A Low-Power and Robust Micromachined Thermal Convective Accelerometer

Abstract

1. Introduction

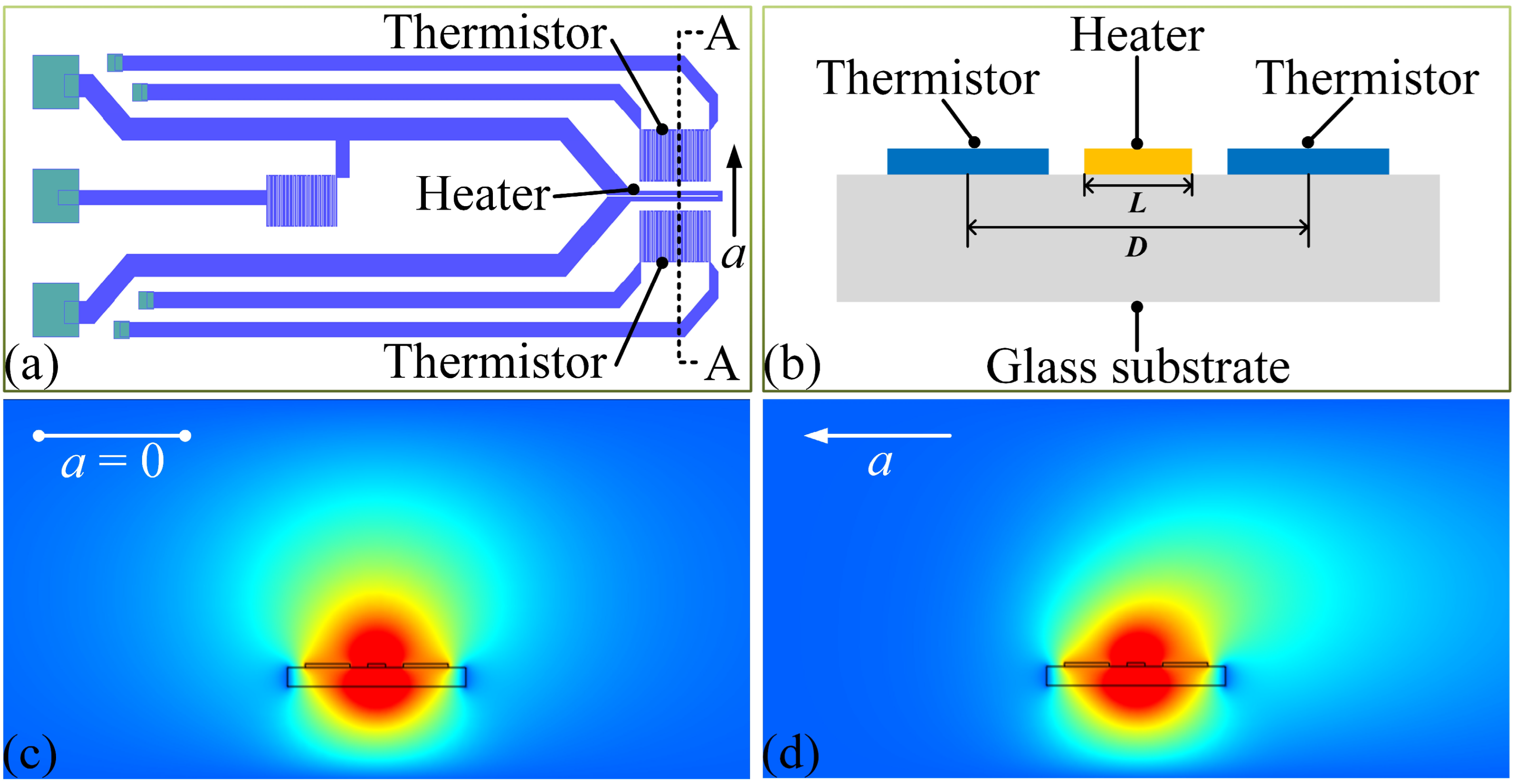

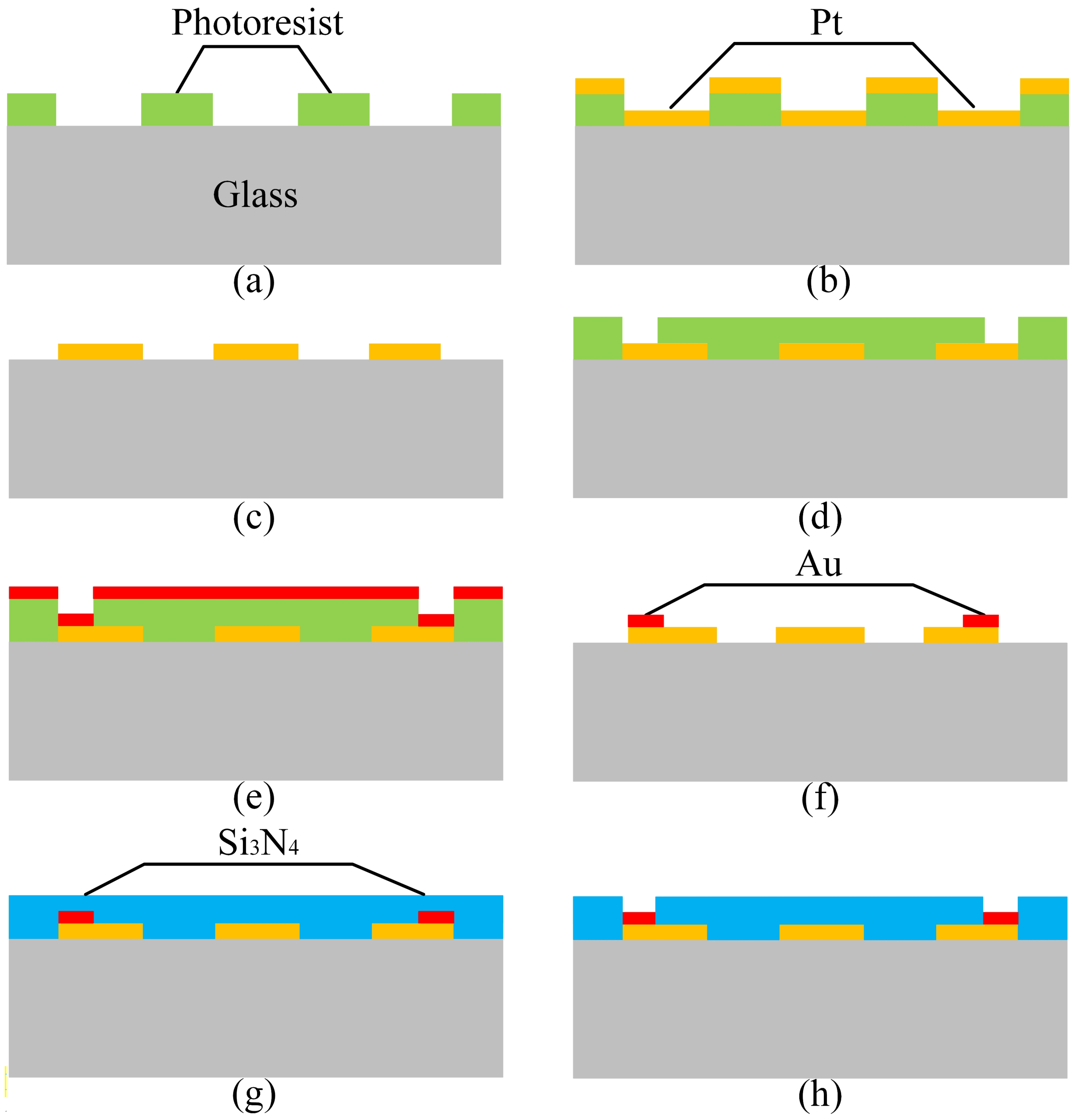

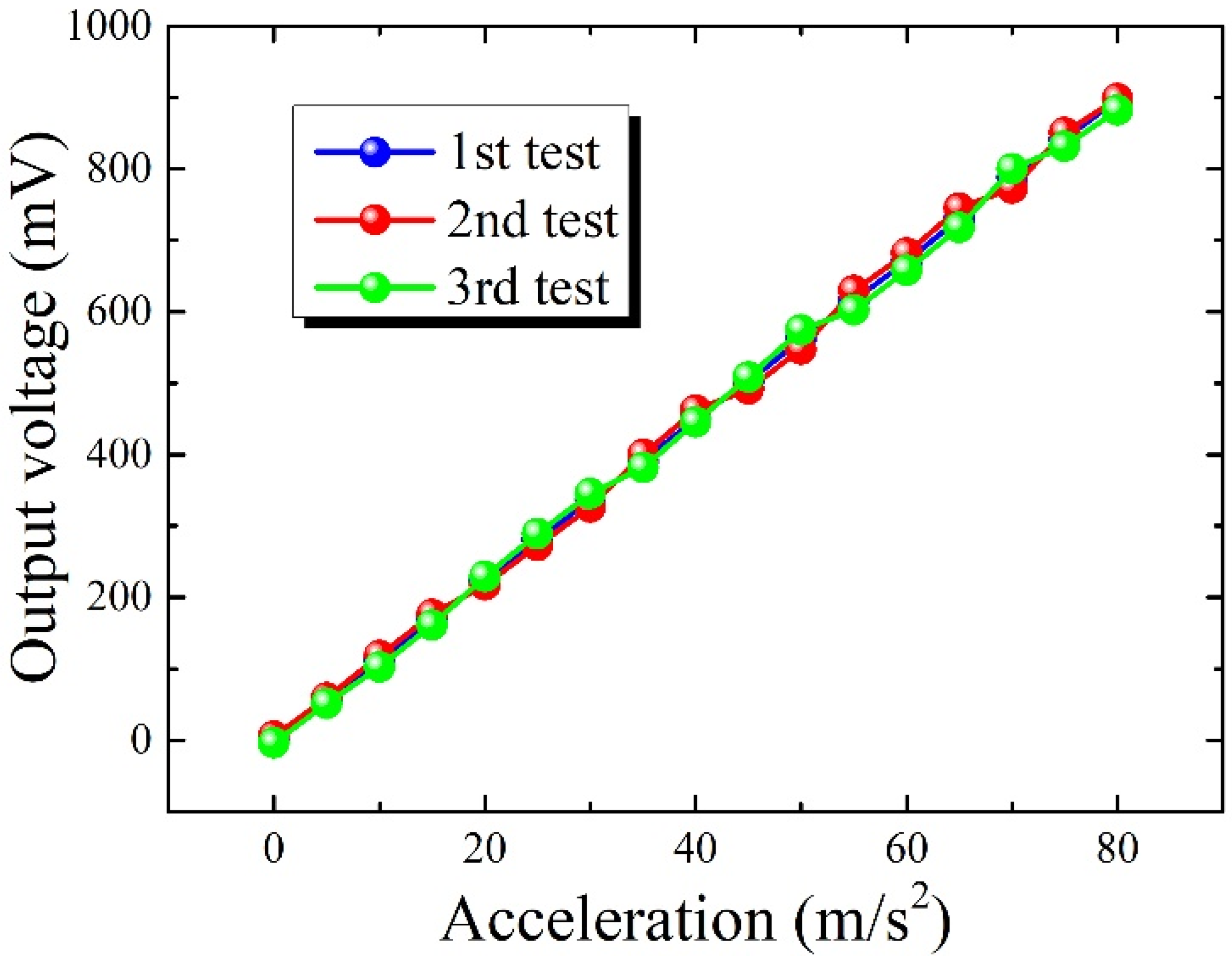

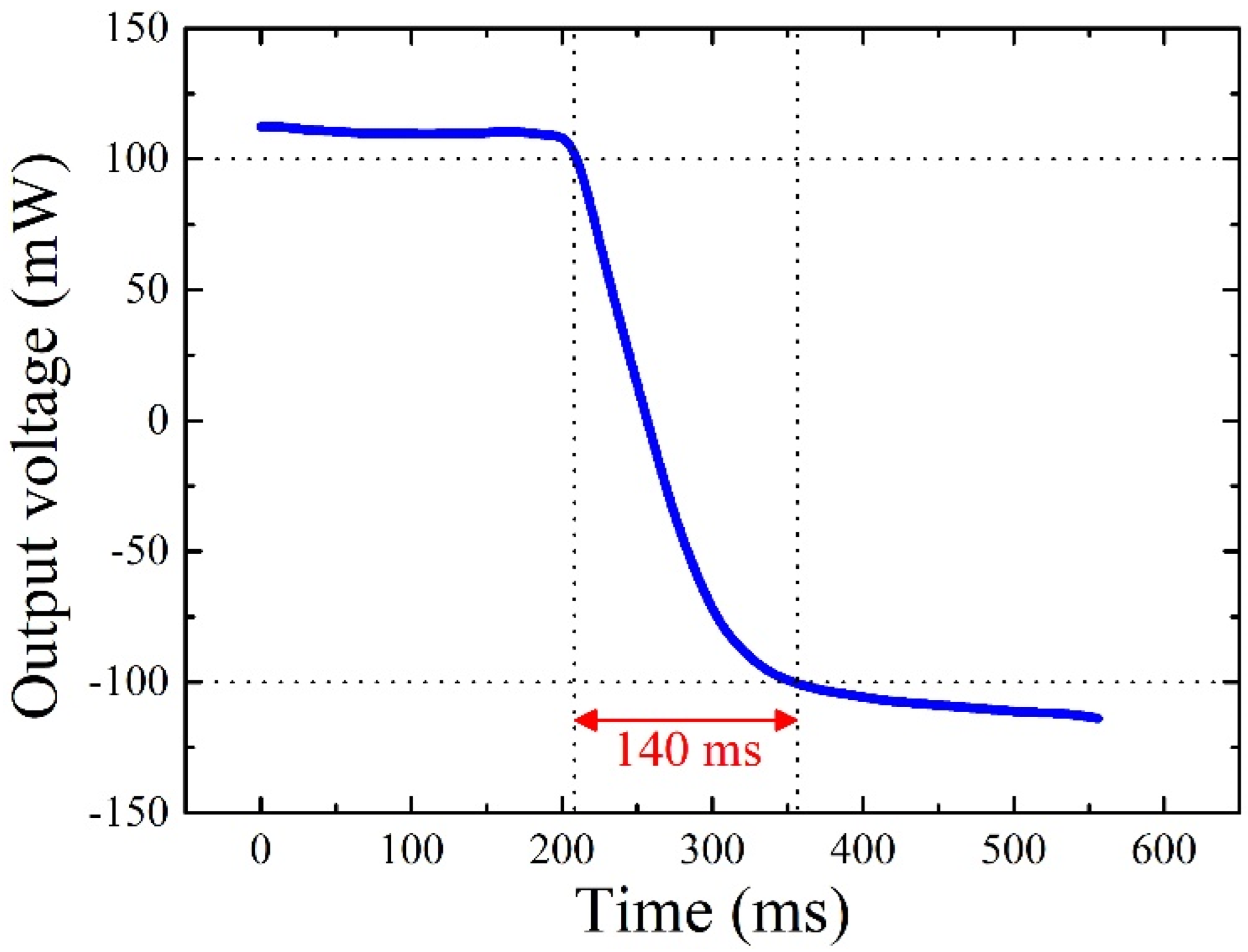

2. Principle and Analysis

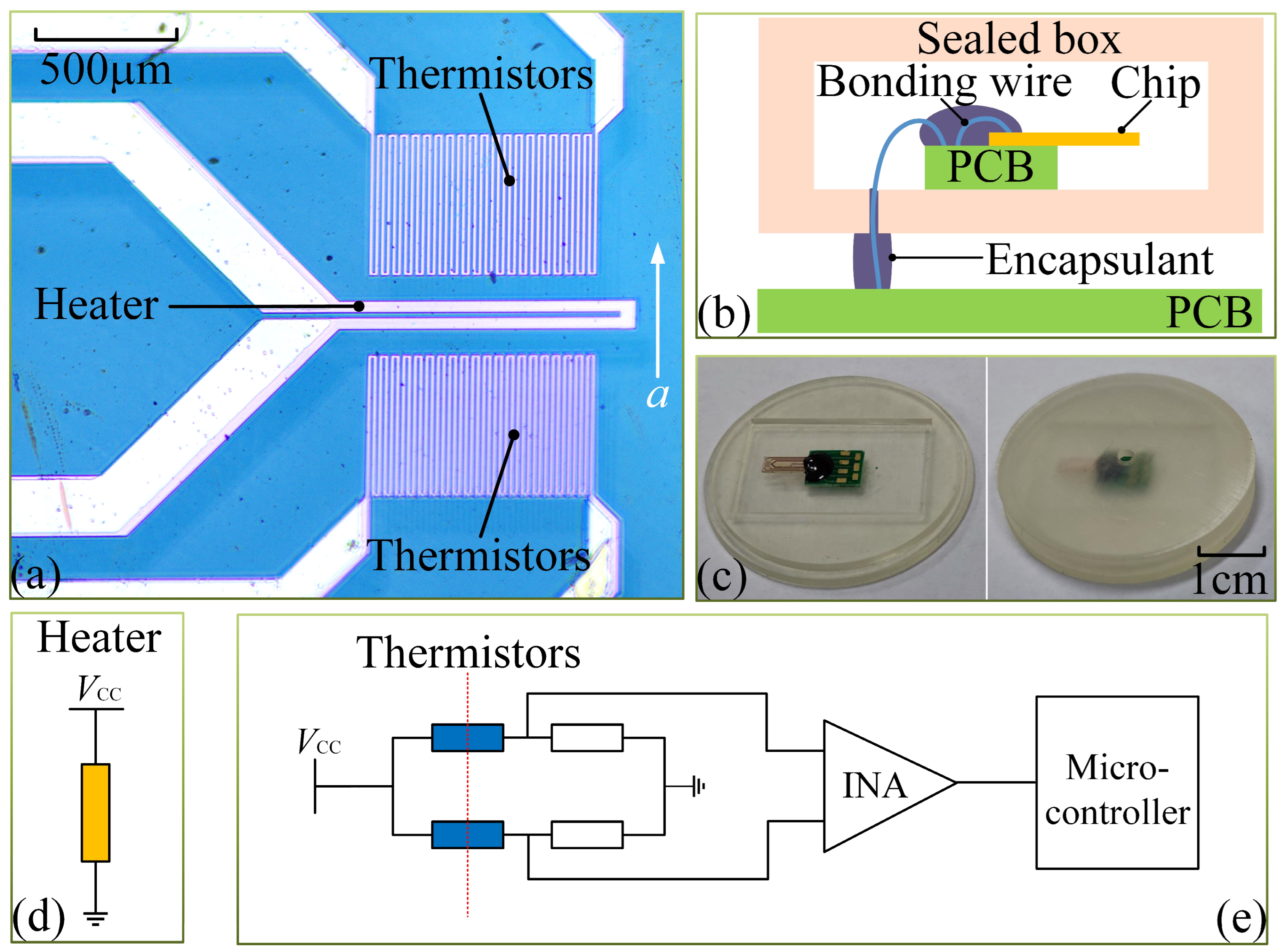

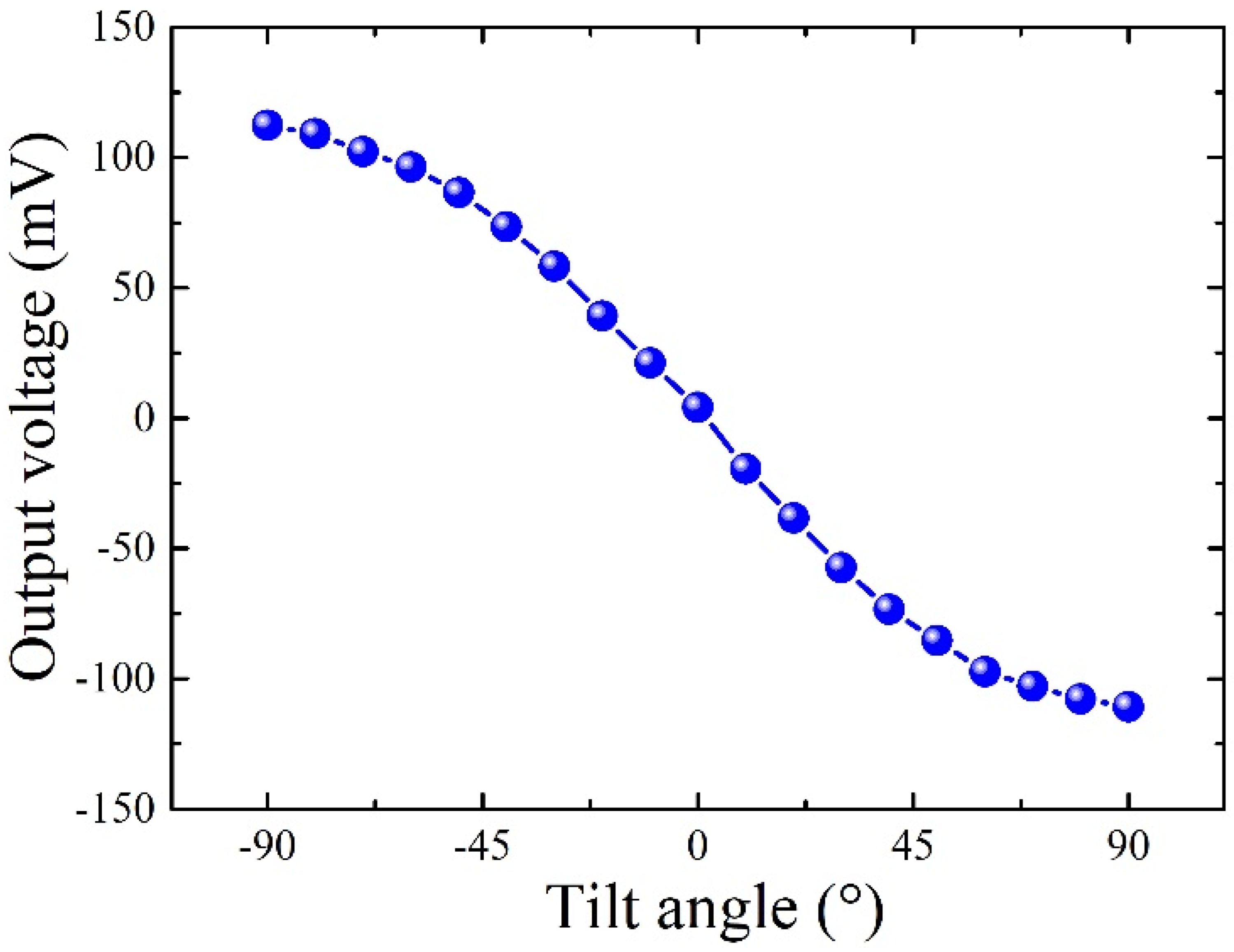

3. Experiment and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Sabato, A.; Niezrecki, C.; Fortino, G. Wireless MEMS-based accelerometer sensor boards for structural vibration monitoring: A review. IEEE Sens. J. 2016, 17, 226–235. [Google Scholar] [CrossRef]

- Lu, Q.; Wang, Y.; Wang, X.; Yao, Y.; Wang, X.; Huang, W. Review of micromachined optical accelerometers: From mg to sub-μg. Opto-Electronic Adv. 2021, 4, 200045. [Google Scholar] [CrossRef]

- Wang, C.; Chen, F.; Wang, Y.; Sadeghpour, S.; Wang, C.; Baijot, M.; Esteves, R.; Zhao, C.; Bai, J.; Liu, H.; et al. Micromachined accelerometers with sub-g/√Hz noise floor: A review. Sensors 2020, 20, 4054. [Google Scholar] [CrossRef]

- Narasimhan, V.; Li, H.; Jianmin, M. Micromachined high-g accelerometers: A review. J. Micromech. Microeng. 2015, 25, 33001–33018. [Google Scholar] [CrossRef]

- Mukherjee, R.; Basu, J.; Mandal, P.; Guha, P.K. A review of micromachined thermal accelerometers. J. Micromech. Microeng. 2017, 27, 123002. [Google Scholar] [CrossRef]

- Zhang, J.; Wu, T.; Liu, Y.; Lin, C.; Su, Y. Thermal stress resistance for the structure of MEMS-based silicon differential resonant accelerometer. IEEE Sens. J. 2023, 23, 9146–9157. [Google Scholar] [CrossRef]

- Zhao, C.; Pandit, M.; Sobreviela, G.; Steinmann, P.; Mustafazade, A.; Zou, X.; Seshia, A. A resonant MEMS accelerometer with 56ng bias stability and 98ng/Hz1/2 noise floor. J. Microelectromech. Syst. 2019, 28, 324–326. [Google Scholar] [CrossRef]

- Zotov, S.A.; Simon, B.R.; Trusov, A.A.; Shkel, A.M. High quality factor resonant MEMS accelerometer with continuous thermal compensation. IEEE Sens. J. 2015, 15, 5045–5052. [Google Scholar] [CrossRef]

- Yang, J.; Zhang, M.; Si, C.; Han, G.; Ning, J.; Yang, F.; Wang, X. A T-shape aluminum nitride thin-film piezoelectric MEMS resonant accelerometer. J. Microelectromech. Syst. 2019, 28, 776–781. [Google Scholar] [CrossRef]

- Chen, Z.-H.; Li, C.-Y.; Chu, S.-Y.; Tsai, C.-C.; Wang, Y.-H.; Kao, H.-Y.; Wei, C.-L.; Huang, Y.-H.; Hsiao, P.-Y.; Liu, Y.-H. The design of aluminum nitride-based lead-free piezoelectric MEMS accelerometer system. IEEE Trans. Electron. Devices 2020, 67, 4399–4404. [Google Scholar] [CrossRef]

- Tez, S.; Aykutlu, U.; Torunbalci, M.M.; Akin, T. A bulk-micromachined three-axis capacitive MEMS accelerometer on a single die. J. Microelectromech. Syst. 2015, 24, 1264–1274. [Google Scholar] [CrossRef]

- Hosseini, F.; Mehran, M.; Mohajerzadeh, S.; Shoaei, O. Design, analysis, simulation, and fabrication of a novel linear MEMS capacitive inclinometer. IEEE Sens. J. 2018, 18, 6962–6968. [Google Scholar] [CrossRef]

- Daeichin, M.; Miles, R.N.; Towfighian, S. Large-stroke capacitive MEMS accelerometer without pull-in. IEEE Sens. J. 2021, 21, 3097–3106. [Google Scholar] [CrossRef]

- Wang, X.; Xu, W.; Luo, H.; Lee, Y. Theoretical modeling, numerical simulations and experimental study of micro thermal convective accelerometers. J. Microelectromech. Syst. 2019, 28, 790–798. [Google Scholar] [CrossRef]

- Wang, X.; Lee, Y.-K.; Xu, W. Sensitivity and frequency response improvement of the micro thermal convective accelerometer with structure optimization. J. Microelectromech. Syst. 2022, 31, 753–759. [Google Scholar] [CrossRef]

- Park, U.; Kim, D.; Kim, J.; Moon, I.-K.; Kim, C.-H. Development of a complete dual-axis micromachined convective accelerometer with high sensitivity. In Proceedings of the IEEE Sensors, Lecce, Italy, 26–29 October 2008; pp. 670–673. [Google Scholar]

- Mukherjee, R.; Mandal; Guha, P.K. Sensitivity improvement of a dual axis thermal accelerometer with modified cavity structure. Microsyst. Technol. 2017, 23, 5357–5363. [Google Scholar] [CrossRef]

- Zhu, R.; Cai, S.; Ding, H.; Yang, Y.J.; Su, Y. A micromachined gas inertial sensor based on thermal expansion. Sens. Actuators A Phys. 2014, 212, 173–180. [Google Scholar] [CrossRef]

- Wu, M.; Hong, L.; Li, Y. A novel optical accelerometer based on slant-ended fiber. IEEE Sens. J. 2022, 22, 11673–11681. [Google Scholar] [CrossRef]

- Yan, B.; Liang, L. A novel fiber Bragg grating accelerometer based on parallel double flexible hinges. IEEE Sens. J. 2020, 20, 4713–4718. [Google Scholar] [CrossRef]

- Soltanian, E.; Jafari, K.; Abedi, K. A novel differential optical MEMS accelerometer based on intensity modulation using an optical power splitter. IEEE Sens. J. 2019, 19, 12024–12030. [Google Scholar] [CrossRef]

- Sheikhaleh, A.; Abedi, K.; Jafari, K. An optical MEMS accelerometer based on a two-dimensional photonic crystal add-drop filter. J. Light. Technol. 2017, 35, 3029–3034. [Google Scholar] [CrossRef]

- Hong, L.; Wu, M.; Chen, Y.; Li, Y. Low-cost fiber optic cantilever accelerometer with a spherical tip based on gaussian beam focusing. IEEE Photonics J. 2021, 13, 1–6. [Google Scholar] [CrossRef]

- Bahari, J.; Jones, J.D.; Leung, A.M. Sensitivity improvement of micromachined convective accelerometers. J. Microelectromech. Syst. 2012, 21, 646–655. [Google Scholar] [CrossRef]

- Xu, W.; Wang, X.; Zhao, X.; Lee, Y.K. Two-dimensional CMOS MEMS thermal flow sensor with high sensitivity and improved accuracy. J. Microelectromech. Syst. 2020, 29, 248–254. [Google Scholar] [CrossRef]

- Xu, W.; Li, Z.; Fang, Z.; Wang, B.; Hong, L.; Yang, G.; Han, S.-T.; Zhao, X.; Wang, X. A sub-5mW monolithic CMOS-MEMS thermal flow sensing SoC with ±6m/s linear range. EEE J. Solid-State Circuits 2023, 59, 1486–1496. [Google Scholar] [CrossRef]

- Wang, X.; Lim, G.; Xu, W.; Lee, Y.-K. Sensitivity improvement of micro thermal convective accelerometer with structure optimization: Theoretical and experimental studies. In Proceedings of the IEEE SENSORS, Montreal, QC, Canada, 27–30 October 2019; pp. 1–4. [Google Scholar]

- Li, Y.; Jiang, Z. An overview of reliability and failure mode analysis of microelectromechanical systems (MEMS). In Handbook Performability Engineering; Springer: London, UK, 2008; pp. 953–966. [Google Scholar]

- Harman, G. Reliability and yield problems of wire bonding in microelectronics. In International Society for Hybrid Microelectronics; McGraw-Hill: New York, NY, USA, 1993. [Google Scholar]

- Wang, X.; Xu, W.; Izhar; Lee, Y.-K. Theoretical and experimental study and compensation for temperature drifts of micro thermal convective accelerometer. J. Microelectromech. Syst. 2020, 29, 277–284. [Google Scholar] [CrossRef]

- Behrmann, O.; Lisec, T.; Gojdka, B. Towards robust thermal MEMS: Demonstration of a novel approach for solid thermal isolation by substrate-level integrated porous microstructures. Micromachines 2022, 13, 1178. [Google Scholar] [CrossRef]

- Ye, Y.; Wan, S.; Li, S.; Peng, Y.; He, X.; Qin, M. Fabrication and characterization of a MEMS thermal convective accelerometer on silicon-in-glass substrate. IEEE Sens. J. 2024, 24, 9619–9625. [Google Scholar] [CrossRef]

- Park, U.; Park, B.; Moon, I.-K.; Kim, D.; Kim, J. Development of a dual-axis micromachined convective accelerometer with an effective heater geometry. Microelectron. Eng. 2011, 88, 276–281. [Google Scholar] [CrossRef]

- Luo, X.B.; Li, Z.X.; Guo, Z.Y.; Yang, Y.J. Thermal optimization on micromachined convective accelerometer. Heat Mass Transf. 2002, 38, 705–712. [Google Scholar] [CrossRef]

- Mezghani, B.; Tounsi, F.; Masmoudi, M. Convection behavior analysis of CMOS MEMS thermal accelerometers using FEM and Hardee’s model. Analog. Integr. Circuits Signal Process. 2014, 78, 301–311. [Google Scholar] [CrossRef]

- Garraud, A.; Giani, A.; Combette, P.; Charlot, B.; Richard, M. A dual axis CMOS micromachined convective thermal accelerometer. Sens. Actuators A Phys. 2011, 170, 44–50. [Google Scholar] [CrossRef]

- Gao, S.; Yi, Z.; Ye, Y.; Qin, M.; Huang, Q.-A. Temperature effect and its compensation of a micromachined 2-D anemometer. IEEE Sens. J. 2019, 19, 5454–5459. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ye, Y.; Wan, S.; Hou, C.; He, X.; Li, S. A Low-Power and Robust Micromachined Thermal Convective Accelerometer. Micromachines 2024, 15, 844. https://doi.org/10.3390/mi15070844

Ye Y, Wan S, Hou C, He X, Li S. A Low-Power and Robust Micromachined Thermal Convective Accelerometer. Micromachines. 2024; 15(7):844. https://doi.org/10.3390/mi15070844

Chicago/Turabian StyleYe, Yizhou, Shu Wan, Chen Hou, Xuefeng He, and Shunbo Li. 2024. "A Low-Power and Robust Micromachined Thermal Convective Accelerometer" Micromachines 15, no. 7: 844. https://doi.org/10.3390/mi15070844

APA StyleYe, Y., Wan, S., Hou, C., He, X., & Li, S. (2024). A Low-Power and Robust Micromachined Thermal Convective Accelerometer. Micromachines, 15(7), 844. https://doi.org/10.3390/mi15070844