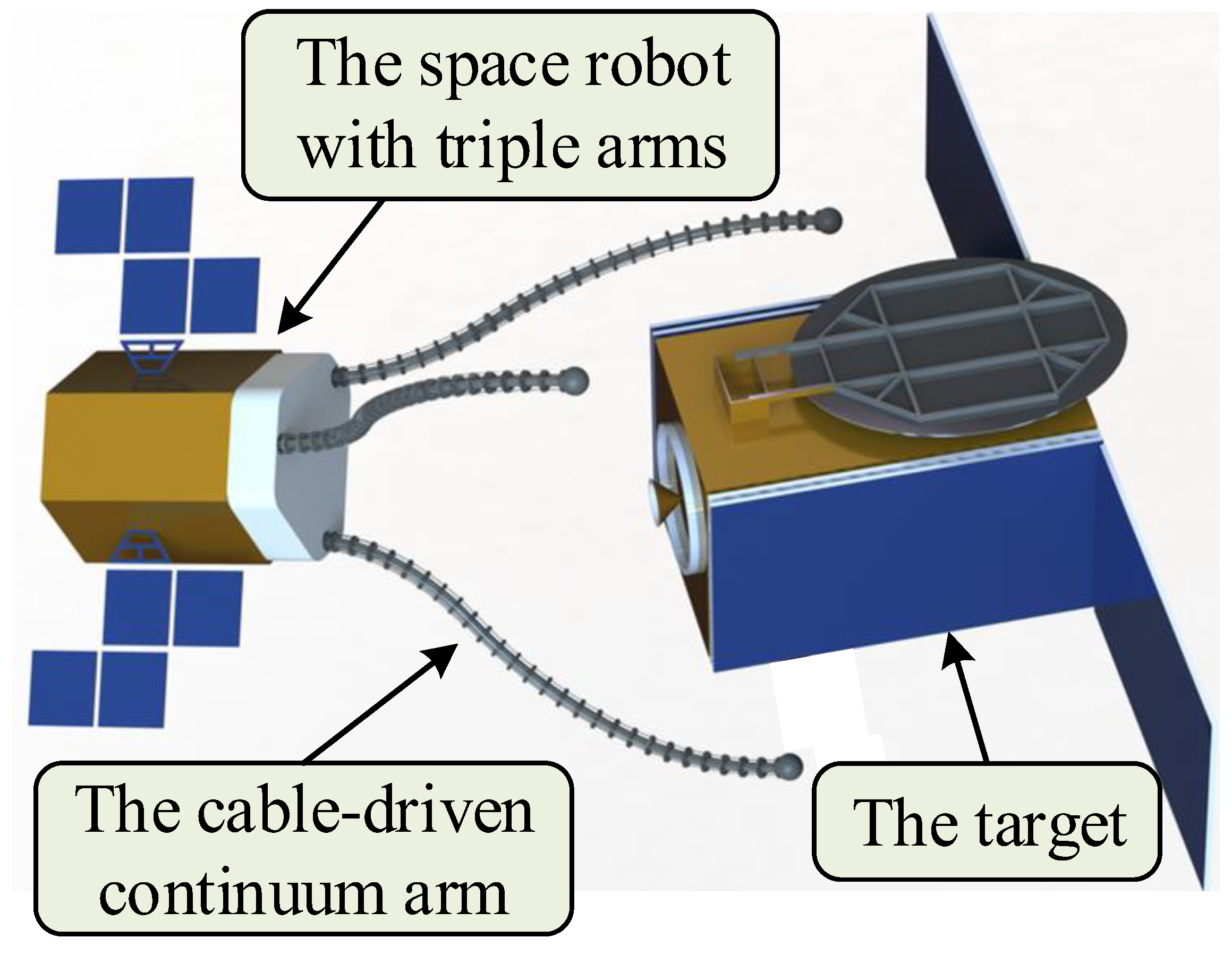

A Novel Space Robot with Triple Cable-Driven Continuum Arms for Space Grasping

Abstract

1. Introduction

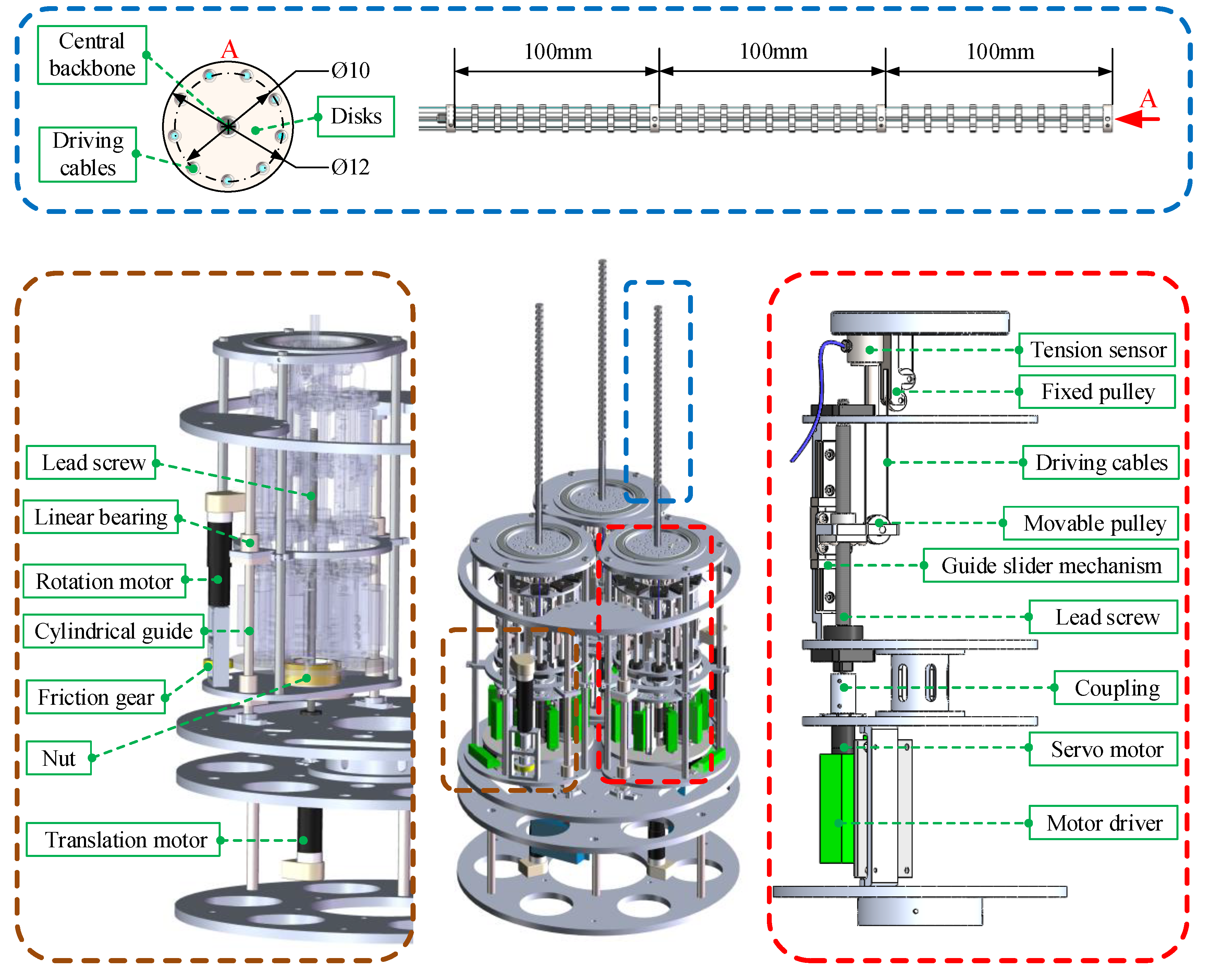

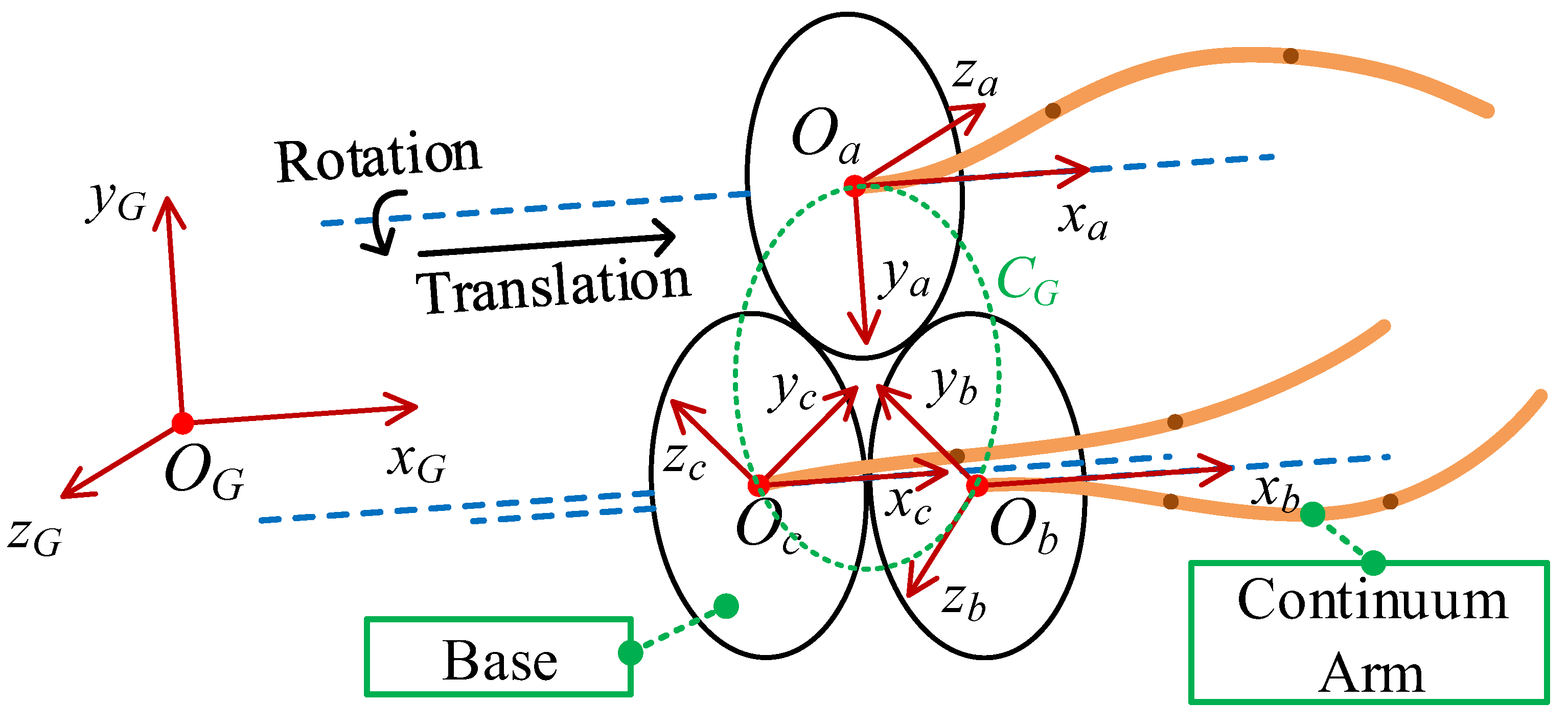

2. Mechanical Design

3. Kinematic Modeling

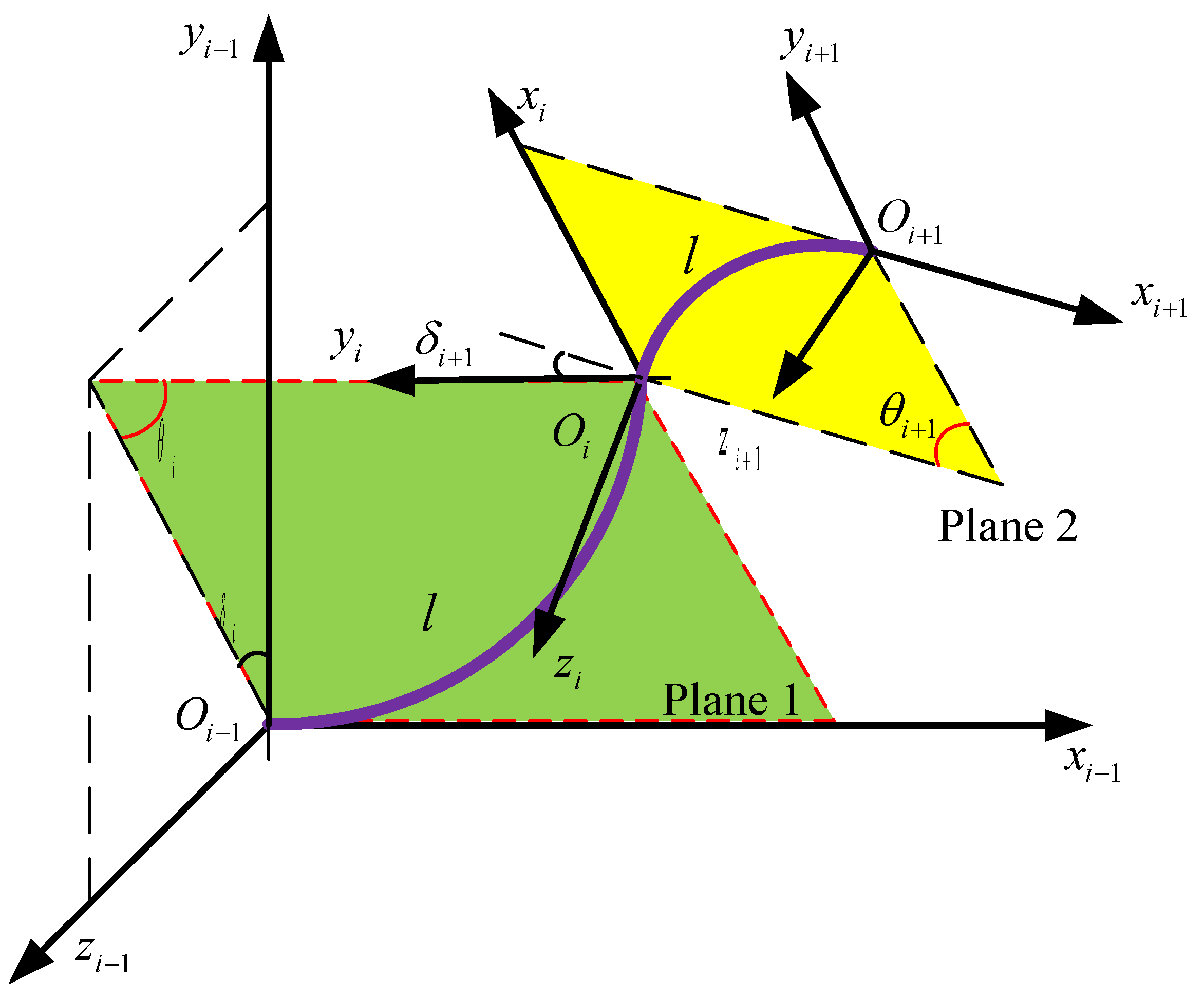

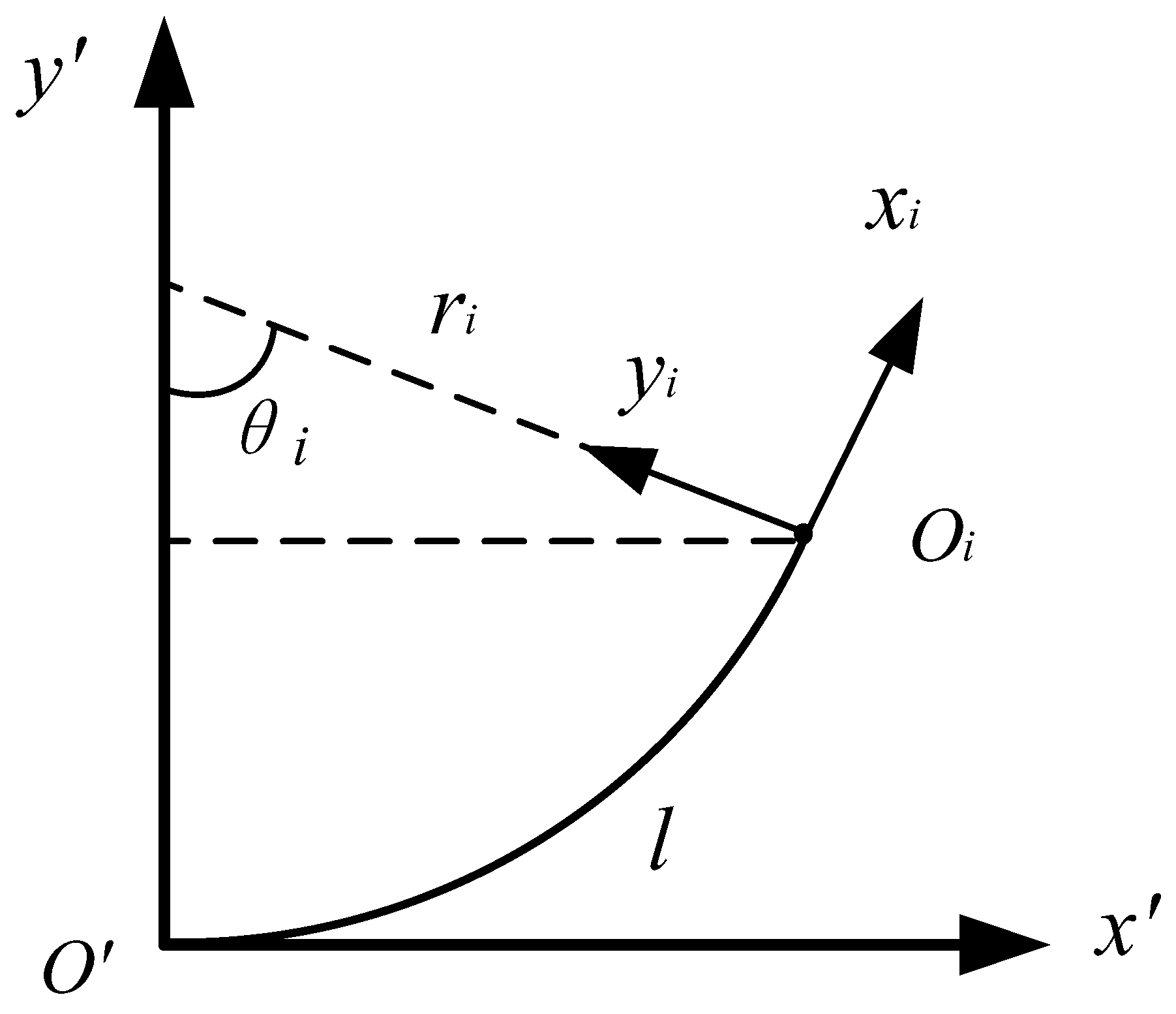

3.1. Mapping between Joint Space and Task Space

3.1.1. From Joint Space to Task Space

- (1)

- Rotate the coordinate system by angle around the -axis, and obtain the coordinate .

- (2)

- Rotate the coordinate by angle around the -axis. Then translate the origin to coincide with the origin of coordinate .

3.1.2. From Task Space to Joint Space

- When < , the number of unknowns is smaller than the number of equations. There is no accurate solution.

- When = , the number of unknowns is equal to the number of equations. There is a unique solution.

- When > , the number of unknowns is larger than the number of equations. There are infinite solutions.

3.2. Mapping between Joint Space and Cable Space

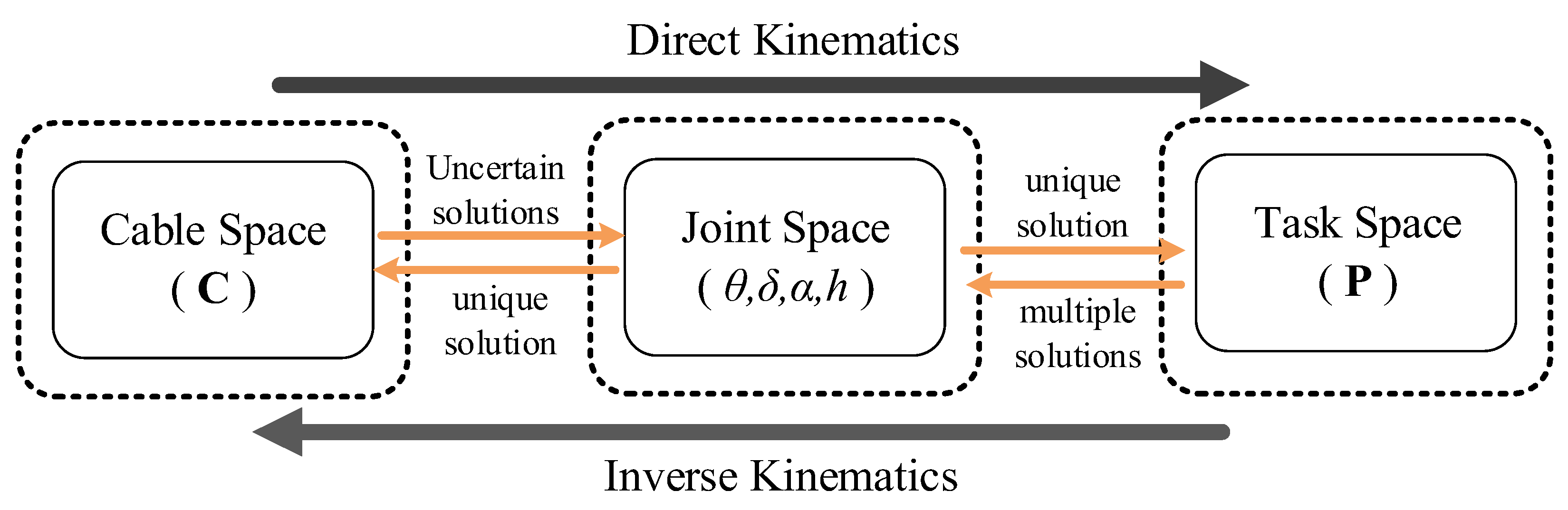

3.3. Analysis of Forward and Inverse Kinematics of the Arm

4. Simulation

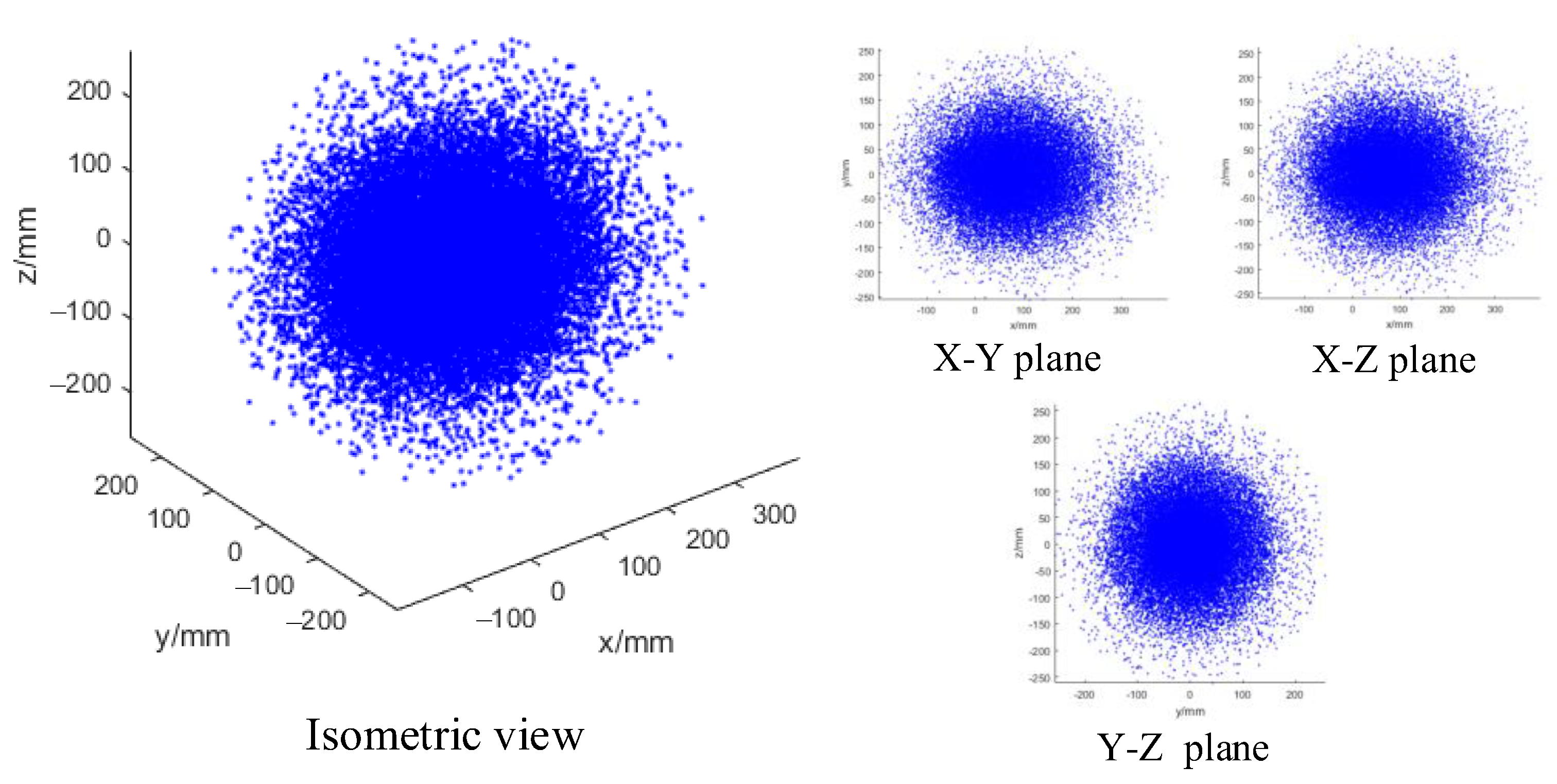

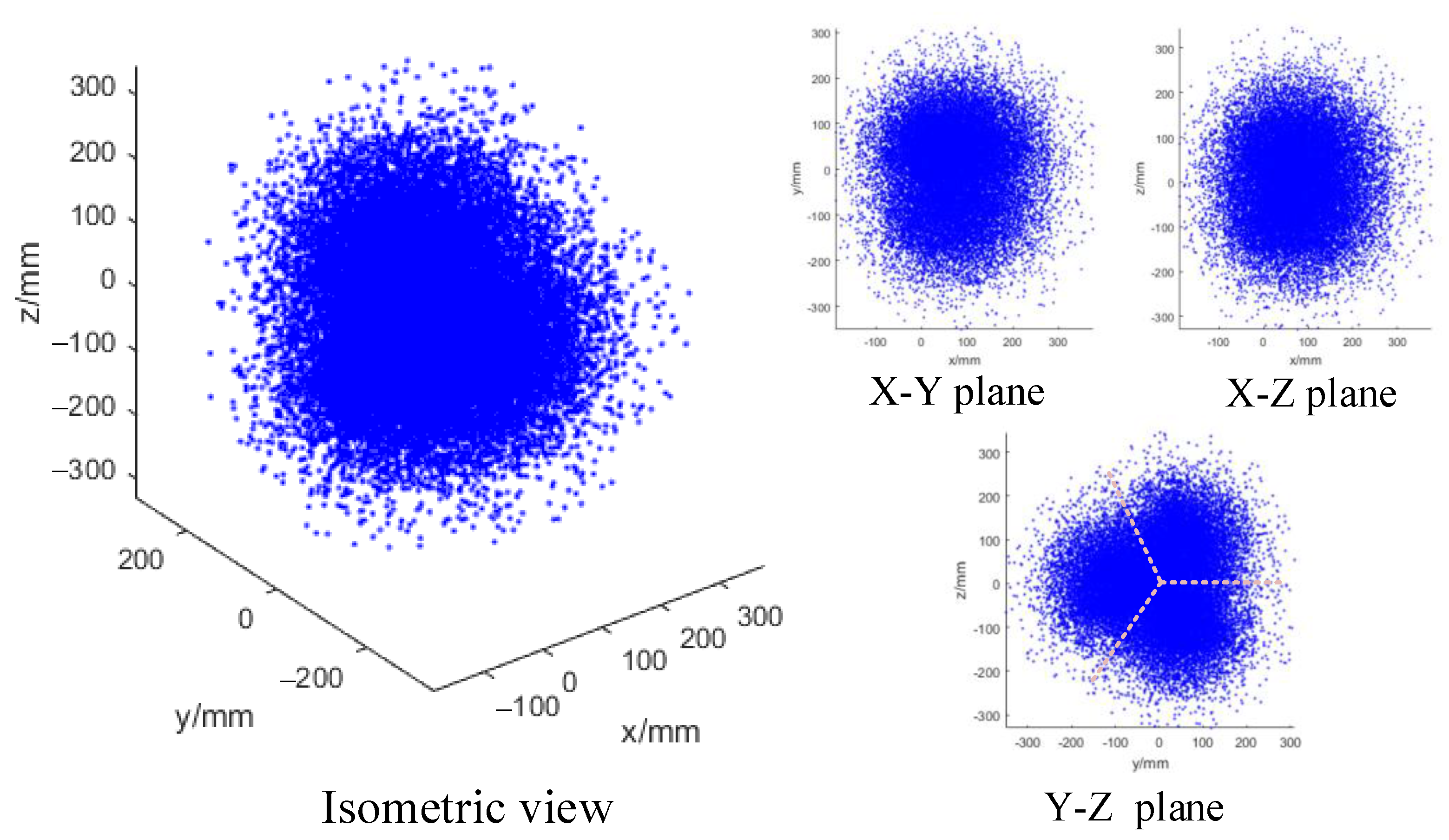

4.1. Working Space Analysis

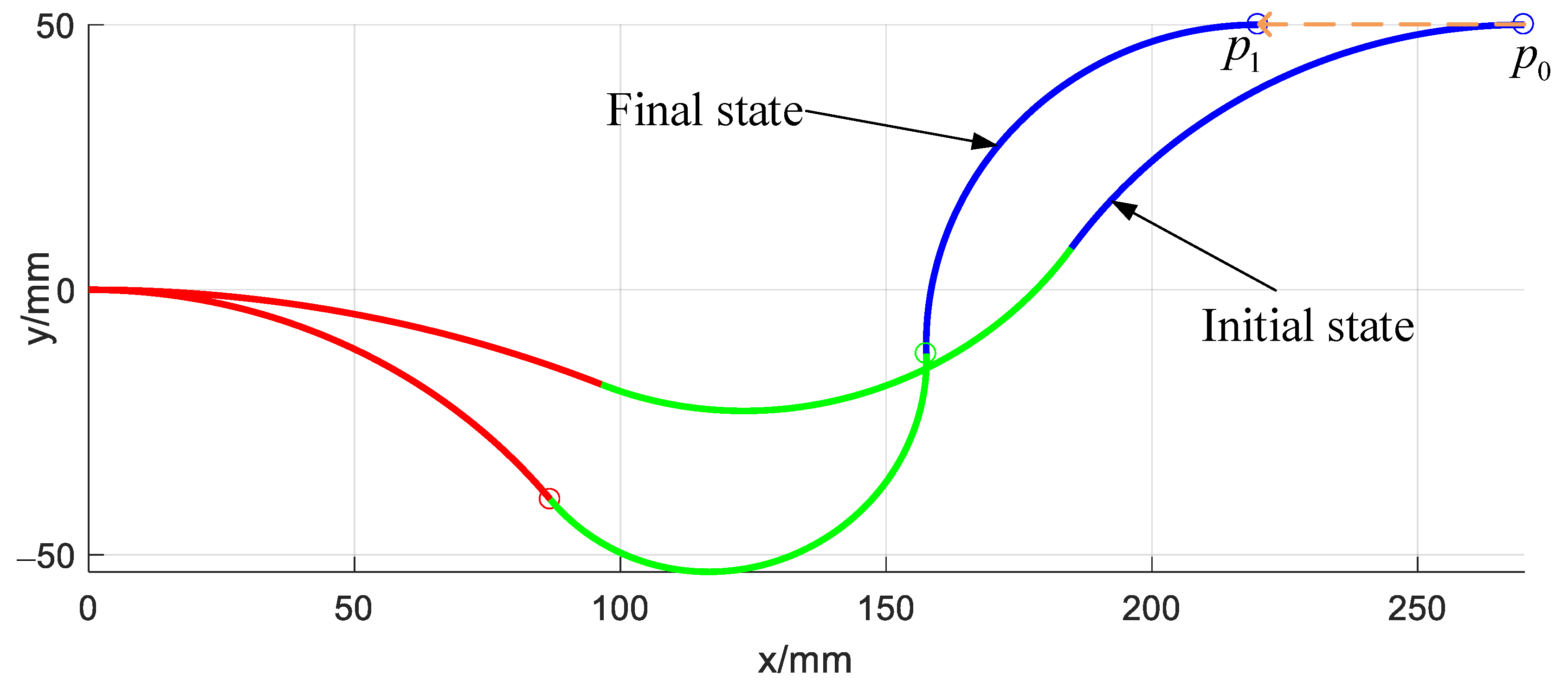

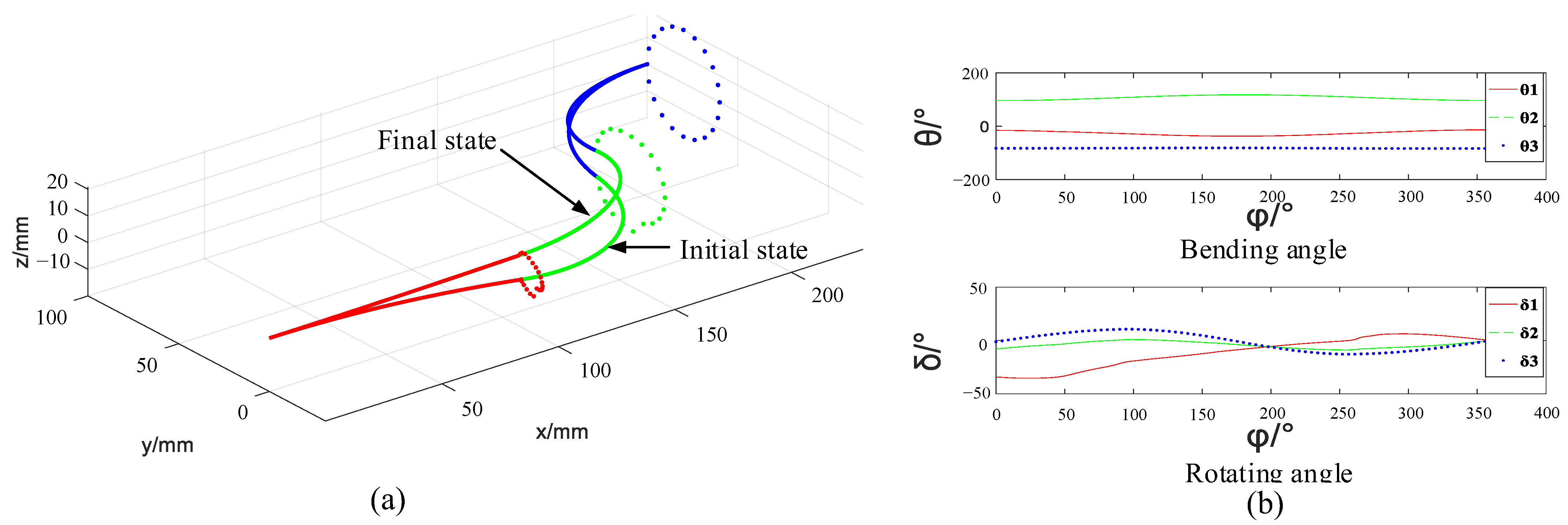

4.2. Trajectory Following Simulation of the Single Arm

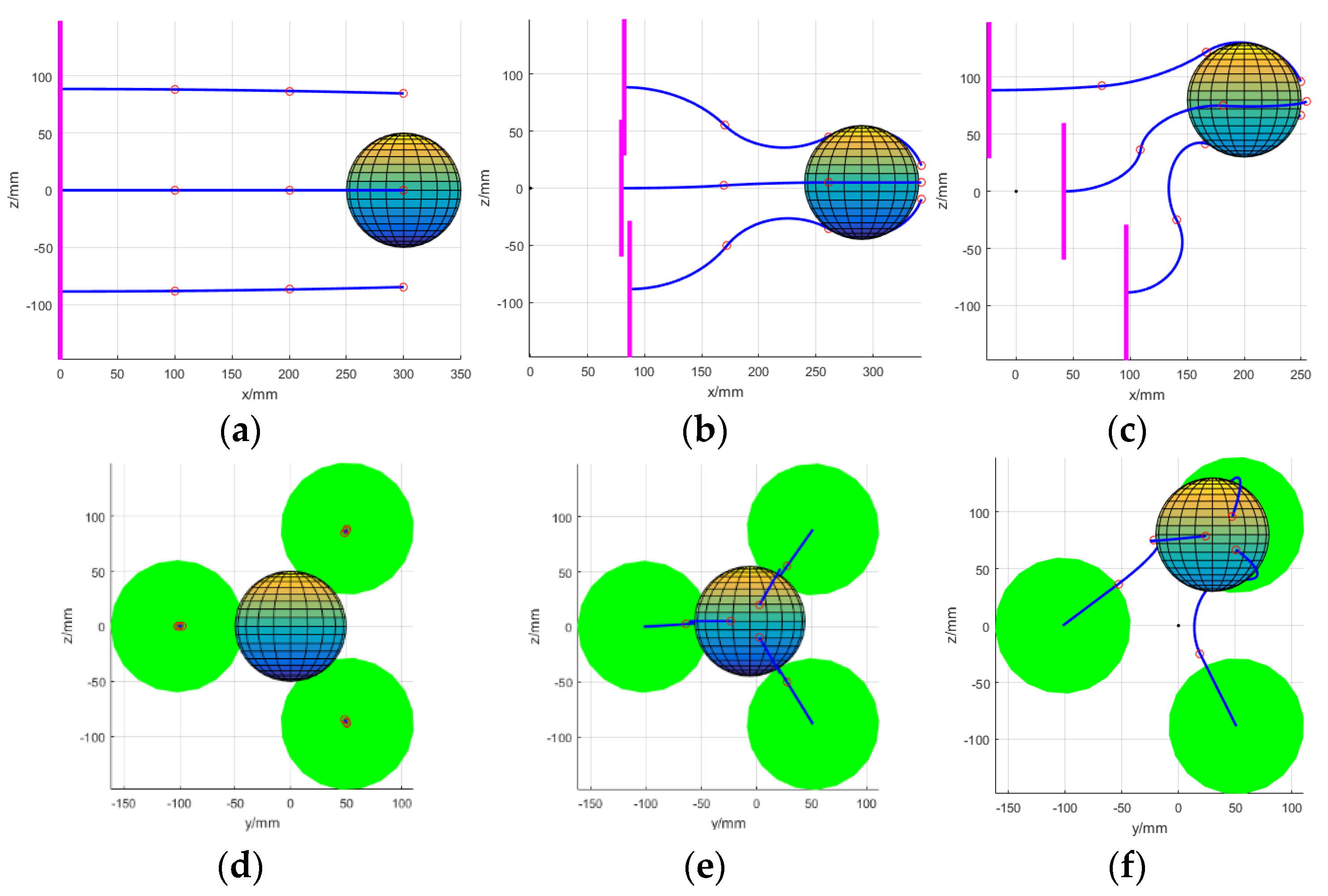

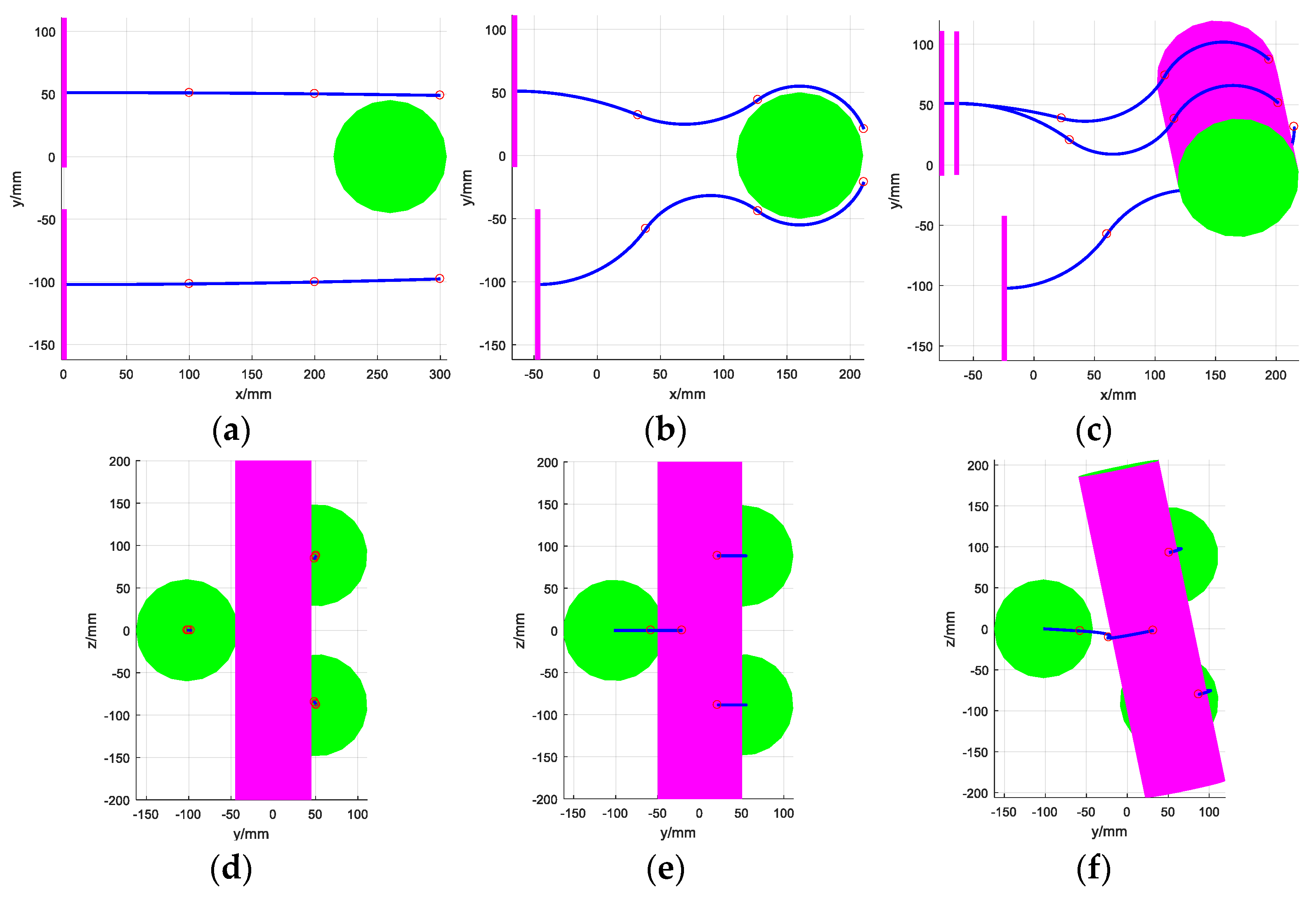

4.3. Cooperative Grasping Simulation of the Multi-Arm Space Robot

5. Experiment

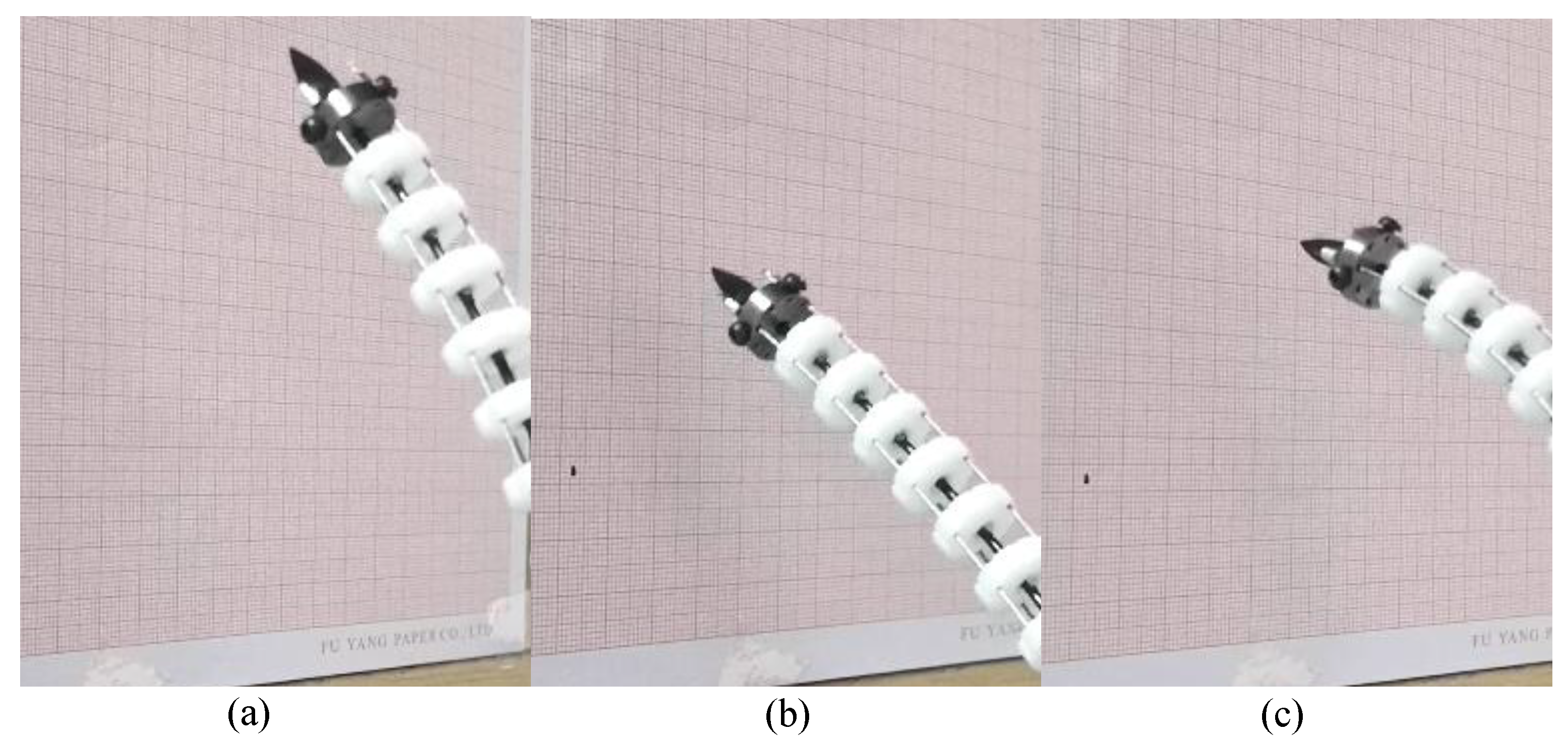

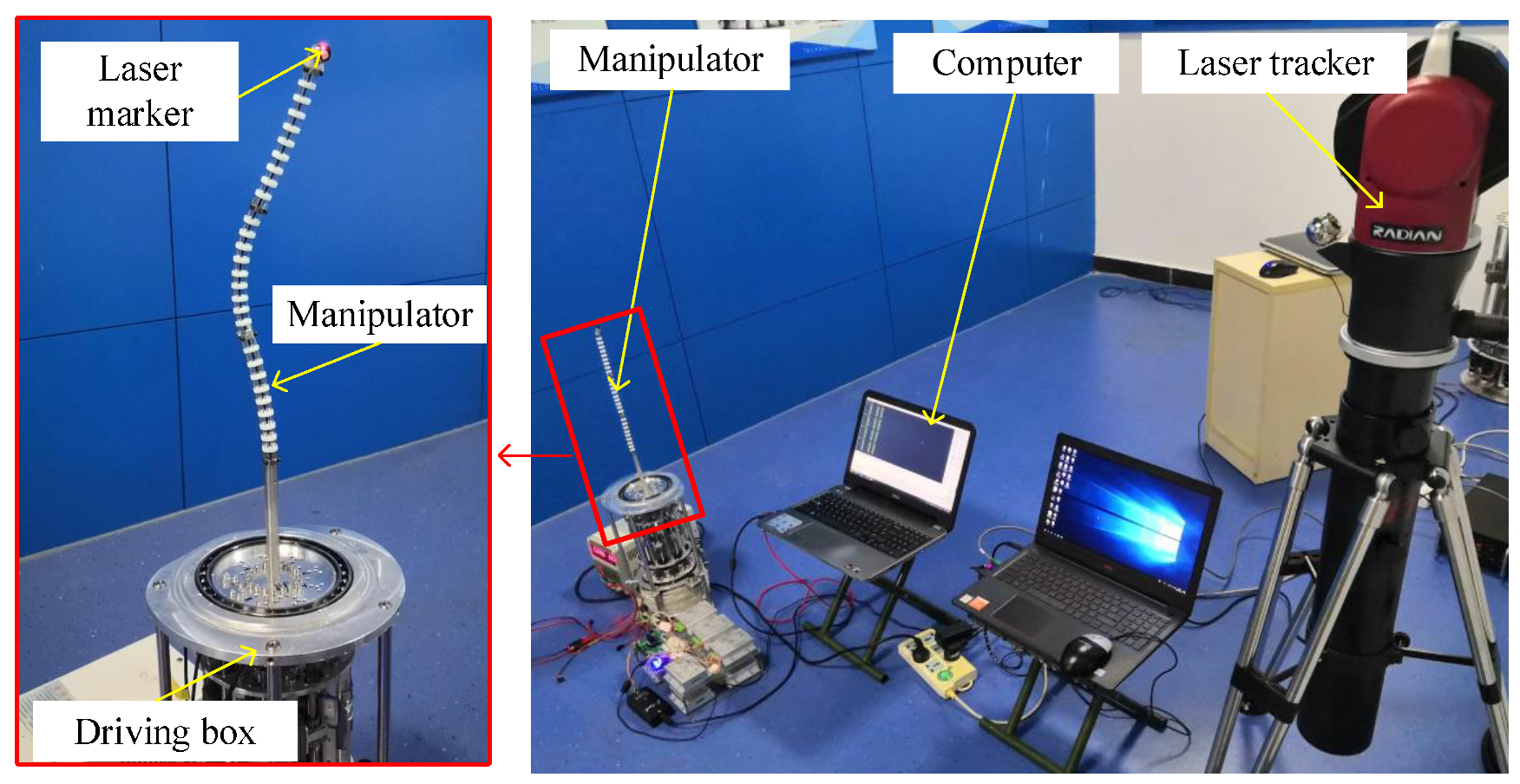

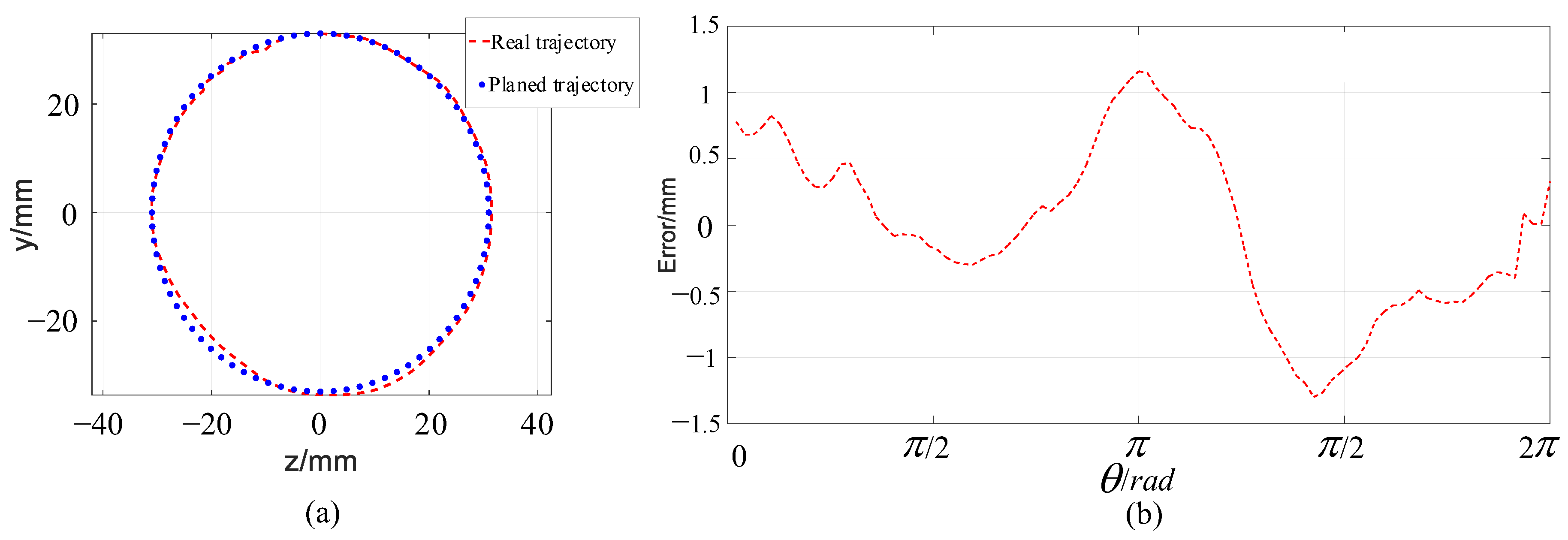

5.1. Experiments of the Single Arm

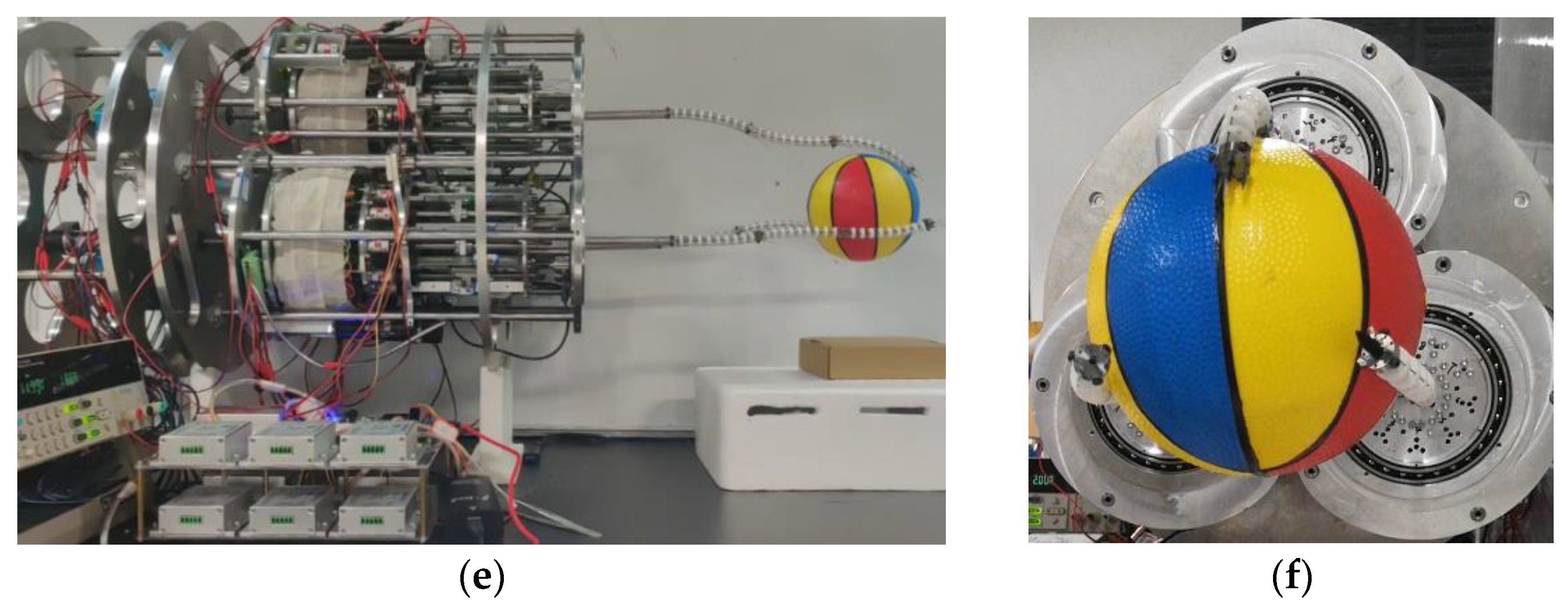

5.2. Cooperative Grasping of the Multi-Arm Space Robot

5.3. Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Jialun, P. Model design of on-orbit autonomous assembly multi-robot systems. In Proceedings of the 2010 2nd International Conference on Industrial and Information Systems, Dalian, China, 10–11 July 2010; Volume 2, pp. 472–475. [Google Scholar]

- Oda, M.; Kibe, K.; Yamagata, F. ETS-VII, space robot in-orbit experiment satellite. In Proceedings of the IEEE International Conference on Robotics and Automation, Minneapolis, MN, USA, 22–28 April 1996; Volume 1, pp. 739–744. [Google Scholar]

- Xinyu, L.; Que, D.; Lijian, Z.; Shaohua, M. Research on robot dexterous grasping for aerospace product parts. In Proceedings of the 2021 International Conference on Intelligent Computing, Automation and Systems (ICICAS), Chongqing, China, 29–31 December 2021; pp. 412–416. [Google Scholar]

- Zhong, X.; Peng, X.; Zhou, J. Dynamic collision avoidance of mobile robot based on velocity obstacles. In Proceedings of the 2011 International Conference on Transportation, Mechanical, and Electrical Engineering (TMEE), Changchun, China, 16–18 December 2011; pp. 2410–2413. [Google Scholar]

- Shin, H.; Kim, S.; Seo, K.; Rhim, S. A Real-Time Human-Robot Collision Safety Evaluation Method for Collaborative Robot. In Proceedings of the 2019 Third IEEE International Conference on Robotic Computing (IRC), Naples, Italy, 25–27 February 2019; pp. 509–513. [Google Scholar]

- Park, J.-J.; Song, J.-B.; Haddadin, S. Collision analysis and safety evaluation using a collision model for the frontal robot–human impact. Robotica 2015, 33, 1536–1550. [Google Scholar] [CrossRef]

- Mu, Z.; Yuan, H.; Xu, W.; Liu, T.; Liang, B. A Segmented Geometry Method for Kinematics and Configuration Planning of Spatial Hyper-Redundant Manipulators. IEEE Trans. Syst. Man Cybern Syst. 2020, 50, 1746–1756. [Google Scholar] [CrossRef]

- Peng, J.; Zhang, C.; Ge, D.; Han, Y. Two trajectory tracking control methods for space hyper-redundant cable-driven robots considering model uncertainty. Multibody Syst. Dyn. 2022, 56, 123–152. [Google Scholar] [CrossRef]

- Zhou, J.; Chen, Y.; Hu, Y.; Wang, Z.; Li, Y.; Gu, G.; Liu, Y. Adaptive Variable Stiffness Particle Phalange for Robust and Durable Robotic Grasping. Soft Robot. 2020, 7, 743–757. [Google Scholar] [CrossRef] [PubMed]

- Xu, W.; Zhang, H.; Yuan, H.; Liang, B. A Compliant Adaptive Gripper and Its Intrinsic Force Sensing Method. IEEE Trans. Robot. 2021, 37, 1584–1603. [Google Scholar] [CrossRef]

- Dai, Y.; Li, X.; Wang, X.; Yuan, H. Investigation on the Shape Reconstruction of Cable-Driven Continuum Manipulators Considering Super-Large Deflections and Variable Structures. In Proceedings of the Intelligent Robotics and Applications; Liu, H., Yin, Z., Liu, L., Jiang, L., Gu, G., Wu, X., Ren, W., Eds.; Springer International Publishing: Cham, Switzerland, 2022; pp. 183–194. [Google Scholar]

- Qin, G.; Ji, A.; Cheng, Y.; Zhao, W.; Pan, H.; Shi, S.; Song, Y. A Snake-Inspired Layer-Driven Continuum Robot. Soft Robot. 2021, 9, 788–797. [Google Scholar] [CrossRef] [PubMed]

- Walker, I.D.; Dawson, D.M.; Flash, T.; Grasso, F.W.; Hanlon, R.T.; Hochner, B.; Kier, W.M.; Pagano, C.C.; Rahn, C.D.; Zhang, Q.M. Continuum Robot Arms Inspired by Cephalopods; Gerhart, G.R., Shoemaker, C.M., Gage, D.W., Eds.; SPIE: Orlando, FL, USA, 2005; p. 303. [Google Scholar]

- Neppalli, S.; Jones, B.A. Design, construction, and analysis of a continuum robot. In Proceedings of the 2007 IEEE/RSJ International Conference on Intelligent Robots and Systems, San Diego, CA, USA, 29 October–2 November 2007; pp. 1503–1507. [Google Scholar]

- Bhattacherjee, S.; Chattopadhayay, S.; Rao, V.; Seth, S.; Mukherjee, S.; Sengupta, A.; Bhaumik, S. Kinematics and Teleoperation of Tendon Driven Continuum Robot. Procedia Comput. Sci. 2018, 133, 879–886. [Google Scholar] [CrossRef]

- Burgner-Kahrs, J.; Rucker, D.C.; Choset, H. Continuum Robots for Medical Applications: A Survey. IEEE Trans. Robot. 2015, 31, 1261–1280. [Google Scholar] [CrossRef]

- Nahar, D.; Yanik, P.M.; Walker, I.D. Robot tendrils: Long, thin continuum robots for inspection in space operations. In Proceedings of the 2017 IEEE Aerospace Conference, Big Sky, MT, USA, 4–11 March 2017; pp. 1–8. [Google Scholar]

- Dong, X.; Palmer, D.; Axinte, D.; Kell, J. In-situ repair/maintenance with a continuum robotic machine tool in confined space. J. Manuf. Process. 2019, 38, 313–318. [Google Scholar] [CrossRef]

- Dong, X.; Axinte, D.; Palmer, D.; Cobos, S.; Raffles, M.; Rabani, A.; Kell, J. Development of a slender continuum robotic system for on-wing inspection/repair of gas turbine engines. Robot. Comput. -Integr. Manuf. 2017, 44, 218–229. [Google Scholar] [CrossRef]

- Mu, Z.; Liu, T.; Xu, W.; Lou, Y.; Liang, B. A Hybrid Obstacle-Avoidance Method of Spatial Hyper-Redundant Manipulators for Servicing in Confined Space. Robotica 2019, 37, 998–1019. [Google Scholar] [CrossRef]

- Ranzani, T.; Gerboni, G.; Cianchetti, M.; Menciassi, A. A bioinspired soft manipulator for minimally invasive surgery. Bioinspir. Biomim. 2015, 10, 035008. [Google Scholar] [CrossRef] [PubMed]

- Teeple, C.B.; Koutros, T.N.; Graule, M.A.; Wood, R.J. Multi-segment soft robotic fingers enable robust precision grasping. Int. J. Robot. Res. 2020, 39, 1647–1667. [Google Scholar] [CrossRef]

- Liu, C.-H.; Chung, F.-M.; Chen, Y.; Chiu, C.-H.; Chen, T.-L. Optimal Design of a Motor-Driven Three-Finger Soft Robotic Gripper. IEEE/ASME Trans. Mechatron. 2020, 25, 1830–1840. [Google Scholar] [CrossRef]

- Fei, Y.; Wang, J.; Pang, W. A Novel Fabric-Based Versatile and Stiffness-Tunable Soft Gripper Integrating Soft Pneumatic Fingers and Wrist. Soft Robot. 2018, 6, 1–20. [Google Scholar] [CrossRef] [PubMed]

- Hock, O.; Drgoňa, P.; Paškala, M. Simulation model of adjustable arm using Denavit-Hartenberg parameters. In Proceedings of the 2014 ELEKTRO, Rajecke Teplice, Slovakia, 19–20 May 2014; pp. 176–179. [Google Scholar]

- Yuan, H.; Zhou, L.; Xu, W. A comprehensive static model of cable-driven multi-section continuum robots considering friction effect. Mech. Mach. Theory 2019, 135, 130–149. [Google Scholar] [CrossRef]

- Huang, S.; Zhang, Q.; Liu, Z.; Wang, X.; Liang, B. Control of a piecewise constant curvature continuum manipulator via policy search method. In Proceedings of the 2018 IEEE International Conference on Robotics and Biomimetics (ROBIO), Kuala Lumpur, Malaysia, 12–15 December 2018; pp. 1777–1782. [Google Scholar]

- Webster, R.J.; Jones, B.A. Design and Kinematic Modeling of Constant Curvature Continuum Robots: A Review. Int. J. Robot. Res. 2010, 29, 1661–1683. [Google Scholar] [CrossRef]

- Peng, J.; Xu, W.; Liu, T.; Yuan, H.; Liang, B. End-effector pose and arm-shape synchronous planning methods of a hyper-redundant manipulator for spacecraft repairing. Mech. Mach. Theory 2021, 155, 104062. [Google Scholar] [CrossRef]

- Barea, R.; Lopez, E.; Bergasa, L.M.; Alvarez, S.; Ocana, M. Detection Model in Collaborative Multi-Robot Monte Carlo Localization. In Proceedings of the IEEE Workshop on Distributed Intelligent Systems: Collective Intelligence and Its Applications (DIS’06), Prague, Czech Republic, 15–16 June 2006; pp. 49–54. [Google Scholar]

- Liu, X.-F.; Cai, G.-P.; Wang, M.-M.; Chen, W.-J. Contact control for grasping a non-cooperative satellite by a space robot. Multibody Syst. Dyn. 2020, 50, 119–141. [Google Scholar] [CrossRef]

- Yan, L.; Xu, W.; Hu, Z.; Liang, B. Multi-objective configuration optimization for coordinated capture of dual-arm space robot. Acta Astronaut. 2020, 167, 189–200. [Google Scholar] [CrossRef]

- Hu, Z.; Xu, W.; Yan, L.; Peng, J.; Liang, B. Dynamic Closest Point Identification and Estimation for Tumbling Target Capturing. In Proceedings of the 2018 IEEE/ASME International Conference on Advanced Intelligent Mechatronics (AIM), IEEE, Auckland, New Zealand, 9–12 July 2018; pp. 1130–1135. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dai, Y.; Li, Z.; Chen, X.; Wang, X.; Yuan, H. A Novel Space Robot with Triple Cable-Driven Continuum Arms for Space Grasping. Micromachines 2023, 14, 416. https://doi.org/10.3390/mi14020416

Dai Y, Li Z, Chen X, Wang X, Yuan H. A Novel Space Robot with Triple Cable-Driven Continuum Arms for Space Grasping. Micromachines. 2023; 14(2):416. https://doi.org/10.3390/mi14020416

Chicago/Turabian StyleDai, Yicheng, Zuan Li, Xinjie Chen, Xin Wang, and Han Yuan. 2023. "A Novel Space Robot with Triple Cable-Driven Continuum Arms for Space Grasping" Micromachines 14, no. 2: 416. https://doi.org/10.3390/mi14020416

APA StyleDai, Y., Li, Z., Chen, X., Wang, X., & Yuan, H. (2023). A Novel Space Robot with Triple Cable-Driven Continuum Arms for Space Grasping. Micromachines, 14(2), 416. https://doi.org/10.3390/mi14020416