Ultra-Bend-Resistant 4-Core Simplex Cable Used for Short-Reach Dense Spatial Division Multiplexing Optical Transmission

Abstract

1. Introduction

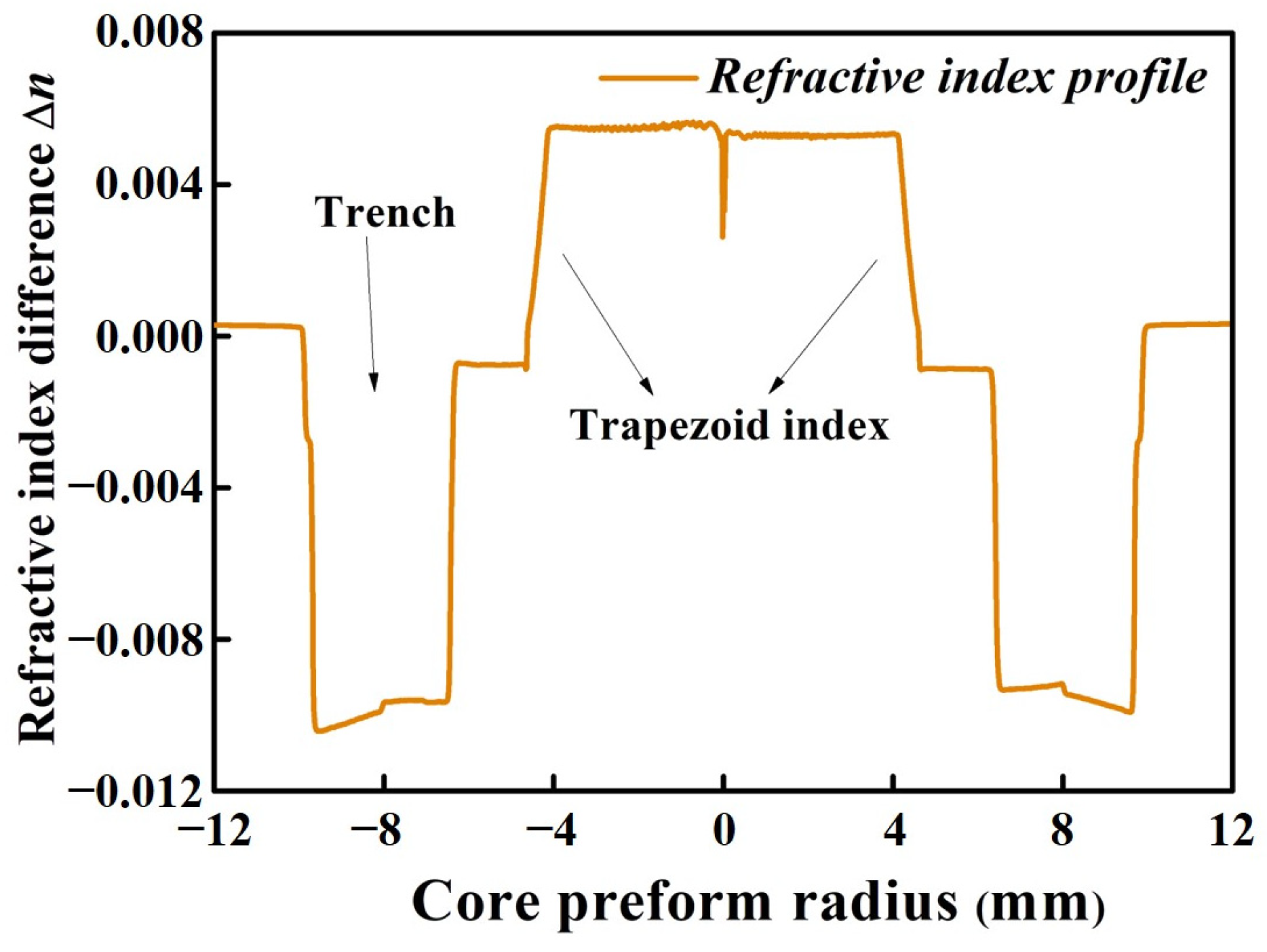

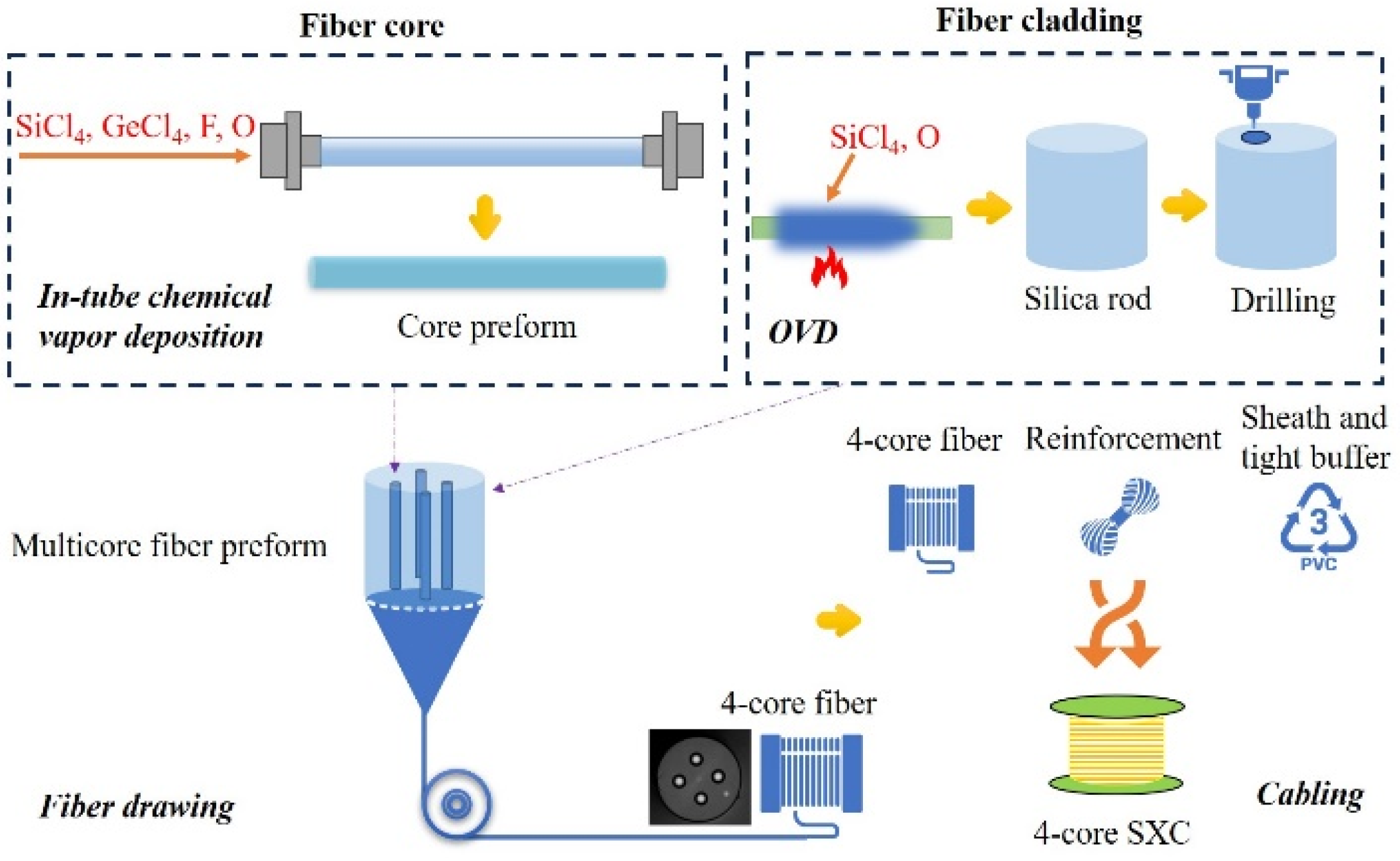

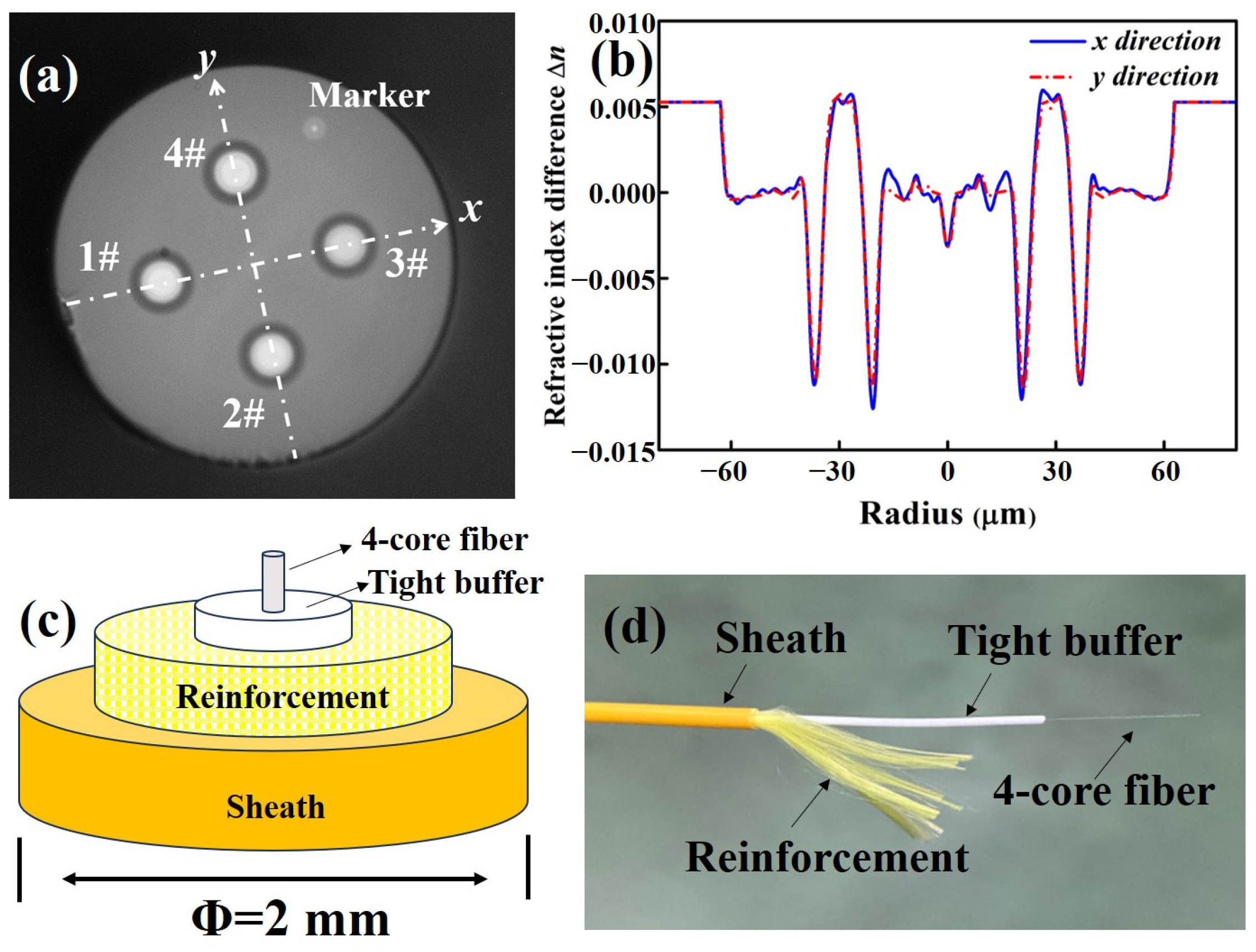

2. Fabrication of the Ultra-Bend-Resistant 4-Core SXC

3. Transmission Characteristics of Ultra-Bend-Resistant 4-Core SXC

3.1. Transmission Loss

3.2. Macro-Bending Loss

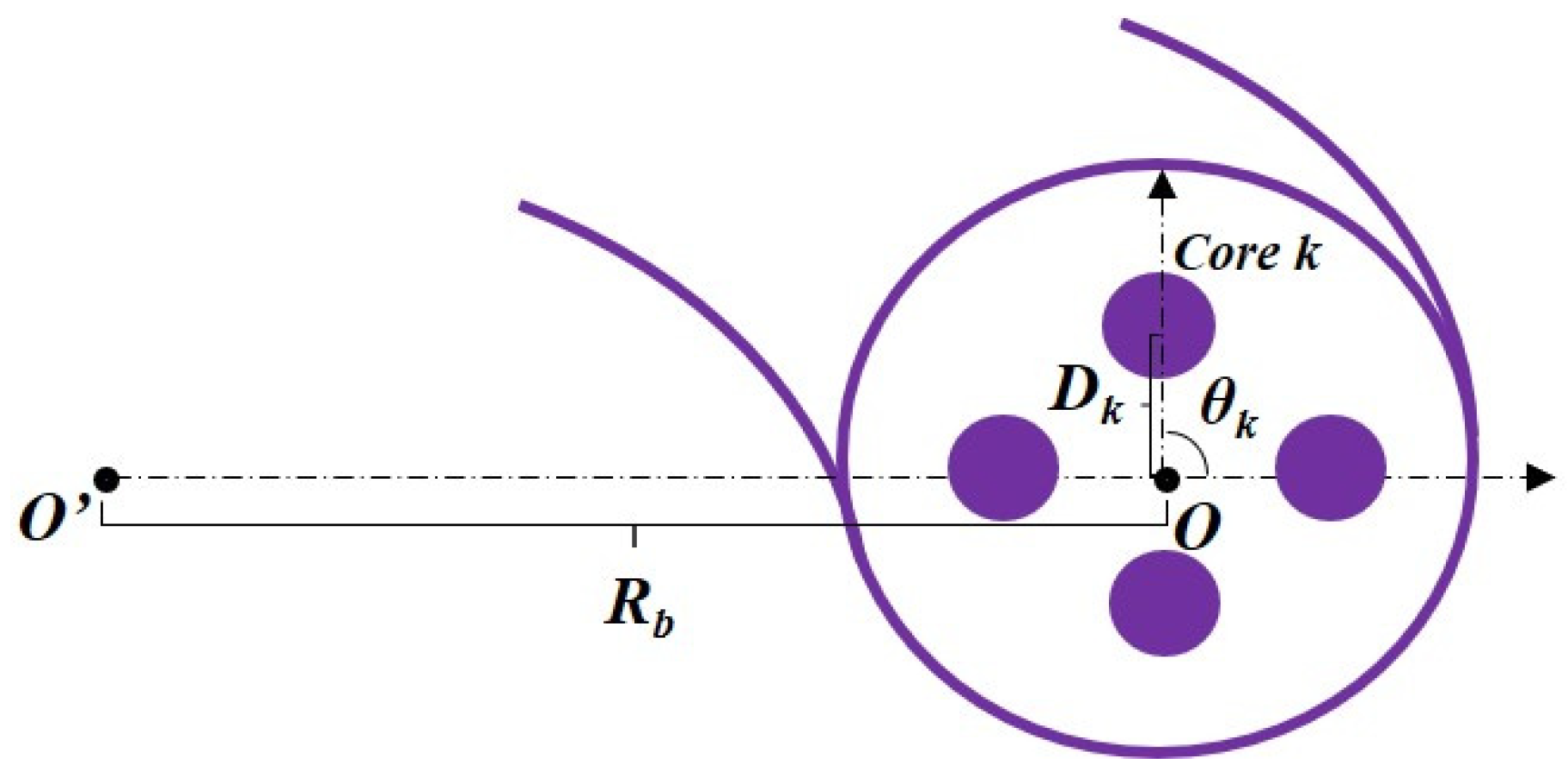

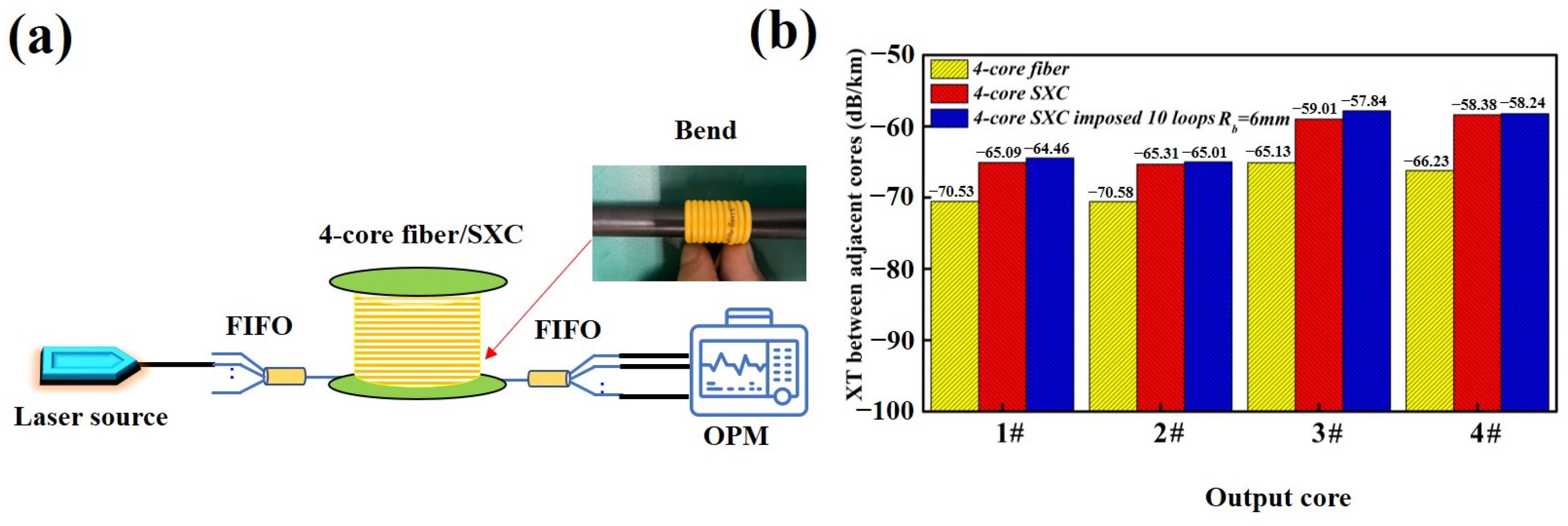

3.3. XT between Adjacent Cores

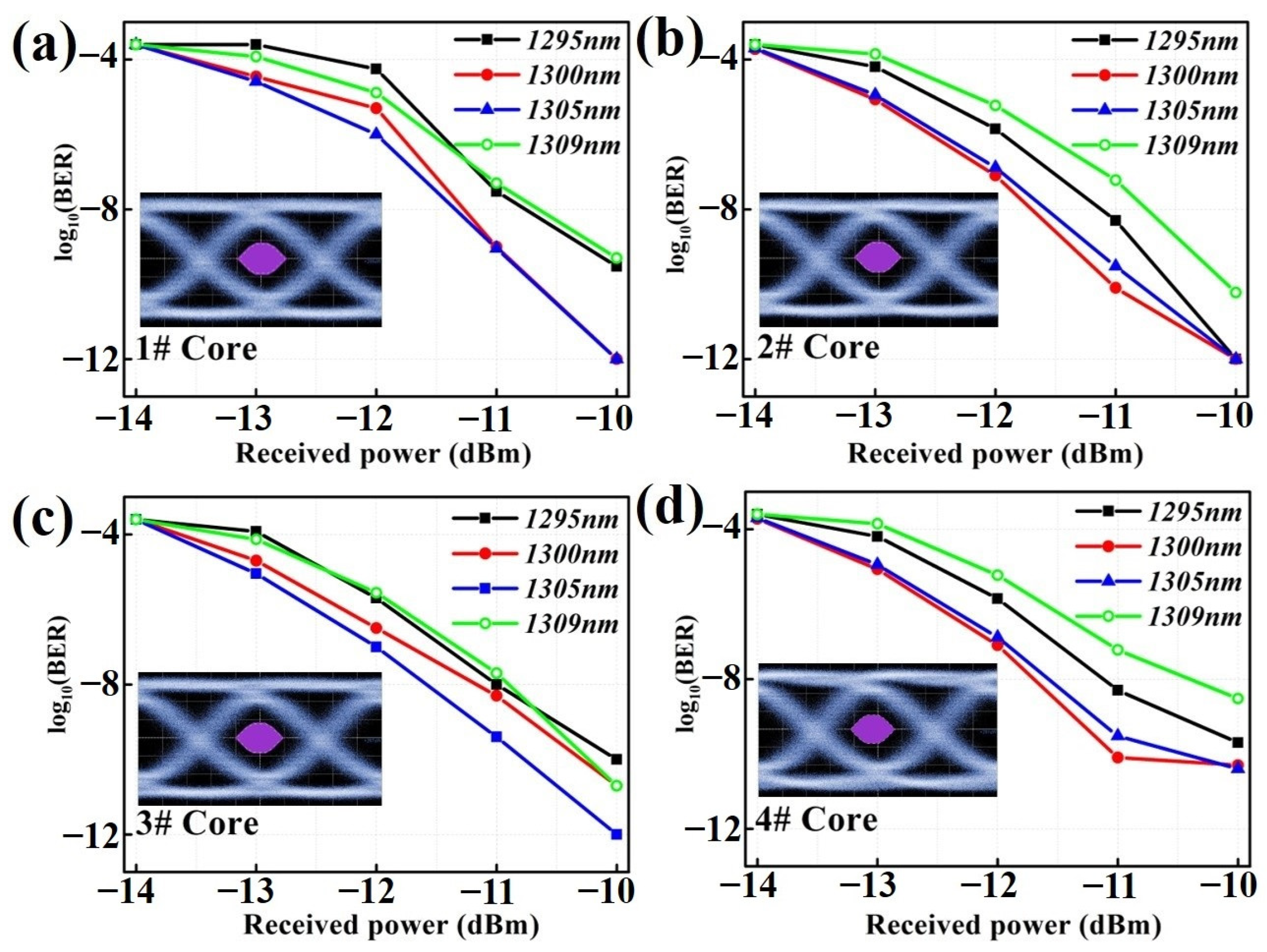

4. Signal Transmission of Ultra-Bend-Resistant 4-Core SXC

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Hayashi, T.; Nakanishi, T.; Hirashima, K.; Shimakawa, O.; Sato, F.; Koyama, K.; Furuya, A.; Murakami, Y.; Sasaki, T. 125-μm-Cladding Eight-Core Multi-Core Fiber Realizing Ultra-High-Density Cable Suitable for O-Band Short-Reach Optical Interconnects. J. Light. Technol. 2016, 34, 85–92. [Google Scholar] [CrossRef]

- Matsuo, S.; Yamashiro, K.; Tsujimoto, Y.; Miyata, M.; Murata, A.; Ishikawa, T.; Nakajima, T.; Osato, K. 1,728-Fiber Cable With 12-Fiber Ribbons Comprising 160-μm-Coating Fiber with 80-μm Cladding. J. Light. Technol. 2022, 40, 1552–1559. [Google Scholar] [CrossRef]

- Sasaki, Y.; Fukumoto, R.; Takenaga, K.; Shimizu, S.; Aikawa, K. Optical-Fiber Cable Employing 200-μm-Coated Four-Core Multicore Fibers. J. Light. Technol. 2022, 40, 1560–1566. [Google Scholar] [CrossRef]

- Takeda, D.; Isaji, M.; Namazue, A.; Osato, K.; Murata, A.; Yamanaka, M.; Okada, N. Development of Wrapping Tube Cable with SPIDERWEB RIBBON using 200 μm coated fiber. In Proceedings of the 63rd IWCS 757, Providence, RI, USA, 10–12 November 2014. [Google Scholar]

- Shao, P.S.; Li, S.G.; Meng, X.J.; Guo, Y.; Wang, L.Y.; Li, Z.H.; Ma, L.L.; Li, J.S.; Chen, T.L.; Xu, W.W.; et al. Low crosstalk and large effective mode field area heterogeneous 13-core 6-mode fiber with double high refractive index rings. Opt. Commun. 2023, 530, 129136. [Google Scholar] [CrossRef]

- Shao, P.S.; Wang, L.Y.; Wang, Y.; Li, S.G.; Li, Z.H.; Wang, X.K.; Ma, L.L.; Meng, X.J.; Guo, Y.; Li, J.S.; et al. Preparation and transmission characteristics of seven-core few-mode fiber with low loss and low inter-core crosstalk. Opt. Express 2022, 30, 27746–27762. [Google Scholar] [CrossRef] [PubMed]

- Kopp, V.I.; Park, J.; Zhang, J.; Singer, J.; Neugroschl, D.; Oda, T.; Mukai, K.; Nasir, U. Ultra-dense, 1152-core, broadband multicore fiber link deployed in a metro network. Opt. Express 2023, 31, 5794–5800. [Google Scholar] [CrossRef] [PubMed]

- Oda, T.; Kajikawa, S.; Takenaga, K.; Mukai, O.; Takeda, D.; Ichii, K. Loss performance of field-deployed high-density 1152-channel link constructed with 4-core multicore fiber cable. In Proceedings of the Optical Fiber Communication Conference 2023 Tu2C.4, San Diego, CA, USA, 5–9 March 2023. [Google Scholar]

- Nomoto, E.; Hiruma, K.; Sugawara, T.; Tanaka, K.; Lee, Y. SC-type multi-core optical-fiber connectors using a pressurization spring. Opt. Rev. 2015, 22, 679–685. [Google Scholar] [CrossRef]

- Li, T.; Dorrestein, S.; Soenen, W.; Li, C.H.; Stabile, R.; Yin, X.; Raz, O. Low Cost 100 Gbps Multicore VCSEL Based Transmitter Module Platform. In Proceedings of the CLEO: Science and Innovations 2018 SW3B.5, San Diego, CA, USA, 13–18 May 2018. [Google Scholar]

- Sawadogo, B.A.; Bandyopadhyay, A.; Zegaoui, M.; Zaknoune, M.; Szriftgiser, P.; Bigot, L. 100 Gbit/s THz Data Transmission and Beyond using Multicore Fiber Combined with UTC Photodiode Array. In Proceedings of the Optical Fiber Communication Conference and Exibition (OFC 2022) Th2A.26, San Diego, CA, USA, 26–28 March 2022. [Google Scholar]

- Shikama, K.; Abe, Y.; Kishi, T.; Takeda, K.; Fujii, T.; Matsuo, S. Multicore-Fiber LC Receptacle with Compact Fan-in/Fan-out for Short-Reach Transceivers. In Proceedings of the Optical Fiber Communication Conference W1A.7, San Diego, CA, USA, 6–10 March 2018. [Google Scholar]

- Karppinen, M.; Tanskanen, A.; Salminen, N.; Ollila, J.; Westbergh, P.; Gustavsson, J. Integration of 150 Gbps/fiber optical engines based on multicore fibers and 6-channel VCSELs and PDs. In Proceedings of the SPIE Optical Interconnects ⅩⅥ, San Diego, CA, USA, 28 August–1 September 2016; Volume 9753. [Google Scholar]

- Stampoulidis, L.; Kehayas, E.; Karppinen, M.; Tanskanen, A.; Ollila, J.; Larsson, A. High-speed, low-power and board-mountable optical transceivers for scalable & energy efficient advanced on-board digital processors. In Proceedings of the SPIE International Conference on Space Optics, Chania, Greece, 9–12 October 2018; Volume 11180. [Google Scholar]

- Pinguet, T.; Dobbelaere, P.M.D.; Foltz, D.; Gloeckner, S.; Hovey, S.; Liang, Y. Silicon Photonics Multicore Transceivers. In Proceedings of the IEEE Photonics Society Summer Topical Meeting Series WC4.1, Seattle, WA, USA, 9–11 July 2012. [Google Scholar]

- Hayashi, T.; Sasaki, T.; Sasaoka, E.; Saitoh, K.; Koshiba, M. Physical interpretation of inter-core crosstalk in multicore fiber: Effects of macrobend, structure fluctuation, and microbend. Opt. Express 2013, 11, 5401–5412. [Google Scholar] [CrossRef]

- Shao, P.S.; Li, Z.H.; Zhao, X.S.; Wang, Y.; Li, S.G. Low crosstalk trapezoid-index thirteen-core single-mode fiber for multi-channel and high-density applications. Opt. Express 2023, 31, 20919–20929. [Google Scholar] [CrossRef]

- Lukowiak, A.; Chiappini, A.; Chiasera, A.; Ristic, D.; Vasilchenko, I.; Armellini, C.; Carpentiero, A.; Varas, S.; Speranza, G.; Taccheo, S.; et al. Sol–gel-derived photonic structures handling erbium ions luminescence. Opt. Quant. Electron. 2015, 47, 117–124. [Google Scholar] [CrossRef]

- Ahmed, S.; Bostjan, B. Stack-and-Draw Manufacture Process of a Seven-Core Optical Fiber for Fluorescence Measurements. Fiber Integr. Opt. 2017, 10, 1–10. [Google Scholar]

- Ji, W.; Yu, R.W.; Wang, C.Y.; Yan, Z.Y.; Liu, L.Y.; Xu, L.; Chen, W.; Chiang, K.S.; Xiao, L.M. Spacing-tailored multicore fiber for efficient FIFO devices. J. Light. Technol. 2022, 40, 5682–5688. [Google Scholar] [CrossRef]

- Wiltshire, B.; Reeve, M.H. A Review of the Environmental Factors Affecting Optical Cable Design. J. Light. Technol. 1988, 6, 179–185. [Google Scholar] [CrossRef]

- Xie, Y.H.; Pei, L.; Zheng, J.J.; Zhao, Q.; Ning, T.G.; Li, J. Impact analysis of a dense hole-assisted structure on crosstalk and bending loss in homogeneous few-mode multi-core fibers. Opt. Express 2020, 28, 23806–23818. [Google Scholar] [CrossRef] [PubMed]

- Astapovich, M.S.; Egorova, O.N.; Semenov, S.L. Bending Dependence of Optical Delay Difference between Multicore Fiber Cores. Bull. Lebedev Phys. Inst. 2016, 43, 361–364. [Google Scholar] [CrossRef]

- Chen, X.; Zakharian, A.R.; Johnson, S.; Hurley, J.E.; Butler, D.L.; Bennett, K.W.; Dong, H.; Li, M.J. Multimode and single-mode transmission over universal fiber for data center applications. Opt. Fiber Technol. 2017, 71, 102941. [Google Scholar] [CrossRef]

- Gupta, D.; Kumar, A.; Thyagarajan, K. Polarization mode dispersion in single mode optical fibers due to core-ellipticity. Opt. Commun. 2006, 263, 36–41. [Google Scholar] [CrossRef]

- Saitoh, K.; Matsuo, S. Multicore fibers for large capacity transmission. Nanophotonics 2013, 2, 441–454. [Google Scholar] [CrossRef]

- Wadud, A.; Basalamah, A. Performance and challenges of Bi-directional resource allocation in multi-core space division multiplexing elastic optical networks. Opt. Switch Netw. 2022, 46, 100685. [Google Scholar] [CrossRef]

- Sagae, Y.; Iwaya, T.; Mori, T.; Sakamoto, T.; Matsui, T.; Nakajima, K. Crosstalk Noise in Bi-Directional Transmission on Multi-Core Fiber Link with Distributed Raman Amplifier. J. Light. Technol. 2023, 41, 1519–1525. [Google Scholar] [CrossRef]

- Wiltshire, B.; Reeve, M. Long-Term Reliability of Transmission Loss in Optical Fiber Cables. J. Light. Technol. 1988, 6, 210–217. [Google Scholar]

- Nagase, R. Optical Connectivities for Multicore Fiber. In Proceedings of the Optical Fiber Communication Conference Th3l.1, San Diego, CA, USA, 8–12 March 2020. [Google Scholar]

- Amma, Y.; Takenaga, K.; Matsue, S.; Aikawa, K. Fusion splice techniques for multicore fibers. Opt. Fiber Technol. 2017, 35, 72–79. [Google Scholar] [CrossRef]

- Manna, S.; Kim, J.W.; Takahashi, Y.; Shpyrko, O.G.; Fullerton, E.E. Synthesis of single-crystalline anisotropic gold nano-crystals via chemical vapor deposition. J. Appl. Phys. 2016, 119, 174301. [Google Scholar] [CrossRef]

- Khan, T.K.; Khan, S.U.; Khan, S.U.; Ahmad, A.; Abbasi, S.A.; Khan, E.M.; Mehigan, S. Silver nanoparticle films by flowing gas atmospheric pulsed laser deposition and application to surface-enhanced Raman spectroscopy. Int. J. Energy Res. 2020, 44, 11443–11452. [Google Scholar] [CrossRef]

| Bending Radius | Macro-Bending Loss (dB/10 Turns) | |||

|---|---|---|---|---|

| 1# | 2# | 3# | 4# | |

| Rb = 6.0 mm | 0.37 | 0.22 | 0.37 | 0.21 |

| Rb = 8.2 mm | <0.10 | <0.10 | <0.10 | <0.10 |

| Rb = 10.0 mm | <0.04 | <0.04 | <0.04 | <0.04 |

| Rb = 18.3 mm | ≤0.02 | ≤0.02 | ≤0.02 | ≤0.02 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Z.; Qin, Y.; Zhu, J.; Wang, C.; Jiang, X.; Shen, Y.; Xiao, L. Ultra-Bend-Resistant 4-Core Simplex Cable Used for Short-Reach Dense Spatial Division Multiplexing Optical Transmission. Micromachines 2024, 15, 108. https://doi.org/10.3390/mi15010108

Zhang Z, Qin Y, Zhu J, Wang C, Jiang X, Shen Y, Xiao L. Ultra-Bend-Resistant 4-Core Simplex Cable Used for Short-Reach Dense Spatial Division Multiplexing Optical Transmission. Micromachines. 2024; 15(1):108. https://doi.org/10.3390/mi15010108

Chicago/Turabian StyleZhang, Zelin, Yu Qin, Jie Zhu, Caoyuan Wang, Xinli Jiang, Yichun Shen, and Limin Xiao. 2024. "Ultra-Bend-Resistant 4-Core Simplex Cable Used for Short-Reach Dense Spatial Division Multiplexing Optical Transmission" Micromachines 15, no. 1: 108. https://doi.org/10.3390/mi15010108

APA StyleZhang, Z., Qin, Y., Zhu, J., Wang, C., Jiang, X., Shen, Y., & Xiao, L. (2024). Ultra-Bend-Resistant 4-Core Simplex Cable Used for Short-Reach Dense Spatial Division Multiplexing Optical Transmission. Micromachines, 15(1), 108. https://doi.org/10.3390/mi15010108