Simulation and Experimental Study of a Novel Negative-Pressure Flapper–Nozzle Mechanism

Abstract

:1. Introduction

2. System Design and Modeling

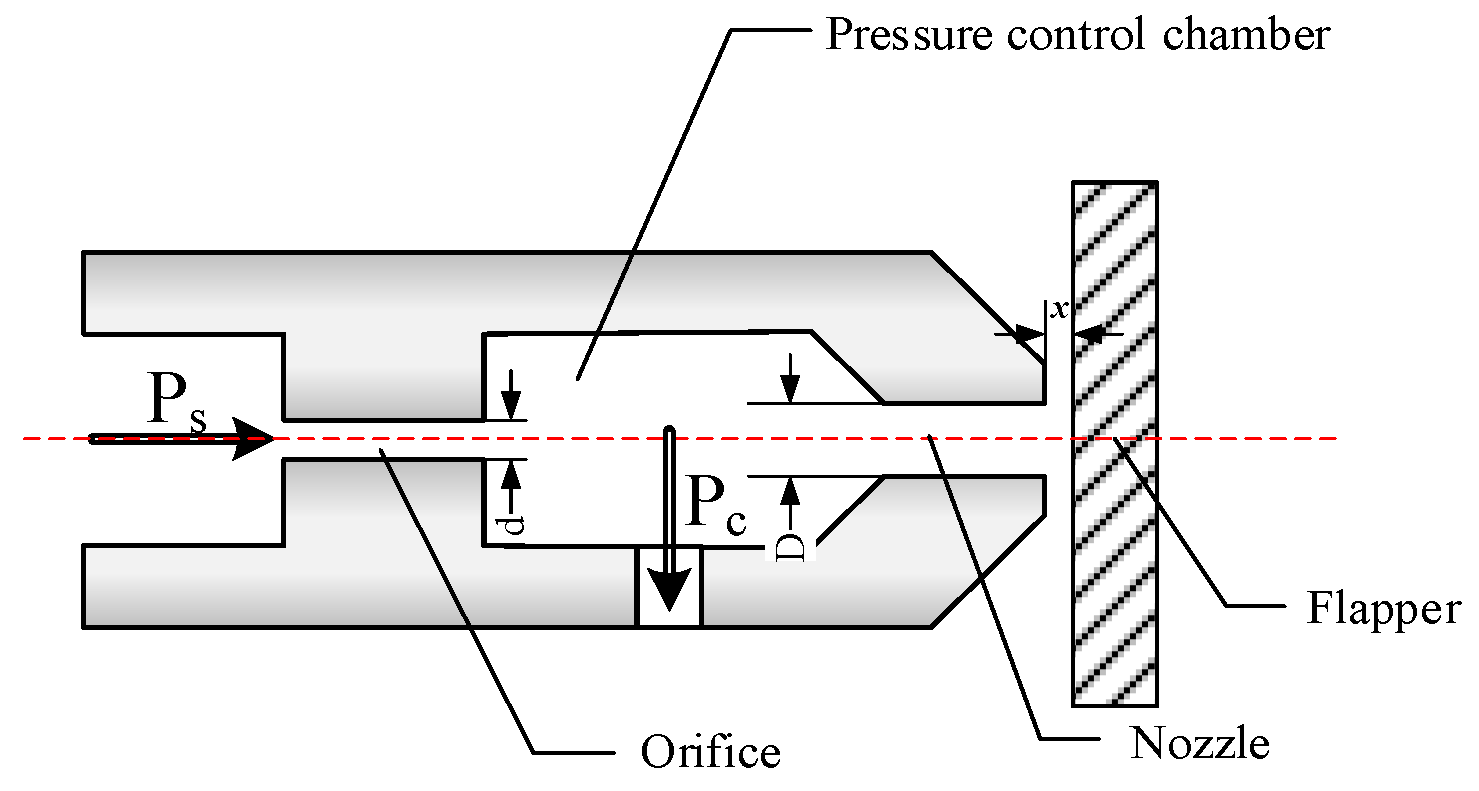

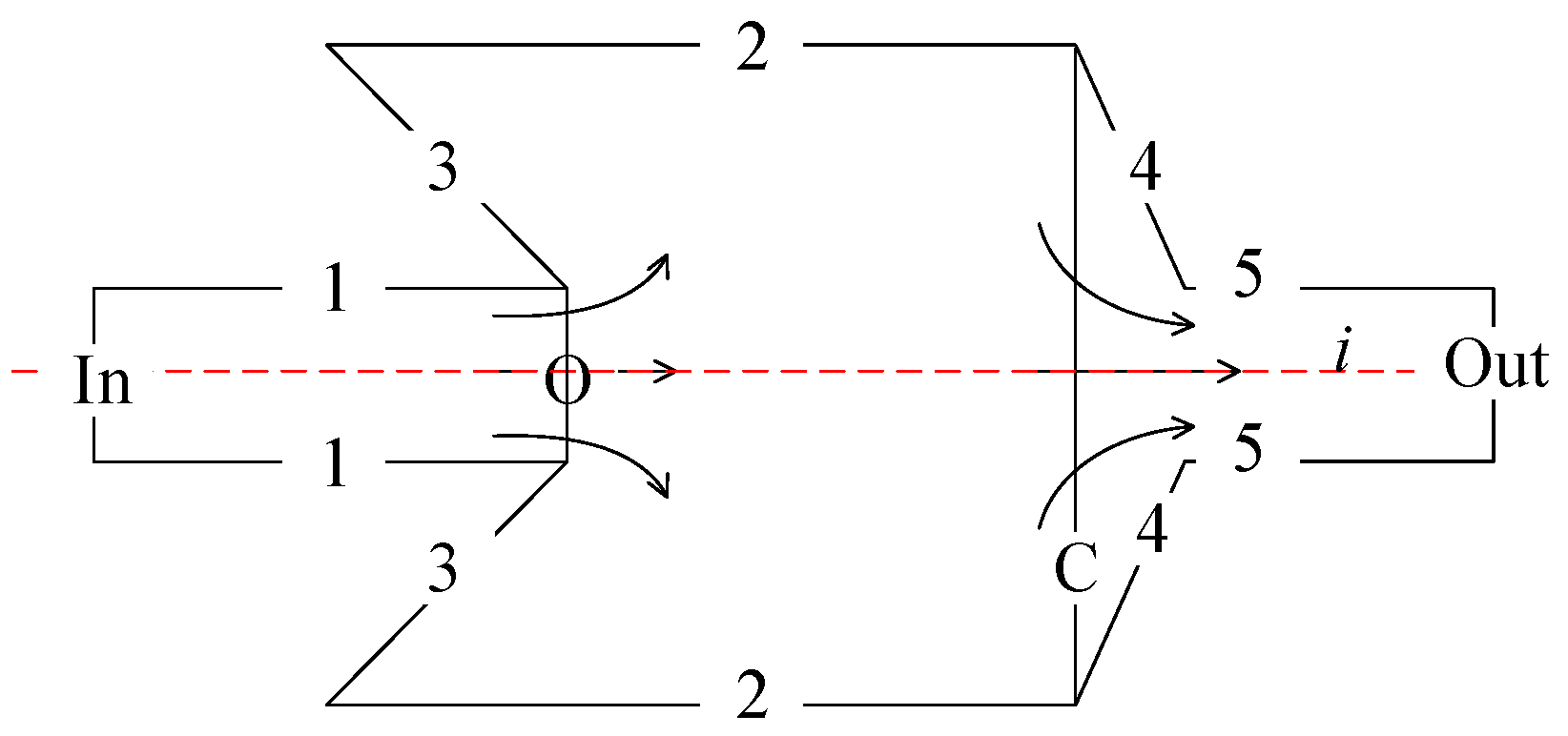

2.1. Flapper–Nozzle Mechanism Operating Principle

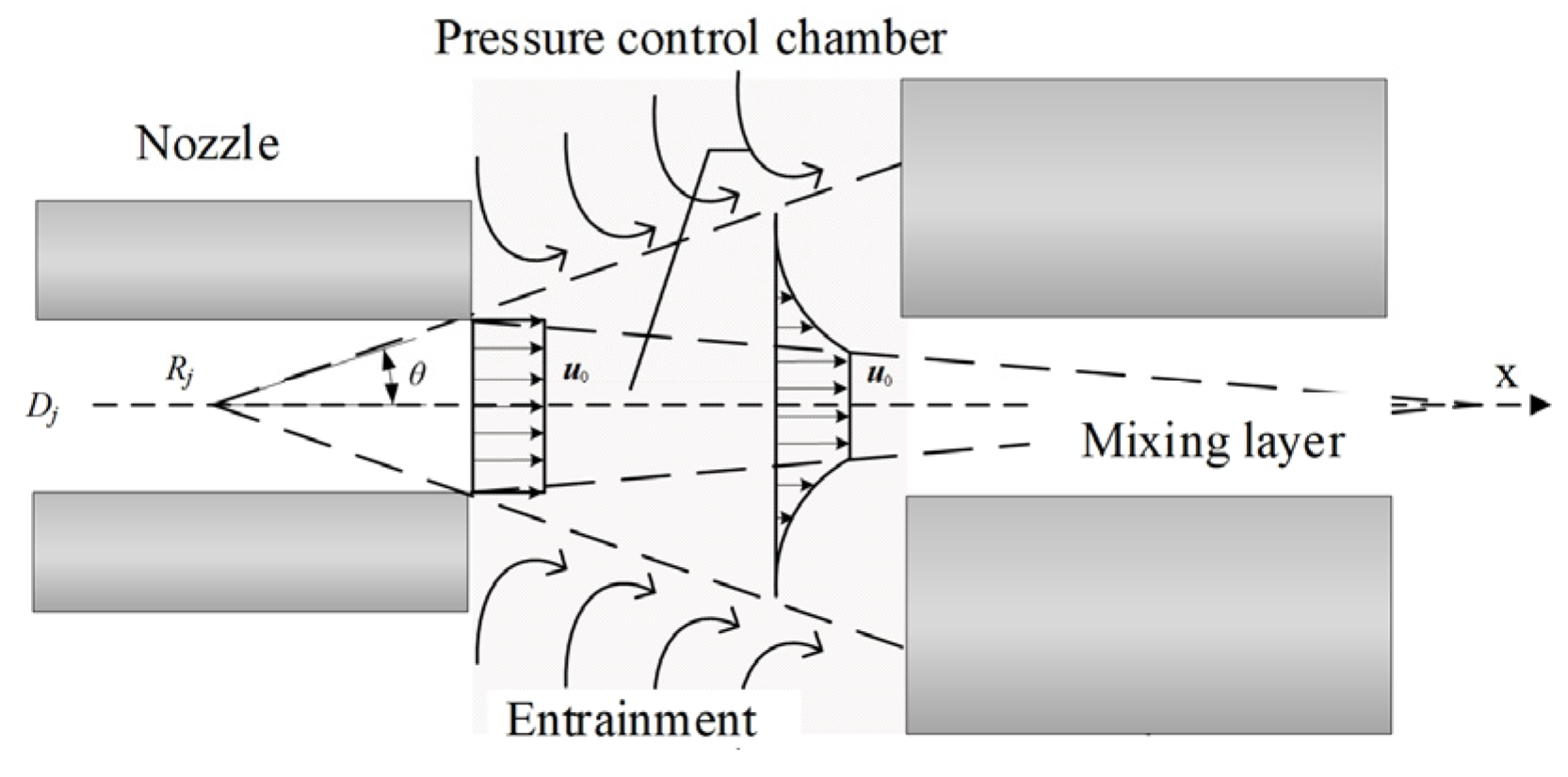

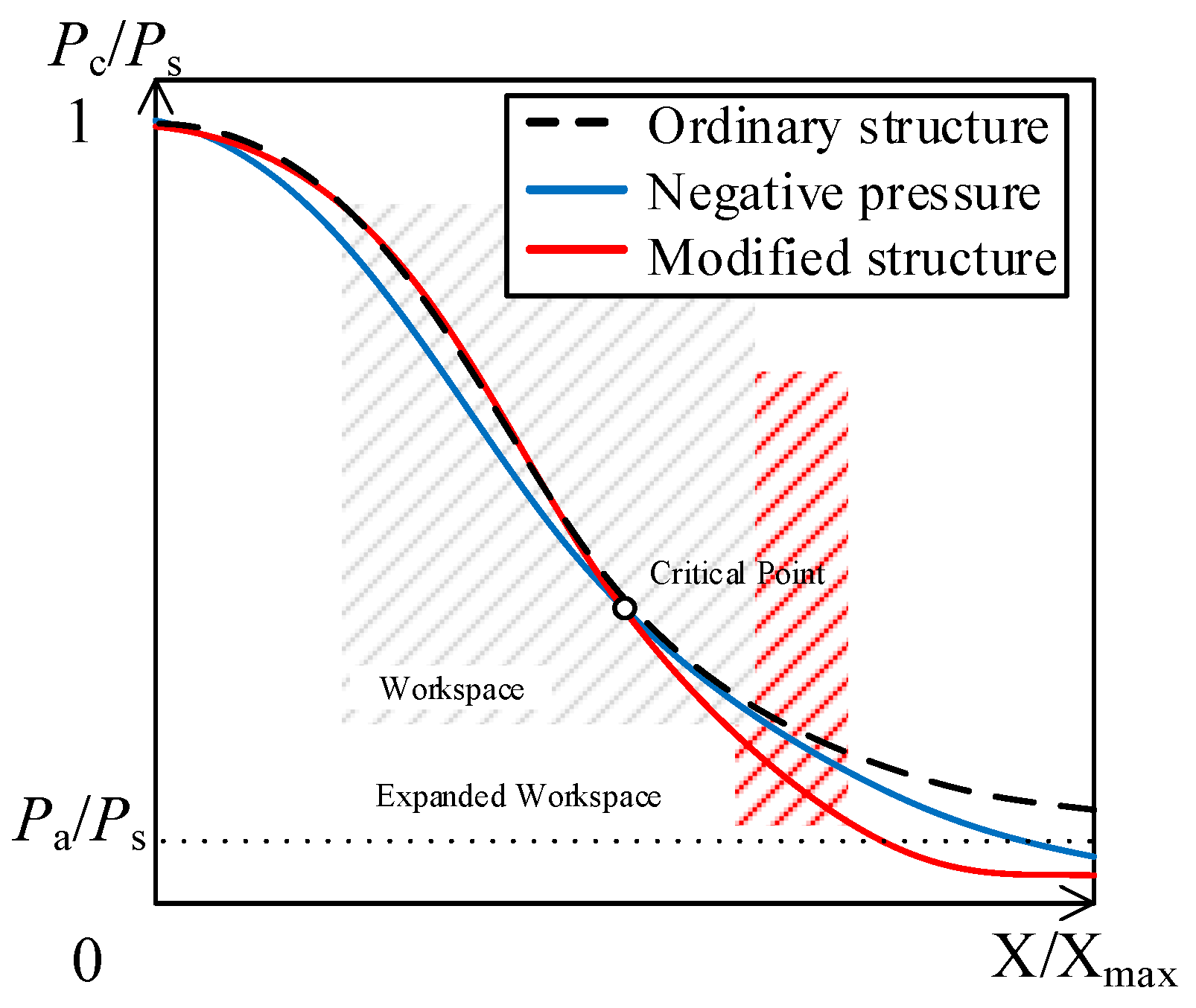

2.2. Working Principle of the Negative-Pressure Flapper–Nozzle Mechanism

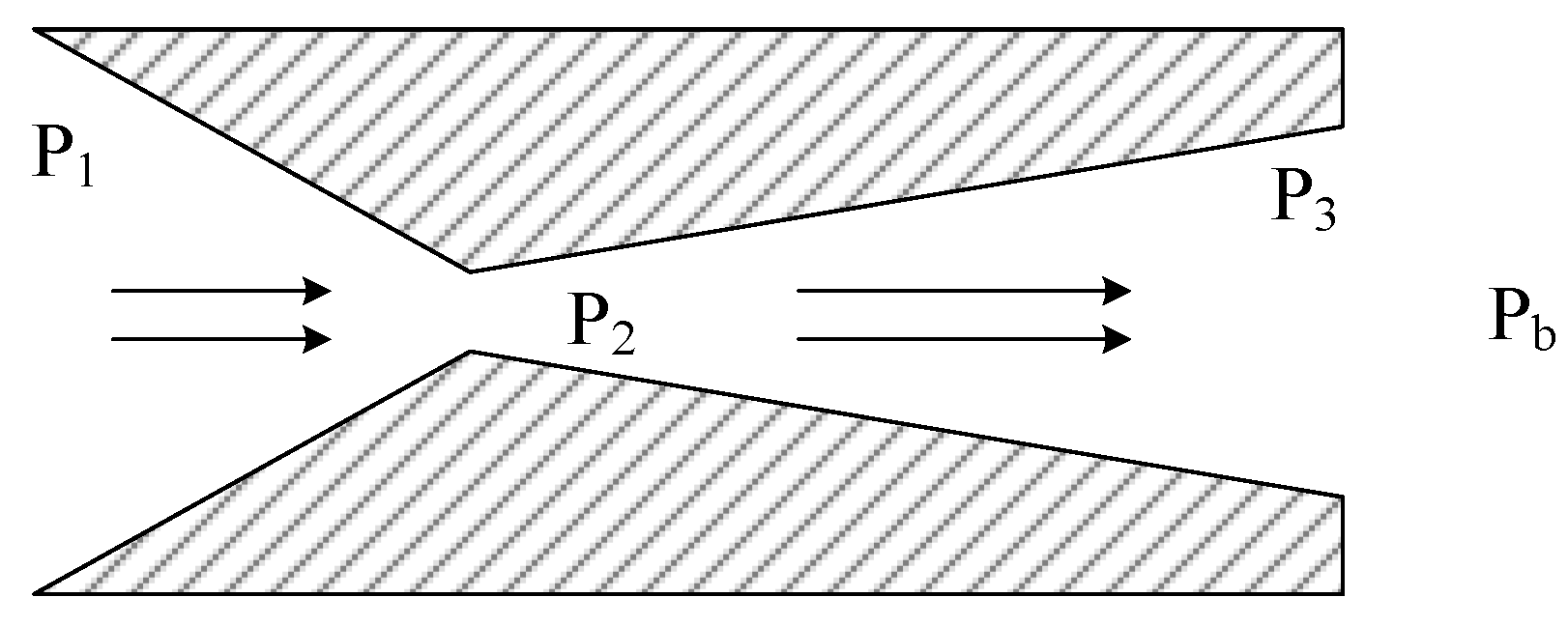

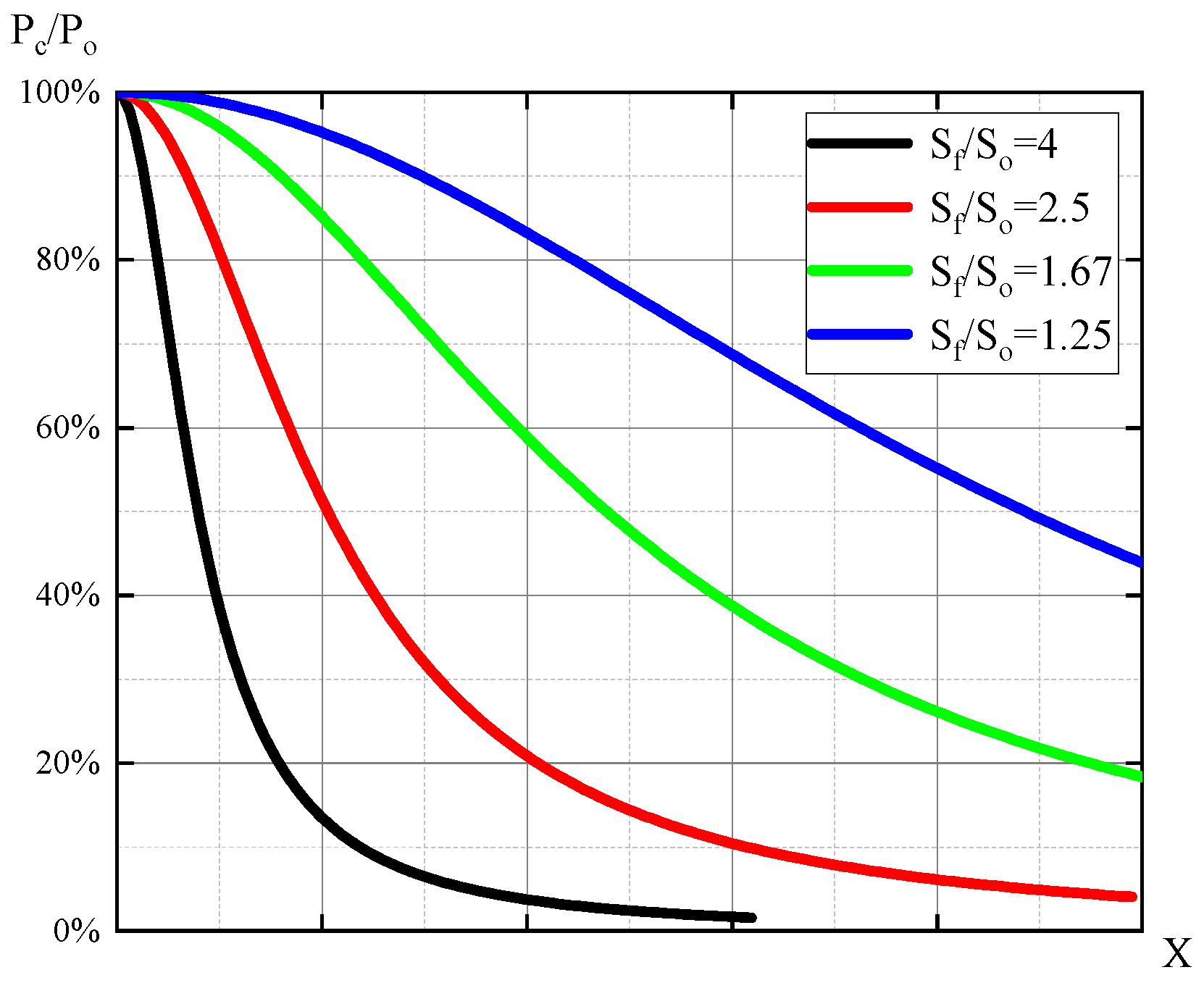

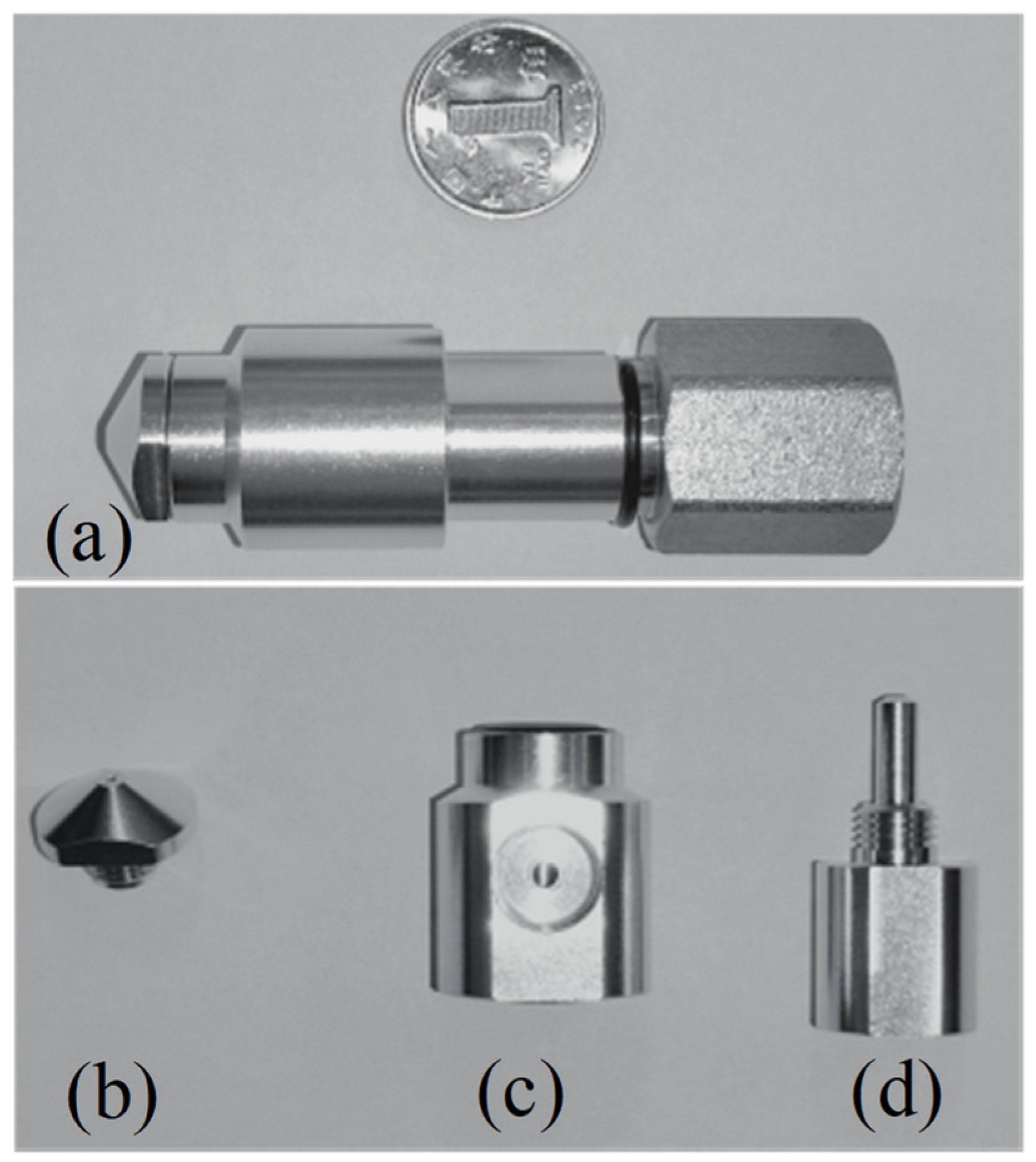

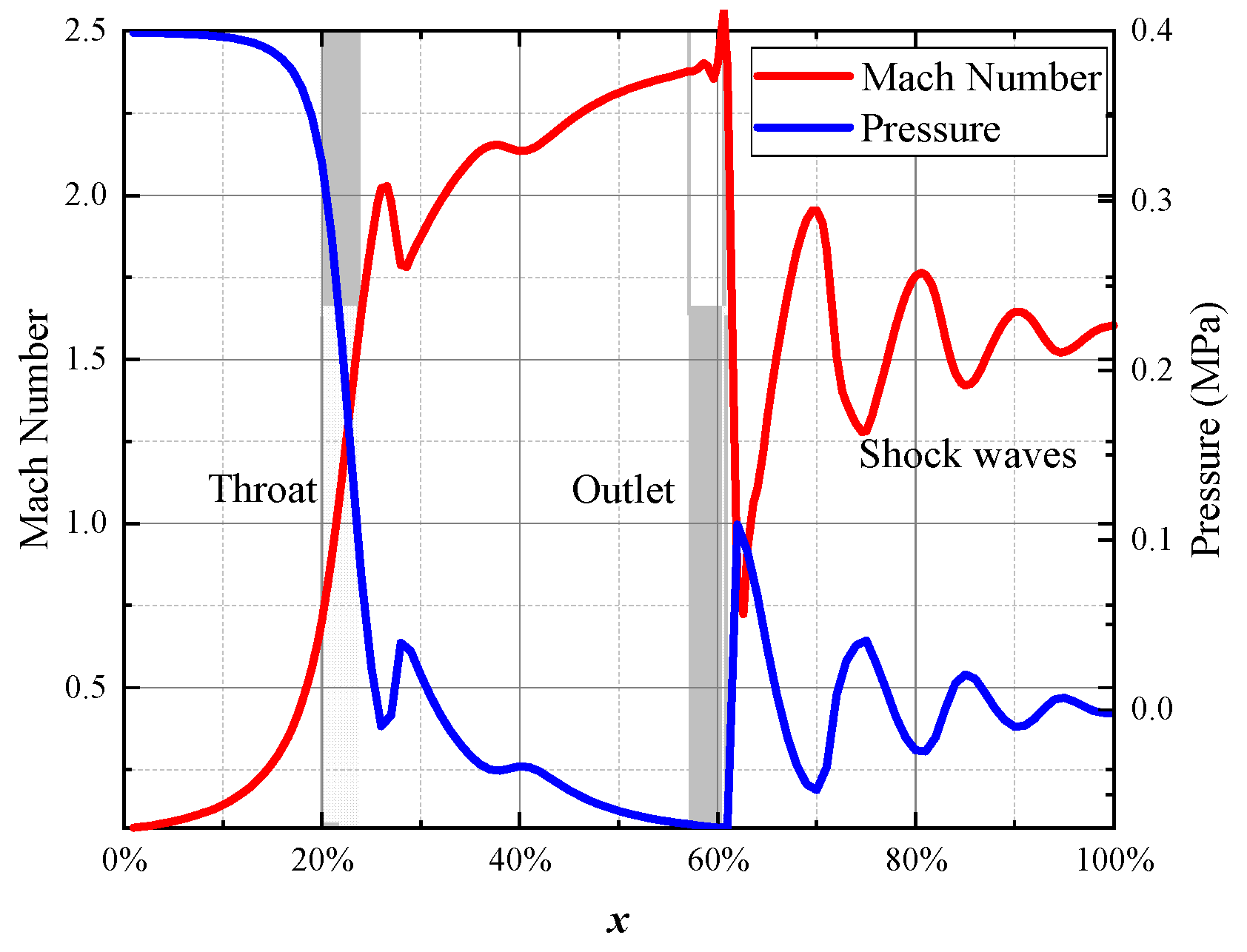

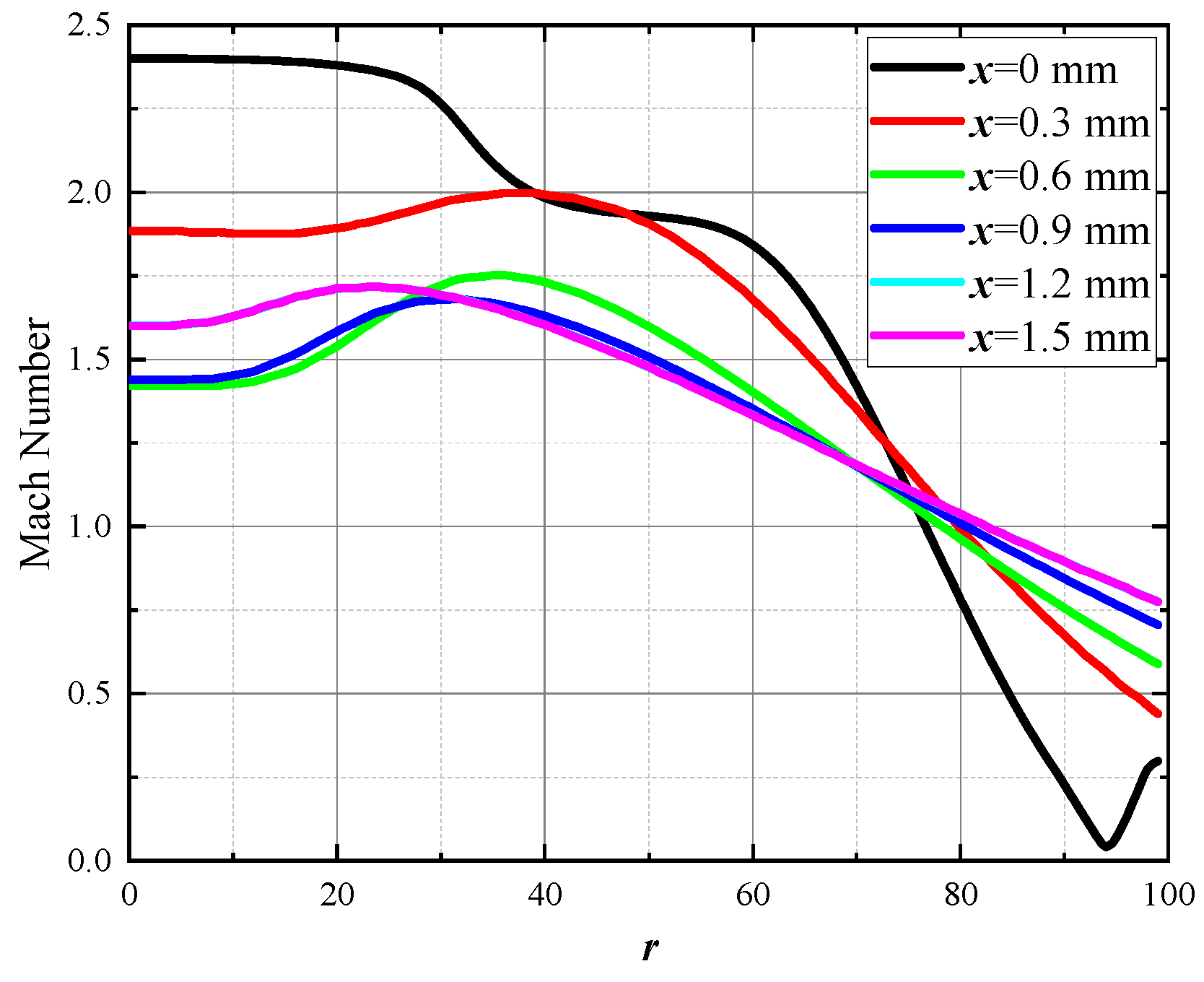

2.3. Convergent–Divergent Throttle Nozzle

2.4. Mechanism Modeling and Selection

3. Simulation Methods and Experimental Preparation

3.1. Governing Equations

3.2. Turbulence Models (Two-Equation Model)

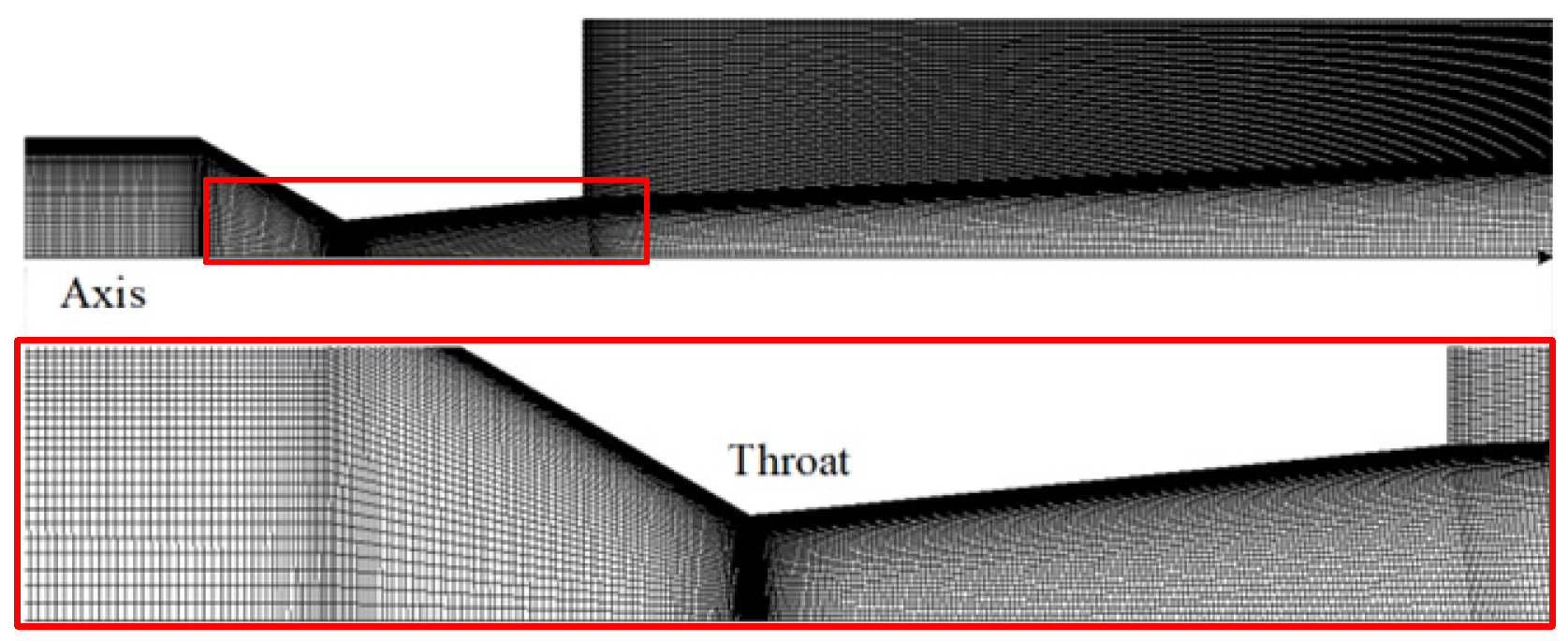

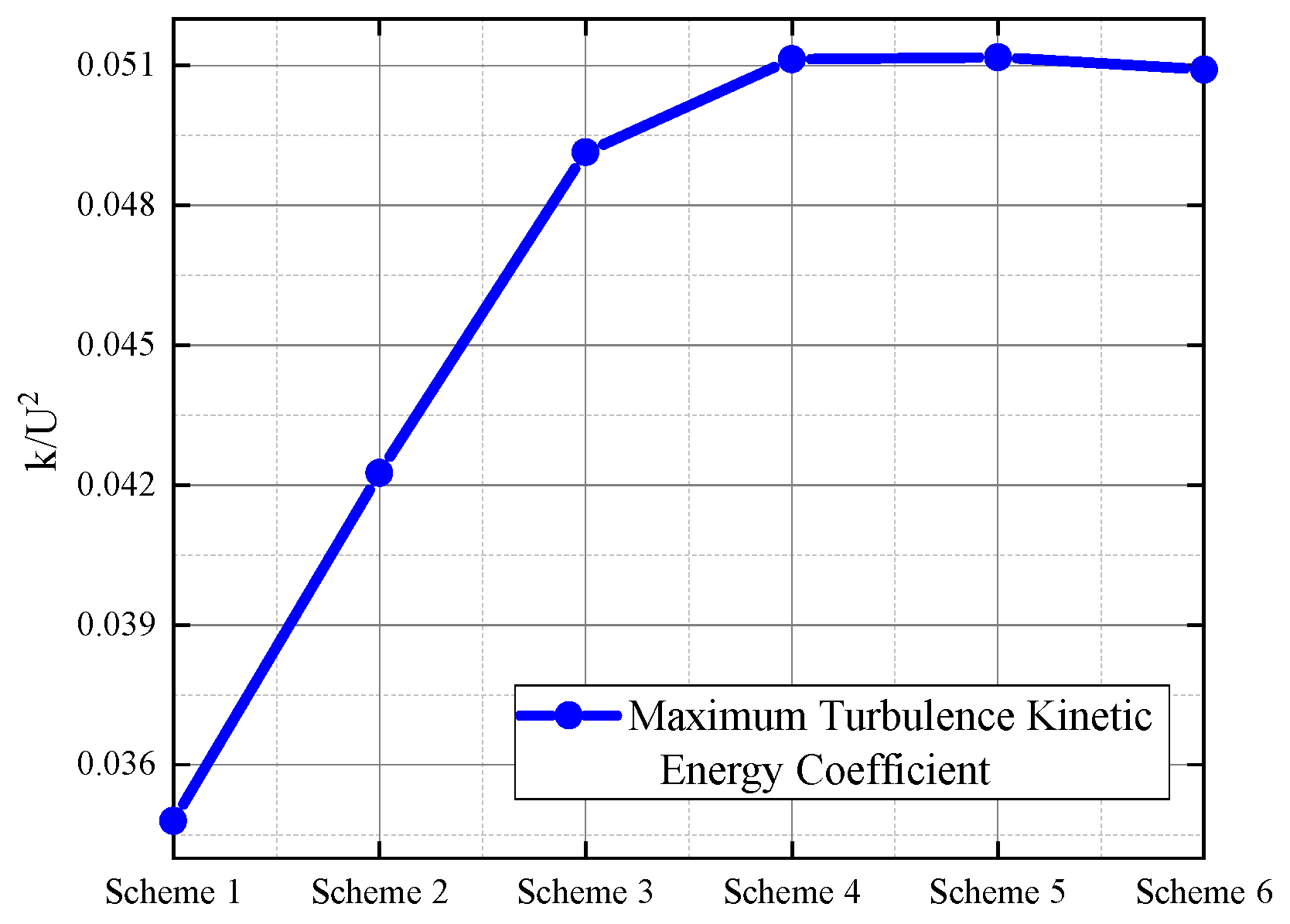

3.3. Grid Generation and Grid Independence Verification for Orifice Flow

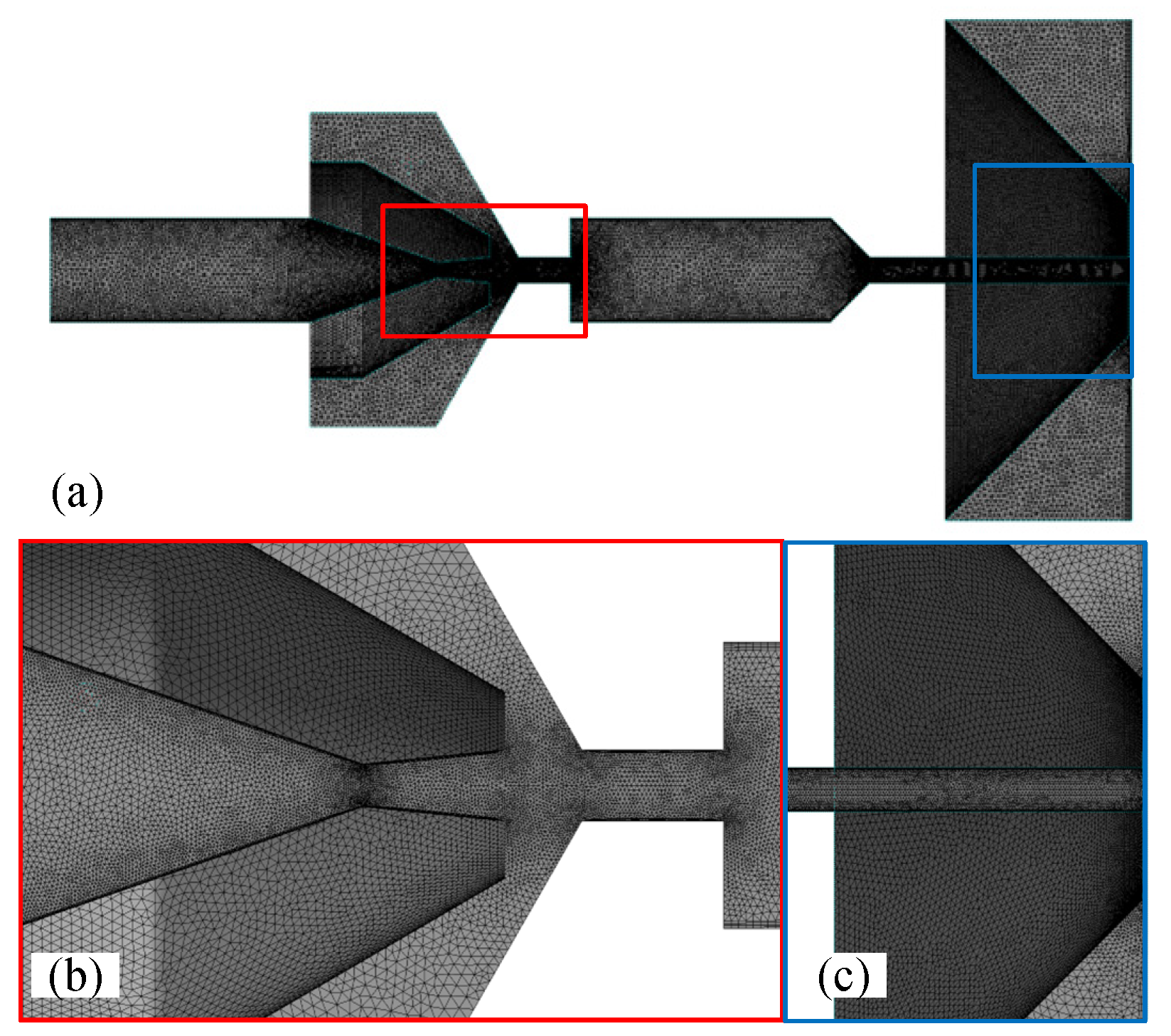

3.4. Grid Generation and Grid Independence Verification for Internal Nozzle Flow

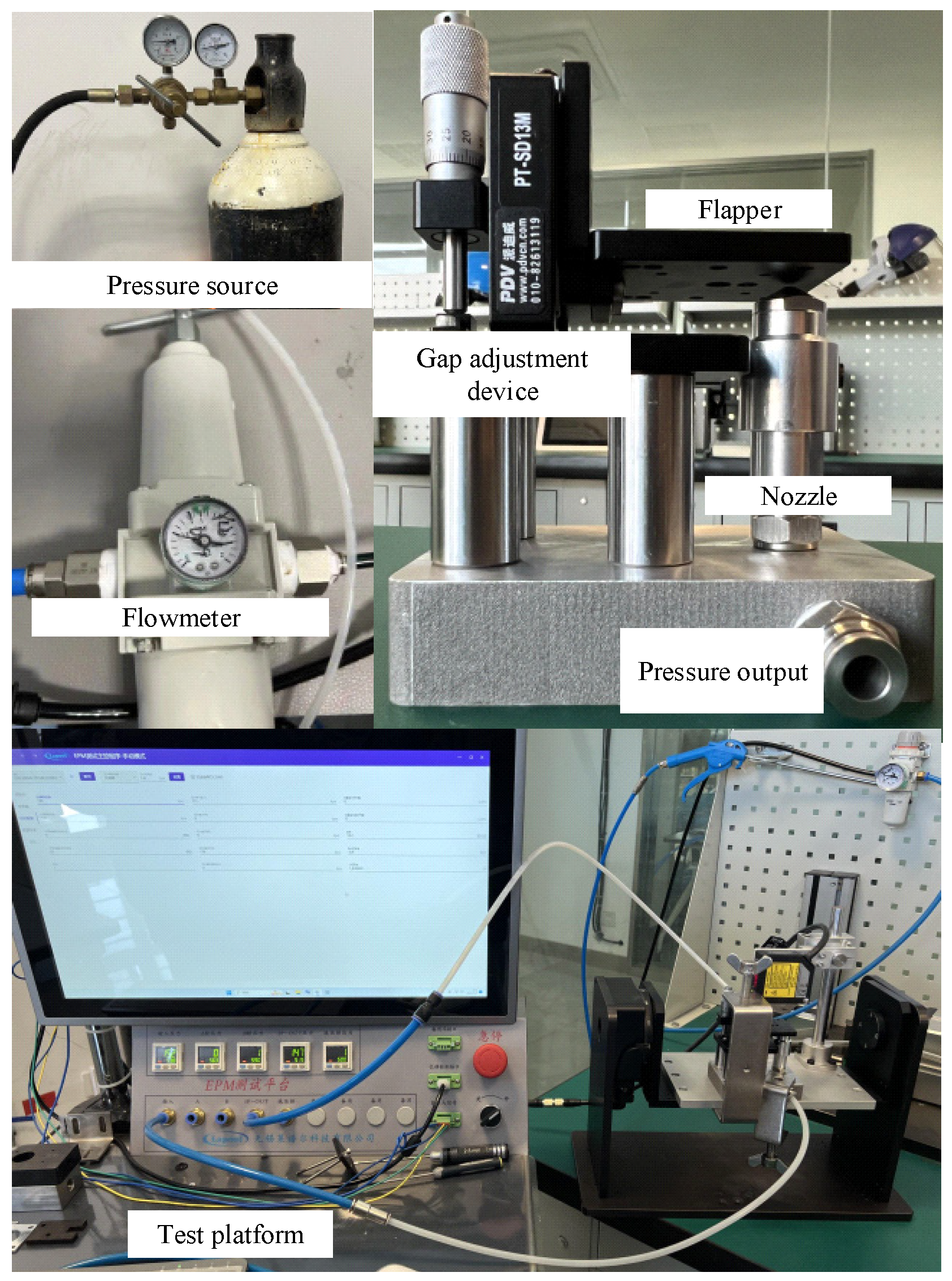

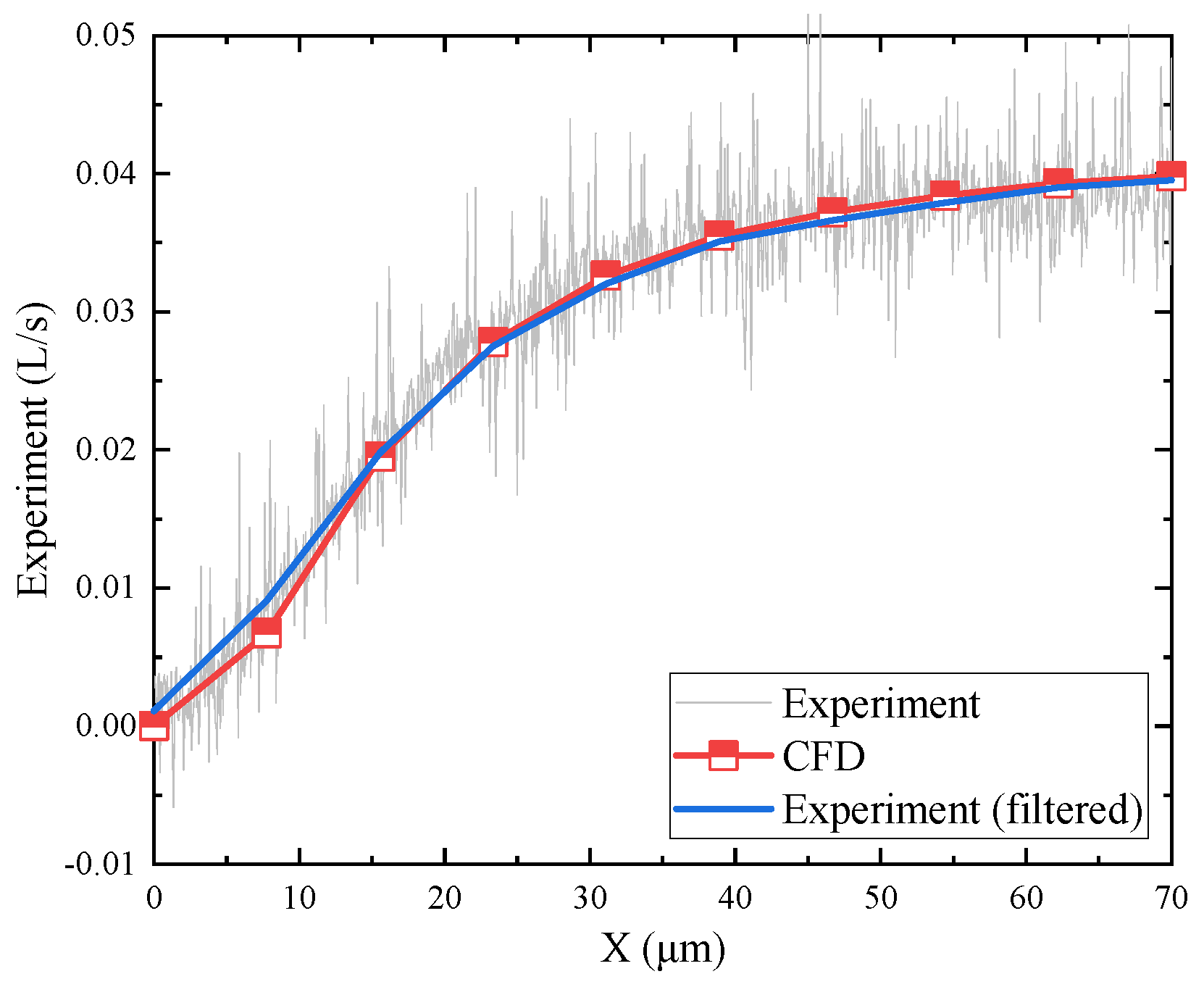

3.5. Experimental Design

4. Results and Discussion

4.1. Numerical Analysis of the Orifice

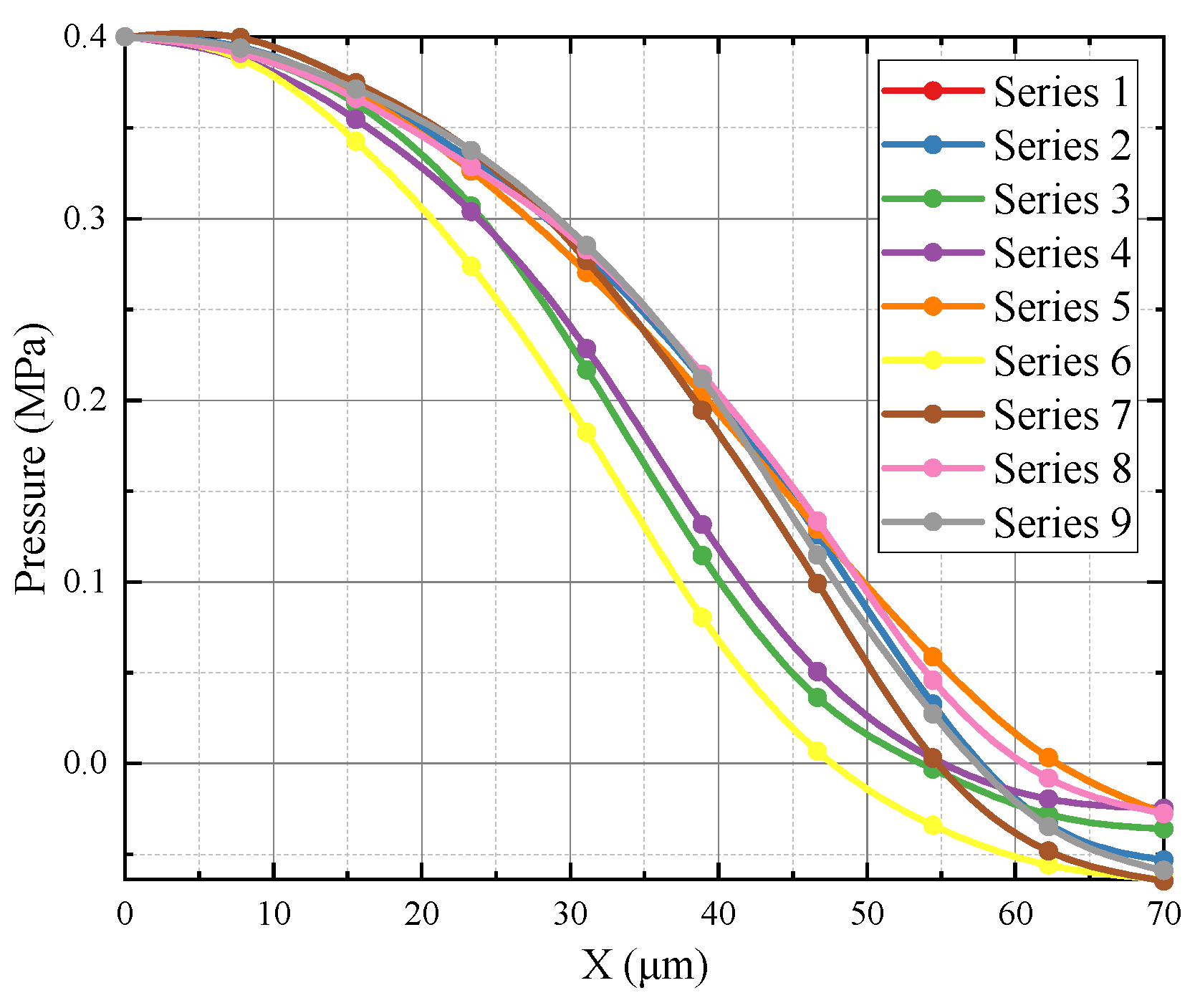

4.2. Negative-Pressure Flapper–Nozzle Characteristic Curve Simulations and Experimental Analysis

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, T.; Cai, M.; Kawashima, K.; Kagawa, T. Model of a nozzle-flapper type pneumatic servo valve and differential pressure control system design. In Proceedings of the JFPS International Symposium on Fluid Power, Tsukuba, Japan, 7–10 November 2005; The Japan Fluid Power System Society: Tokyo, Japan, 2005; Volume 2005, pp. 322–327. [Google Scholar]

- Burazer, J.; Skoko, D.; Bukurov, M.; Novković, Đ.; Adžić, V.; Lečić, M.; Vorotović, G. Possibility for improving the performance of a differential pneumatic comparator by inclining the measuring nozzle. Measurement 2023, 208, 112415. [Google Scholar] [CrossRef]

- Murty, D.V.S. Transducers and Instrumentation; PHI Learning Pvt. Ltd.: Delhi, India, 2010. [Google Scholar]

- Peter, B. Pneumatic Drives System Design, Modeling and Control; Springer: Berlin/Heidelberg, Germany, 2007. [Google Scholar]

- Kagawa, T. Heat Transfer Effects on the Frequency Response of a Pneumatic Nozzle Flapper. J. Dyn. Sys. Meas. Control 1985, 107, 332–336. [Google Scholar] [CrossRef]

- Wang, T.; Kawashima, K.; Kagawa, T. Modelling of a 4-port Nozzle-flapper Type Pneumatic Servo Valve. In Systems Modeling and Simulation: Theory and Applications, Asia Simulation Conference; Springer: Tokyo, Japan, 2006; pp. 248–252. [Google Scholar]

- Gang, B.; Tinghai, C.; Yao, H.; Xiangdong, G.; Han, G. A nozzle flapper electro-pneumatic proportional pressure valve driven by piezoelectric motor. Proceedings of 2011 International Conference on Fluid Power and Mechatronics, Beijing, China, 17–20 August 2011; IEEE: Piscataway, NJ, USA, 2011; pp. 191–195. [Google Scholar]

- Razminia, A.; Baleanu, D. Fractional order models of industrial pneumatic controllers. In Abstract and Applied Analysis; Hindawi: London, UK, 2014; Volume 2014. [Google Scholar]

- Prsic, D.; Fragassa, C.; Nedic, N.; Pavlovic, A. Describing function of the pneumatic flapper-nozzle valve. Mech. Syst. Signal Process. 2019, 124, 696–714. [Google Scholar] [CrossRef]

- Yu SC, M.; Poh, H.J.; Tso, C.P. Numerical simulation on the flow structure around the injection nozzles for pneumatic dimensional control systems. J. Fluids Eng. 2000, 122, 735–742. [Google Scholar]

- Yang, H.; Wang, W.; Lu, K. Numerical simulations on flow characteristics of a nozzle-flapper servo valve with diamond nozzles. IEEE Access 2019, 7, 28001–28010. [Google Scholar] [CrossRef]

- Kang, S.; Kong, X.; Zhang, J.; Du, R. Research on Pressure-Flow Characteristics of Pilot Stage in Jet Pipe Servo-Valve. Sensors 2022, 23, 216. [Google Scholar] [CrossRef] [PubMed]

- Yang, H.; Wang, W.; Lu, K. Cavitation and flow forces in the flapper-nozzle stage of a hydraulic servo-valve manipulated by continuous minijets. Adv. Mech. Eng. 2019, 15, 1687814019851436. [Google Scholar] [CrossRef]

- Yang, H.; Wang, W.; Lu, K.; Chen, Z. Cavitation reduction of a flapper-nozzle pilot valve using continuous microjets. Int. J. Heat Mass Transf. 2019, 133, 1099–1109. [Google Scholar] [CrossRef]

- Yang, Q.; Aung, N.Z.; Li, S. Confirmation on the effectiveness of rectangle-shaped flapper in reducing cavitation in flapper–nozzle pilot valve. Energy Convers. Manag. 2015, 98, 184–198. [Google Scholar] [CrossRef]

- Zhang, S.; Li, S. Cavity shedding dynamics in a flapper–nozzle pilot stage of an electro-hydraulic servo-valve: Experiments and numerical study. Energy Convers. Manag. 2015, 100, 370–379. [Google Scholar] [CrossRef]

- Chu, Y.; Yuan, Z.; Chang, W. Research on the dynamic erosion wear characteristics of a nozzle flapper pressure servo valve used in aircraft brake system. Math. Probl. Eng. 2020, 2020, 3136412. [Google Scholar] [CrossRef]

- Lourier, J.M.; Huber, A.; Noll, B.; Aigner, M. Numerical analysis of indirect combustion noise generation within a subsonic nozzle. AIAA J. 2014, 52, 2114–2126. [Google Scholar] [CrossRef]

- Zhao, T.; Deng, Q.; Zhang, C.; Feng, K.; Zhou, Z.; Yuan, J. Orthogonal experimental research on dielectrophoresis polishing (DEPP) of silicon wafer. Micromachines 2020, 11, 544. [Google Scholar] [CrossRef] [PubMed]

- Kim, Y.H.; Lee, M.; Hwang, I.J.; Kim, Y.J. Noise reduction of an extinguishing nozzle using the response surface method. Energies 2019, 12, 4346. [Google Scholar] [CrossRef]

- Hotz, C.; Haas, M.; Wachter, S.; Fleck, S.; Kolb, T. Experimental investigation on entrainment in two-phase free jets. Fuel 2023, 335, 126912. [Google Scholar] [CrossRef]

- Colin, S.; Bonnet, A.; Caen, R. A New High Supply Pressure Pneumatic Flapper-Nozzle with Linear Behavior. J. Dyn. Syst. Meas. Control 1996, 118, 259–266. [Google Scholar] [CrossRef]

- Aupoix, B.; Spalart, P.R. Extensions of the Spalart–Allmaras turbulence model to account for wall roughness. Int. J. Heat Fluid Flow 2003, 24, 454–462. [Google Scholar] [CrossRef]

- Avila, K.; Moxey, D.; De Lozar, A.; Avila, M.; Barkley, D.; Hof, B. The onset of turbulence in pipe flow. Science 2011, 333, 192–196. [Google Scholar] [CrossRef] [PubMed]

- Su, L.; Zhang, J.; Wang, C.; Zhang, Y.; Li, Z.; Song, Y.; Jin, T.; Ma, Z. Identifying main factors of capacity fading in lithium ion cells using orthogonal design of experiments. Appl. Energy 2016, 163, 201–210. [Google Scholar] [CrossRef]

| Schemes | Number of Orifice Nodes | Number of External Nodes | Grid Growth Rate | Total Grid Number |

|---|---|---|---|---|

| 1 | 300 × 100 | 200 × 200 | 1.5 | 66,381 |

| 2 | 350 × 150 | 250 × 250 | 1.5 | 106,840 |

| 3 | 450 × 200 | 300 × 300 | 1.2 | 215,465 |

| 4 | 550 × 300 | 400 × 400 | 1.1 | 395,079 |

| 5 | 650 × 350 | 450 × 450 | 1.05 | 524,789 |

| 6 | 750 × 400 | 500 × 500 | 1.05 | 811,908 |

| Schemes | Number of Orifice Nodes | Number of External Nodes | Grid Growth Rate | Total Grid Number |

|---|---|---|---|---|

| 1 | 0.1 | 0.5 | 1.5 | 33,970 |

| 2 | 0.05 | 0.1 | 1.2 | 110,981 |

| 3 | 0.02 | 0.1 | 1.2 | 333,599 |

| 4 | 0.01 | 0.05 | 1.1 | 951,110 |

| 5 | 0.005 | 0.02 | 1.05 | 1,843,588 |

| 6 | 0.002 | 0.01 | 1.05 | 3,371,818 |

| Simulation Plan | Contraction Angle | Expansion Angle | Contraction Length (mm) | Expansion Length (mm) |

|---|---|---|---|---|

| 1 | 15° | 0° | 0.5 | 1.5 |

| 2 | 15° | 5° | 1.5 | 2.5 |

| 3 | 15° | 10° | 1 | 3 |

| 4 | 30° | 0° | 1.5 | 3 |

| 5 | 30° | 5° | 1 | 1.5 |

| 6 | 30° | 10° | 0.5 | 2.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, A.; Xiao, H.; Yan, X.; Kong, X.; Rong, F.; Zhang, L.; Zhao, S. Simulation and Experimental Study of a Novel Negative-Pressure Flapper–Nozzle Mechanism. Micromachines 2024, 15, 55. https://doi.org/10.3390/mi15010055

Ma A, Xiao H, Yan X, Kong X, Rong F, Zhang L, Zhao S. Simulation and Experimental Study of a Novel Negative-Pressure Flapper–Nozzle Mechanism. Micromachines. 2024; 15(1):55. https://doi.org/10.3390/mi15010055

Chicago/Turabian StyleMa, Aixiang, Heruizhi Xiao, Xihao Yan, Xianghao Kong, Feng Rong, Lu Zhang, and Sihai Zhao. 2024. "Simulation and Experimental Study of a Novel Negative-Pressure Flapper–Nozzle Mechanism" Micromachines 15, no. 1: 55. https://doi.org/10.3390/mi15010055

APA StyleMa, A., Xiao, H., Yan, X., Kong, X., Rong, F., Zhang, L., & Zhao, S. (2024). Simulation and Experimental Study of a Novel Negative-Pressure Flapper–Nozzle Mechanism. Micromachines, 15(1), 55. https://doi.org/10.3390/mi15010055