Characteristics of Elliptical Vibration-Assisted Cutting with Variations in Tilt Angle of Elliptical Locus

Abstract

:1. Introduction

2. Elliptical Vibration-Assisted Cutting Device and Method

2.1. EVAC Device and Kinematical Analysis

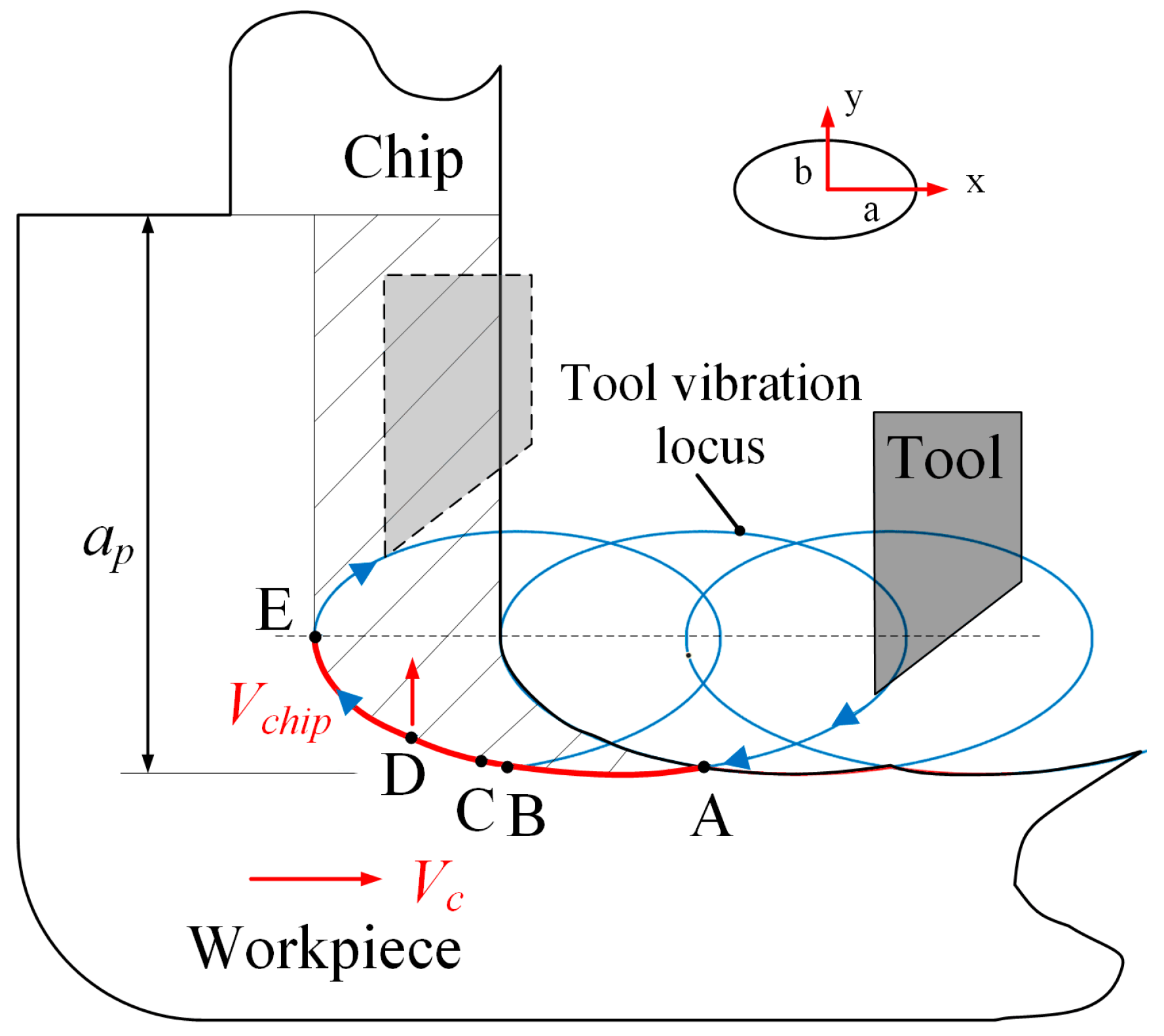

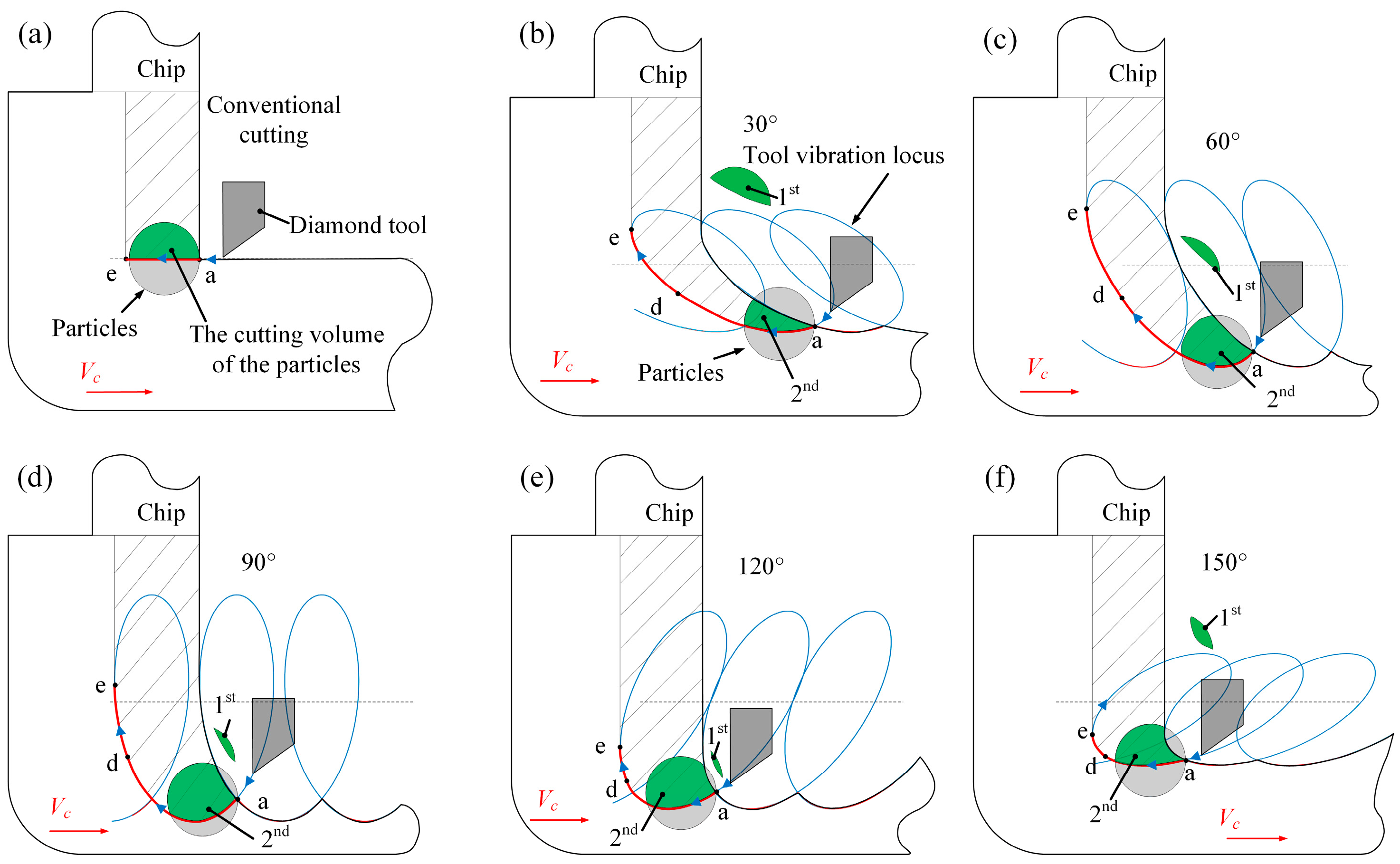

2.2. The Principle of the Elliptical Vibration-Assisted Cutting Process

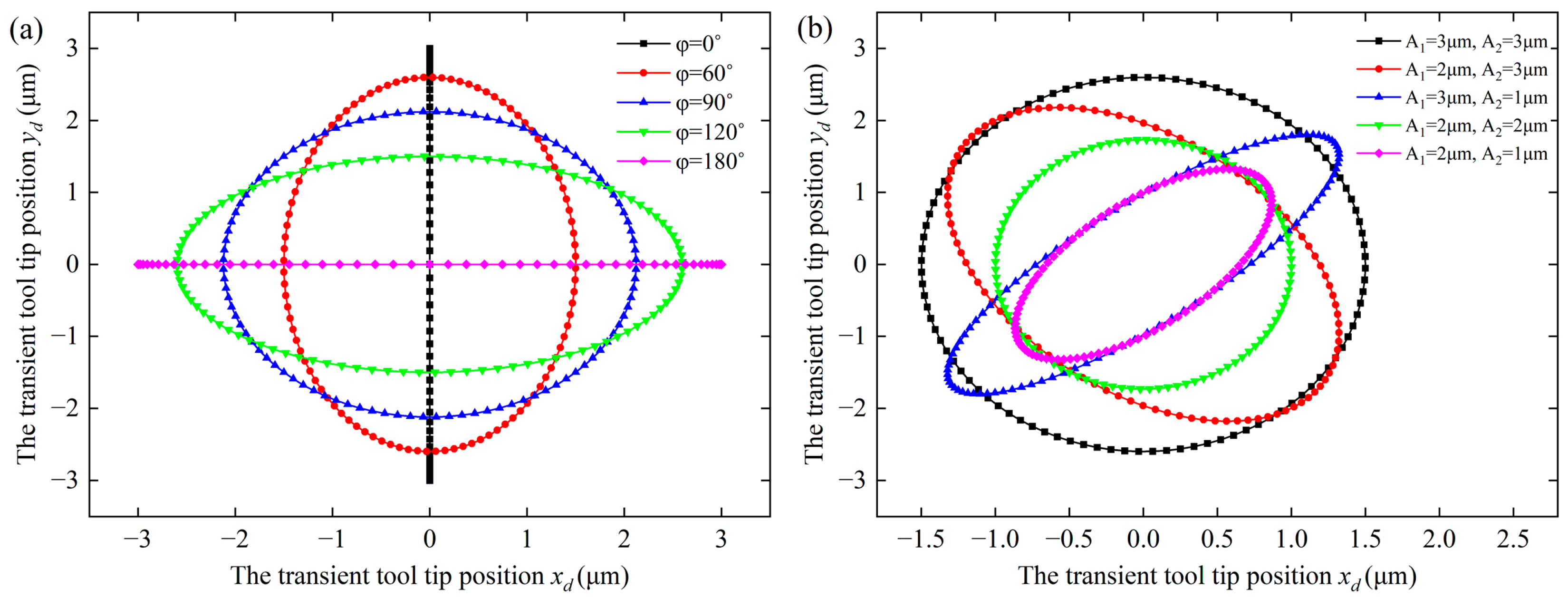

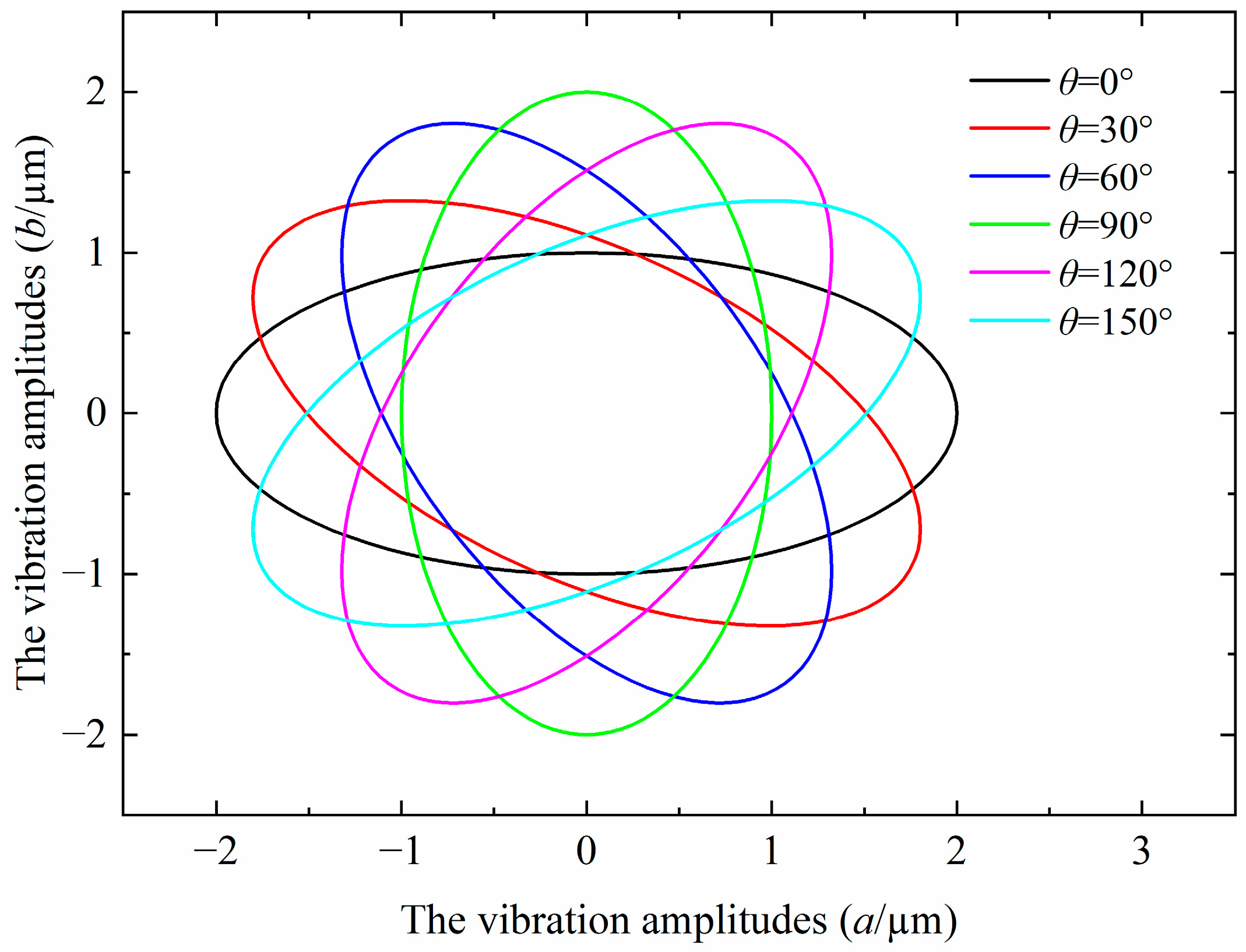

2.3. Generation of the Elliptical Locus with Variations in the Tilt Angle

3. Experimental Setup

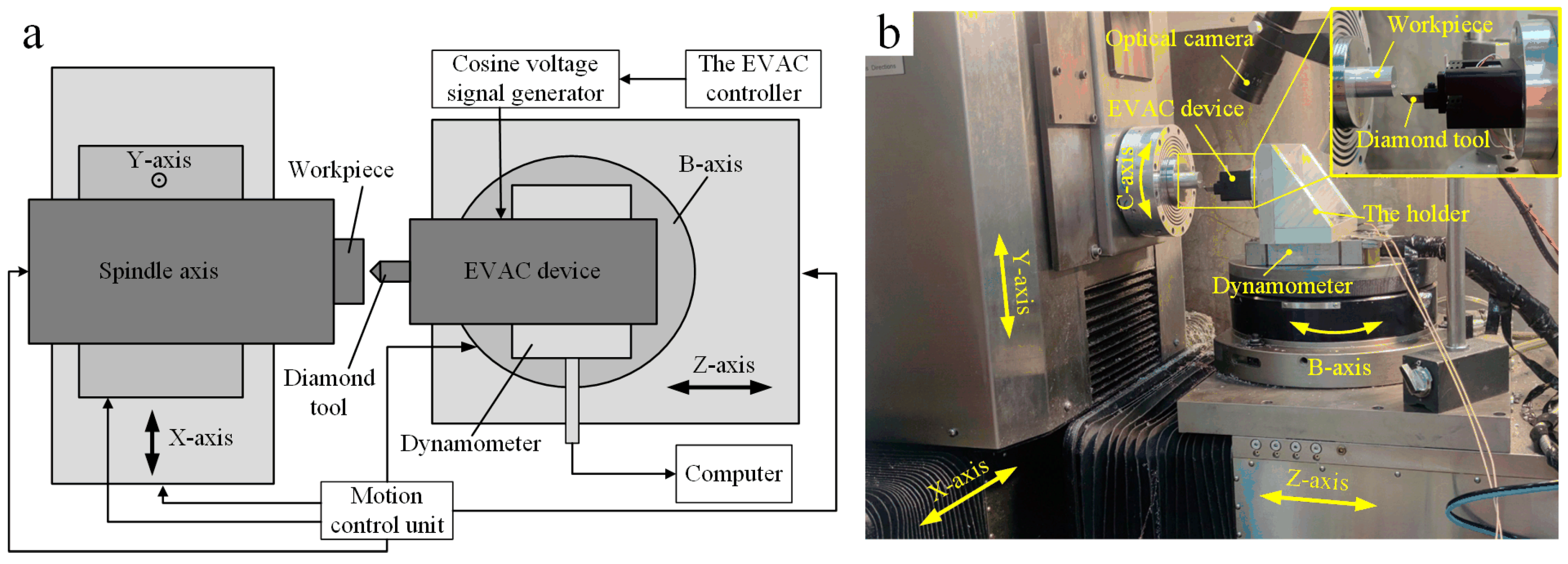

3.1. Elliptical Vibration-Assisted Cutting System Configuration

3.2. Experiment Preparations

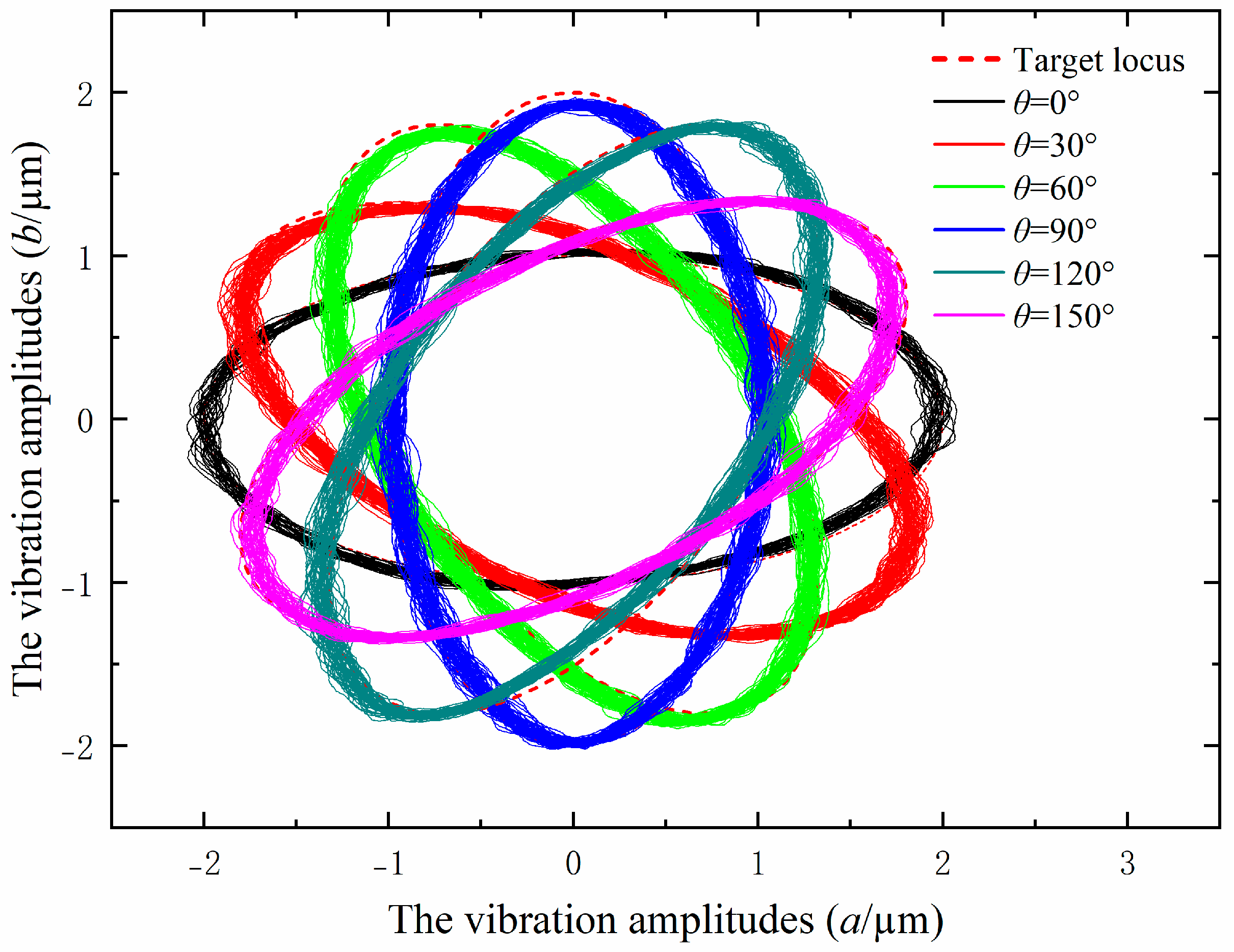

3.3. Performance Test of the Output Elliptical Locus

4. Results and Discussion

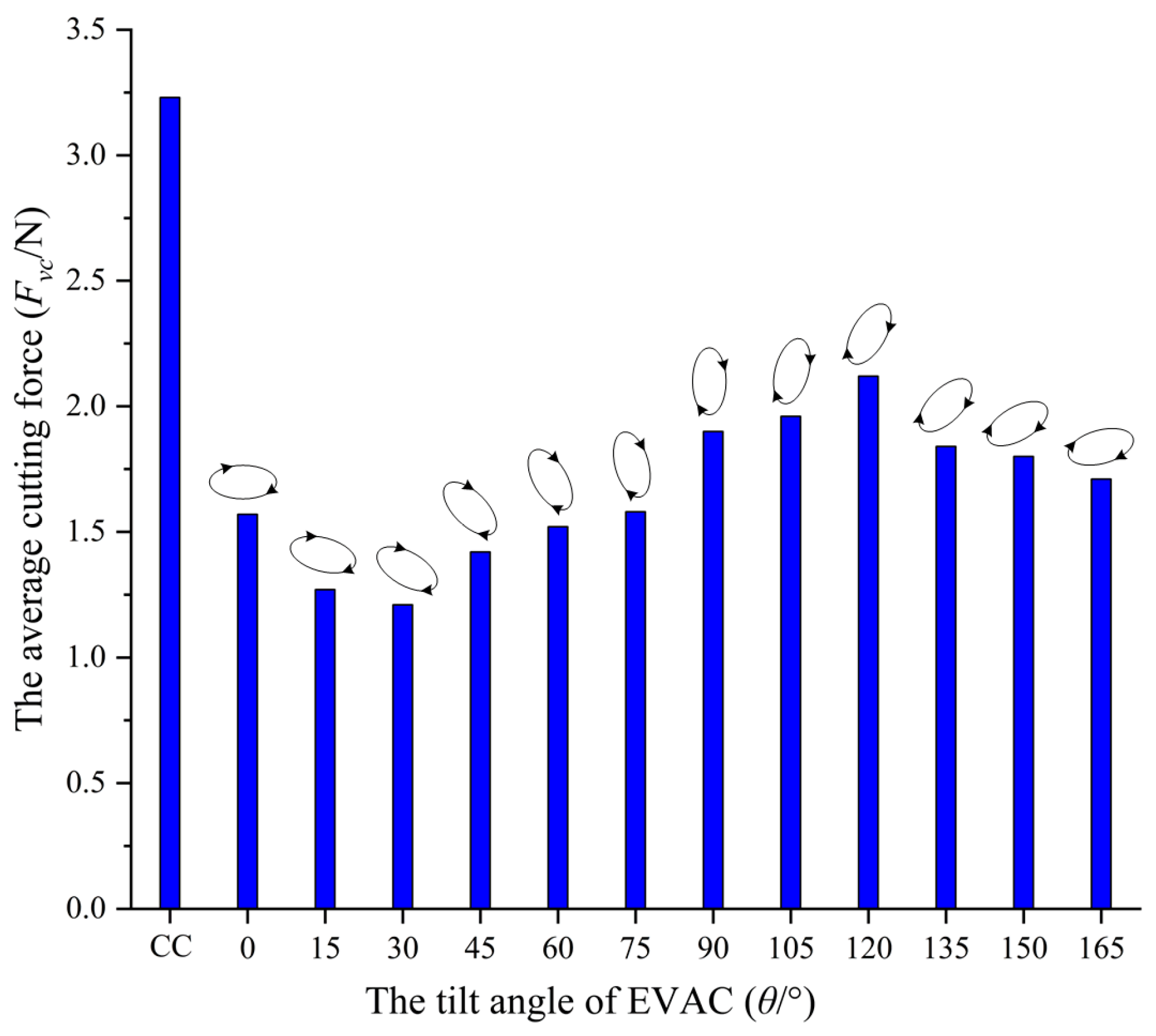

4.1. Effects of the Tilt Angle on Cutting Force in Elliptical Vibration-Assisted Cutting

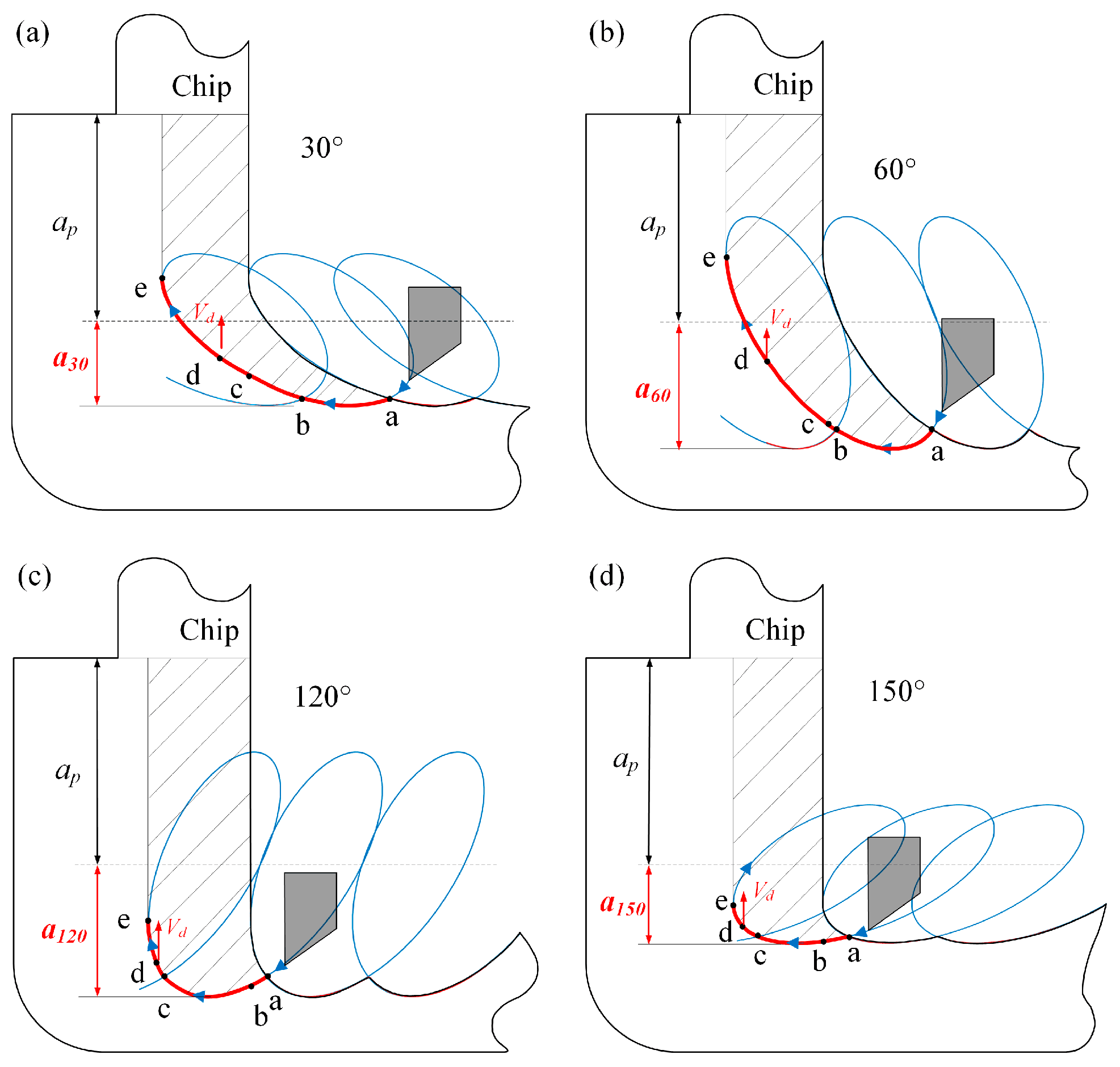

4.2. Chip Formation with Different Tilt Angles

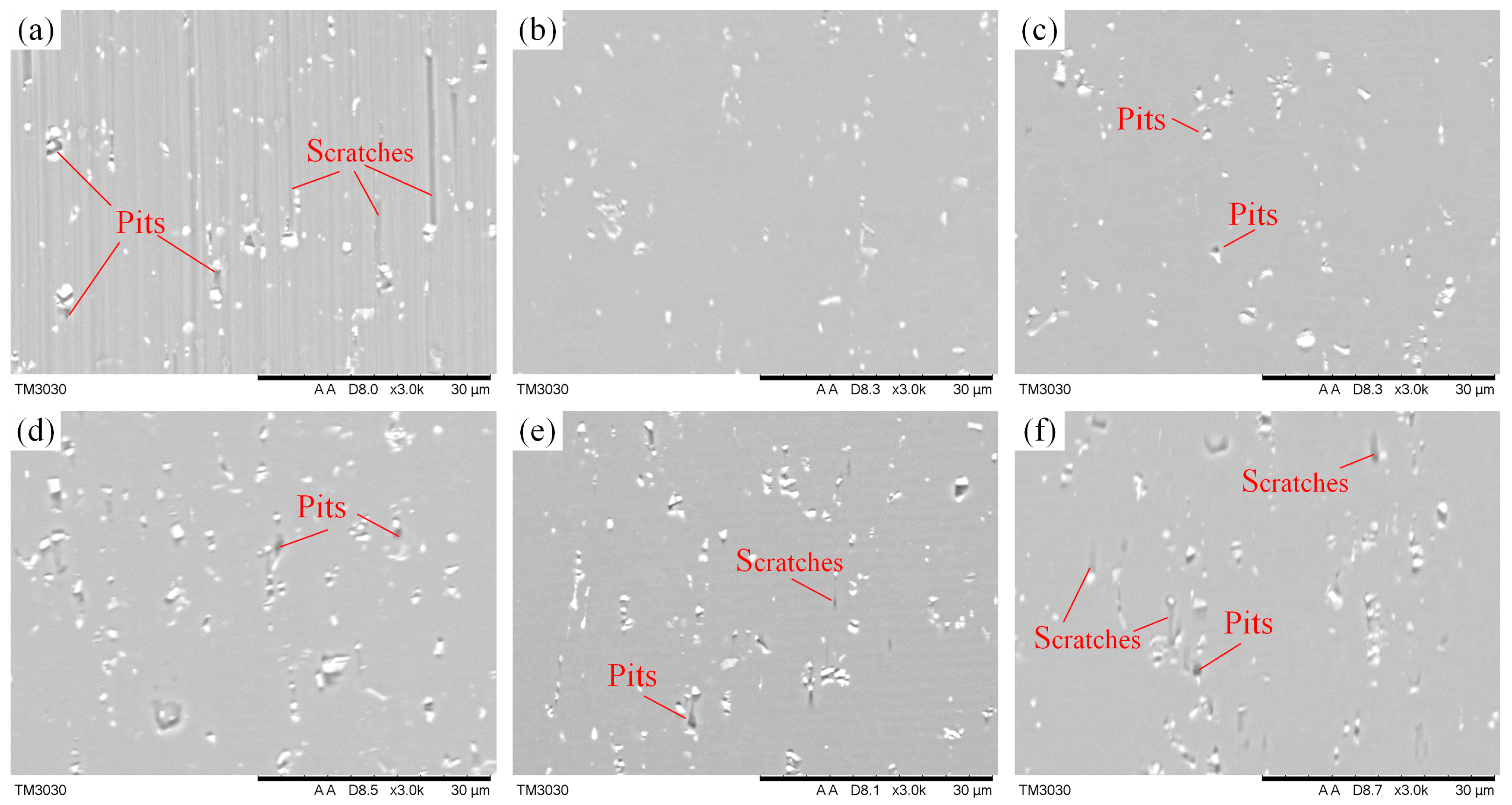

4.3. Effects of the Tilt Angle on Machined Surface Defects

4.4. Effect of the Tilt Angle on Machined Surface Roughness

5. Conclusions

- (1)

- To investigate the influence of the tilt angle on the elliptical trajectory, a mathematical model of the elliptical locus with variations in the tilt angle is analyzed and established via geometric analysis. A performance test of the output elliptical trajectory in the EVAC device is conducted. The test results show that the output elliptical trajectories are highly consistent with the target locus, both in terms of the tilt angles and the vibration amplitudes.

- (2)

- The effects of different tilt angles on the cutting force are studied. The experimental results show that the cutting force presented a high correlation with the tilt angle of the EVAC. The cutting forces of the EVAC with the positive tilt angle (θ < 90°) are lower than those of the negative tilt angle (θ > 90°). In addition, the cutting forces are minimal at a tilt angle of 30°, while being maximal at a tilt angle of 120°. Through theoretical analysis, the reason found for these phenomena is that different tilt angles lead to different lengths of the cutting process and of the real cutting depth.

- (3)

- The chip formation experiment results showed that EVAC generates a smaller chip thickness compared to that obtained through conventional cutting. Furthermore, when the tilt angle is less than 60°, the chip lifting effect increases along with the tilt angle. However, when the tilt angle is more than 90°, the chip lifting effect decreases with the tilt angle increase. As a result, the best chip lifting effect with the min chip thickness is determined at the tilt angle of 60°.

- (4)

- Different tilt angles show significantly different effects on surface defects and surface roughness. The tilt angle with the lowest surface roughness and almost no defects is found (θ = 30°). Above the determined tilt angle (especially in θ = 90°), the machined surface will generate a lager number and size of scratches and pits, resulting in higher surface roughness. This implies that a suitable tilt angle will suppress the defects and achieve the best surface roughness.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, Y.; Yang, J.; Wang, Z.; Kong, X.; Sun, X.; Tian, J.; Zhang, X.; Zhao, X.; Liu, Y.; Li, H.; et al. The development and progression of micro-nano optics. Front. Chem. 2022, 10, 916553. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.D.; Tao, Y.H.; Xu, Y.; Niu, L.G.; Li, A.W. Ultra-compact micro-optical elements for generating high-order Bessel beams. J. Mod. Opt. 2022, 69, 523–530. [Google Scholar] [CrossRef]

- Liu, H.; Du, Y.; Yin, X.T.; Bai, M.; Liu, W. Micro/Nanostructures for light trapping in monocrystalline silicon solar cells. J. Nanomater. 2022, 2022, 8139174. [Google Scholar] [CrossRef]

- Hsieh, M.; Liao, C.H.; Lin, J.Y. Optical relative humidity sensor based on a polyvinyl alcohol film and a phase-enhancement total-internal-reflection heterodyne interferometer. Sens. Actuators A Phys. 2020, 316, 112412. [Google Scholar] [CrossRef]

- Xu, X.F.; Cheng, L.F.; Zhao, X.J.; Wang, J.; Chen, X. Micro/nano periodic surface structures and performance of stainless steel machined using femtosecond lasers. Micromachines 2022, 13, 976. [Google Scholar] [CrossRef]

- Gong, S.Q.; Sun, Y. Experimental study on forming consistent accuracy and tool electrode wear involved in fabricating array microelectrodes and array micro holes using electrical discharge machining. J. Manuf. Process. 2022, 79, 126–141. [Google Scholar] [CrossRef]

- Shamoto, E.; Moriwaki, T. Study on elliptical vibration cutting. CIRP Ann.-Manuf. Technol. 1994, 43, 35–38. [Google Scholar] [CrossRef]

- Zheng, L.; Chen, W.Q.; Huo, D.H. Review of vibration devices for vibration-assisted machining. Int. J. Adv. Manuf. Technol. 2020, 108, 1631–1651. [Google Scholar] [CrossRef]

- Farrus, N.; Joao, D.; Milliken, N.; Tutunea-Fatan, O.R.; Bordatchev, E. Reduction of cutting forces by elliptical vibration in multi-pass ultraprecise single point axial cutting of V-grooves. Procedia Manuf. 2020, 48, 570–578. [Google Scholar] [CrossRef]

- Pan, Y.A.; Kang, P.K.; Bao, Y.; Yin, S.; Dong, Z. Study on tool wear mechanism of single-crystal diamond in ultrasonic vibration elliptical cutting of tungsten heavy alloy. Wear 2023, 516–517, 204616. [Google Scholar] [CrossRef]

- Zhang, C.; Guo, P.; Ehmann, K.F.; Li, Y. Turning of microgrooves both with and without aid of ultrasonic elliptical vibration. Adv. Manuf. Process. 2015, 30, 1001–1009. [Google Scholar] [CrossRef]

- Kim, G.D.; Loh, B.G. An ultrasonic elliptical vibration cutting device for micro V-groove machining: Kinematical analysis and micro V-groove machining characteristics. J. Mater. Process. Technol. 2007, 190, 181–188. [Google Scholar] [CrossRef]

- Li, L.; Tan, Y.F.; Xu, W.X.; Ni, Y.; Yang, J.; Tan, D. Fluid-induced transport dynamics and vibration patterns of multiphase vortex in the critical transition states. Int. J. Mech. Sci. 2023, 252, 108376. [Google Scholar] [CrossRef]

- Li, L.; Xu, W.X.; Tan, Y.F.; Yang, Y.; Yang, J.; Tan, D. Fluid-induced vibration evolution mechanism of multiphase free sink vortex and the multi-source vibration sensing method. Mech. Syst. Signal Process. 2023, 189, 110058. [Google Scholar] [CrossRef]

- Nath, C.; Rahman, M. Effect of machining parameters in ultrasonic vibration cutting. Int. J. Mach. Tools Manu. 2008, 48, 965–974. [Google Scholar] [CrossRef]

- Celaya, A.; Lopez de Lacalle, L.N.; Campa, F.J.; Lamikiz, A. Ultrasonic assisted turning of mild steels. Int. J. Mater. Prod. Technol. 2010, 37, 60–70. [Google Scholar] [CrossRef]

- Suárez, A.; Veiga, F.; de Lacalle, L.N.L.; Polvorosa, R.; Lutze, S.; Wretland, A. Effects of ultrasonics-assisted face milling on surface integrity and fatigue life of Ni-Alloy 718. J. Mater. Eng. Perform. 2016, 25, 5076–5086. [Google Scholar] [CrossRef]

- Suzuki, N.; Yokoi, H.; Shamoto, E. Micro/nano sculpturing of hardened steel by controlling vibration amplitude in elliptical vibration cutting. Precis. Eng. 2011, 35, 44–50. [Google Scholar] [CrossRef]

- Zhang, J.; Suzuki, N.; Wang, Y.; Shamoto, E. Ultra-precision nano-structure fabrication by amplitude control sculpturing method in elliptical vibration cutting. Precis. Eng. 2015, 39, 86–99. [Google Scholar] [CrossRef]

- Zhou, X.; Zuo, C.; Liu, Q.; Lin, J. Surface generation of freeform surfaces in diamond turning by applying double-frequency elliptical vibration cutting. Int. J. Mach. Tool. Manuf. 2016, 104, 45–57. [Google Scholar] [CrossRef]

- Zhou, X.; Zuo, C.; Liu, Q.; Wang, R.; Lin, J. Development of a double-frequency elliptical vibration cutting apparatus for freeform surface diamond machining. Int. J. Adv. Manuf. Technol. 2016, 87, 2099–20111. [Google Scholar] [CrossRef]

- Kim, G.D.; Loh, B.G. Characteristics of chip formation in micro V-grooving using elliptical vibration cutting. J. Micromech. Microeng. 2007, 17, 1458. [Google Scholar] [CrossRef]

- Kim, G.D.; Loh, B.G. Cutting force variation with respect to tilt angle of trajectory in elliptical vibration V-grooving. Int. J. Precis. Eng. Manuf. 2013, 14, 1861–1864. [Google Scholar] [CrossRef]

- Zhang, J.G.; Cui, T.; Ge, C.; Sui, Y.; Yang, H. Review of micro/nano machining by utilizing elliptical vibration cutting. Int. J. Mach. Tool. Manuf. 2016, 106, 109–126. [Google Scholar] [CrossRef]

- Wang, S.J.; Xia, S.B.; Wang, H.L.; Yin, Z.Q.; Sun, Z. Prediction of surface roughness in diamond turning of Al6061 with precipitation effect. J. Manuf. Process. 2020, 60, 292–298. [Google Scholar] [CrossRef]

- Ukar, E.; Lamikiz, A.; Martinez, S.; Tabernero, I.; De Lacalle, L.L. Roughness prediction on laser polished surfaces. J. Mater. Process. Technol. 2012, 212, 1305–1313. [Google Scholar] [CrossRef]

| Parameters | Value |

|---|---|

| Amplitude in cutting direction (a/µm) | 2 |

| Amplitude in cutting depth direction (b/µm) | 1 |

| Frequency (f/Hz) | 1200 |

| Tilt angle (θ/°) | 0,15,30,45,60,75,90, 105,120,135,150,165 |

| Cutting speed Vc (mm/s) | 2 |

| Depth of cut ap (µm) | 10 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xia, S.; Yin, Z.; Huang, C.; Guo, Y.; Zhang, C. Characteristics of Elliptical Vibration-Assisted Cutting with Variations in Tilt Angle of Elliptical Locus. Micromachines 2023, 14, 1426. https://doi.org/10.3390/mi14071426

Xia S, Yin Z, Huang C, Guo Y, Zhang C. Characteristics of Elliptical Vibration-Assisted Cutting with Variations in Tilt Angle of Elliptical Locus. Micromachines. 2023; 14(7):1426. https://doi.org/10.3390/mi14071426

Chicago/Turabian StyleXia, Senbin, Ziqiang Yin, Cheng Huang, Yawen Guo, and Chao Zhang. 2023. "Characteristics of Elliptical Vibration-Assisted Cutting with Variations in Tilt Angle of Elliptical Locus" Micromachines 14, no. 7: 1426. https://doi.org/10.3390/mi14071426

APA StyleXia, S., Yin, Z., Huang, C., Guo, Y., & Zhang, C. (2023). Characteristics of Elliptical Vibration-Assisted Cutting with Variations in Tilt Angle of Elliptical Locus. Micromachines, 14(7), 1426. https://doi.org/10.3390/mi14071426