Effect of Drilling Parameters and Tool Geometry on the Thrust Force and Surface Roughness of Aerospace Grade Laminate Composites

Abstract

1. Introduction

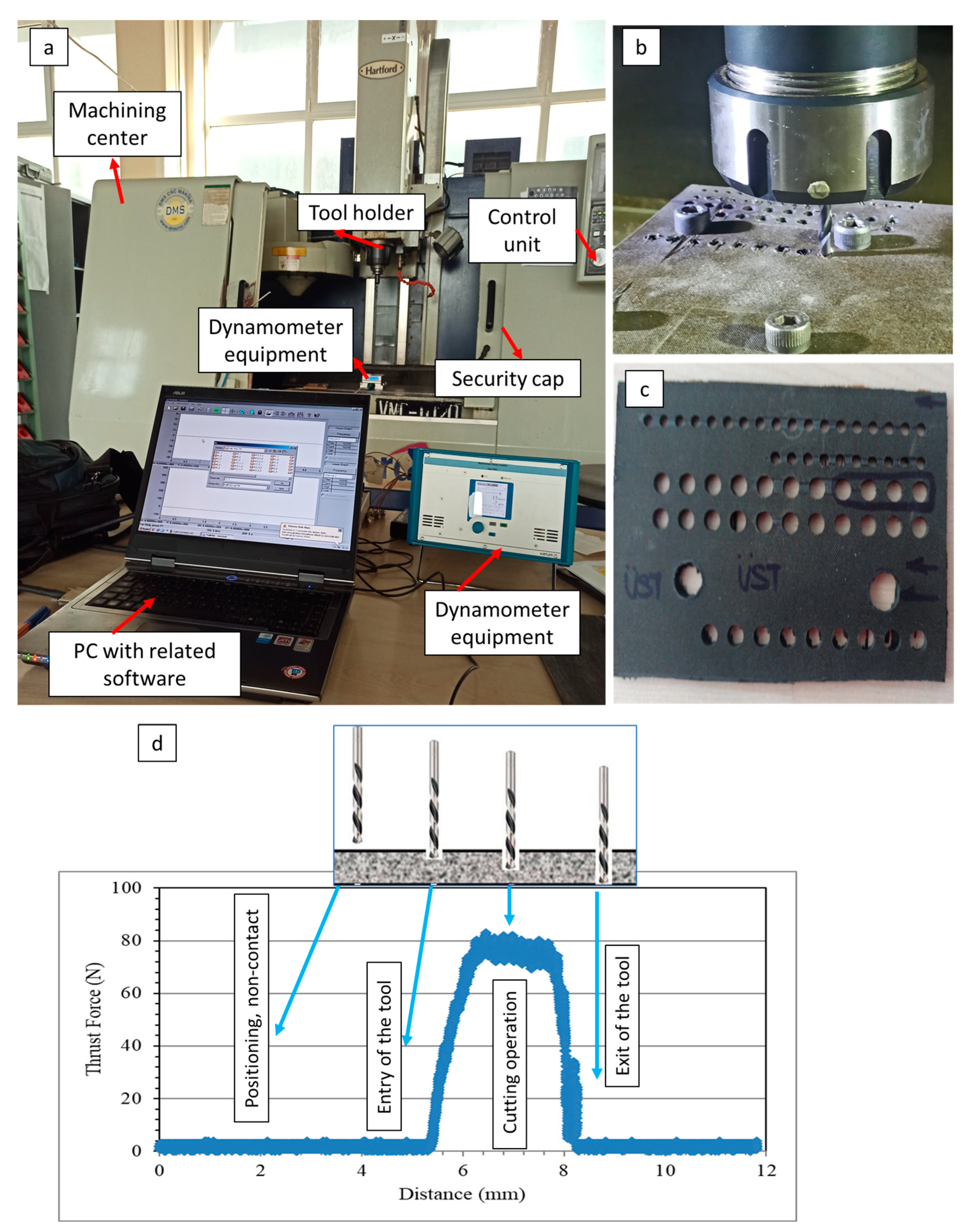

2. Materials and Methods

2.1. Composite Constituents and Sample Manufacturing

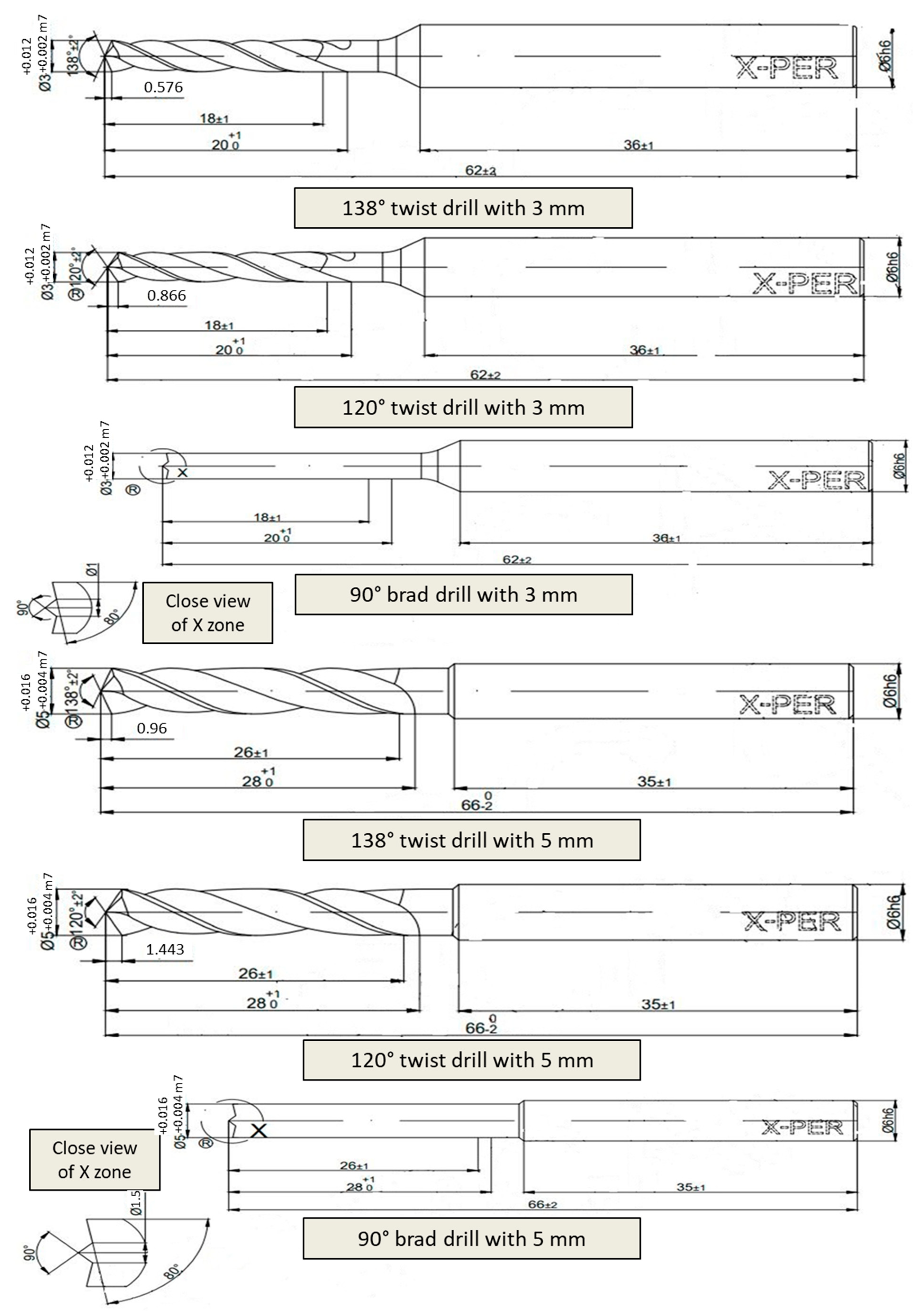

2.2. Taguchi Experiment Design and Drilling Process Conditions

3. Results and Discussions

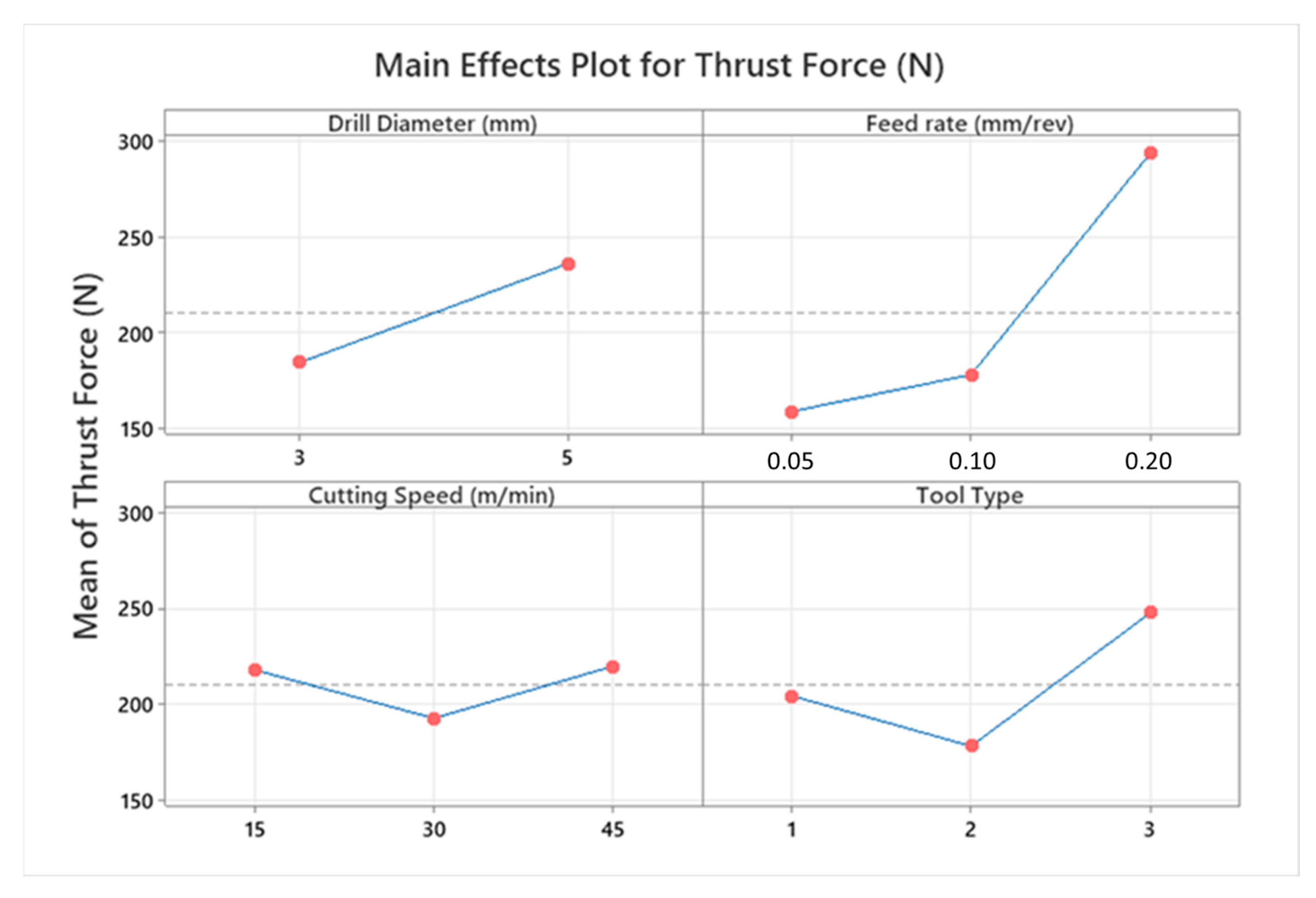

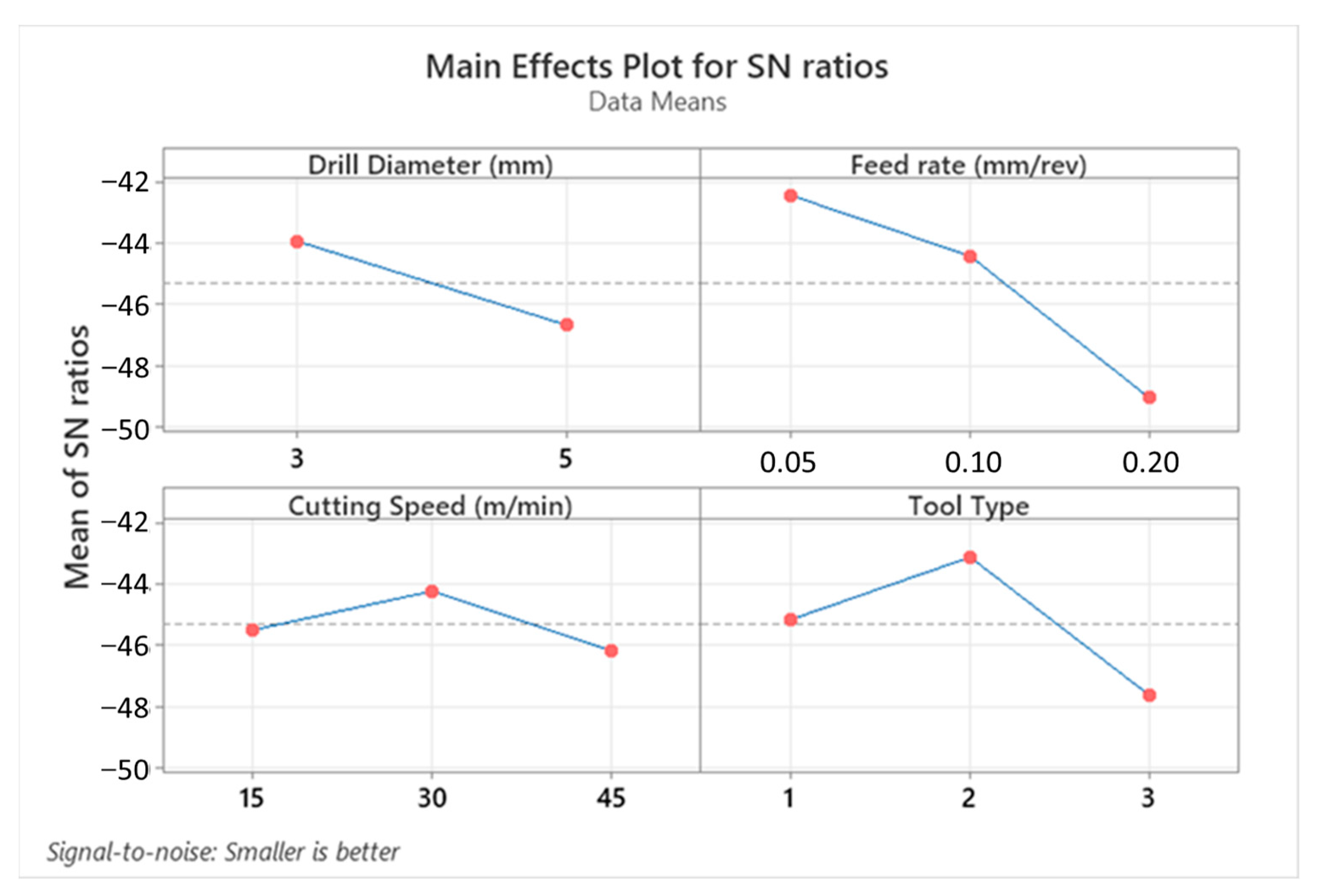

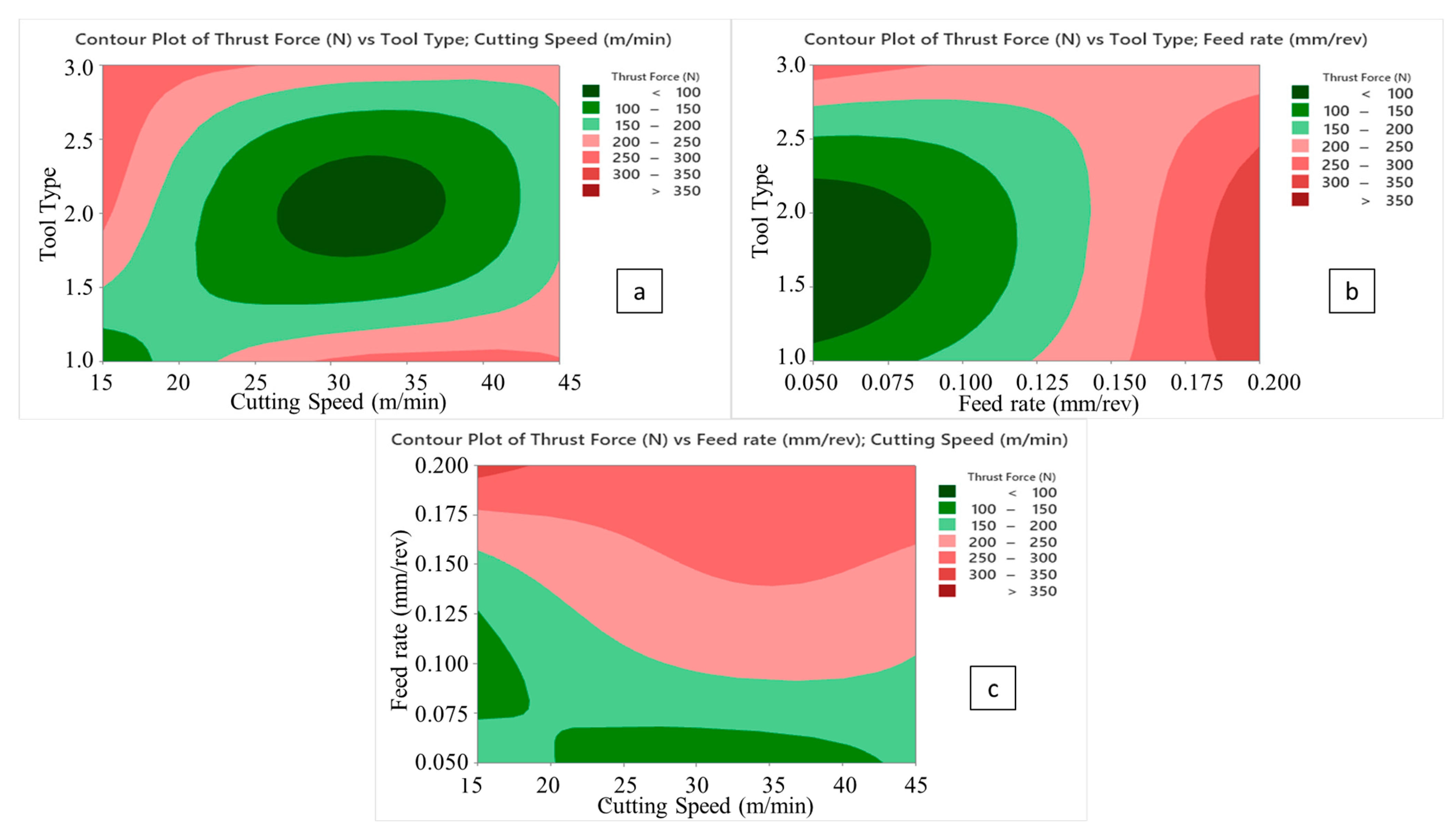

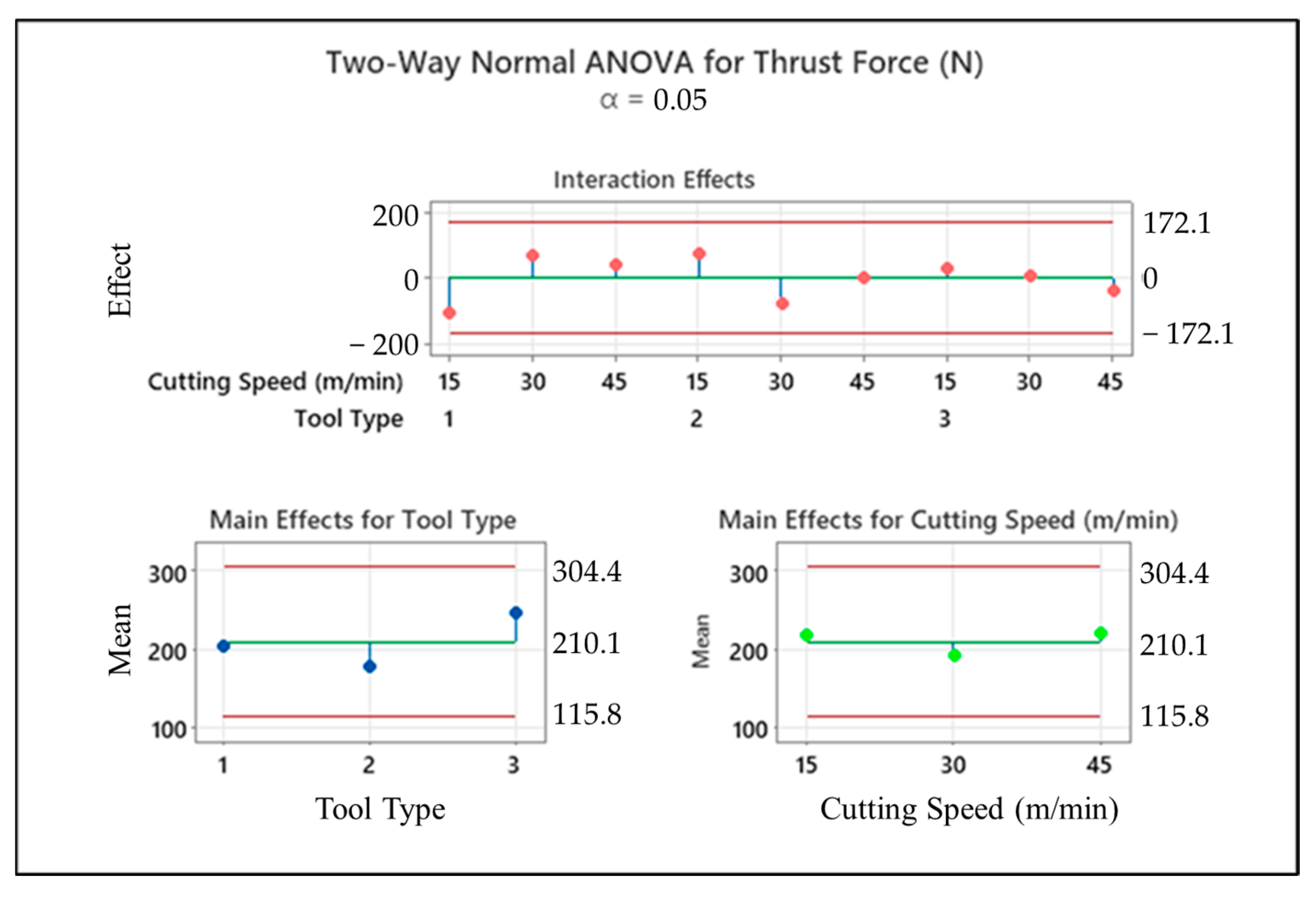

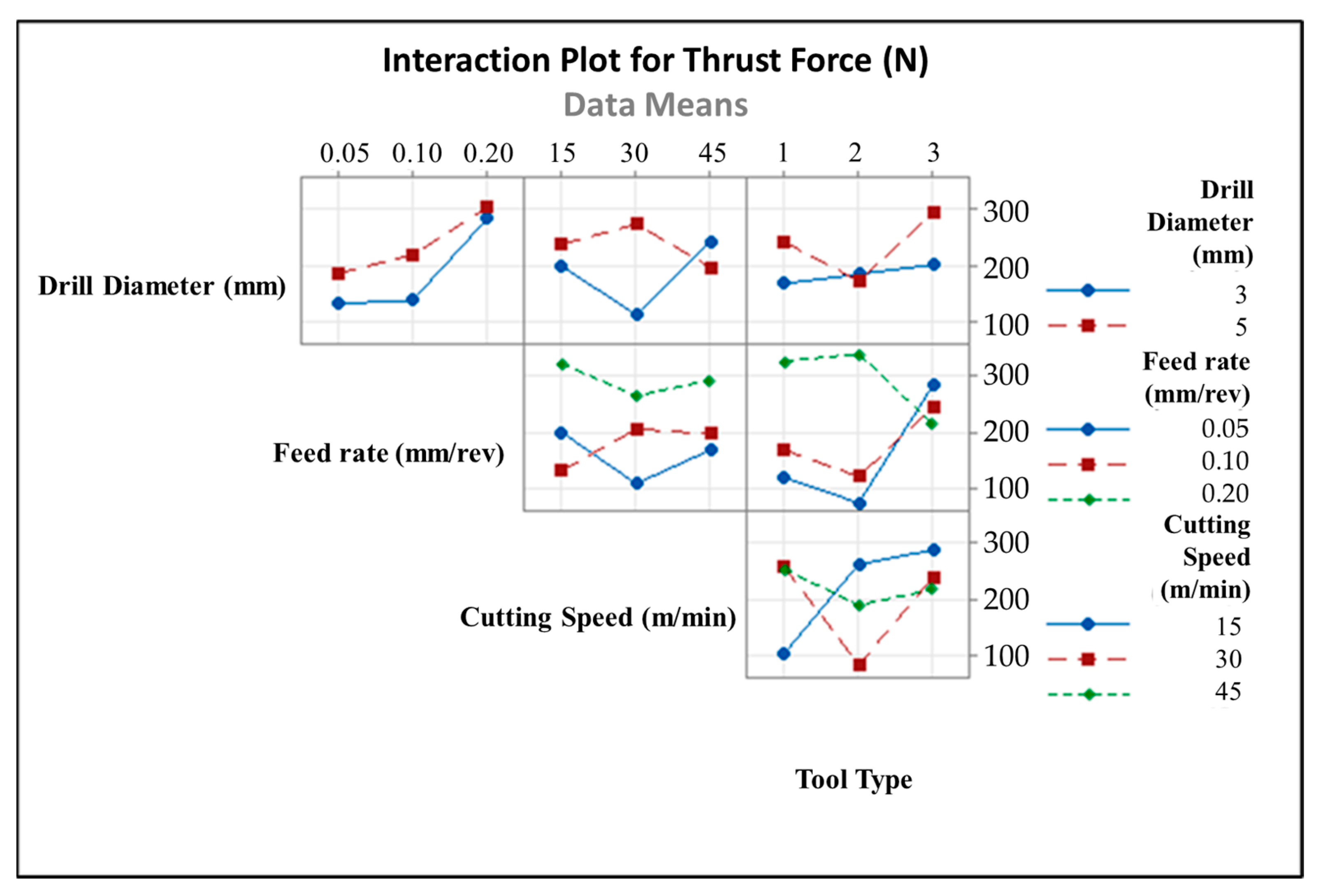

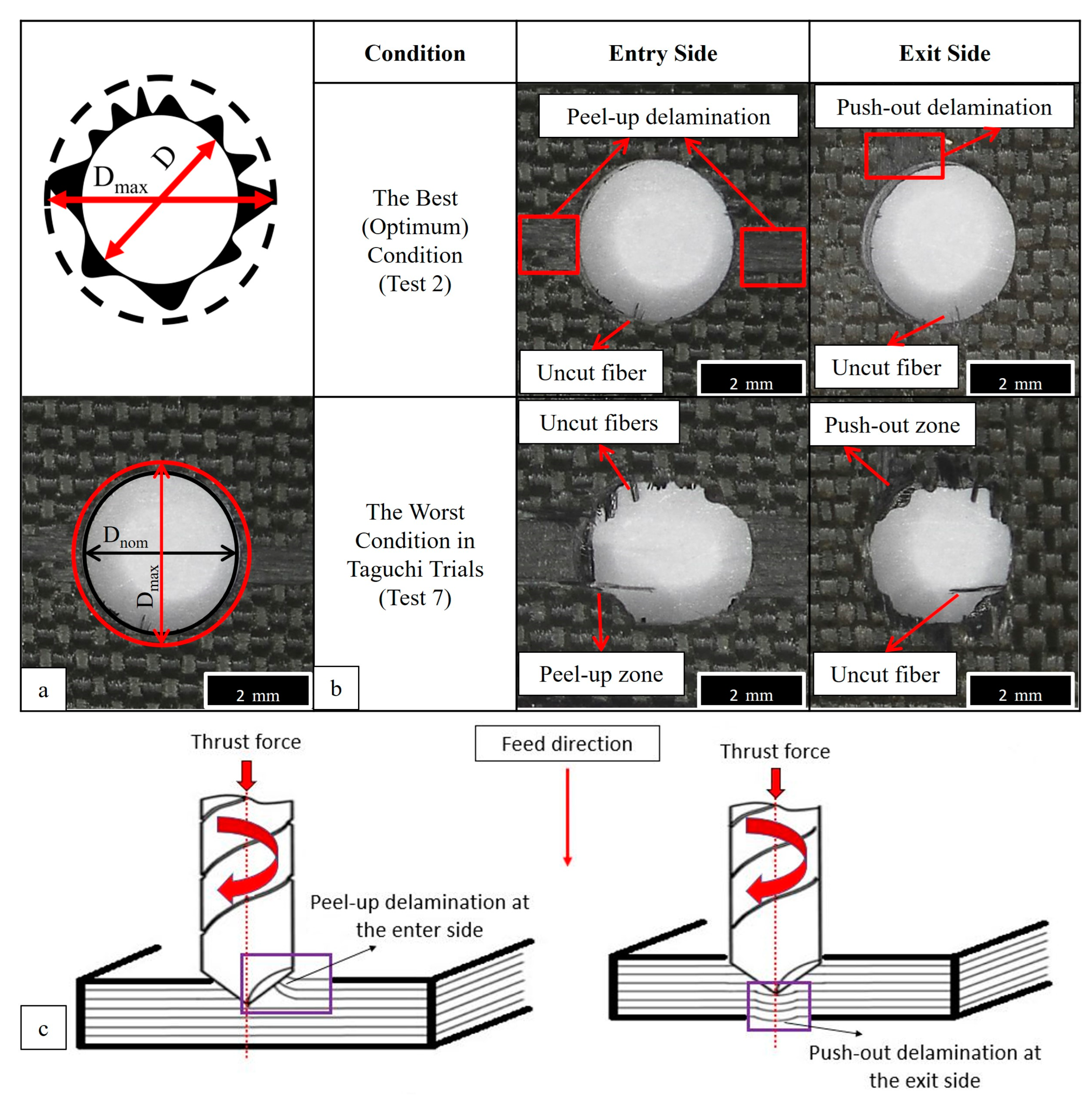

3.1. Thrust Force Analyses

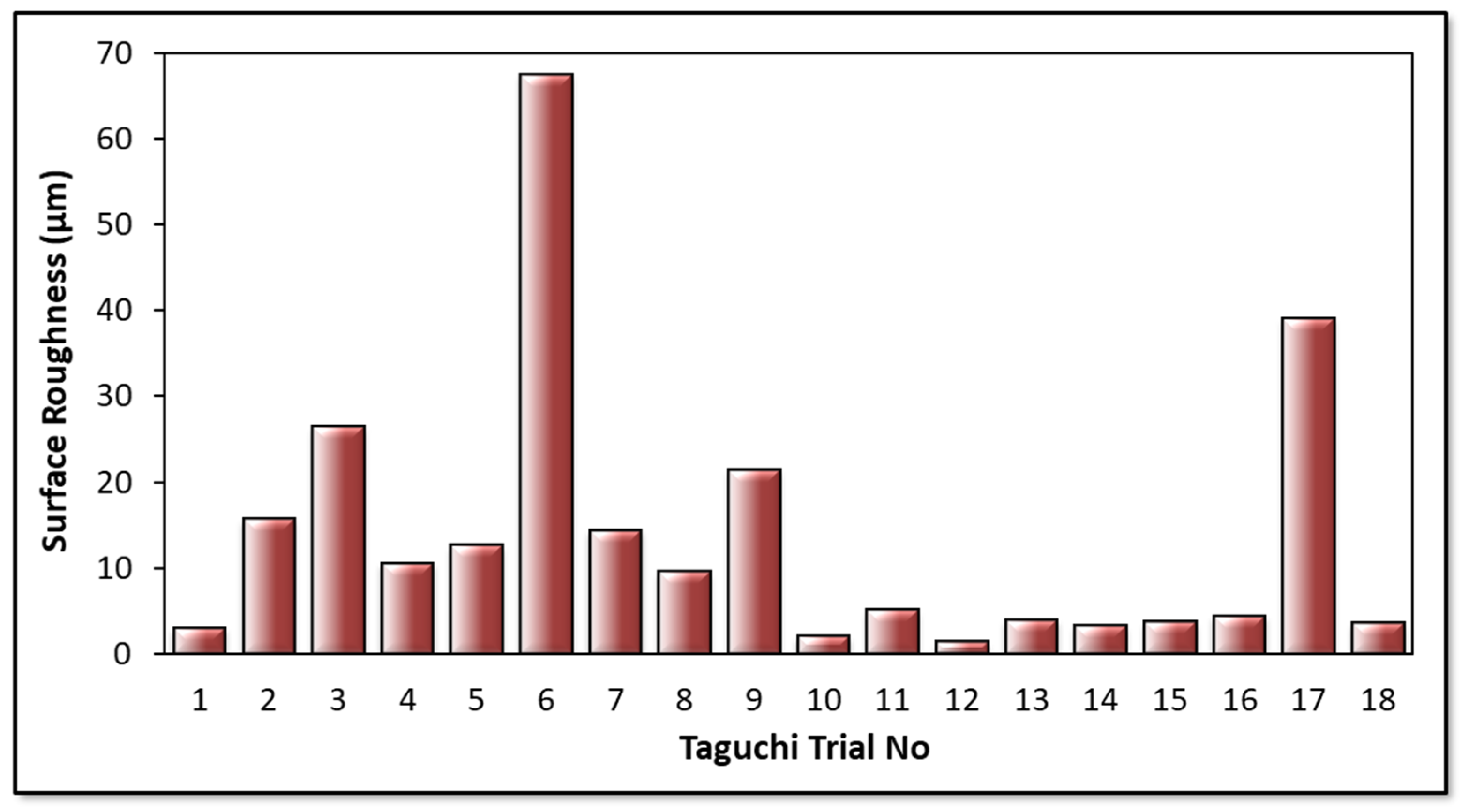

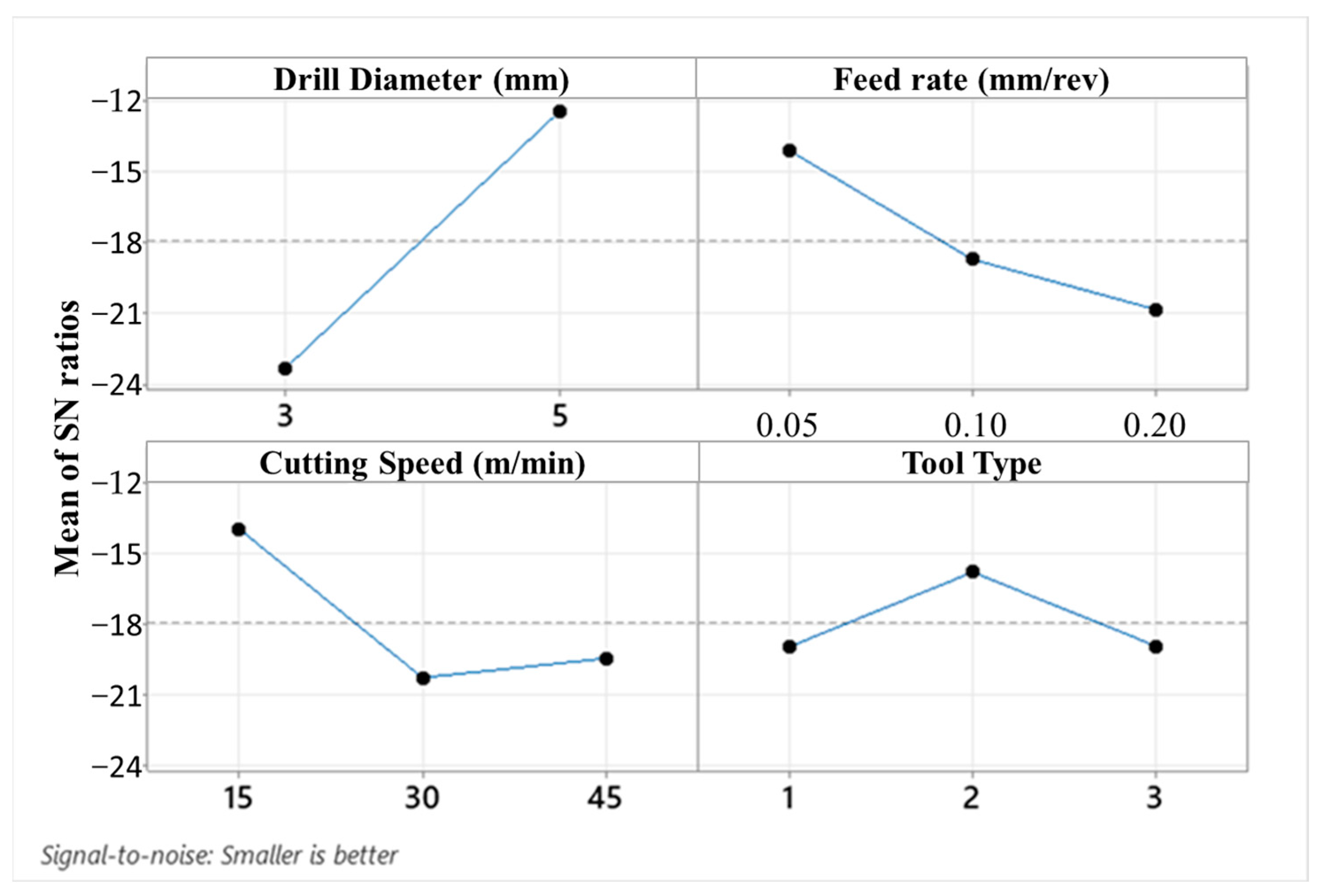

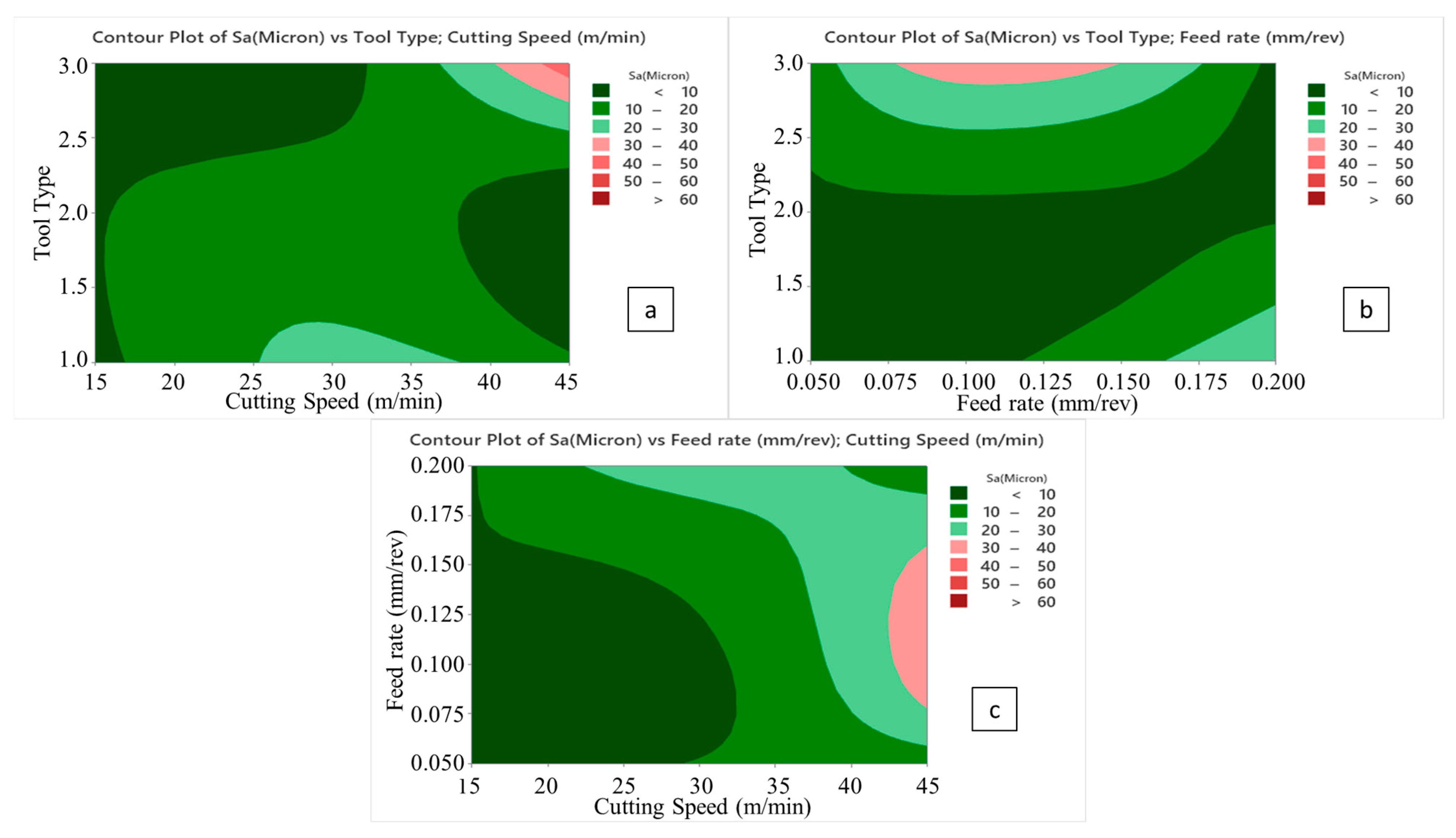

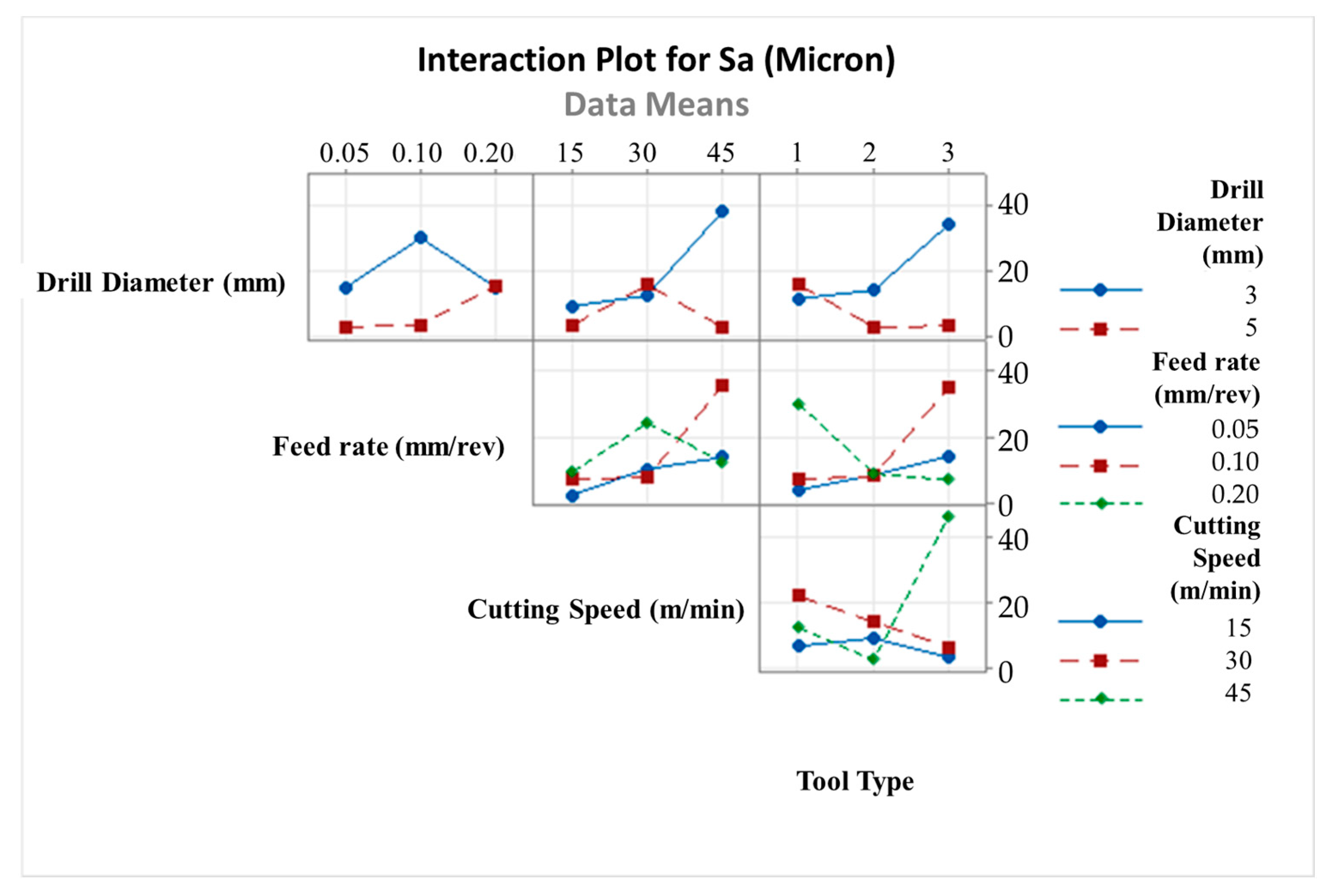

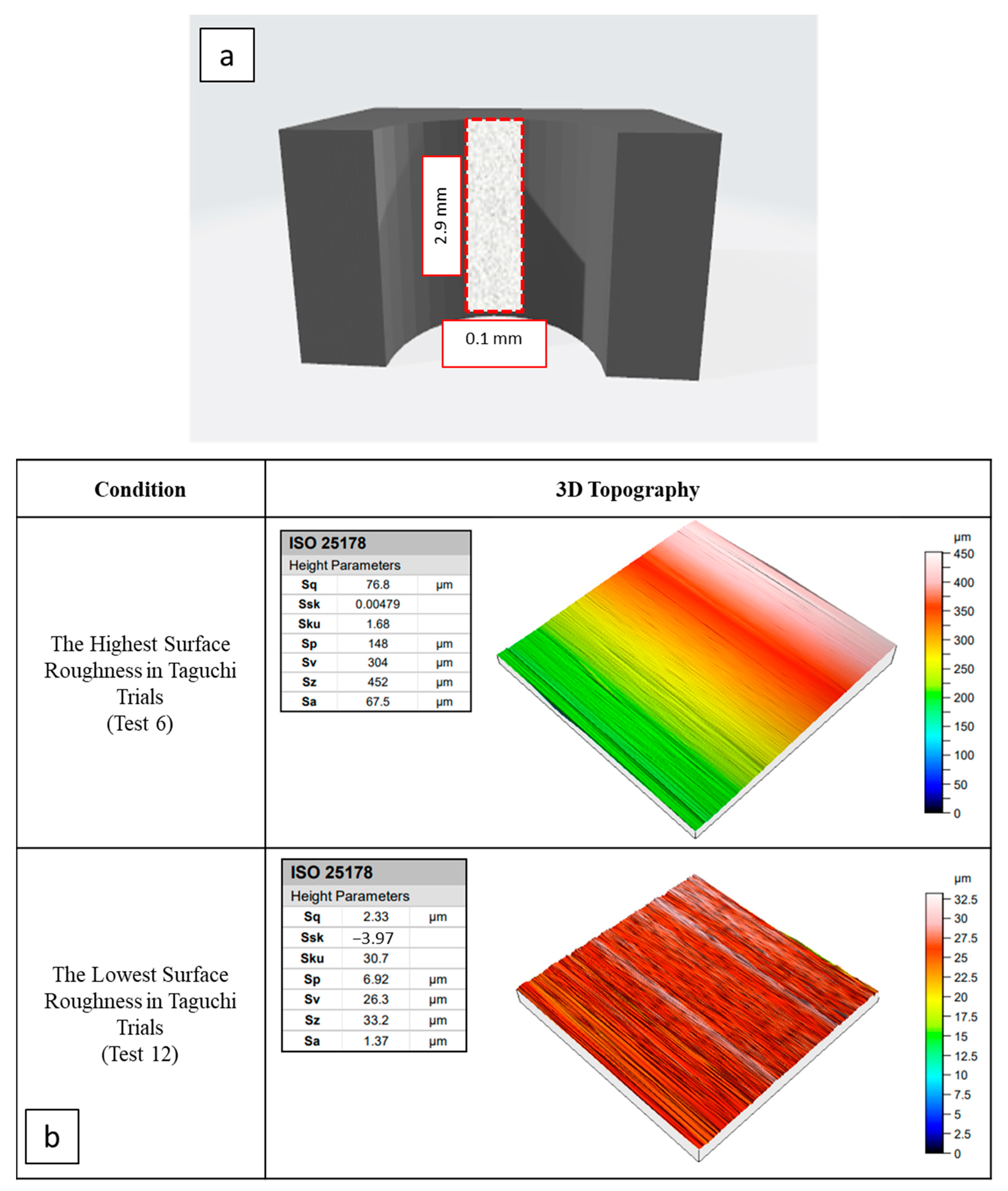

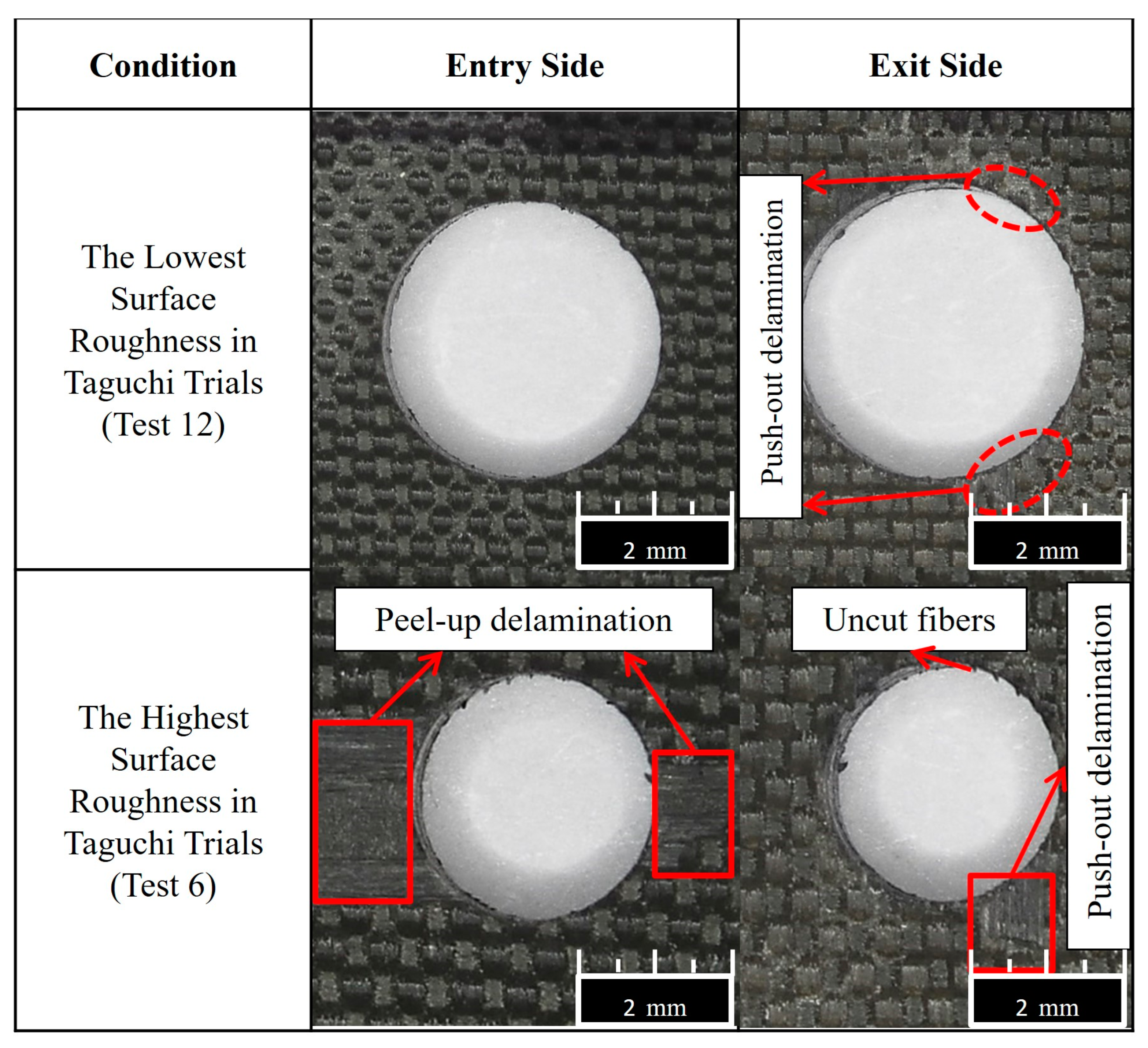

3.2. Surface Roughness Analyses

4. Conclusions

- ➢

- It is known that chip flow becomes more difficult with the softening of the polymer content at low cutting speed and high feed rates in polymeric-based composites. Therefore, the higher thrust force was measured with a cutting speed of 15 m/min and a feed rate of 0.2 mm/rev using a 5 mm tool diameter.

- ➢

- Brad tool design of type III caused a further increase in thrust force, areal surface roughness and delamination. On the other hand, the type II drill with a 120° point angle has an advantage on cutting force, surface roughness, and delamination.

- ➢

- Areal surface roughness rose with increasing feed rate, cutting speed, and point angle. In addition, an increase in drill diameter caused a diminishment in surface roughness and an increase in thrust force.

- ➢

- Finally, from Taguchi analyses and measurements, the 2nd and 12th drilling conditions can be evaluated as reasonable for low drilling force, areal surface roughness, and delamination.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kopparthy, S.D.S.; Netravali, A.N. Green composites for structural applications. Compos. Part C Open Access 2021, 6, 100169. [Google Scholar] [CrossRef]

- Olabi, A.G.; Abdelkareem, M.A. Renewable energy and climate change. Renew. Sustain. Energy Rev. 2022, 158, 112111. [Google Scholar] [CrossRef]

- Kupski, J.; De Freitas, S.T. Design of adhesively bonded lap joints with laminated CFRP adherends: Review, challenges and new opportunities for aerospace structures. Compos. Struct. 2021, 268, 113923. [Google Scholar] [CrossRef]

- Stephen, C.; Mourad, A.H.I.; Shivamurthy, B.; Selvam, R. Energy absorption and damage assessment of non-hybrid and hybrid fabric epoxy composite laminates: Experimental and numerical study. J. Mater. Res. Technol. 2021, 14, 3080–3091. [Google Scholar] [CrossRef]

- Garrido, M.; Teixeira, R.; Correia, J.R.; Sutherland, L.S. Quasi-static indentation and impact in glass-fibre reinforced polymer sandwich panels for civil and ocean engineering applications. J. Sandw. Struct. Mater. 2021, 23, 194–221. [Google Scholar] [CrossRef]

- Mazzuca, P.; Firmo, J.P.; Correia, J.R.; Castilho, E. Influence of elevated temperatures on the mechanical properties of glass fibre reinforced polymer laminates produced by vacuum infusion. Constr. Build. Mater. 2022, 345, 128340. [Google Scholar] [CrossRef]

- Ramezani, F.; Carbas, R.J.; Marques, E.A.; Ferreira, A.M.; da Silva, L.F. A study of the fracture mechanisms of hybrid carbon fiber reinforced polymer laminates reinforced by thin-ply. Polym. Compos. 2023, 44, 1672–1683. [Google Scholar] [CrossRef]

- Zhang, K.; Ma, L.H.; Song, Z.Z.; Gao, H.; Zhou, W.; Liu, J.; Tao, R. Strength prediction and progressive damage analysis of carbon fiber reinforced polymer-laminate with circular holes by an efficient Artificial Neural Network. Compos. Struct. 2022, 296, 115835. [Google Scholar] [CrossRef]

- Kumar, S.; Sharma, N.; Biswas, R.; Singh, K.K. Effect of temperature on the flexural and ILSS behaviour of symmetric and asymmetric basalt fibre-reinforced polymer composites. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Biswas, R.; Sharma, N.; Singh, K.K. Influence of fiber areal density on mechanical behavior of basalt fiber/epoxy composites under varying loading rates: An experimental and statistical approach. Polym. Compos. 2023, 44, 2222–2235. [Google Scholar] [CrossRef]

- Yang, G.; Park, M.; Park, S.J. Recent progresses of fabrication and characterization of fibers-reinforced composites: A review. Compos. Commun. 2019, 14, 34–42. [Google Scholar] [CrossRef]

- Shrivastava, R.; Singh, K.K. Interlaminar fracture toughness characterization of laminated composites: A review. Polym. Rev. 2020, 60, 542–593. [Google Scholar] [CrossRef]

- Kim, S.Y.; Park, S.J.; Kim, Y.H. Optimization of HNT nanoparticle distribution based on EPD process in epoxy–CFRP composites. Mod. Phys. Lett. B 2022, 36, 2242039. [Google Scholar] [CrossRef]

- Nugroho, G.; Budiyantoro, C. Optimization of Fiber Factors on Flexural Properties for Carbon Fiber Reinforced Polypropylene. J. Compos. Sci. 2022, 6, 160. [Google Scholar] [CrossRef]

- Mulenga, T.K.; Ude, A.U.; Vivekanandhan, C. Techniques for Modelling and Optimizing the Mechanical Properties of Natural Fiber Composites: A Review. Fibers 2021, 9, 6. [Google Scholar] [CrossRef]

- Cai, Y.; An, X.; Zou, Q.; Yao, D.; Fu, H.; Zhang, H.; Yang, X. Numerical Investigation on the Design and Optimization of Stacking Pattern for High Flexural Performance Carbon Fiber Reinforced Resin Matrix Composites. Fibers Polym. 2022, 23, 2719–2735. [Google Scholar] [CrossRef]

- Boddeti, N.; Rosen, D.W.; Maute, K.; Dunn, M.L. Multiscale optimal design and fabrication of laminated composites. Compos. Struct. 2019, 228, 111366. [Google Scholar] [CrossRef]

- Krogh, C.; Bak, B.L.; Lindgaard, E.; Olesen, A.M.; Hermansen, S.M.; Broberg, P.H.; Jakobsen, J. A simple MATLAB draping code for fiber-reinforced composites with application to optimization of manufacturing process parameters. Struct. Multidiscip. Optim. 2021, 64, 457–471. [Google Scholar] [CrossRef]

- Yaşar, N.; Günay, M. Experimental investigation on novel drilling strategy of CFRP laminates using variable feed rate. J. Braz. Soc. Mech. Sci. Eng. 2019, 41, 150. [Google Scholar] [CrossRef]

- Aamir, M.; Giasin, K.; Tolouei-Rad, M.; Ud Din, I.; Hanif, M.I.; Kuklu, U.; Pimenov, D.Y.; Ikhlaq, M. Effect of Cutting Parameters and Tool Geometry on the Performance Analysis of One-Shot Drilling Process of AA2024-T3. Metals 2021, 11, 854. [Google Scholar] [CrossRef]

- Prakash, C.; Pramanik, A.; Basak, A.K.; Dong, Y.; Debnath, S.; Shankar, S.; Singh, S.; Wu, L.Y.; Zheng, H.Y. Investigating the Efficacy of Adhesive Tape for Drilling Carbon Fibre Reinforced Polymers. Materials 2021, 14, 1699. [Google Scholar] [CrossRef] [PubMed]

- Shanmugam, V.; Marimuthu, U.; Rajendran, S.; Veerasimman, A.; Basha, A.M.; Majid, M.S.B.A.; Esmaeely Neisiany, R.; Försth, M.; Sas, G.; Javad Razavi, S.M.; et al. Experimental Investigation of Thrust Force, Delamination and Surface Roughness in Drilling Hybrid Structural Composites. Materials 2021, 14, 4468. [Google Scholar] [CrossRef] [PubMed]

- Ravai-Nagy, S.; Pop, A.B.; Titu, A.M. Determination of Processing Precision of Hole in Industrial Plastic Materials. Polymers 2023, 15, 347. [Google Scholar] [CrossRef]

- Shahri, M.N.; Najafabadi, M.A.; Akhlaghi, M. On the improvement of analytical delamination model for drilling of laminated composites using Galerkin method. Compos. Part B Eng. 2020, 194, 108021. [Google Scholar] [CrossRef]

- Khashaba, U.A.; Abd-Elwahed, M.S.; Najjar, I.; Melaibari, A.; Ahmed, K.I.; Zitoune, R.; Eltaher, M.A. Heat-Affected Zone and Mechanical Analysis of GFRP Composites with Different Thicknesses in Drilling Processes. Polymers 2021, 13, 2246. [Google Scholar] [CrossRef]

- Upputuri, H.B.; Nimmagadda, V.S.; Duraisamy, E. Optimization of drilling parameters on carbon fiber reinforced polymer composites using fuzzy logic. Mater. Today Proc. 2020, 23, 528–535. [Google Scholar] [CrossRef]

- Yu, J.; Chen, T.; Zhao, Y. Study on Optimization of Drilling Parameters for Laminated Composite Materials. Materials 2023, 16, 1796. [Google Scholar] [CrossRef]

- Mudhukrishnan, M.; Hariharan, P.; Palanikumar, K. Measurement and analysis of thrust force and delamination in drilling glass fiber reinforced polypropylene composites using different drills. Measurement 2020, 149, 106973. [Google Scholar] [CrossRef]

- Abd-Elwahed, M.S. Drilling Process of GFRP Composites: Modeling and Optimization Using Hybrid ANN. Sustainability 2022, 14, 6599. [Google Scholar] [CrossRef]

- Lee, J.H.; Ge, J.C.; Song, J.H. Study on Burr Formation and Tool Wear in Drilling CFRP and Its Hybrid Composites. Appl. Sci. 2021, 11, 384. [Google Scholar] [CrossRef]

- Goutham, K.B.; Mathew, N.T.; Vijayaraghavan, L. Delamination and tool wear in drilling of carbon fabric reinforced epoxy composite laminate. Mater. Today Proc. 2022, 50, 823–829. [Google Scholar] [CrossRef]

- Khashaba, U.A. A novel approach for characterization of delamination and burr areas in drilling FRP composites. Compos. Struct. 2022, 290, 115534. [Google Scholar] [CrossRef]

- Babu, N.M.; Mathivanan, N.R.; Kumar, K.V. Influence of machining parameters on the response variable during drilling of the hybrid laminate. Aust. J. Mech. Eng. 2022, 20, 285–294. [Google Scholar] [CrossRef]

- Venkatasudhahar, M.; Velu, R. Effect of Drilling Force on Delamination of Abaca/Kenaf/Carbon Fiber Reinforced Hybrid Composite. Curr. Mater. Sci. Former. Recent Pat. Mater. Sci. 2019, 12, 99–105. [Google Scholar] [CrossRef]

- Karakılınç, U.; Ergene, B.; Yalçın, B.; Aslantaş, K.; Erçetin, A. Comparative Analysis of Minimum Chip Thickness, Surface Quality and Burr Formation in Micro-Milling of Wrought and Selective Laser Melted Ti64. Micromachines 2023, 14, 1160. [Google Scholar] [CrossRef]

- Ergene, B.; Bolat, C.; Karakilinc, U.; Irez, A.B. A comprehensive investigation of drilling performance of anisotropic stacked glass-carbon fiber reinforced hybrid laminate composites. Polym. Compos. 2023, 44, 2656–2670. [Google Scholar] [CrossRef]

- Low, K.O.; Teng, S.M.; Johar, M.; Israr, H.A.; Wong, K.J. Mode I delamination behaviour of carbon/epoxy composite at different displacement rates. Compos. Part B Eng. 2019, 176, 107293. [Google Scholar] [CrossRef]

- Standard EN 6032; Aerospace Series—Fibre Reinforced Plastics—Test Method—Determination of the Glass Transition Temperatures. European Committee for Standardization (CEN): Brussels, Belgium, 2015.

- ASTM D3039/D3039M-17; Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials. ASTM: West Conshohocken, PA, USA, 2015.

- ASTM Standard D695; Standard Test Method for Compressive Properties of Rigid Plastics. ASTM International: West Conshohocken, PA, USA, 2015.

- Standard BS EN2563; Carbon Fibre Reinforced Plastics. Unidirectional Laminates. Determination of the Apparent Interlaminar Shear Strength. The British Standards Institution: London, UK, 1997.

- Taheri, M.; Moghaddam, M.R.A.; Arami, M. Improvement of the/Taguchi/design optimization using artificial intelligence in three acid azo dyes removal by electrocoagulation. Environ. Prog. Sustain. Energy 2015, 34, 1568–1575. [Google Scholar] [CrossRef]

- Yalçın, B.; Yüksel, A.; Aslantaş, K.; Der, O.; Ercetin, A. Optimization of Micro-Drilling of Laminated Aluminum Composite Panel (Al–PE) Using Taguchi Orthogonal Array Design. Materials 2023, 16, 4528. [Google Scholar] [CrossRef]

- Dutta, S.; Narala, S.K. Optimizing turning parameters in the machining of AM alloy using Taguchi methodology. Measurement 2021, 169, 108340. [Google Scholar] [CrossRef]

- Xu, J.; Li, C.; El Mansori, M.; Liu, G.; Chen, M. Study on the frictional heat at tool-work interface when drilling CFRP composites. Procedia Manuf. 2018, 26, 415–423. [Google Scholar] [CrossRef]

- Ramesh, M.; Gopinath, A. Measurement and analysis of thrust force in drilling sisal-glass fiber reinforced polymer composites. IOP Conf. Ser. Mater. Sci. Eng. 2017, 197, 012056. [Google Scholar] [CrossRef]

- Marques, A.T.; Durão, L.M.; Magalhães, A.G.; Silva, J.F.; Tavares, J.M.R. Delamination analysis of carbon fibre reinforced laminates: Evaluation of a special step drill. Compos. Sci. Technol. 2009, 69, 2376–2382. [Google Scholar] [CrossRef]

- Lu, S.R.; Wei, C.; Yu, J.H.; Yang, X.W.; Jiang, Y.M. Preparation and characterization of epoxy nanocomposites by using PEO-grafted silica particles as modifier. J. Mater. Sci. 2007, 42, 6708–6715. [Google Scholar] [CrossRef]

- Soepangkat, B.O.P.; Norcahyo, R.; Effendi, M.K.; Pramujati, B. Multi-response optimization of carbon fiber reinforced polymer (CFRP) drilling using back propagation neural network-particle swarm optimization (BPNN-PSO). Eng. Sci. Technol. Int. J. 2020, 23, 700–713. [Google Scholar] [CrossRef]

- Rodriguez, I.; Soriano, D.; Ortiz-de-Zarate, G.; Cuesta, M.; Pušavec, F.; Arrazola, P.J. Effect of Tool Geometry and LCO2 Cooling on Cutting Forces and Delamination when Drilling CFRP Composites Using PCD Tools. Procedia CIRP 2022, 108, 752–757. [Google Scholar] [CrossRef]

- Xu, J.; Yin, Y.; Davim, J.P.; Li, L.; Ji, M.; Geier, N.; Chen, M. A critical review addressing drilling-induced damage of CFRP composites. Compos. Struct. 2022, 294, 115594. [Google Scholar] [CrossRef]

- Mohan, N.S.; Kulkarni, S.M.; Ramachandra, A. Delamination analysis in drilling process of glass fiber reinforced plastic (GFRP) composite materials. J. Mater. Process. Technol. 2007, 186, 265–271. [Google Scholar] [CrossRef]

- Velaga, M.; Cadambi, R.M. Drilling of GFRP composites for minimising delamination effect. Mater. Today Proc. 2017, 4, 11229–11236. [Google Scholar] [CrossRef]

- Köklü, U.; Demir, O.; Avcı, A.; Etyemez, A. Drilling performance of functionally graded composite: Comparison with glass and carbon/epoxy composites. J. Mech. Sci. Technol. 2017, 31, 4703–4709. [Google Scholar] [CrossRef]

- Melentiev, R.; Priarone, P.C.; Robiglio, M.; Settineri, L. Effects of tool geometry and process parameters on delamination in CFRP drilling: An overview. Procedia Cirp 2016, 45, 31–34. [Google Scholar] [CrossRef]

- Krishnaraj, V.; Vijayarangan, S.; Suresh, G. An investigation on high speed drilling of glass fibre reinforced plastic (GFRP). Indian J. Eng. Mater. Sci. 2005, 12, 189–195. [Google Scholar]

- ISO 25178-2:2012; Geometrical Product Specifications (GPS)—Surface Texture: Areal, Part 1: Terms, Definitions and Surface Texture Parameters. ISO: Geneva, Switzerland, 2012.

- Devesa, L.F.S.; Matos, J.E.; Durão, L.M.P. Experimental assessment of delamination extension on carbon/epoxy drilled plates. Compos. Part C Open Access 2021, 5, 100144. [Google Scholar] [CrossRef]

| Name | Property | Standard |

|---|---|---|

| Resin content (%) | 40 | - |

| Composite thickness (mm) | 2.92 | - |

| Nominal ply thickness (mm) | 0.184 | - |

| Laminate density (kg/m3) | 1570 | - |

| Glass-transition temperature (°C) | 190 | EN 6032 [38] |

| Tensile strength (MPa) | 3520 | ASTM D3039 [39] |

| Tensile modulus (GPa) | 176 | ASTM D3039 [39] |

| Compression strength (MPa) | 1880 | ASTM D695 [40] |

| Compression modulus (GPa) | 156 | ASTM D695 [40] |

| Interlaminar shear strength (MPa) | 105 | EN 2563 [41] |

| Symbols | Drilling Parameters | Levels | ||

|---|---|---|---|---|

| 1 | 2 | 3 | ||

| A | Drill diameter (mm) | 3 | 5 | |

| B | Feed rate (mm/rev) | 0.05 | 0.1 | 0.2 |

| C | Cutting speed (m/min) | 15 | 30 | 45 |

| D | Tool type (Point Angle) | Twist drill (138°) | Twist drill (120°) | Twist drill (90°) |

| Trial No | Tool Diameter (mm) | Feed Rate (mm/rev) | Cutting Speed (m/min) | Tool Type |

|---|---|---|---|---|

| 1 | 3 | 0.05 | 15 | 1 |

| 2 | 3 | 0.05 | 30 | 2 |

| 3 | 3 | 0.05 | 45 | 3 |

| 4 | 3 | 0.10 | 15 | 1 |

| 5 | 3 | 0.10 | 30 | 2 |

| 6 | 3 | 0.10 | 45 | 3 |

| 7 | 3 | 0.20 | 15 | 2 |

| 8 | 3 | 0.20 | 30 | 3 |

| 9 | 3 | 0.20 | 45 | 1 |

| 10 | 5 | 0.05 | 15 | 3 |

| 11 | 5 | 0.05 | 30 | 1 |

| 12 | 5 | 0.05 | 45 | 2 |

| 13 | 5 | 0.10 | 15 | 2 |

| 14 | 5 | 0.10 | 30 | 3 |

| 15 | 5 | 0.10 | 45 | 1 |

| 16 | 5 | 0.20 | 15 | 3 |

| 17 | 5 | 0.20 | 30 | 1 |

| 18 | 5 | 0.20 | 45 | 2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bolat, Ç.; Karakılınç, U.; Yalçın, B.; Öz, Y.; Yavaş, Ç.; Ergene, B.; Ercetin, A.; Akkoyun, F. Effect of Drilling Parameters and Tool Geometry on the Thrust Force and Surface Roughness of Aerospace Grade Laminate Composites. Micromachines 2023, 14, 1427. https://doi.org/10.3390/mi14071427

Bolat Ç, Karakılınç U, Yalçın B, Öz Y, Yavaş Ç, Ergene B, Ercetin A, Akkoyun F. Effect of Drilling Parameters and Tool Geometry on the Thrust Force and Surface Roughness of Aerospace Grade Laminate Composites. Micromachines. 2023; 14(7):1427. https://doi.org/10.3390/mi14071427

Chicago/Turabian StyleBolat, Çağın, Uçan Karakılınç, Bekir Yalçın, Yahya Öz, Çağlar Yavaş, Berkay Ergene, Ali Ercetin, and Fatih Akkoyun. 2023. "Effect of Drilling Parameters and Tool Geometry on the Thrust Force and Surface Roughness of Aerospace Grade Laminate Composites" Micromachines 14, no. 7: 1427. https://doi.org/10.3390/mi14071427

APA StyleBolat, Ç., Karakılınç, U., Yalçın, B., Öz, Y., Yavaş, Ç., Ergene, B., Ercetin, A., & Akkoyun, F. (2023). Effect of Drilling Parameters and Tool Geometry on the Thrust Force and Surface Roughness of Aerospace Grade Laminate Composites. Micromachines, 14(7), 1427. https://doi.org/10.3390/mi14071427