Fabrication of Chemofluidic Integrated Circuits by Multi-Material Printing

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Equipment

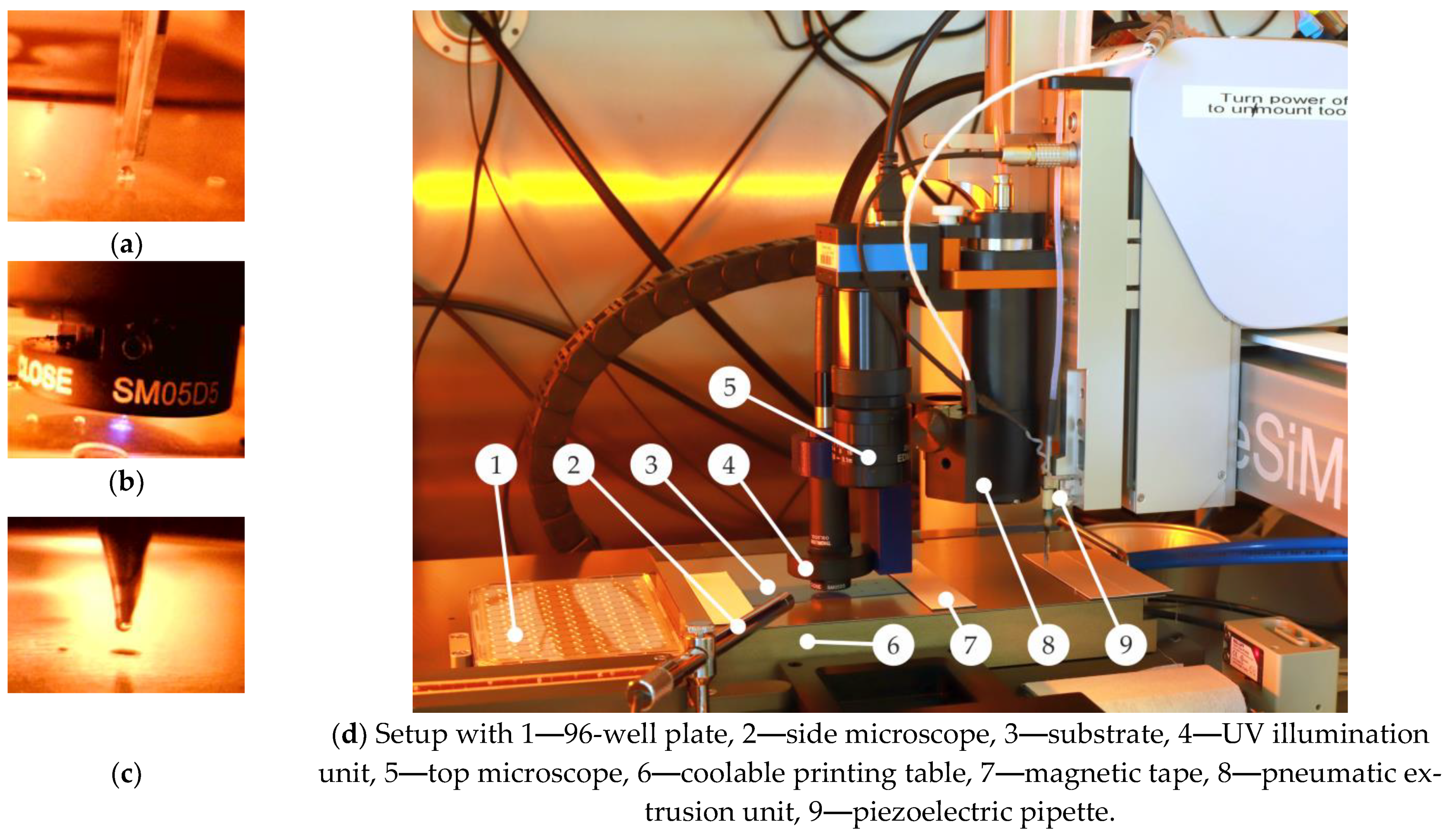

2.2.1. Multi-Material Printing Station

2.2.2. Excimer ExciJet172 55-130 Lab System

2.2.3. Compact Laser Micromachining System RDX500

2.2.4. Microfluidic Test Station

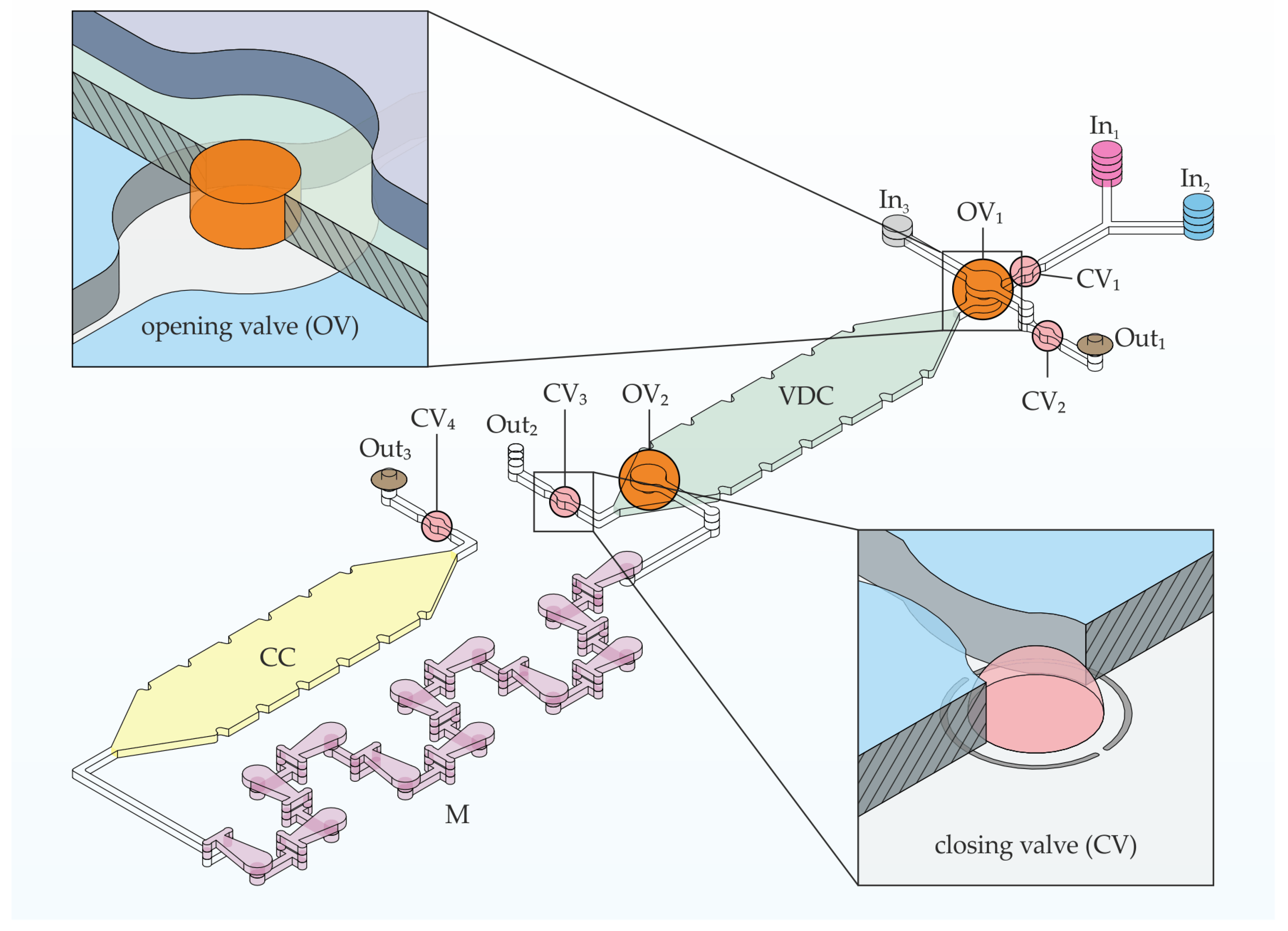

2.3. Application Chip

2.3.1. Preparation of Prepolymer Solution for Hydrogel Printing

2.3.2. Chip Manufacturing

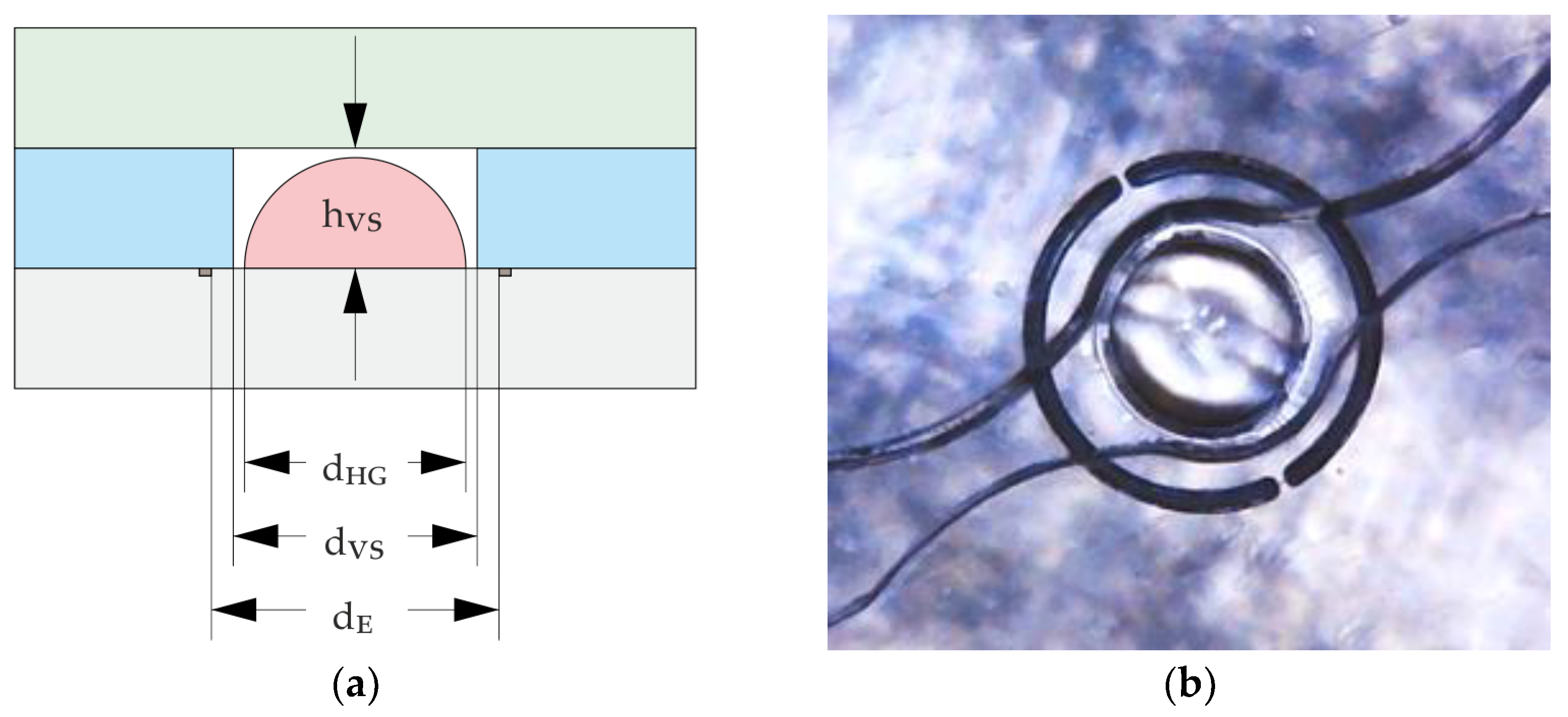

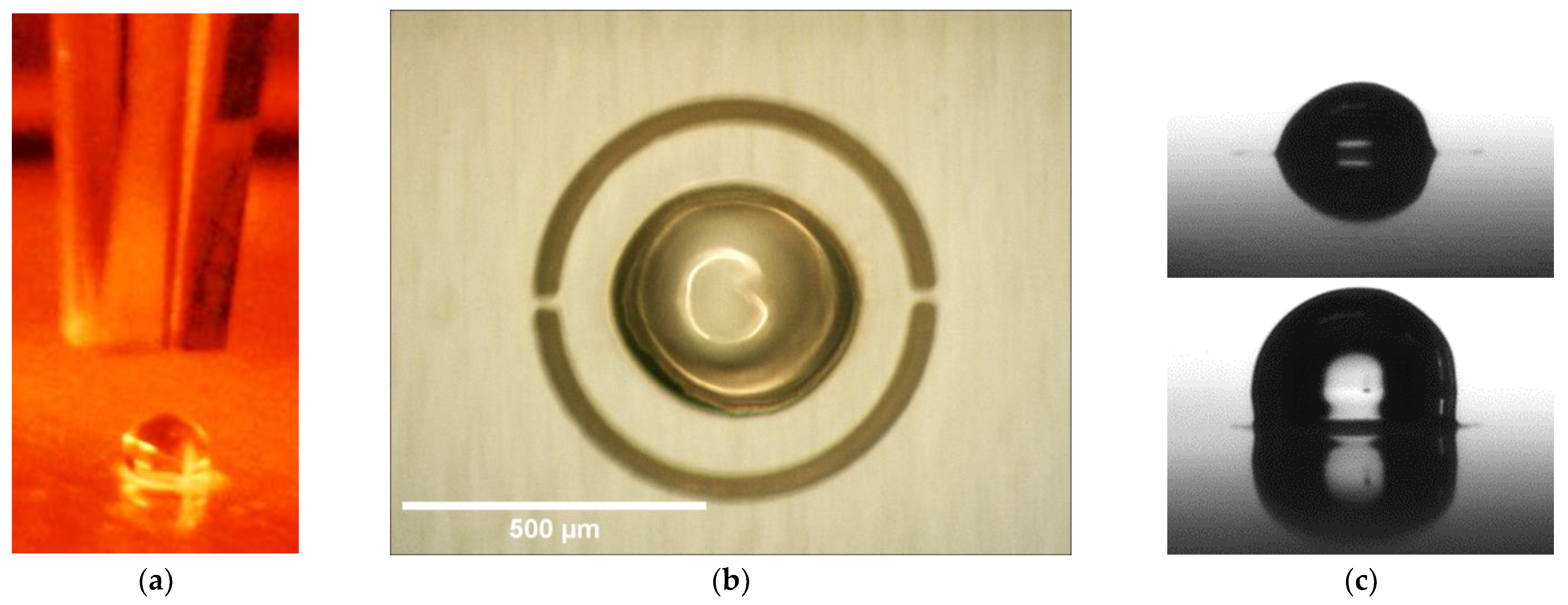

2.3.3. Fabrication of Hydrogel-Based Closing Valves

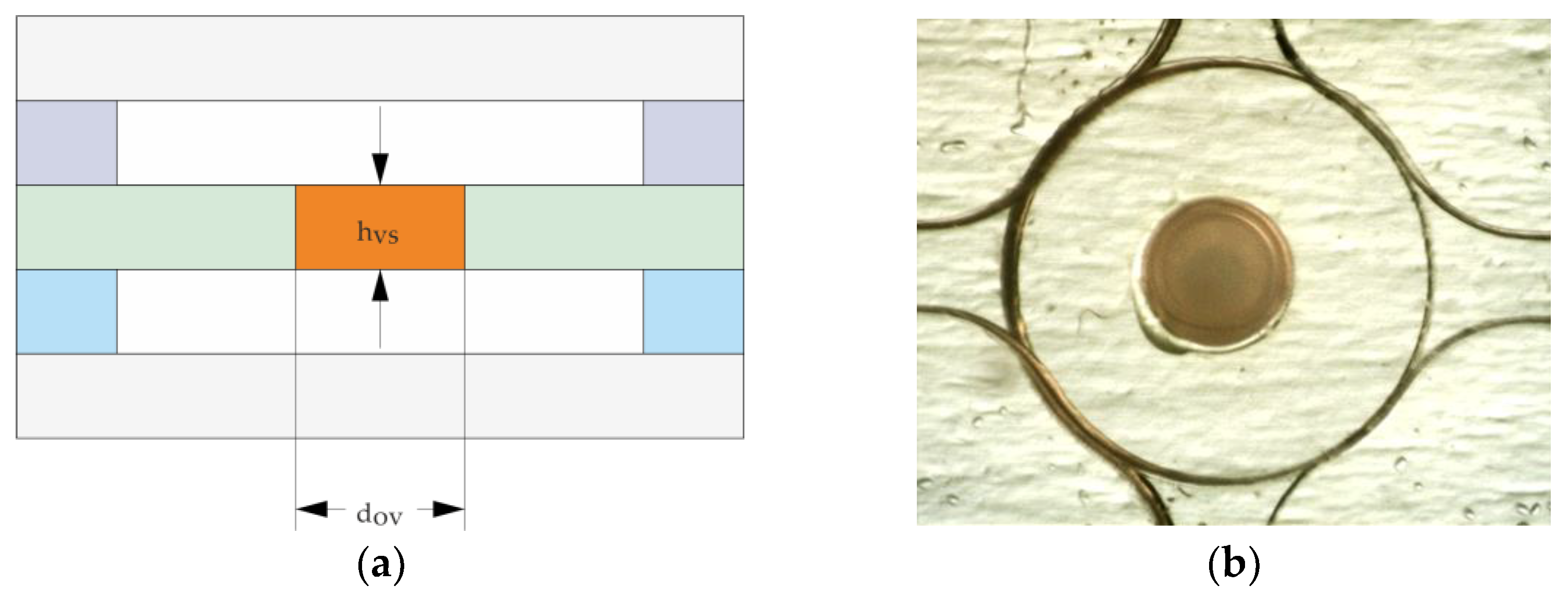

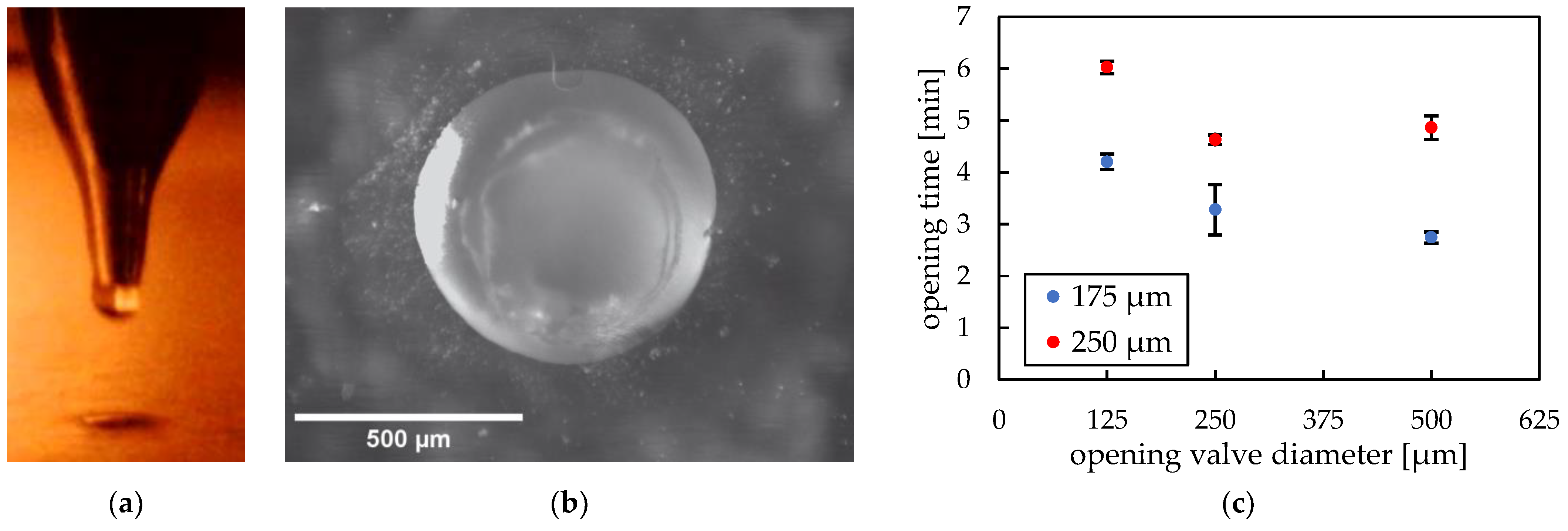

2.3.4. Fabrication of PEG-Based Opening Valves

2.3.5. Test Station to Characterize the Opening Valves, Closing Valves and Application Chip

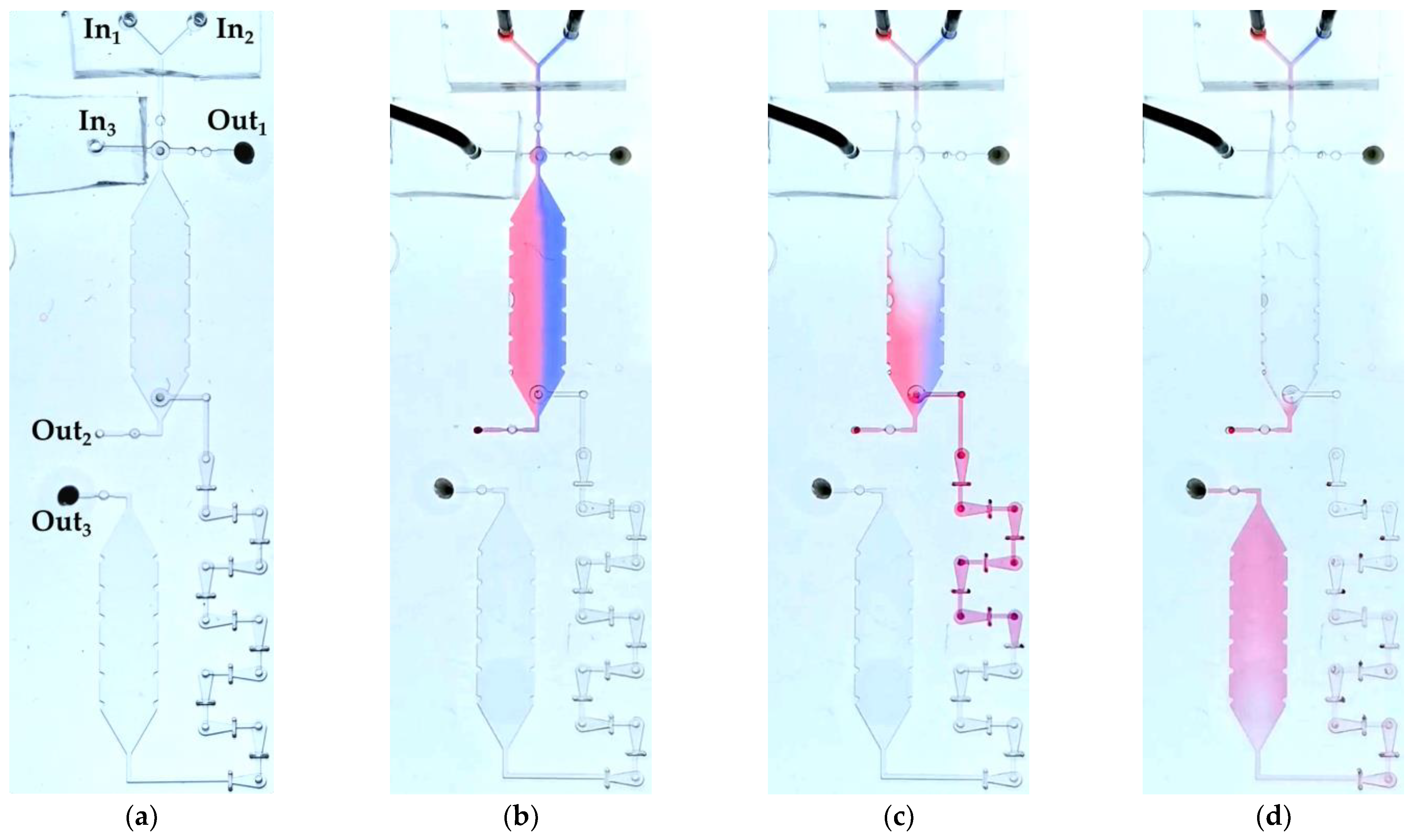

2.3.6. Design of the Application Chip and IC Program

3. Results

3.1. Characterization of the Hydrogel-Based Closing Valves

3.1.1. Design Parameters

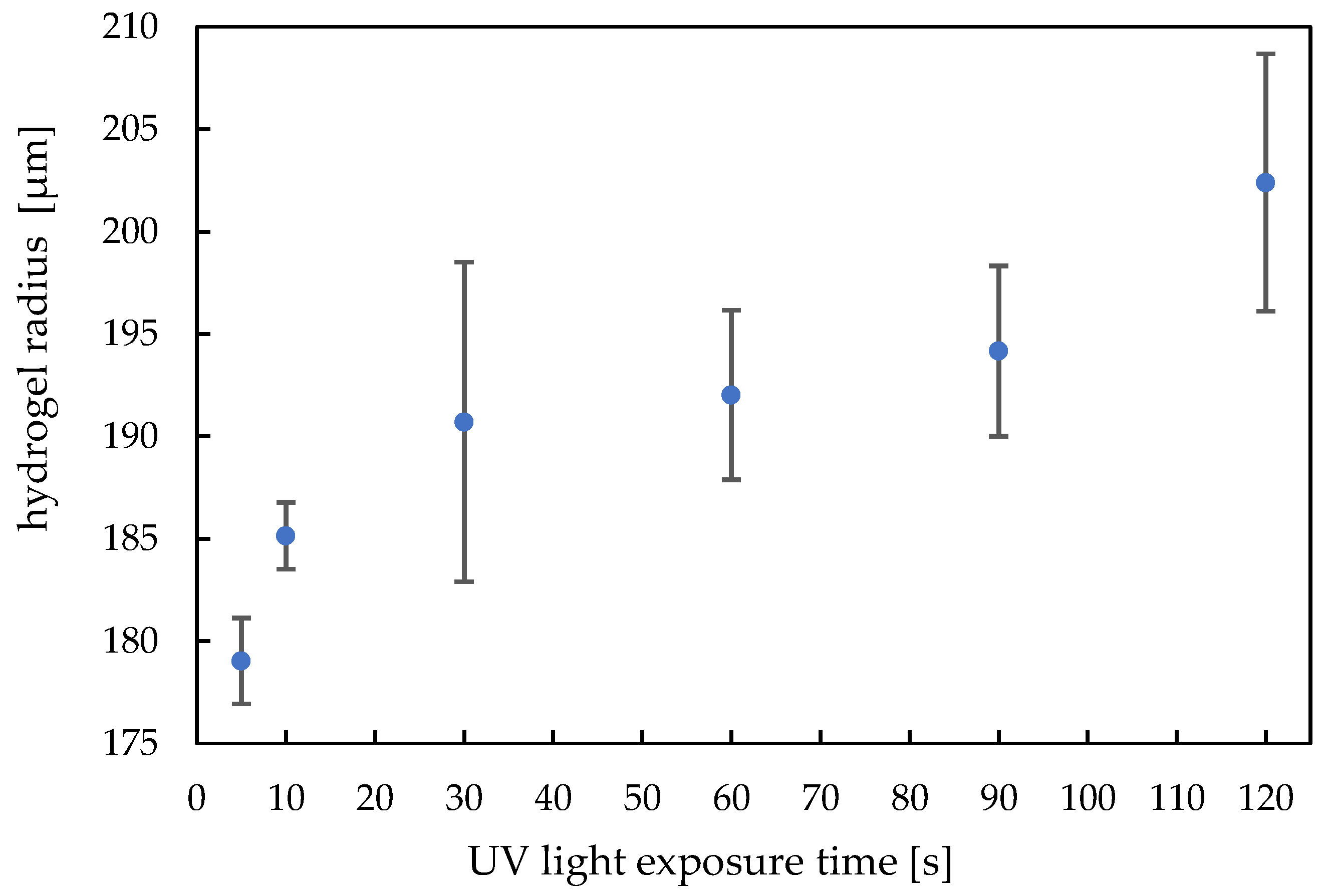

3.1.2. Synthesis Parameters

3.2. Characterization of the PEG-Based Opening Valves

3.3. Application Chip

4. Discussion

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Hamilton, S. Taking Moore’s Law into the next Century. Computer 1999, 32, 43–48. [Google Scholar] [CrossRef]

- Thorsen, T.; Maerkl, S.J.; Quake, S.R. Microfluidic Large-Scale Integration. Science (1979) 2002, 298, 580–584. [Google Scholar] [CrossRef] [PubMed]

- Melin, J.; Quake, S.R. Microfluidic Large-Scale Integration: The Evolution of Design Rules for Biological Automation. Annu. Rev. Biophys. Biomol. Struct. 2007, 36, 213–231. [Google Scholar] [CrossRef] [PubMed]

- Au, A.K.; Lai, H.; Utela, B.R.; Folch, A. Microvalves and Micropumps for BioMEMS. Micromachines 2011, 2, 179–220. [Google Scholar] [CrossRef]

- Rhee, M.; Burns, M.A. Microfluidic Pneumatic Logic Circuits and Digital Pneumatic Microprocessors for Integrated Microfluidic Systems. Lab Chip 2009, 9, 3131–3143. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Q.; Zhang, M.; Djeghlaf, L.; Bataille, J.; Gamby, J.; Haghiri-Gosnet, A.M.; Pallandre, A. Logic Digital Fluidic in Miniaturized Functional Devices: Perspective to the next Generation of Microfluidic Lab-on-Chips. Electrophoresis 2017, 38, 953–976. [Google Scholar] [CrossRef]

- Frank, P.; Schreiter, J.; Haefner, S.; Paschew, G.; Voigt, A.; Richter, A. Integrated Microfluidic Membrane Transistor Utilizing Chemical Information for On-Chip Flow Control. PLoS ONE 2016, 11, e0161024. [Google Scholar] [CrossRef]

- Frank, P.; Gräfe, D.; Probst, C.; Haefner, S.; Elstner, M.; Appelhans, D.; Kohlheyer, D.; Voit, B.; Richter, A.; Frank, P.; et al. Autonomous Integrated Microfluidic Circuits for Chip-Level Flow Control Utilizing Chemofluidic Transistors. Adv. Funct. Mater. 2017, 27, 1700430. [Google Scholar] [CrossRef]

- Beck, A.; Mehner, P.J.; Voigt, A.; Obst, F.; Marschner, U.; Richter, A. Logic Circuits Based on Chemical Volume Phase Transition Transistors for Planar Microfluidics and Lab-on-a-Chip Automation. Adv. Mater. Technol. 2022, 7, 2200185. [Google Scholar] [CrossRef]

- Greiner, R.; Allerdissen, M.; Voigt, A.; Richter, A. Fluidic Microchemomechanical Integrated Circuits Processing Chemical Information. Lab Chip 2012, 12, 5034–5044. [Google Scholar] [CrossRef]

- Allerdissen, M.; Greiner, R.; Richter, A. Microfluidic Microchemomechanical Systems. Adv. Sci. Technol. 2013, 81, 84–89. [Google Scholar] [CrossRef]

- Hoffmann, J.; Plötner, M.; Kuckling, D.; Fischer, W.J. Photopatterning of Thermally Sensitive Hydrogels Useful for Microactuators. Sens. Actuators A Phys. 1999, 77, 139–144. [Google Scholar] [CrossRef]

- Beebe, D.J.; Moore, J.S.; Bauer, J.M.; Yu, Q.; Liu, R.H.; Devadoss, C.; Jo, B.H. Functional Hydrogel Structures for Autonomous Flow Control inside Microfluidic Channels. Nature 2000, 404, 588–590. [Google Scholar] [CrossRef]

- Obst, F.; Beck, A.; Bishayee, C.; Mehner, P.J.; Richter, A.; Voit, B.; Appelhans, D. Hydrogel Microvalves as Control Elements for Parallelized Enzymatic Cascade Reactions in Microfluidics. Micromachines 2020, 11, 167. [Google Scholar]

- Obst, F.; Simon, D.; Mehner, P.J.J.; Neubauer, J.W.W.; Beck, A.; Stroyuk, O.; Richter, A.; Voit, B.; Appelhans, D. One-Step Photostructuring of Multiple Hydrogel Arrays for Compartmentalized Enzyme Reactions in Microfluidic Devices. React. Chem. Eng. 2019, 4, 2141–2155. [Google Scholar] [CrossRef]

- Yu, C.; Mutlu, S.; Selvaganapathy, P.; Mastrangelo, C.H.; Svec, F.; Fréchet, J.M.J.J. Flow Control Valves for Analytical Microfluidic Chips without Mechanical Parts Based on Thermally Responsive Monolithic Polymers. Anal. Chem. 2003, 75, 1958–1961. [Google Scholar] [CrossRef]

- Simon, D.; Obst, F.; Haefner, S.; Heroldt, T.; Peiter, M.; Simon, F.; Richter, A.; Voit, B.; Appelhans, D. Hydrogel/Enzyme Dots as Adaptable Tool for Non-Compartmentalized Multi-Enzymatic Reactions in Microfluidic Devices. React. Chem. Eng. 2019, 4, 67–77. [Google Scholar] [CrossRef]

- Heo, J.; Crooks, R.M. Microfluidic Biosensor Based on an Array of Hydrogel-Entrapped Enzymes. Anal. Chem. 2005, 77, 6843–6851. [Google Scholar] [CrossRef]

- Eddington, D.T.; Beebe, D.J. Flow Control with Hydrogels. Adv. Drug Deliv. Rev. 2004, 56, 199–210. [Google Scholar] [CrossRef]

- Beck, A.; Obst, F.; Busek, M.; Grünzner, S.; Mehner, P.J.; Paschew, G.; Appelhans, D.; Voit, B.; Richter, A. Hydrogel Patterns in Microfluidic Devices by Do-It-Yourself UV-Photolithography Suitable for Very Large-Scale Integration. Micromachines 2020, 11, 479. [Google Scholar] [CrossRef]

- Haefner, S.; Koerbitz, R.; Frank, P.; Elstner, M.; Richter, A. High Integration of Microfluidic Circuits Based on Hydrogel Valves for MEMS Control. Adv. Mater. Technol. 2018, 3, 1700108. [Google Scholar] [CrossRef]

- Haefner, S.; Rohn, M.; Frank, P.; Paschew, G.; Elstner, M.; Richter, A. Improved Pnipaam-Hydrogel Photopatterning by Process Optimisation with Respect to Uv Light Sources and Oxygen Content. Gels 2016, 2, 10. [Google Scholar] [CrossRef] [PubMed]

- Valentin, T.M.; DuBois, E.M.; Machnicki, C.E.; Bhaskar, D.; Cui, F.R.; Wong, I.Y. 3D Printed Self-Adhesive PEGDA–PAA Hydrogels as Modular Components for Soft Actuators and Microfluidics. Polym. Chem. 2019, 10, 2015–2028. [Google Scholar] [CrossRef]

- Champeau, M.; Heinze, D.A.; Viana, T.N.; de Souza, E.R.; Chinellato, A.C.; Titotto, S. 4D Printing of Hydrogels: A Review. Adv. Funct. Mater. 2020, 30, 1910606. [Google Scholar] [CrossRef]

- Distler, T.; Boccaccini, A.R. 3D Printing of Electrically Conductive Hydrogels for Tissue Engineering and Biosensors—A Review. Acta Biomater. 2020, 101, 1–13. [Google Scholar] [CrossRef]

- Weigel, N.; Männel, M.J.; Thiele, J. Flexible Materials for High-Resolution 3D Printing of Microfluidic Devices with Integrated Droplet Size Regulation. ACS Appl. Mater. Interfaces 2021, 13, 31086–31101. [Google Scholar] [CrossRef]

- Kirchmajer, D.M.M.; Gorkin, R.; In Het Panhuis, M.; Gorkin III, R.; In Het Panhuis, M. An Overview of the Suitability of Hydrogel-Forming Polymers for Extrusion-Based 3D-Printing. J. Mater. Chem. B 2015, 3, 4105–4117. [Google Scholar] [CrossRef]

- Frank, P.; Haefner, S.; Elstner, M.; Richter, A. Fully-Programmable, Low-Cost, “Do-It-Yourself” Pressure Source for General Purpose Use in the Microfluidic Laboratory. Inventions 2016, 1, 13. [Google Scholar] [CrossRef]

- Cho, Y.K.; Lee, J.G.; Park, J.M.; Lee, B.S.; Lee, Y.; Ko, C. One-Step Pathogen Specific DNA Extraction from Whole Blood on a Centrifugal Microfluidic Device. Lab Chip 2007, 7, 565–573. [Google Scholar] [CrossRef]

- Hadwen, B.; Broder, G.R.; Morganti, D.; Jacobs, A.; Brown, C.; Hector, J.R.; Kubota, Y.; Morgan, H. Programmable Large Area Digital Microfluidic Array with Integrated Droplet Sensing for Bioassays. Lab Chip 2012, 12, 3305–3313. [Google Scholar] [CrossRef]

- Viktorov, V.; Mahmud, M.R.; Visconte, C. Design and Characterization of a New H-C Passive Micromixer up to Reynolds Number 100. Chem. Eng. Res. Des. 2016, 108, 152–163. [Google Scholar] [CrossRef]

- Beck, A.; Obst, F.; Gruner, D.; Voigt, A.; Mehner, P.J.; Gruenzner, S.; Koerbitz, R.; Shahadha, M.H.; Kutscher, A.; Paschew, G.; et al. Fundamentals of Hydrogel-Based Valves and Chemofluidic Transistors for Lab-on-a-Chip Technology: A Tutorial Review. Adv. Mater. Technol. 2022, 8, 2200417. [Google Scholar] [CrossRef]

- Richter, A.; Howitz, S.; Kuckling, D.; Arndt, K.F. Influence of Volume Phase Transition Phenomena on the Behavior of Hydrogel-Based Valves. Sens. Actuators B Chem. 2004, 99, 451–458. [Google Scholar] [CrossRef]

- Richter, A.; Howitz, S.; Kuckling, D.; Kretschmer, K.; Arndt, K.-F.F. Automatically and Electronically Controllable Hydrogel Based Valves and Microvalves - Design and Operating Performance. Macromol. Symp. 2004, 210, 447–456. [Google Scholar] [CrossRef]

- Matsuo, E.S.; Tanaka, T. Kinetics of Discontinuous Volume-Phase Transition of Gels. J. Chem. Phys. 1988, 89, 1695–1703. [Google Scholar] [CrossRef]

- Stimuli-Responsive Gels; Kuckling, D., Ed.; MDPI: Basel, Switzerland, 2018; p. 288. [Google Scholar] [CrossRef]

- Naegel, A.; Heisig, M.; Wittum, G. Computational Modeling of the Skin Barrier. Methods Mol. Biol. 2011, 763, 1–32. [Google Scholar]

- Voigt, A.; Greiner, R.; Allerdißen, M.; Richter, A.; Henker, S.; Völp, M. Towards computation with microchemomechanical systems. Int. J. Found. Comput. Sci. 2014, 25, 507–523. [Google Scholar] [CrossRef]

- Richter, A.; Klatt, S.; Paschew, G.; Klenke, C. Micropumps Operated by Swelling and Shrinking of Temperature-Sensitive Hydrogels. Lab Chip 2009, 9, 613–618. [Google Scholar] [CrossRef]

- Richter, A.; Klenke, C.; Arndt, K.F. Adjustable Low Dynamic Pumps Based on Hydrogels. Macromol. Symp. 2004, 210, 377–384. [Google Scholar] [CrossRef]

- Haefner, S.; Frank, P.; Elstner, M.; Nowak, J.; Odenbach, S.; Richter, A. Smart Hydrogels as Storage Elements with Dispensing Functionality in Discontinuous Microfluidic Systems. Lab Chip 2016, 16, 3977–3989. [Google Scholar] [CrossRef]

- Haefner, S.; Frank, P.; Langer, E.; Gruner, D.; Schmidt, U.; Elstner, M.; Gerlach, G.; Richter, A. Chemically Controlled Micro-Pores and Nano-Filters for Separation Tasks in 2D and 3D Microfluidic Systems. RSC Adv. 2017, 7, 49279–49289. [Google Scholar] [CrossRef]

- Ehrenhofer, A.; Bingel, G.; Paschew, G.; Tietze, M.; Schröder, R.; Richter, A.; Wallmersperger, T. Permeation Control in Hydrogel-Layered Patterned PET Membranes with Defined Switchable Pore Geometry - Experiments and Numerical Simulation. Sens. Actuators B Chem. 2016, 232, 499–505. [Google Scholar] [CrossRef]

- Richter, A.; Türke, A.; Pich, A. Controlled Double-Sensitivity of Microgels Applied to Electronically Adjustable Chemostats. Adv. Mater. 2007, 19, 1109–1112. [Google Scholar] [CrossRef]

- Richter, A.; Wenzel, J.; Kretschmer, K. Mechanically Adjustable Chemostats Based on Stimuli-Responsive Polymers. Sens. Actuators B Chem. 2007, 125, 569–573. [Google Scholar] [CrossRef]

- Hart, R.A.; Da Silva, A.K. Self-Optimizing, Thermally Adaptive Microfluidic Flow Structures. Microfluid. Nanofluid. 2013, 14, 121–132. [Google Scholar] [CrossRef]

- Mao, Z.; Yoshida, K.; Kim, J. wan A Micro Vertically-Allocated SU-8 Check Valve and Its Characteristics. Microsyst. Technol. 2019, 25, 245–255. [Google Scholar] [CrossRef]

- Mao, Z.; Yoshida, K.; Kim, J. wan Study on the Fabrication of a SU-8 Cantilever Vertically-Allocated in a Closed Fluidic Microchannel. Microsyst. Technol. 2018, 24, 2473–2483. [Google Scholar] [CrossRef]

- Dong, L.; Agarwal, A.K.; Beebe, D.J.; Jiang, H. Variable-Focus Liquid Microlenses and Microlens Arrays Actuated by Thermoresponsive Hydrogels. Adv. Mater. 2007, 19, 401–405. [Google Scholar] [CrossRef]

- Richter, A.; Paschew, G. Optoelectrothermic Control of Highly Integrated Polymer-Based MEMS Applied in an Artificial Skin. Adv. Mater. 2009, 21, 979–983. [Google Scholar] [CrossRef]

- Liu, X.; Liu, J.; Lin, S.; Zhao, X. Hydrogel Machines. Mater. Today 2020, 36, 102–124. [Google Scholar] [CrossRef]

- Erol, O.; Pantula, A.; Liu, W.; Gracias, D.H. Transformer Hydrogels: A Review. Adv. Mater. Technol. 2019, 4, 1900043. [Google Scholar] [CrossRef]

- Kutscher, A.; Richter, A. Magnetically Hybridized Inkjet-Printed Und Photo-Polymerized Multi-Hydrogel Thermo-Responsive Soft Gripper. In Proceedings of the ACTUATOR 2022; International Conference and Exhibition on New Actuator Systems and Applications, Mannheim, Germany, 29–30 June 2022; pp. 1–3. [Google Scholar]

| Number of droplets | 400 | 460 | 500 | 600 | 700 | 800 | 900 | 1000 |

| Yield in % | 100 | 100 | 100 | 100 | 73 | 93 | 47 | 33 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kutscher, A.; Kalenczuk, P.; Shahadha, M.; Grünzner, S.; Obst, F.; Gruner, D.; Paschew, G.; Beck, A.; Howitz, S.; Richter, A. Fabrication of Chemofluidic Integrated Circuits by Multi-Material Printing. Micromachines 2023, 14, 699. https://doi.org/10.3390/mi14030699

Kutscher A, Kalenczuk P, Shahadha M, Grünzner S, Obst F, Gruner D, Paschew G, Beck A, Howitz S, Richter A. Fabrication of Chemofluidic Integrated Circuits by Multi-Material Printing. Micromachines. 2023; 14(3):699. https://doi.org/10.3390/mi14030699

Chicago/Turabian StyleKutscher, Alexander, Paula Kalenczuk, Mohammed Shahadha, Stefan Grünzner, Franziska Obst, Denise Gruner, Georgi Paschew, Anthony Beck, Steffen Howitz, and Andreas Richter. 2023. "Fabrication of Chemofluidic Integrated Circuits by Multi-Material Printing" Micromachines 14, no. 3: 699. https://doi.org/10.3390/mi14030699

APA StyleKutscher, A., Kalenczuk, P., Shahadha, M., Grünzner, S., Obst, F., Gruner, D., Paschew, G., Beck, A., Howitz, S., & Richter, A. (2023). Fabrication of Chemofluidic Integrated Circuits by Multi-Material Printing. Micromachines, 14(3), 699. https://doi.org/10.3390/mi14030699