Effect of Channel Shape on Performance of Printed Indium Gallium Zinc Oxide Thin-Film Transistors

Abstract

:1. Introduction

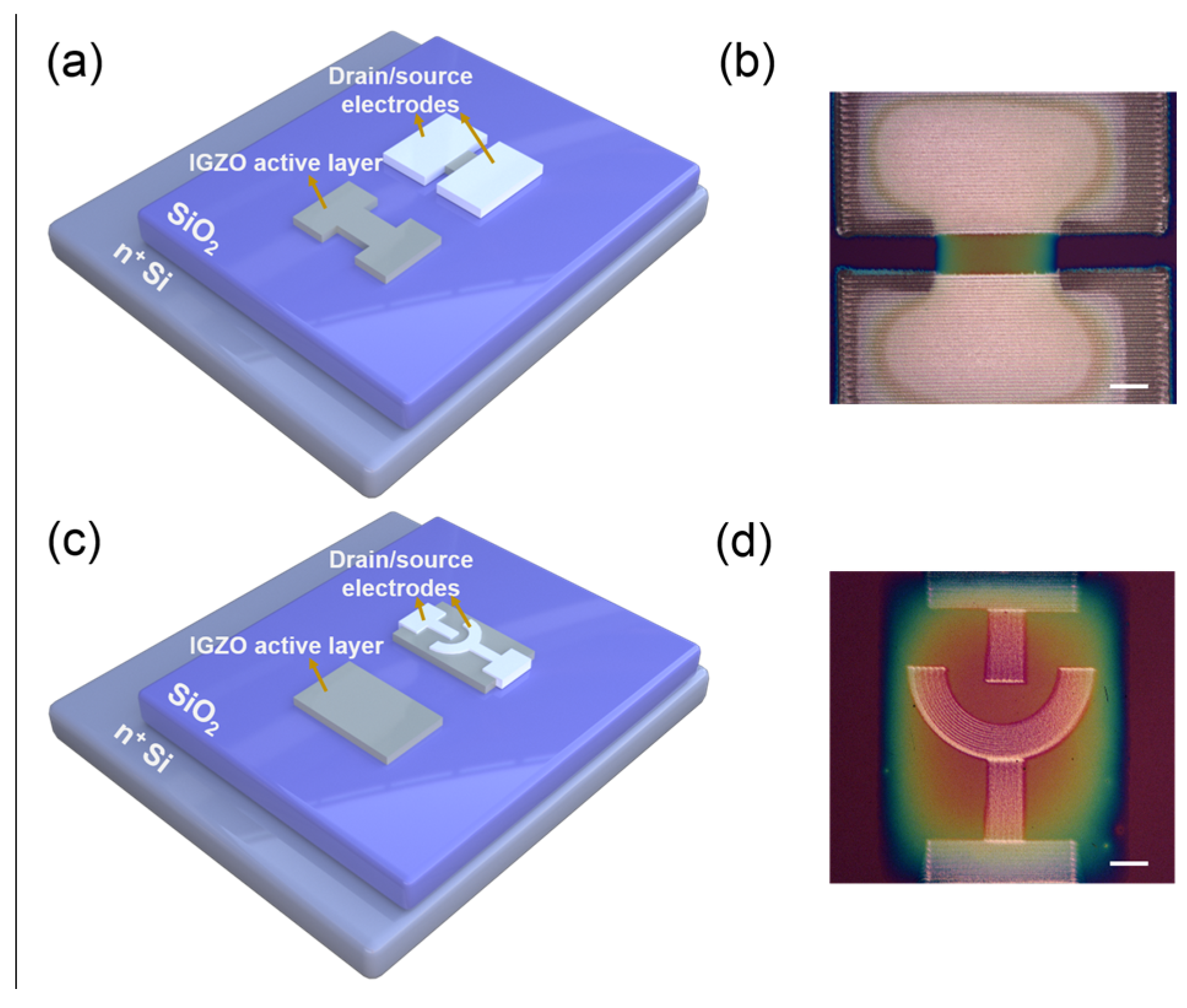

2. Materials and Methods

2.1. Preparation of TFT Devices

2.2. Characterization

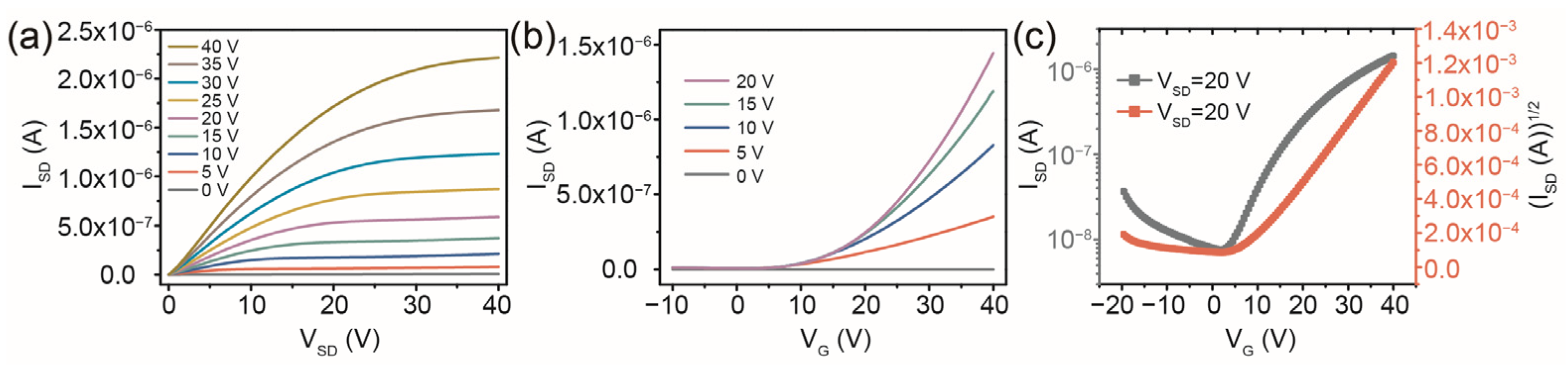

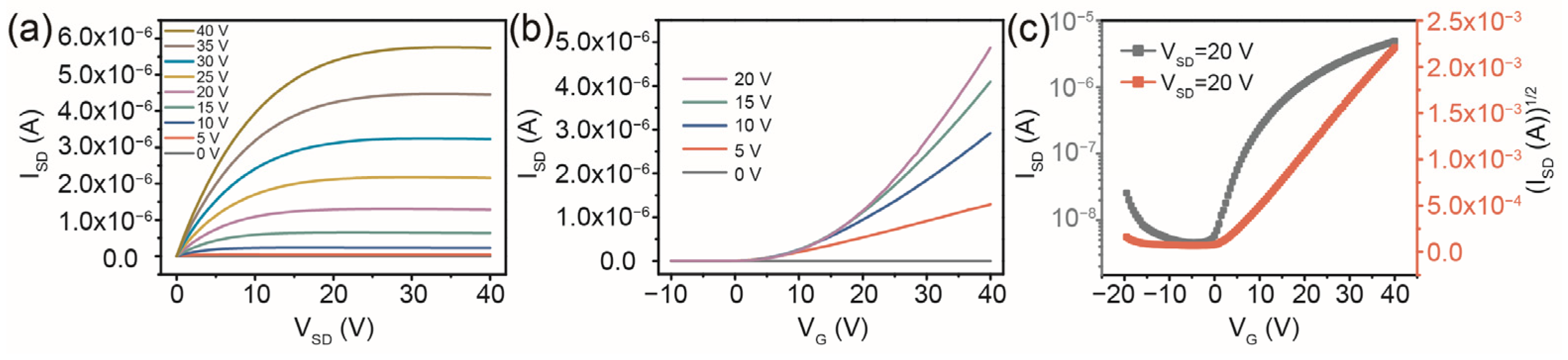

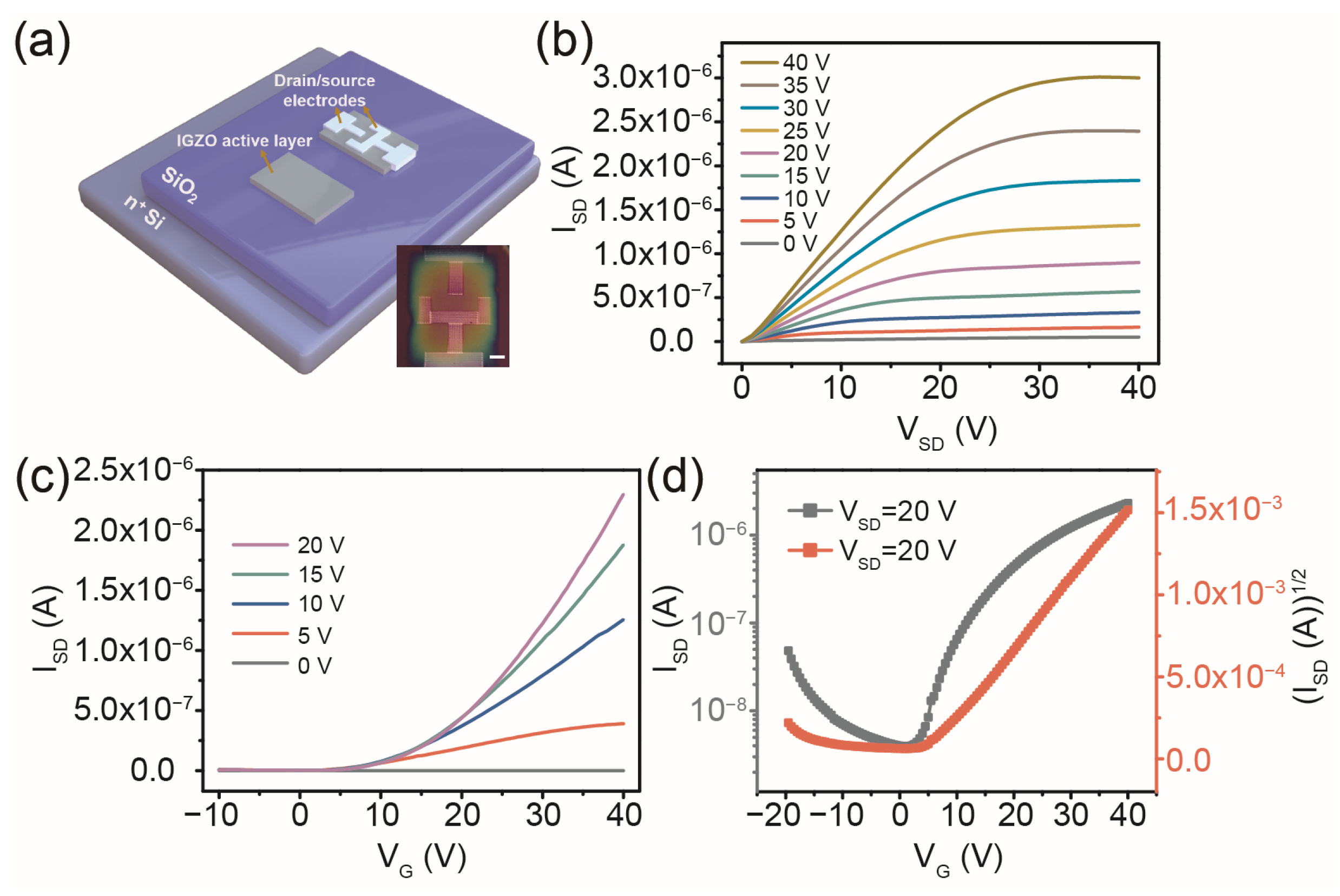

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Nomura, K.; Ohta, H.; Ueda, K.; Kamiya, T.; Hirano, M.; Hosono, H. Thin–film transistor fabricated in single-crystalline transparent oxide semiconductor. Science 2003, 300, 1269–1272. [Google Scholar] [CrossRef] [PubMed]

- Gelinck, G.; Huitema, H.; Veenendaal, E.; Cantatore, E.; Schrijnemakers, L.; Putten, J.; Geuns, T.; Beenhakkers, M.; Giesbers, J.; Huisman, B.; et al. Flexible active-matrix displays and shift registers based on solution-processed organic transistors. Nat. Mater. 2004, 3, 106–110. [Google Scholar] [CrossRef] [PubMed]

- Dimitrakopoulos, C.D.; Purushothaman, S.; Kymissis, J.; Callegari, A.; Shaw, J.M. Low–Voltage Organic Transistors on Plastic Comprising High-Dielectric Constant Gate Insulators. Science 1999, 283, 822–824. [Google Scholar] [CrossRef]

- Fortunato, E.; Barquinha, P.; Pimentel, A.; Goncalves, A.; Marque, A.; Pereira, L.; Martins, R. Wide-Bandgap High-Mobility ZnO Thin-Film Transistors Produced at Room Temperature. Appl. Phys. Lett. 2004, 85, 2541–2543. [Google Scholar] [CrossRef]

- Tang, Y.; Huang, C.H.; Nomura, K. Vacuum-Free Liquid-Metal-Printed 2D Indium-Tin Oxide Thin-Film Transistor for Oxide Inverters. ACS Nano 2022, 16, 3280–3289. [Google Scholar] [CrossRef]

- Jana, S.; Martins, R.; Fortunato, E. Stacking-Dependent Electrical Transport in a Colloidal CdSe Nanoplatelet Thin-Film Transistor. Nano Lett. 2022, 22, 2780–2785. [Google Scholar] [CrossRef] [PubMed]

- Wu, L.; Dong, Z.C.; Li, F.Y.; Zhou, H.H.; Song, Y.L. Emerging Progress of Inkjet Technology in Printing Optical Materials. Adv. Opt. Mater. 2016, 4, 1915–1932. [Google Scholar] [CrossRef]

- Avis, C.; Hwang, H.R.; Jang, J. Effect of Channel Layer Thickness on the Performance of Indium–Zinc–Tin Oxide Thin Film Transistors Manufactured By Inkjet Printing. Appl. Mater. Interfaces 2014, 6, 10941–10945. [Google Scholar] [CrossRef] [PubMed]

- Fortunato, E.; Barquinha, P.; Martins, R. Oxide Semiconductor Thin-Film Transistors: A Review of Recent Advances. Adv. Mater. 2012, 24, 2945–2986. [Google Scholar] [CrossRef] [PubMed]

- Rim, Y.S.; Chen, H.J.; Kou, X.L.; Duan, H.S.; Zhou, H.P.; Cai, M.; Kim, H.J.; Yang, Y. Boost up mobility of solution–processed metal oxide thin–film transistors via confining structure on electron pathways. Adv. Mater. 2014, 26, 4273–4278. [Google Scholar] [CrossRef]

- Scheideler, W.J.; Subramanian, V. How to print high-mobility metal oxide transistors—Recent advances in ink design processing, and device engineering. Appl. Phys. Lett. 2022, 121, 220502. [Google Scholar] [CrossRef]

- Park, J.W.; Kang, B.H.; Kim, H.J. A Review of Low-Temperature Solution-Processed Metal Oxide Thin-Film Transistors for Flexible Electronics. Adv. Funct. Mater. 2020, 30, 1904632. [Google Scholar] [CrossRef]

- Hamlin, A.B.; Ye, Y.; Huddy, J.E.; Rahman, M.S.; Scheideler, W.J. 2D transistors rapidly printed from the crystalline oxide skin of molten indium. npj 2D Mater. Appl. 2022, 6, 16. [Google Scholar] [CrossRef]

- Liu, F.; Gillan, L.; Leppaniemi, J.; Alastalo, A. Focused Review on Print-Patterned Contact Electrodes for Metal-Oxide Thin-Film Transistors. Adv. Mater. Interfaces 2023, 10, 2202258. [Google Scholar] [CrossRef]

- Fukuda, K.; Takeda, Y.; Yoshimura, Y.; Shiwaku, R.; Tran, L.T.; Sekine, T.; Mizukami, M.; Kumaki, D.; Tokito, S. Fully-printed high-performance organic thin-film transistors and circuitry on one-micron-thick polymer films. Nat. Commun. 2014, 5, 4147. [Google Scholar] [CrossRef]

- Ruiz-Preciado, L.A.; Baek, S.; Strobel, N.; Xia, K.; Seiberlich, M.; Park, S.; Lemmer, U.; Jung, S.; Hernandez-Sosa, G. Monolithically printed all-organic flexible photosensor active matrix. npj Flexible Electron. 2023, 7, 6. [Google Scholar] [CrossRef]

- Cao, C.; Andrews, J.B.; Kumar, A.; Franklin, A.D. Improving contact interfaces in fully printed carbon nanotube thin–film transistors. ACS Nano 2016, 10, 5221–5229. [Google Scholar] [CrossRef]

- Ha, J.; Yoo, H.; Seo, J.; Yoon, J.; Hong, Y. Photoresponse Analysis of All-Inkjet-Printed Single-Walled Carbon Nanotube Thin-Film Transistors for Flexible Light-Insensitive Transparent Circuit Applications. ACS Appl. Mater. Interfaces 2023, 15, 3192–3201. [Google Scholar] [CrossRef] [PubMed]

- Kuribara, K.; Wang, H.; Uchiyama, N.; Fukuda, K.; Yokota, T.; Zschieschang, U.; Jaye, C.; Fischer, D.; Klauk, H.; Yamamoto, T.; et al. Organic transistors with high thermal stability for medical applications. Nat. Commun. 2012, 3, 723. [Google Scholar] [CrossRef]

- Gillan, L.; Li, S.; Lahtinen, J.; Chang, C.H.; Alastalo, A.; Leppaniemi, J. Inkjet-Printed Ternary Oxide Dielectric and Doped Interface Layer for Metal-Oxide Thin-Film Transistors with Low Voltage Operation. Adv. Mater. Interfaces 2021, 8, 2100728. [Google Scholar] [CrossRef]

- Divya, M.; Pradhan, J.R.; Priyadarsini, S.S.; Dasgupta, S. High Operation Frequency and Strain Tolerance of Fully Printed Oxide Thin Film Transistors and Circuits on PET Substrates. Small 2022, 18, 2202891. [Google Scholar] [CrossRef] [PubMed]

- Lee, Y.G.; Choi, W.S. Effect of PGMEA Addition on Zinc-Tin-Oxide Thin-Film Transistor Fabricated by Inkjet-Printing Process. Adv. Eng. Mater. 2022, 24, 2200128. [Google Scholar] [CrossRef]

- Wang, R.; Liang, K.; Wang, S.; Cao, Y.; Xin, Y.; Peng, Y.; Ma, X.; Zhu, B.; Wang, H.; Hao, Y. Printable Epsilon-Type Structure Transistor Arrays with Highly Reliable Physical Unclonable Functions. Adv. Mater. 2023, 35, 2210621. [Google Scholar] [CrossRef]

- Liang, K.; Wang, R.; Ren, H.; Li, D.; Tang, Y.; Wang, Y.; Chen, Y.; Song, C.; Li, F.; Liu, G.; et al. Printable Coffee-Ring Structures for Highly Uniform All Oxide Optoelectronic Synaptic Transistors. Adv. Opt. Mater. 2022, 10, 2201754. [Google Scholar] [CrossRef]

- Secor, E.B.; Smith, J.; Marks, T.J.; Hersam, M.C. High-performance inkjet-printed indium-gallium-zinc-oxide transistors enabled by embedded, chemically stable graphene electrodes. ACS Appl. Mater. Interfaces 2016, 8, 17428–17434. [Google Scholar] [CrossRef]

- Kim, W.G.; Tak, Y.J.; Yoo, H.; Kim, H.T.; Park, J.W.; Choi, D.H.; Kim, H.J. Photo-induced Reactive Oxygen Species Activation for Amorphous Indium-Gallium-Zinc Oxide Thin-Film Transistors Using Sodium Hypochlorite. ACS Appl. Mater. Interfaces 2021, 13, 44531–44540. [Google Scholar] [CrossRef] [PubMed]

- Nomura, K.; Ohta, H.; Takagi, A.; Kamiya, T.; Hirano, M.; Hosono, H. Room–Temperature Fabrication of Transparent Flexible Thin–Film Transistors Using Amorphous Oxide Semiconductors. Nature 2004, 432, 488–492. [Google Scholar] [CrossRef]

- Chen, R.; Lan, L. Solution–processed metal–oxide thin–film transistors: A review of recent developments. Nanotechnology 2019, 30, 312001. [Google Scholar] [CrossRef]

- Shao, S.; Wang, S.; Li, M.; Xie, T.; Fang, Y.; Guo, P.; Chen, Z.; Zhao, J. 75 kbit printed indium oxide (IO)/indium gallium zinc oxide (IGZO) heterojunction photoelectric synaptic transistor arrays for an artificial visual memory system. J. Mater. Chem. C 2023, 11, 7019. [Google Scholar] [CrossRef]

- Yan, X.; Li, B.; Song, K.; Zhang, Y.; Wang, Y.; Yang, F.; Wang, C.; Chi, Y.; Yang, X. Fabrication and properties of InGaZnO thin-film transistors based on sol-gel method with different electrode patterns. Micromachines 2022, 13, 2207. [Google Scholar] [CrossRef]

- Jang, J.; Kang, H.; Chakravarthula, H.C.N.; Subramanian, V. Fully Inkjet-Printed Transparent Oxide Thin Film Transistors Using a Fugitive Wettability Switch. Adv. Electron. Mater. 2015, 1, 1500086. [Google Scholar] [CrossRef]

- Munteanu, D.; Cristoloveanu, S.; Hovel, H. Circular pseudo-metal oxide semiconductor field effect transistor in silicon-on-insulator. Electrochem. Solid-State Lett. 1999, 2, 242–243. [Google Scholar] [CrossRef]

- Zhao, C.; Fung, T.C.; Kanicki, J. Half-Corbino short-channel amorphous In-Ga-Zn-O thin-film transistors with a-SiOx or a-SiOx/a-SiNx passivation layers. Solid-State Electron. 2016, 120, 25–31. [Google Scholar] [CrossRef]

- Lee, H.; Yoo, G.; Yoo, J.S.; Kanicki, J. Asymmetric electrical properties of fork a-Si:H thin-film transistor and its application to flat panel displays. J. Appl. Phys. 2009, 105, 124522. [Google Scholar] [CrossRef]

| Type | On/Off Ratio | Field Effect Mobility (cm2 V−1 s−1) | Threshold Voltage (V) |

|---|---|---|---|

| Symmetrical rectangular channel | 1.8 × 102 | 0.069 | 6.1 |

| Rectangular groove channel | 5.9 × 102 | 0.093 | 3.1 |

| Circular arc channel | 1.1 × 103 | 0.208 | 2.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yan, X.; Li, B.; Zhang, Y.; Wang, Y.; Wang, C.; Chi, Y.; Yang, X. Effect of Channel Shape on Performance of Printed Indium Gallium Zinc Oxide Thin-Film Transistors. Micromachines 2023, 14, 2121. https://doi.org/10.3390/mi14112121

Yan X, Li B, Zhang Y, Wang Y, Wang C, Chi Y, Yang X. Effect of Channel Shape on Performance of Printed Indium Gallium Zinc Oxide Thin-Film Transistors. Micromachines. 2023; 14(11):2121. https://doi.org/10.3390/mi14112121

Chicago/Turabian StyleYan, Xingzhen, Bo Li, Yiqiang Zhang, Yanjie Wang, Chao Wang, Yaodan Chi, and Xiaotian Yang. 2023. "Effect of Channel Shape on Performance of Printed Indium Gallium Zinc Oxide Thin-Film Transistors" Micromachines 14, no. 11: 2121. https://doi.org/10.3390/mi14112121

APA StyleYan, X., Li, B., Zhang, Y., Wang, Y., Wang, C., Chi, Y., & Yang, X. (2023). Effect of Channel Shape on Performance of Printed Indium Gallium Zinc Oxide Thin-Film Transistors. Micromachines, 14(11), 2121. https://doi.org/10.3390/mi14112121