Suitability of Embedded Liquid Cooling and Heat Generation for Chips

Abstract

:1. Introduction

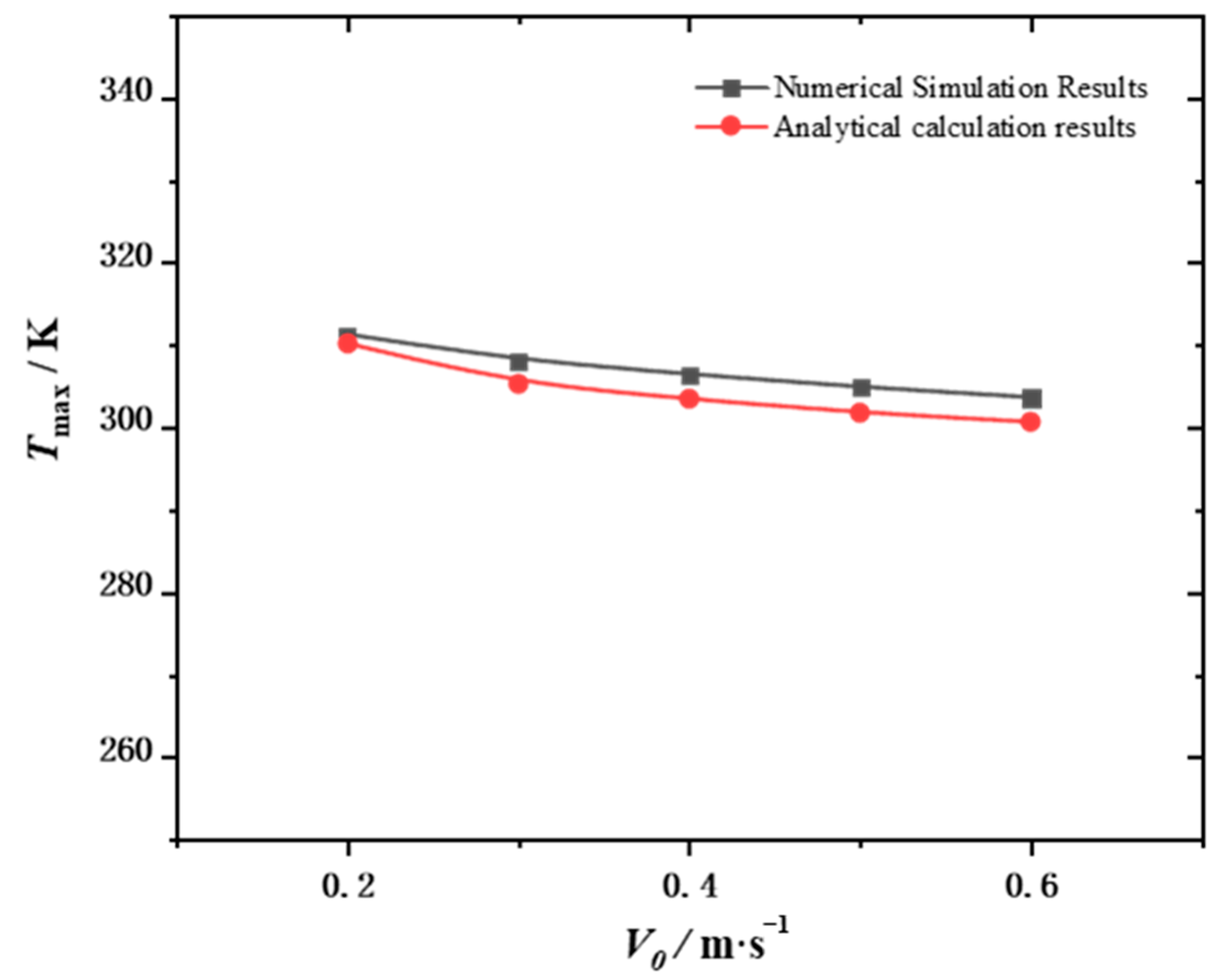

2. Model Building

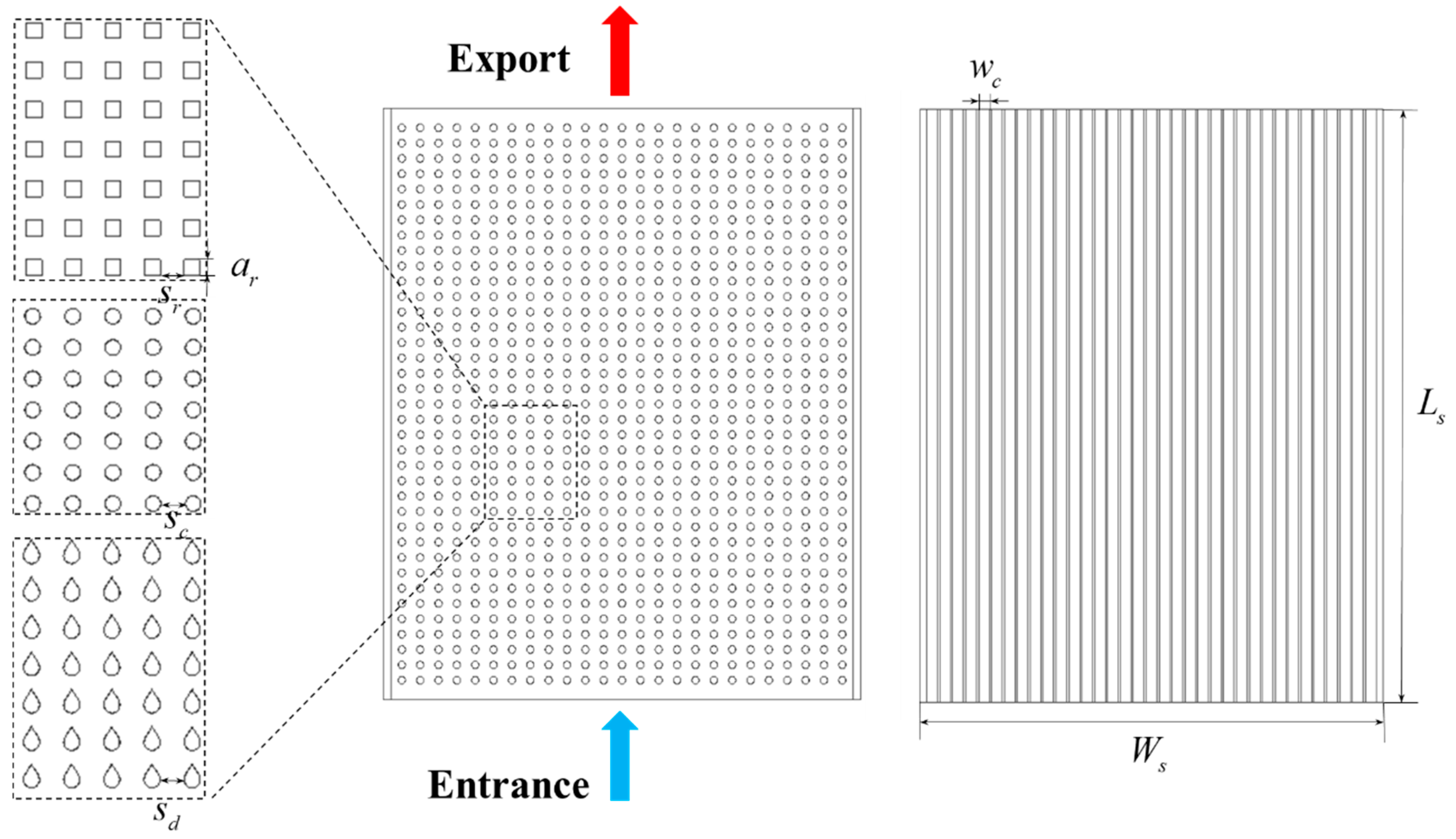

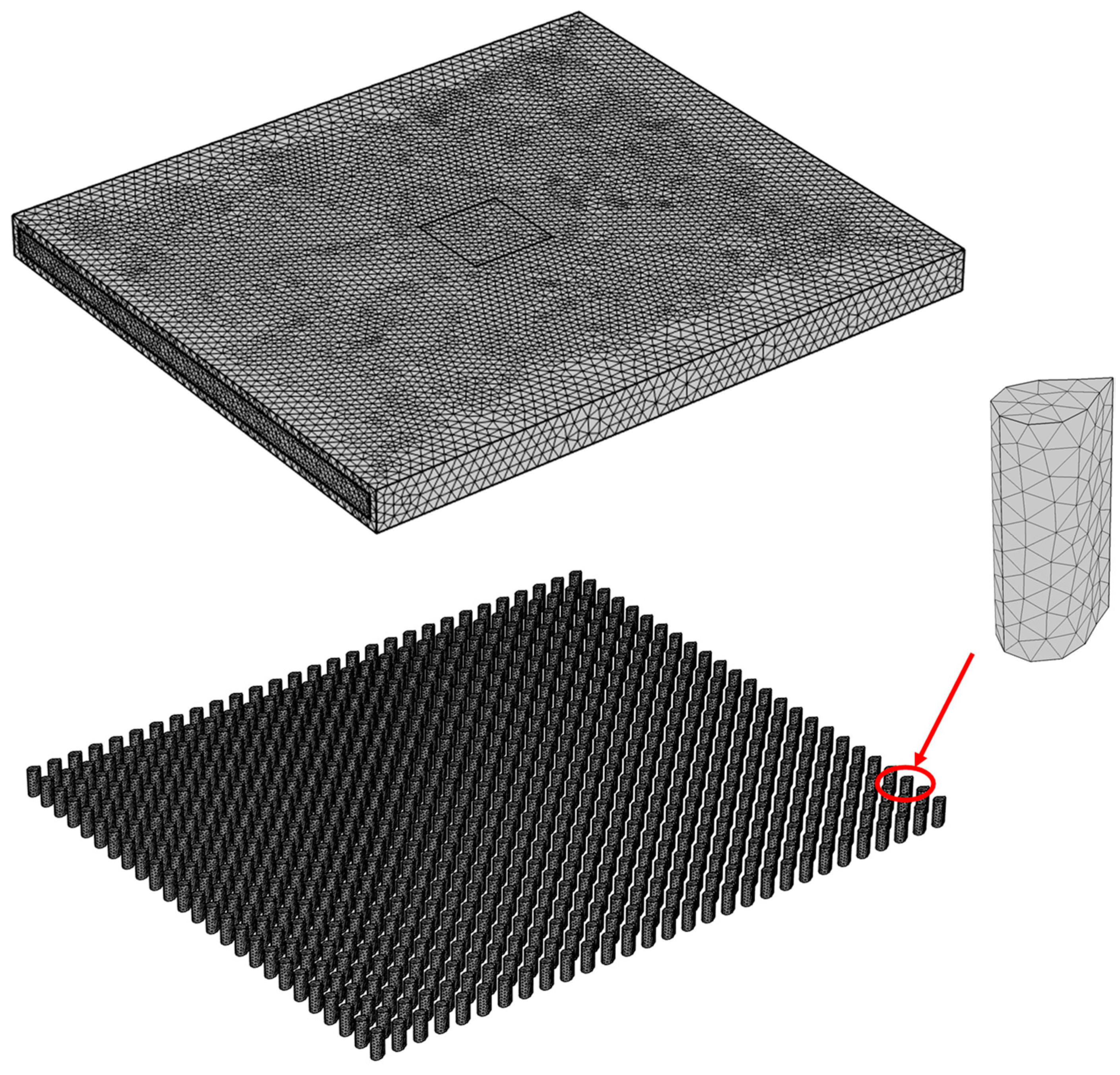

2.1. Geometric Model

2.2. Physical Model

- (1)

- Fluid flow and heat transfer are in a steady state, the coolant is incompressible, and the flow state is laminar.

- (2)

- The fluid and solid materials are constant, and the solid heat conduction materials are isotropic.

- (3)

- A no-slip boundary condition is adopted on the flow channel wall.

- (4)

- The dissipation heat caused by radiation heat transfer and viscous dissipation is not considered.

- (1)

- Fully developed flow and heat transfer and constant inlet water temperature.

- (2)

- Inlet Reynolds number ranges from 250 to 1500.

- (3)

- The outlet relative pressure is 0 Pa.

- (4)

- Given the heat flow density of each partition of the chip—except for the position in contact with the chip—other outer wall surfaces of the heat sink are adiabatic.

2.3. Performance Specifications

2.3.1. Maximum Temperature

2.3.2. Temperature Uniformity Factor

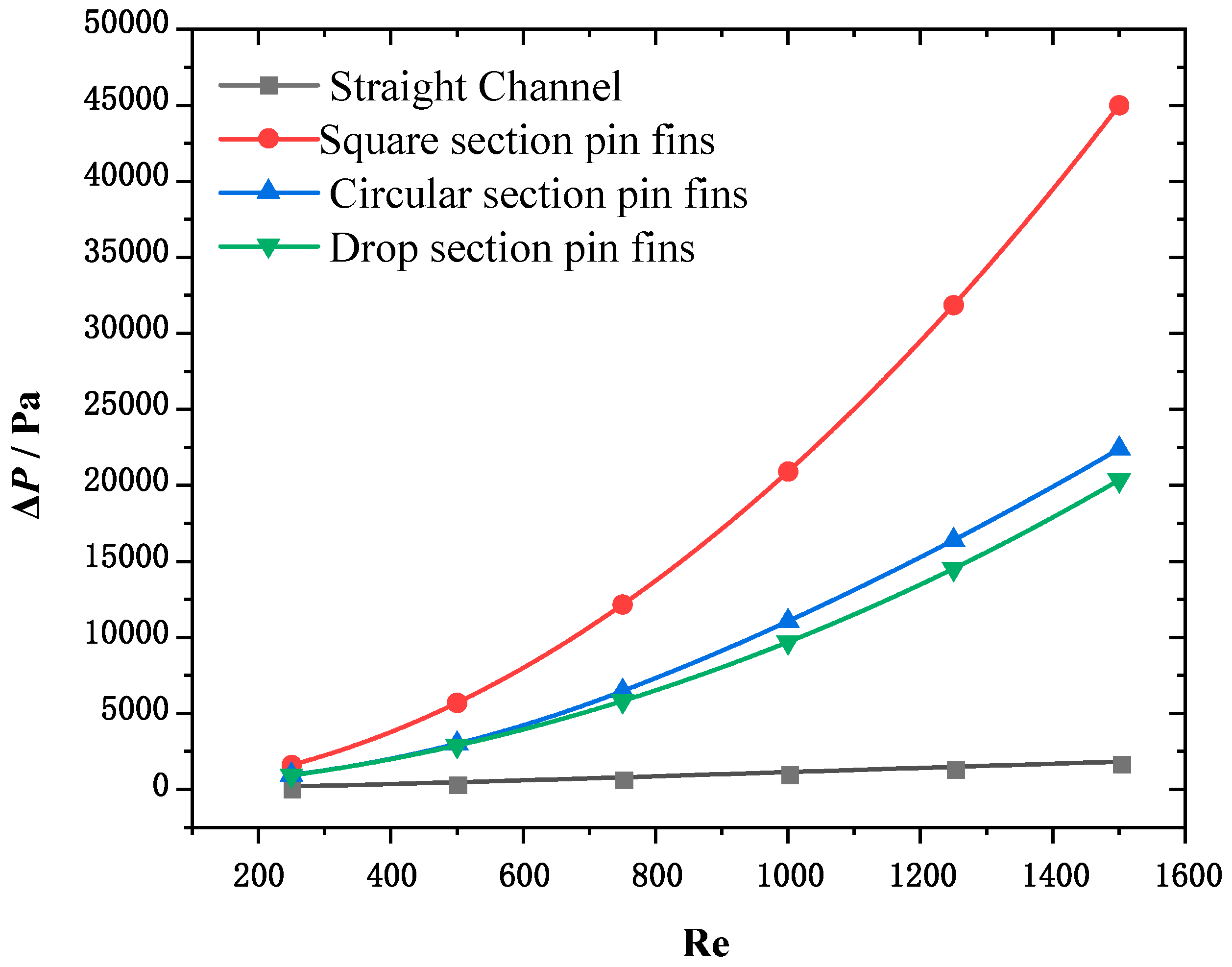

2.3.3. Inlet and Outlet Pressure Drop

2.3.4. Composite Performance Indicators

2.3.5. Power Dispersion

3. Results and Discussion

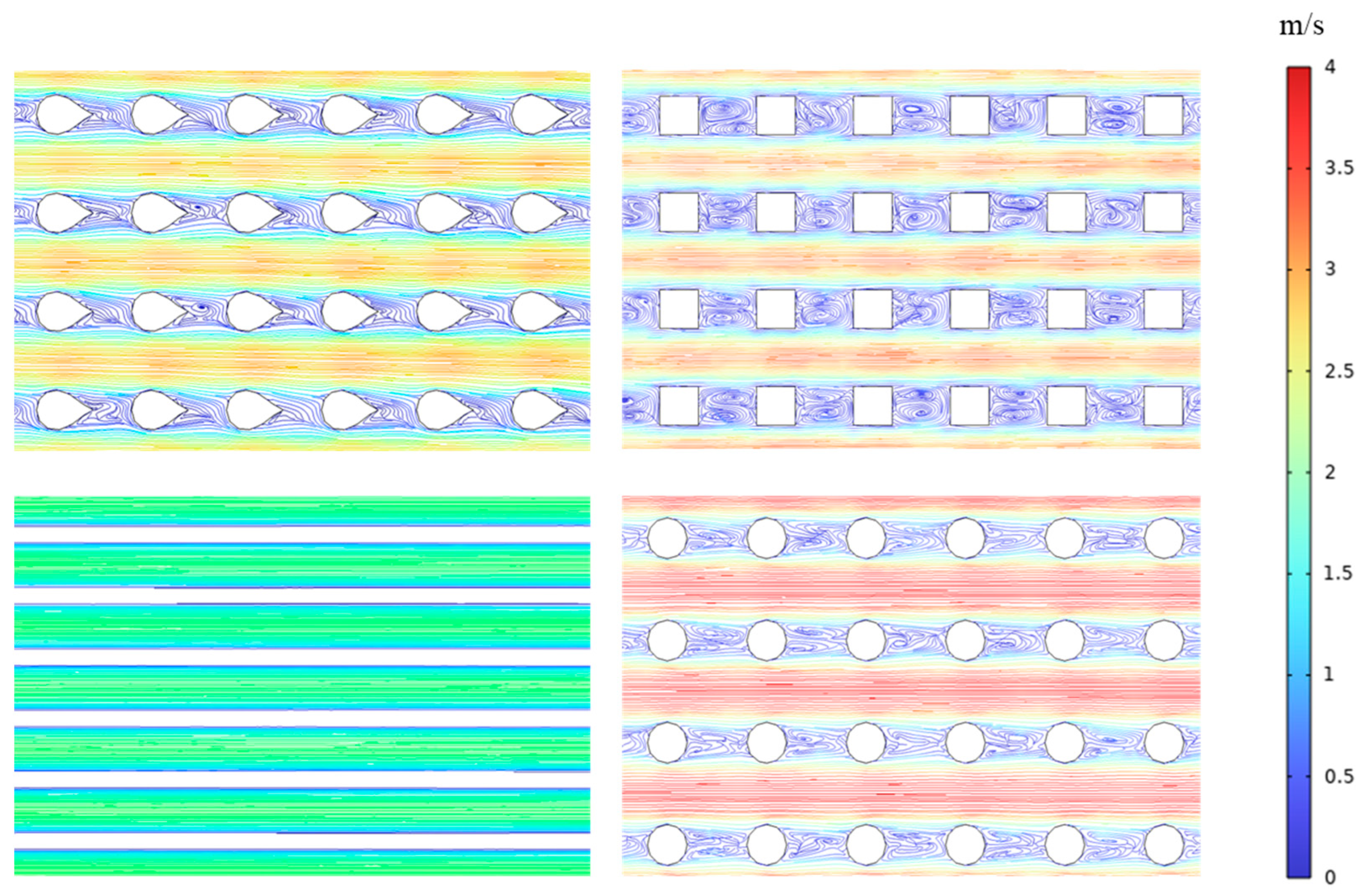

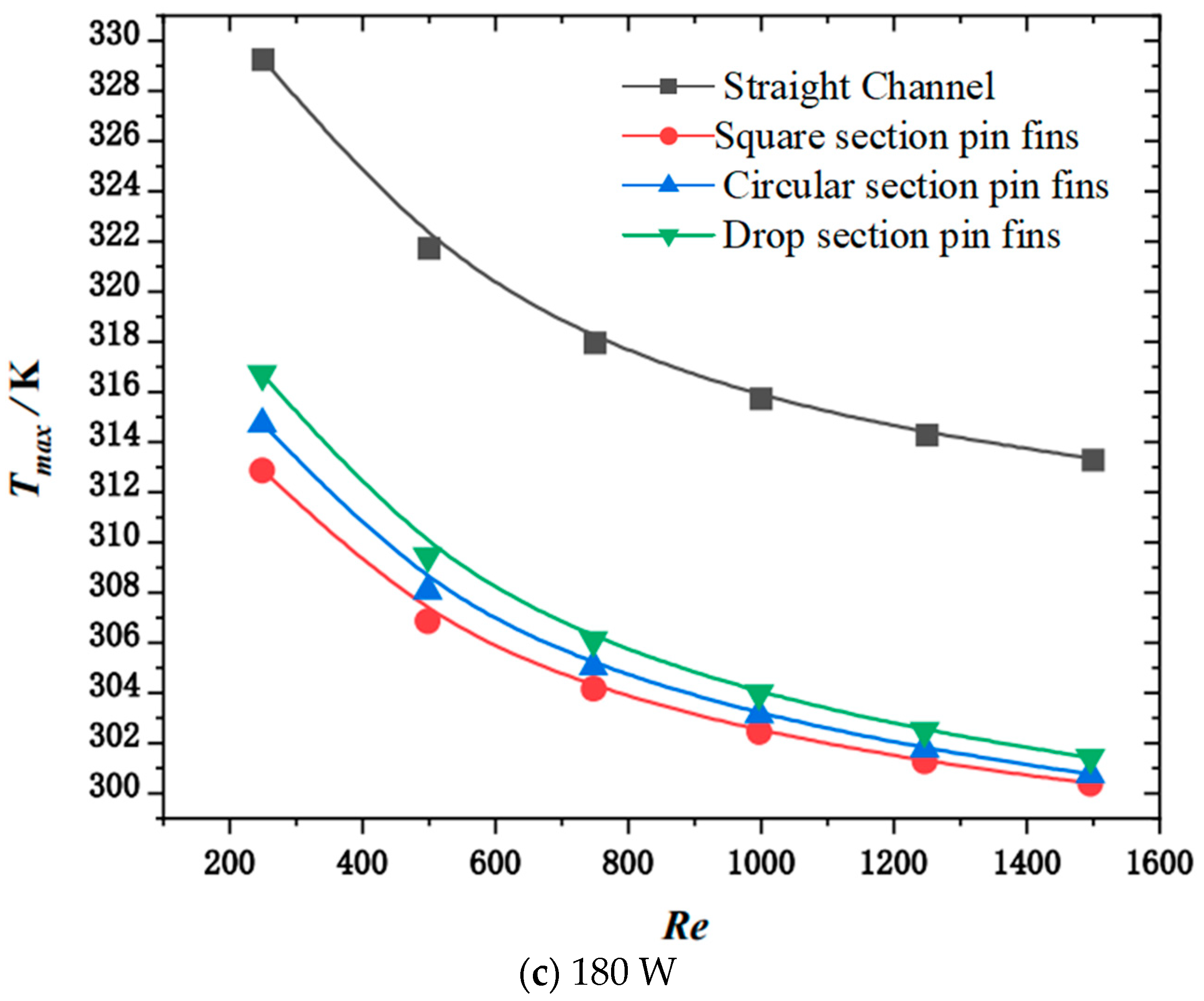

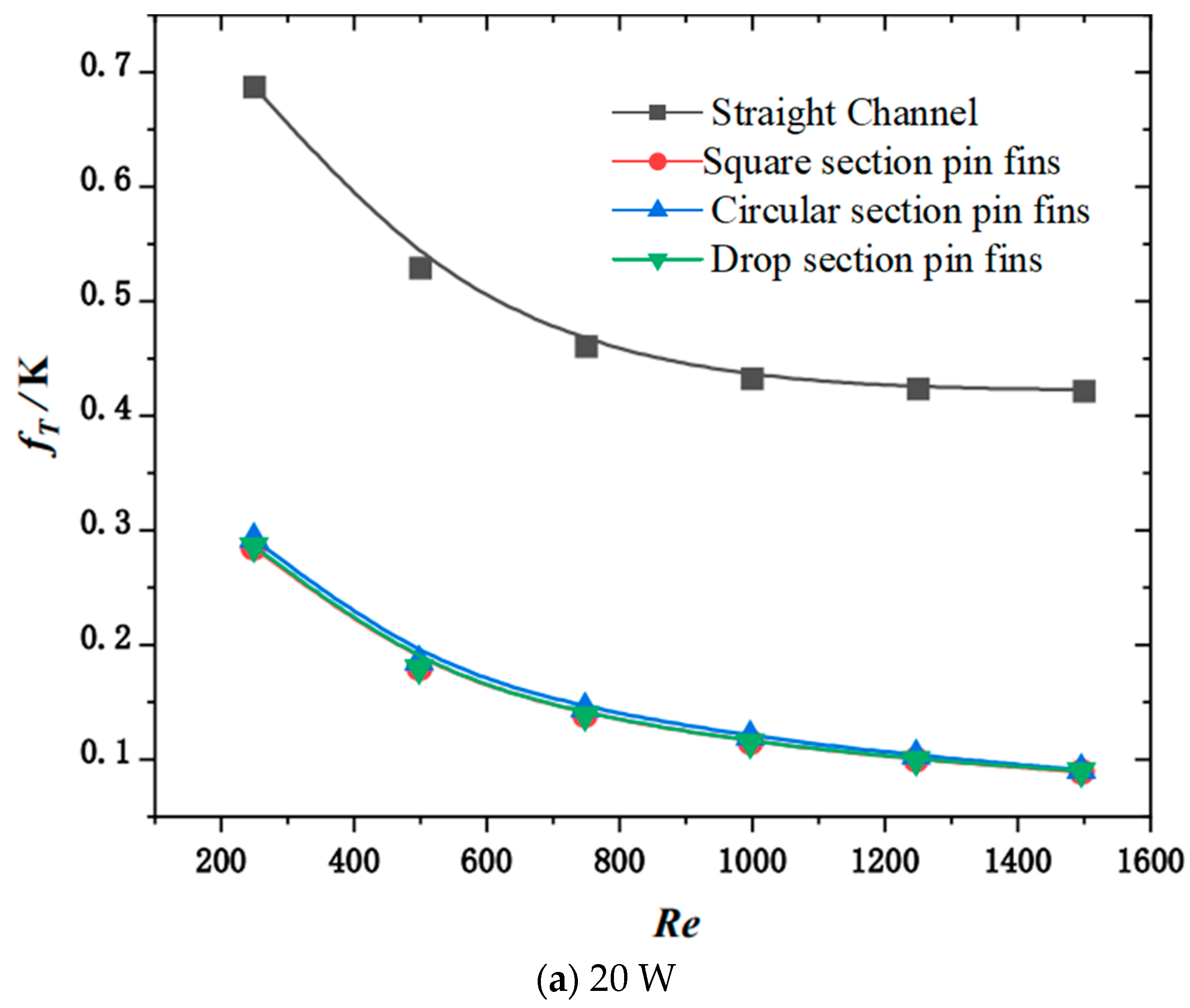

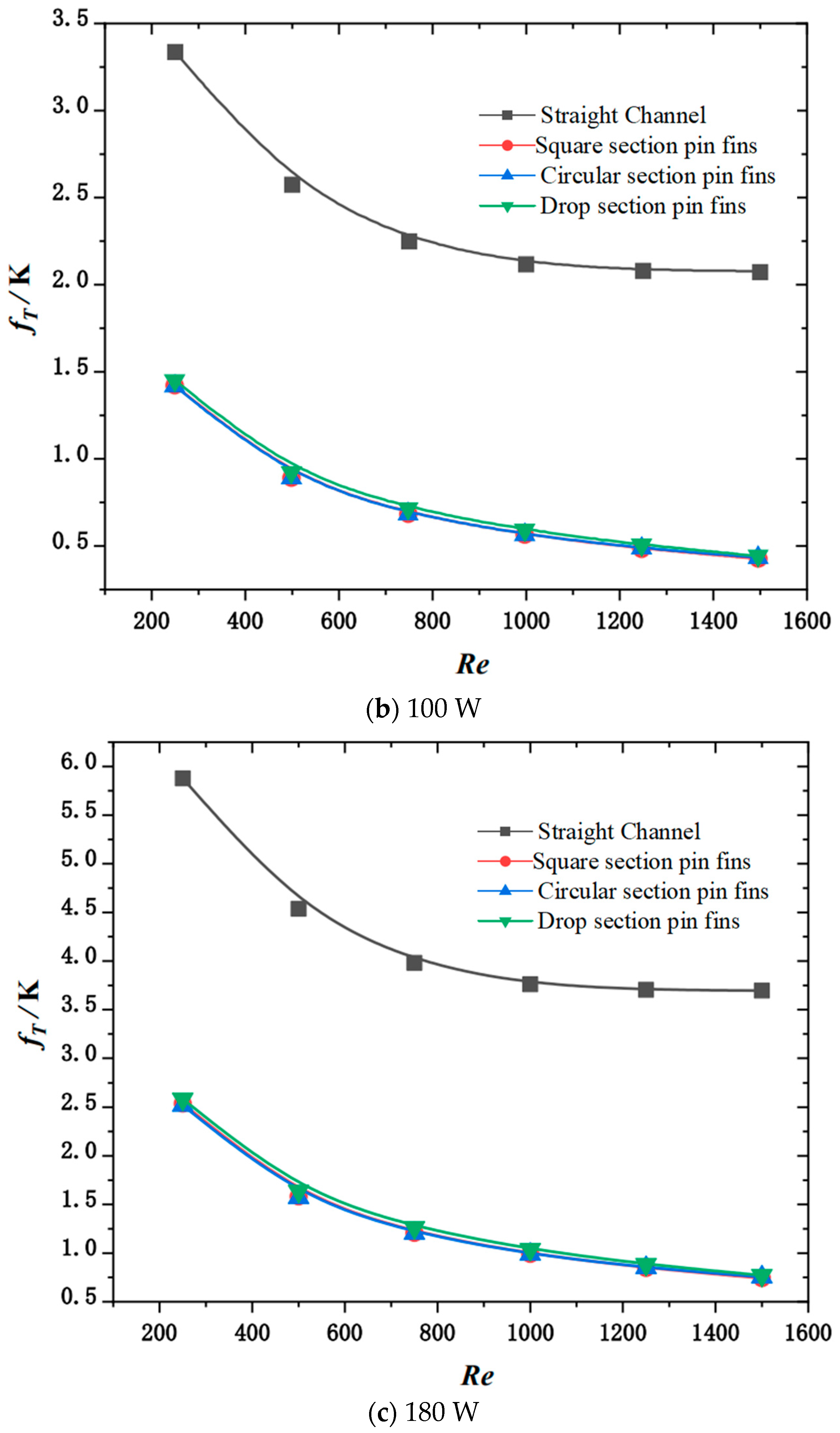

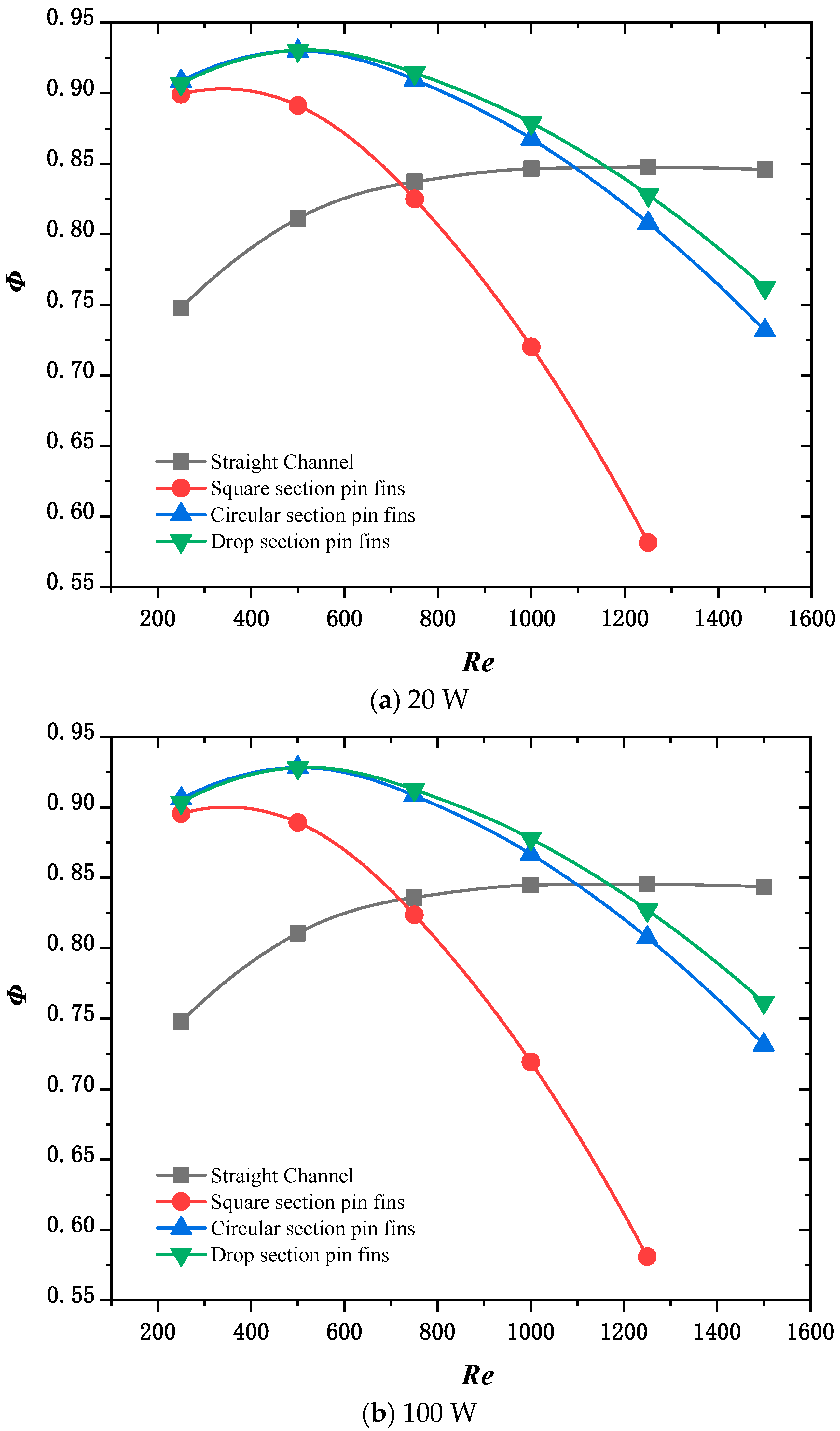

3.1. Variation in Heat Sink Suitability with Thermal Load under Uniform Heat Source

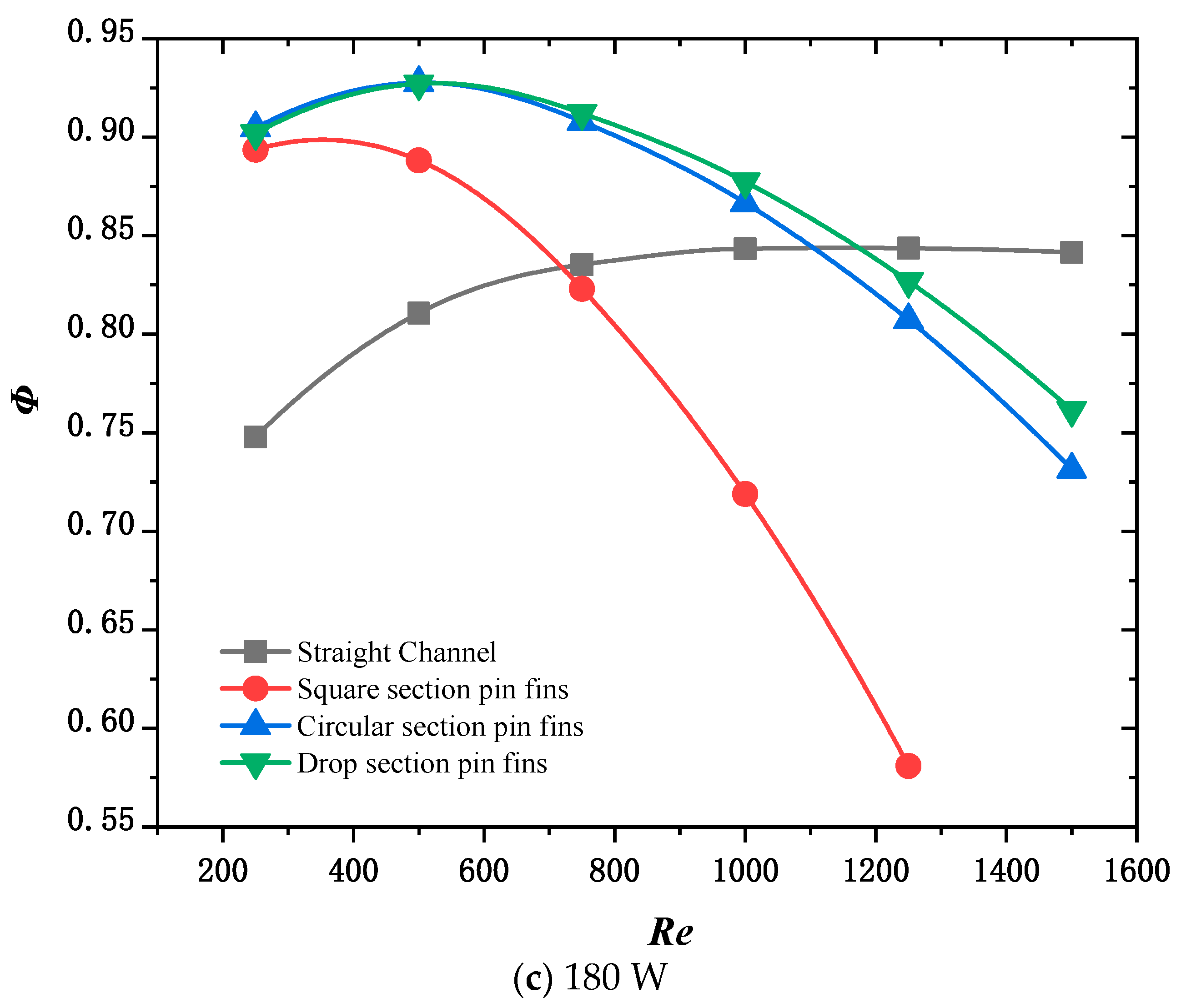

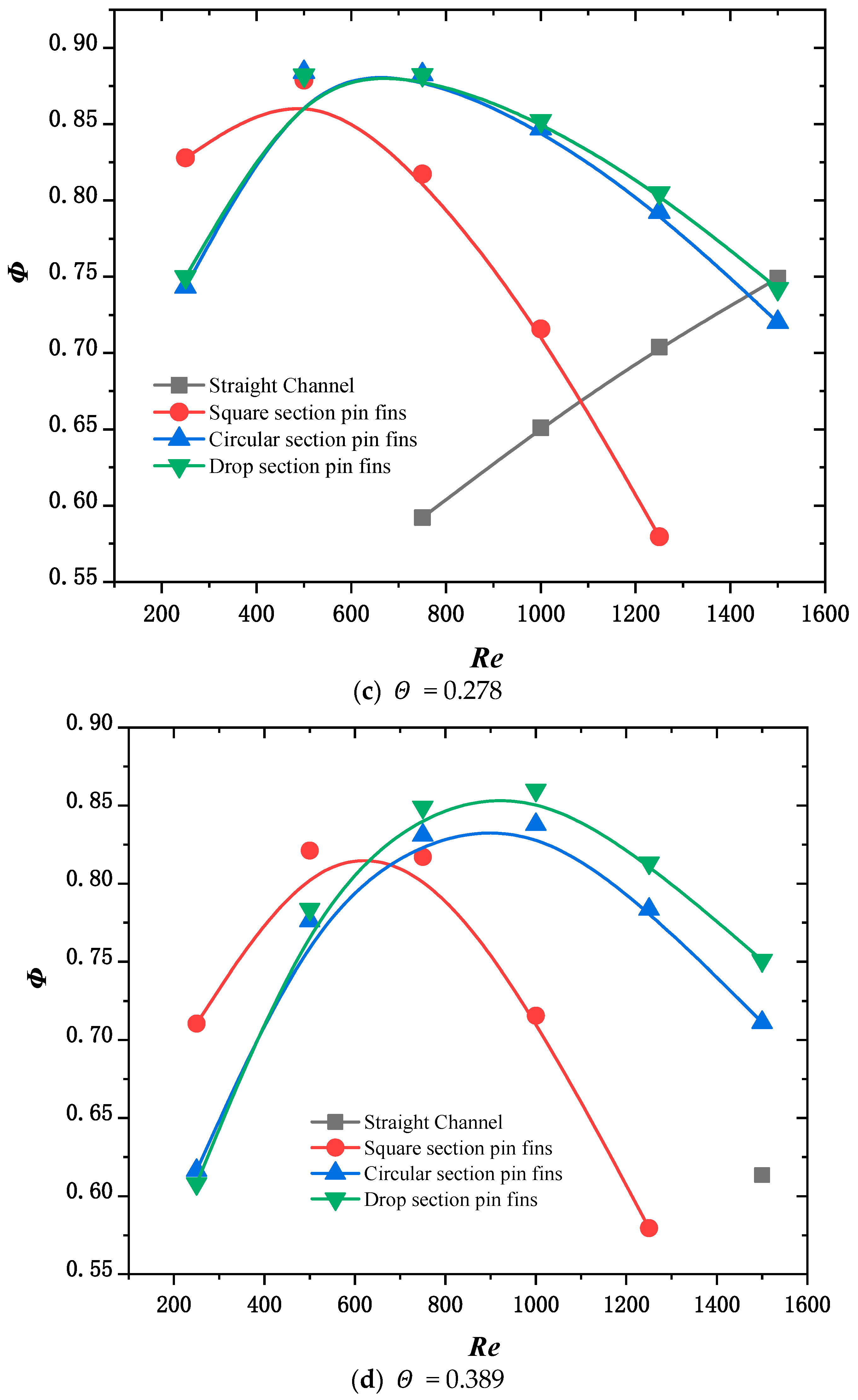

3.2. Variation in Heat Sink Suitability with Thermal Load under Non-Uniform Heat Source

4. Conclusions

- (1)

- For equal characteristic lengths and volumes, the heat sink of the rectangular channel has the weakest cooling capacity and the least pressure drop; in the structure of the heat sink of the pin fin, the square section fin has the strongest cooling capacity and the largest pressure drop, while the drop section fin has the weakest cooling capacity and the least pressure drop.

- (2)

- The composite performance index function value of the heat sink first increases and then decreases with the Reynolds number, and there exists an optimal inlet Reynolds number to maximize the composite performance index. Further, as the thermal load of the heat source increases, the demand of the heat source for the cooling capacity of the channel increases and the optimal inlet Reynolds number corresponding to the maximum composite performance index also increases.

- (3)

- The suitability laws for different internal fin shapes and inlet Reynolds numbers under different heat source loads were analyzed, the optimal design was obtained by comparing multiple schemes, and a new optimization design method for chip heat dissipation was established.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Moore, G.E. Cramming more components onto integrated circuits. Electronics 1965, 38, 114–117. [Google Scholar] [CrossRef]

- Murshed, S.M.S.; de Castro, C.A.N. A critical review of traditional and emerging techniques and fluids for electronics cooling. Renew. Sustain. Energy Rev. 2017, 78, 821–833. [Google Scholar] [CrossRef]

- He, S.; Zhou, P.; Liu, W.; Liu, Z. Experimental study on thermal performance of loop heat pipe with a composite-material evaporator for cooling of electronics. Appl. Therm. Eng. 2020, 168, 114897. [Google Scholar] [CrossRef]

- Nan, G.; Xie, Z.; Guan, X.; Ji, X.; Lin, D. Constructal design for the layout of multi-chip module based on thermal-flow-stress coupling calculation. Microelectron. Reliab. 2021, 127, 114417. [Google Scholar] [CrossRef]

- Xiao, H.; Liu, Z.; Liu, W. Turbulent heat transfer enhancement in the mini-channel by enhancing the original flow pattern with v-ribs. Int. J. Heat Mass Transf. 2020, 163, 120378. [Google Scholar] [CrossRef]

- Yang, M.; Cao, B.Y. Advances of capillary filling of Newtonian fluids in micro- and nanochannels. Chin. Sci. Bull. 2016, 61, 1574–1584. [Google Scholar] [CrossRef]

- Cao, B.Y.; Chen, M.; Guo, Z.Y. Effect of surface roughness on gas flow in microchannels by molecular dynamics simulation. Int. J. Eng. Sci. 2006, 44, 927–937. [Google Scholar] [CrossRef]

- Cheng, X.; Wu, H. Improved flow boiling performance in high-aspect-ratio interconnected microchannels. Int. J. Heat Mass Transf. 2021, 165, 120627. [Google Scholar] [CrossRef]

- Li, F.; Ma, Q.; Xin, G.; Zhang, J.; Wang, X. Heat transfer and flow characteristics of microchannels with solid and porous ribs. Appl. Therm. Eng. 2020, 178, 115639. [Google Scholar] [CrossRef]

- Zhang, C.; Shen, C.; Chen, Y. Experimental study on flow condensation of mixture in a hydrophobic microchannel. Int. J. Heat Mass Transf. 2017, 104, 1135–1144. [Google Scholar] [CrossRef]

- van Erp, R.; Soleimanzadeh, R.; Nela, L.; Kampitsis, G.; Matioli, E. Co-designing electronics with microfluidics for more sustainable cooling. Nature 2020, 585, 211–216. [Google Scholar] [CrossRef] [PubMed]

- Li, W.; Xie, Z.; Xi, K.; Xia, S.; Ge, Y. Constructal optimization of rectangular microchannel heat sink with porous medium for entropy generation minimization. Entropy 2021, 23, 1528. [Google Scholar] [CrossRef] [PubMed]

- Chen, L.G.; Wang, L.; Xie, Z.H.; Sun, F.R. Constructal studies on hexagonal microchannel heat sinks based on multi-physics field coupling calculations. Sci. Sin. Technol. 2019, 49, 741–752. [Google Scholar] [CrossRef]

- Salvi, S.S.; Jain, A. A Review of Recent Research on Heat Transfer in Three-Dimensional Integrated Circuits (3D ICs). IEEE Trans. Compon. Packag. Manuf. Technol. 2021, 11, 802–821. [Google Scholar] [CrossRef]

- Bar-Cohen, A.; Maurer, J.J.; Felbinger, J.G. DARPA’s Intra/Interchip Enhanced Cooling (ICECool) Program. In Proceedings of the International Conference on Compound Semiconductor Manufacturing Technology, New Orleans, FL, USA, 13–16 May 2013. [Google Scholar]

- Brunschwiler, T.; Michel, B.; Rothuizen, H.; Kloter, U.; Wunderle, B.; Oppermann, H.; Reichl, H. Interlayer cooling potential in vertically integrated packages. Microsyst. Technol. 2009, 15, 57–74. [Google Scholar] [CrossRef]

- Ding, B.; Zhang, Z.H.; Gong, L.; Zhu, C.Y.; Xu, M.H. Coupling management optimization of temperature and thermal stress inside 3D-IC with multi-cores and various power density. Int. Commun. Heat Mass Transf. 2021, 120, 105021. [Google Scholar] [CrossRef]

- Sridhar, A.; Vincenzi, A.; Ruggiero, M.; Brunschwiler, T.; Atienza, D. 3D-ICE: Fast compact transient thermal modeling for 3D ICs with inter-tier liquid cooling. In Proceedings of the 2010 IEEE/ACM International Conference on Computer-Aided Design (ICCAD), San Jose, CA, USA, 7–11 November 2010. [Google Scholar] [CrossRef]

- Zhang, X.; Han, X.; Sarvey, T.E.; Green, C.E.; Kottke, P.A.; Fedorov, A.G.; Joshi, Y.; Bakir, M.S. Three-Dimensional integrated circuit with embedded microfluidic cooling: Technology, thermal performance, and electrical implications. J. Electron. Package 2016, 138, 010910. [Google Scholar] [CrossRef]

- Hu, Y.; Joshi, Y. Single-Phase microfluidic cooling of 2.5D-SICs for heterogeneous integration. IEEE Trans. Compon. Packag. Manuf. Technol. 2020, 10, 1499–1506. [Google Scholar] [CrossRef]

- Feng, H.; You, J.; Chen, L.; Ge, Y.; Xia, S. Constructal design of a non-uniform heat generating disc based on entropy generation minimization. Eur. Phys. J. Plus. 2020, 135, 257. [Google Scholar] [CrossRef]

- Chen, C.; You, J.; Feng, H.; Chen, L. A multi-objective study on the constructal design of non-uniform heat generating disc cooled by radial-and dendritic-pattern cooling channels. Sci. China Technol. Sci. 2021, 64, 729–744. [Google Scholar] [CrossRef]

- Joshi, S.N.; Yu, Z.; Sennoun, H.; Hampshire, J.; Dede, E.M. Single-phase cooling performance of a topology optimized and additivelymanufactured multi-pass branching microchannel heat sink. In Proceedings of the 2020 19th IEEE Intersociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems (ITherm), Orlando, FL, USA, 26–29 May 2020. [Google Scholar]

- Ozguc, S.; Teague, T.F.; Pan, L.; Weibel, J.A. Experimental study of topology optimized, additively manufactured microchannel heat sinks designed using a homogenization approach. Int. J. Heat Mass Transf. 2023, 209, 124108. [Google Scholar] [CrossRef]

- Zhang, J.; Xie, Z.; Lu, Z.; Li, P.; Xi, K. Research on intelligent distribution of liquid flow rate in embedded channels for cooling 3D Multi-Core Chips. Micromachines 2022, 13, 918. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Guo, W.Y.; Xie, Z.H. Optimization of fin layout in liquid-cooled microchannels for multi-core chips. Case Stud. Therm. Eng. 2022, 41, 102615. [Google Scholar] [CrossRef]

- Ansari, D.; Kim, K.Y. Hotspot thermal management using a microchannel-pinfin hybrid heat sink. Int. J. Therm. Sci. 2018, 134, 27–39. [Google Scholar] [CrossRef]

- Lee, Y.J.; Lee, P.S.; Chou, S.K. Hotspot mitigating with obliquely finned microchannel heat sink—An experimental study. IEEE Trans. Compon. Packag. Manuf. Technol. 2013, 3, 1332–1341. [Google Scholar] [CrossRef]

- Rajalingam, A.; Chakraborty, S. Estimation of the thermohydraulic performance of a microchannel heat sink with gradual and sudden variation of the flow passage. Int. J. Heat Mass Transf. 2022, 190, 122776. [Google Scholar] [CrossRef]

- Fan, J.F.; Ding, W.K.; Zhang, J.F.; He, Y.L.; Tao, W.Q. A performance evaluation plot of enhanced heat transfer techniques oriented for energy-saving. Int. J. Heat Mass Transf. 2009, 52, 33–44. [Google Scholar] [CrossRef]

- Peles, Y.; Koşar, A.; Mishra, C.; Kuo, C.J.; Schneider, B. Forced convective heat transfer across a pin fin micro heat sink. Int. J. Heat Mass Transf. 2005, 48, 3615–3627. [Google Scholar] [CrossRef]

- Cheng, X.T.; Xu, X.H.; Liang, X.G. Homogenization of temperature field and temperature gradient field. Sci. China Ser. E: Technol. Sci. 2009, 52, 2937–2942. [Google Scholar] [CrossRef]

| Geometry | Expression |

|---|---|

| 15,000 µm | |

| 13,000 µm | |

| 1000 µm | |

| 200 µm | |

| 200 µm | |

| 25 | |

| 29 | |

| 300 µm | |

| 26 | |

| 25 | |

| 37 | |

| 25 | |

| 31 |

| Material | ρ [Kg·m−3] | cp [J·Kg−1·K−1] | k [W·m−1·K−1] | μ [Pa·s] |

|---|---|---|---|---|

| Silicon | 2330 | 712 | 148 | - |

| Deionized water | 998.2 | 4182 | 0.6 | 0.001003 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, J.; Wu, J.; Xie, Z.; Lu, Z.; Guan, X.; Ge, Y. Suitability of Embedded Liquid Cooling and Heat Generation for Chips. Micromachines 2024, 15, 9. https://doi.org/10.3390/mi15010009

Zhang J, Wu J, Xie Z, Lu Z, Guan X, Ge Y. Suitability of Embedded Liquid Cooling and Heat Generation for Chips. Micromachines. 2024; 15(1):9. https://doi.org/10.3390/mi15010009

Chicago/Turabian StyleZhang, Jian, Jiechang Wu, Zhihui Xie, Zhuoqun Lu, Xiaonan Guan, and Yanlin Ge. 2024. "Suitability of Embedded Liquid Cooling and Heat Generation for Chips" Micromachines 15, no. 1: 9. https://doi.org/10.3390/mi15010009

APA StyleZhang, J., Wu, J., Xie, Z., Lu, Z., Guan, X., & Ge, Y. (2024). Suitability of Embedded Liquid Cooling and Heat Generation for Chips. Micromachines, 15(1), 9. https://doi.org/10.3390/mi15010009