A False Trigger-Strengthened and Area-Saving Power-Rail Clamp Circuit with High ESD Performance

Abstract

1. Introduction

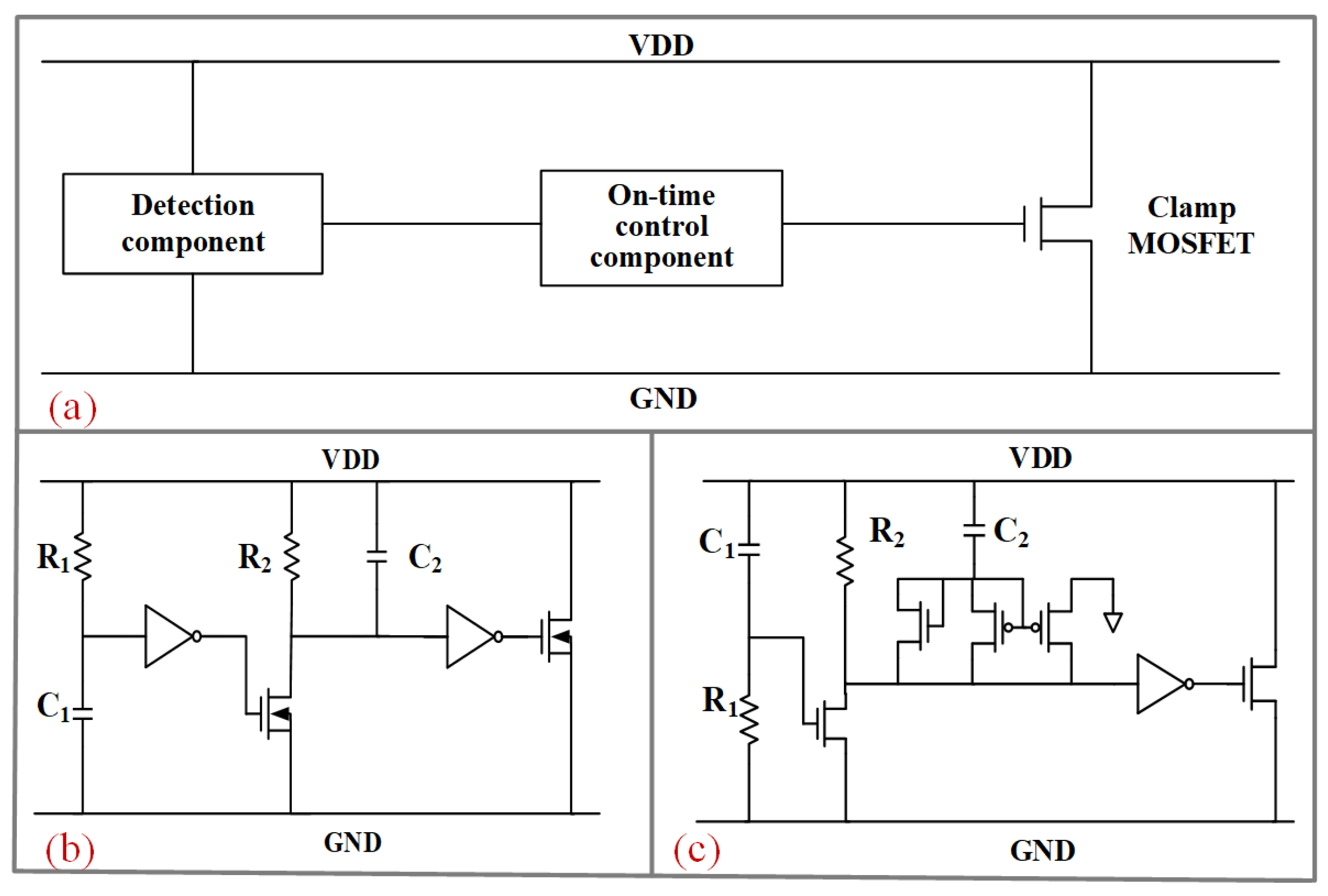

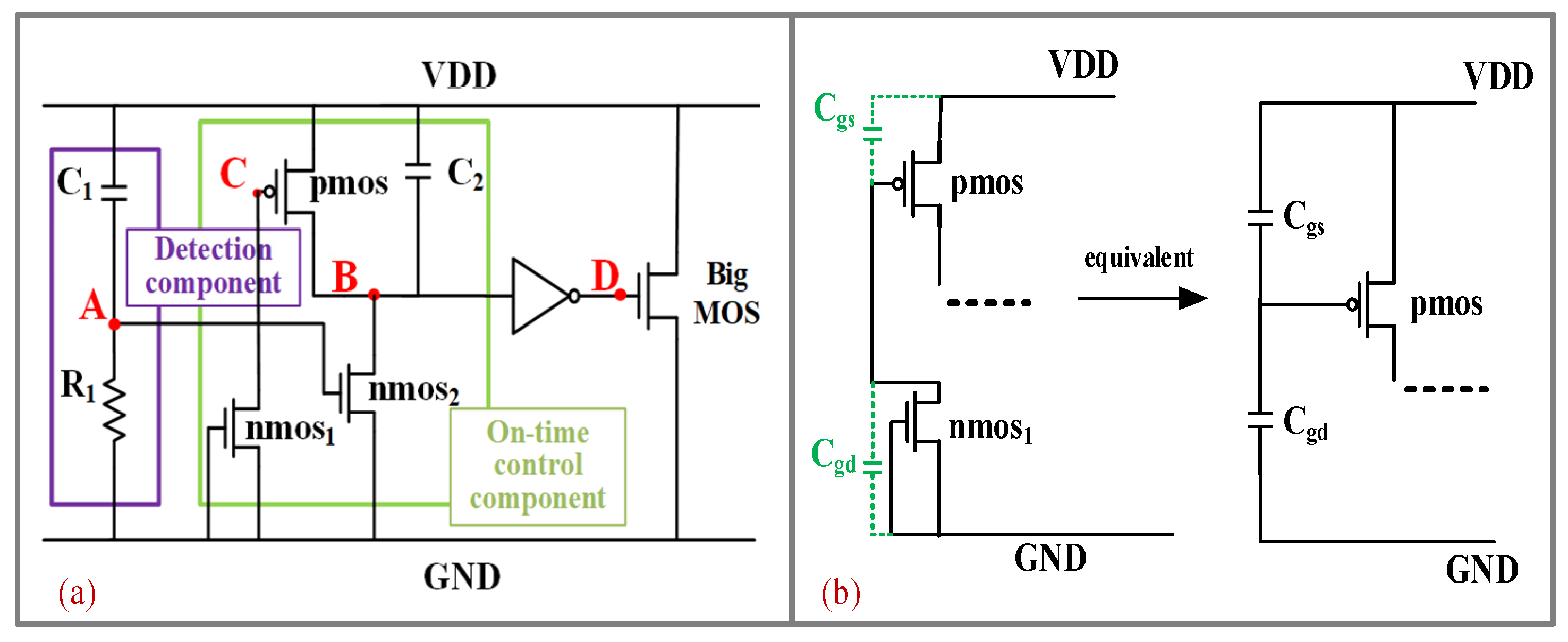

2. The Proposed Power-Rail ESD Clamp Circuit

2.1. Structure of Proposed Circuit

2.2. Principle of Operation

3. Simulation and Results Discussion

3.1. The Circuit-Level TLP Test

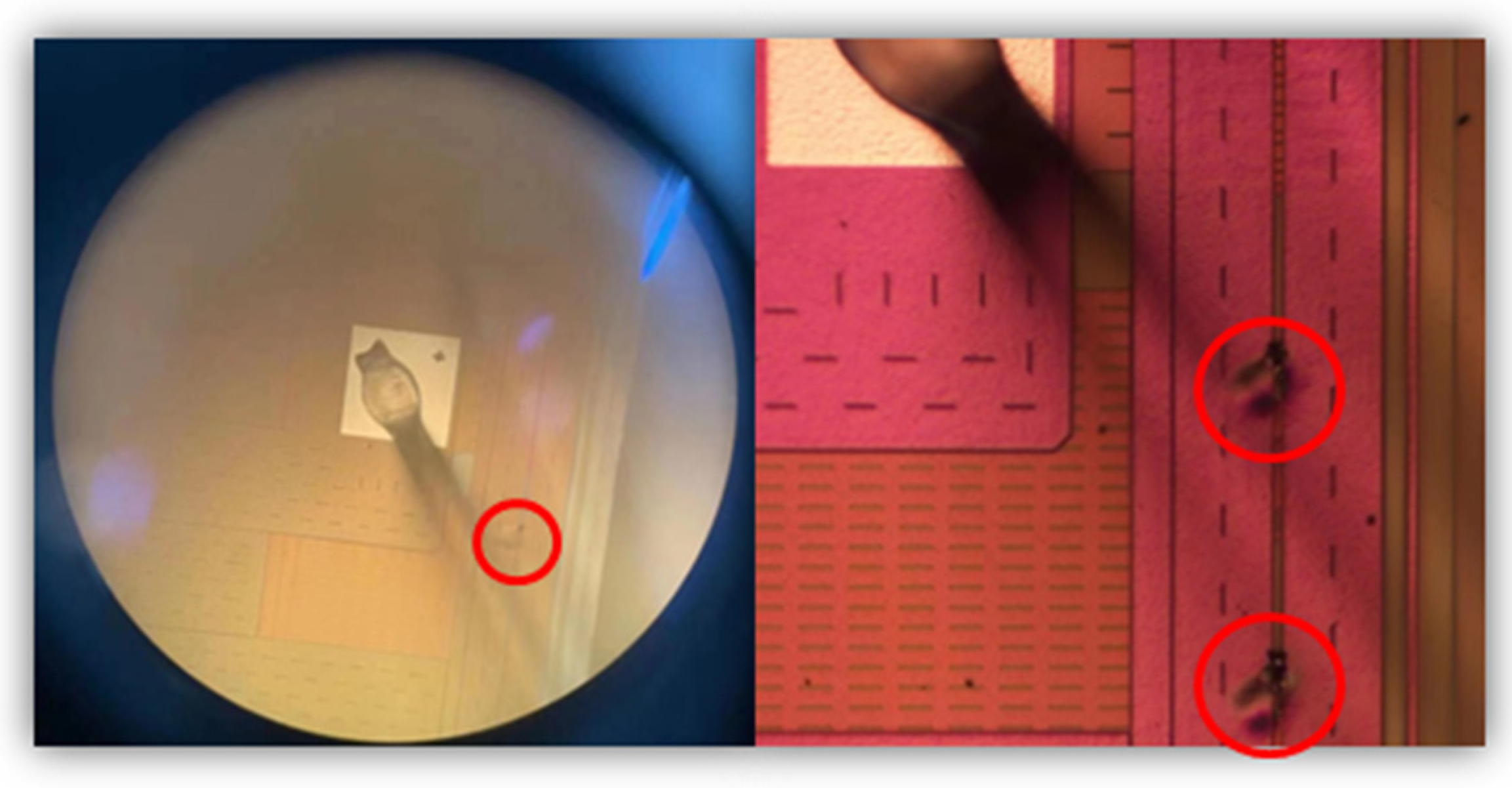

3.2. Area-Efficiency Evaluation

3.3. Circuit-Level ESD Test

3.4. Immunity to the Fast Power Events

3.5. Immunity to Noise Characteristics

3.6. The Low Leakage Characteristic

4. Performance Comparisons

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Mergens, M.; Wybo, G.; Van Camp, B.; Keppens, B.; De Ranter, F.; Verhaege, K.; Jozwiak, P.; Armer, J.; Russ, C. ESD protection circuit design for ultra-sensitive IO applications in advanced sub-90 nm CMOS technolo-gies. In Proceedings of the 2005 IEEE International Symposium on Circuits and Systems, Kobe, Japan, 23–26 May 2005; pp. 1194–1197. [Google Scholar]

- Duvvury, C. ESD qualification changes for 45nm and beyond. In Proceedings of the 2008 IEEE International Electron Devices Meeting, San Francisco, CA, USA, 15–17 December 2008; pp. 1–4. [Google Scholar] [CrossRef]

- Ker, M.-D. Whole-chip ESD protection design with efficient VDD-to-VSS ESD clamp circuits for submicron CMOS VLSI. IEEE Trans. Electron Devices 1999, 46, 173–183. [Google Scholar] [CrossRef]

- Karalkar, S.P.; Ganesan, V.; Paul, M.; Hwang, K.; Gauthier, R. Design Optimization of MV-NMOS to Improve Holding Voltage of a 28 nm CMOS Technology ESD Power Clamp. In Proceedings of the 2021 IEEE International Reliability Physics Symposium (IRPS), Monterey, CA, USA, 21–24 May 2021; pp. 1–5. [Google Scholar] [CrossRef]

- Li, C.; Zhang, F.; Wang, C.; Qi, C.; Lu, F.; Wang, H.; Di, M.; Cheng, Y.; Zhao, H.; Wang, A. Temperature Dependence of Diode and ggNMOS ESD Protection Structures in 28 nm CMOS. In Proceedings of the 2018 14th IEEE International Conference on Solid-State and Integrated Circuit Technology (ICSICT), Qingdao, China, 31 October–3 November 2018; pp. 1–3. [Google Scholar] [CrossRef]

- Song, W.; Du, F.; Hou, F.; Liu, J.; Huang, X.; Liu, Z.; Liou, J.J. Design of A Novel Low Voltage Triggered Silicon Controlled Rectifier (SCR) for ESD Applications. In Proceedings of the 2020 International EOS/ESD Symposium on Design and System (IEDS), Chengdu, China, 23–25 June 2021. [Google Scholar] [CrossRef]

- Qian, L.; Li, M.; Wang, Y.; Wu, H.; Liu, T.; Guo, J.; Zhu, W.; Hu, S. A Novel Segmented LDMOS-SCR Structure With 8-kV HBM ESD Robustness in CMOS Analog Multiplexer. IEEE Trans. Electron Devices 2022, 69, 6904–6909. [Google Scholar] [CrossRef]

- Di, M.; Pan, Z.; Li, C.; Wang, A. ESD Design Verification Aided by Mixed-Mode Multiple-Stimuli ESD Simulation. IEEE J. Electron Devices Soc. 2021, 9, 1194–1201. [Google Scholar] [CrossRef]

- Lu, G.; Wang, Y.; Wang, Y.; Zhang, X. Low-Leakage ESD Power Clamp Design with Adjustable Triggering Voltage for Nanoscale Applications. IEEE Trans. Electron Devices 2017, 64, 3569–3575. [Google Scholar] [CrossRef]

- Lu, G.; Wang, Y.; Zhang, X. Transient and Static Hybrid-Triggered Active Clamp Design for Power-Rail ESD Protection. IEEE Trans. Electron Devices 2016, 63, 4654–4660. [Google Scholar] [CrossRef]

- Miller, J.W.; Torres, C.A.; Cooper, T.L. Circuit for Electrostatic Discharge Protection. U.S. Patent No. 5946177, 31 August 1999. [Google Scholar]

- Liu, Q.; Wang, Y.; Cao, J.; Lu, G.; Zhang, X. Design of power-rail ESD clamp circuit with separate detection component and delay component against mis-triggering. In Proceedings of the 2013 IEEE International Conference of Electron Devices and Solid-State Circuits, Singapore, 1–4 June 2015; pp. 1–3. [Google Scholar] [CrossRef]

- Cao, J.; Xue, X.; Wang, Y.; Lu, G.; Zhang, X. A prolonged discharge time ESD power-rail clamp circuit structure with strong ability to prevent false triggering. In Proceedings of the 2016 13th IEEE International Conference on Solid-State and Integrated Circuit Technology (ICSICT), Hangzhou, China, 25–28 October 2016; pp. 1291–1293. [Google Scholar] [CrossRef]

- Wang, A. ESDTest Models and Standards. In Practical ESD Protection Design; Wiley-IEEE Press: Hoboken, NJ, USA, 2022; pp. 51–76. [Google Scholar] [CrossRef]

- EOS/ESD Standard for ESD Sensitivity Testing; EOS/ESD Association: New York, NY, USA, 1993.

- Chen, J.-T.; Ker, M.-D. Design of Power-Rail ESD Clamp With Dynamic Timing-Voltage Detection Against False Trigger During Fast Power-ON Events. IEEE Trans. Electron Devices 2018, 65, 838–846. [Google Scholar] [CrossRef]

- Cao, J.; Ye, Z.; Wang, Y.; Lu, G.; Zhang, X. A Low Leakage Power Clamp ESD Protection Circuit with Prolonged ESD Dis-charge Time and Compact Detection Network. In Proceedings of the 2015 IEEE 11th International Conference on ASIC (ASICON), Chengdu, China, 3–6 November 2015. [Google Scholar]

- Liu, H.; Yang, Z.; Li, L.; Zhuo, Q. A novel ESD power supply clamp circuit with double pull-down paths. Sci. China Inf. Sci. 2012, 56, 1–8. [Google Scholar] [CrossRef]

- Narita, K.; Okushima, M. Low-Leakage and Variable VHOLD Power Clamp for Wide Stress Time Range From ESD to Surge Test. IEEE Trans. Device Mater. Reliab. 2020, 20, 641–649. [Google Scholar] [CrossRef]

- Shen, Z.; Wang, Y.; Zhang, X.; Wang, Y. A Novel Low-Leakage ESD Power Clamp Circuit with Adjustable Transient Response Time. In Proceedings of the 2022 IEEE International Symposium on Circuits and Systems (ISCAS), Austin, TX, USA, 27 May–1 June 2022; pp. 3488–3492. [Google Scholar] [CrossRef]

- Shen, Z.; Wang, Y.; Zhang, X.; Wang, Y. Area-Efficient Power-Rail ESD Clamp Circuit With False-Trigger Immunity in 28nm CMOS Process. IEEE J. Electron Devices Soc. 2022, 10, 876–884. [Google Scholar] [CrossRef]

| The Classic [11] | The Modified [12] | The Proposed | |

|---|---|---|---|

| R1 | 10 K | 10 K | 10 K |

| C1 | 1 p | 1 p | 1 p |

| R2 | 400 K | 30 K | Voltage-biased MOSFET |

| C2 | 1 p | 1 p | 100 f |

| Wmos | 2000 μ | 2000 μ | 2000 μ |

| The Classic [11] | The Modified [12] | The Proposed | |

|---|---|---|---|

| Process | 180 nm | 180 nm | 180 nm |

| Wmos | 2000 μ | 2000 μ | 2000 μ |

| Layout area | >5000 | 3660 | 2745 |

| Ileak at 27 °C | 31 nA | μA level | 31 nA |

| False trigger | immune | immune | immune |

| HBM level | 4 KV | 4 KV | 4 KV |

| TED 2018 [16] | TDMR 2020 [19] | ISCAS 2022 [20] | TED 2022 [21] | The Proposed | |

|---|---|---|---|---|---|

| Process | 180 nm | BCD Process | 28 nm | 28 nm | 180 nm |

| Ileak | N/A | 31 nA | 7 nA | 6.8 nA | 31 nA |

| TC area-reduction ratio | No Reduction | No Reduction | ~50% over the baseline circuit | ~90% over the baseline circuit | >70% over the baseline circuit |

| False trigger | immune | immune | immune | immune | immune |

| Transient Response Time | 100 ns | μs—level | μs—level | μs—level | μs—level |

| Adjustable time | NO | NO | YES | NO | YES |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, B.; Chen, S.; Wang, S.; Qian, L.; Han, Z.; Huang, W.; Fu, X.; Liu, H. A False Trigger-Strengthened and Area-Saving Power-Rail Clamp Circuit with High ESD Performance. Micromachines 2023, 14, 1172. https://doi.org/10.3390/mi14061172

Ma B, Chen S, Wang S, Qian L, Han Z, Huang W, Fu X, Liu H. A False Trigger-Strengthened and Area-Saving Power-Rail Clamp Circuit with High ESD Performance. Micromachines. 2023; 14(6):1172. https://doi.org/10.3390/mi14061172

Chicago/Turabian StyleMa, Boyang, Shupeng Chen, Shulong Wang, Lingli Qian, Zeen Han, Wei Huang, Xiaojun Fu, and Hongxia Liu. 2023. "A False Trigger-Strengthened and Area-Saving Power-Rail Clamp Circuit with High ESD Performance" Micromachines 14, no. 6: 1172. https://doi.org/10.3390/mi14061172

APA StyleMa, B., Chen, S., Wang, S., Qian, L., Han, Z., Huang, W., Fu, X., & Liu, H. (2023). A False Trigger-Strengthened and Area-Saving Power-Rail Clamp Circuit with High ESD Performance. Micromachines, 14(6), 1172. https://doi.org/10.3390/mi14061172