Electrochemical Milling of Deep-Narrow Grooves on GH4169 Alloy Using Tube Electrode with Wedged End Face

Abstract

:1. Introduction

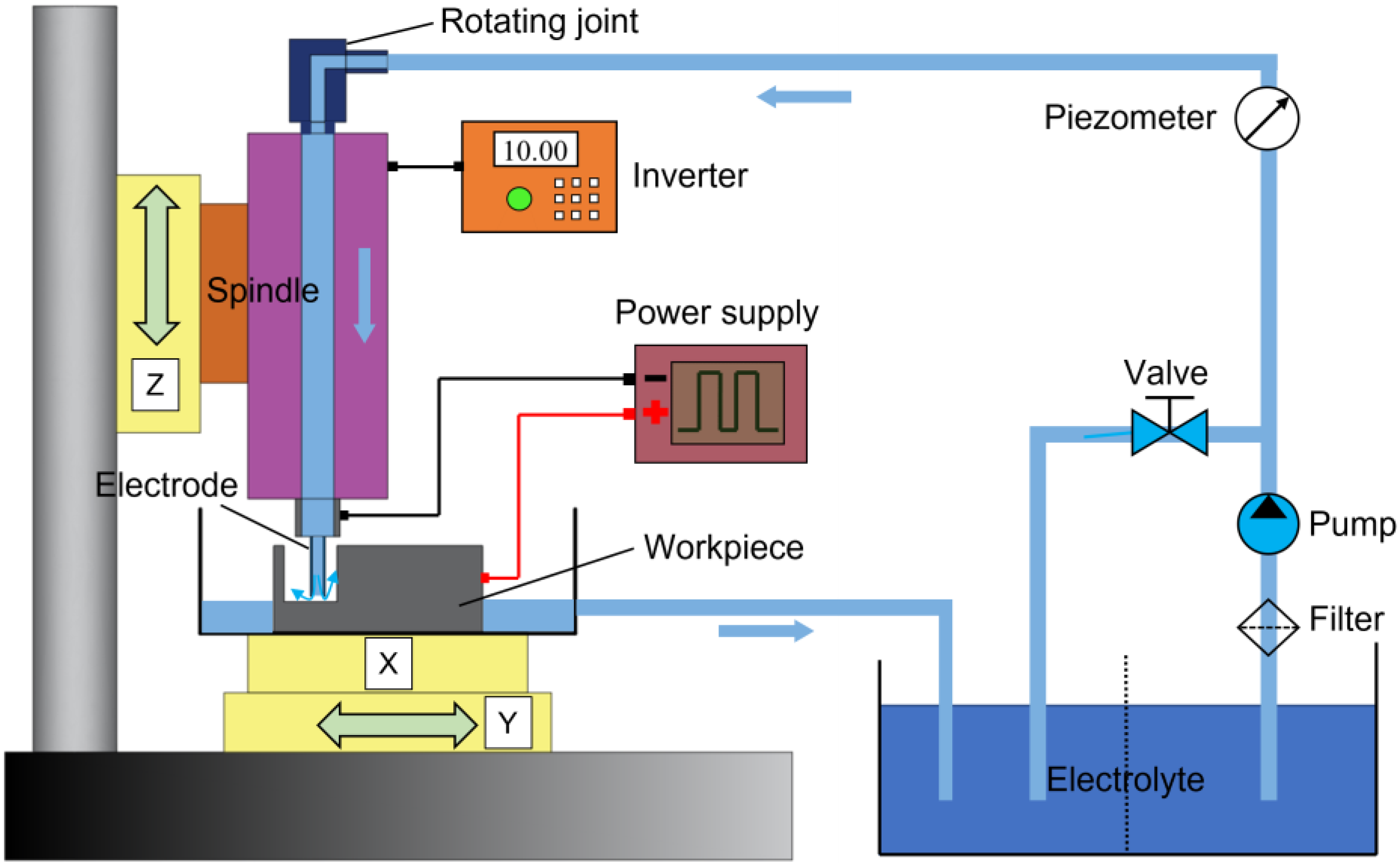

2. Description of the Method and Numerical Simulation

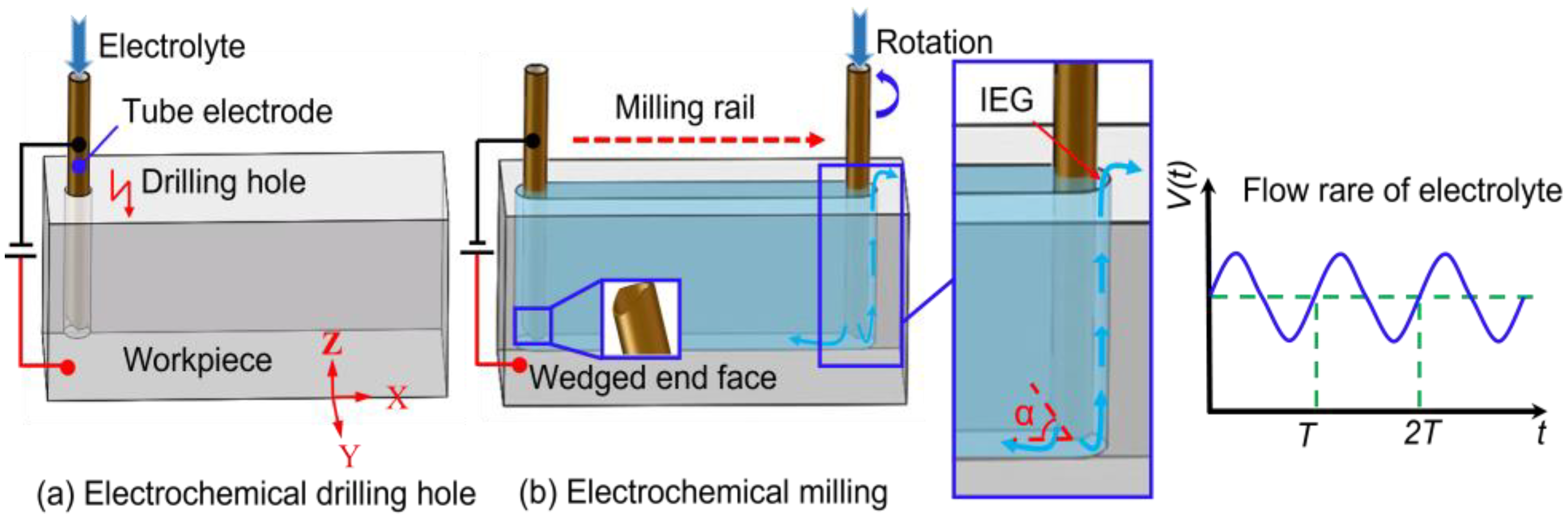

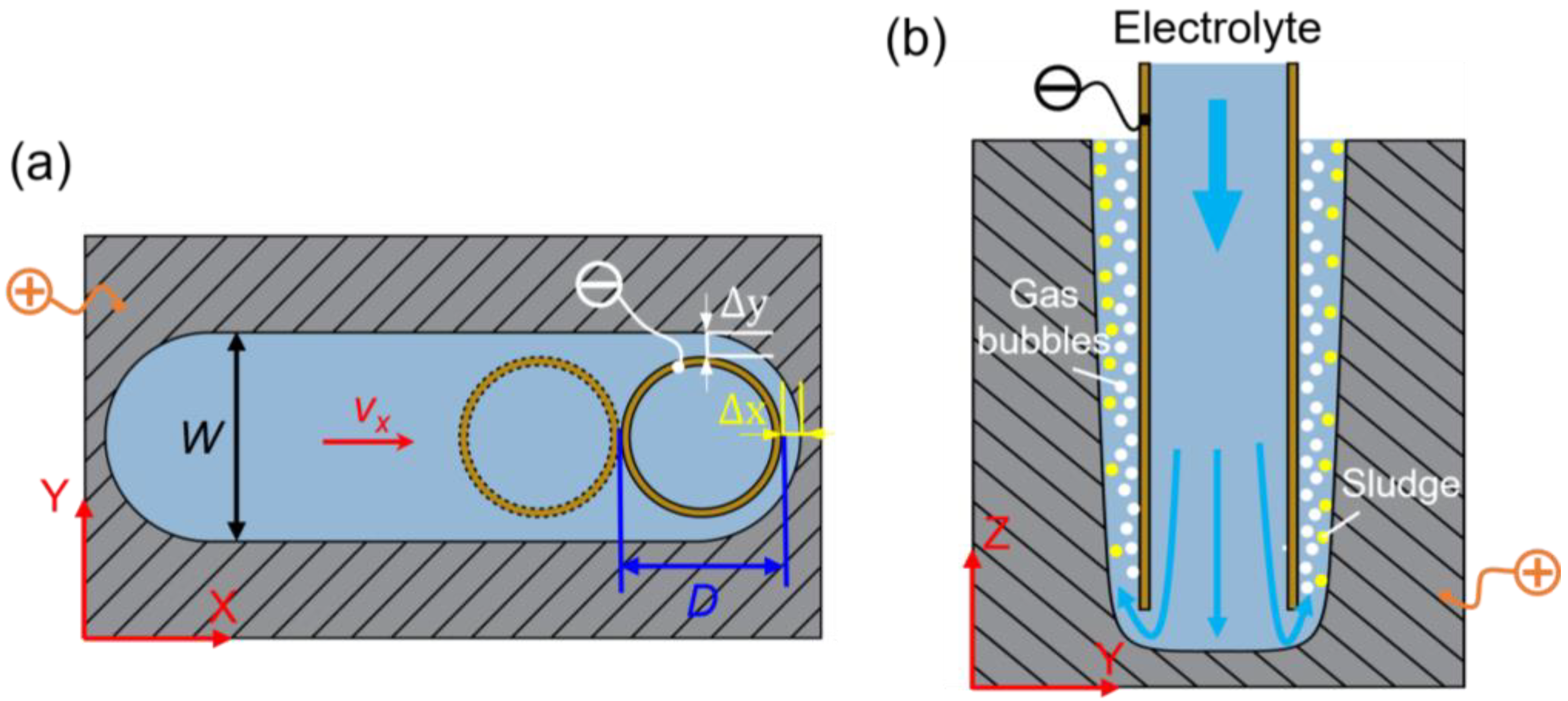

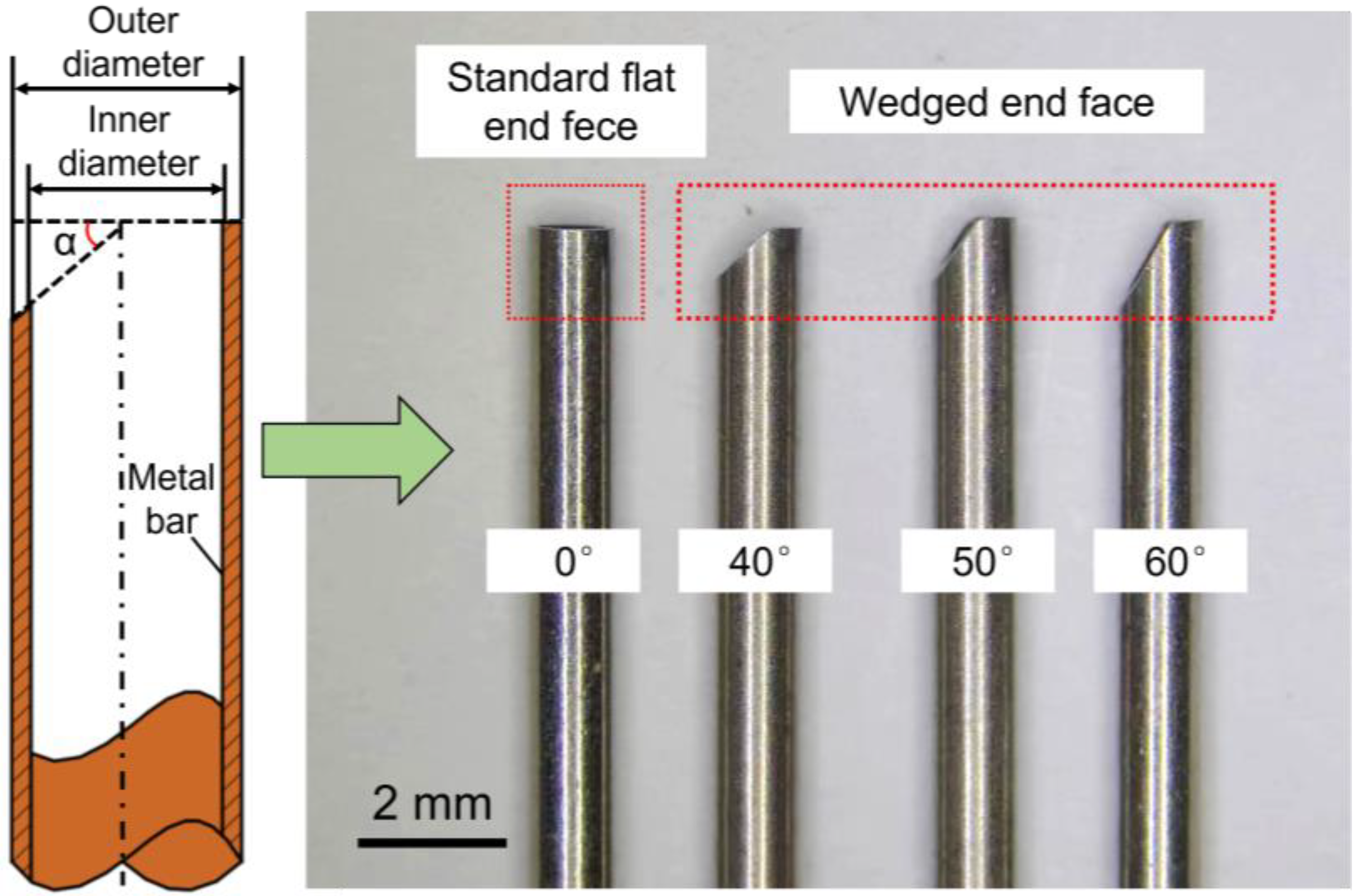

2.1. Description of the Method

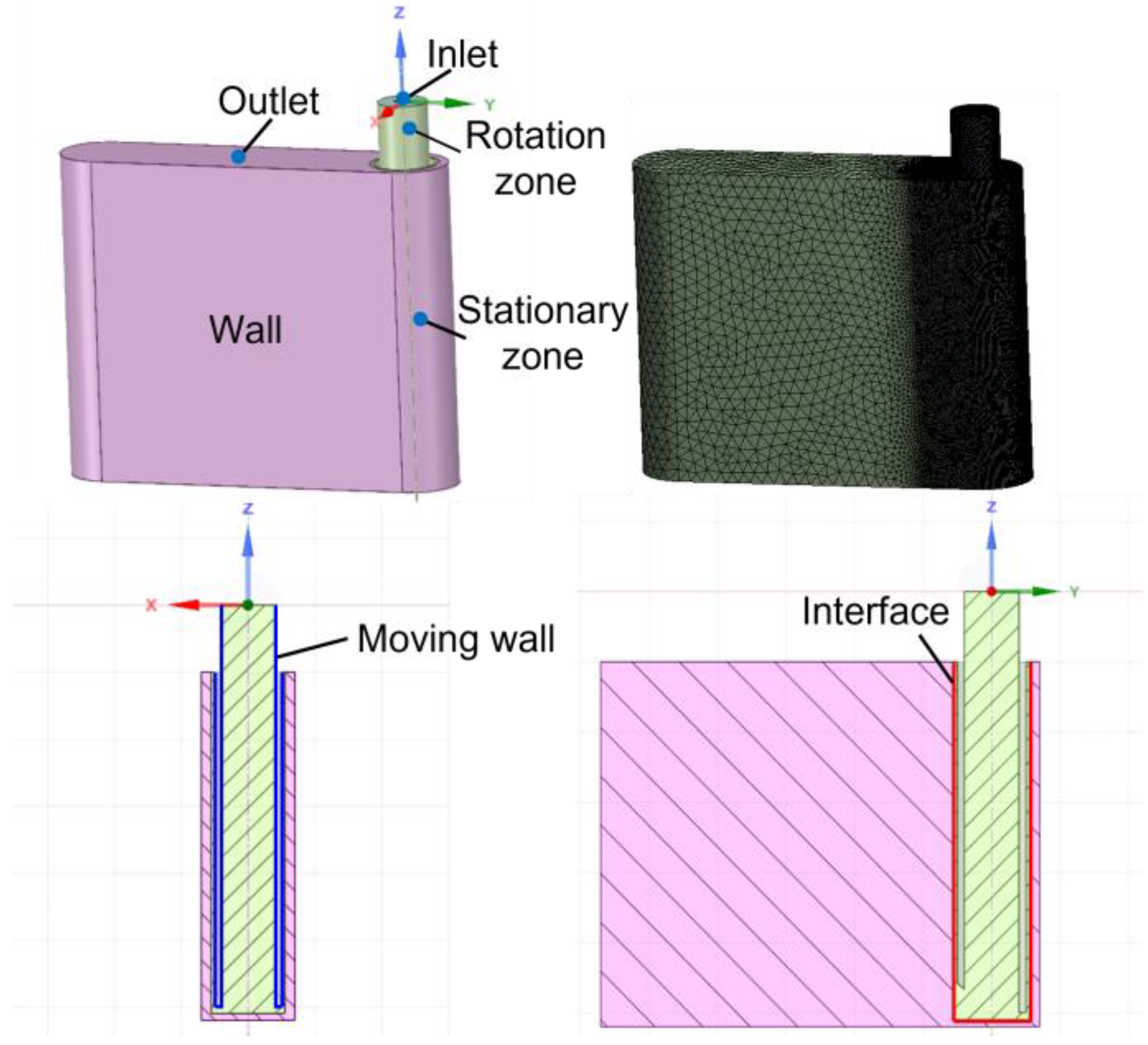

2.2. Numerical Simulation

2.2.1. Model Building

- (1)

- Electrolyte is a continuous incompressible viscous fluid.

- (2)

- The energy dissipation caused by the change of medium temperature and temperature difference is ignored in the machining process, and the flow is constrained by the conservation equation of mass and momentum.

- (3)

- The flow field is not affected by bubbles or particles.

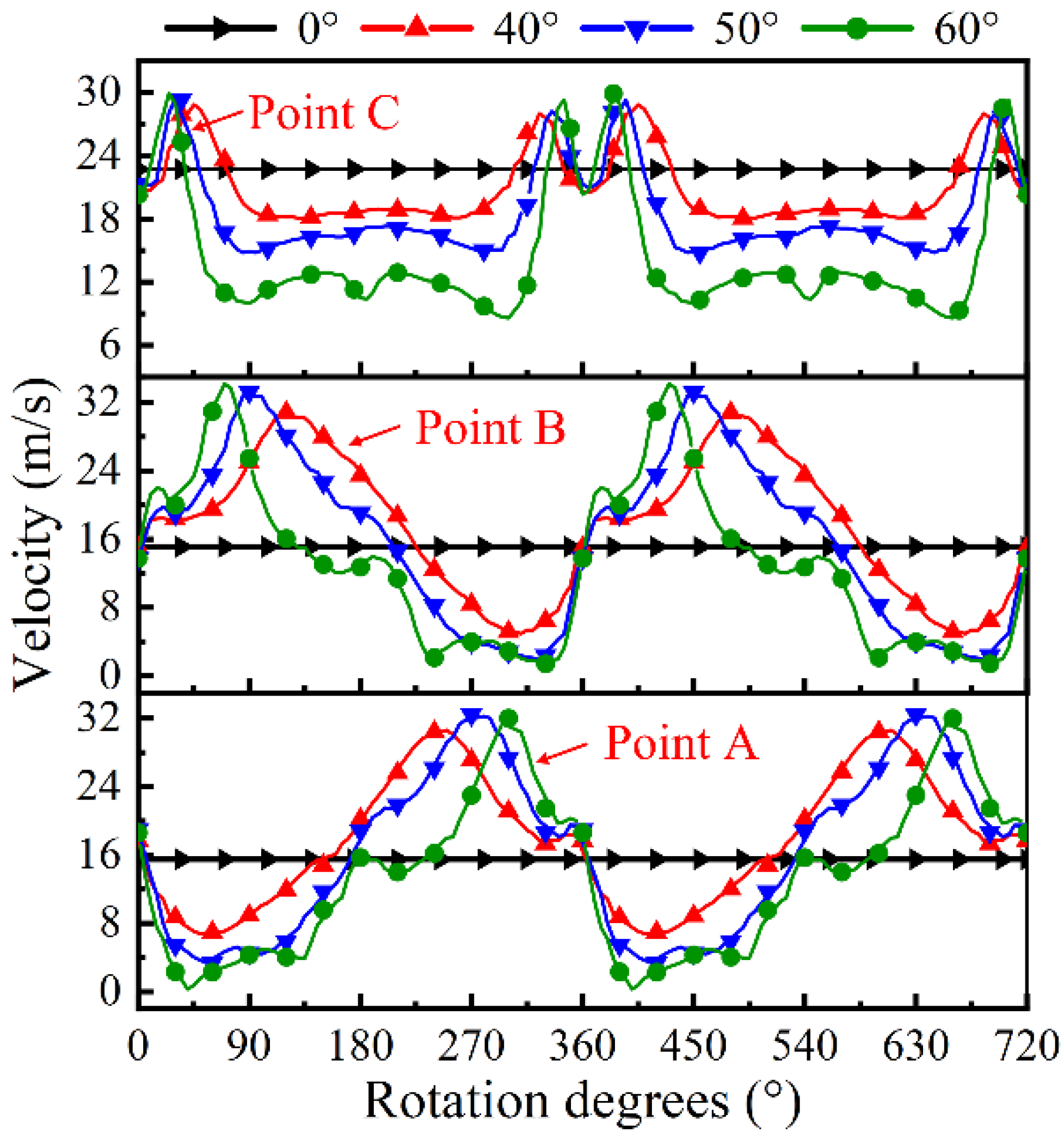

2.2.2. Simulation Results

3. Experimental Section

4. Results and Discussion

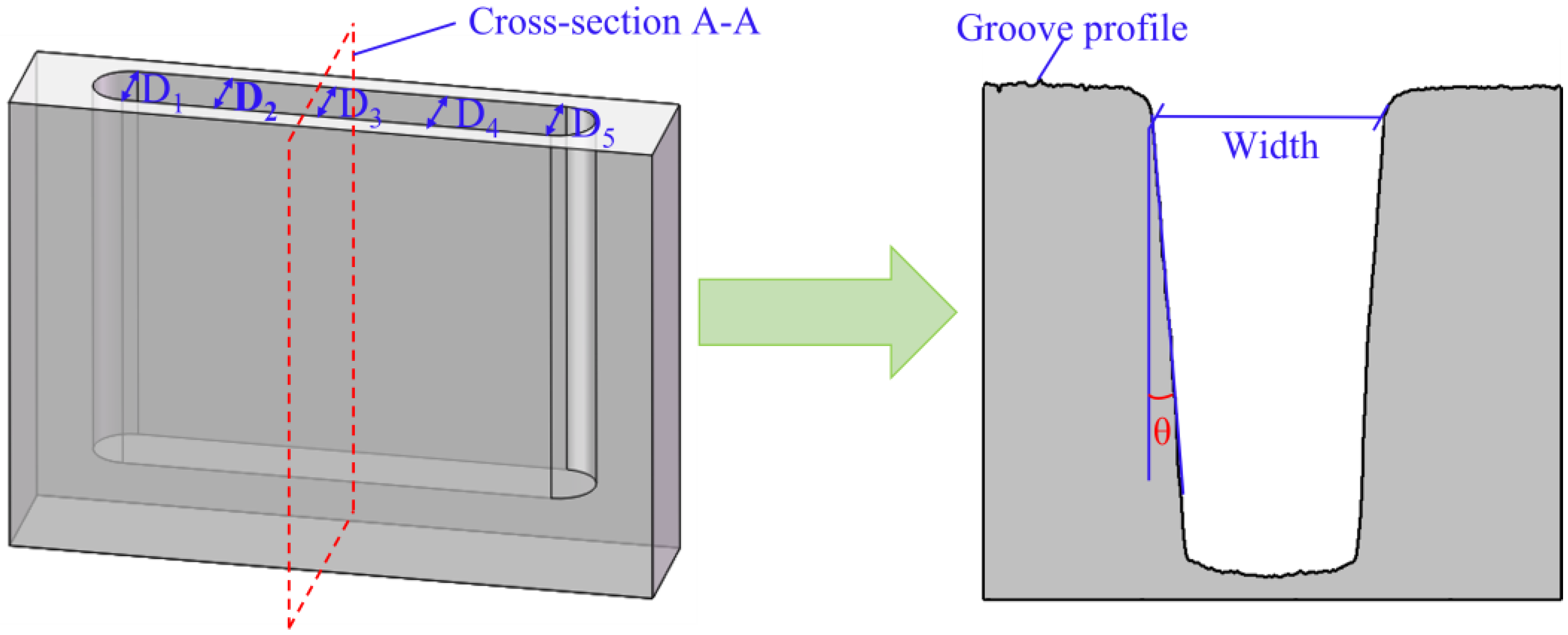

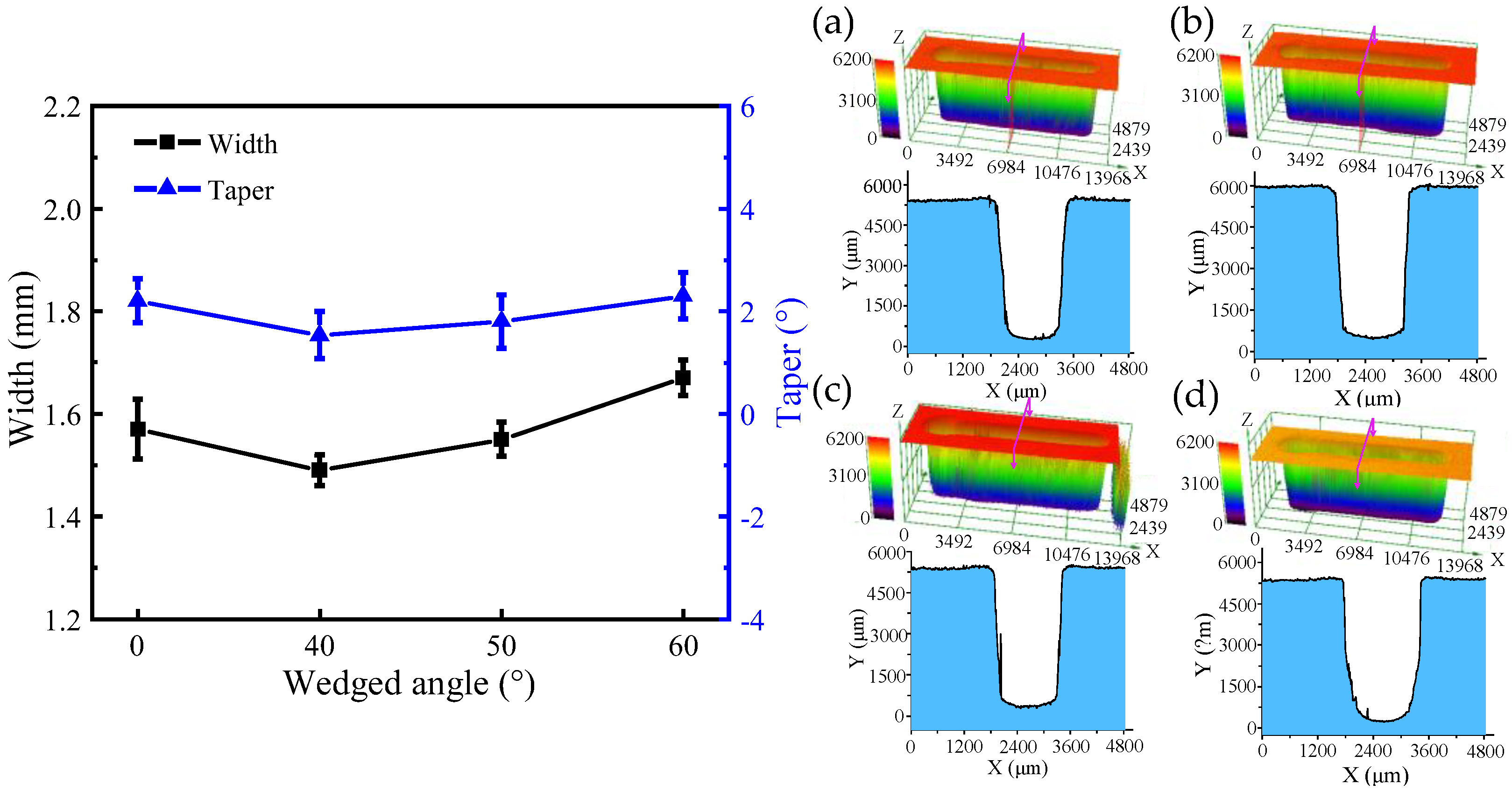

4.1. The Comparison of DNGs Generated with Different Wedged Angles

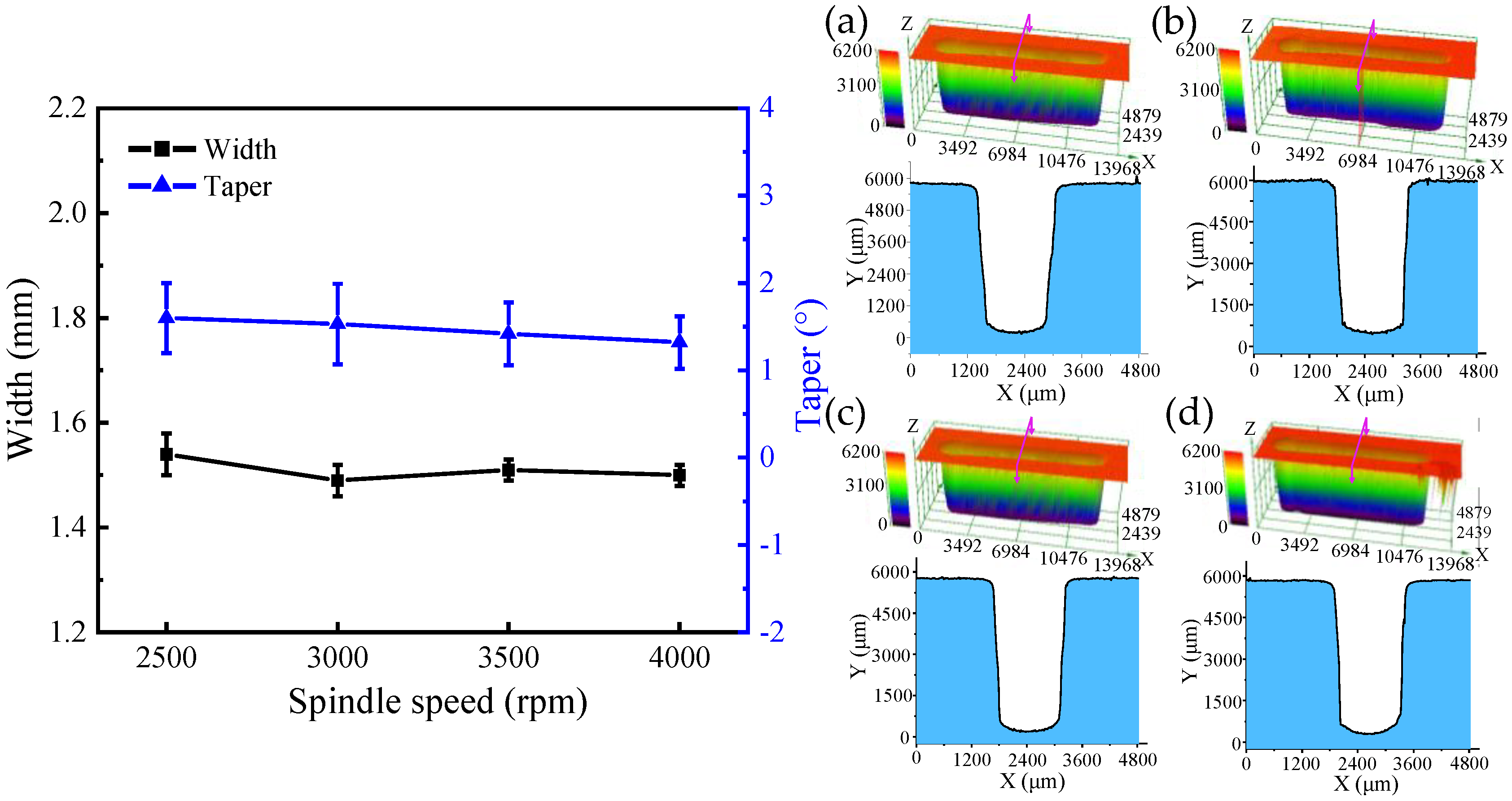

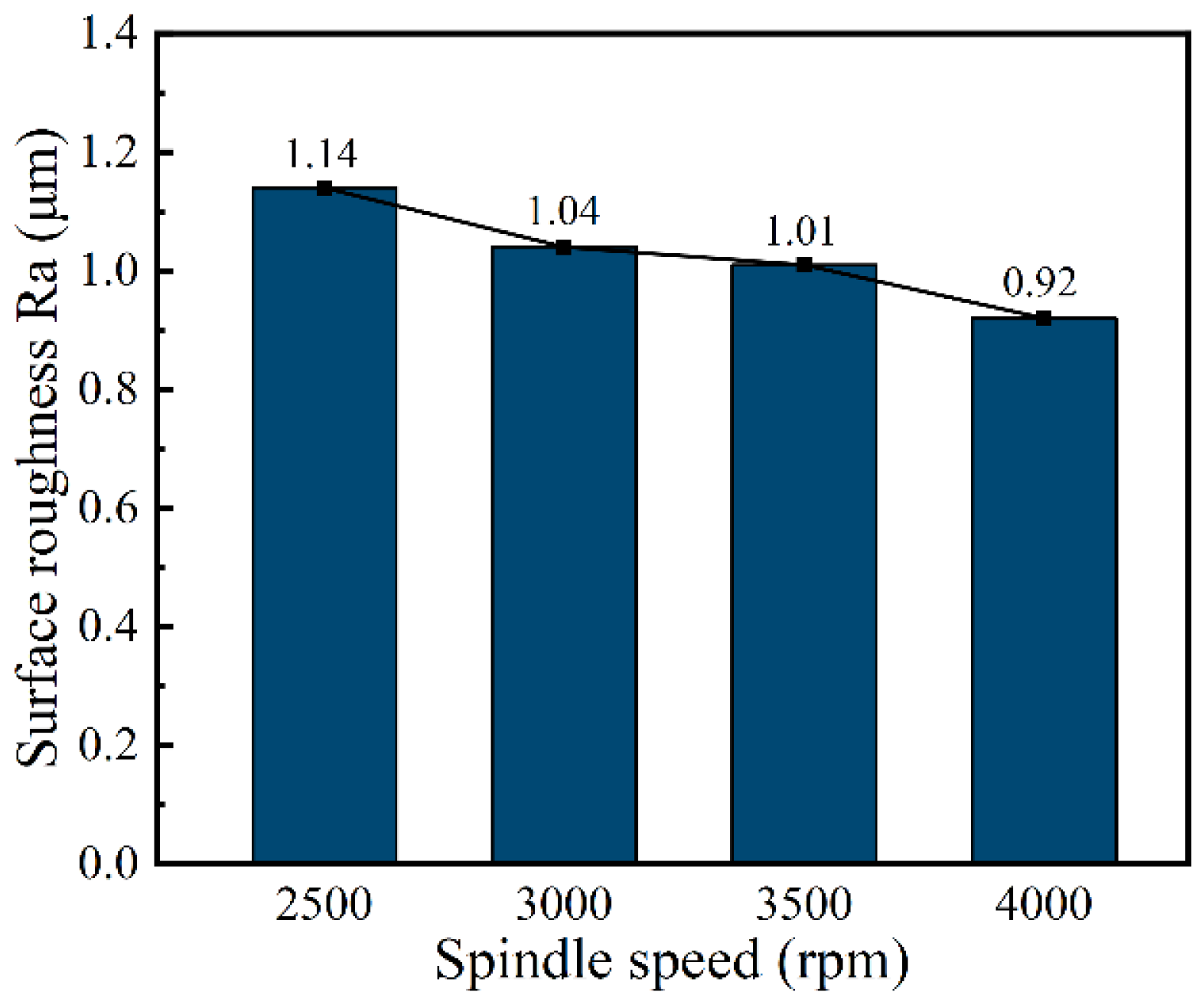

4.2. The Effect of Spindle Speed on the Generation of DNGs

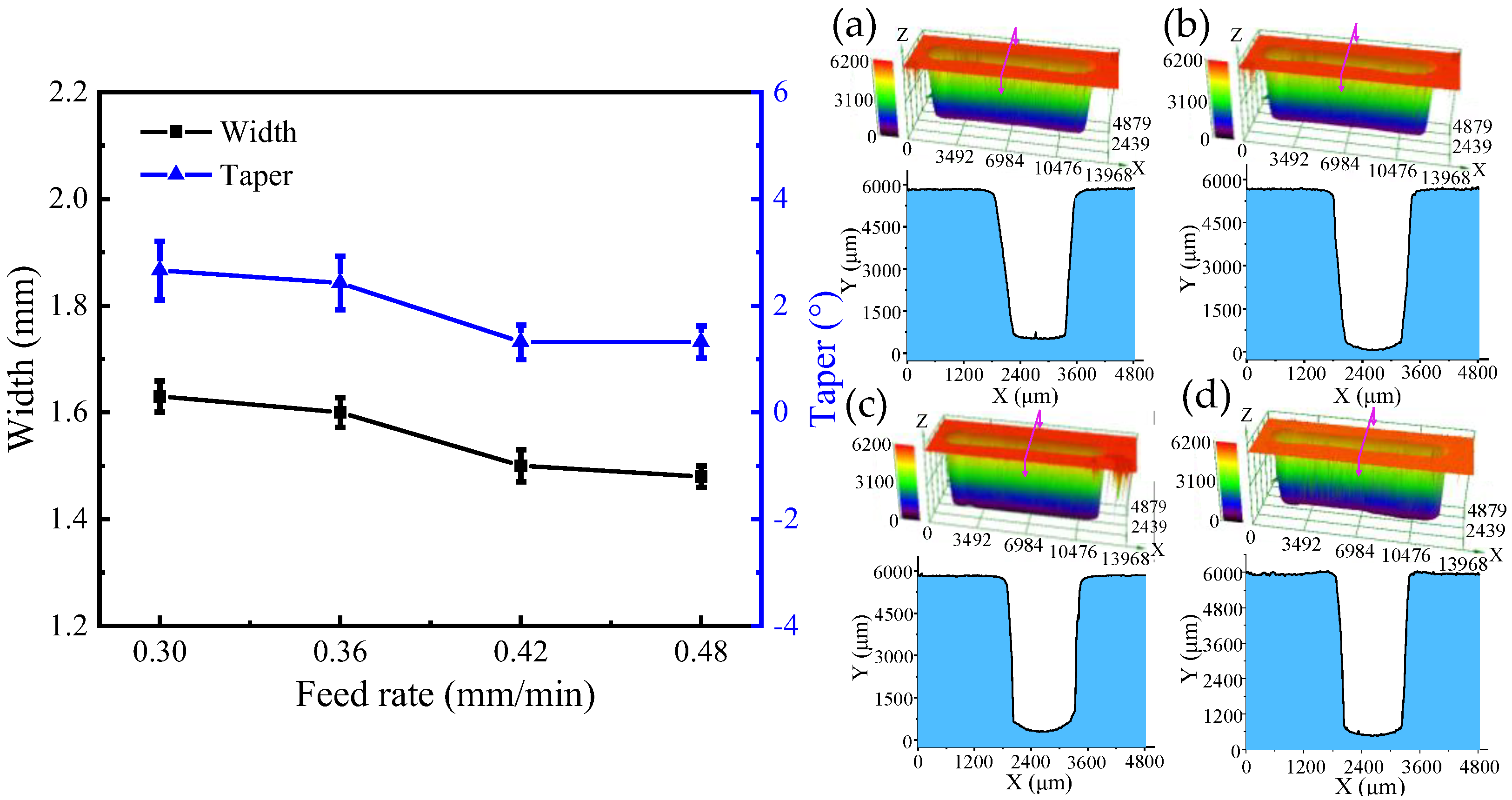

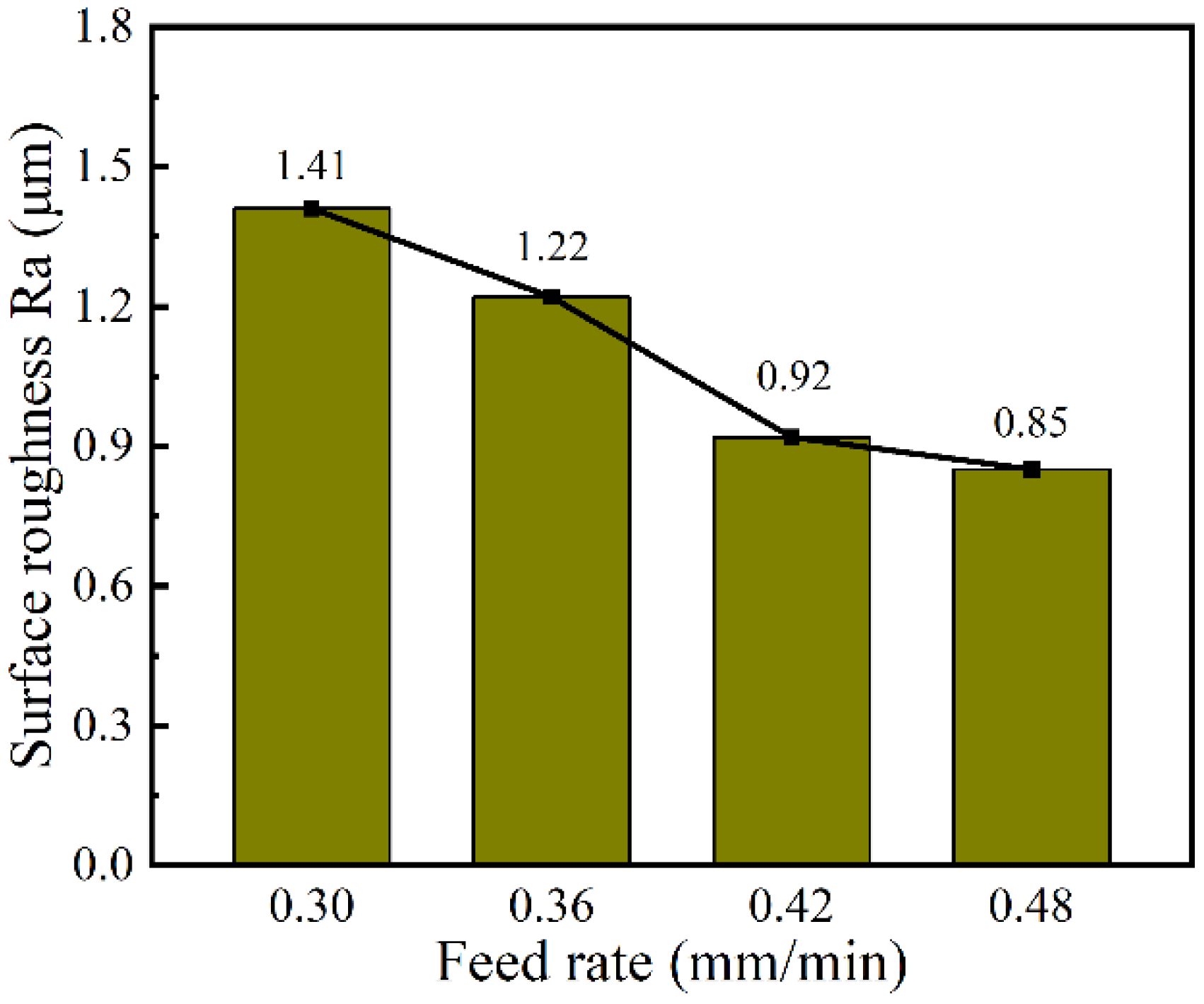

4.3. The Effect of Feed Rate on the Generation of DNGs

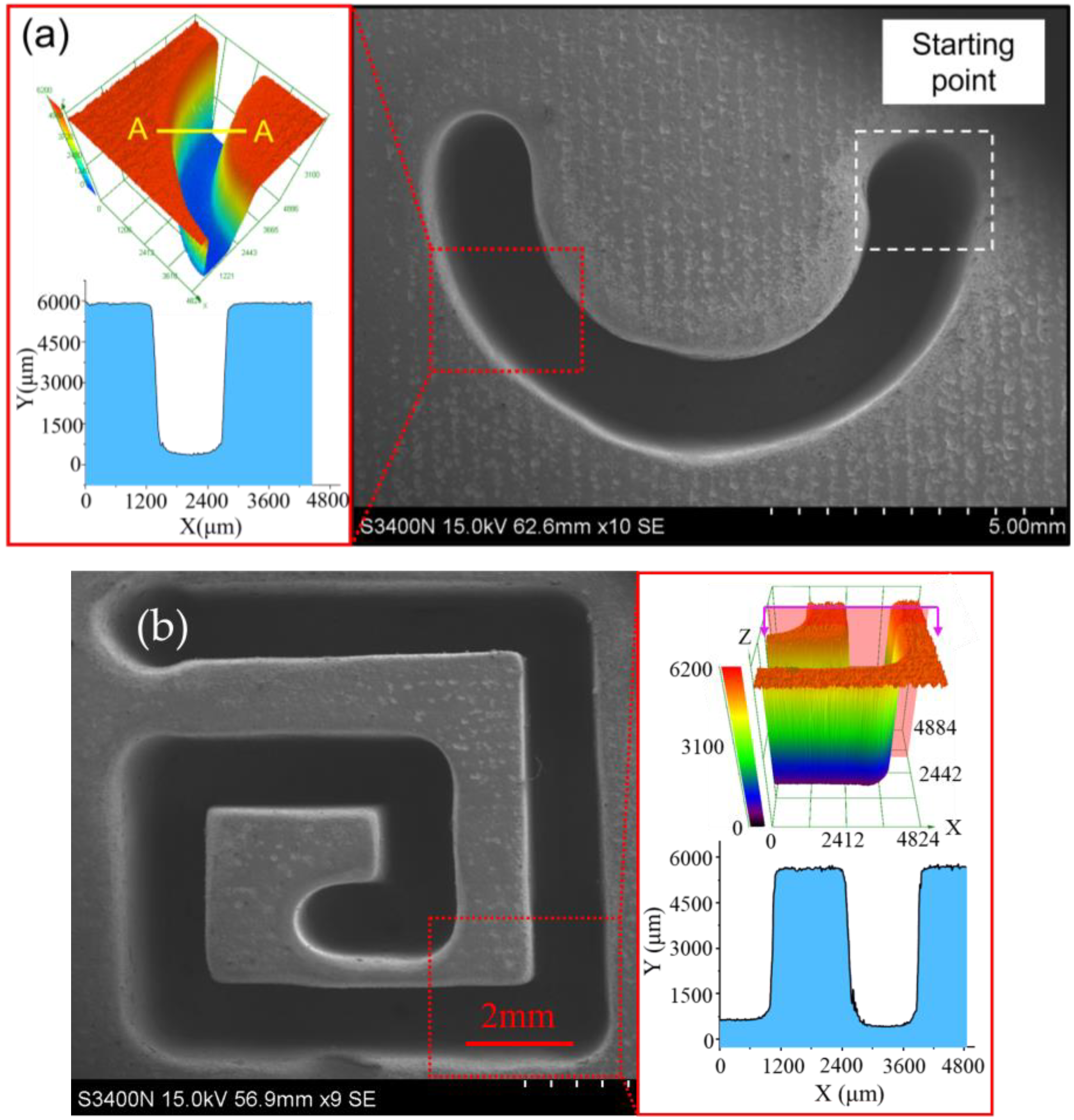

4.4. EC-Milling of Complex Narrow Grooves by Using Wedged Tube Electrode

5. Conclusions

- The simulation results indicated that the pulsating electrolyte could be generated in the inter-electrode gap by using a tube electrode with wedged end face. With the increase in wedged angle, the pulsating amplitude of electrolyte increased, but the minimum velocity electrolyte decreased.

- Experiments verified that a pulsating electrolyte generated by the wedged angle of 40° was more suitable for the EC-milling process, and both the machining accuracy and surface quality were improved. Additionally, the average width and taper of DNG was 1.49 mm ± 0.04 mm and 1.53° ± 0.46°, respectively. The surface roughness (Ra) of the sidewall reduced to 1.04 μm at the same time.

- The machining quality of DNG was improved by increasing the electrode rotational speed and feed rate. When the spindle speed was 4000 rpm and feed rate was 0.48 mm/min, the average width and taper of DNG was 1.48 mm and 1.32°, respectively. And the surface roughness (Ra) of sidewall was 0.85 μm.

- A complex deep-narrow groove structure with the depth of 5 mm was fabricated stably on a GH4169 nickel-based alloy in one-pass feed by using a wedged end face tube electrode with wedged angle of 40° at a spindle speed of 4000 rpm and feed rate of 0.48 mm/min.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Geng, P.H.; Qin, G.L.; Zhou, J. A computational modeling of fully friction contact-interaction in linear friction welding of Ni-based superalloys. Mater. Des. 2020, 185, 108244. [Google Scholar] [CrossRef]

- Zhang, Z.W.; Fu, Q.; Wang, J.; Yang, R.; Xiao, P.; Ke, F.J.; Lu, C.S. Atomistic modeling for the extremely low and high temperature-dependent yield strength in a Ni-based single crystal superalloy. Mater. Today Commun. 2021, 27, 102451. [Google Scholar] [CrossRef]

- Wang, Z.B.; Hou, G.S.; Sun, J.F.; Guo, J.Z.; Chen, W.Y. Characterization of residual stresses and grain structure in hot forging of GH4169. Aerospace 2022, 9, 92. [Google Scholar] [CrossRef]

- Wang, M.L.; Qu, N.S. Improving performance of macro electrolyte jet machining of TC4 titanium alloy: Experimental and numerical studies. Chin. J. Aeronant. 2022, 35, 280–294. [Google Scholar] [CrossRef]

- Xin, L.J.; Zhang, B.; Zhao, G.L.; Liu, H.L.; Yang, Y.F.; Li, L. Laser-induced oxidation-assisted micromilling of deep narrow microgroove on Inconel 718. Int. J. Adv. Manuf. Technol. 2021, 114, 173–184. [Google Scholar] [CrossRef]

- Chen, X.L.; Zhu, J.J.; Xu, Z.Z.; Su, G.K. Modeling and experimental research on the evolution process of micro through-slit array generated with masked jet electrochemical machining. J. Mater. Process. Technol. 2021, 298, 117304. [Google Scholar] [CrossRef]

- Li, H.S.; Fu, S.X.; Zhang, Q.L.; Niu, S.; Qu, N.S. Simulation and experimental investigation of inner-jet electrochemical grinding of GH4169 alloy. Chin. J. Aeronant. 2018, 31, 608–616. [Google Scholar] [CrossRef]

- Zhang, C.Y.; Yao, J.B.; Zhang, C.Y.; Chen, X.L.; Liu, J.W.; Zhang, Y.J. Electrochemical milling of narrow grooves with high aspect ratio using a tube electrode. J. Mater. Process. Technol. 2020, 282, 116695. [Google Scholar] [CrossRef]

- Natsu, W.; Ikeda, T.; Kunieda, M. Generating complicated surface with electrolyte jet machining. Precis. Eng. 2007, 31, 33–39. [Google Scholar] [CrossRef]

- Mitchell-Smith, J.; Speridel, A.; Gaskell, J.; Clare, A.T. Energy distribution modulation by mechanical design for electrochemical jet processing techniques. Int. J. Mach. Tools Manuf. 2017, 122, 32–46. [Google Scholar] [CrossRef]

- Liu, Y.; Chen, H.R.; Wnag, S.H.; Wang, K.; Li, M.H.; Peng, T.F. Micro electrochemical milling of micro metal parts with rotating ultrasonic electrode. Sensors 2020, 20, 6617. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Qu, N.S. Electrochemical Milling of TB6 Titanium Alloy in NaNO3 Solution. J. Electrochem. Soc. 2019, 166, 35–49. [Google Scholar] [CrossRef]

- Liu, Y.; Jiang, Y.; Guo, C.S.; Deng, S.H.; Kong, H.H. Experimental Resarch on machining localization and surface quality in micro electrochemical milling of Nickel-Based Superalloy. Micromachines 2018, 9, 402. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Rathod, V.; Doloi, B.; Bhattacharyya, B. Experimental investigations into machining accuracy and surface roughness of microgrooves fabricated by electrochemical micromachining. Proc. Inst. Mech. Eng. B J. Eng. Manuf. 2014, 229, 1781–1802. [Google Scholar]

- Ghoshal, B.; Bhattacharyya, B. Investigation on profile of microchannel generated by electrochemical micromachining. J. Mater. Process. Technol. 2015, 222, 410–421. [Google Scholar] [CrossRef]

- Wang, F.; Zhao, J.S.; Lv, Y.M.; Yang, Z.W.; Yao, J.; He, Y.F.; Tian, Z.J. Electrochemical machining of deep narrow slits on TB6 titanium alloys. Int. J. Adv. Manuf. Technol. 2017, 92, 3063–3071. [Google Scholar] [CrossRef]

- Bilgi, D.S.; Jadhav, P.V. Enhancement of surface finish of pulse electrochemically machined (PECM) surface using rotationg electrode. Int. J. Comput. Commun. Inform. Syst. 2010, 12, 49–54. [Google Scholar]

- Niu, S.; Qu, N.S.; Fu, S.X.; Fang, X.L.; Li, H.S. Investigation of inner-jet electrochemical milling of nickel-based alloy GH4169/Inconel 718. Int. J. Adv. Manuf. Technol. 2017, 93, 2123–2132. [Google Scholar] [CrossRef]

- Qu, N.S.; Fang, X.L.; Zhang, X.D.; Zhu, D. Enhancement of surface roughness in electrochamical machining of Ti6Al4V by pulsating electrolyte. Int. J. Adv. Manuf. Technol. 2013, 69, 2703–2709. [Google Scholar] [CrossRef]

- Yahya, A.; Hammouda, S.; Slimene, S.; Dhahri, H. Effect of cathode pulsating flow on mass transport and performance of solid oxide fuel cell. Int. J. Therm. Sci. 2022, 174, 107437. [Google Scholar] [CrossRef]

- Zhu, D.; Wang, K.; Qu, N.S. Mircro wire electrochemical cutting by using in situ favricated wire electrode. CIRP Ann. 2007, 56, 241–244. [Google Scholar] [CrossRef]

- Fang, X.L.; Qu, N.S.; Zhang, Y.D.; Xu, Z.Y.; Zhu, D. Effect of pulsating electrolyte flow in electrochemical machining. J. Mater. Process. Technol. 2014, 214, 36–43. [Google Scholar] [CrossRef]

- Yahagi, Y.; Koyano, T.; Kunieda, M.; Yang, X.D. Micro drilling EDM with high rotation speed of tool electrode using the electrostatic induction feeding method. Procedia Cirp 2012, 1, 162–165. [Google Scholar] [CrossRef]

- Feng, G.L.; Yang, X.D.; Chi, G.X. Experimental and simulation study on micro hole machining in EDM with high-speed tool electrode rotation. Procedia Cirp 2012, 1, 162–165. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Inlet pressure, pin | 1.2 MPa |

| Outlet pressure, pout | 0 MPa |

| Rotational speed, ω | 3000 rpm |

| Inter-electrode gap, Δ | 0.25 mm |

| Dynamic viscosity of electrolyte, μ | 1.003 × 10−3 Pa·s |

| Density of electrolyte, ρ | 1100 kg/m3 |

| External diameter of tube electrode, D | 1 mm |

| Internal diameter of tube electrode, d | 0.8 mm |

| Wedged angles, α | 0°, 40°, 50°, 60° |

| Groove length, L | 5 mm |

| Groove depth, H | 5 mm |

| Parameters | Value |

|---|---|

| Electrolyte concentration | 12% (wt.%), NaNO3 |

| Electrolyte temperature | 25 °C |

| Electrolyte pressure | 1.2 MPa |

| External diameter of tube electrode | 1 mm |

| Internal diameter of tube electrode | 0.8 mm |

| Wedge angle | 0°, 40°, 50°, 60° |

| Spindle speed | 2500, 3000, 3500, 4000 rpm |

| Feed rate | 0.30, 0.36, 0.42, 0.48 mm/min |

| Applied voltage | 25 V |

| Pulse frequency | 1 kHz |

| Pulse duty cycle | 50% |

| Machining depth | 5 mm |

| Machining length | 10 mm |

| Material of workpiece | GH4169 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ye, Z.; Qiu, G.; Chen, X. Electrochemical Milling of Deep-Narrow Grooves on GH4169 Alloy Using Tube Electrode with Wedged End Face. Micromachines 2022, 13, 1051. https://doi.org/10.3390/mi13071051

Ye Z, Qiu G, Chen X. Electrochemical Milling of Deep-Narrow Grooves on GH4169 Alloy Using Tube Electrode with Wedged End Face. Micromachines. 2022; 13(7):1051. https://doi.org/10.3390/mi13071051

Chicago/Turabian StyleYe, Zhisen, Guilin Qiu, and Xiaolei Chen. 2022. "Electrochemical Milling of Deep-Narrow Grooves on GH4169 Alloy Using Tube Electrode with Wedged End Face" Micromachines 13, no. 7: 1051. https://doi.org/10.3390/mi13071051

APA StyleYe, Z., Qiu, G., & Chen, X. (2022). Electrochemical Milling of Deep-Narrow Grooves on GH4169 Alloy Using Tube Electrode with Wedged End Face. Micromachines, 13(7), 1051. https://doi.org/10.3390/mi13071051