Dahl Friction Model for Driving Characteristics of V-Shape Linear Ultrasonic Motors

Abstract

:1. Introduction

2. Friction Modelling of the Stator/Slider

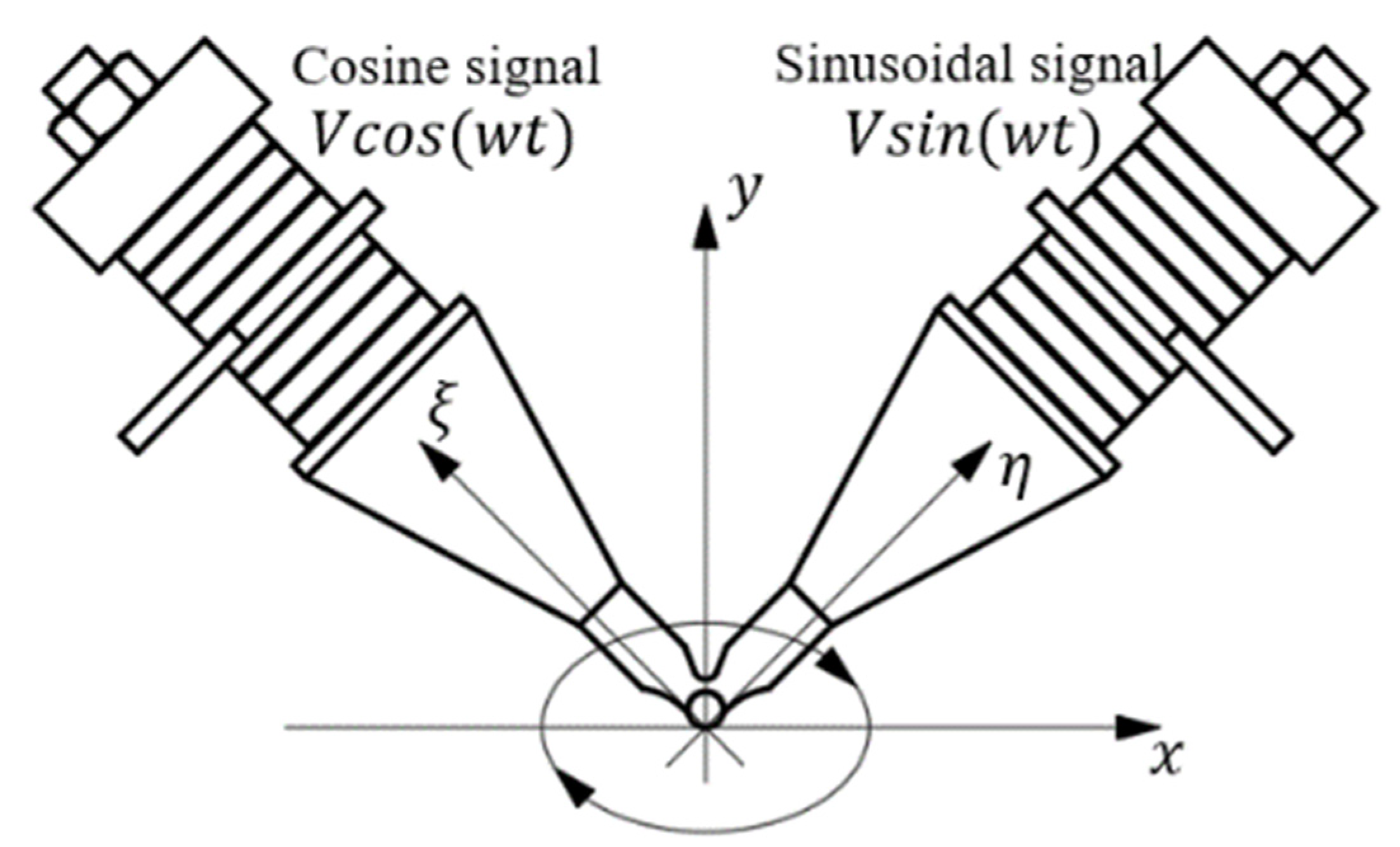

2.1. Elliptic Motion at the End of Stator Tip

2.2. Dynamic Normal Force Analysis

2.3. Dynamic Tangential Force Analysis

3. Driving Characteristic Simulation

3.1. Simulation Flowchart and Parameters

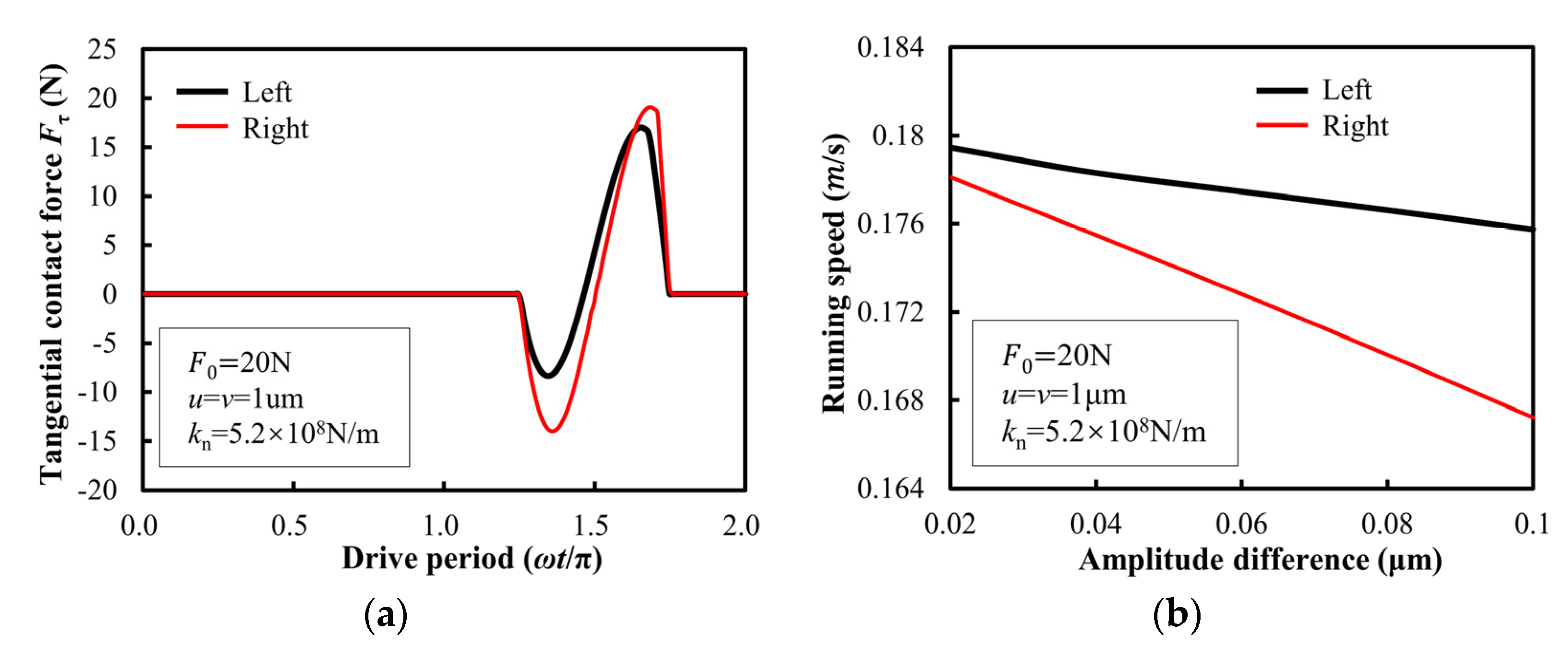

3.2. Tangential Contact Force

3.3. Asymmetry of Forwarding and Reverse Speeds

4. Experimental Detail and Results

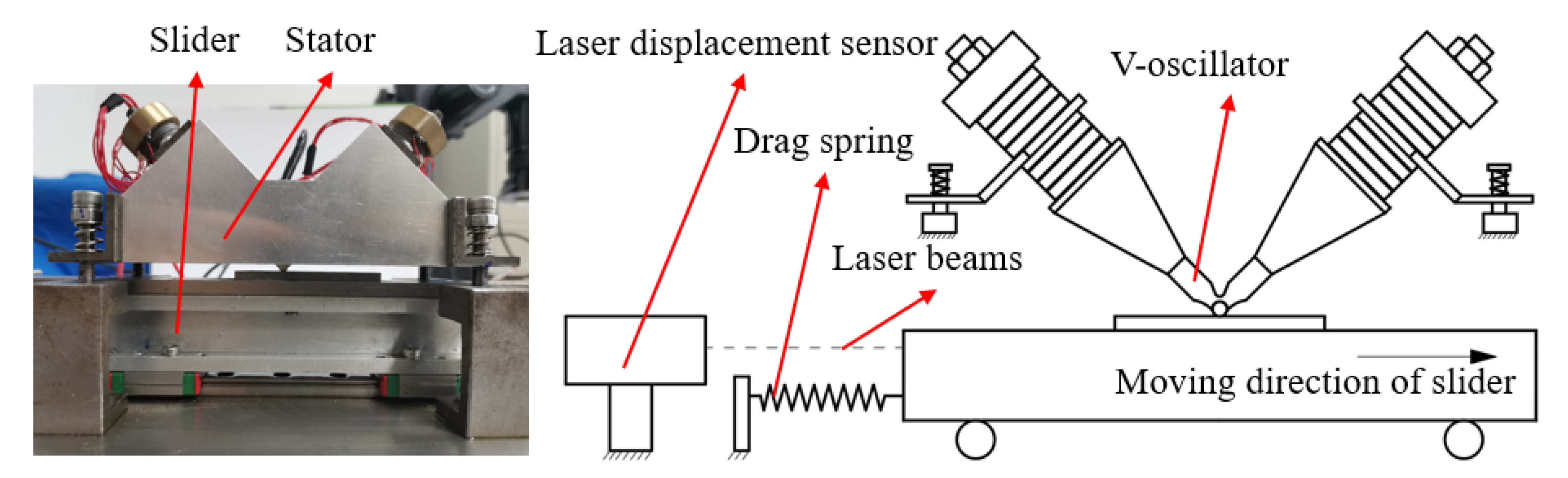

4.1. Experimental Apparatus and Test Method

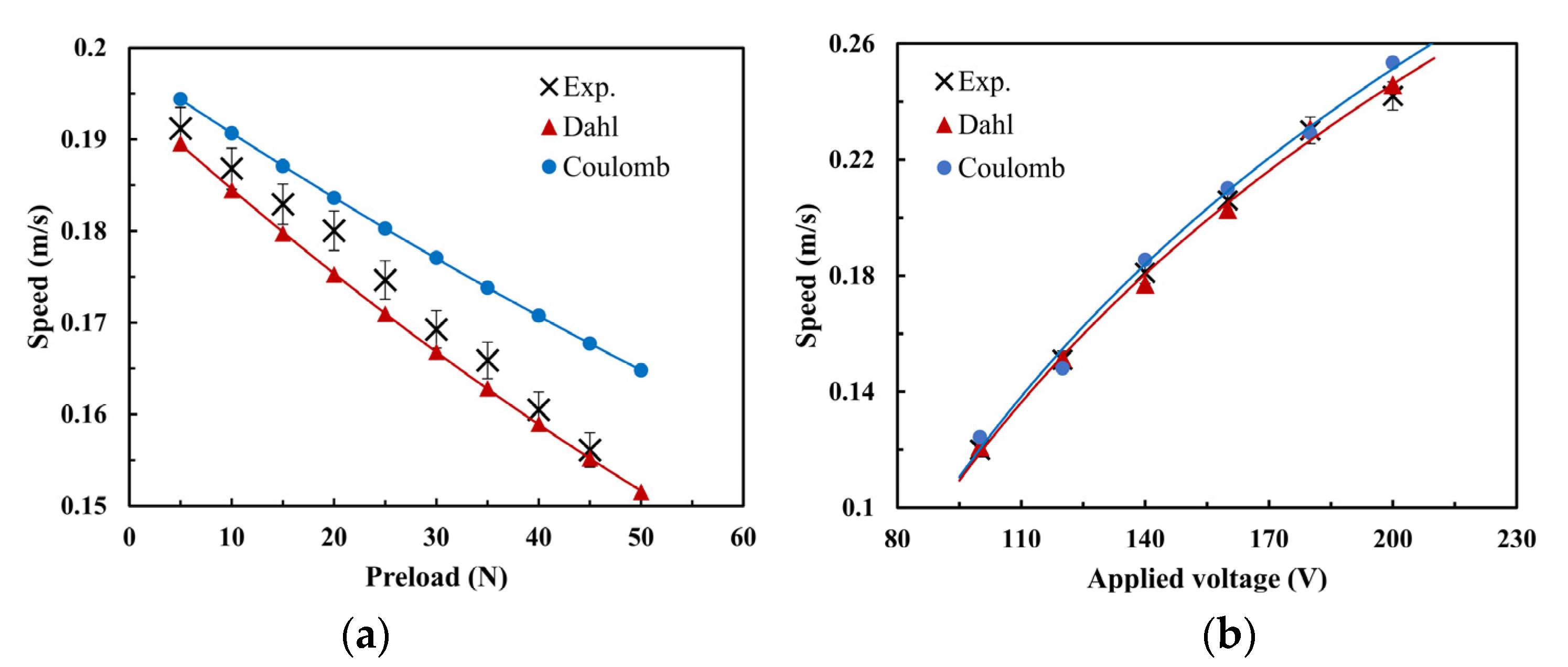

4.2. Experimental Verification

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Gao, X.; Yang, J.; Wu, J.; Xin, X.; Li, Z.; Yuan, X.; Shen, X.; Dong, S. Piezoelectric Actuators and Motors: Materials, Designs, and Applications. Adv. Mater. Technol. 2020, 5, 1900716. [Google Scholar] [CrossRef]

- Tian, X.; Liu, Y.; Deng, J.; Wang, L.; Chen, W. A review on piezoelectric ultrasonic motors for the past decade: Classification, operating principle, performance, and future work perspectives. Sens. Actuators A Phys. 2020, 306, 111971. [Google Scholar] [CrossRef]

- Lu, D.; Lin, Q.; Chen, B.; Jiang, C.; Hu, X. A single-modal linear ultrasonic motor based on multi vibration modes of PZT ceramics. Ultrasonics 2020, 107, 106158. [Google Scholar] [CrossRef]

- Kurosawa, M.K.; Kodaira, O.; Tsuchitoi, Y.; Higuchi, T. Transducer for high speed and large thrust ultrasonic linear motor using two sandwich-type vibrators. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 1998, 45, 1188–1195. [Google Scholar] [CrossRef]

- Nakamura, K.; Ueha, S. Potential ability of ultrasonic motors: A discussion focused on the friction control mechanism. Electron. Commun. Jpn. 1998, 81, 57–68. [Google Scholar] [CrossRef]

- Wallaschek, J. Contact mechanics of piezoelectric ultrasonic motors. Smart Mater. Struct. 1998, 7, 369–381. [Google Scholar] [CrossRef]

- Ryndzionek, R.; Sienkiewicz, L. A review of recent advances in the single- and multi-degree-of-freedom ultrasonic piezoelectric motors. Ultrasonics 2021, 116, 106471. [Google Scholar] [CrossRef]

- Liu, Y.; Deng, J.; Su, Q. Review on Multi-Degree-of-Freedom Piezoelectric Motion Stage. IEEE Access 2018, 6, 59986–60004. [Google Scholar] [CrossRef]

- Snitka, V. Ultrasonic actuators for nanometre positioning. Ultrasonics 2000, 38, 20–25. [Google Scholar] [CrossRef]

- Liu, Y.; Chen, W.; Liu, J.; Yang, X. A High-Power Linear Ultrasonic Motor Using Bending Vibration Transducer. IEEE Trans. Ind. Electron. 2012, 60, 5160–5166. (In English) [Google Scholar] [CrossRef]

- Tanoue, Y.; Morita, T. Opposing preloads type ultrasonic linear motor with quadruped stator. Sens. Actuators A Phys. 2020, 301, 111764. [Google Scholar] [CrossRef]

- Behera, B. Micro motion of a piezoelectric linear actuator driven by liquid interacting with Rayleigh surface acoustic wave. Sens. Actuators A Phys. 2021, 331, 112756. [Google Scholar] [CrossRef]

- Sanikhani, H.; Akbari, J. Design and analysis of an elliptical-shaped linear ultrasonic motor. Sens. Actuators A Phys. 2018, 278, 67–77. [Google Scholar] [CrossRef]

- Kim, S.-C.; Kim, S.H. A precision linear actuator using piezoelectrically driven friction force. Mechatronics 2001, 11, 969–985. [Google Scholar] [CrossRef]

- Ho, S.-T.; Jan, S.-J. A piezoelectric motor for precision positioning applications. Precis. Eng. 2016, 43, 285–293. [Google Scholar] [CrossRef]

- Chen, Y.; Zhou, T.Y.; Zhang, Q.; Chen, X.Y.; Chen, S.H. A study on the friction of a self-correction ultrasonic stepping motor. Ultrasonics 2002, 39, 667–671. [Google Scholar] [CrossRef]

- Yun, C.-H.; Ishii, T.; Nakamura, K.; Ueha, S.; Akashi, K. A High Power Ultrasonic Linear Motor Using a Longitudinal and Bending Hybrid Bolt-Clamped Langevin Type Transducer. Jpn. J. Appl. Phys. 2001, 40, 3773–3776. [Google Scholar] [CrossRef]

- Delibas, B.; Koc, B. A Method to Realize Low Velocity Movability and Eliminate Friction Induced Noise in Piezoelectric Ultrasonic Motors. IEEE/ASME Trans. Mechatron. 2020, 25, 2677–2687. [Google Scholar] [CrossRef]

- Ming, M.; Liang, W.; Feng, Z.; Ling, J.; Al Mamun, A.; Xiao, X. PID-type sliding mode-based adaptive motion control of a 2-DOF piezoelectric ultrasonic motor driven stage. Mechatronics 2021, 76, 102543. [Google Scholar] [CrossRef]

- Makarem, S.; Delibas, B.; Koc, B. Data-Driven Tuning of PID Controlled Piezoelectric Ultrasonic Motor. Actuators 2021, 10, 148. [Google Scholar] [CrossRef]

- Liang, W.; Ma, J.; Ng, C.; Ren, Q.; Huang, S.; Tan, K.K. Optimal and intelligent motion control scheme for an Ultrasonic-Motor-Driven X-Y stage. Mechatronics 2019, 59, 127–139. [Google Scholar] [CrossRef]

- Zhang, Y.; Jin, X.; Yuan, X.; Zhou, Y.; Zhou, Y.; Han, L.; Li, J.; Ni, Z.; Wang, X. Measurement and evaluation on mechanical performances of standing-wave piezoelectric motor of V-shaped sandwich-type transducer having arc tip. Measurement 2022, 190, 110766. [Google Scholar] [CrossRef]

- Yan, Y.; Yang, M.; Yang, T.; Ye, S.; Jiang, W. Speed Sensorless Control of Linear Ultrasonic Motors Based on Stator Vibration Amplitude Compensation. Sensors 2020, 20, 6705. [Google Scholar] [CrossRef]

- Endo, A.; Sasaki, N. Investigation of Frictional Material for Ultrasonic Motor. Jpn. J. Appl. Phys. 1987, 26, 197. [Google Scholar] [CrossRef]

- Ishii, T.; Ueha, S.; Nakamura, K.; Ohnishi, K. Wear Properties and Life Prediction of Frictional Materials for Ultrasonic Motors. Jpn. J. Appl. Phys. 1995, 34, 2765–2770. [Google Scholar] [CrossRef]

- Rehbein, P.; Wallaschek, J. Friction and wear behaviour of polymer/steel and alumina/alumina under high-frequency fretting conditions. Wear 1998, 216, 97–105. [Google Scholar] [CrossRef]

- Ko, H.-P.; Kim, S.; Kim, J.-S.; Kim, H.-J.; Yoon, S.-J. Wear and dynamic properties of piezoelectric ultrasonic motor with frictional materials coated stator. Mater. Chem. Phys. 2005, 90, 391–395. [Google Scholar] [CrossRef]

- Kummel, M.; Goldschmidt, S.; Wallaschek, J. Theoretical and experimental studies of a piezoelectric ultrasonic linear motor with respect to damping and nonlinear material behaviour. Ultrasonics 1998, 36, 103–109. (In English) [Google Scholar] [CrossRef]

- Zhang, Y.; Qu, J.; Wang, H. Wear Characteristics of Metallic Counterparts under Elliptical-Locus Ultrasonic Vibration. Appl. Sci. 2016, 6, 289. [Google Scholar] [CrossRef]

- Shi, M.; Liu, X.; Feng, K.; Zhang, K. Experimental and numerical investigation of a self-adapting non-contact ultrasonic motor. Tribol. Int. 2021, 153, 106624. [Google Scholar] [CrossRef]

- Gong, Z.; Zhang, Y.; Fu, H.; Zhou, Y.; Liang, H.; Ji, J. Fracture behaviours of brittle ceramics under elliptical ultrasonic vibration: Near-to-limit contact analysis of an elastic flat punch. Int. J. Mech. Mater. Des. 2021, 17, 969–986. [Google Scholar] [CrossRef]

- Hu, J.; Li, G.; Chan, H.L.W.; Choy, C.L. A standing wave-type noncontact linear ultrasonic motor. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2001, 48, 699–708. (In English) [Google Scholar] [PubMed]

- Kim, T.-Y.; Kim, B.-J.; Park, T.-G.; Kim, M.-H.; Uchino, K. Design and driving characteristics of ultrasonic linear motor. Ferroelectrics 2001, 263, 113–118. [Google Scholar] [CrossRef]

- Mracek, M.; Hemsel, T. Synergetic driving concepts for bundled miniature ultrasonic linear motors. Ultrasonics 2006, 44, e597–e602. [Google Scholar] [CrossRef]

- Qu, H.; Liu, C.; Zhang, L.; Qu, J.; Song, B. A Longitudinal-Bending Hybrid Linear Ultrasonic Motor and Its Driving Characteristic. Shock Vib. 2022, 2022, 5701014. [Google Scholar] [CrossRef]

- Qiu, W.; Mizuno, Y.; Adachi, K.; Nakamura, K. Ultrasonic motor performance influenced by lubricant properties. Sens. Actuators A Phys. 2018, 282, 183–191. [Google Scholar] [CrossRef]

- Liu, X.; Huang, X.; Zhang, J.; Sun, W. Influence mechanism of surface texture on the output performance of an ultrasonic motor. Ind. Lubr. Tribol. 2021, 73, 750–755. [Google Scholar] [CrossRef]

- Qiu, W.; Mizuno, Y.; Nakamura, K. Tribological performance of ceramics in lubricated ultrasonic motors. Wear 2016, 352–353, 188–195. [Google Scholar] [CrossRef]

- Zhang, Y.; Fu, Y.; Hua, X.; Quan, L.; Qu, J. Characteristics and attenuation mechanism of linear standing-wave piezoelectric motors with ceramics-mated friction couples. Tribol. Int. 2021, 153, 106580. [Google Scholar] [CrossRef]

- Zhou, L.; Yao, Z.; Dai, S.; He, Y.; Xu, H. Modeling and verification of life prediction of a V-shaped linear ultrasonic motor. Rev. Sci. Instrum. 2021, 92, 045003. [Google Scholar] [CrossRef]

- Ishii, T.; Matsuo, E.; Nakamura, K.; Ueha, S.; Ohnishi, K. Characteristics of Ultrasonic Motors Driven in a Vacuum. Jpn. J. Appl. Phys. 1998, 37, 2956–2959. [Google Scholar] [CrossRef]

- Li, J.; Wang, Y.; Chen, Z.; Cheng, F.; Yu, Q. A Compact Linear Ultrasonic Motor Composed by Double Flexural Vibrator. Micromachines 2021, 12, 958. [Google Scholar] [CrossRef] [PubMed]

- Li, H.; Deng, J.; Zhang, S.; Yu, H.; Liu, Y. Design and experiment of a three-feet linear ultrasonic motor using third bending hybrid modes. Sens. Actuators A Phys. 2021, 331, 112990. [Google Scholar] [CrossRef]

- Zhang, J.J.; Diao, W.D.; Fan, K.; Wang, Z.Q.; Shi, R.Q.; Feng, Z.H. A miniature standing wave linear ultrasonic motor. Sens. Actuators A Phys. 2021, 332, 113113. [Google Scholar] [CrossRef]

- Yin, Z.; Dai, C.; Cao, Z.; Li, W.; Chen, Z.; Li, C. Modal analysis and moving performance of a single-mode linear ultrasonic motor. Ultrasonics 2020, 108, 106216. [Google Scholar] [CrossRef]

- Yang, C.-P.; Xie, K.-J.; Chang, J.-Y. Design and simulation of an ultrasonic linear motor with dual piezoelectric actuators. Microsyst. Technol. 2020, 26, 71–78. [Google Scholar] [CrossRef]

- Niu, R.; Zhu, H.; Zhao, C. A four-legged linear ultrasonic motor: Design and experiments. Rev. Sci. Instrum. 2020, 91, 076107. [Google Scholar] [CrossRef]

- Li, X.; Huang, Y.; Zhou, L. Integrated performance improvement for a bimodal linear ultrasonic motor using a dual-frequency asymmetric excitation method. Ultrasonics 2020, 108, 106224. [Google Scholar] [CrossRef]

- Kurosawa, M.; Takahashi, M.; Higuchi, T. Friction drive surface acoustic wave motor. Ultrasonics 1996, 34, 243–246. [Google Scholar] [CrossRef]

- Maeno, T.; Toeda, M. Friction drive mechanisms of ultrasonic motors and their improvement. Jpn. J. Tribol. 2008, 53, 9–16. [Google Scholar]

- Adachi, K.; Kato, K.; Sasatani, Y. The micro-mechanism of friction drive with ultrasonic wave. Wear 1996, 194, 137–142. [Google Scholar] [CrossRef]

- Kurosawa, M.K.; Itoh, H.; Asai, K. Elastic friction drive of surface acoustic wave motor. Ultrasonics 2003, 41, 271–275. [Google Scholar] [CrossRef]

- Littmann, W.; Storck, H.; Wallaschek, J. Sliding friction in the presence of ultrasonic oscillations: Superposition of longitudinal oscillations. Arch. Appl. Mech. 2001, 71, 549–554. [Google Scholar] [CrossRef]

- Dong, S.; Wang, S.; Li, L.; Uchino, K. Frictional Noise and Noise Restraint of the Piezoelectric–Ultrasonic Motor. J. Intell. Mater. Syst. Struct. 2004, 15, 471–478. [Google Scholar] [CrossRef]

- Mukhopadhyay, S.; Behera, B.; Kumar, J. A brief review on the recent evolution in piezoelectric linear ultrasonic motors. Eng. Res. Express 2021, 3, 042003. [Google Scholar] [CrossRef]

- Peled, G.; Yasinov, R.; Karasikov, N. Performance and Applications of L1B2 Ultrasonic Motors. Actuators 2016, 5, 15. [Google Scholar] [CrossRef]

- Zhang, Y.; Qu, J.; Li, J. Friction and wear behavior of linear standing-wave ultrasonic motors with V-shape transducers. Tribol. Int. 2016, 95, 95–108. [Google Scholar] [CrossRef]

- Li, X.; Yao, Z. Analytical modeling and experimental validation of a V-shape piezoelectric ultrasonic transducer. Smart Mater. Struct. 2016, 25, 075026. [Google Scholar] [CrossRef]

- Mo, J.-S.; Qiu, Z.-C.; Wei, J.-Y.; Zhang, X.-M. Adaptive positioning control of an ultrasonic linear motor system. Robot. Comput. Manuf. 2017, 44, 156–173. [Google Scholar] [CrossRef]

- Shi, Y.; Zhao, C.; Zhang, J. Contact analysis and modeling of standing wave linear ultrasonic motor. J. Wuhan Univ. Technol. Sci. Ed. 2011, 26, 1235–1242. [Google Scholar] [CrossRef]

- Wan, Z.; Hu, H. Modeling and experimental analysis of the linear ultrasonic motor with in-plane bending and longitudinal mode. Ultrasonics 2013, 54, 921–928. [Google Scholar] [CrossRef] [PubMed]

- Panusittikorn, W.; Lee, M.C.; Ro, P.I. Modeling and Sliding-Mode Control of Friction-Based Object Transport Using Two-Mode Ultrasonic Excitation. IEEE Trans. Ind. Electron. 2004, 51, 917–926. [Google Scholar] [CrossRef]

- Leus, M.; Gulowski, P. Analysis of longitudinal tangential contact vibration effect on friction force using Coulomb and Dahl models. J. Theor. Appl. Mech. 2008, 46, 171–184. [Google Scholar] [CrossRef]

- Li, X.; Yao, Z.; Wu, R. Modeling and analysis of stick-slip motion in a linear piezoelectric ultrasonic motor considering ultrasonic oscillation effect. Int. J. Mech. Sci. 2016, 107, 215–224. [Google Scholar] [CrossRef]

- Li, X.; Yao, Z.; Lv, Q.; Liu, Z. Modeling stick-slip-separation dynamics in a bimodal standing wave ultrasonic motor. J. Sound Vib. 2016, 382, 140–157. [Google Scholar] [CrossRef]

- Lv, Q.; Yao, Z.; Li, X. Modeling and experimental validation of a linear ultrasonic motor considering rough surface contact. Smart Mater. Struct. 2017, 26, 45023. [Google Scholar] [CrossRef]

- Lv, Q.; Yao, Z.; Li, X. Contact analysis and experimental investigation of a linear ultrasonic motor. Ultrasonics 2017, 81, 32–38. [Google Scholar] [CrossRef]

- Gutowski, P.; Leus, M. Computational model for friction force estimation in sliding motion at transverse tangential vibrations of elastic contact support. Tribol. Int. 2015, 90, 455–462. [Google Scholar] [CrossRef]

- Dahl, P.R. Solid Friction Damping of Mechanical Vibrations. AIAA J. 1976, 14, 1675–1682. [Google Scholar] [CrossRef]

- Li, X.; Chen, Z.; Yao, Z. Contact analysis and performance evaluation of standing-wave linear ultrasonic motors via a physics-based contact model. Smart Mater. Struct. 2018, 28, 015032. [Google Scholar] [CrossRef]

- Mindlin, R.D. Compliance of Elastic Bodies in Contact. J. Appl. Mech. 1949, 16, 259–268. [Google Scholar] [CrossRef]

| Part | Material | Density (g/cm3) | Elastic Modulus (GPa) | Poison’s Ratio |

|---|---|---|---|---|

| End-cover | Brass | 8.73 | 108 | 0.31 |

| Electrode | Copper | 8.96 | 110 | 0.32 |

| Front-cover | 2A12 | 2.70 | 70 | 0.3 |

| Bolt | 304 steel | 7.93 | 209 | 0.24 |

| Nut | 304 steel | 7.93 | 209 | 0.24 |

| Tip | Alumina | 3.70 | 300 | 0.2 |

| Piezo ring | PZT4 | 7.45 | 83.3 | 0.3 |

| Parameter | Symbol | Value | Unit |

|---|---|---|---|

| Elastic modulus of drive tip | E1 | 300 | GPa |

| Vibration amplitude | A | 0.5~4 | μm |

| Stator mass | me | 273 | g |

| Slider mass | ms | 273 | g |

| Applied preload | F0 | 5~50 | N |

| Applied voltage | Vp | 100~200 | V |

| Normal stiffness | kn | 2.0~6.5 × 107 | N/m |

| Tangential stiffness | kt | 0.4~1.3 × 107 | N/m |

| Exciting frequency | f | 32.4 | kHz |

| Surface roughness | Ra | 0.25 | μm |

| Contact ratio coefficient | ca | 0.85~0.99 | − |

| COF of tip and slider | μ | 0.3 | − |

| COF of slider assembly | μd | 0.004 | − |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, B.; Yuan, X.; Zeng, Y.; Lang, L.; Liang, H.; Zhang, Y. Dahl Friction Model for Driving Characteristics of V-Shape Linear Ultrasonic Motors. Micromachines 2022, 13, 1407. https://doi.org/10.3390/mi13091407

Zhang B, Yuan X, Zeng Y, Lang L, Liang H, Zhang Y. Dahl Friction Model for Driving Characteristics of V-Shape Linear Ultrasonic Motors. Micromachines. 2022; 13(9):1407. https://doi.org/10.3390/mi13091407

Chicago/Turabian StyleZhang, Bo, Xianghui Yuan, Yuansong Zeng, Lihui Lang, Hailong Liang, and Yanhu Zhang. 2022. "Dahl Friction Model for Driving Characteristics of V-Shape Linear Ultrasonic Motors" Micromachines 13, no. 9: 1407. https://doi.org/10.3390/mi13091407

APA StyleZhang, B., Yuan, X., Zeng, Y., Lang, L., Liang, H., & Zhang, Y. (2022). Dahl Friction Model for Driving Characteristics of V-Shape Linear Ultrasonic Motors. Micromachines, 13(9), 1407. https://doi.org/10.3390/mi13091407