In gf bonding, silicon wafers are sealed through a thermo-mechanical process by exploiting low melting point glasses, i.e., lead or lead-silicate glasses, as an intermediate layer. The glass transformation into the viscous paste is critical in this method; hence, there are criteria to obtain a high bonding quality, e.g., controlling the grain size [

7]. The knowledge of gf properties and its thermo-mechanical behaviour are of paramount importance for the modelling, simulation, and critical understanding of the bonding process which leads to residual stresses and wafer warpage. The gf material used in this research is a lead–silicate glass (DL11-036) made by Ferro [

26]. Oxides contained in the glass are reported in

Table 1.

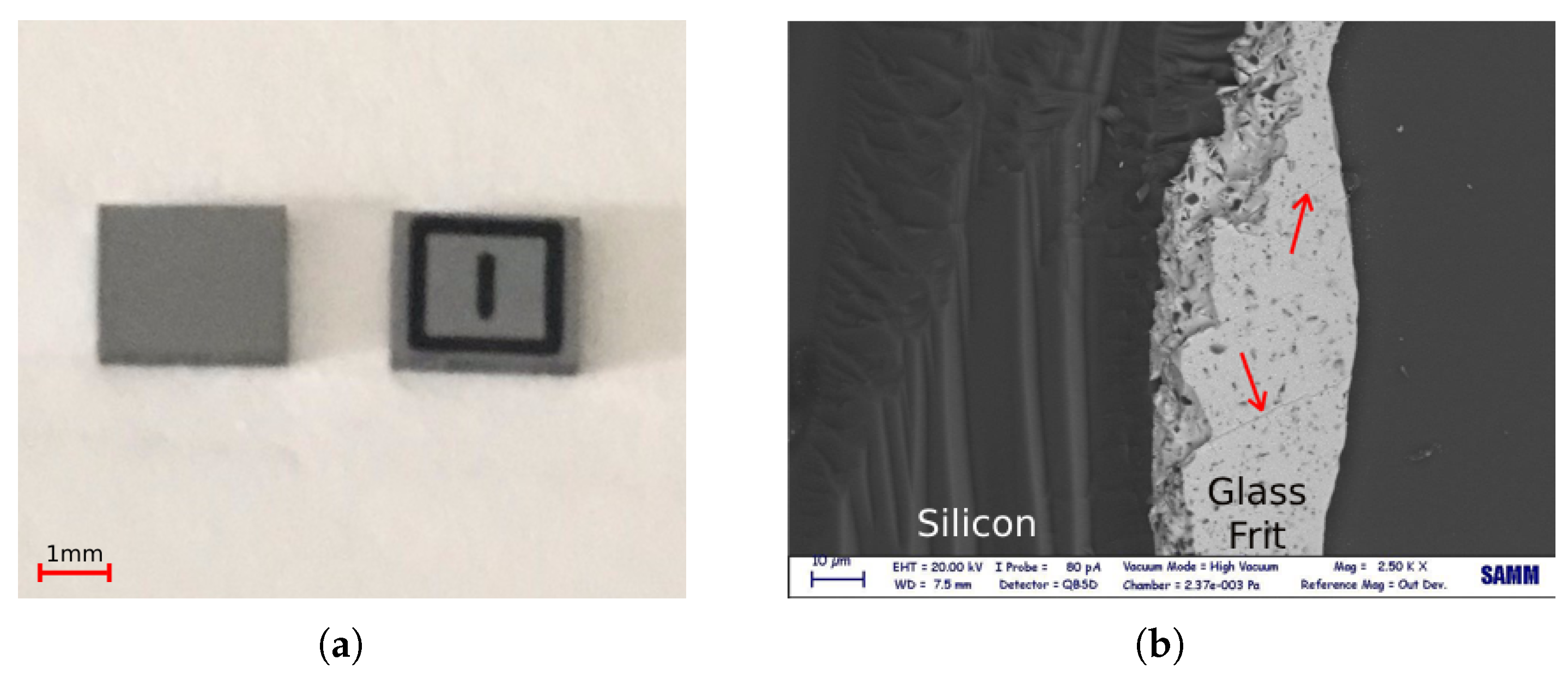

There are two sets of specimens used in this research: (i) the gf paste on silicon wafer after thermal conditioning, hereafter known as pre-bond; (ii) silicon die after gf bonding and dicing with Si–gf-Si structure (whose thicknesses are 725, 20 and 725 m, respectively), hereafter known as post-bond. The specimens were tested by adopting various experimental methods; in this Section, the obtained results are reported and critically discussed.

2.1. Confocal Laser Profilometry

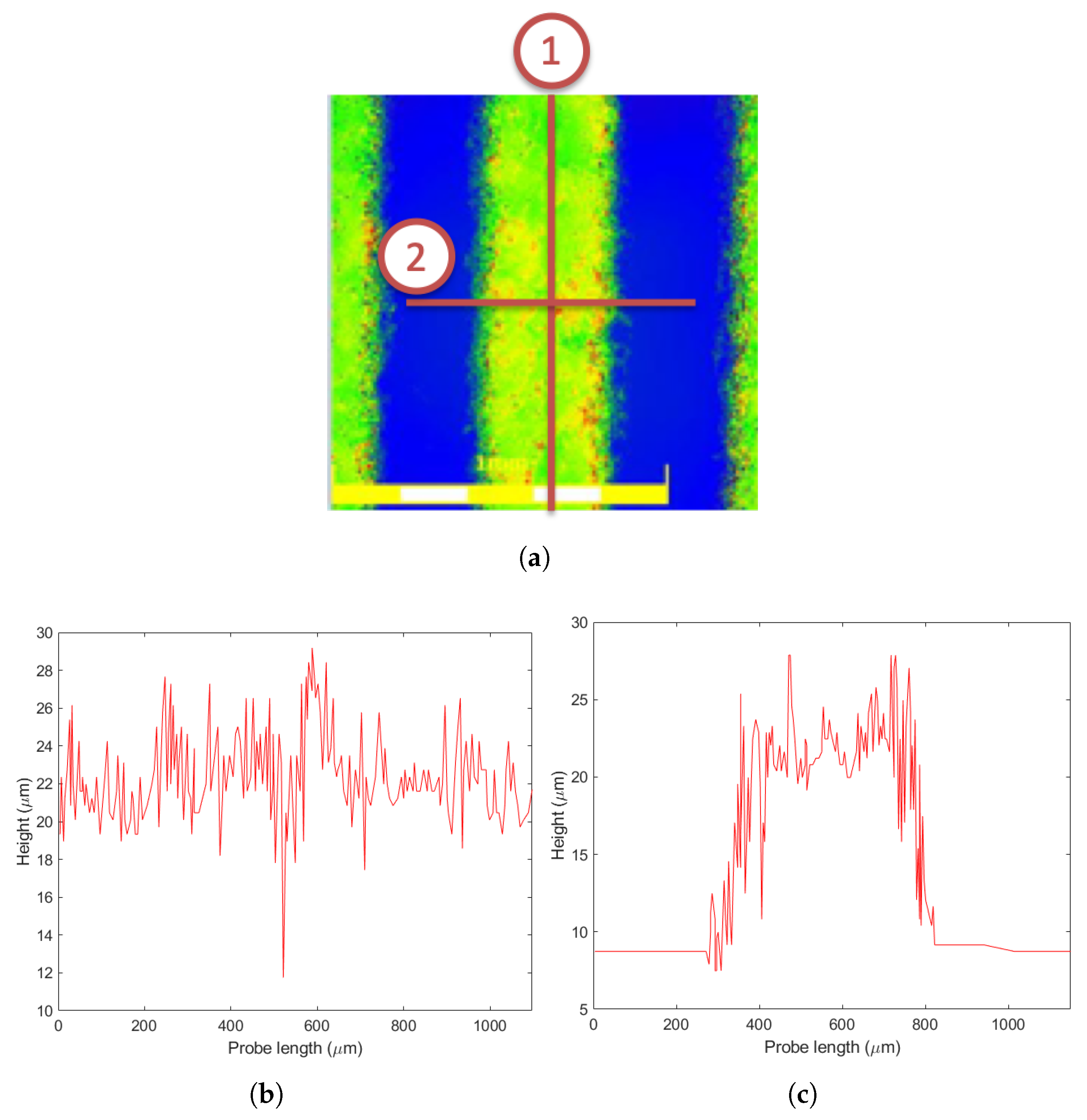

Surface roughness plays a secondary role in gf wafer level packaging because during the thermo-compressive bonding the glass reaches a wetting temperature causing the material to become soft enough to flow and fuse with the wafer surface layer at the atomic level; after cooling, the obtained bond can be quite strong. The material retains a low viscosity in order to avoid flooding the cavity where the MEMS is placed. Therefore, it is the temperature more than the pressure that is important, the former in the range 425–450 °C, the latter necessary to deal with a possible wafer bow and warp. However, in the initial temperature rise, the wafers are put into contact with the gf in between by applying a mechanical pressure in addition to the partial glass melting; hence, the gaps induced by the roughness between the gf film and the silicon wafer are compensated if they are not excessive. To study the topology of gf film as well as its surface roughness, confocal laser profilometry tests were carried out on pre-bond specimens. In this test, two different probe paths, longitudinal and transversal, as depicted in

Figure 1a, were selected. The longitudinal profile travelled on the gf layer surface and determined the mean height of the asperities, while the transversal profile measured the height with respect to the silicon surface, considered as the reference plane. The corresponding height profiles for each path are presented in

Figure 1b,c. The surface roughness parameters, in addition to the topological parameter of the gf film obtained from the profiles, are reported in

Table 2.

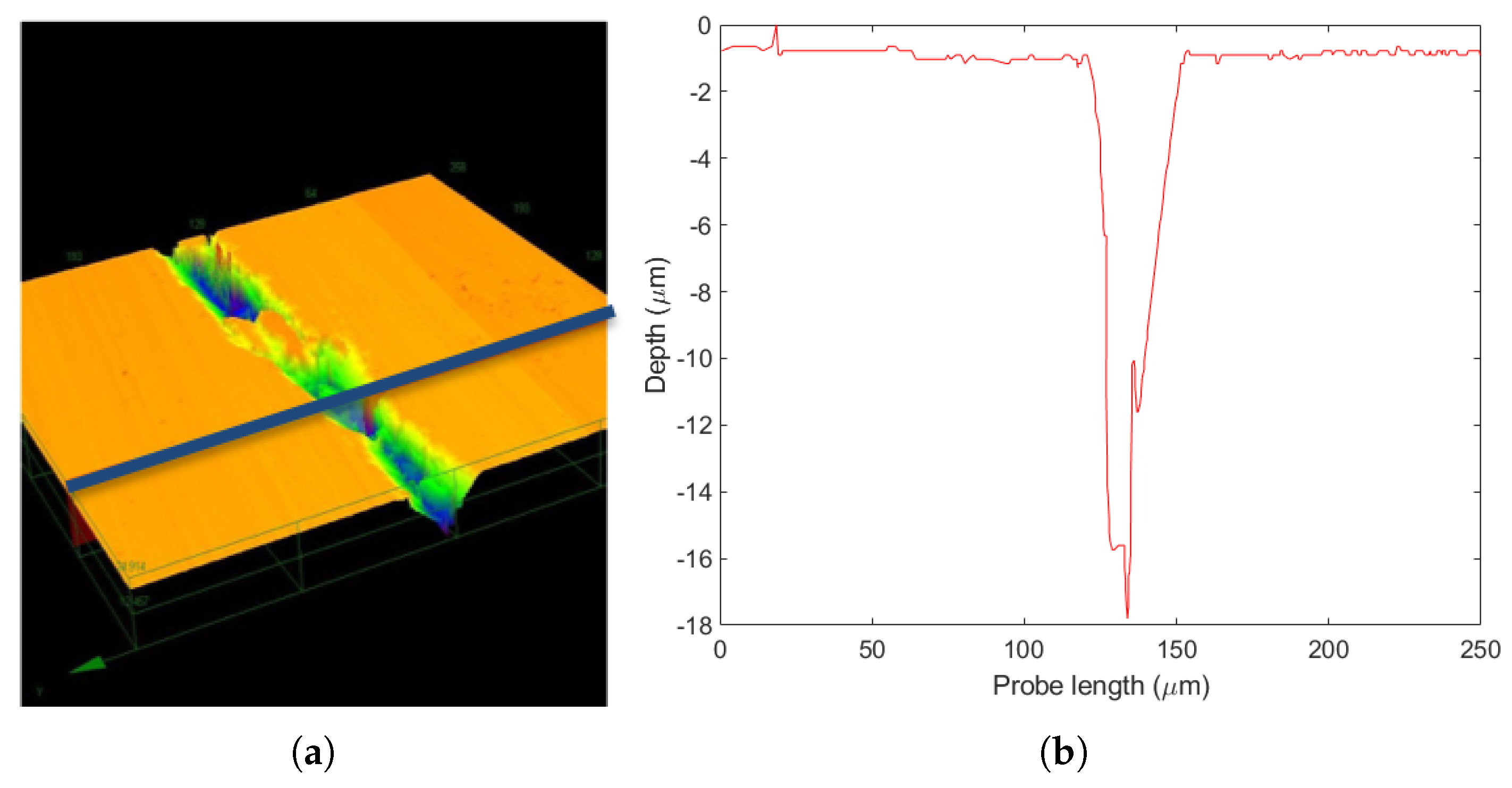

Another set of tests was carried out for post-bond specimens along the thickness on a silicon die (with the Si–gf–Si structure mentioned above). By performing the profilometry on the cross section of this structure (blue line in

Figure 2a), a difference of about 17

m was observed in the gf region (

Figure 2b). This valley-shaped profile showed that the gf thermal expansion coefficient was significantly higher than the silicon one, thus leading to a larger gf contraction in the bonding cooling phase with respect to the silicon.

2.2. Nanoindentation Tests

To estimate the effective elastic mechanical behaviour for the considered bonding material, a Berkovich nanoindenter was used at room temperature on gf strips deposited on a silicon wafer substrate (pre-bond specimens). Two sets of measurements were carried out, one at the centre of the wafer and the other near the wafer edge. To avoid the scattering due to the surface roughness compared to the indenter radius, for each position on the wafer a set of measurements was carried out: 17 tests were performed at 100

m intervals along the axis of the strip; then, the procedure was repeated along two additional lines, parallel to the axis but at an offset of ±100

m, for a total of 51 measurements at each position (i.e., centre, periphery) on the wafer.

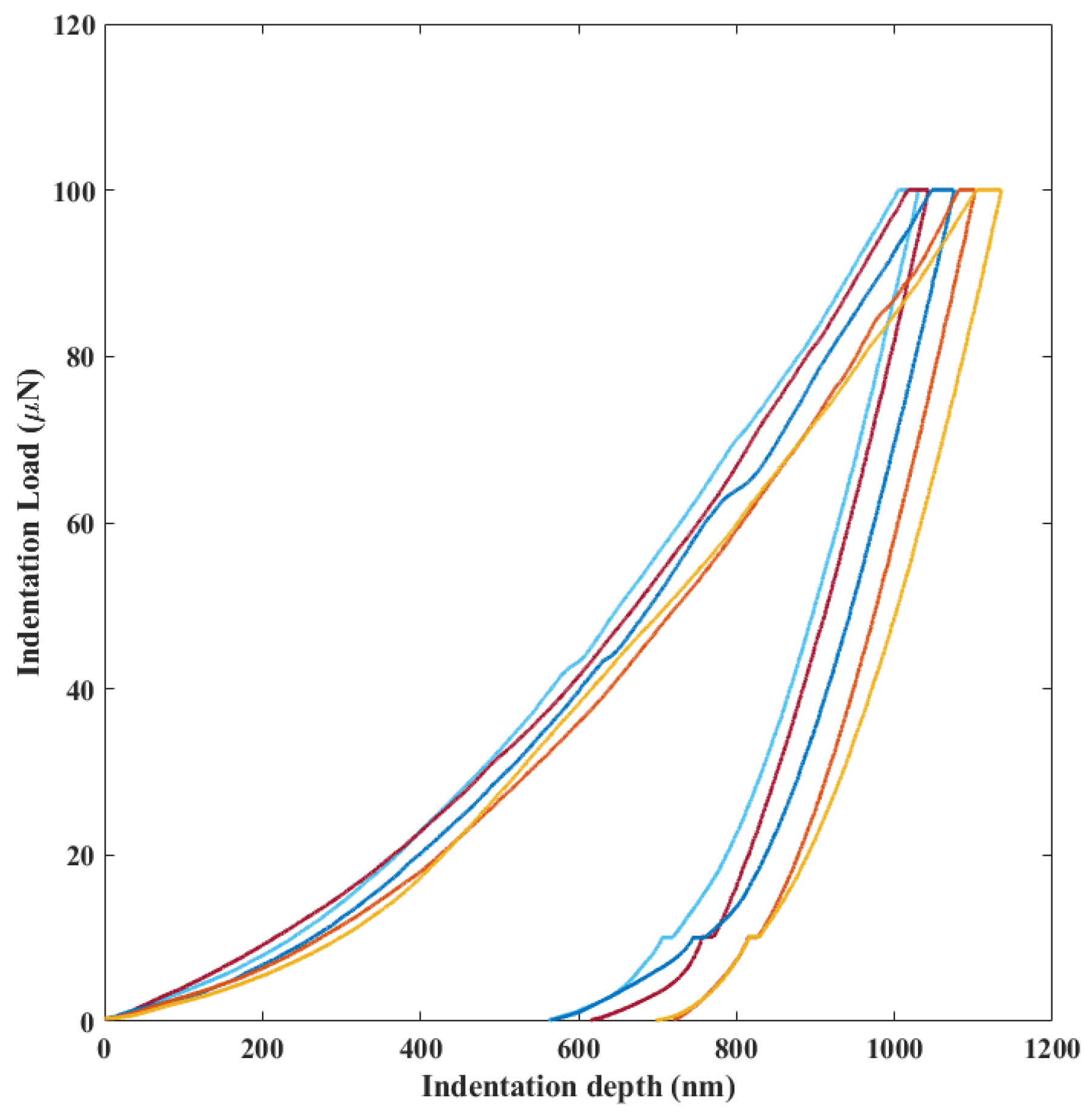

Figure 3 shows instances of the force-depth curves of the nano-indentations tests. As shown in

Table 3, no significant changes were observed between the results obtained at the centre and those obtained at the periphery (i.e., near the wafer edge) for the effective elastic properties at room temperature. An average (including both centre and peripheral positions) effective Young’s modulus of 86.5 ± 9.5 GPa, a Poisson’s ratio of 0.19 ± 0.02, and a hardness of 5.26 ± 0.8 GPa were therefore measured.

Since gf mechanical properties are highly dependent on the composition, different values are reported in the literature. For instance, Ebert and Bagdahn [

27] indicated

E = 50 GPa and

= 0.23 for Young’s modulus and Poisson’s ratio, respectively. Grabham et al. [

28] inspected the mechanical properties of gf binder material through experiments on cantilever beams loaded at the free ends and numerical simulations. Different gf materials were deposited on a silicon substrate; the authors obtained an effective Young’s modulus for two gf pastes equal to 22 GPa and 33.5 GPa, respectively, but they commented that these values were more indicative of the aggregate than of the actual gf material. Dresbach et al. [

12] reported instead

GPa and

; Xu et al. [

14] investigated the effect of Young’s modulus on the final warpage of the gf bonding, observing that the higher the Young’s modulus, the higher the final warpage: the material in the present study, therefore, should emphasize the warping effect.

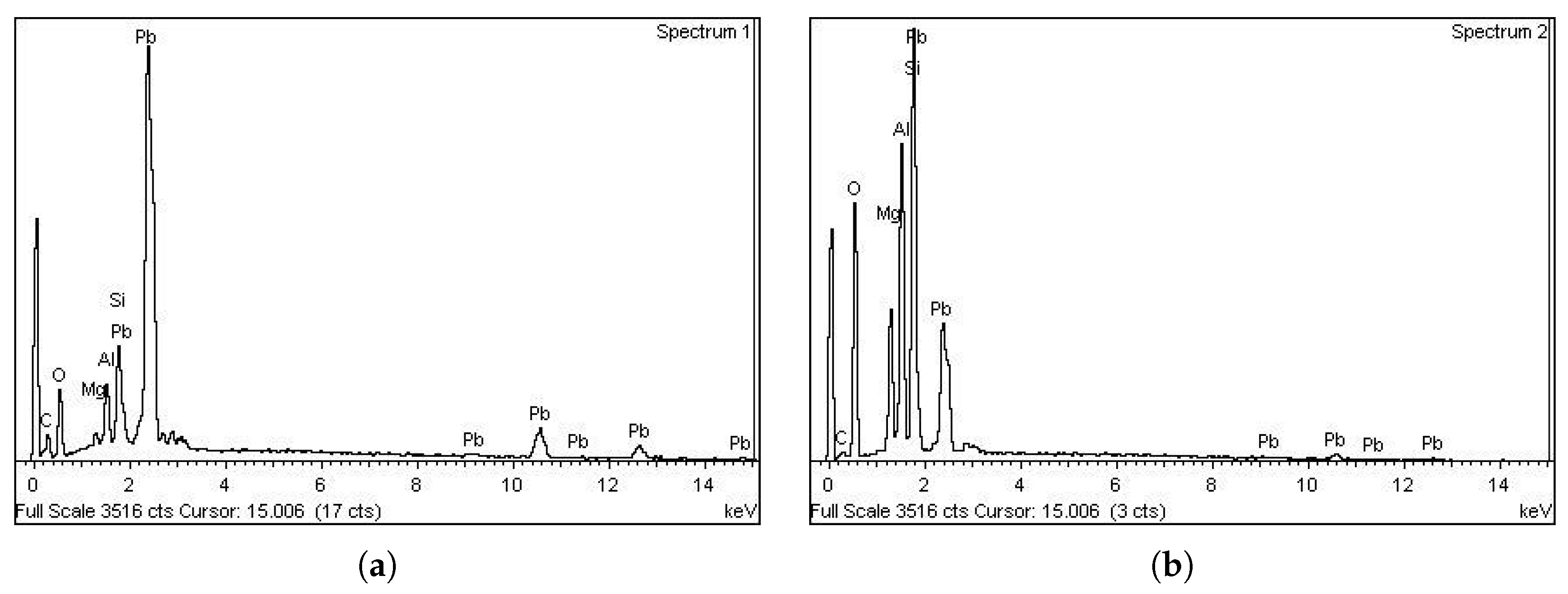

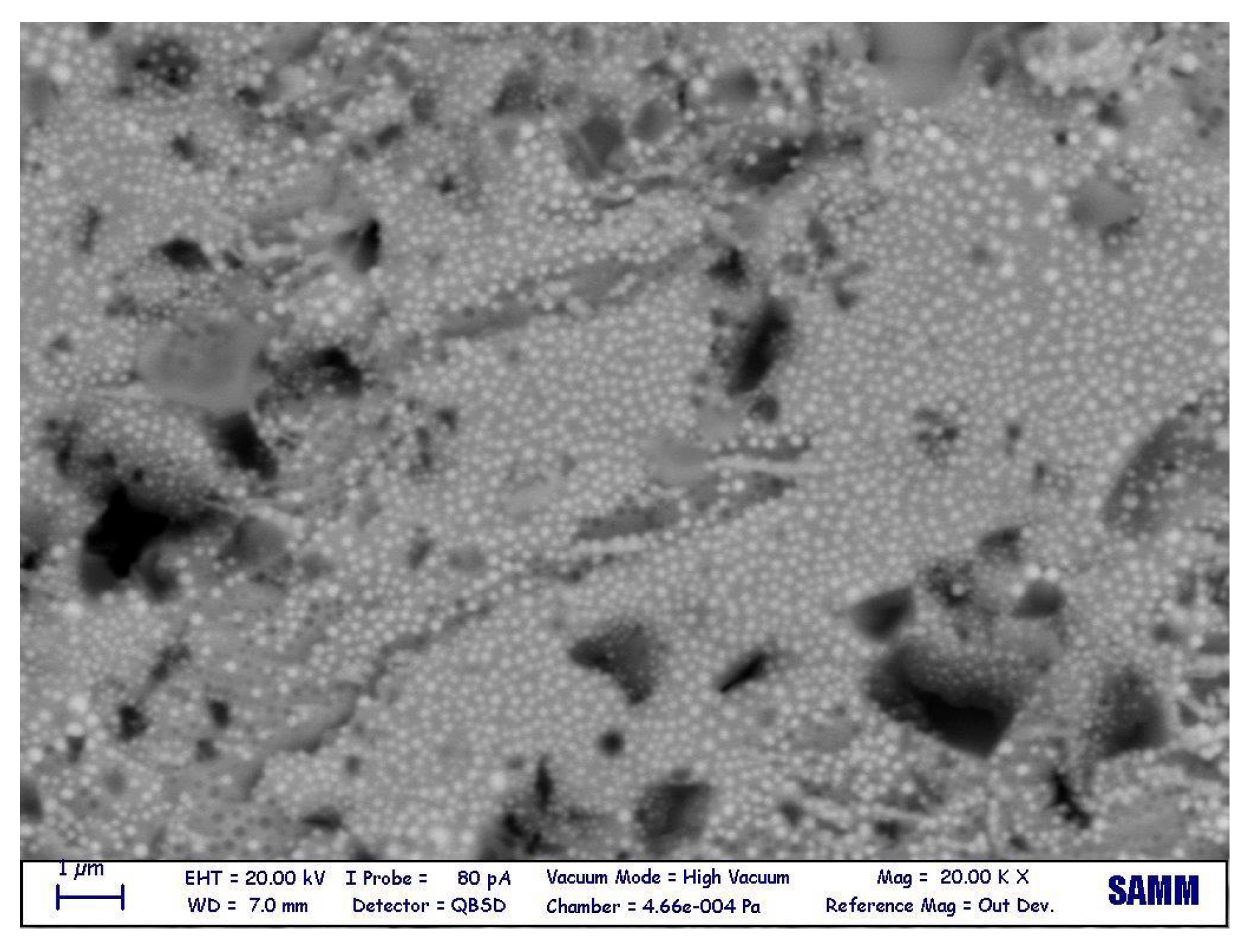

2.3. Microstructural Study

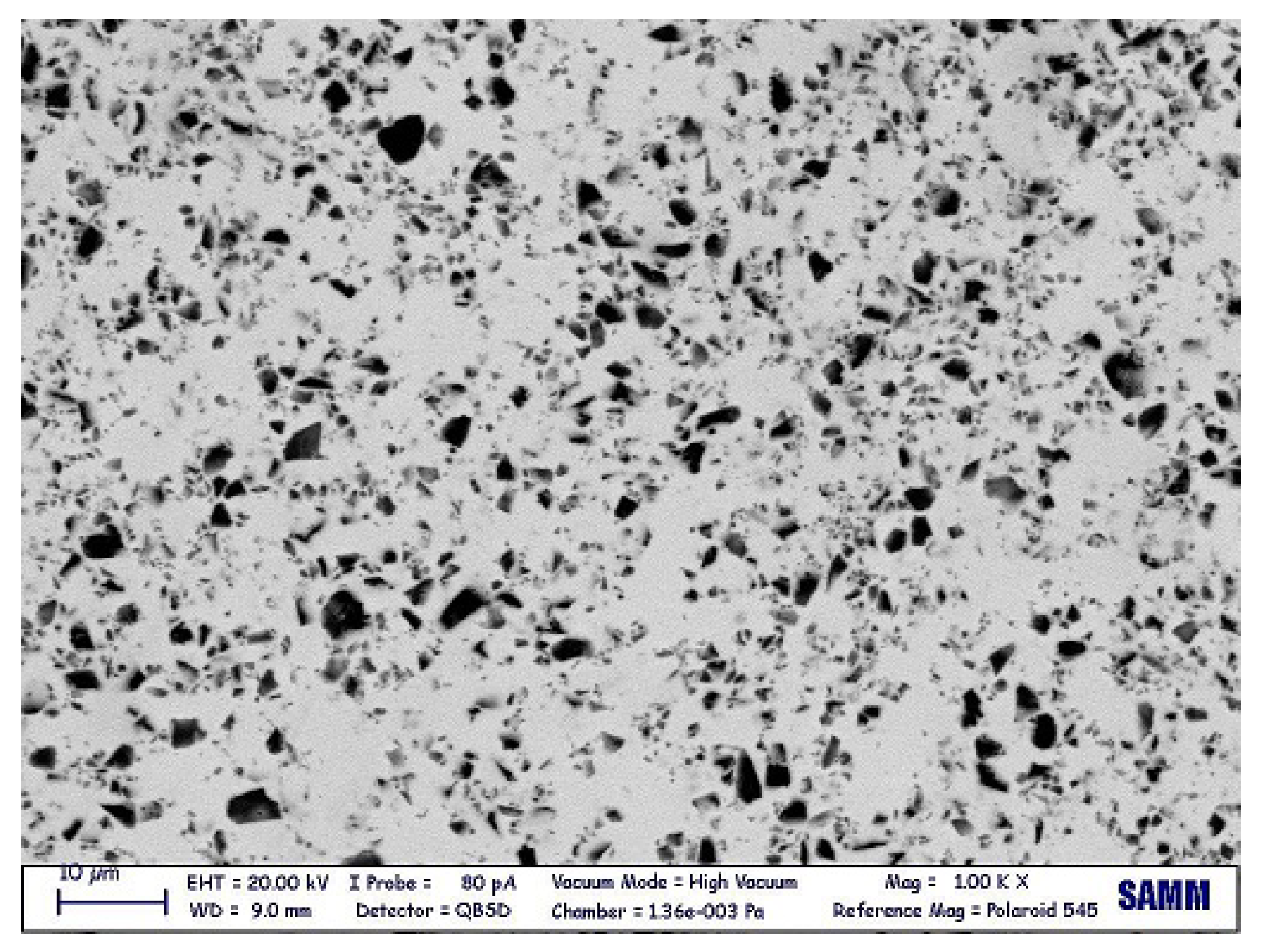

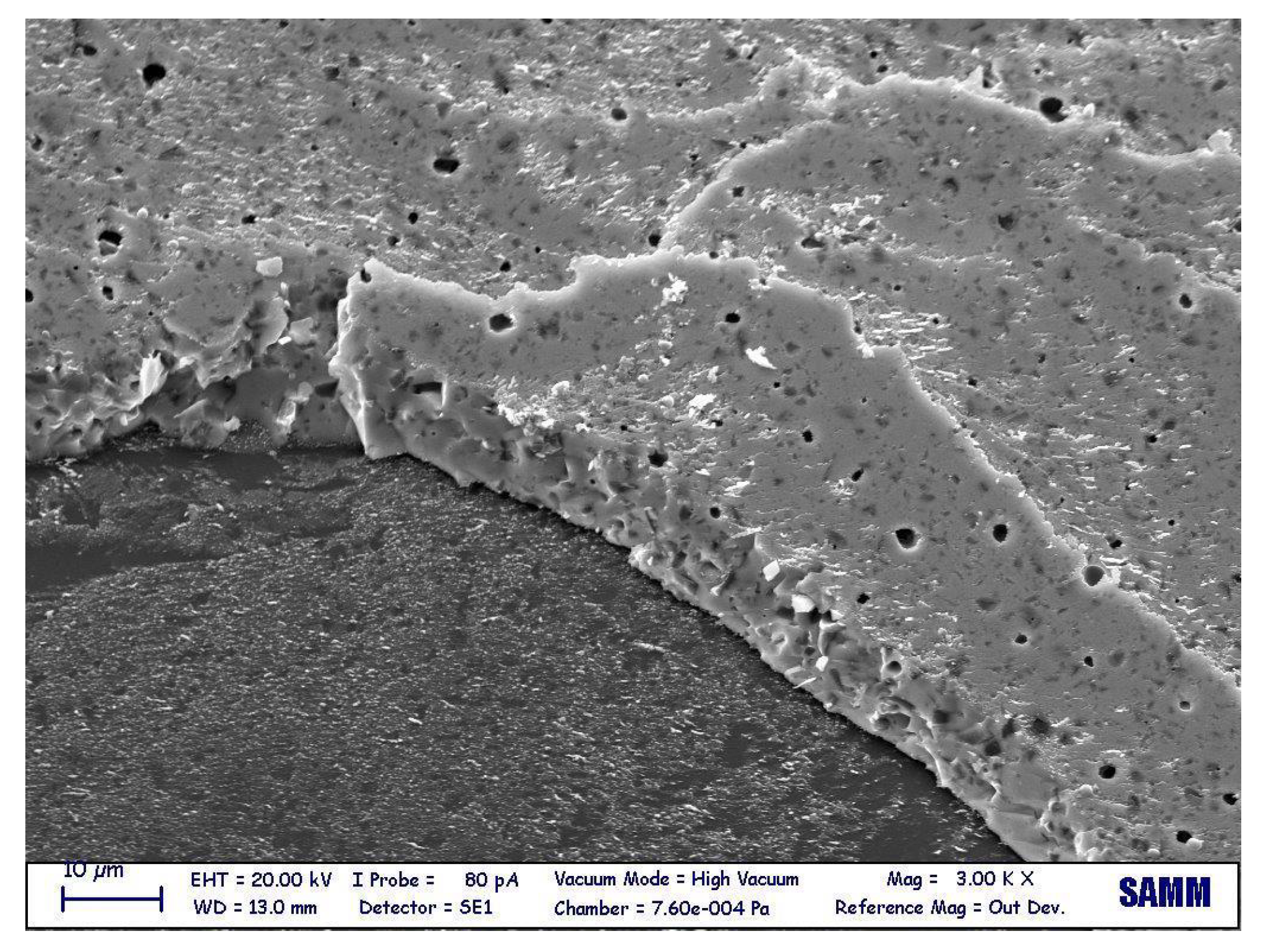

A SEM observation was carried out to characterize the microstructural features of the gf film. The image, obtained in backscattered electron beam mode, is shown in

Figure 4 and demonstrates the dual-phase morphology, in the sense of distribution of a darker filler (Al

O

) in a brighter matrix (PbO). Initially, the filler area ratio was calculated by image processing, obtaining 17.3%.

Next, for a deeper study, EDX was performed on each phase to obtain the chemical components. Based on the results of this test, shown in

Figure 5, the chemical composition of the matrix appeared to be lead, while cordierite ((Mg,Fe)

Al

(Si

AlO

)) was detected as the secondary phase.

Notable remarks related to gf are the following: by increasing the amount of lead in lead silicate glass, the hardness of the material decreases [

29]; the kinetics of phase separation and inter-phase atomic diffusion in lead-silicate glasses starts at 500 °C [

30]. Hence, during the bonding process, where the maximum temperature is below the aforementioned value at about 440 °C, the phase ratio and distribution will not change.

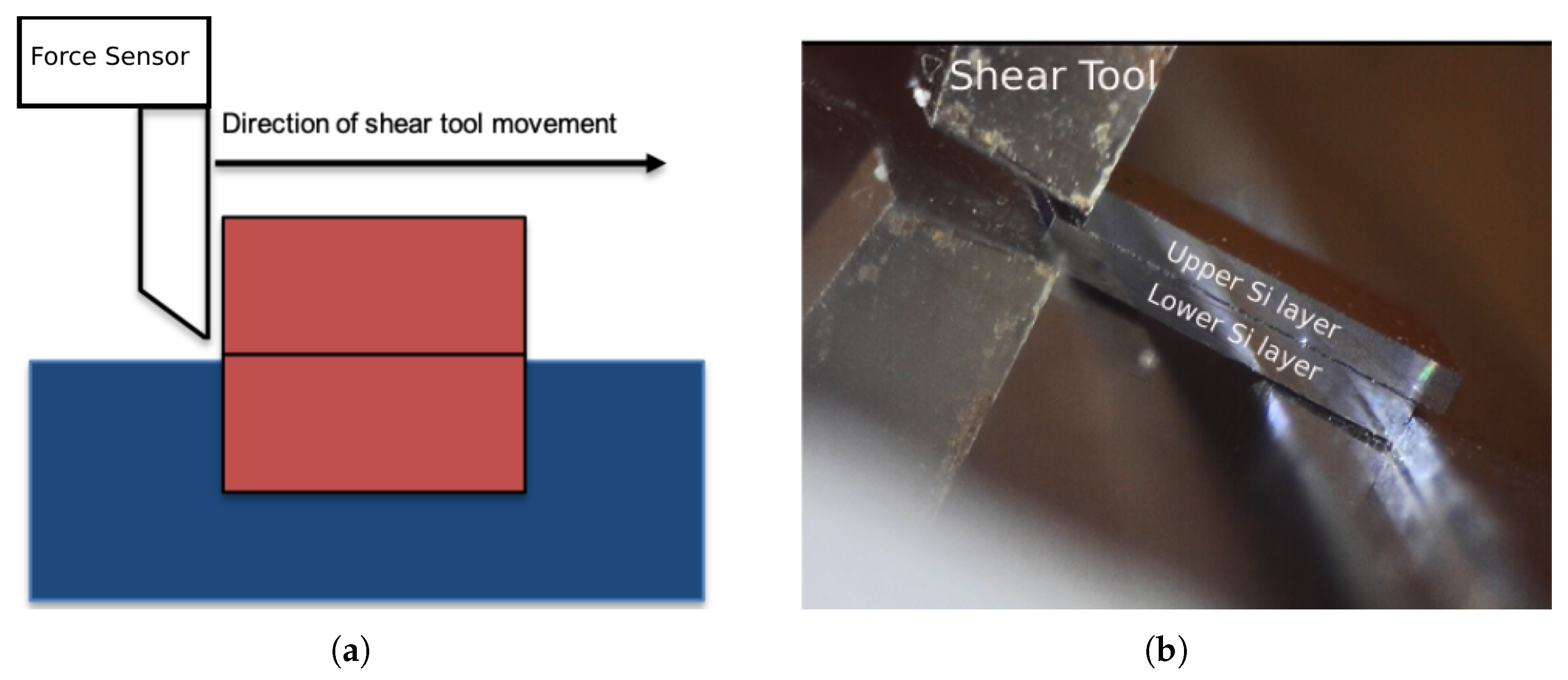

2.4. Die Shear Test

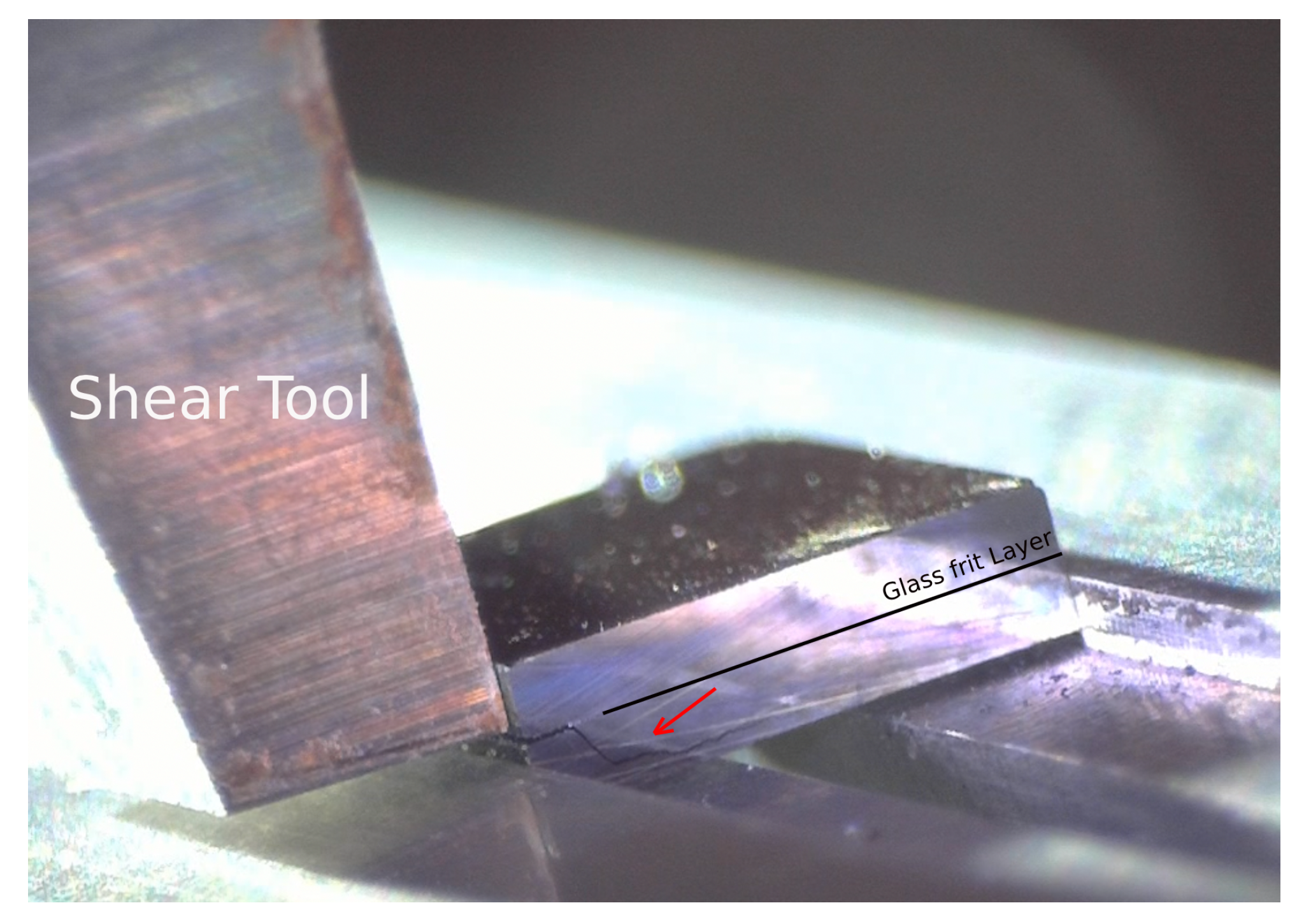

The mechanical strength and reliability of silicon dies bonded by gf were measured by die shear tests, according to the standard MIL-STD-883E [

31]. In these tests, for a single closed and naked die, the upper silicon cap was displaced by a metallic tool, while the silicon substrate was held in place by a convenient grip (

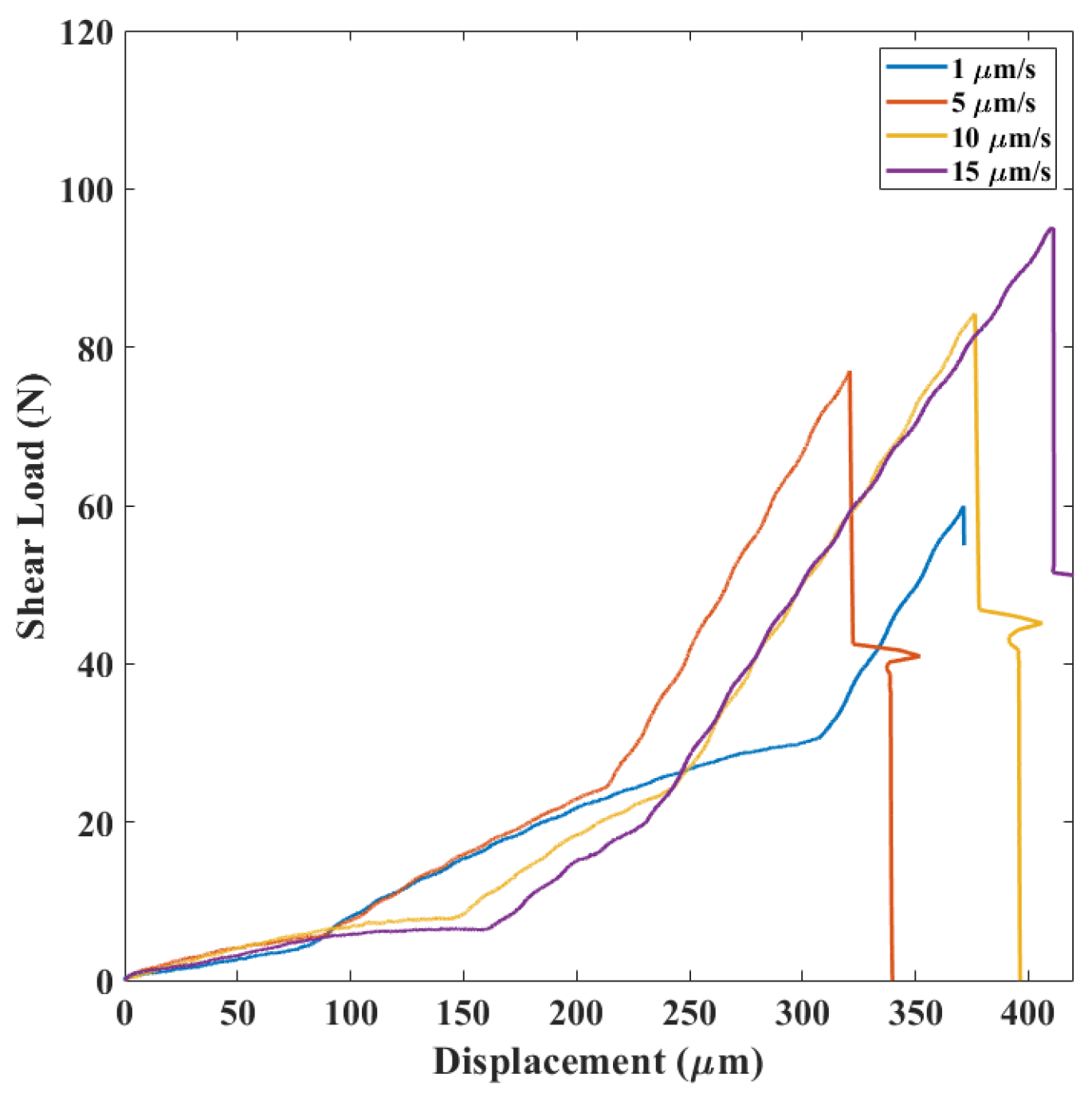

Figure 6a); a Condor Sigma Lite machine by XYZTEC was used. During the tests, the tool displacement was imposed and the reaction force, as obtained by the force sensor at the tool itself, was measured. In the standard, the failure load determines the sufficient bonding strength with respect to the die size; in this work the test was carried out at different displacement rates (1, 5, 10, and 15

m/s) to study the gf behaviour. In total, 65 post bond specimens were tested. To control and investigate the detachment behaviour under shear load, the tests were observed by a DinoLite USB microscope as shown in

Figure 6b, which could magnify the image up to 140% in the long focal distance.

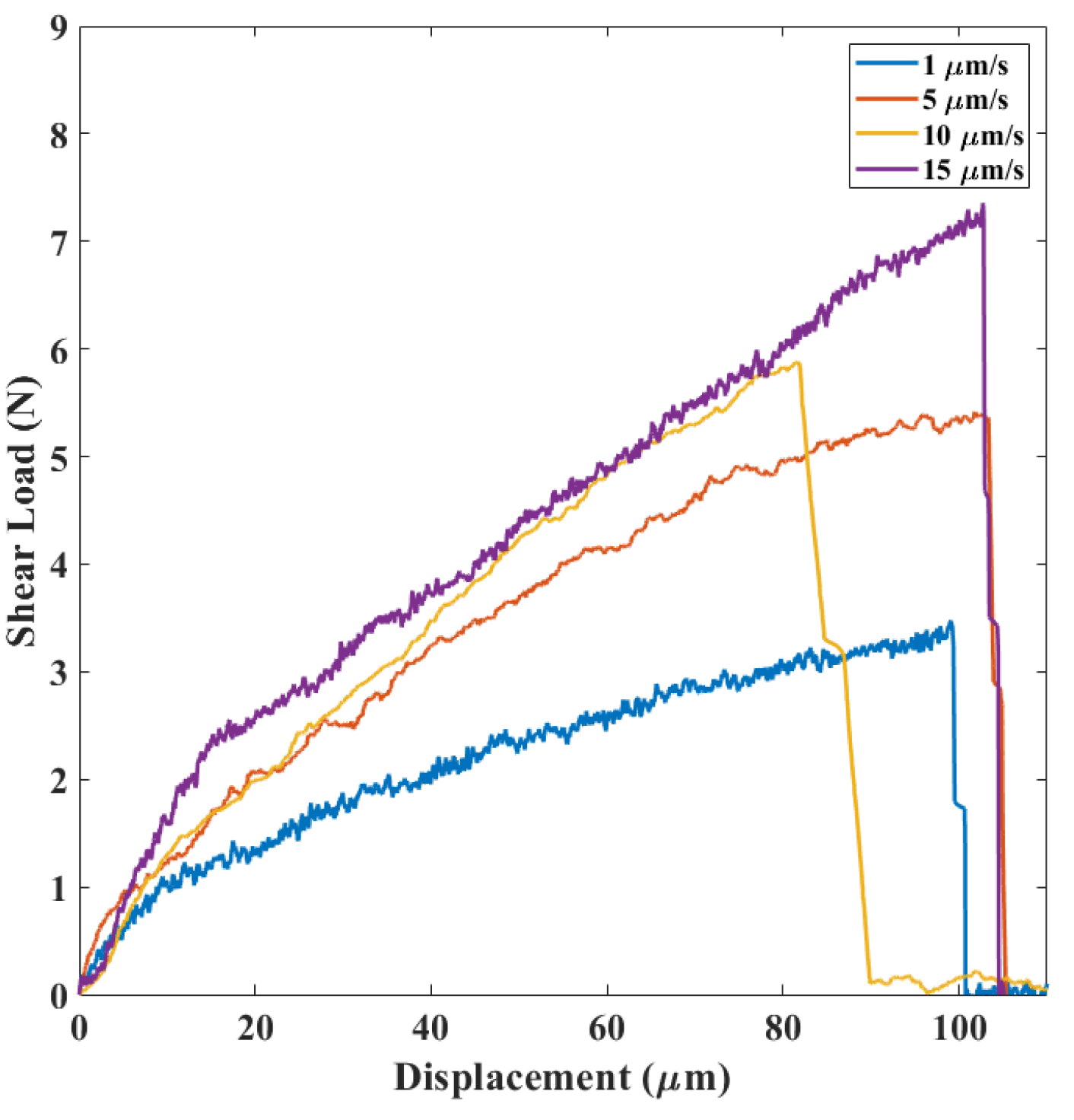

The results of the die shear tests could be categorized into three groups based on the load-displacement curves and the detachment behavior of the upper silicon layer.

In category A, see

Figure 7, a nonlinear relationship between shear load and displacement with progressive stiffness reduction was observed. Moreover, after completion of debonding, the upper part of the silicon die was displaced in the direction of the load applied by the shear tool.

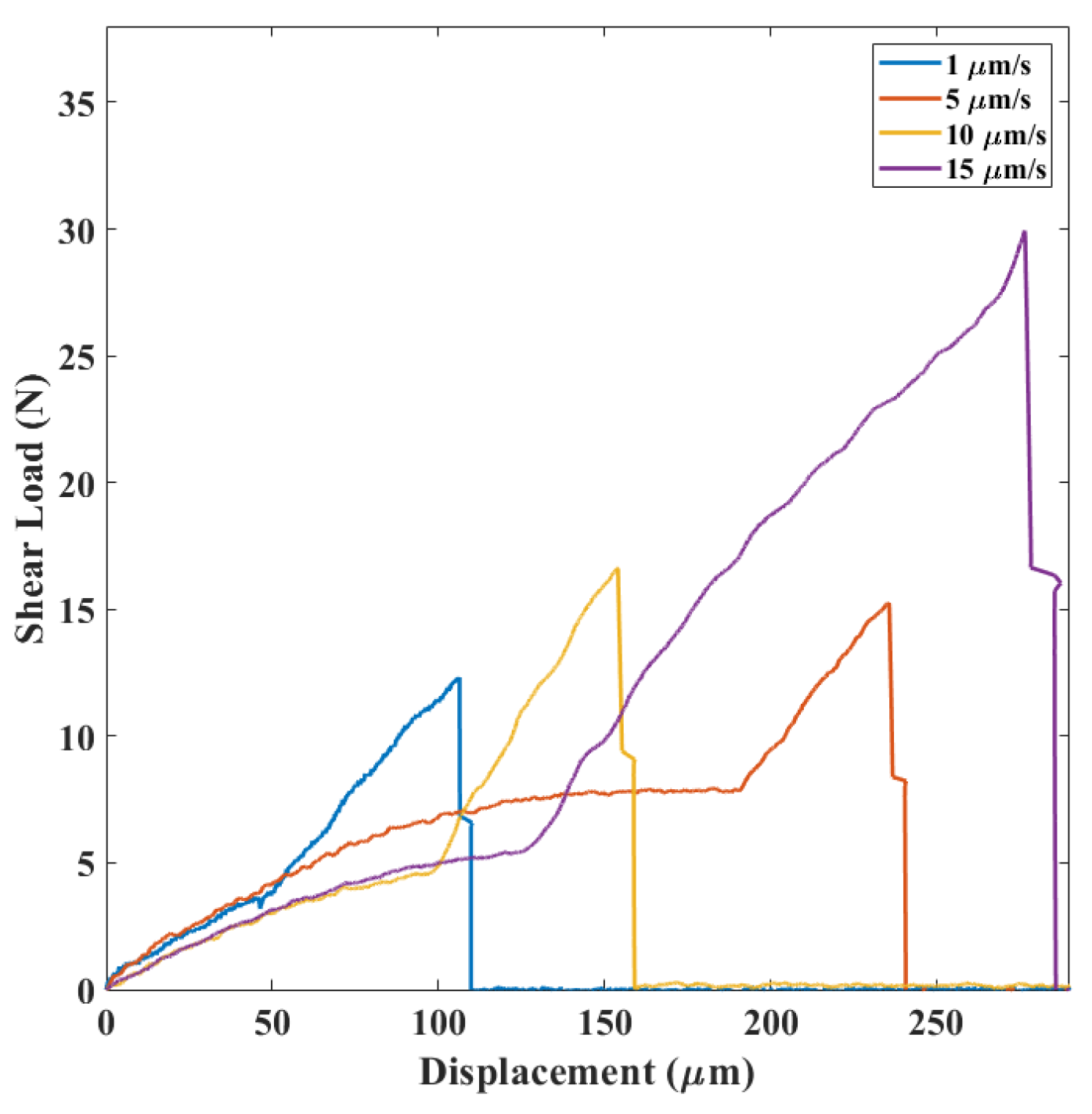

In category B, see

Figure 8, a sudden increase of stiffness was observed after a behavior similar to the first case. The upper part of the silicon die experienced a rapid displacement in the load direction and normal to it.

In category C, see

Figure 9, a three-part curve was obtained. Crack initiation and propagation within the silicon layer was noticed in these cases.

In category A, after die failure, the gf layer remained almost intact, as shown in

Figure 10a. Furthermore, cracks were detected on the fracture surface of gf via SEM, see

Figure 10b. These implied that in this category mode-II fracture (pure shear mode) occurred at the Si–gf interface.

Spherical lead particles were also observable on the fracture surface after debonding, see

Figure 11. The same appearance was reported for the fracture surface after gf debonding in the mode-I fracture (opening mode) by Dresbach et al. [

12].

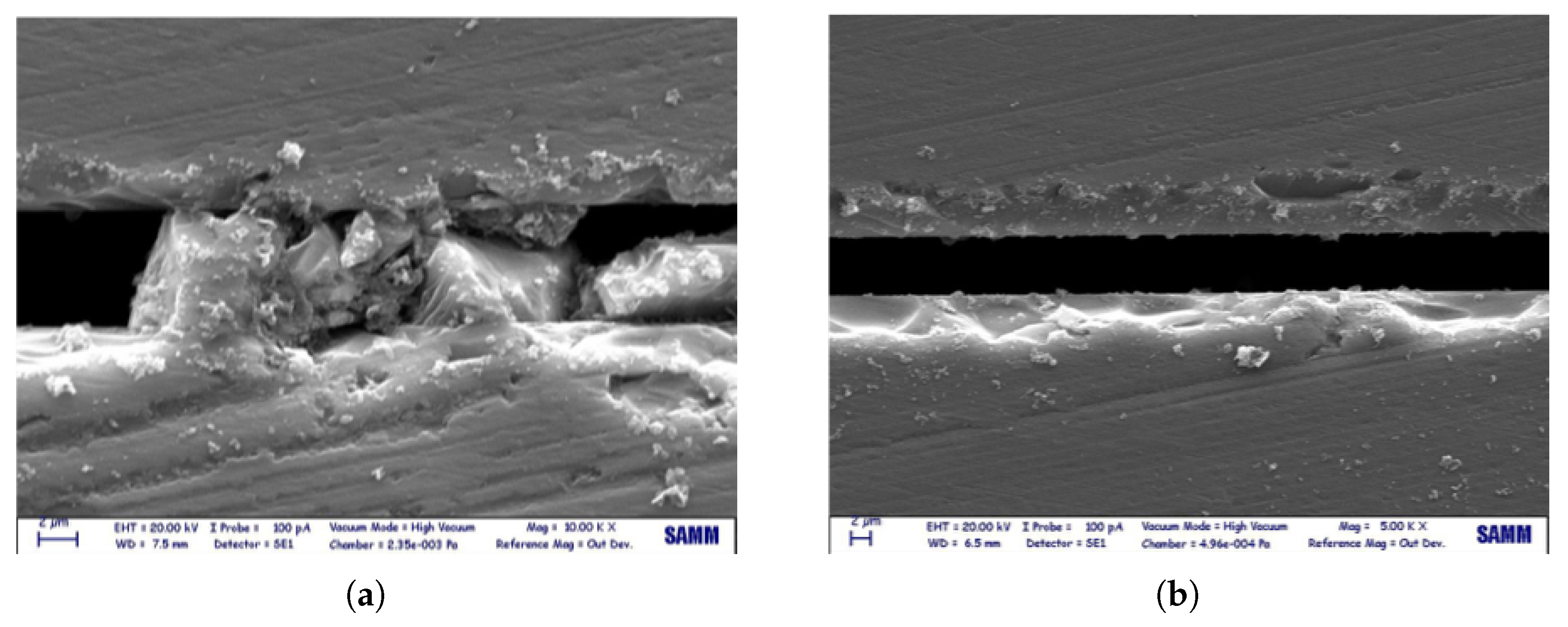

The failure mechanisms for the categories B and C stem most probably from the dicing as a subsequent step after thermo-mechanical bonding during the microsystem fabrication. Dicing left silicon debris at the interspace between silicon layers in the die; moreover, it introduced microcracks and defects in the silicon layer, where material is mechanically susceptible because of the higher stress intensity.

Figure 12 shows dicing effects on a single die bonded with gf.

In failure category B, the presence of silicon debris led to deviation of the effective applied load from the tangential to the normal direction with respect to the gf plane. The silicon layer experienced a projectile motion after debonding. Moreover,

Figure 13, which is a SEM image of the fracture surface failure in this category, shows a crack propagation perpendicular to the gf layer. It was concluded that the failure mechanism corresponding to this behaviour was a mix of mode-I and mode-II fracture, and the additional linear part of the load-displacement curve with respect to category A was originated from an additional mode-I fracture opening.

In category C, the die failed because of a silicon rupture, most probably by propagation of the cracks initiated at the defects of the pre-existing microcracks brought in by the dicing saw and then deviated into the silicon layer (see

Figure 14). Since the silicon layer mechanical strength is significantly higher than the gf layer’s strength, the peak load was higher among all failure mechanisms.

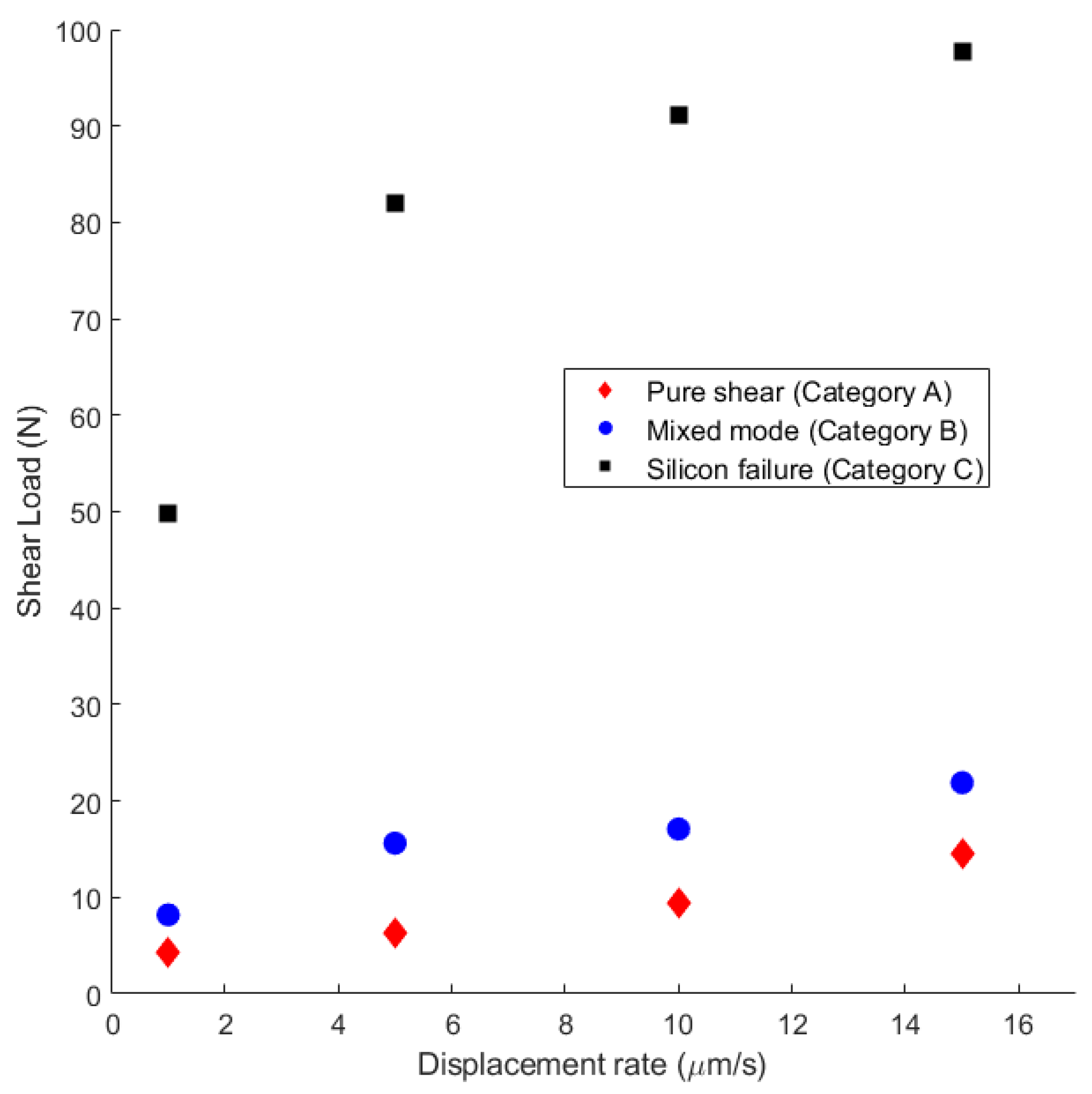

By studying the relationship between the average shear load and the displacement rate for each mechanism (

Figure 15) at different applied displacement rates in the range 1–15

m/s, all the failure mechanisms were observed. Second, regardless of the mechanism, the higher the displacement rate, the higher the failure load was. Moreover, by comparing the load-displacement curves for different failure mechanisms (

Figure 7,

Figure 8 and

Figure 9), the slope of each region was constant at different strain rates, indicating that each region belonged to a specific failure mechanism.

It can be concluded that there was a competition between each mechanism, and depending on the condition of the die under the test, the failure occurred following a specific mechanism.

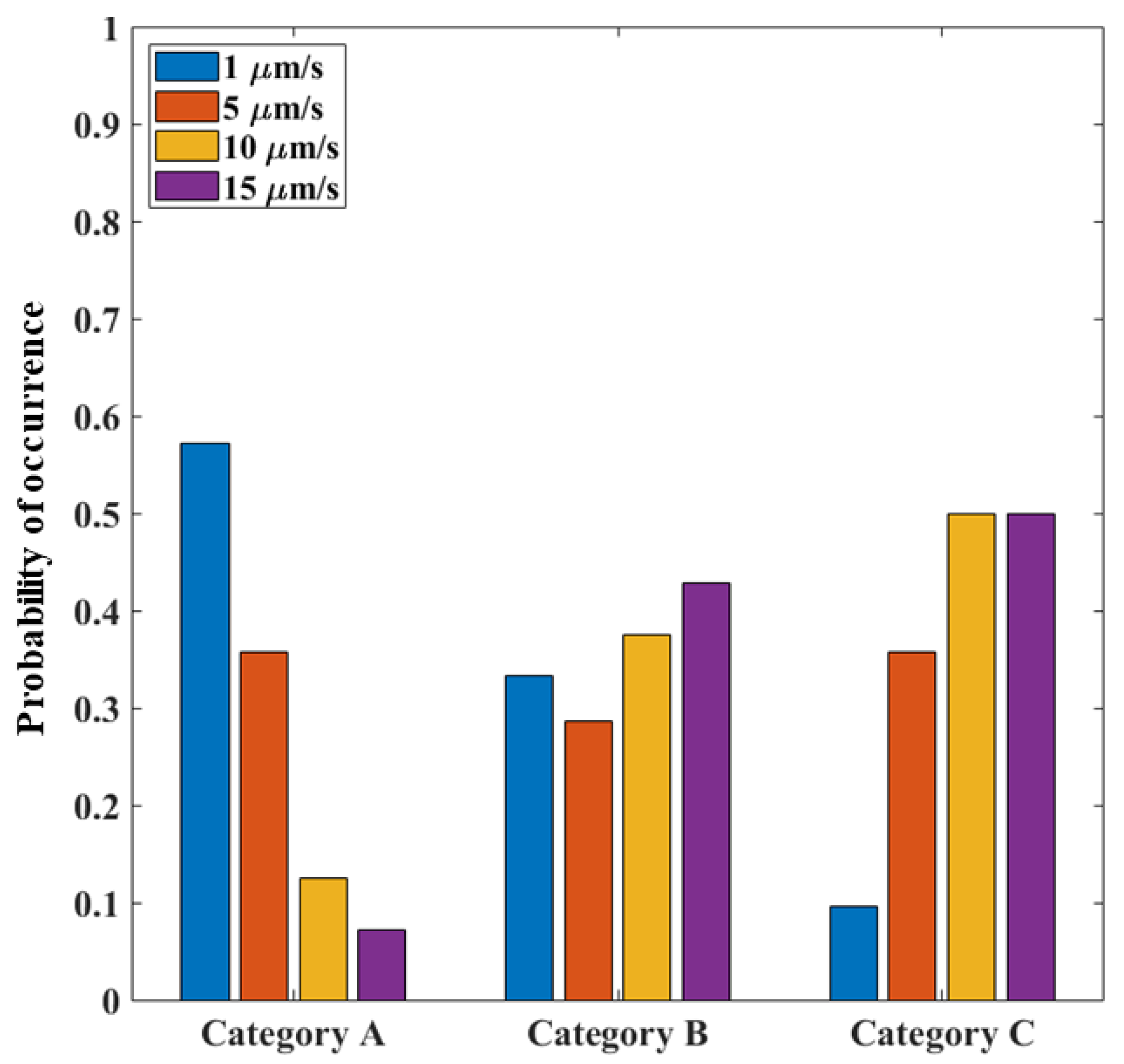

To investigate the effect of strain rate on the probability of occurrence related to a failure category, the percentage of each failure mechanism at a given strain rate was calculated and shown in

Figure 16. The results showed that the category A (pure mode-II failure) was highly probable at the lower displacement rates, since the lower rate was not high enough for the dislocation of the debris or the creation of cracks in silicon, and the die failed at the Si−gf interface.

Category C (silicon rupture) mainly occurred instead at high strain rates due to the vulnerability to defects at higher strain rates.

For the mixed mode mechanism related to category B, the probability was found at similar values for all the applied displacement rates because of the presence of silicon debris at the silicon layer interstices with randomly distributed sizes.

Both for category B and C, the load was higher than for category A because the crack path diverged from the purely horizontal (shear-induced) direction and started deviating slightly inside the gf layer itself or inside the silicon layers; globally, the resistance appeared to increase. This behaviour confirmed the good quality of the attained gf bonding.

In view of all the considerations above, category B and C responses could not be included in the interface strength characterization because of the mode mixity and of the crack propagation variability.

Table 4,

Table 5 and

Table 6 show the nominal shear strength (defined as the horizontal force over gf area) for different failure mechanisms. It should be emphasised that since the crack surface in categories B and C deviated from the Si–gf interface and because of the complete rupture (i.e., destruction) of the specimen (in category C), there was no possibility to measure the fracture surface; therefore, the reader should understand that the true shear stress for these mechanisms would be different. As presented in

Figure 6, failure by pure shear mode (category A) was a subset with respect to the two other failure types, and it could not be strictly considered as the die strength., However, it only represented the strength of the Si–gf interface in the mode-II fracture, i.e., a lower bound.