Development and Performance Evaluation of Photovoltaic (PV) Evaluation and Fault Detection System Using Hardware-in-the-Loop Simulation for PV Applications

Abstract

1. Introduction

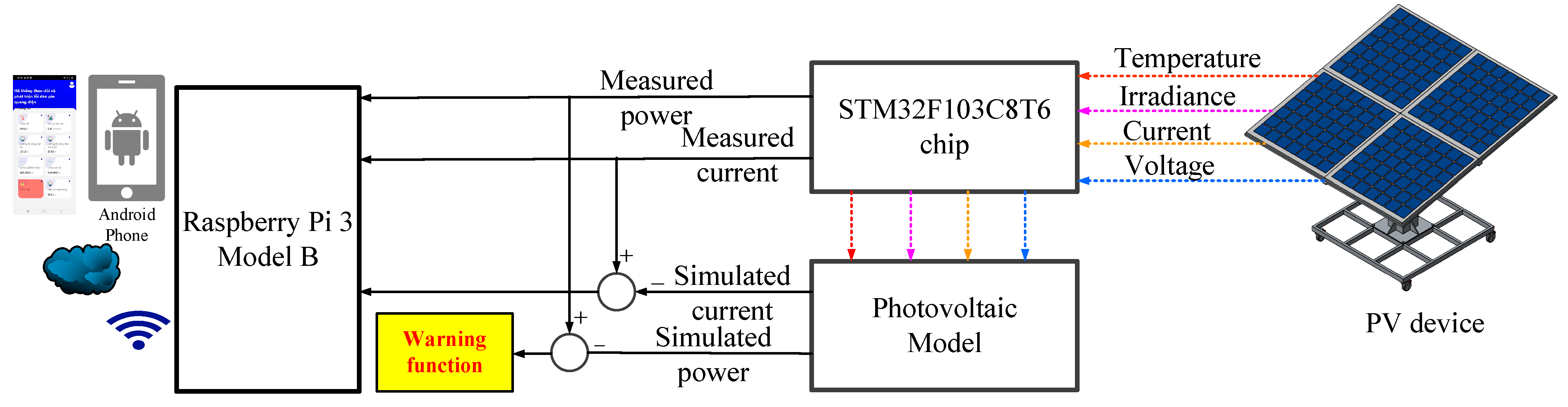

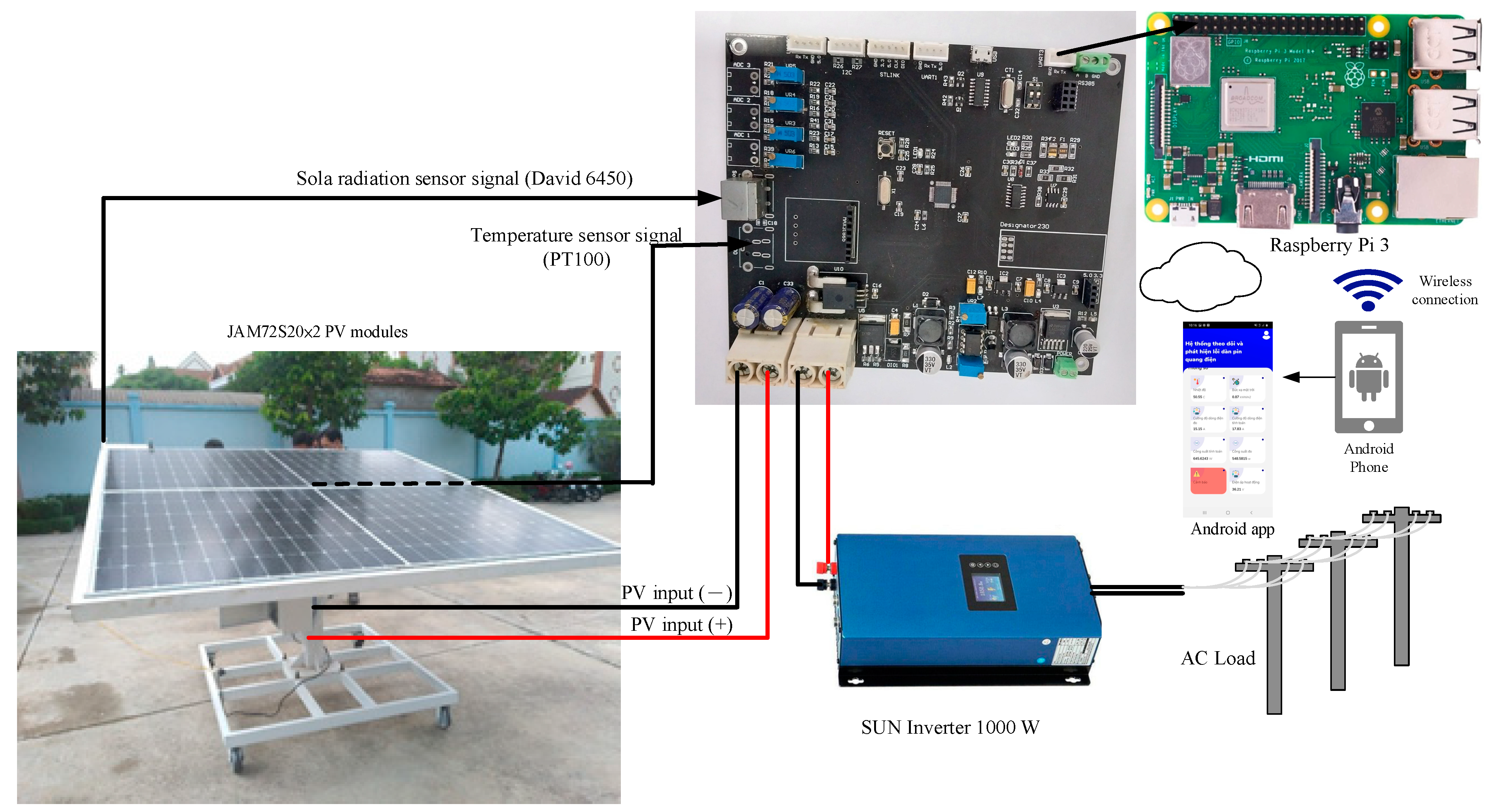

2. Development of IoT-Based PVEFD System

2.1. System Description

2.2. PV Mathematical Model

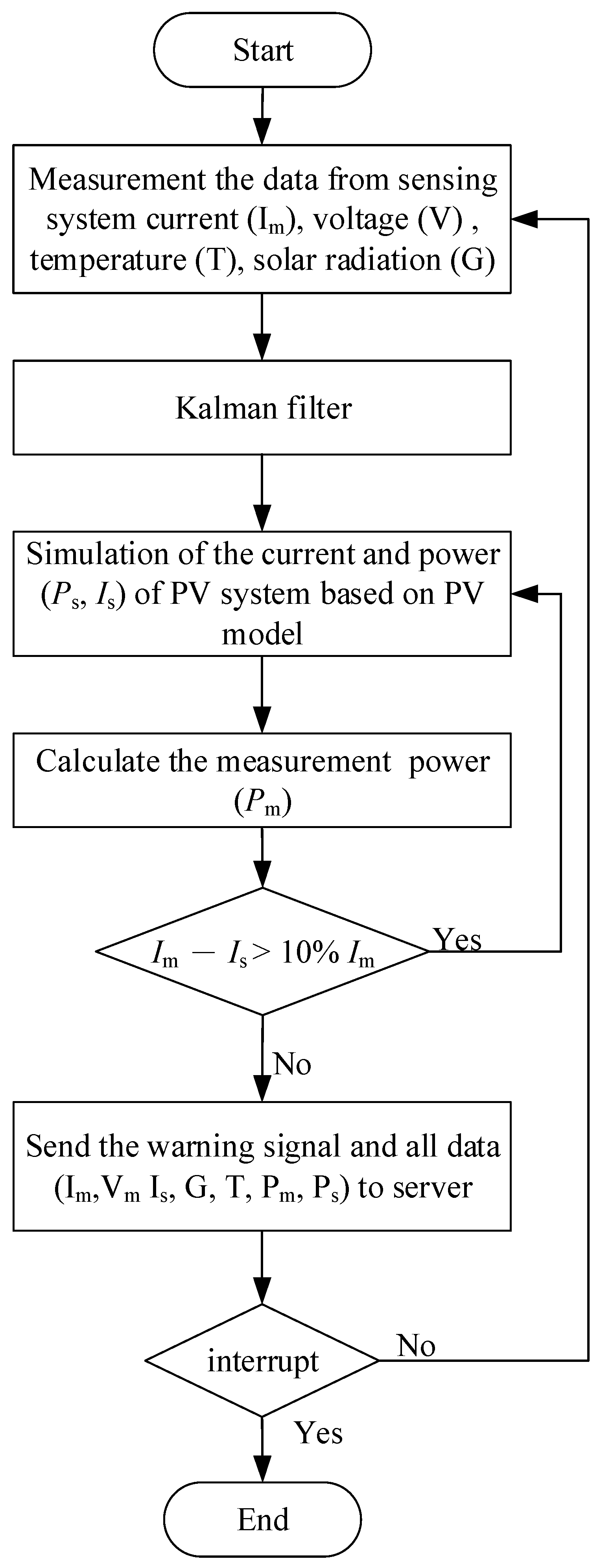

2.3. Firmware Design

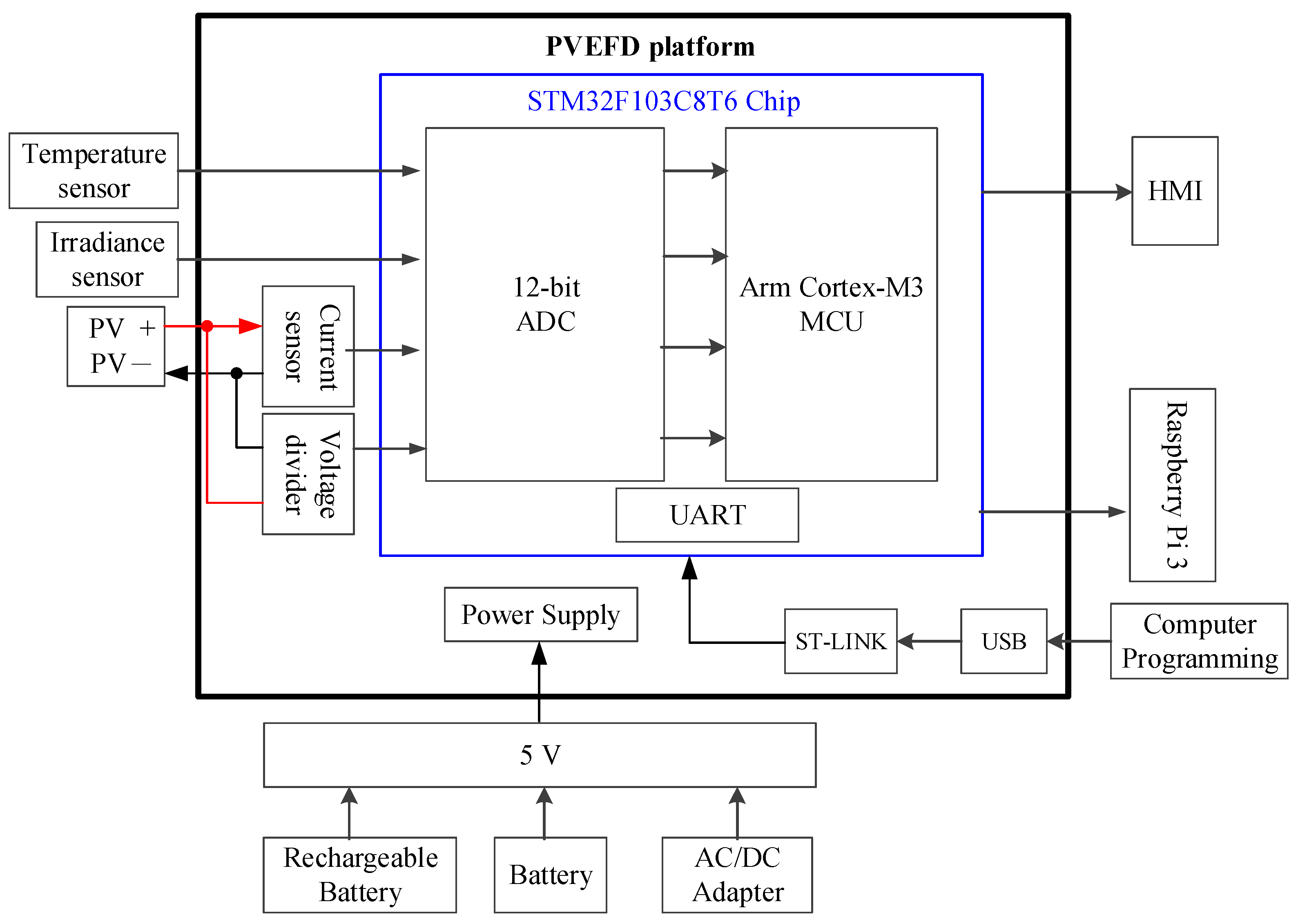

2.4. Hardware Design

3. System Implementation and Experimental Configuration

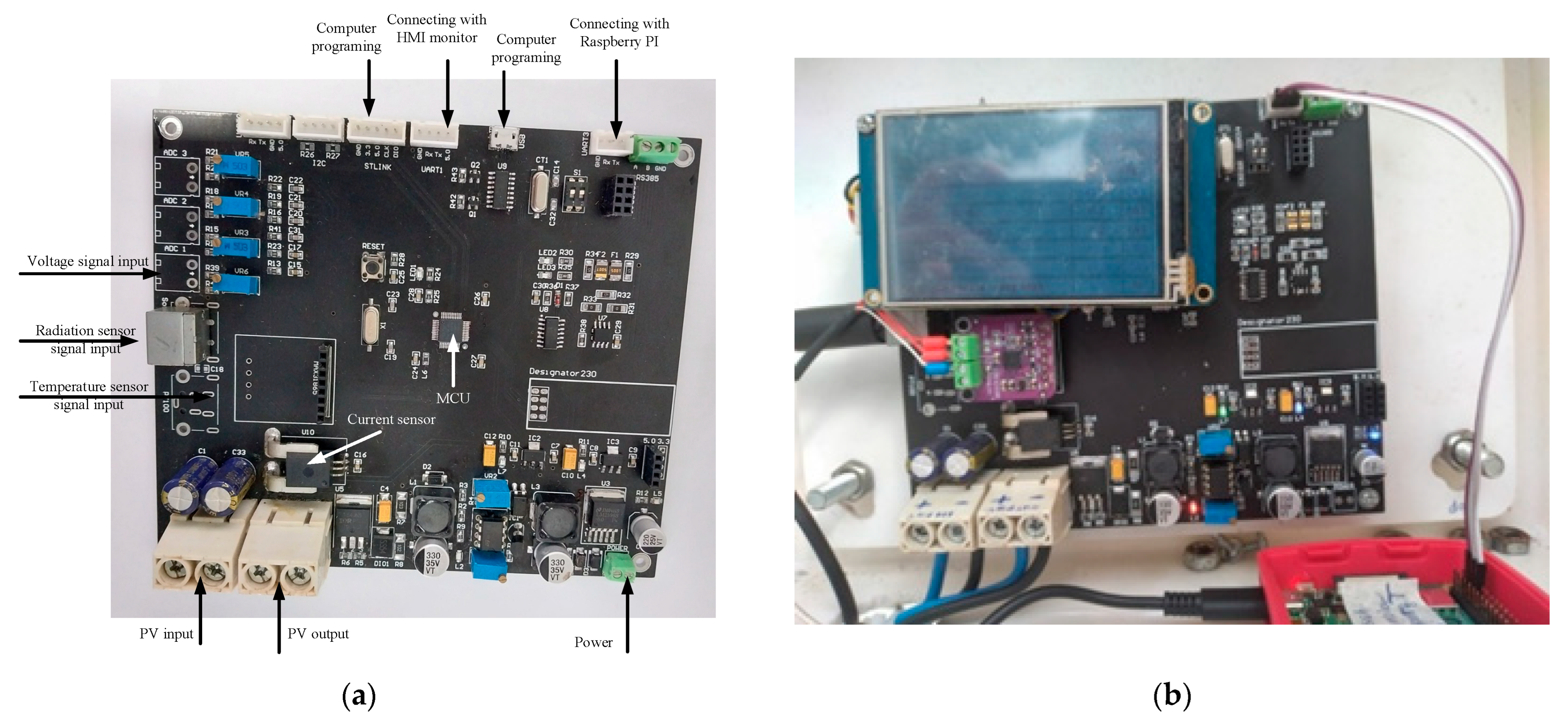

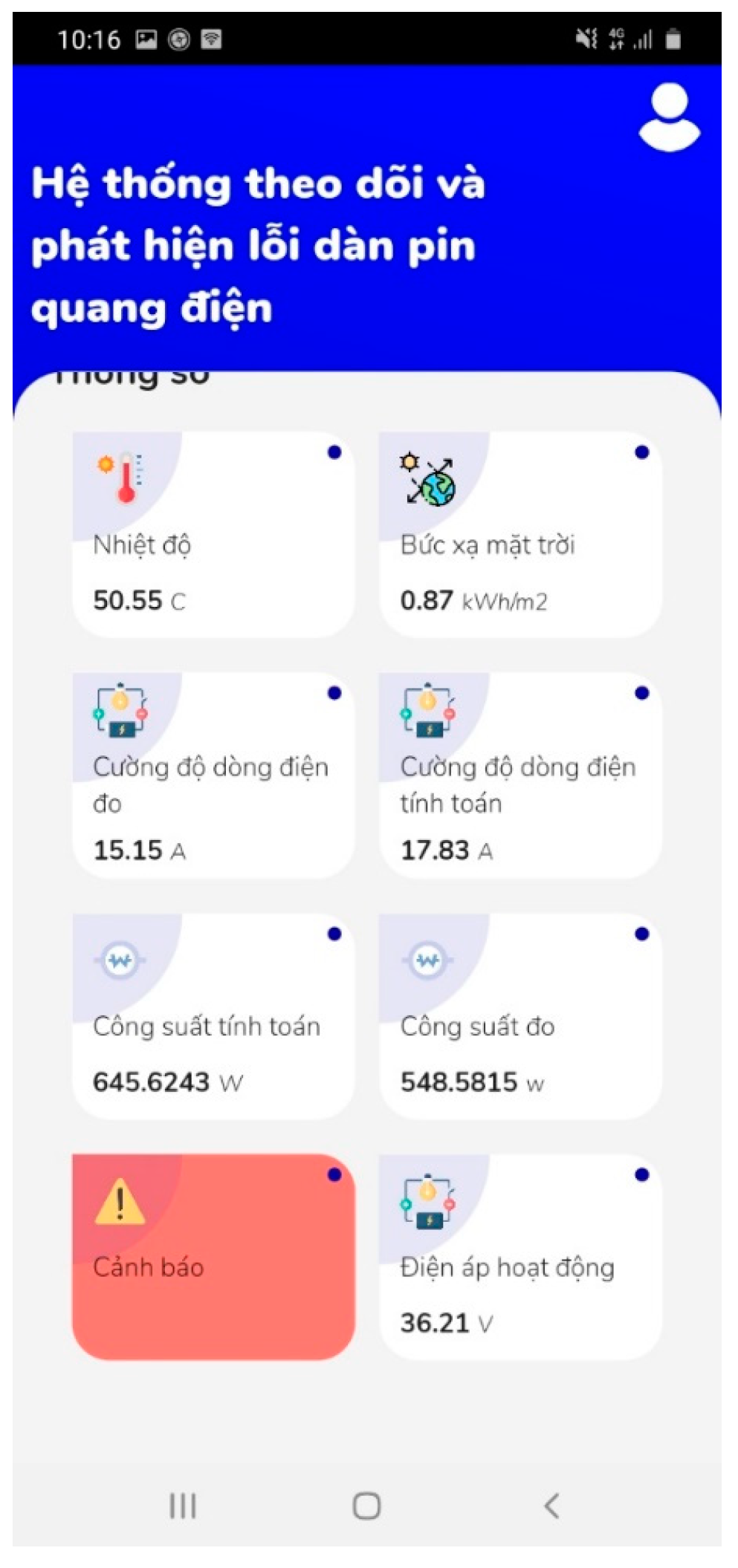

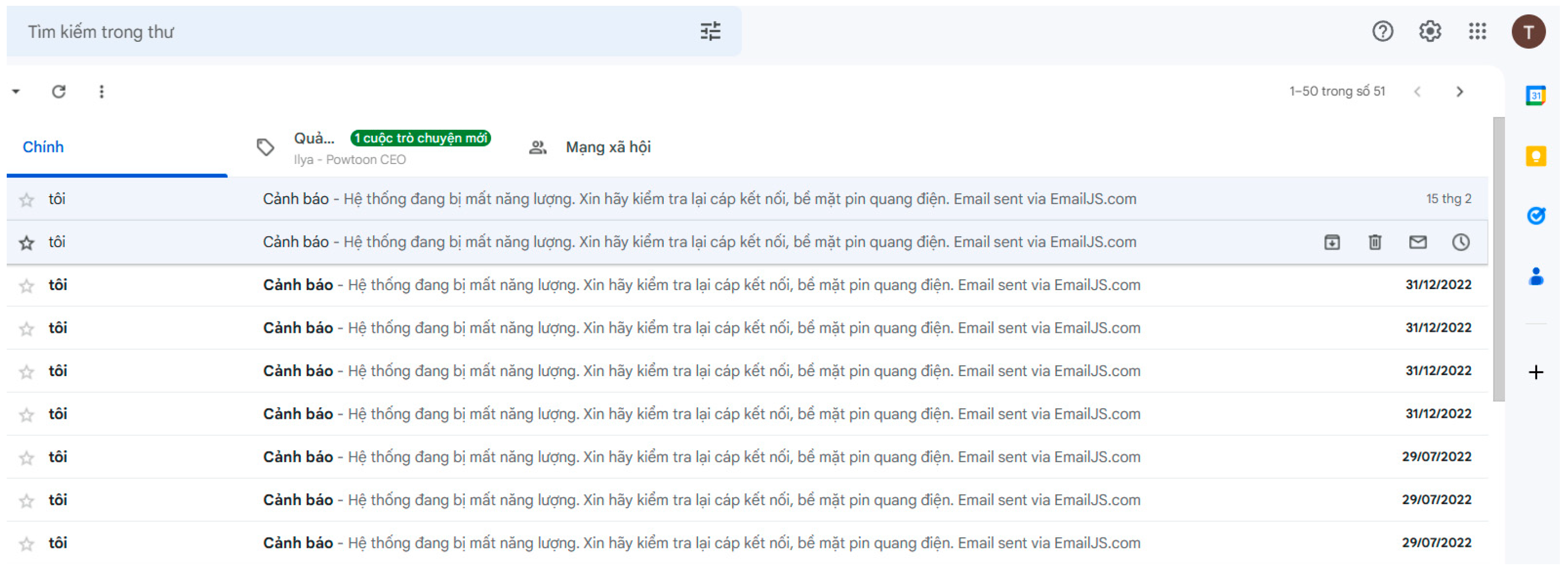

3.1. Implementation of the PVEFD System

3.2. Set-Up of Experimental Test Rig

4. Results and Discussion

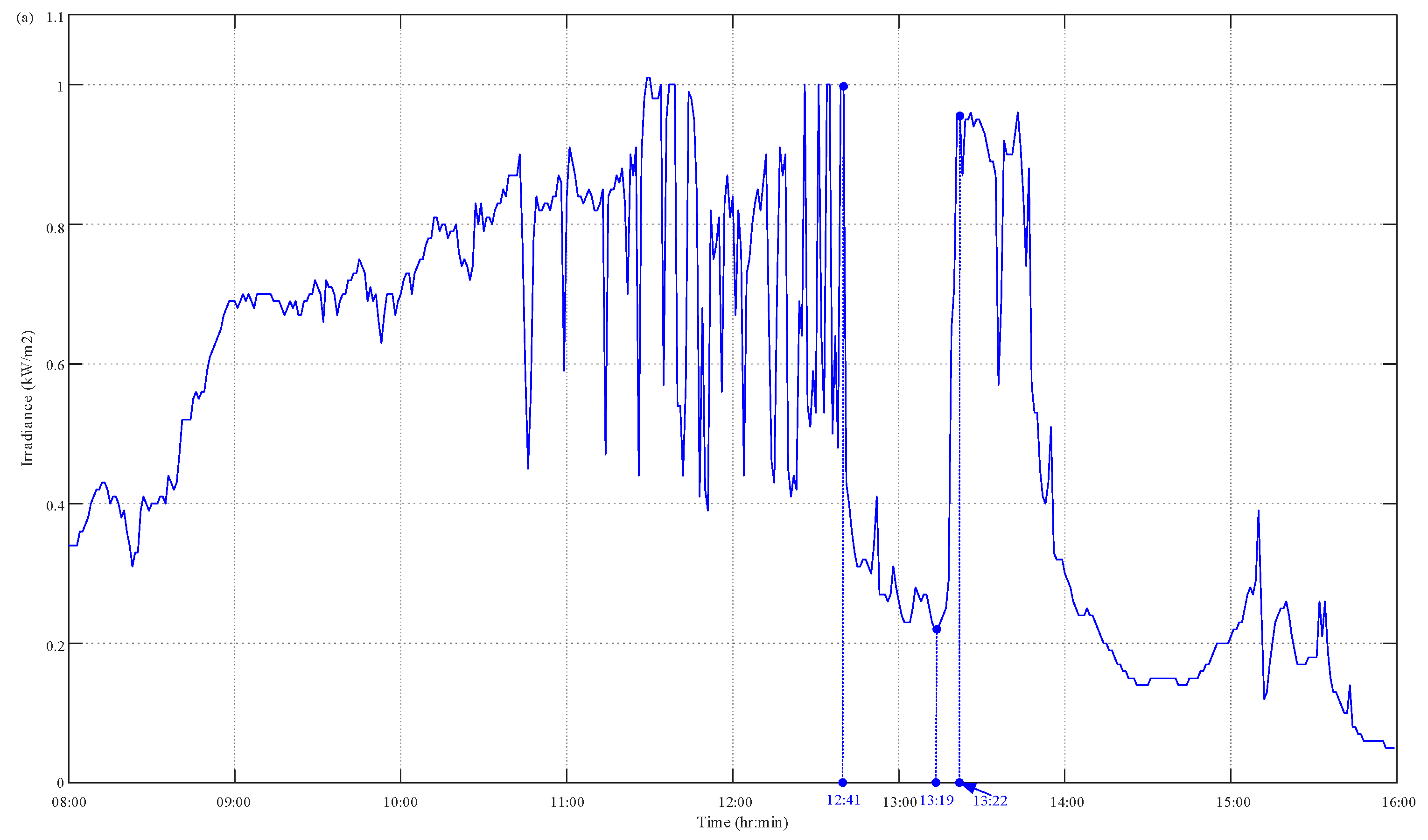

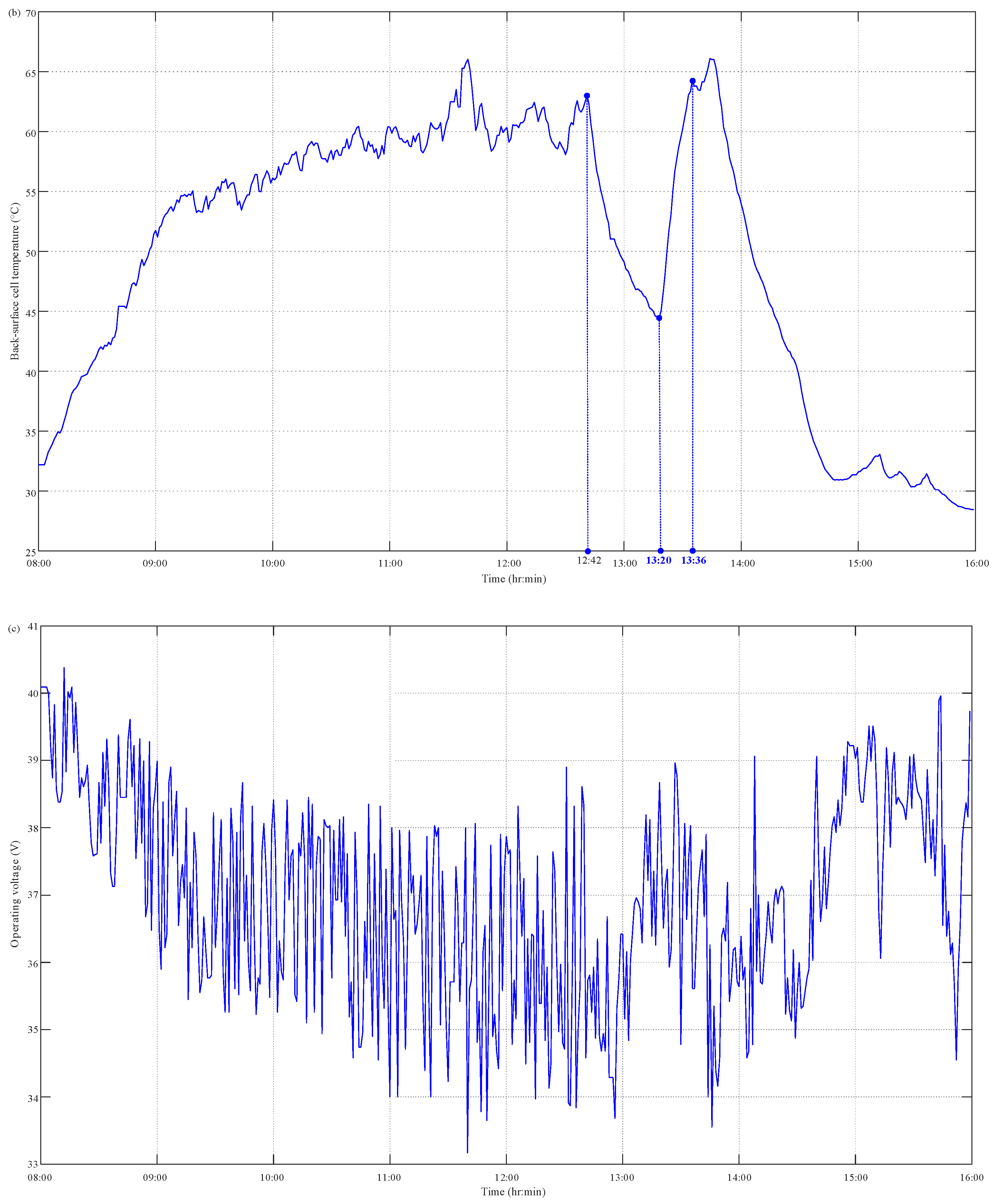

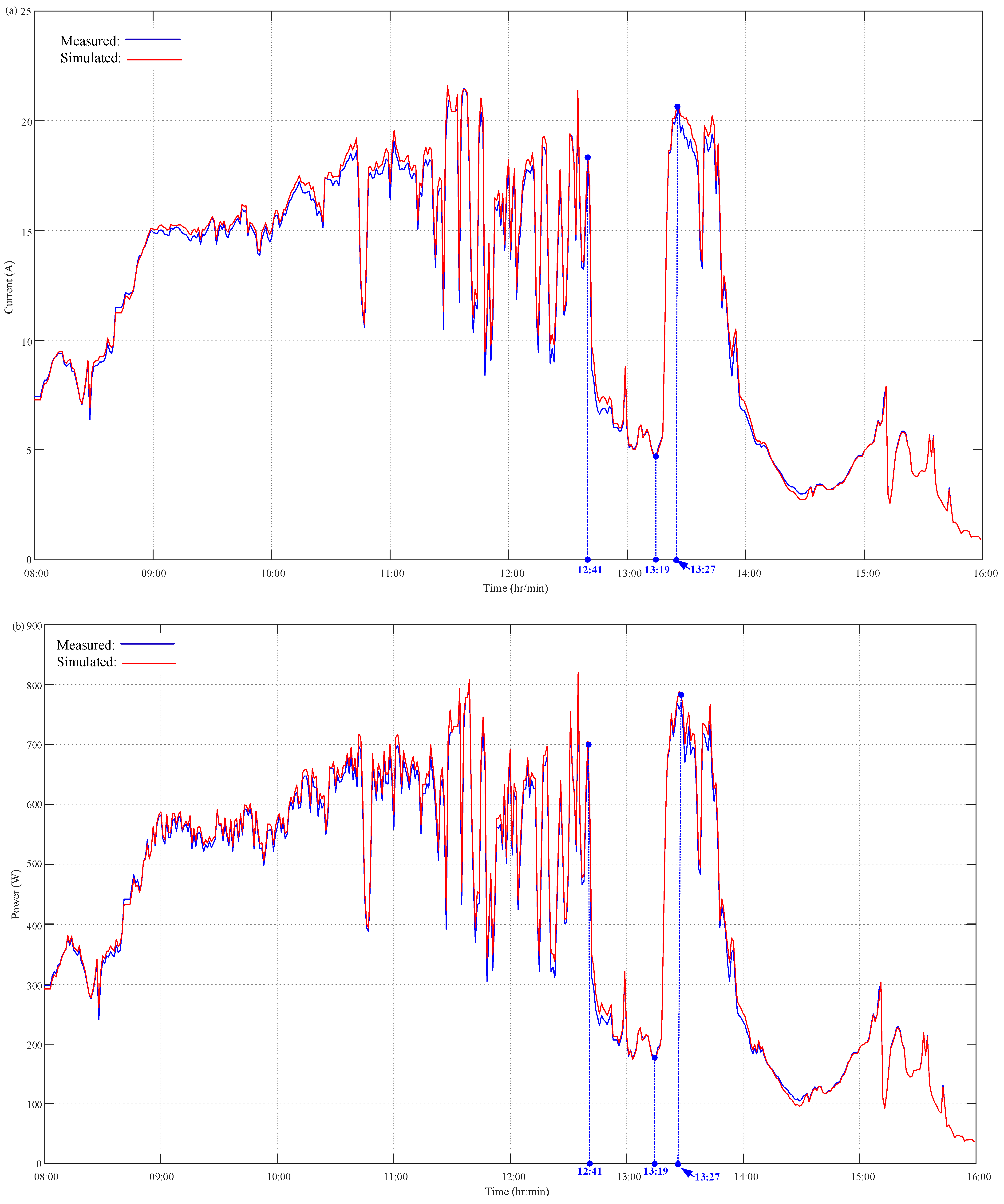

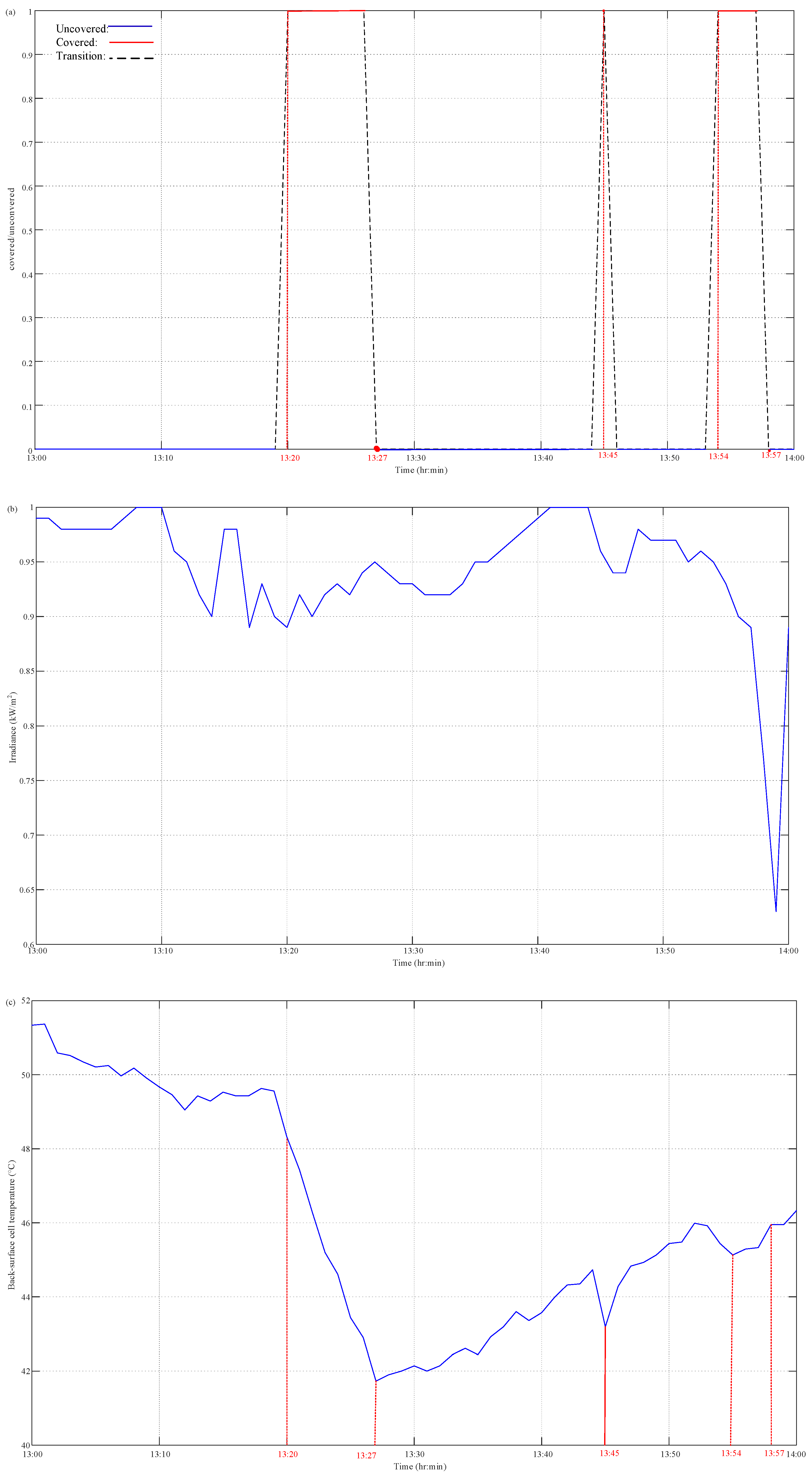

4.1. Analysis of Experimental Results

4.2. Accuracy Analysis of Experimental Results

4.3. Fault Detection on PV System

4.4. Discussions

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Davarifar, M.; Rabhi, A.; El-Hajjaji, A.; Dahmane, M. Real-time model base fault diagnosis of PV panels using statistical signal processing. In Proceedings of the 2013 International Conference on Renewable Energy Research and Applications (ICRERA), Madrid, Spain, 20–23 October 2013; pp. 599–604. [Google Scholar]

- Elyes, G.; Fouzi, H.; Ying, S.; Kamel, K.; Aissa, C.; Santiago, S. Statistical fault detection in photovoltaic systems. Sol. Energy 2017, 150, 485–499. [Google Scholar]

- King, I.S. Fault detection algorithm of the photovoltaic system using wavelet transform. In Proceedings of the 2010 India International Conference on Power Electronics (IICPE), New Delhi, India, 8–30 January 2011; pp. 1–6. [Google Scholar]

- Huang, Z.; Guo, L. Research and implementation of microcomputer online fault detection of solar array. In Proceedings of the 4th International Conference on Computer Science & Education (2009 ICCSE’09), Nanning, China, 25–28 July 2009; pp. 1052–1055. [Google Scholar]

- Paredes-Parra, J.M.; Mateo-Aroca, A.; Silvente-Niñirola, G.; Bueso, M.C.; Molina-García, Á. PV module monitoring system based on low-cost solutions: Wireless Raspberry application and assessment. Energies 2018, 11, 3051. [Google Scholar] [CrossRef]

- Omana, M.; Grossi, M.; Metra, C. Early detection of photovoltaic system inverter faults. Microelectron. Reliab. 2022, 135, 114594. [Google Scholar] [CrossRef]

- Chao, K.H.; Chen, P.Y.; Wang, M.H.; Chen, C. An intelligent fault detection method of a photovoltaic module mrray using wireless sensor networks. Int. J. Distrib. Sens. Netw. 2014, 10, 540147. [Google Scholar] [CrossRef]

- Abdullah, N.; Rosd, K.A. Development of photovoltaic data observing with IoT interface. J. Eng. Sci. 2022, 18, 1–16. [Google Scholar]

- Didi, Z.; Azami, E.I. Monitoring photovoltaic panels using the ESP32 microcontroller via low-power Bluetooth communication. In Proceedings of the International Conference on Intelligent Systems and Computer Vision (ISCV), Fez, Morocco, 18–20 May 2022; pp. 1–6. [Google Scholar]

- Pachauri, K.R.; Mahela, P.O.; Khan, B.; Kumar, A.; Agarwal, S.; Alhelou, H.H.; Bai, J. Development of Arduino assisted data acquisition system for solar photovoltaic array characterization under partial shading conditions. Comput. Electr. Eng. 2021, 92, 107175. [Google Scholar] [CrossRef]

- Li, Y.; Lin, P.; Zhou, H.; Chen, Z.; Wu, L.; Cheng, S.; Su, F. On-line monitoring system based on open source platform for photovoltaic array. Energy Procedia 2018, 145, 427–433. [Google Scholar] [CrossRef]

- Reddy, H.Y.; Ali, A.; Sha, Z.A.; Madhulaya, P.; Madhulatha, P.; Varahi, G.; Lakshmisravya, P.; Varaprasad, R. Photovoltaic, internet-of-things-enabled intelligent agricultural surveillance system. South Asian Res. J. Eng. Technol. 2022, 4, 78–85. [Google Scholar] [CrossRef]

- Ongaro, F.; Saggini, S.; Mattavell, P. Li-ion battery-supercapacitor hybrid storage system for a long lifetime, photovoltaic-based wireless sensor network. IEEE Trans. Power Electron. 2012, 27, 3944–3952. [Google Scholar] [CrossRef]

- Balakumar, P.; Vinopraba, T.; Chandrasekaran, K. Machine learning based demand response scheme for IoT enabled PV integrated smart building. Sustain. Cities Soc. 2023, 89, 104260. [Google Scholar]

- Das, S.; Sparks, A.; Poves, E.; Videv, S.; Fakidis, J.; Haas, H. Effect of sunlight on photovoltaics as optical wireless communication receivers. J. Light. Technol. 2021, 39, 6182–6190. [Google Scholar] [CrossRef]

- Tavakkolnia, I.; Jagadamma, L.K.; Bian, R.; Manousiadis, P.P.; Videv, S.; Turnbull, A.G.; Samuel, W.D.; Haas, H. Organic photovoltaics for simultaneous energy harvesting and high-speed MIMO optical wireless communications. Sci. Appl. 2021, 10, 41. [Google Scholar] [CrossRef] [PubMed]

- Habib, M.; Gram, A.; Harrag, A.; Wang, Q. Optimized management of reactive power reserves of transmission grid-connected photovoltaic plants driven by an IoT solution. Int. J. Electr. Power Energy Syst. 2022, 143, 109455. [Google Scholar] [CrossRef]

- Zhou, B.; Pei, J.; Calautit, K.J. Solar self-powered wireless charging pavement a review on photovoltaic pavement and wireless charging for electric vehicles. Sustain. Energy Fuels 2021, 5, 5139–5159. [Google Scholar] [CrossRef]

- Corti, F.; Laudani, A.; Lozito, M.G.; Reatti, A.; Bartolini, A.; Ciani, L. Model-based power management for smart farming wireless sensor networks. IEEE Trans. Circuits Syst.-I Regul. Pap. 2022, 69, 2235–2245. [Google Scholar] [CrossRef]

- Zheng, Y.; Cheng, Z.; Liu, C.; Liu, H.; Amirabadi, M.; Lehman, B. Modular wireless power transmission for photovoltaic subpanel system. In Proceedings of the IEEE Energy Conversion Congress and Exposition (ECCE 2021), Vancouver, BC, Canada, 10–14 October 2021; pp. 546–553. [Google Scholar]

- Pereira, S.I.R.; Duponta, M.I.; Carvalhoa, C.M.P.; Jucá, C.S.S. IoT embedded Linux system based on Raspberry Pi applied to real-time cloud monitoring of a decentralized photovoltaic plant. Measurement 2018, 114, 286–297. [Google Scholar] [CrossRef]

- Zhang, S.; Bristow, N.; David, W.T.; Elliott, F.; O’Mahony, J.; Kettle, J. Development of an organic photovoltaic energy harvesting system for wireless sensor networks; application to autonomous building information management systems and optimisation of OPV module sizes for future applications. Sol. Energy Mater. Sol. Cells 2022, 236, 111550. [Google Scholar] [CrossRef]

- Hu, T.; Zheng, M.; Tan, J.; Zhu, L.; Miao, W. Intelligent photovoltaic monitoring based on solar irradiance big data and wireless sensor networks. Ad. Hoc. Netw. 2015, 35, 127–136. [Google Scholar] [CrossRef]

- Derdar, A.; Bensiali, N.; Adjabi, M.; Boutasseta, N.; Bouakkaz, S.M.; Attoui, I.; Fergani, N.; Bouraiou, A. Photovoltaic energy generation systems monitoring and performance optimization using wireless sensors network and metaheuristics. Sustain. Comput. Inform. Syst. 2022, 35, 100684. [Google Scholar] [CrossRef]

- Xie, N.; Chen, Y.; He, P. Application of wireless sensor network technology using intelligent algorithm in mismatch detection of photovoltaic power generation. Wirel. Commun. Mob. Comput. 2020, 2022, 7688109. [Google Scholar] [CrossRef]

- Iqbal, S.M.; Niazi, K.A.Y.; Khan, A.U.; Lee, B. Real-time fault detection system for large scale grid integrated solar photovoltaic power plants. Electr. Power Energy Syst. 2021, 130, 106902. [Google Scholar] [CrossRef]

- Voutsinas, S.; Karolidis, D.; Voyiatzis, I.; Samarakou, M. Development of a multi-output feed-forward neural network for fault detection in photovoltaic systems. Energy Rep. 2022, 8, 33–42. [Google Scholar] [CrossRef]

- Zakir, M.; Arshad, A.; Sher, H.A.; Al-Durra, A. Design and implementation of a fault detection method for a PV-fed DC-microgrid with power control mechanism. IET Electr. Power Appl. 2022, 16, 16–1071. [Google Scholar] [CrossRef]

- Zakir, M.; Sher, H.A.; Arshad, A.; Lehtonen, M. A fault detection, localization, and categorization method for PV fed DC-microgrid with power-sharing management among the nano-grids. Int. J. Electr. Power Energy Syst. 2022, 137, 137–107858. [Google Scholar] [CrossRef]

- Le, P.T.; Tsai, H.L.; Lam, T.H. A wireless visualization monitoring, evaluation system for commercial photovoltaic modules solely in MATLAB/Simulink environment. Sol. Energy 2016, 140, 1–11. [Google Scholar] [CrossRef]

- Kintech Engineering. DAVIS 6450 Pyranometer Datasheet. Available online: https://www.kintech-engineering.com/pdf_docs/EN_Pyranometer_Davis_6450.pdf (accessed on 10 March 2023).

- JA SOLAR. JAM72S20-440-465/MR/1000V Datasheet. Available online: https://www.jasolar.com//uploadfile/2020/0619/20200619040220997.pdf (accessed on 10 March 2023).

| Sensor Types | Characteristics | Specifications |

|---|---|---|

| DAVIS 6450 (Pyranometer) | Power supply | 3 V |

| Sensitivity | 1.67 mV/1 W/m2 | |

| Accuracy | ±5% | |

| Range | 0 to 1800 W/m2 | |

| Resolution and units | 1 W/m2 | |

| ACS756SCB-050B (Current sensor) | Power supply | 3–5 V |

| Sensitivity | 40 mV/A | |

| Accuracy | ±5% | |

| Current sensing | 50 A | |

| PT100 (Temperature sensor) | Temperature range | −50 °C to +200 °C |

| Accuracy | ±1 °C | |

| Nominal resistance | 100 Ω at 0 °C |

| Characteristics | Specifications |

|---|---|

| Rated Maximum Power (Pmax) | 455 W |

| Open-Circuit Voltage (VOC) | 49.85 V |

| Maximum Power Voltage (Vmpp) | 41.82 V |

| Short-Circuit Current (ISC) | 11.41 A |

| Maximum Power Current (Imp) | 10.88 A |

| Module Efficiency | 20.4% |

| Power Tolerance | 0–5 W |

| Temperature Coefficient of ISC (α_ ISC) | +0.044%/°C |

| Temperature Coefficient of VOC (β_ VOC) | −0.272%/°C |

| Temperature Coefficient of Pmax (γ_ Pmax) | −0.350%/°C |

| Cell type | Mono-Crystalline |

| Number of cells | 144 |

| Items | Difference Range | MAE | MAPE | RMSE |

|---|---|---|---|---|

| Current | −0.4400–1.1100 A | 0.2546 A | 0.3134% | 0.3384 A |

| Power | −17.2964–39.5900 W | 9.2999 W | 1.2156% | 12.3099 W |

| No. | System Function | Reference | ||

|---|---|---|---|---|

| Detection | Localization | Categorization | ||

| 1 | ✓ | × | Array aging, shadow, and short-circuit/open-circuit fault | Xie et al. [25] |

| 2 | ✓ | ✓ | PV faulty in a string, single or multiple faulty PV strings, partial shading, and soiling on a string. | Iqbal et al. [26] |

| 3 | ✓ | × | Short-circuit/open-circuit fault, array aging, shadow, mismatch fault, and unidentifiable fault | Voutsinas et al. [27] |

| 4 | ✓ | ✓ | Line-to-line (L–L) and line-to-ground electrical faults | Zakir et al. [29] |

| 5 | ✓ | × | Partial shading fault, PV aging, short-circuit/open-circuit faults | Proposed PCEFD system |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Le, P.-T.; Tsai, H.-L.; Le, P.-L. Development and Performance Evaluation of Photovoltaic (PV) Evaluation and Fault Detection System Using Hardware-in-the-Loop Simulation for PV Applications. Micromachines 2023, 14, 674. https://doi.org/10.3390/mi14030674

Le P-T, Tsai H-L, Le P-L. Development and Performance Evaluation of Photovoltaic (PV) Evaluation and Fault Detection System Using Hardware-in-the-Loop Simulation for PV Applications. Micromachines. 2023; 14(3):674. https://doi.org/10.3390/mi14030674

Chicago/Turabian StyleLe, Phuong-Truong, Huan-Liang Tsai, and Phuong-Long Le. 2023. "Development and Performance Evaluation of Photovoltaic (PV) Evaluation and Fault Detection System Using Hardware-in-the-Loop Simulation for PV Applications" Micromachines 14, no. 3: 674. https://doi.org/10.3390/mi14030674

APA StyleLe, P.-T., Tsai, H.-L., & Le, P.-L. (2023). Development and Performance Evaluation of Photovoltaic (PV) Evaluation and Fault Detection System Using Hardware-in-the-Loop Simulation for PV Applications. Micromachines, 14(3), 674. https://doi.org/10.3390/mi14030674