3.1. Effect of Particle Cutting Force on Surface Material Removal of Fe–C Alloy

The cutting force exerted by particles on the Fe–C alloy workpiece atoms can indirectly reflect the material removal rule and the cutting process, and it is an important physical parameter in the cutting action. In order to investigate the influence of particle cutting velocity on the cutting force variation, the particle cutting force variation under different velocity conditions in the microcutting process was studied.

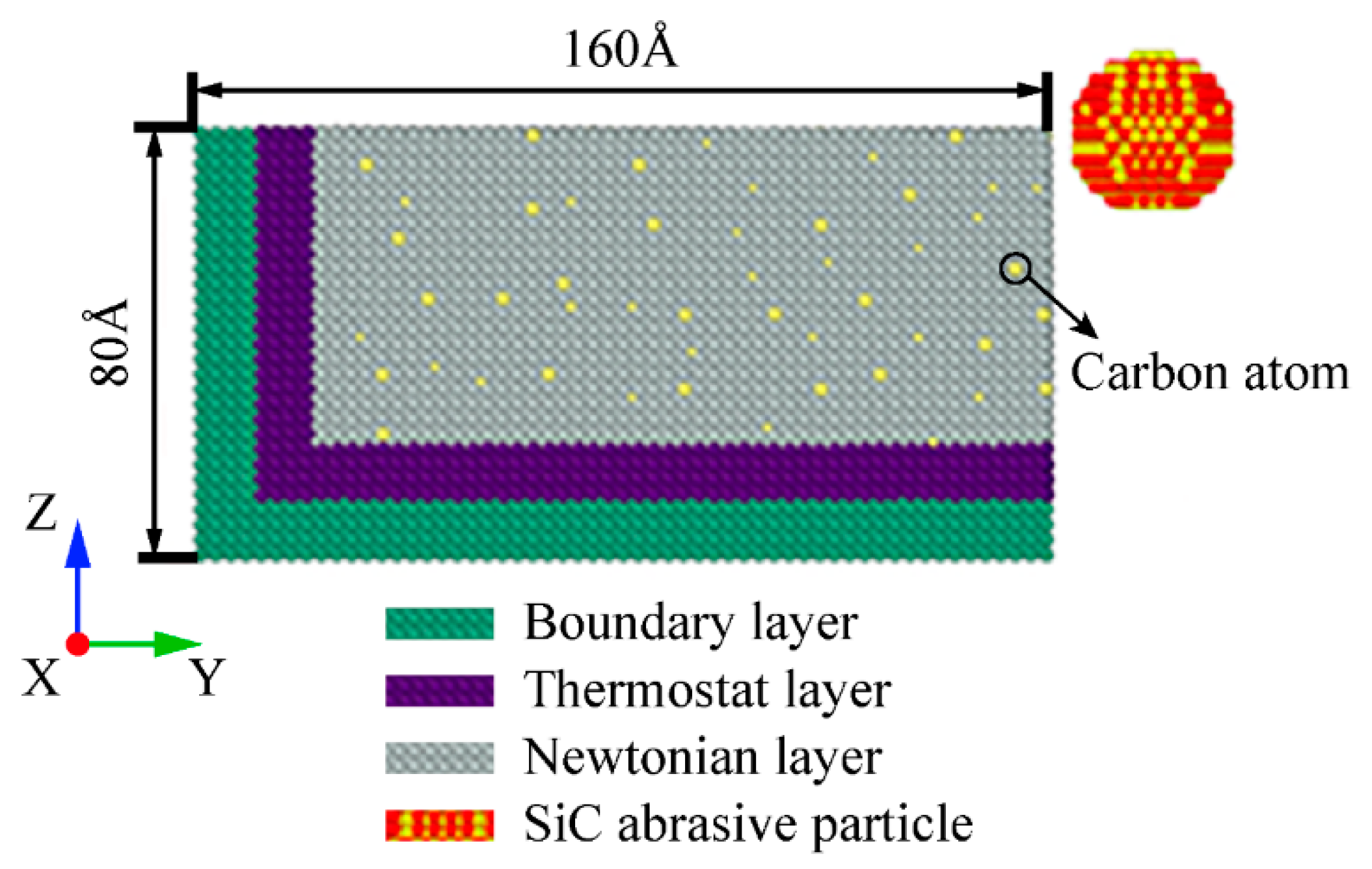

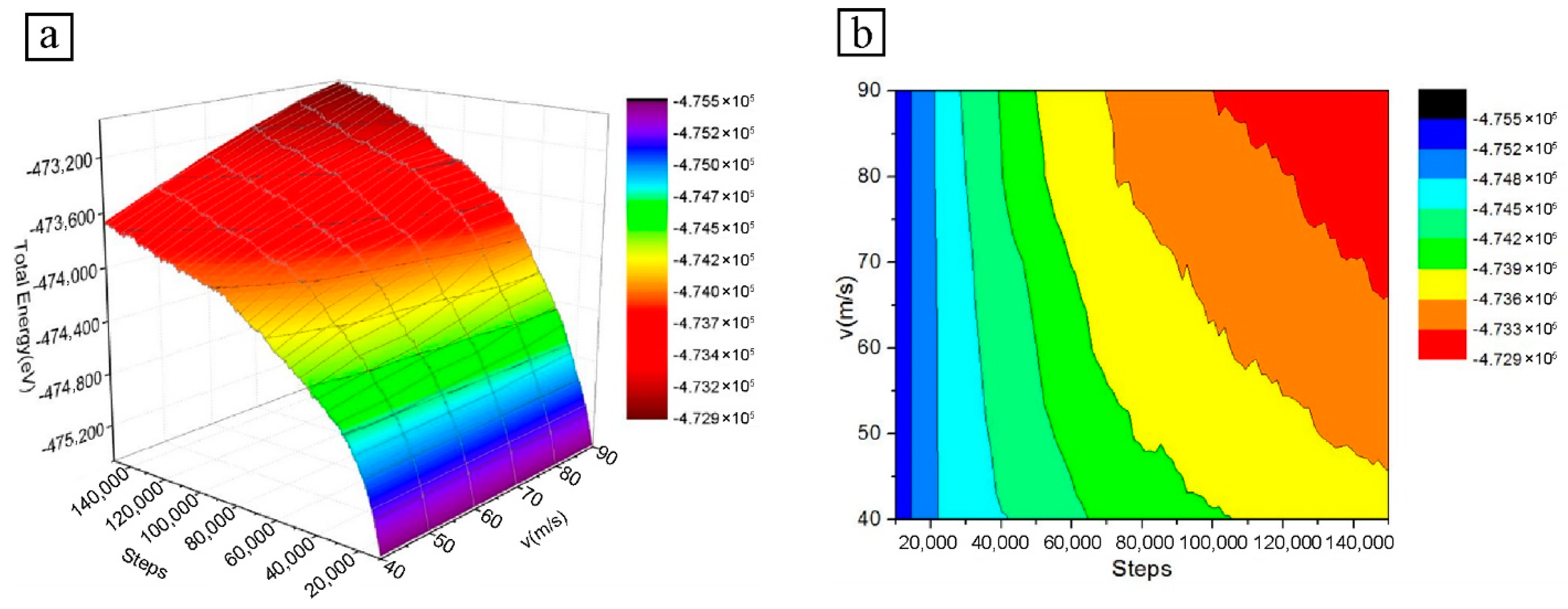

Figure 2 shows the 3D curve diagram and isoline diagram of the cutting force changing with the number of simulated steps at different velocities. Since the cutting force of particles in the X direction comes from the friction between particle atoms and workpiece atoms, Fx only fluctuates up and down along Fx = 0 eV/Å in the cutting process, and its overall trend does not show a significant increase or decrease. The cutting forces Fy and Fz of particles in Y and Z directions gradually increase to a stable value and then continue to fluctuate within a certain range. According to the isoline diagram, with an increase in particle cutting velocity, the cutting forces in both Y and Z directions increase, among which the main cutting force Fy is the most obvious.

At the initial stage of microcutting, the SiC particles and the Fe–C alloy workpiece have not yet made contact, and the cutting force of the particles is a collection of repulsion forces between atoms. At this time, the cutting velocity of particles has no direct influence on the cutting force, so the cutting force is the same at different velocities. However, the cutting distance is different at the same time due to different cutting velocities. With the progress of microcutting, the high-velocity particles make contact with the atoms of the workpiece. Before the initial deformation of the workpiece can occur, the particle atoms need to overcome the bond energy between the Fe–C alloy atoms; that is, to break the chemical bond between Fe atoms and C atoms, and force the workpiece atoms to produce a large displacement. This results in the increase of the cutting force of SiC particles.

When the low-velocity particles come into contact with the workpiece, the high-velocity particles have completely cut into the surface of the workpiece, and the number of atoms that have made contact with the particles increases. By the combined effects of surface hardening, the corresponding inter-atomic bonding forces gradually increase and the bonding energy needed to be overcome becomes larger. As the particles move, the atoms of the workpiece in the cutting area accumulate in front of the particles, which has a great effect on the cutting of particles. As a result, the cutting force gradually increases. When the low-velocity particles cut into the workpiece surface completely, the high-velocity particles have entered the stable cutting stage. The atom accumulation in the front end of the particles becomes larger, which further impedes the cutting. The cutting force of high-velocity particles increases due to the joint hindrance of atomic bond energy and atomic stacking.

In the late cutting period, the cutting states of particles with different velocities gradually converge. Although there are some differences, the overall cutting force change trend is consistent. In the process of microcutting, the cutting force fluctuates continuously. The main reason for this is that the energy generated by lattice deformation keeps accumulating and releasing, forcing lattice reconstruction.

3.2. Effect of Particle Cutting Energy on Surface Material Removal of Fe–C Alloy

3.2.1. Kinetic Energy Analysis

In order to study the effect of kinetic energy on the surface material removal of Fe–C alloy in the microcutting process, the numerical analysis of the particle microcutting process under different velocity conditions is carried out, and the influence of atomic kinetic energy variation on the microcutting process of the Fe–C alloy workpiece is discussed.

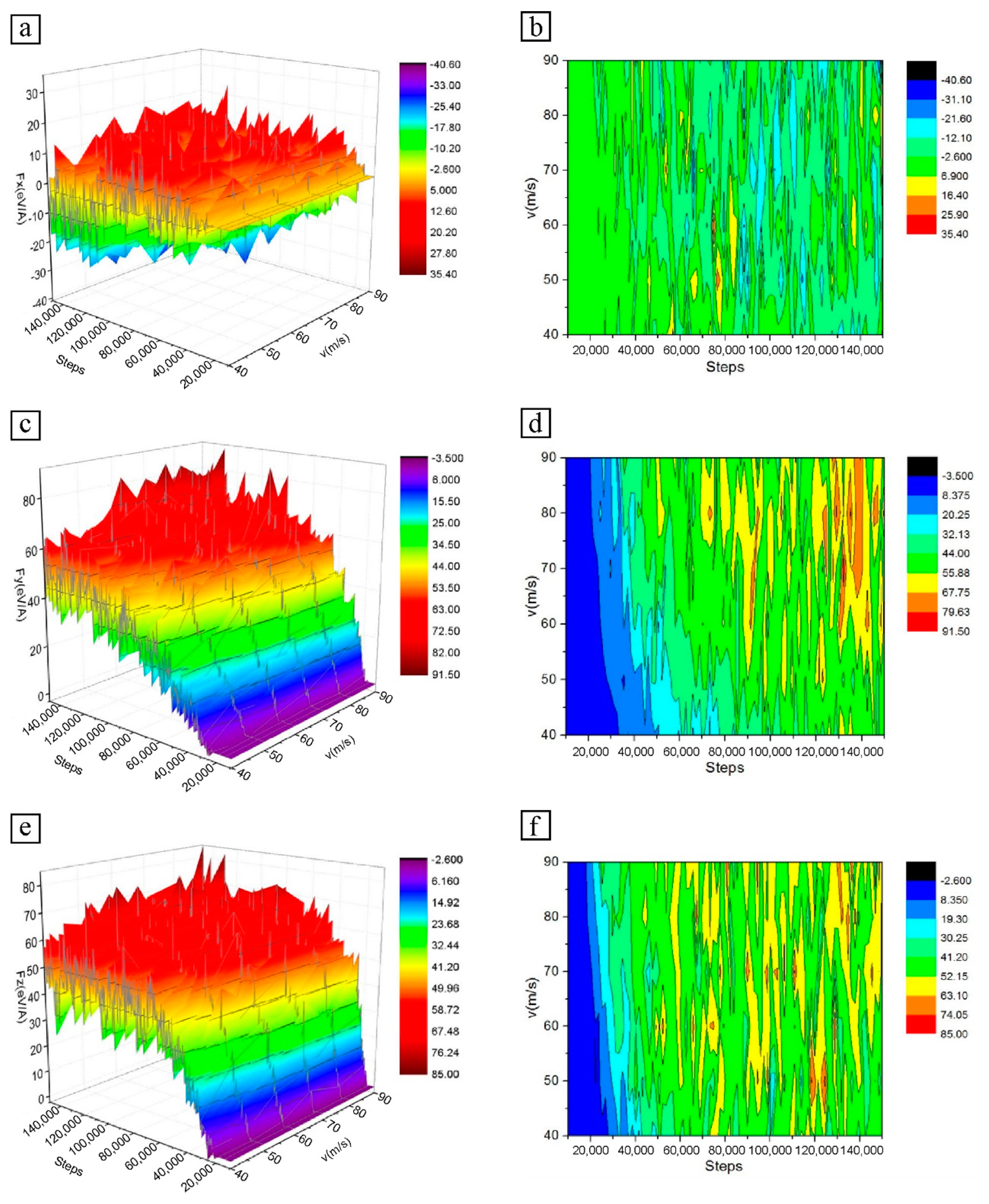

The variation of atomic kinetic energy with the number of simulation steps for different particle velocity conditions is shown in

Figure 3. The atomic kinetic energy of the Fe–C workpiece in the 3D curve diagram fluctuates during the microcutting process. This phenomenon arises mainly from the dynamic balance between the interconversion of atomic potential and kinetic energies. The generation of dislocations and the deformation of the lattice due to the motion also cause a continuous accumulation and release of strain energy.

In the early stages of cutting, the atomic kinetic energy of the workpiece increases with increasing cutting velocity. The reason for this is that the high-velocity particles cut longer distances in the same amount of time, and more atoms accumulate at the front of the particles. However, as the smallest-velocity particles cut completely into the workpiece surface, the atomic build-up occurs at the front of the particles and the difference in build-up is not significant. Therefore, the effect of different particle velocities on the atomic kinetic energy of the workpiece decreases in the later stages of microcutting.

In

Figure 3, the change in cutting velocity does not cause a significant change in the atomic kinetic energy of the Fe–C workpiece, which varies very little. Although the microcutting effect of the particles on the material results in local Fe–C atoms having a certain velocity on the surface of the workpiece, some of the atoms in the cutting area are displaced a certain distance to either side of the particle and then accumulate on the surface. Some of the atoms move downwards and form a machined surface under friction; the velocity of these atoms does not change significantly depending on the particle velocity. Only a small number of workpiece atoms move with the particles at the same velocity at the front of the particles, where they gradually accumulate to a certain extent and are removed from the workpiece surface by the particles in the form of chips.

In short, a smaller proportion of the workpiece atoms are displaced and an even smaller proportion move forward with the particles at the same velocity and are finally discharged as chips. Therefore, the particle cutting velocity does not have much influence on the displacement velocity of the workpiece atoms.

Temperature has the greatest influence on the kinetic energy of the atoms of the Fe–C workpiece in the simulation system. In NVT, most of the heat generated during cutting is transferred to the thermostat layer, where the temperature difference in the local atoms caused by the different cutting velocities of the particle also has only a small effect on the kinetic energy. Therefore, the different velocity conditions can only cause a weak change in the total kinetic energy of the workpiece atoms.

3.2.2. Potential Energy Analysis

In order to investigate the effect of particle velocity on atomic potential energy of the workpiece, the variation of atomic potential energy under different particle velocities during microcutting is studied.

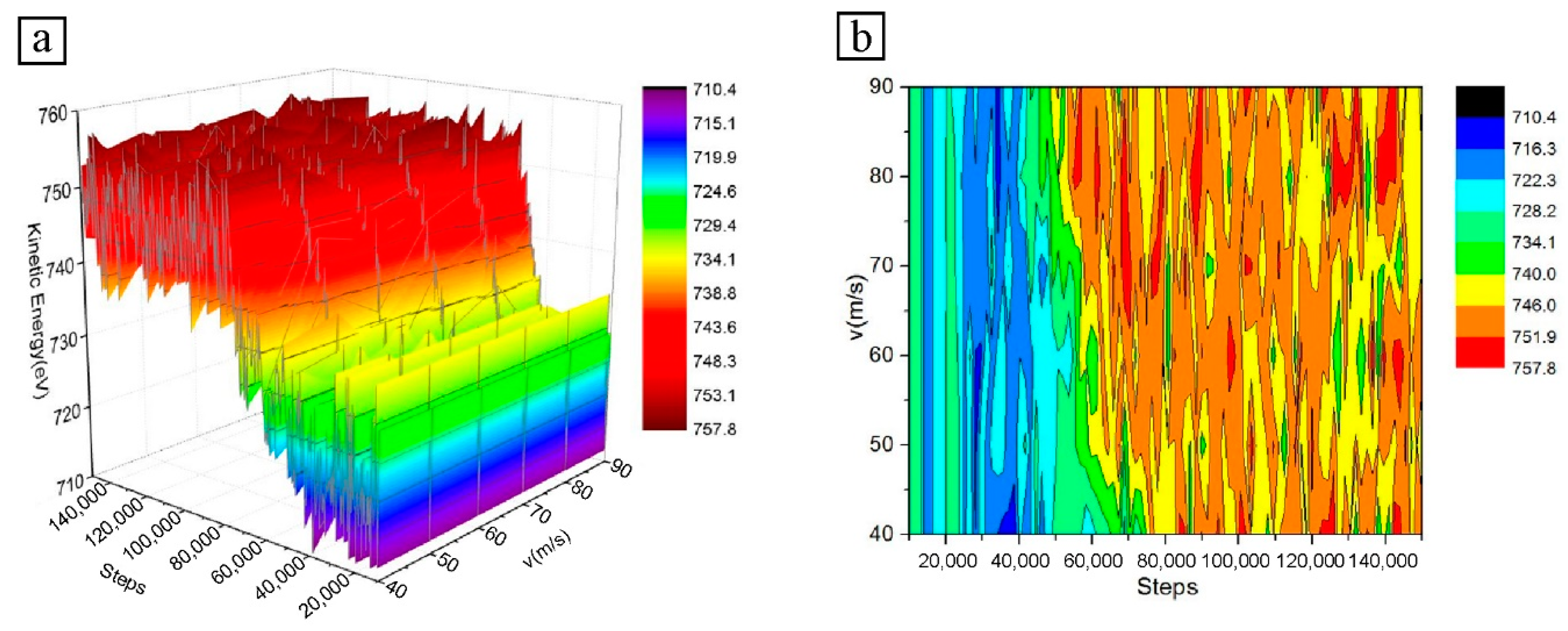

The variation of atomic potential energy at different velocities is shown in

Figure 4. The atomic potential energy of the workpiece increases with ab increase in cutting velocity. At the initial stage of particle microcutting, the initial cutting force is approximately equal to the sum of the repulsive forces between SiC particle atoms and Fe–C alloy atoms. The atomic repulsion force causes the atoms of the workpiece close to the particle to be squeezed, and a small amount of the atoms of the Fe–C alloy workpiece appear to achieve a small level of displacement. The local lattice structure deforms slightly, the atomic potential energy increases, and the resulting strain energy accumulates continuously in the lattice. In this stage, there is not much difference between values of atomic potential energy at different particle velocities.

As the microcutting progresses, the particles with higher velocity are already in contact with the surface of the Fe–C workpiece. The displacement of Fe and C atoms in the Fe–C workpiece gradually increases under the action of cutting force, resulting in a higher atomic potential energy. The relatively small-velocity particles are still not in contact with the Fe–C workpiece, and there is no obvious atomic potential energy change

By the time the low-velocity particles come into contact with the Fe–C workpiece, the high-velocity particles have already cut completely into the workpiece. In contrast, not only is the displacement of the atoms of the high-velocity particles greater, but also more strain energy and dislocation energy from lattice deformation is released during the microcutting process. By the time the low-velocity particles have completely cut into the workpiece, the high-velocity particles have already cut a long distance on the workpiece surface, driving more atomic movement and relatively large displacement in the cutting area. The lattice and dislocation changes are more intense, and the strain energy accumulated in the lattice is released and transformed into atomic potential energy. As the particle velocity increases, the atomic potential energy of the workpiece increases significantly at this stage.

3.2.3. Total Energy Analysis

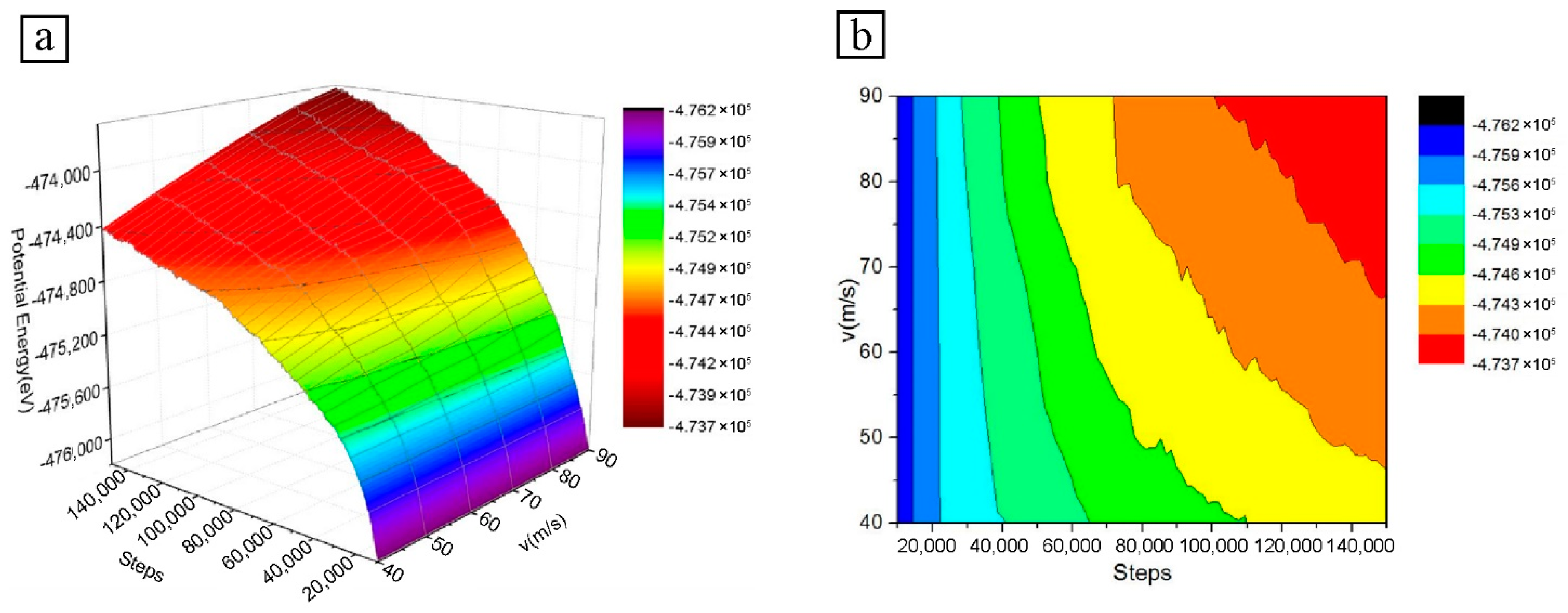

Figure 5 shows the variation of the total energy with the number of simulation steps for different particle cutting velocities. The total thermodynamic energy is the sum of the kinetic and potential energy of the atoms. From

Figure 3 and

Figure 4, the atomic kinetic energy is low in relation to the potential energy during microcutting. A comparison of

Figure 4 and

Figure 5 shows that the change in total energy follows a very similar trend to the change in potential energy. As the cutting velocity increases, the total atomic energy of the Fe–C workpiece also tends to increase gradually, as does the atomic potential energy.

The reason for this is that the effect of cutting velocity on the kinetic energy of the atoms is not as significant as the potential energy of the atoms, and that the kinetic energy is a smaller proportion of the total energy, with the difference between the total atomic energies arising mainly from the effect of different velocities on the potential energy of the atoms. The different cutting velocities of the particles also result in different cutting distances on the surface of the Fe–C workpiece and, therefore, corresponding differences in workpiece atomic displacement and local atomic velocities, which affect the lattice deformation and dislocation, change within the material. The combination of the various changes in the workpiece caused by the different cutting velocities manifests itself as a difference in the total atomic energy.

3.3. Effect of Particle Cutting Atom Displacement on Surface Material Removal of Fe–C Alloy

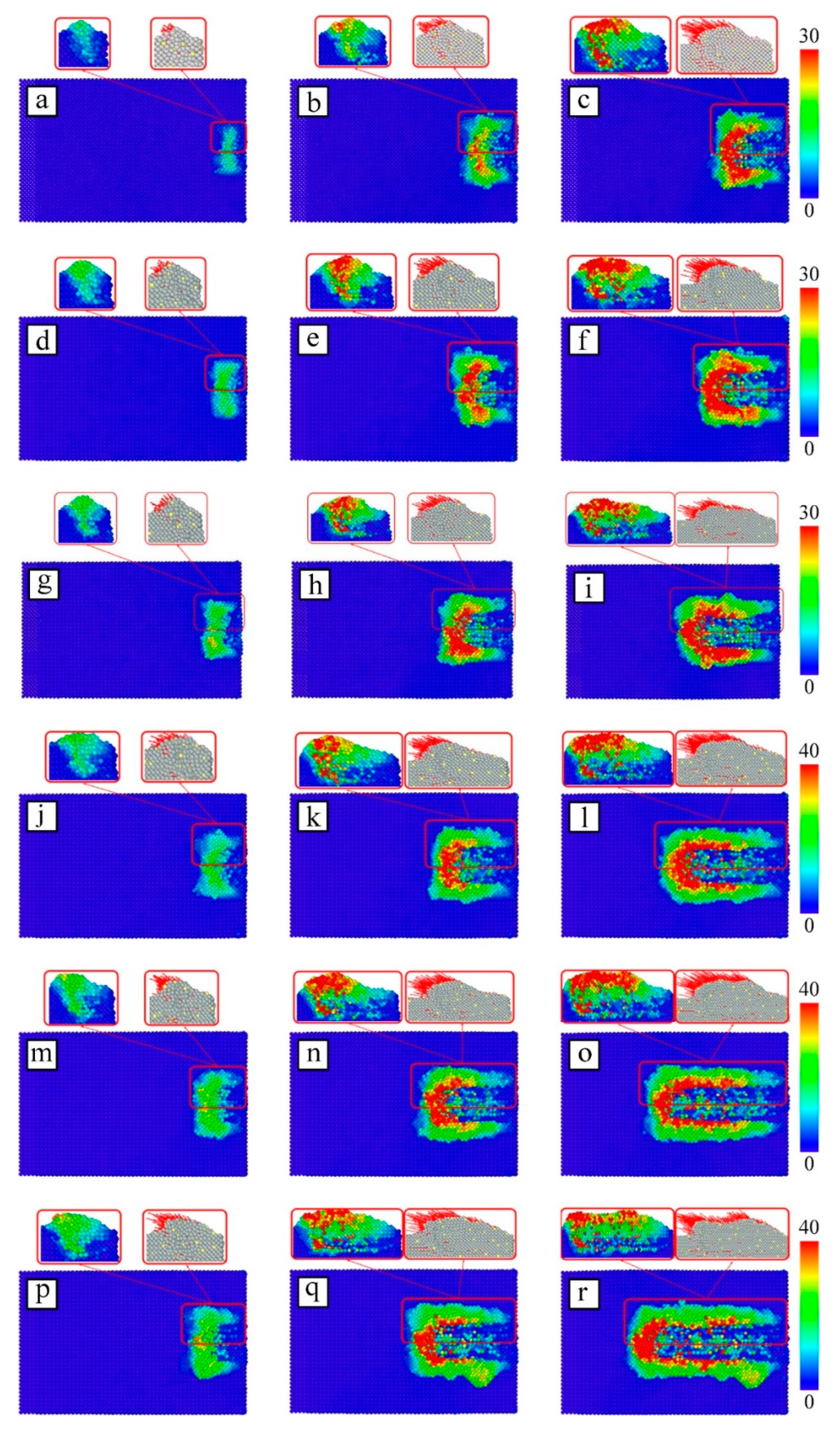

In order to investigate the influence of particle microcutting velocity on the atomic displacement of the Fe–C alloy workpiece surface, and to discuss the action form of particles on the workpiece, the material removal process, chip generation, and change under different microcutting velocity conditions, different atomic displacements in the workpiece are marked with different colors.

Figure 6 shows the displacement of atoms on the surface at different particle cutting velocities of 40 ps, 80 ps, and 120 ps. The arrows on the atoms in the partial profile indicate the displacement vector. The higher cutting velocity makes the cutting distance of SiC particles on the workpiece surface become longer; the number of workpiece atoms that produce displacement increases and the displacement of some atoms increases, and the local deformation of the material in the cutting area intensifies. As can be seen, the cutting velocity has a direct influence on the forming time of the machined surface. The higher the velocity, the faster the surface of the workpiece is formed.

Now, we contrast the changes in atomic profile and displacement of the Fe–C workpiece at different cutting velocities. The high-velocity particles are the first to cut into the Fe–C workpiece, causing plastic deformation of the material surface. The low-velocity particles are later in making contact with the workpiece, and only the initial elastic deformation exists. As the microcutting proceeds, the high-velocity particles not only cut longer distances on the surface of the Fe–C workpiece, but also squeeze some of the atoms to the sides and below the particle, while also pushing a small number of atoms at the front of the particles at the same velocity. When these atoms have accumulated to a certain extent at the front of the particle, they are stripped from the surface of the workpiece in the form of chips.

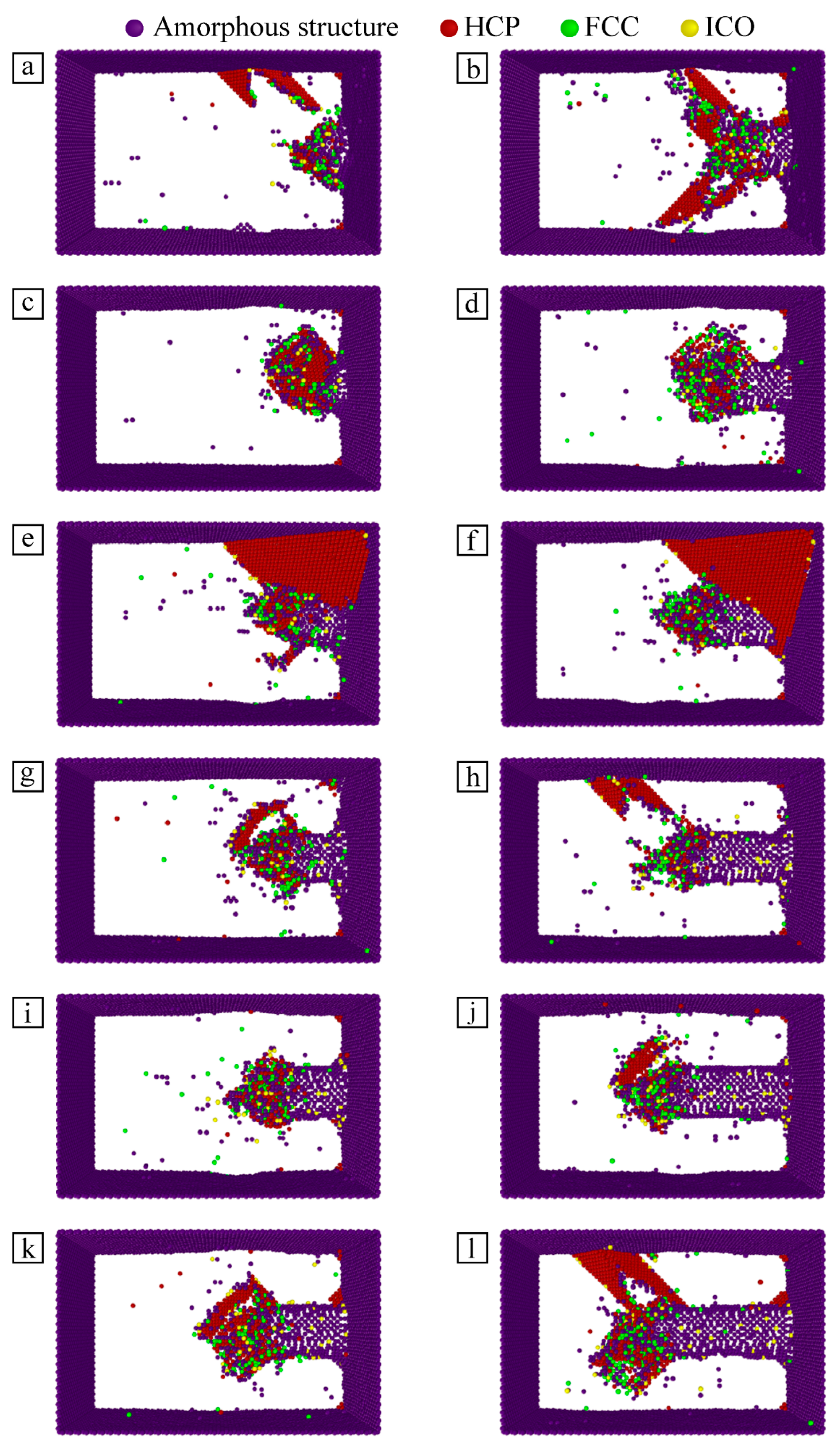

3.4. Analysis of Lattice Structure Change of Workpiece

Ackland–Jones bond angle analysis [

29] is used to investigate the changes in the lattice structure within the Fe–C workpiece during particle microcutting with cutting velocity as a variable, and to investigate the atomic arrangement of the workpiece’s Newtonian layer. The type and distribution of defective structures within the material can be identified based on the calculated crystal structure type.

Figure 7 shows the lattice structure diagram of the cutting zone section of the Fe–C alloy workpiece at different cutting velocities at the simulation times of 70 ps and 110 ps. Due to a certain degree of distortion of the lattice containing carbon atoms in the workpiece prior to microcutting, some of the atoms are identified as other cubic structures despite the small atomic offset. In order to facilitate the observation and analysis of structural changes in the cutting layer of the workpiece, such atoms of the workpiece that still maintain the original structure before microcutting are hidden in

Figure 7. In the microcutting process of SiC particles, the Fe–C alloy material includes body-centered cubic (BCC) lattice structure, hexagonal close-packed (HCP) lattice structure, face-centered cubic (FCC) structure, icosahedron (ICO) structure, and amorphous structure.

In order to overcome the atomic bond energy before the material is removed, the cutting force must gradually rise to the extreme value beyond the binding force between atoms, so as to destroy the interaction between atoms. During this period, the particle cutting force disrupts the original lattice in the cutting region of the Fe–C alloy workpiece and destroys the orderly lattice structure inside the material. Bonds between atoms are broken and reborn, resulting in some atomic arrangements gradually becoming disordered and some amorphous structures in the cutting area. As the particle move, the number of amorphous structures gradually increases. Amorphous structures are basically distributed in the processed area. Some of the amorphous structures will be transformed into other lattice structures under the action of microcutting, and some of them will be removed in the form of chips, as described above.

With the progress of microcutting, the Fe–C alloy material is subjected to continuous friction. Some of the atomic layers slip on the dense plane of the crystal and result in dislocations. Part of original lattice gradually transforms into HCP structures. The local strain increases, forcing the atoms gradually out of equilibrium. When the strain variable breaks through the bearing limit before phase transformation, the local workpiece atoms become metastable. In a metastable state, HCP structures gradually increase in number, and some atomic stress is released. As a result, the temperature in the system has an increasing trend, which drives the growth of atomic kinetic energy. Under the joint action of shear force and friction force, the amorphous structure in the cutting area shifts with the continuous movement of particles, which changes the atomic arrangement state again, and the amorphous structure begins to change to HCP structure. At the same time, part of the HCP structures generated in the previous process gradually transform into amorphous structures.

According to the analysis of the atomic potential energy above, with the progress of microcutting, Fe atoms and C atoms are displaced under the action of cutting force, which destroys the crystal lattice structure. The elastic stress field is generated inside the material, which continuously stores the strain energy in the lattice. When the strain energy increases to the lattice bearing limit, the original lattice structure is disturbed to release the strain energy. The atoms of the workpiece are forced to rearrange in the form of low-energy lattice structures, and part of the BCC structure gradually transforms into an FCC structure with the movement of particles. When SiC particles cut and extrude the atoms, the original lattice structure is destroyed, and a small amount of ICO structure is also generated in the material. Compared with other crystal structures, FCC and ICO structures contribute relatively small percentages, so they have little influence on the microcutting process of particles.

By comparing the changes of the internal structure of the Fe–C alloy workpiece with different particle cutting velocities, it is found that there is always a variety of crystal structures in the material, and their quantity and distribution change obviously. However, there is no linear relationship between this change and particle cutting velocity. Different cutting velocities result in the change of atomic energy, which affects the accumulation and release of strain energy in the material. According to the changes in material cutting layers (in

Figure 7a–l), the cutting distances of particles on the workpiece surface are different at different cutting velocities. At the same simulation time, the relative positions of particles and workpiece are different, so the stress states of atoms in the cutting area and the energy of local atomic groups are greatly different, and the lattice deformation degree is also significantly different.

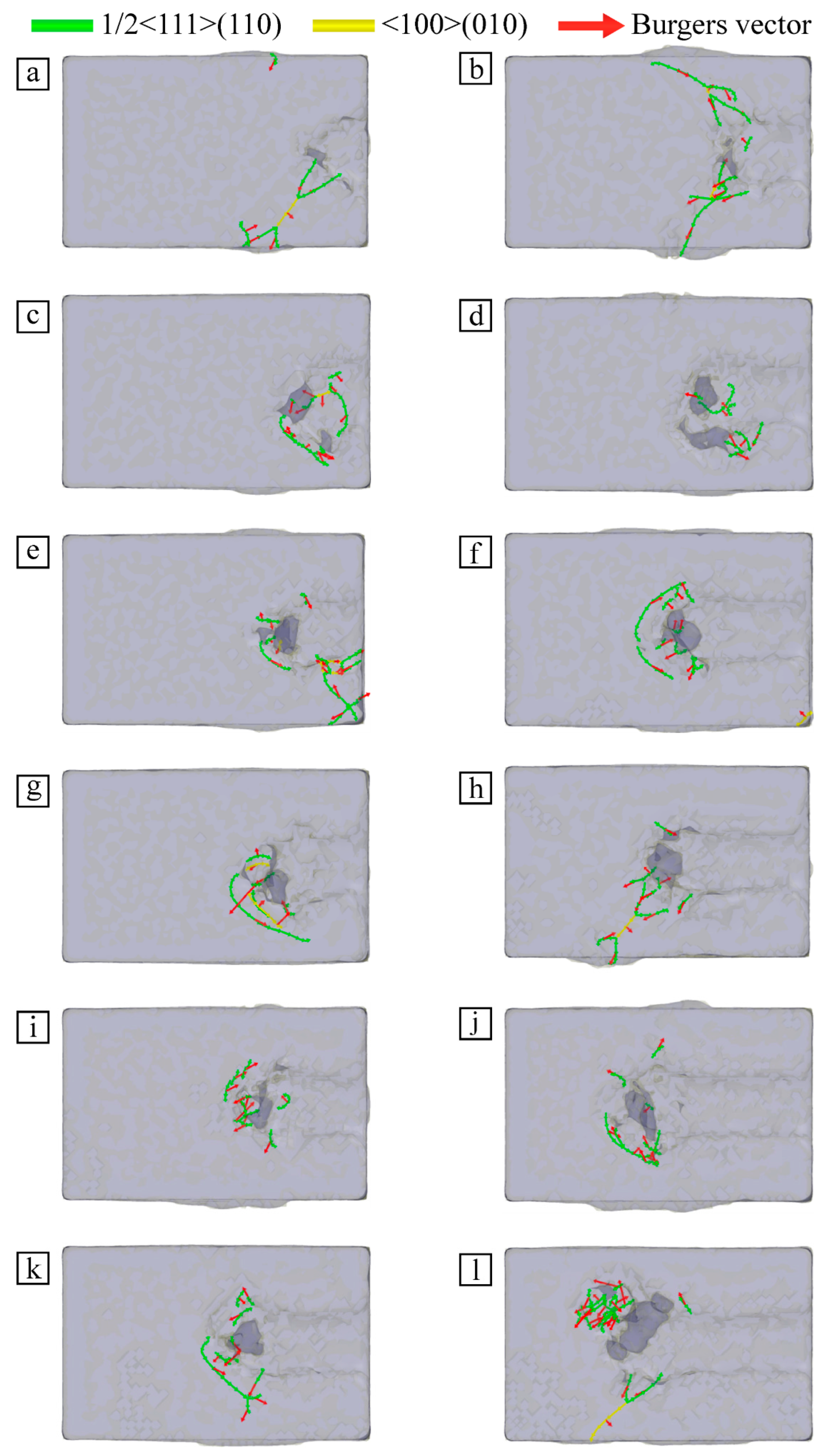

3.5. Analysis of Dislocation Change in Workpiece

Under the combined action of cutting and friction of SiC particles, the atoms of the Fe–C alloy workpiece shift and change the original configuration. The atomic lattice structure in the cutting area is destroyed, and the local atoms demonstrate a regular dislocation phenomenon, which leads to dislocation in the workpiece. In order to discuss the change of internal dislocations in material at different cutting velocities, the discrete extraction algorithm (DXA) [

30] is used to identify the dislocation defects in material, as shown in

Figure 8.

Figure 8 shows the internal dislocation distribution of the Fe–C alloy workpiece at different velocities. The internal dislocation distribution of the workpiece at different cutting velocities is analyzed from the upper surface of the workpiece at t = 70 ps and 110 ps, respectively, and the Burgers vector is marked by a red arrow. It can be seen that there are ½ <111>(110) dislocations and <100>(010) dislocations in the Fe–C alloy workpiece at different cutting velocities. However, there were significant differences in the number and distribution of dislocations, and 1/2<111>(110) was the majority of the dislocations in the material. Due to the greater cutting velocity, the longer the cutting distance of SiC particles on the workpiece surface, the higher the number of displaced atoms in the workpiece, and some atoms move farther. This leads to aggravation of the local deformation of the material in the cutting area; this results in numbers and distributions of various dislocations that are significantly different.

According to the dislocation variation in

Figure 8a–l, the faster the particle cutting velocity is, the more dislocations are found in the workpiece and the denser the cutting area. Most of the dislocations are concentrated near the grain and the lattice changes are complex. This phenomenon arises not only from the differences in atomic arrangement under microcutting action, but also from the trace increase in particle shear stress due to the increase in cutting speed. This leads to an enhanced inhomogeneous stress field and a small increase in the number of dislocations proliferating. At the same time, the change of atomic energy caused by the different cutting velocities also influences differences in the dislocation change degree in the material at different cutting velocities, which affects the accumulation and release of strain energy. Excessive particle cutting velocities exceed the threshold of the alloy’s ability to return to steady state, so dislocations are not transferred to adjacent locations. So, a large amount of strain energy blocks in the processing area, leaving a large number of dislocations.