- Kim, J.; Bayro, A.; Lee, J.; Soltis, I.; Kim, M.; Jeong, H.; Yeo, W.-H. Mixed reality-integrated soft wearable biosensing glove for manipulating objects. Biosens. Bioelectron. X 2023, 14, 100343. [Google Scholar] [CrossRef]

- Luo, J.; Zhang, L.; Wu, T.; Song, H.; Tang, C. Flexible piezoelectric pressure sensor with high sensitivity for electronic skin using near-field electrohydrodynamic direct-writing method. Extrem. Mech. Lett. 2021, 48, 101279. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, L.; Pang, J.; Lu, X.; Zhang, X.; Zhang, X. Wearable Flexible Wireless Pressure Sensor Based on Poly(vinyl alcohol)/Carbon Nanotube/MXene Composite for Health Monitoring. Micromachines 2025, 16, 1132. https://doi.org/10.3390/mi16101132

Zhang L, Pang J, Lu X, Zhang X, Zhang X. Wearable Flexible Wireless Pressure Sensor Based on Poly(vinyl alcohol)/Carbon Nanotube/MXene Composite for Health Monitoring. Micromachines. 2025; 16(10):1132. https://doi.org/10.3390/mi16101132

Chicago/Turabian StyleZhang, Lei, Junqi Pang, Xiaoling Lu, Xiaohai Zhang, and Xinru Zhang. 2025. "Wearable Flexible Wireless Pressure Sensor Based on Poly(vinyl alcohol)/Carbon Nanotube/MXene Composite for Health Monitoring" Micromachines 16, no. 10: 1132. https://doi.org/10.3390/mi16101132

APA StyleZhang, L., Pang, J., Lu, X., Zhang, X., & Zhang, X. (2025). Wearable Flexible Wireless Pressure Sensor Based on Poly(vinyl alcohol)/Carbon Nanotube/MXene Composite for Health Monitoring. Micromachines, 16(10), 1132. https://doi.org/10.3390/mi16101132