Electrothermally Driven Reconfiguration of Microrobotic Beam Structures for the ChipSail System

Abstract

1. Introduction

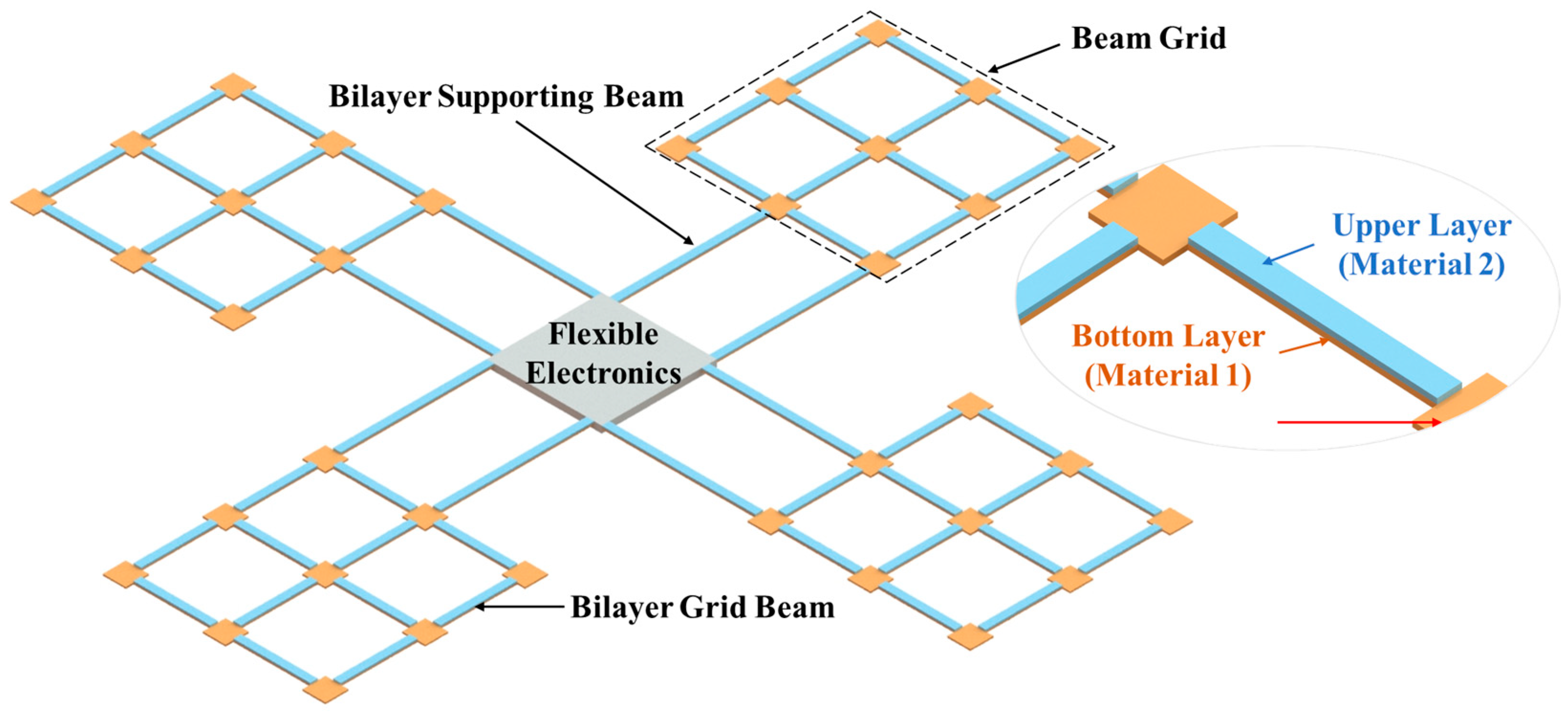

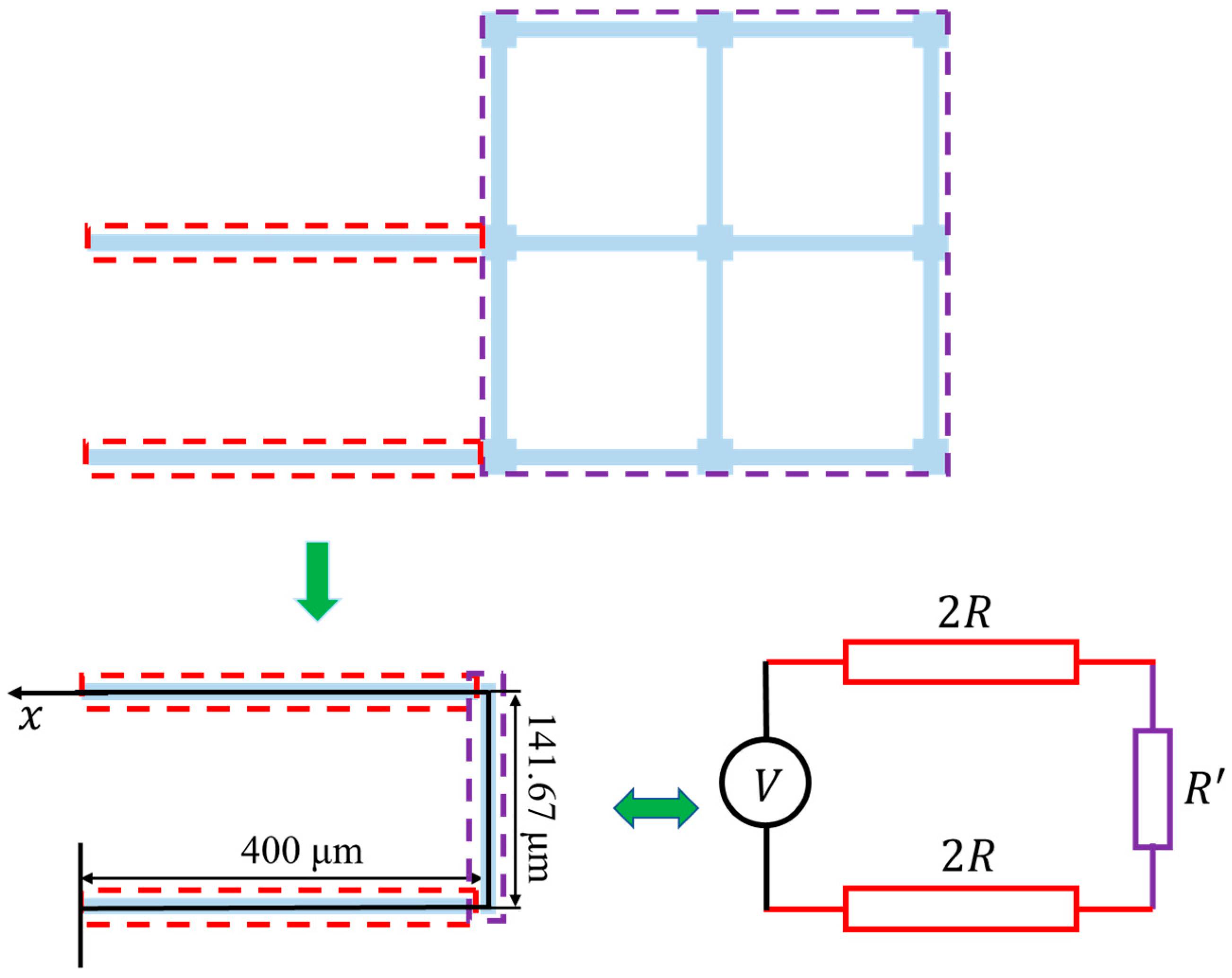

2. Design of Microrobotic ChipSail System

3. Electro-Thermo-Mechanical Model

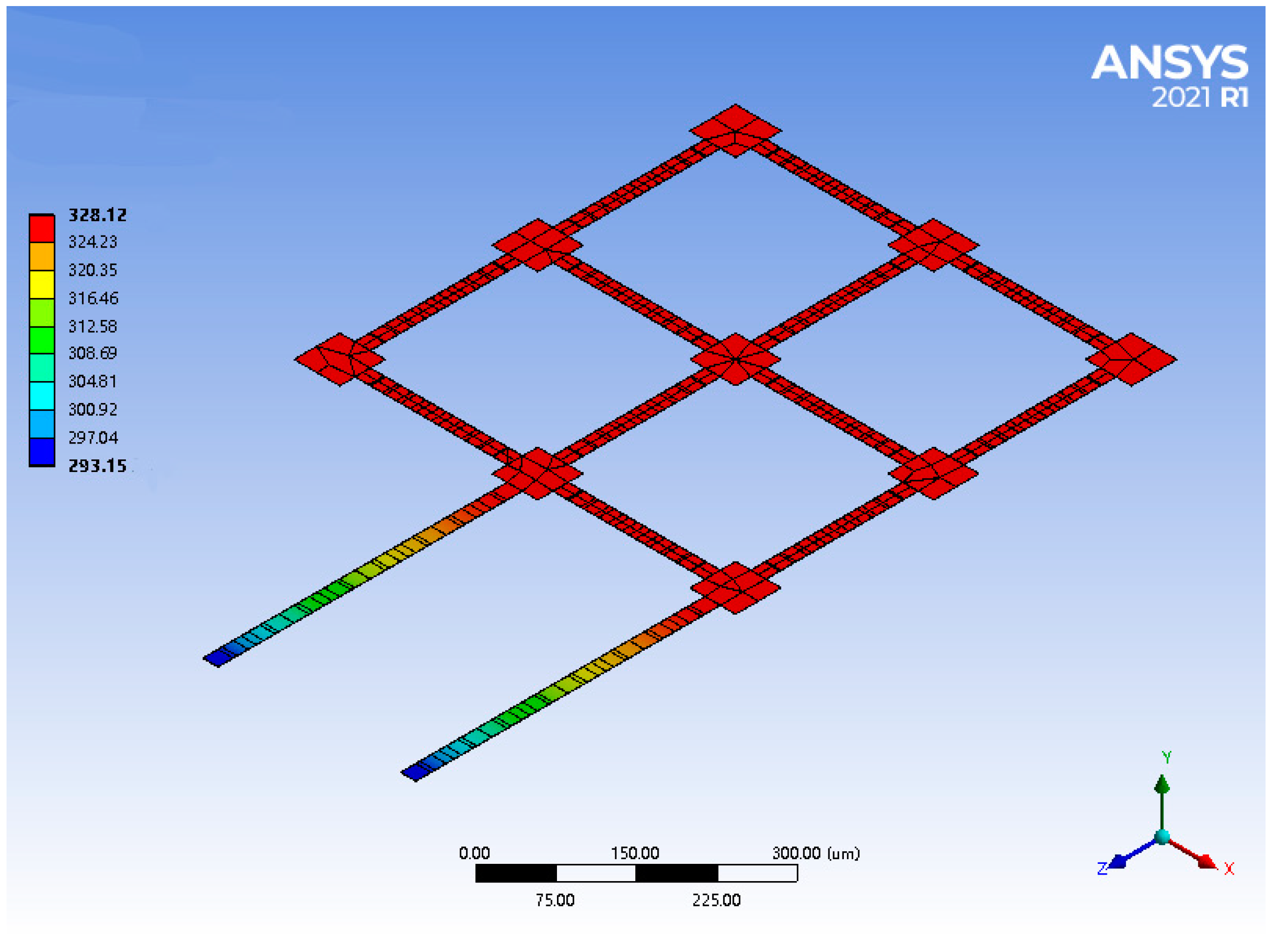

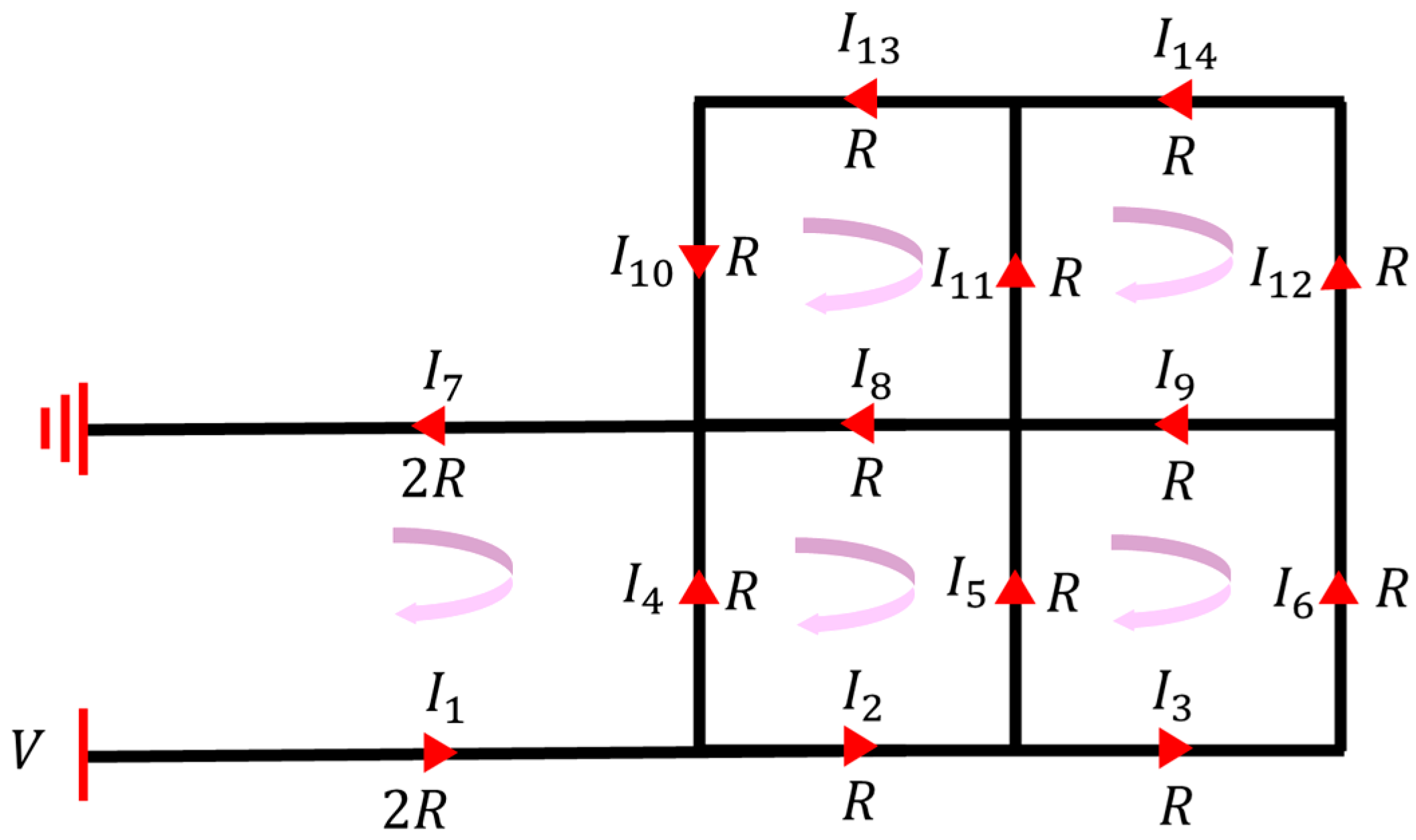

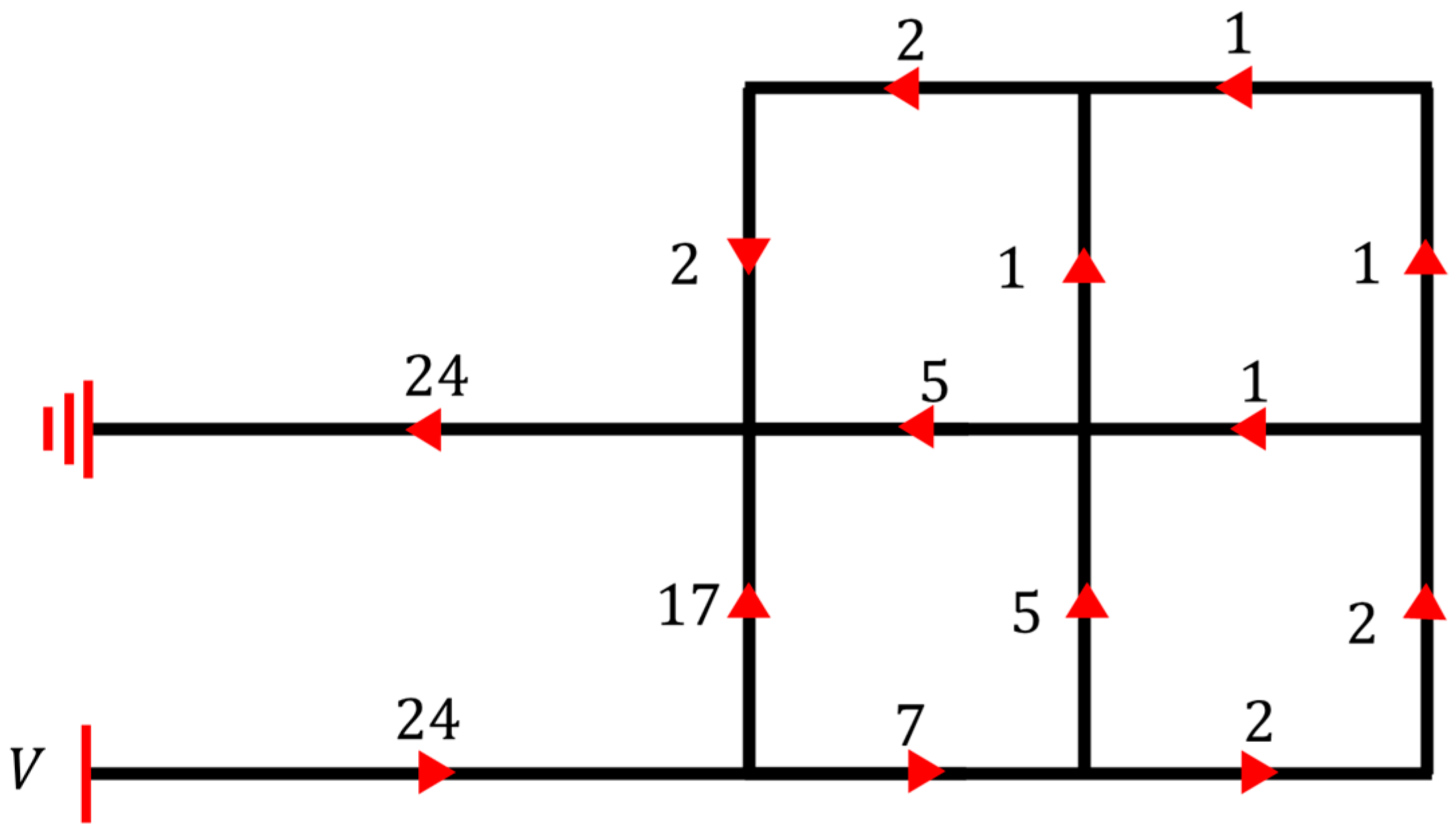

3.1. Electro-Thermal Model

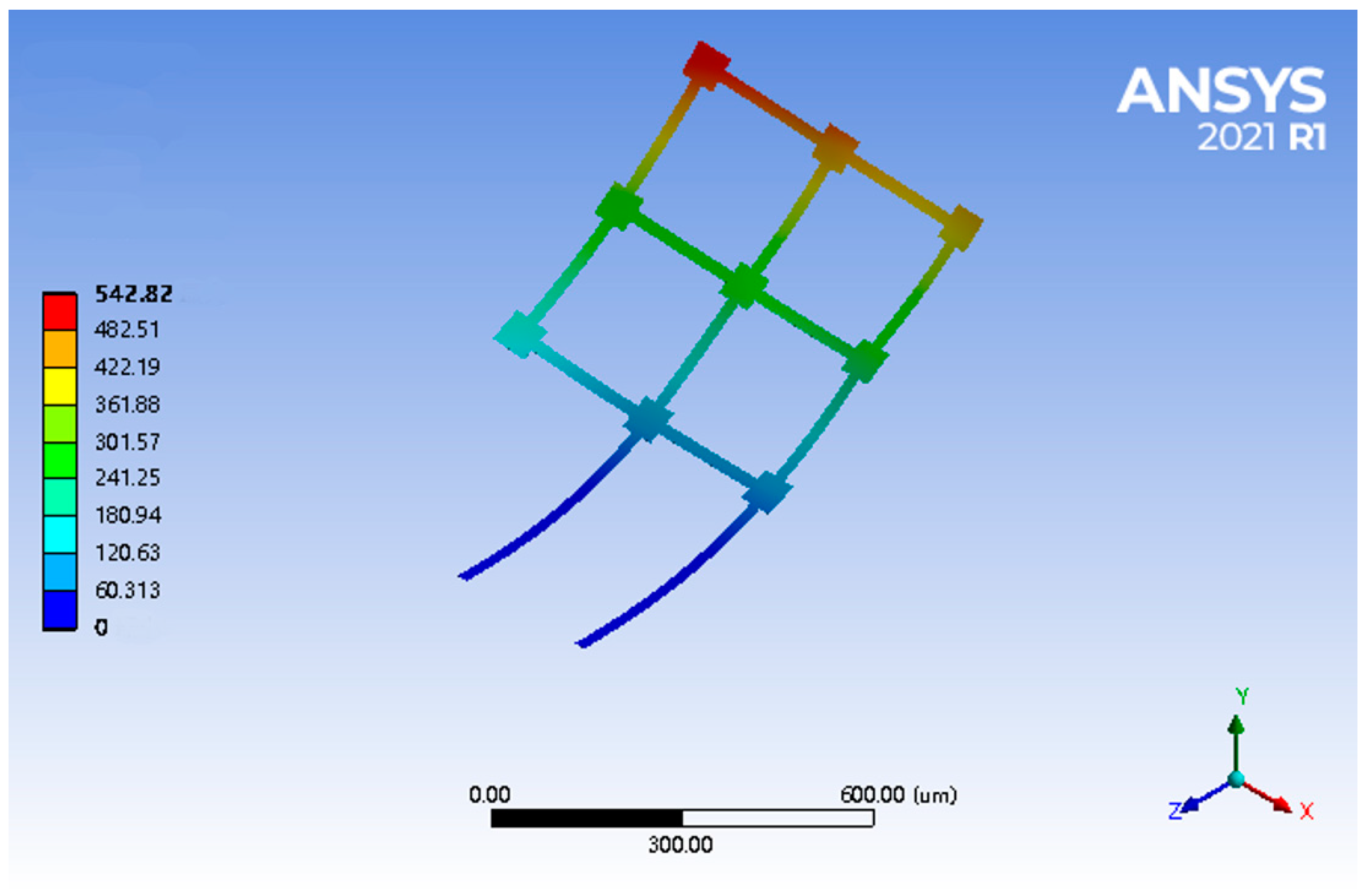

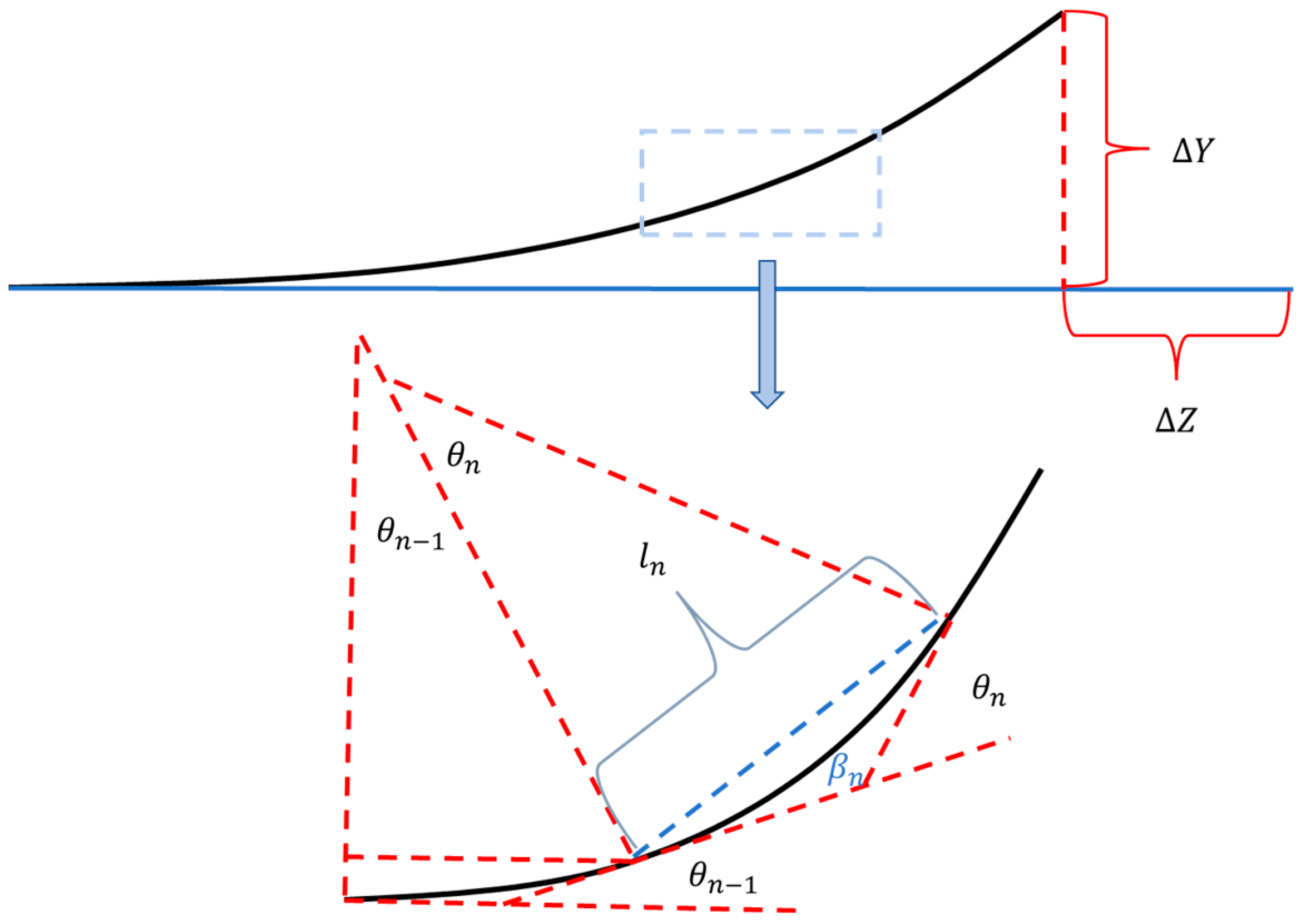

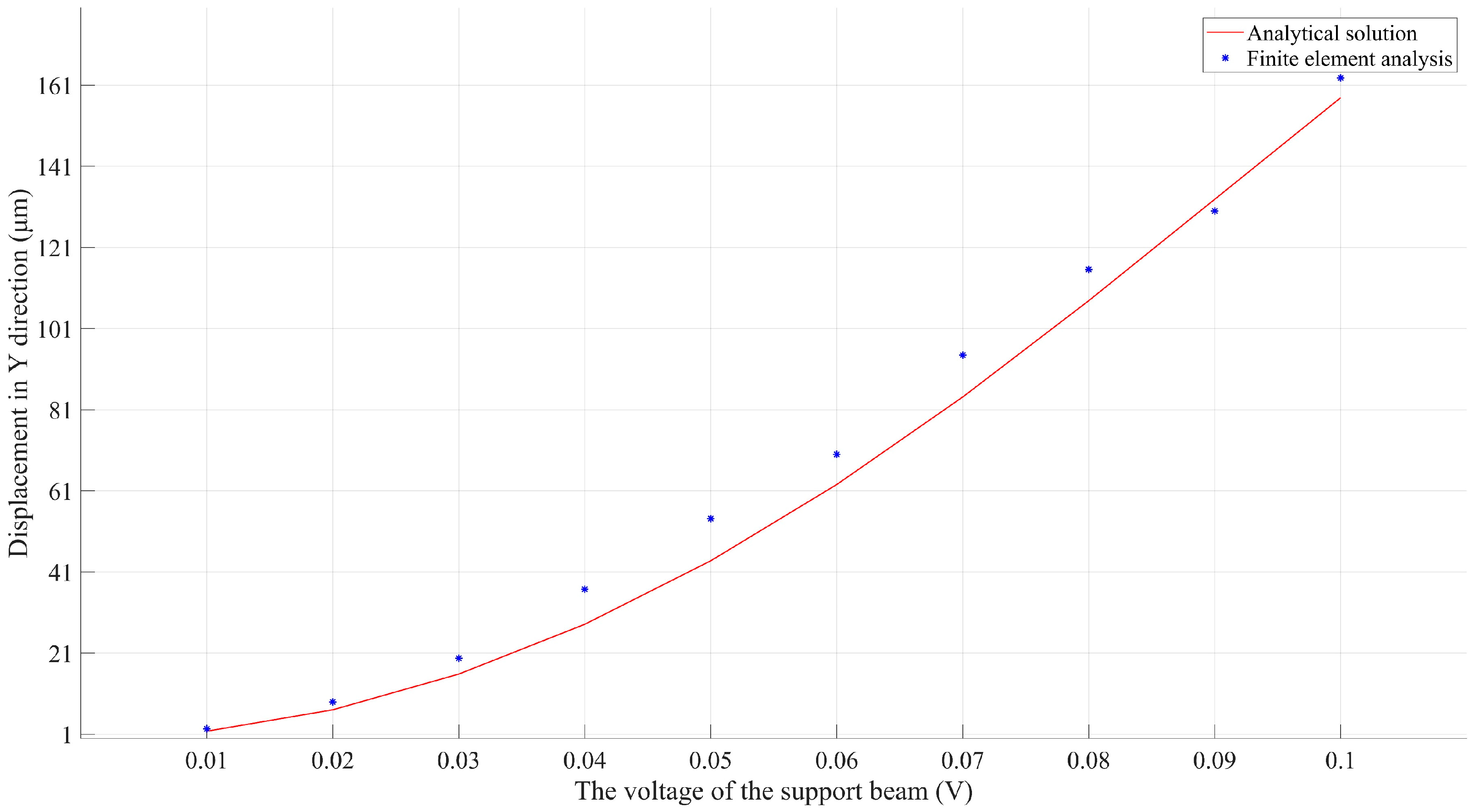

3.2. Thermo-Mechanical Model

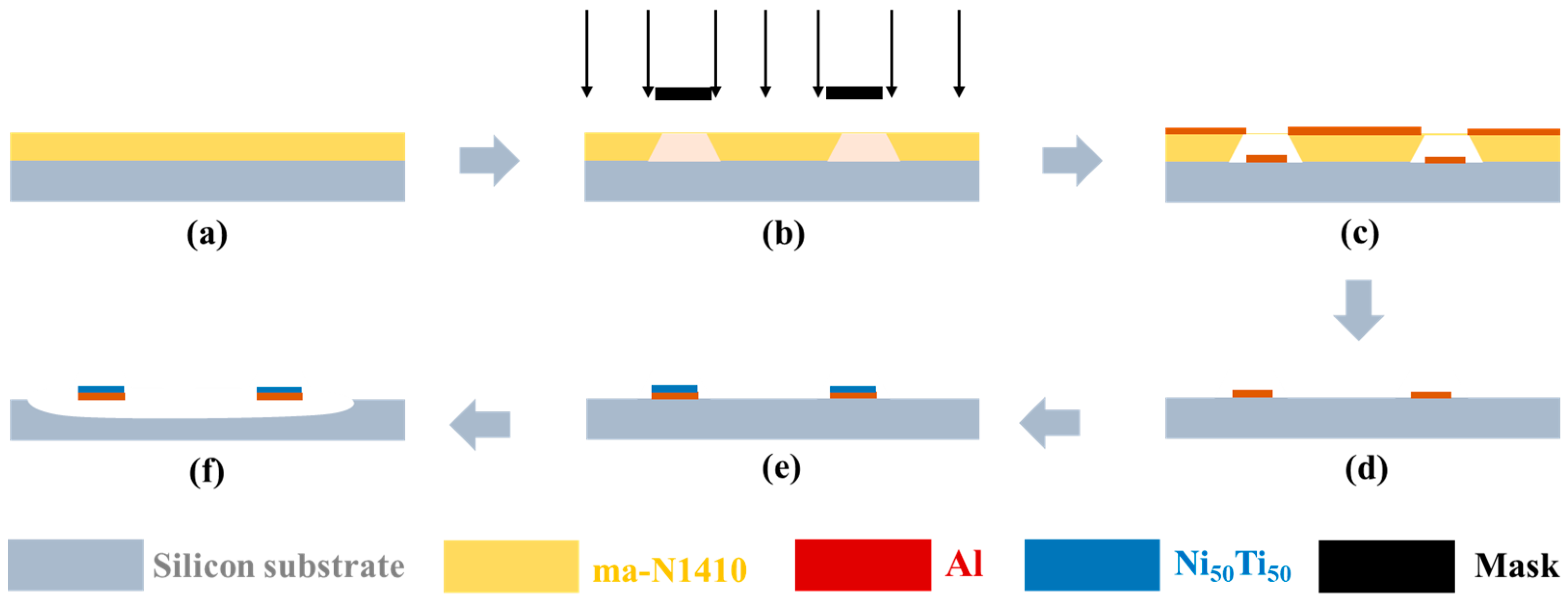

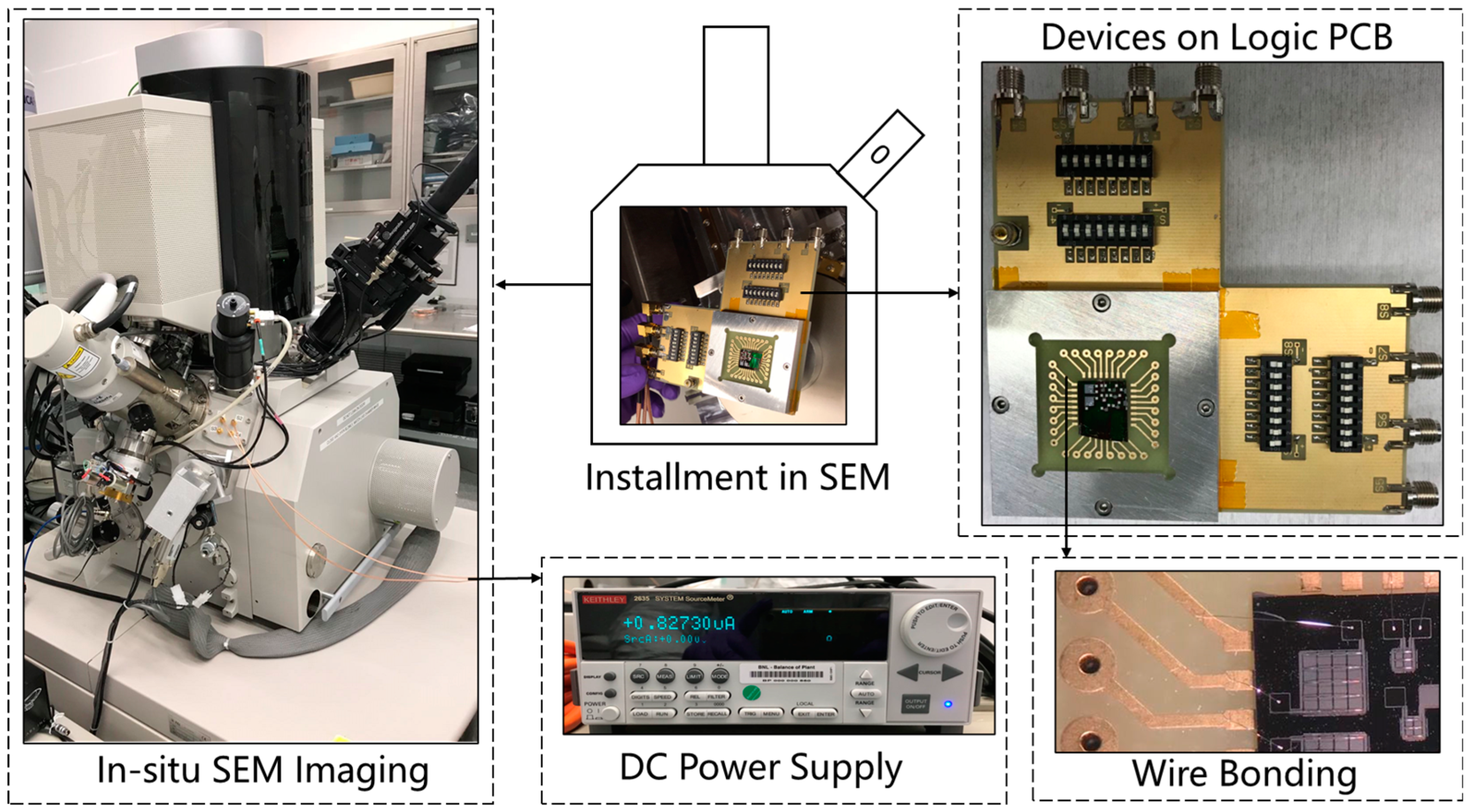

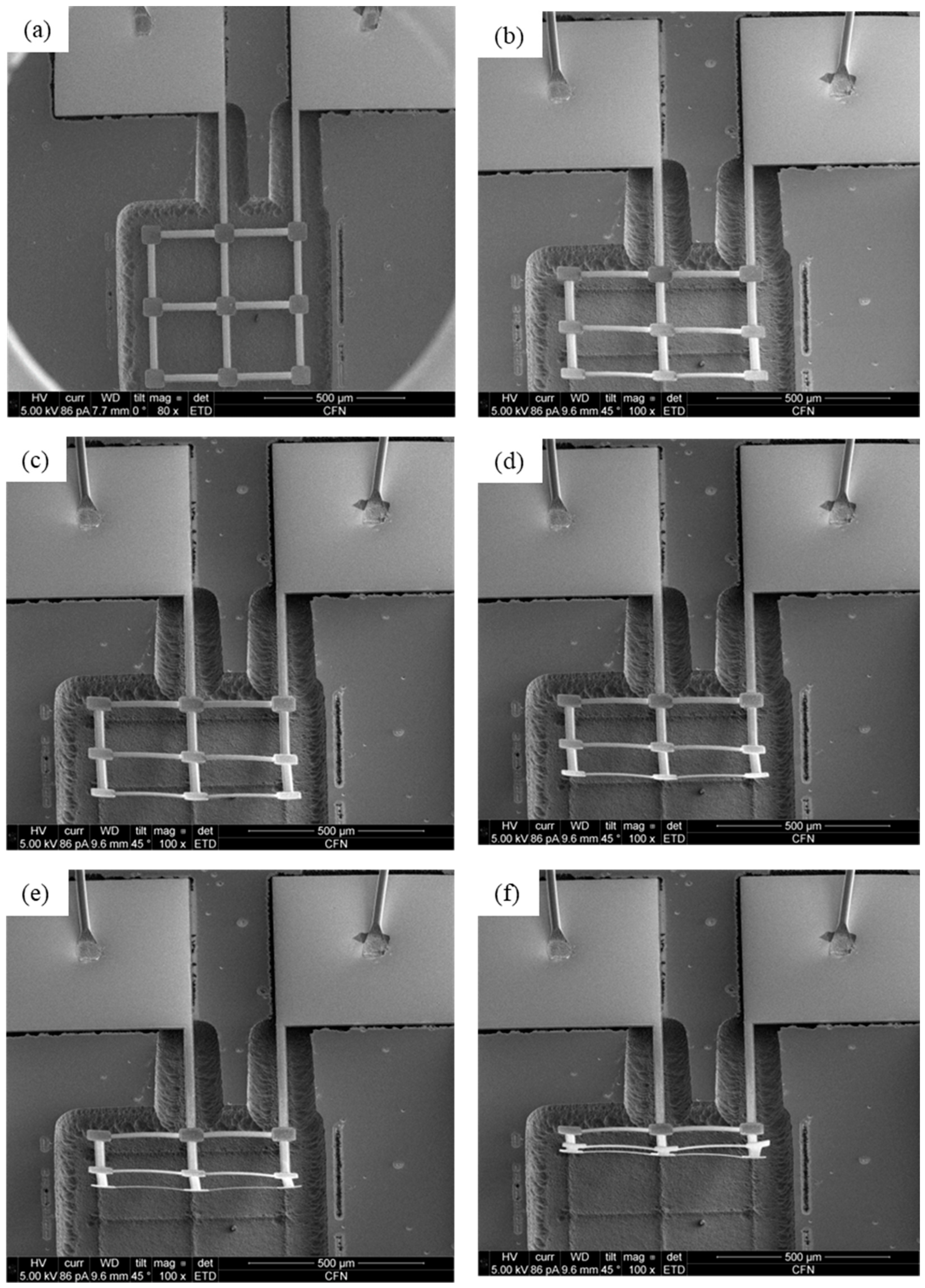

4. Fabrication and Experiment

5. Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| The local gravity in Earth’s orbit, m/s2 | |

| Mass of micro solar sails of the ChipSail, kg | |

| Mass of the satellite body of the ChipSail, kg | |

| Mass of the ChipSail, kg | |

| Young’s modulus of Al, Pa | |

| Density of Al thin film, 2.7 × 103, kg/m3 | |

| Thickness of Al thin film, m | |

| Coefficient of thermal expansion of Al, K−1 | |

| Young’s modulus of Ni50Ti50, Pa | |

| Density of Ni50Ti50 thin film, 6.45 × 103 kg/m3 | |

| Thickness of Ni50Ti50 thin film, m | |

| Effective coefficient of thermal expansion of Ni50Ti50, K−1 | |

| Initial temperature in ambient condition, K | |

| Final temperature via Joule heating, K | |

| Balanced temperature without Joule heating in space, K | |

| Thickness ratio of the Al layer to the Ni50Ti50 layer | |

| Young’s moduli ratio of Al to Ni50Ti50 | |

| The equivalent length of a U-shaped beam, m | |

| The number of U-shaped beam elements | |

| The central angle of the arc, ° | |

| The angle between the string and the tangent line, ° | |

| The length of the string, m | |

| The equivalent radius of the arc, m |

References

- Hines, L.; Petersen, K.; Lum, G.Z.; Sitti, M. Soft actuators for small-scale robotics. Adv. Mater. 2017, 29, 1603483. [Google Scholar] [CrossRef] [PubMed]

- Chen, T.; Bilal, O.R.; Shea, K.; Daraio, C. Harnessing bistability for directional propulsion of soft, untethered robots. Proc. Natl. Acad. Sci. USA 2018, 115, 5698–5702. [Google Scholar] [CrossRef]

- Chirarattananon, P.; Ma, K.Y.; Wood, R.J. Adaptive control of a millimeter-scale flapping-wing robot. Bioinspir Biomim. 2014, 9, 025004. [Google Scholar] [CrossRef] [PubMed]

- Nathan, A.; Ahnood, A.; Cole, M.T.; Sungsik, L.; Suzuki, Y.; Hiralal, P.; Bonaccorso, F.; Hasan, T.; Garcia-Gancedo, L.; Dyadyusha AHaque, S.; et al. Flexible Electronics: The Next Ubiquitous Platform. Proc. IEEE 2012, 100, 1486–1517. [Google Scholar] [CrossRef]

- Khan, S.; Lorenzelli, L.; Dahiya, R.S. Technologies for printing sensors and electronics over large flexible substrates: A review. IEEE Sens. J. 2014, 15, 3164–3185. [Google Scholar] [CrossRef]

- Investigators, P.P.S.T. The penumbra pivotal stroke trial: Safety and effectiveness of a new generation of mechanical devices for clot removal in intracranial large vessel occlusive disease. Stroke 2009, 40, 2761–2768. [Google Scholar]

- Tanaka, M. An industrial and applied review of new MEMS devices features. Microelectron. Eng. 2007, 84, 1341–1344. [Google Scholar] [CrossRef]

- Johnson, L.; Whorton, M.; Heaton, A.; Pinson, R.; Laue, G.; Adams, C. NanoSail-D: A solar sail demonstration mission. Acta Astronaut. 2011, 68, 571–575. [Google Scholar] [CrossRef]

- Tsuda, Y.; Mori, O.; Funase, R.; Sawada, H.; Yamamoto, T.; Saiki, T.; Endo, T.; Kawaguchi, J. Flight status of IKAROS deep space solar sail demonstrator. Acta Astronaut. 2011, 69, 833–840. [Google Scholar] [CrossRef]

- Barnhart, D.J.; Vladimirova, T.; Sweeting, M.N. Very-small-satellite design for distributed space missions. J. Spacecr. Rocket. 2007, 44, 1294–1306. [Google Scholar] [CrossRef]

- Macdonald, M.; McInnes, C. Solar sail science mission applications and advancement. Adv. Space Res. 2011, 48, 1702–1716. [Google Scholar] [CrossRef]

- Reichhardt, T. Space technology: Setting sail for history. Nature 2005, 433, 678–680. [Google Scholar] [CrossRef] [PubMed]

- Ridenoure, R.W.; Munakata, R.; Wong, S.D.; Diaz, A.; Spencer, D.A.; Stetson, D.A.; Betts, B.; Plante, B.A.; Foley, J.D.; Bellardo, J.M. Testing the lightsail program: Advancing solar sailing technology using a cubesat platform. J. Small Satell. 2016, 5, 531–550. [Google Scholar]

- Atchison, J.A.; Peck, M.A. Length Scaling in Spacecraft Dynamics. J. Guid. Control. Dyn. 2011, 34, 231–246. [Google Scholar] [CrossRef]

- Atchison, J.A.; Peck, M.A. A passive, sun-pointing, millimeter-scale solar sail. Acta Astronautica. 2010, 67, 108–121. [Google Scholar] [CrossRef]

- Bovesecchi, G.; Corasaniti, S.; Costanza, G.; Tata, M.E. A novel self-deployable solar sail system activated by shape memory alloys. Aerospace 2019, 6, 78. [Google Scholar] [CrossRef]

- Boschetto, A.; Bottini, L.; Costanza, G.; Tata, M.E. Shape memory activated self-deployable solar sails: Small-scale prototypes manufacturing and planarity analysis by 3D laser scanner. Actuators 2019, 8, 38. [Google Scholar] [CrossRef]

- Ren, Z.; Yuan, J.; Su, X.; Shi, Y. A novel design and thermal analysis of micro solar sails for solar sailing with chip scale spacecraft. Microsyst. Technol. 2021, 27, 2615–2622. [Google Scholar] [CrossRef]

- Wu, L.; Xie, H. A large vertical displacement electrothermal bimorph microactuator with very small lateral shift. Sens. Actuators A Phys. 2008, 145, 371–379. [Google Scholar] [CrossRef]

- Ogando, K.; La Forgia, N.; Zarate, J.; Pastoriza, H. Design and characterization of a fully compliant out-of-plane thermal actuator. Sens. Actuators A Phys. 2012, 183, 95–100. [Google Scholar] [CrossRef]

- Tsai, C.H.; Tsai, C.W.; Chang, H.T.; Liu, S.H.; Tsai, J.C. Electrothermally-Actuated Micromirrors with Bimorph Actuators—Bending-Type and Torsion-Type. Sensors 2015, 15, 14745–14756. [Google Scholar] [CrossRef] [PubMed]

- Zhang, W.-M.; Yan, H.; Peng, Z.-K.; Meng, G. Electrostatic pull-in instability in MEMS/NEMS: A review. Sens. Actuators A Phys. 2014, 214, 187–218. [Google Scholar] [CrossRef]

- Acome, E.; Mitchell, S.; Morrissey, T.; Emmett, M.; Benjamin, C.; King, M.; Radakovitz, M.; Keplinger, C. Hydraulically amplified self-healing electrostatic actuators with muscle-like performance. Science 2018, 359, 61–65. [Google Scholar] [CrossRef]

- Panda, P.; Sahoo, B. PZT to lead free piezo ceramics: A review. Ferroelectrics 2015, 474, 128–143. [Google Scholar] [CrossRef]

- Galos, R.; Shi, Y.; Ren, Z.; Synowicki, R.; Sun, H.; Nykypanchuk, D.; Su, X.; Yuan, J. The dielectric constant of PZT nanofiber at visible and NIR wavelengths. Nano-Struct. Nano-Objects 2018, 15, 205–211. [Google Scholar] [CrossRef]

- Galos, R.; Shi, Y.; Ren, Z.; Zhou, L.; Sun, H.; Su, X.; Yuan, J. Electrical impedance measurements of PZT nanofiber sensors. J. Nanomater. 2017, 50145, 8275139. [Google Scholar] [CrossRef]

- Ren, Z.; Yuan, J.; Yan, P. Digital Control of Active Network Microstructures on Silicon Wafers. In Network-on-Chip-Architecture, Optimization, and Design Explorations; IntechOpen: London, UK, 2021. [Google Scholar]

- Ren, Z.; Yuan, J.; Su, X.; Sun, H.; Galos, R.; Shi, Y.; Mangla, S.; Lu, M.; Camino, F. Vertical Deployment of Multilayered Metallic Microstructures With High Area-to-Mass Ratios by Thermal Actuation. J. Micro Nano-Manuf. 2019, 7, 031002. [Google Scholar] [CrossRef]

- Ren, Z.; Yuan, J.; Su, X.; Sun, H.; Galos, R.; Shi, Y. A New Fabrication Process for Microstructures With High Area-to-Mass Ratios by Stiffness Enhancement. In Proceedings of the International Design Engineering Technical 21 Conferences and Computers and Information in Engineering Conference: American Society of Mechanical Engineers, Quebec City, QC, Canada, 26–29 August 2018; p. V004T08A34. [Google Scholar]

- Sun, H.; Luo, J.; Ren, Z.; Lu, M.; Shi, Y. Effects of deposition and annealing conditions on the crystallization of NiTi thin films by e-beam evaporation. Micro Nano Lett. 2020, 15, 670–673. [Google Scholar] [CrossRef]

- Sun, H.; Luo, J.; Ren, Z.; Lu, M.; Nykypanchuk, D.; Mangla, S.; Shi, Y. Shape Memory Alloy Bimorph Microactuators by Lift-off Process. J. Micro Nano-Manuf. 2020, 8, 031003. [Google Scholar] [CrossRef]

- Ren, Z.; Yuan, J.; Shi, Y. Electro-thermo-mechanical modelling of micro solar sails of chip scale spacecraft in space. Microsyst. Technol. 2021, 27, 4209–4215. [Google Scholar] [CrossRef]

- Kumar, A.; Singh, D.; Kumar, R.; Kaur, D. Effect of crystallographic orientation of nanocrystalline TiN on structural, electrical and mechanical properties of TiN/NiTi thin films. J. Alloys Compd. 2009, 479, 166–172. [Google Scholar] [CrossRef]

- Yamamoto, N.; Gdoutos, E.; Toda, R.; White, V.; Manohara, H.; Daraio, C. Thin Films with Ultra-low Thermal Expansion. Adv. Mater. 2014, 26, 3076–3080. [Google Scholar] [CrossRef] [PubMed]

- Ren, Z.; Yuan, J.; Su, X.; Xu, Y.; Bauer, R.; Mangla, S.; Lu, M.; Shi, Y. Multilayered microstructures with shape memory effects for vertical deployment. Microsyst. Technol. 2021, 27, 3325–3332. [Google Scholar] [CrossRef]

- Ren, Z.; Yuan, J.; Su, X.; Bauer, R.; Xu, Y.; Mangla, S.; Camino, F.; Nam, C.Y.; Lu, M.; Shi, Y. Current divisions and distributed Joule heating of two-dimensional grid microstructures. Microsyst. Technol. 2021, 27, 3339–3347. [Google Scholar] [CrossRef]

- Yan, D.; Khajepour, A.; Mansour, R. Design and modeling of a MEMS bidirectional vertical thermal actuator. J. Micromech. Microeng. 2004, 14, 841. [Google Scholar] [CrossRef]

- Ren, Z. Design, Fabrication and Control of Reconfigurable Active Microstructures for Solar Sails; Stevens Institute of Technology: Hoboken, NJ, USA, 2020. [Google Scholar]

- Ren, Z.; Yuan, J.; Su, X.; Mangla, S.; Nam, C.Y.; Lu, M.; Tenney, S.A.; Shi, Y. Electro-thermal modeling and experimental validation for multilayered metallic microstructures. Microsyst. Technol. 2021, 27, 2041–2048. [Google Scholar] [CrossRef]

- Ren, Z.; Yuan, J.; Su, X.; Mangla, S.; Nam, C.Y.; Lu, M.; Camino, F.; Shi, Y. Thermo-mechanical modeling and experimental validation for multilayered metallic microstructures. Microsyst. Technol. 2021, 27, 2579–2587. [Google Scholar] [CrossRef]

- Timoshenko, S. Analysis of bi-metal thermostats. J. Opt. Soc. Am. 1925, 11, 233–256. [Google Scholar] [CrossRef]

- Ren, Z.; Li, C.; Xie, K.; Mangla, S.; Nam, C.Y.; Camino, F.; Wang, H.; Yuan, J.; Yan, P. Smart material based multilayered microbeam structures for spatial self-deployment and reconfiguration: A residual stress approach. Compos. Struct. 2023, 304, 116468. [Google Scholar] [CrossRef]

| Properties | Bottom Al Layer | Upper Ni50Ti50 Layer |

|---|---|---|

| Electrical resistivity (Ω⋅m) | 2.65 × 10−8 | 82 × 10−8 |

| Young’s modulus (Pa) Coefficient of thermal expansion (K−1) Density (m3/kg) Length of the grid beam (m) Length of the supporting beam (m) Width of the beam structure (m) Thickness of the beam structure (m) | 70 × 109 23.1 × 10−6 2.7 × 103 2 × 10−4 4 × 10−4 2 × 10−5 3 × 10−7 | 56 × 109 11 × 10−6 6.45 × 103 2 × 10−4 4 × 10−4 2 × 10−5 3 × 10−7 |

| Thermal conductivities (W/m⋅K) | 205 | 18 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xie, K.; Li, C.; Sun, S.; Nam, C.-Y.; Shi, Y.; Wang, H.; Duan, W.; Ren, Z.; Yan, P. Electrothermally Driven Reconfiguration of Microrobotic Beam Structures for the ChipSail System. Micromachines 2023, 14, 831. https://doi.org/10.3390/mi14040831

Xie K, Li C, Sun S, Nam C-Y, Shi Y, Wang H, Duan W, Ren Z, Yan P. Electrothermally Driven Reconfiguration of Microrobotic Beam Structures for the ChipSail System. Micromachines. 2023; 14(4):831. https://doi.org/10.3390/mi14040831

Chicago/Turabian StyleXie, Kecai, Chengyang Li, Shouyu Sun, Chang-Yong Nam, Yong Shi, Haipeng Wang, Wu Duan, Zhongjing Ren, and Peng Yan. 2023. "Electrothermally Driven Reconfiguration of Microrobotic Beam Structures for the ChipSail System" Micromachines 14, no. 4: 831. https://doi.org/10.3390/mi14040831

APA StyleXie, K., Li, C., Sun, S., Nam, C.-Y., Shi, Y., Wang, H., Duan, W., Ren, Z., & Yan, P. (2023). Electrothermally Driven Reconfiguration of Microrobotic Beam Structures for the ChipSail System. Micromachines, 14(4), 831. https://doi.org/10.3390/mi14040831