Optimization of Machining Parameters to Minimize Cutting Forces and Surface Roughness in Micro-Milling of Mg13Sn Alloy

Abstract

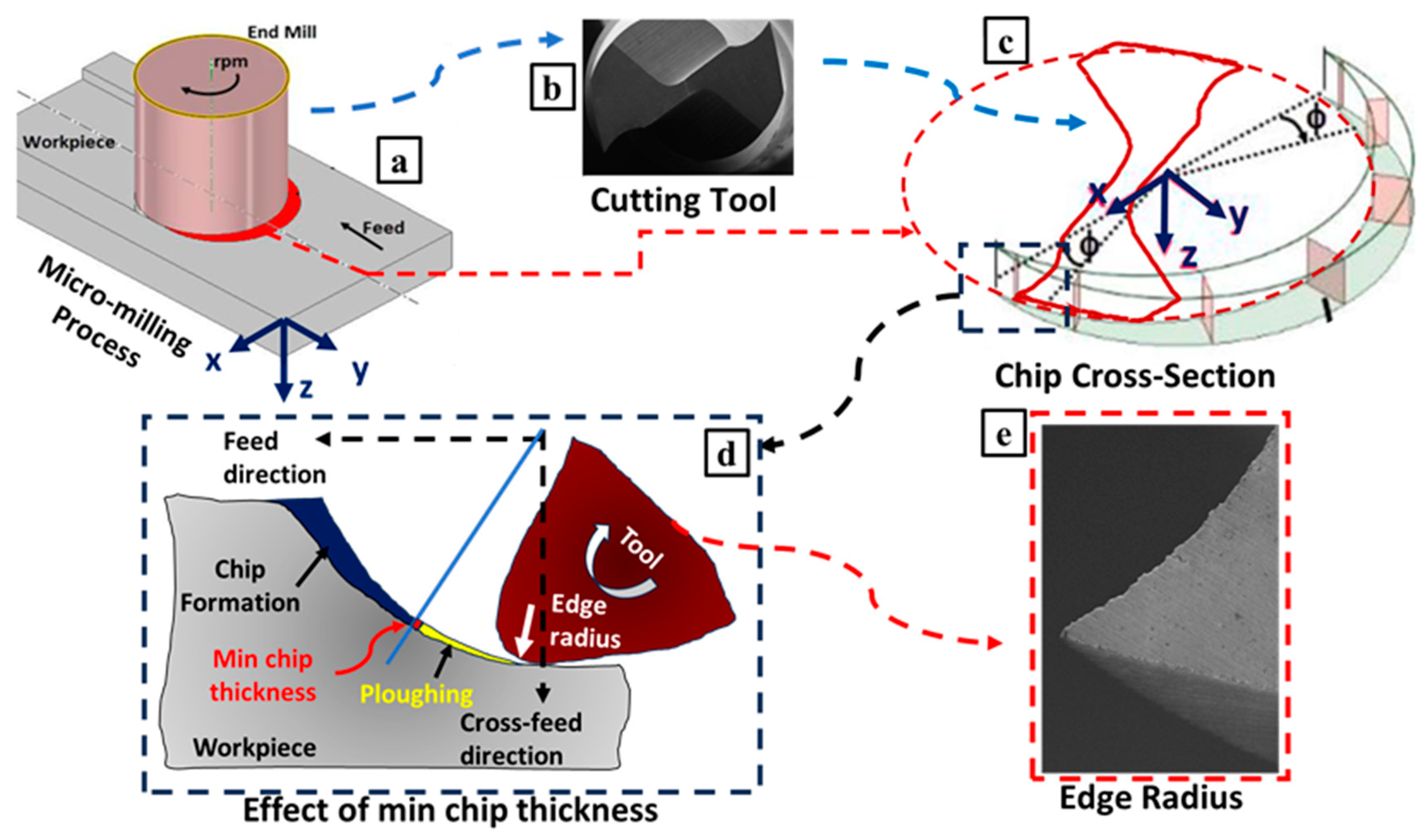

1. Introduction

2. Materials and Methods

3. Results and Discussion

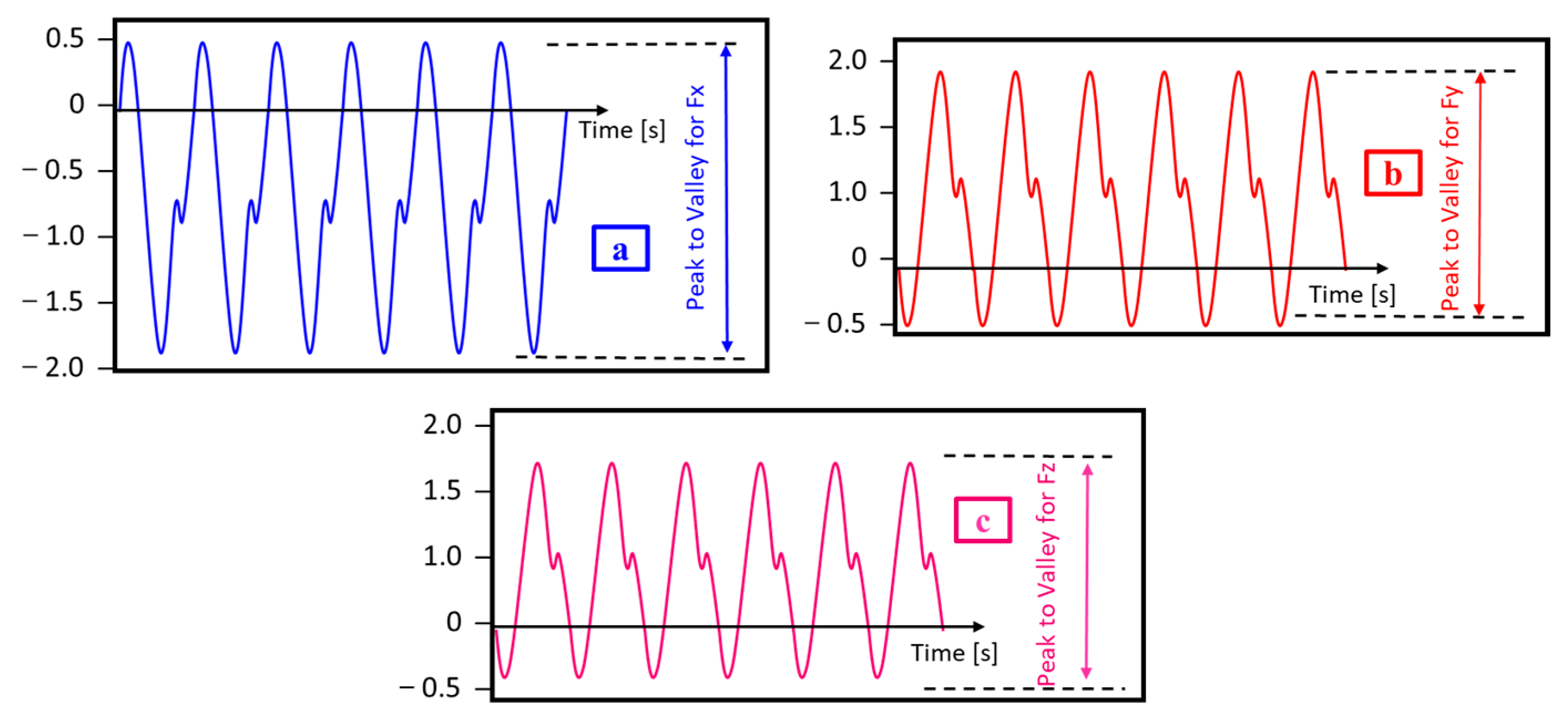

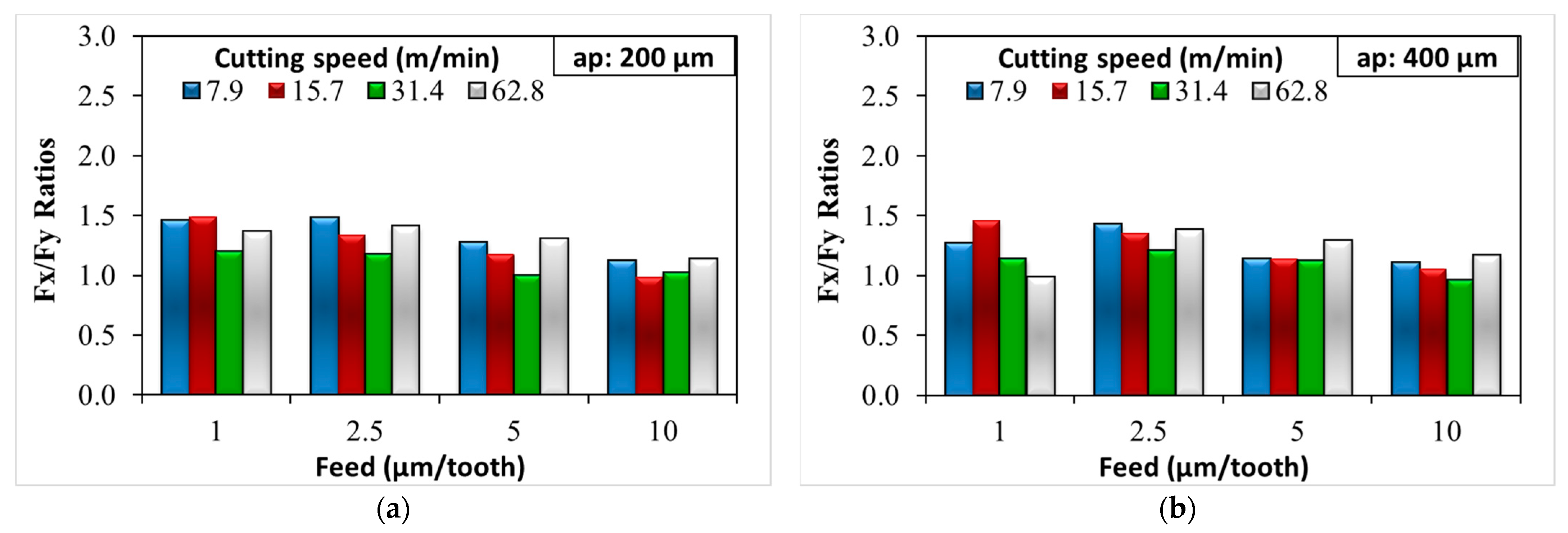

3.1. Cutting Forces

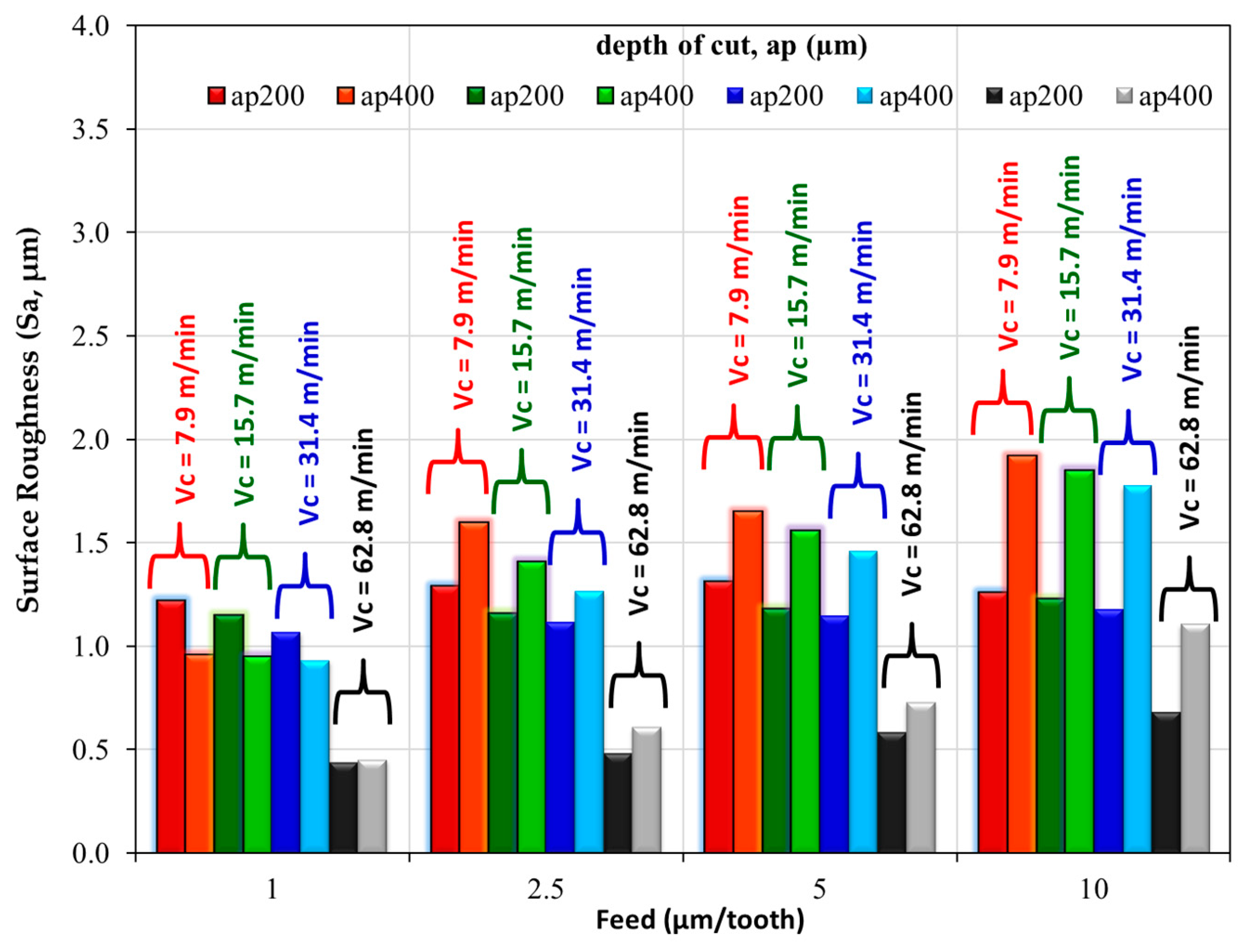

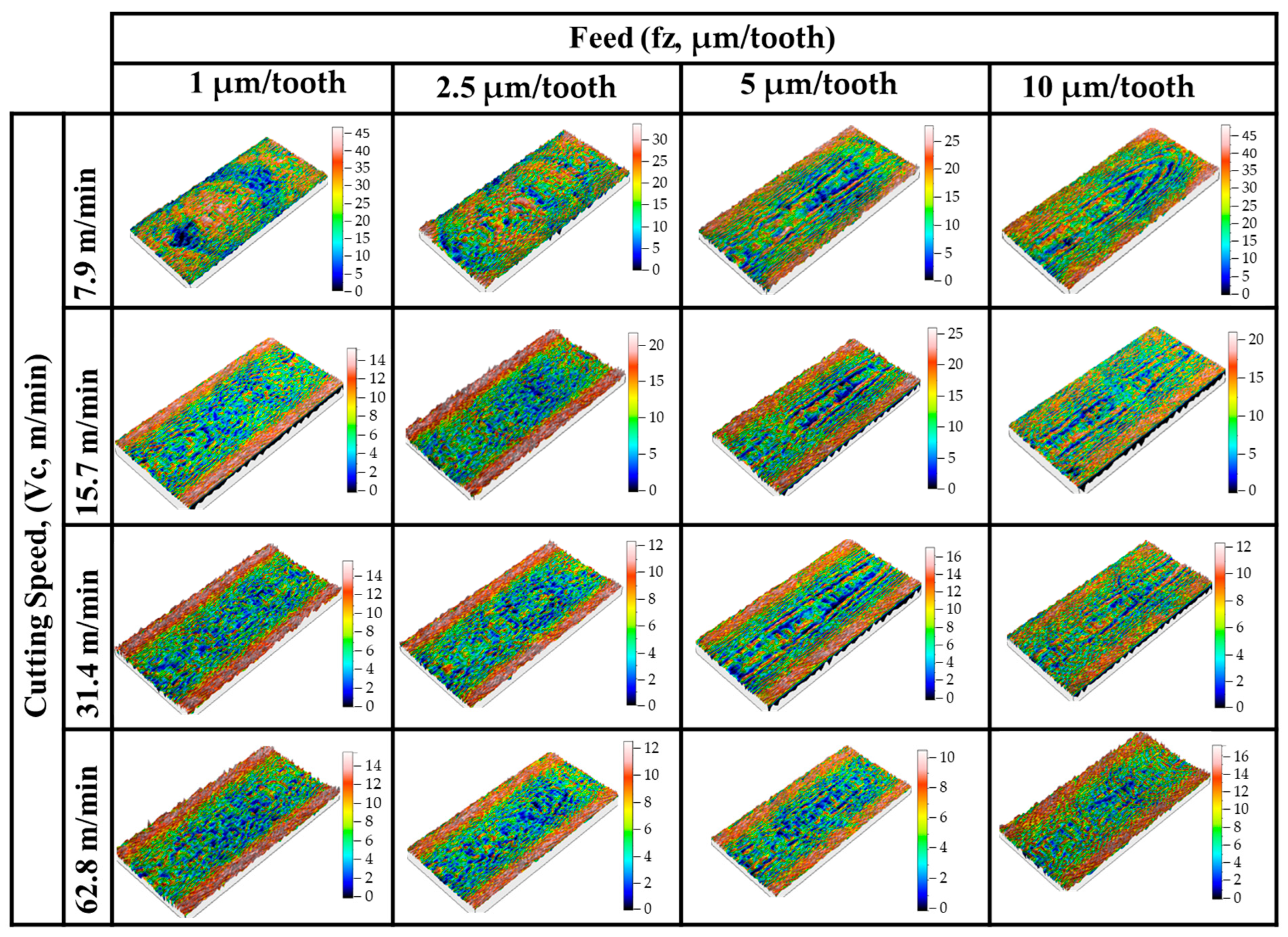

3.2. Surface Roughness

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Madhuri, N.; Jayakumar, V.; Sathishkumar, M. Recent developments and challenges accompanying with wire arc additive manufacturing of Mg alloys: A review. Mater. Today Proc. 2021, 46, 8573–8577. [Google Scholar] [CrossRef]

- Kapinos, D.; Augustyn, B.; Szymanek, M. Methods of introducing alloying elements into liquid magnesium. Metall. Foundry Eng. 2014, 40, 141–160. [Google Scholar] [CrossRef]

- Ghazanfari, H.; Hasanizadeh, S.; Eskandarinezhad, S.; Hassani, S.; Sheibani, M.; Torkamani, A.D.; Fakić, B. Recent progress in materials used towards corrosion protection of Mg and its alloys. J. Compos. Compd. 2020, 2, 205–214. [Google Scholar] [CrossRef]

- Ercetin, A.; Özgün, Ö.; Aslantaş, K.; Der, O.; Yalçın, B.; Şimşir, E.; Aamir, M. Microstructural and Mechanical Behavior Investigations of Nb-Reinforced Mg–Sn–Al–Zn–Mn Matrix Magnesium Composites. Metals 2023, 13, 1097. [Google Scholar] [CrossRef]

- Czerwinski, F. Current Trends in Automotive Lightweighting Strategies and Materials. Materials 2021, 14, 6631. [Google Scholar] [CrossRef]

- Tsakiris, V.; Tardei, C.; Clicinschi, F.M. Biodegradable Mg alloys for orthopedic implants—A review. J. Magnes. Alloys 2021, 9, 1884–1905. [Google Scholar] [CrossRef]

- Kim, J.; Pan, H. Effects of magnesium alloy corrosion on biological response-Perspectives of metal-cell interaction. Prog. Mater. Sci. 2022, 133, 101039. [Google Scholar] [CrossRef]

- Xing, F.; Li, S.; Yin, D.; Xie, J.; Rommens, P.M.; Xiang, Z.; Liu, M.; Ritz, U. Recent progress in Mg-based alloys as a novel bioabsorbable biomaterials for orthopedic applications. J. Magnes. Alloys 2022, 10, 1428–1456. [Google Scholar] [CrossRef]

- Moravej, M.; Mantovani, D. Biodegradable Metals for Cardiovascular Stent Application: Interests and New Opportunities. Int. J. Mol. Sci. 2011, 12, 4250–4270. [Google Scholar] [CrossRef]

- Li, X.; Liu, X.; Wu, S.; Yeung, K.W.K.; Zheng, Y.; Chu, P.K. Design of magnesium alloys with controllable degradation for biomedical implants: From bulk to surface. Acta Biomater. 2016, 45, 2–30. [Google Scholar] [CrossRef]

- Xu, L.; Liu, X.; Sun, K.; Fu, R.; Wang, G. Corrosion Behavior in Magnesium-Based Alloys for Biomedical Applications. Materials 2022, 15, 2613. [Google Scholar] [CrossRef]

- Hornberger, H.; Virtanen, S.; Boccaccini, A.R. Biomedical coatings on magnesium alloys–a review. Acta Biomater. 2012, 8, 2442–2455. [Google Scholar] [CrossRef] [PubMed]

- Chaya, A.; Yoshizawa, S.; Verdelis, K.; Myers, N.; Costello, B.J.; Chou, D.T.; Pal, S.; Maiti, S.; Kumta, P.N.; Sfeir, C. In vivo study of magnesium plate and screw degradation and bone fracture healing. Acta Biomater. 2015, 18, 262–269. [Google Scholar] [CrossRef] [PubMed]

- Yu, Y.; Lu, H.; Sun, J. Long-term in vivo evolution of high-purity Mg screw degradation—Local and systemic effects of Mg degradation products. Acta Biomater. 2018, 71, 215–224. [Google Scholar] [CrossRef]

- Sukotjo, C.; Lima-Neto, T.J.; Santiago Júnior, J.F.; Faverani, L.P.; Miloro, M. Is There a Role for Absorbable Metals in Surgery? A Systematic Review and Meta-Analysis of Mg/Mg Alloy Based Implants. Materials 2020, 13, 3914. [Google Scholar] [CrossRef] [PubMed]

- Rider, P.; Kačarević, Ž.P.; Elad, A.; Rothamel, D.; Sauer, G.; Bornert, F.; Windisch, P.; Hangyási, D.; Molnar, B.; Hesse, B.; et al. Biodegradation of a Magnesium Alloy Fixation Screw Used in a Guided Bone Regeneration Model in Beagle Dogs. Materials 2022, 15, 4111. [Google Scholar] [CrossRef]

- Rahim, M.I.; Ullah, S.; Mueller, P.P. Advances and Challenges of Biodegradable Implant Materials with a Focus on Magnesium-Alloys and Bacterial Infections. Metals 2018, 8, 532. [Google Scholar] [CrossRef]

- Abdudeen, A.; Abu Qudeiri, J.E.; Kareem, A.; Valappil, A.K. Latest Developments and Insights of Orthopedic Implants in Biomaterials Using Additive Manufacturing Technologies. J. Manuf. Mater. Process. 2022, 6, 162. [Google Scholar] [CrossRef]

- Mian, S.H.; Moiduddin, K.; Elseufy, S.M.; Alkhalefah, H. Adaptive Mechanism for Designing a Personalized Cranial Implant and Its 3D Printing Using PEEK. Polymers 2022, 14, 1266. [Google Scholar] [CrossRef]

- Dorozhkin, S.V. Calcium Orthophosphate-Based Bioceramics. Materials 2013, 6, 3840–3942. [Google Scholar] [CrossRef]

- Jiang, W.; Zhao, W.; Zhou, T.; Wang, L.; Qiu, T. A Review on Manufacturing and Post-Processing Technology of Vascular Stents. Micromachines 2022, 13, 140. [Google Scholar] [CrossRef]

- Chen, C.; Karshalev, E.; Guan, J.; Wang, J. Magnesium-based micromotors: Water-powered propulsion, multifunctionality, and biomedical and environmental applications. Small 2018, 14, 1704252. [Google Scholar] [CrossRef]

- Gabalcová, Z.; Gogola, P.; Gerhátová, Ž.; Palcut, M. Corrosion Behavior of an Mg2Sn Alloy. Materials 2022, 15, 2025. [Google Scholar] [CrossRef]

- Seetharaman, S.; Sankaranarayanan, D.; Gupta, M. Magnesium-Based Temporary Implants: Potential, Current Status, Applications, and Challenges. J. Funct. Biomater. 2023, 14, 324. [Google Scholar] [CrossRef] [PubMed]

- Kumar, R.; Katyal, P.; Kumar, K.; Sharma, N. Investigating machining characteristics and degradation rate of biodegradable ZM21 magnesium alloy in end milling process. Int. J. Lightweight Mater. Manuf. 2022, 5, 102–112. [Google Scholar] [CrossRef]

- Zagórski, I.; Korpysa, J. Surface Quality Assessment after Milling AZ91D Magnesium Alloy Using PCD Tool. Materials 2020, 13, 617. [Google Scholar] [CrossRef] [PubMed]

- Zagórski, I.; Kulisz, M.; Kłonica, M.; Matuszak, J. Trochoidal Milling and Neural Networks Simulation of Magnesium Alloys. Materials 2019, 12, 2070. [Google Scholar] [CrossRef]

- Takale, A.M.; Chougule, N.K. Effect of wire electro discharge machining process parameters on surface integrity of Ti49. 4Ni50. 6 shape memory alloy for orthopedic implant application. Mater. Sci. Eng. C 2019, 97, 264–274. [Google Scholar] [CrossRef]

- Bolat, Ç.; Karakılınç, U.; Yalçın, B.; Öz, Y.; Yavaş, Ç.; Ergene, B.; Ercetin, A.; Akkoyun, F. Effect of Drilling Parameters and Tool Geometry on the Thrust Force and Surface Roughness of Aerospace Grade Laminate Composites. Micromachines 2023, 14, 1427. [Google Scholar] [CrossRef]

- Akkoyun, F.; Ercetin, A.; Aslantas, K.; Pimenov, D.Y.; Giasin, K.; Lakshmikanthan, A.; Aamir, M. Measurement of Micro Burr and Slot Widths through Image Processing: Comparison of Manual and Automated Measurements in Micro-Milling. Sensors 2021, 21, 4432. [Google Scholar] [CrossRef]

- Mallick, P.S.; Pratap, A.; Patra, K. Review on cryogenic assisted micro-machining of soft polymer: An emphasis on molecular physics, chamber design, performance analysis and sustainability. J. Manuf. Process. 2022, 80, 930–957. [Google Scholar] [CrossRef]

- Karakılınç, U.; Ergene, B.; Yalçın, B.; Aslantaş, K.; Erçetin, A. Comparative Analysis of Minimum Chip Thickness, Surface Quality and Burr Formation in Micro-Milling of Wrought and Selective Laser Melted Ti64. Micromachines 2023, 14, 1160. [Google Scholar] [CrossRef]

- O’Toole, L.; Kang, C.W.; Fang, F.Z. Precision micro-milling process: State of the art. Adv. Manuf. 2021, 9, 173–205. [Google Scholar] [CrossRef]

- Teng, X.; Huo, D.; Wong, E.; Meenashisundaram, G.; Gupta, M. Micro-machinability of nanoparticle-reinforced Mg-based MMCs: An experimental investigation. Int. J. Adv. Manuf. Technol. 2016, 87, 2165–2178. [Google Scholar] [CrossRef]

- Ercetin, A.; Özgün, Ö.; Aslantas, K.; Aykutoğlu, G. The microstructure, degradation behavior and cytotoxicity effect of Mg–Sn–Zn alloys in vitro tests. SN Appl. Sci. 2020, 2, 173. [Google Scholar] [CrossRef]

- Zheng, Y.F.; Gu, X.N.; Witte, F. Biodegradable metals. Mater. Sci. Eng. R Rep. 2014, 77, 1–34. [Google Scholar] [CrossRef]

- Zhao, C.; Pan, F.; Zhao, S.; Pan, H.; Song, K.; Tang, A. Microstructure, corrosion behavior and cytotoxicity of biodegradable Mg–Sn implant alloys prepared by sub-rapid solidification. Mater. Sci. Eng. C 2015, 54, 245–251. [Google Scholar] [CrossRef] [PubMed]

- Ozgun, O.; Aslantas, K.; Ercetin, A. Powder metallurgy Mg-Sn alloys: Production and characterization. Sci. Iran. 2020, 27, 1255–1265. [Google Scholar]

- Kadirgama, K.; Abou-El-Hossein, K.A.; Noor, M.M.; Sharma, K.V.; Mohammad, B. Tool life and wear mechanism when machining Hastelloy C-22HS. Wear 2011, 270, 258–268. [Google Scholar] [CrossRef]

- Sima, M.; Özel, T. Modified material constitutive models for serrated chip formation simulations and experimental validation in machining of titanium alloy Ti–6Al–4V. Int. J. Mach. Tools Manuf. 2010, 50, 943–960. [Google Scholar] [CrossRef]

- Saglam, H.; Yaldiz, S.; Unsacar, F. The effect of tool geometry and cutting speed on main cutting force and tool tip temperature. Mater. Des. 2007, 28, 101–111. [Google Scholar] [CrossRef]

- Köpf, A.; Feistritzer, S.; Udier, K. Diamond coated cutting tools for machining of non-ferrous metals and fibre reinforced polymers. Int. J. Refract. Met. Hard Mater. 2006, 24, 354–359. [Google Scholar] [CrossRef]

- Malekian, M.; Park, S.S.; Jun, M.B. Tool wear monitoring of micro-milling operations. J. Mater. Process. Technol. 2009, 209, 4903–4914. [Google Scholar] [CrossRef]

- Bao, W.Y.; Tansel, I.N. Tansel Modeling micro-end-milling operations. Part I: Analytical cutting force model. Int. J. Mach. Tool Manuf. 2000, 40, 2155–2173. [Google Scholar] [CrossRef]

- Chae, J.; Park, S.S.; Freiheit, T. Investigation of micro-cutting operations. Int. J. Mach. Tools Manuf. 2006, 46, 313–332. [Google Scholar] [CrossRef]

- Dinesh, S.; Antony, A.G.; Rajaguru, K.; Vijayan, V. Experimental investigation and optimization of material removal rate and surface roughness in centerless grinding of magnesium alloy using grey relational analysis. Mech. Mech. Eng. 2017, 21, 17–28. [Google Scholar]

- Gupta, M.; Kumar, S. Investigation of surface roughness and MRR for turning of UD-GFRP using PCA and Taguchi method. Eng. Sci. Technol. Int. J. 2015, 18, 70–81. [Google Scholar] [CrossRef]

- Uhlmann, E.; Lypovka, P.; Hochschild, L.; Schröer, N. Influence of rail grinding process parameters on rail surface roughness and surface layer hardness. Wear 2016, 366, 287–293. [Google Scholar] [CrossRef]

- Erçetin, A.; Aslantas, K.; Özgün, Ö. Micro-end milling of biomedical TZ54 magnesium alloy produced through powder metallurgy. Mach. Sci. Technol. 2020, 24, 924–947. [Google Scholar] [CrossRef]

| Chemical Composition (wt%) | Density (g·cm−3) | Hardness (HV) | Tensile Strength (MPa) |

|---|---|---|---|

| 87 wt% Mg 13 wt% Sn | 1.898 | 73.3 | 157.2 |

| Geometrical Properties | Characteristic Properties | ||||

|---|---|---|---|---|---|

| Shaft diameter (mm) | 3.2 | Helix length (mm) | 2.3 | Coating type | Uncoated |

| Tool diameter (mm) | 0.508 | Helix angle, θ (°) | 30 | Hardness (HV 0.05) | 1680 |

| Length (mm) | 38.3 | Rake angle, α (°) | 15 | Cutting edge radius (µm) | 1–1.5 |

| Flute number | 2 | Relief angle, γ (°) | 6 | Chemical composition | 92 wt% WC + 8 wt% Co |

| Experiment No | Feed, fz (µm/Tooth) | Cutting Speed, Vc (m/min) | Depth of Cut, ap (µm) |

|---|---|---|---|

| 1; 2; 3; 4 | 1 | 7.9; 15.7; 31.4; 62.8 | 200 |

| 5; 6; 7;8 | 2.5 | ||

| 9; 10; 11; 12 | 5 | ||

| 13; 14; 15; 16 | 10 | ||

| 17; 18; 19; 20 | 1 | 7.9; 15.7; 31.4; 62.8 | 400 |

| 21; 22; 23; 24 | 2.5 | ||

| 25; 26; 27; 28 | 5 | ||

| 29; 30; 31; 32 | 10 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ercetin, A.; Aslantaş, K.; Özgün, Ö.; Perçin, M.; Chandrashekarappa, M.P.G. Optimization of Machining Parameters to Minimize Cutting Forces and Surface Roughness in Micro-Milling of Mg13Sn Alloy. Micromachines 2023, 14, 1590. https://doi.org/10.3390/mi14081590

Ercetin A, Aslantaş K, Özgün Ö, Perçin M, Chandrashekarappa MPG. Optimization of Machining Parameters to Minimize Cutting Forces and Surface Roughness in Micro-Milling of Mg13Sn Alloy. Micromachines. 2023; 14(8):1590. https://doi.org/10.3390/mi14081590

Chicago/Turabian StyleErcetin, Ali, Kubilay Aslantaş, Özgür Özgün, Mustafa Perçin, and Manjunath Patel Gowdru Chandrashekarappa. 2023. "Optimization of Machining Parameters to Minimize Cutting Forces and Surface Roughness in Micro-Milling of Mg13Sn Alloy" Micromachines 14, no. 8: 1590. https://doi.org/10.3390/mi14081590

APA StyleErcetin, A., Aslantaş, K., Özgün, Ö., Perçin, M., & Chandrashekarappa, M. P. G. (2023). Optimization of Machining Parameters to Minimize Cutting Forces and Surface Roughness in Micro-Milling of Mg13Sn Alloy. Micromachines, 14(8), 1590. https://doi.org/10.3390/mi14081590