Theoretical and Experimental Investigation of a Rotational Magnetic Couple Piezoelectric Energy Harvester

Abstract

:1. Introduction

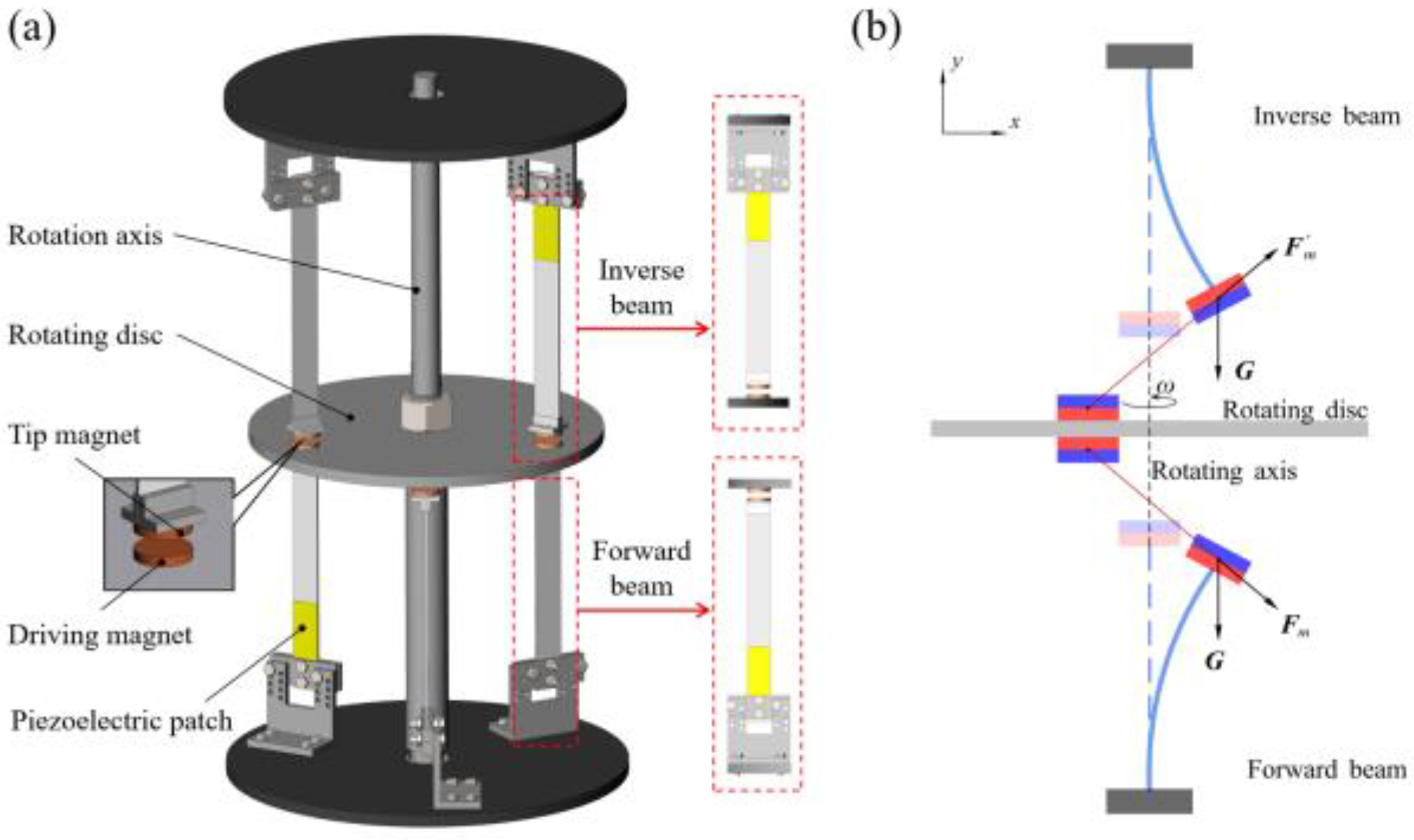

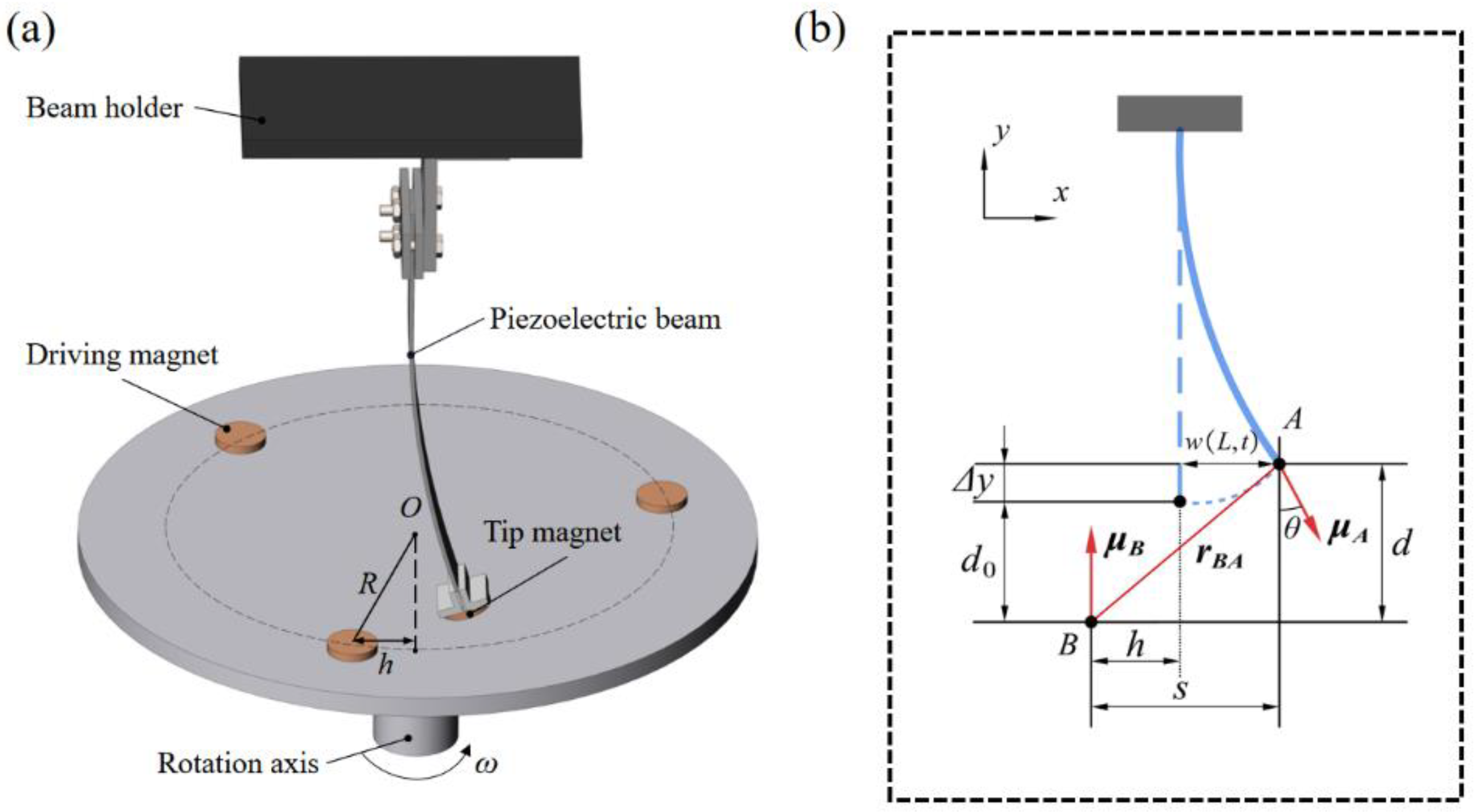

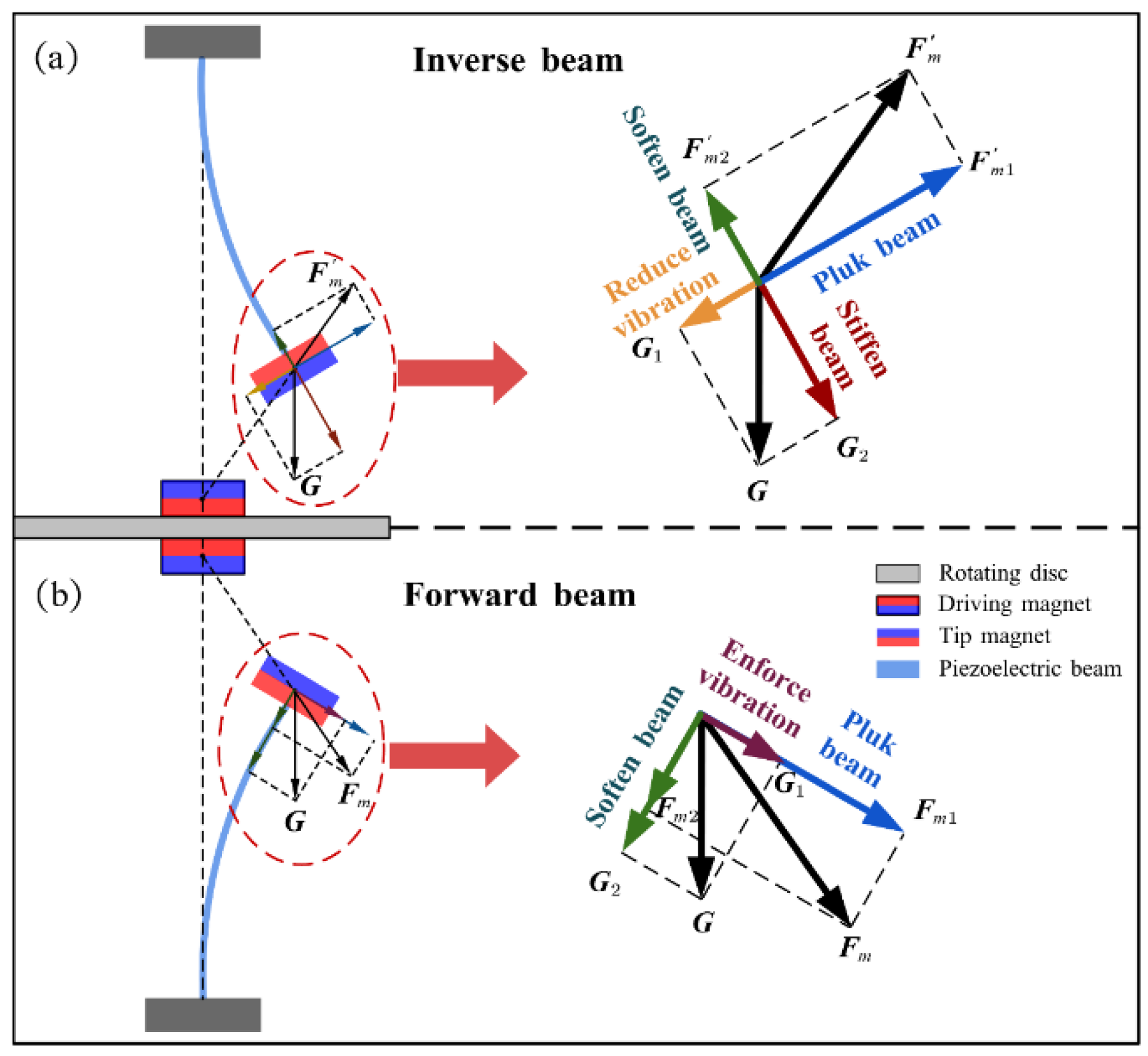

2. Harvester Design and Operating Principle

3. Theoretical Modeling and Analysis

4. Experimental Validations

4.1. Experimental Setup

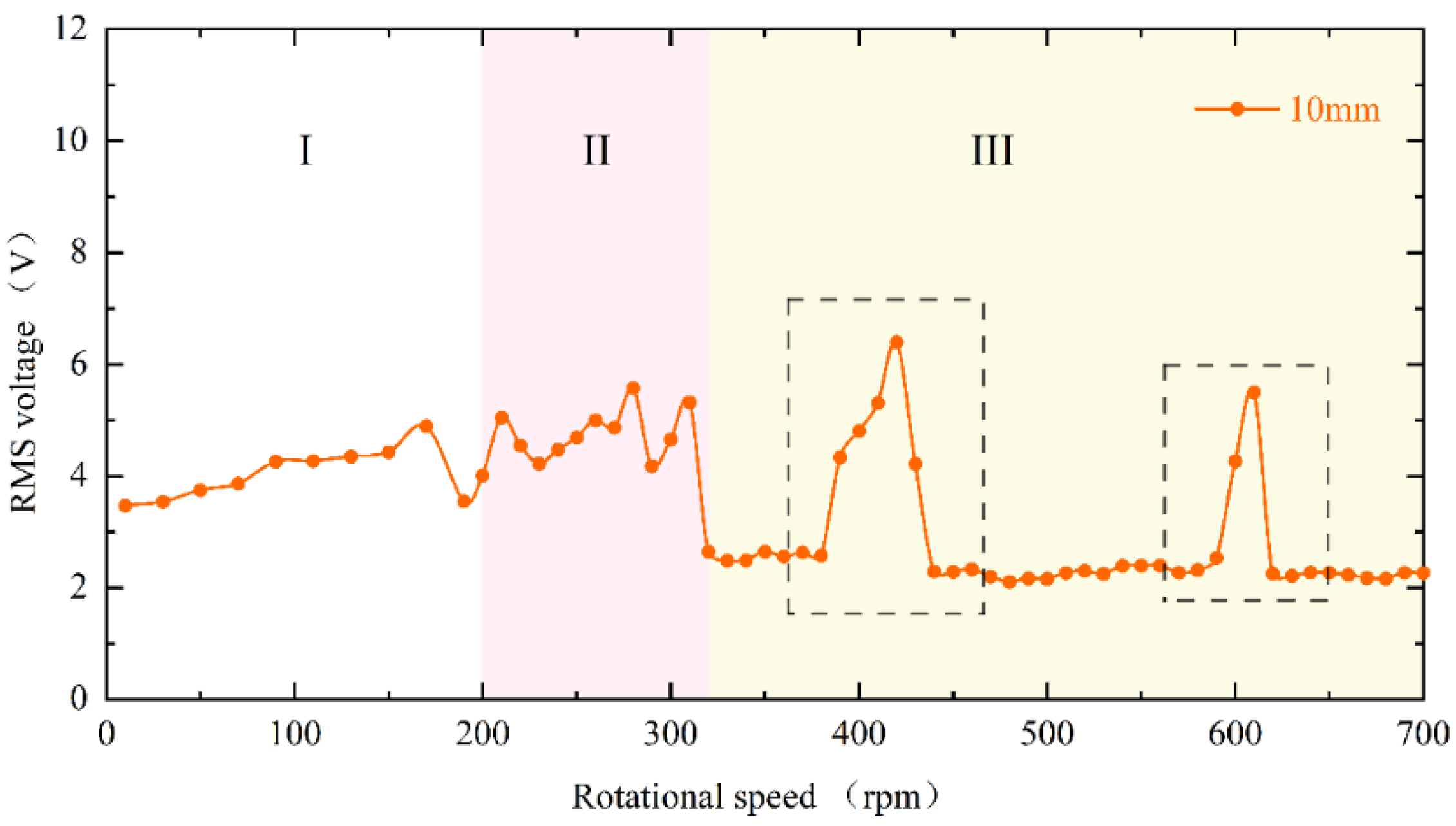

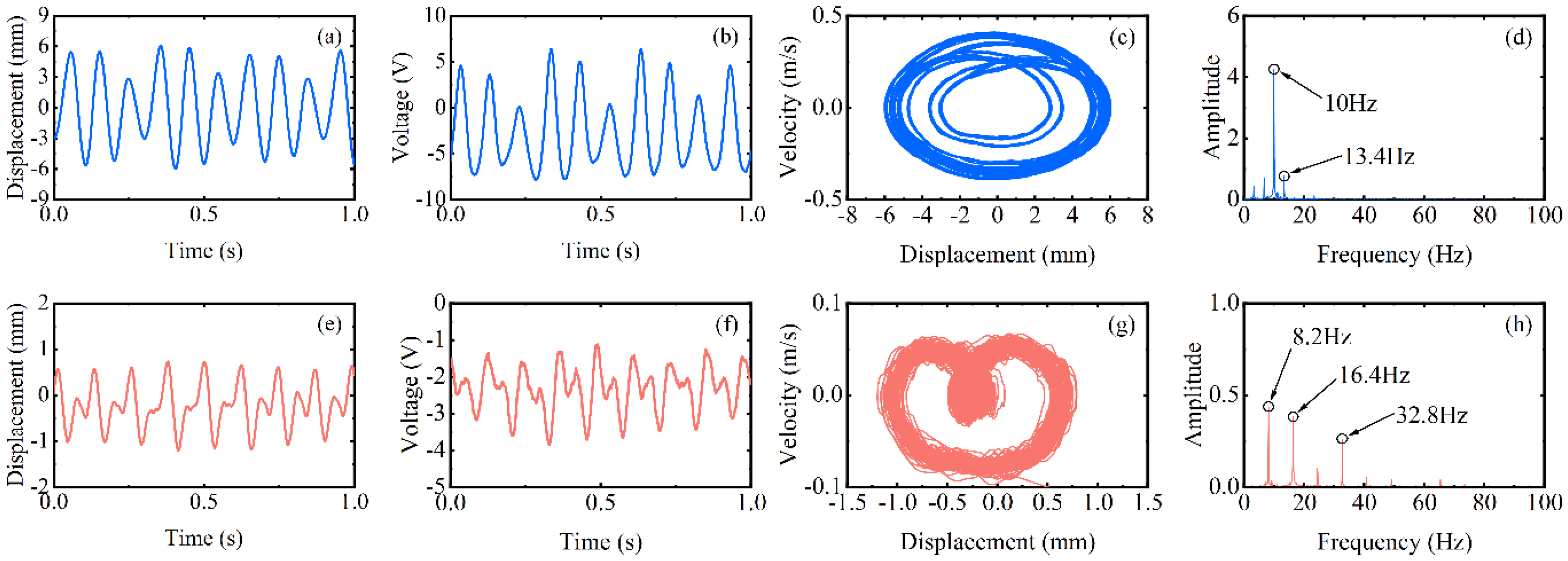

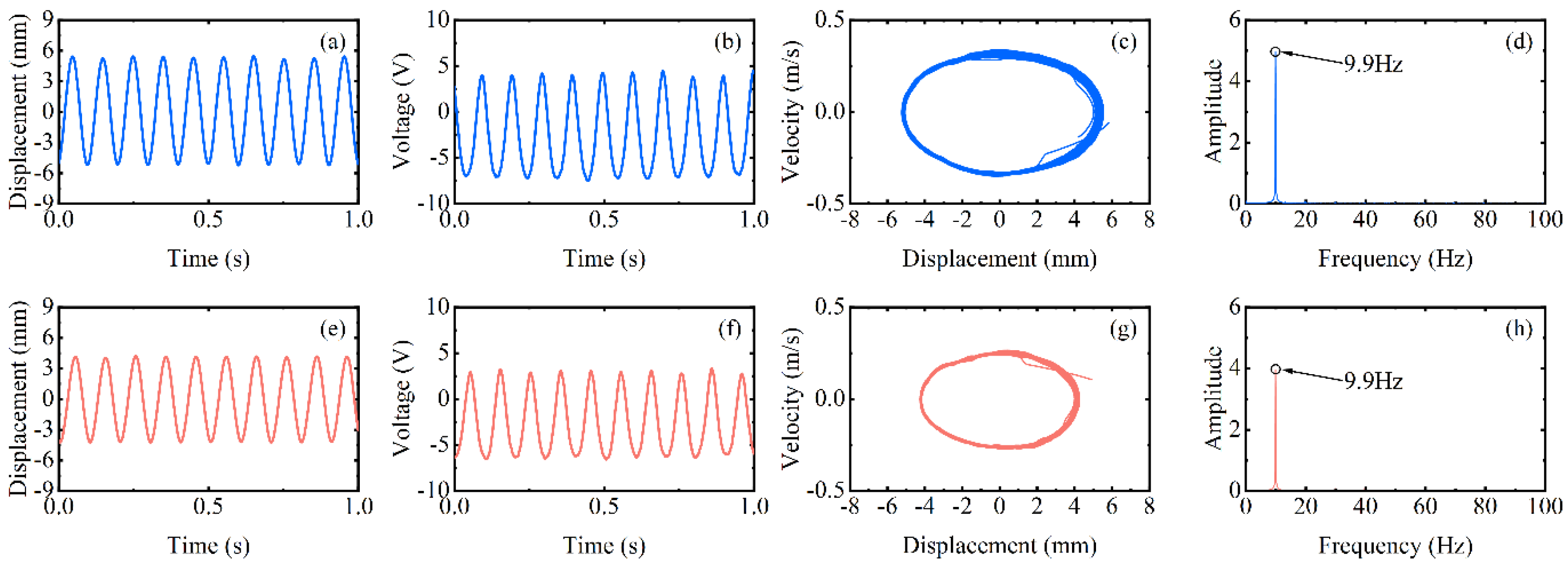

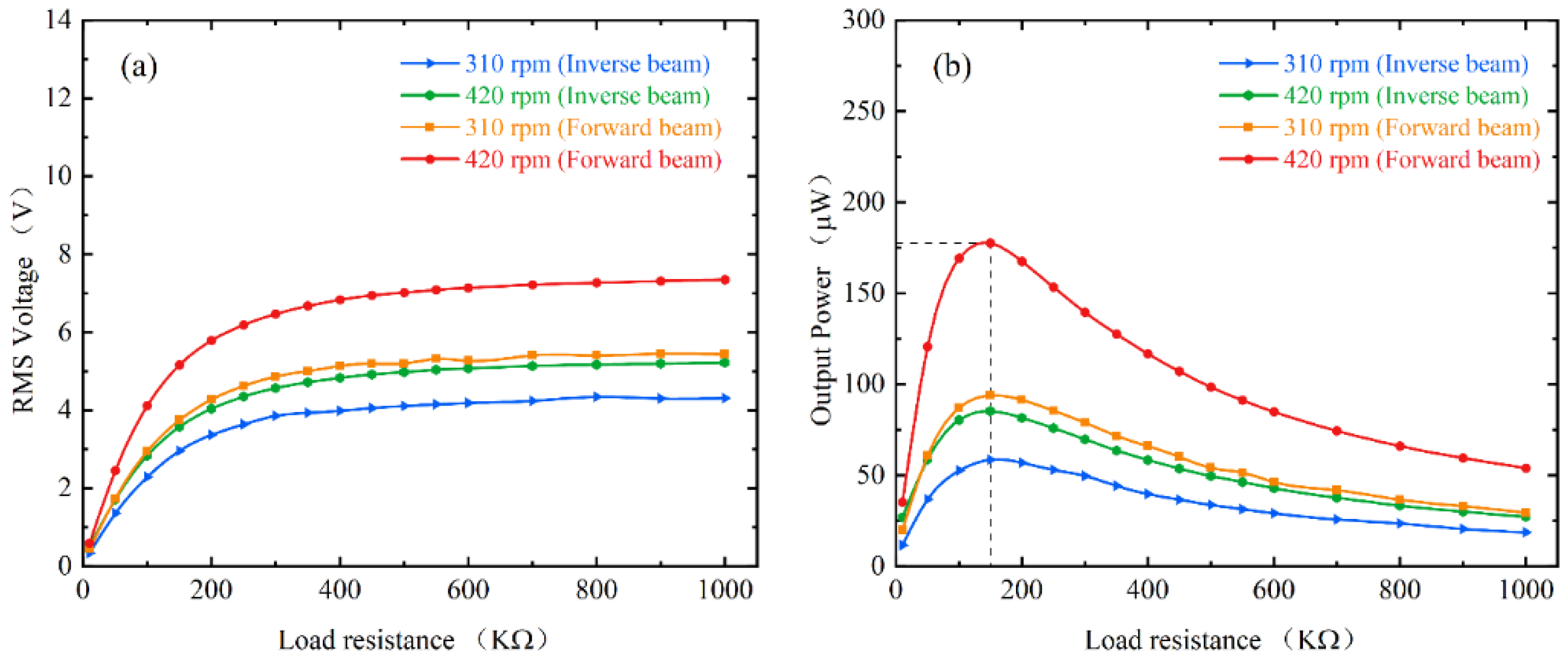

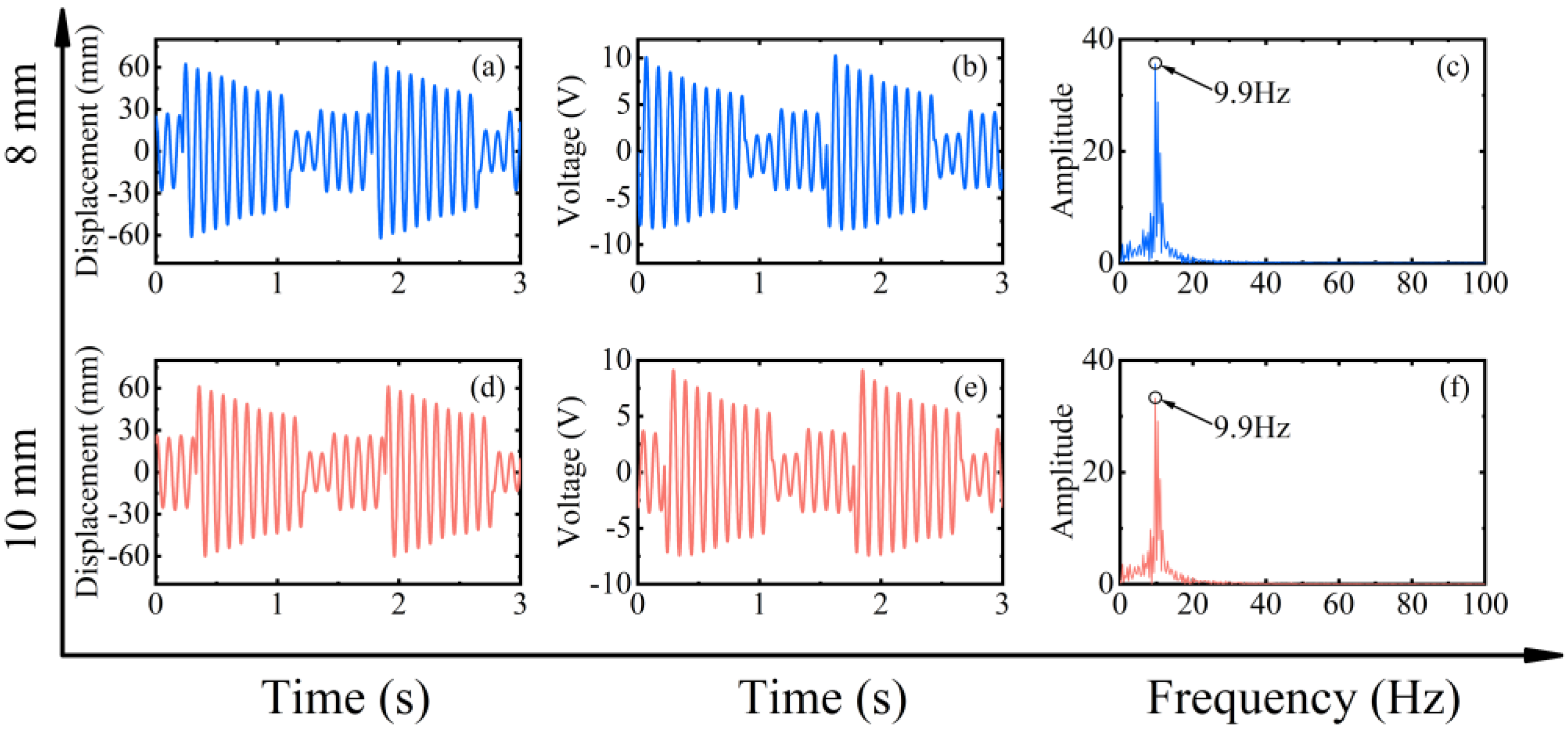

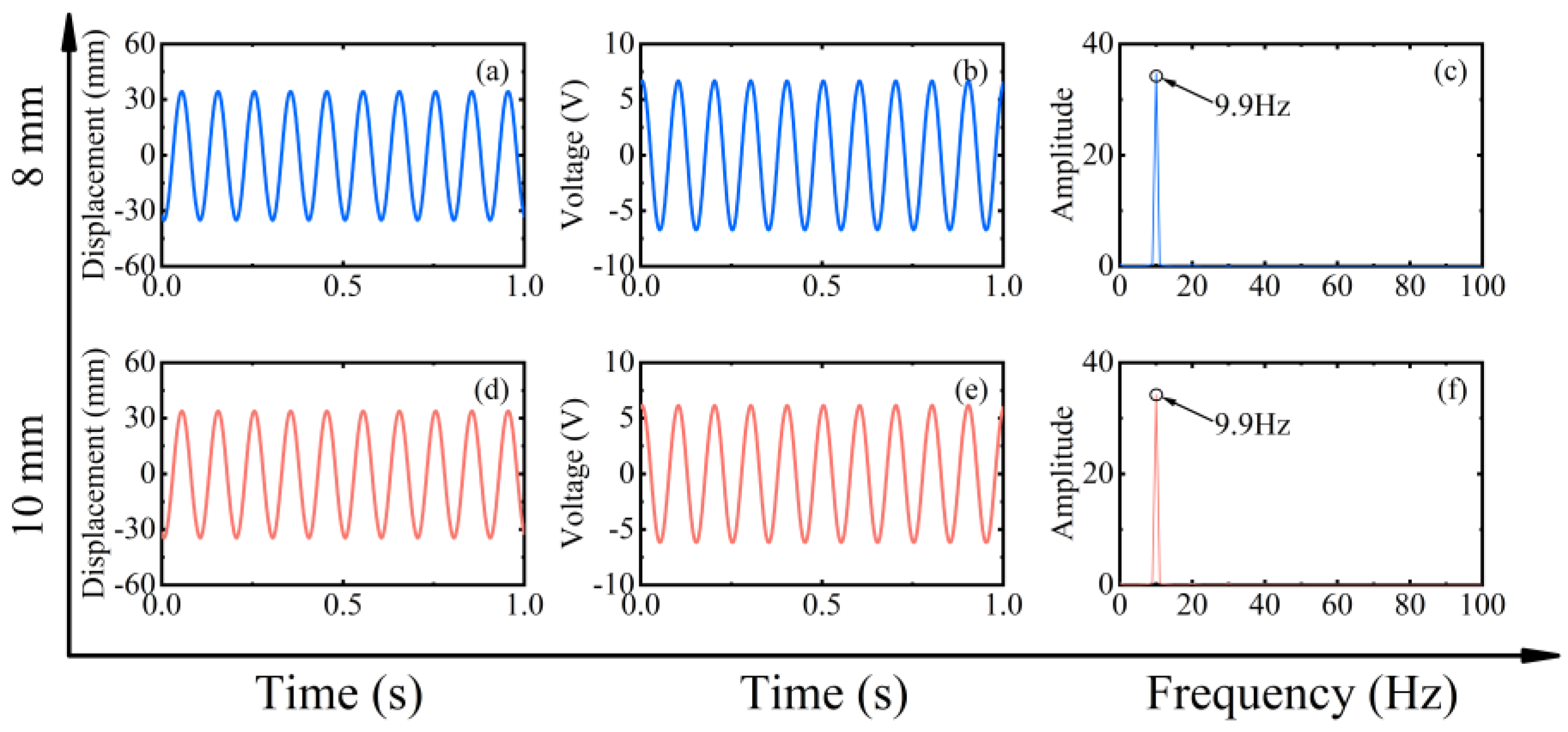

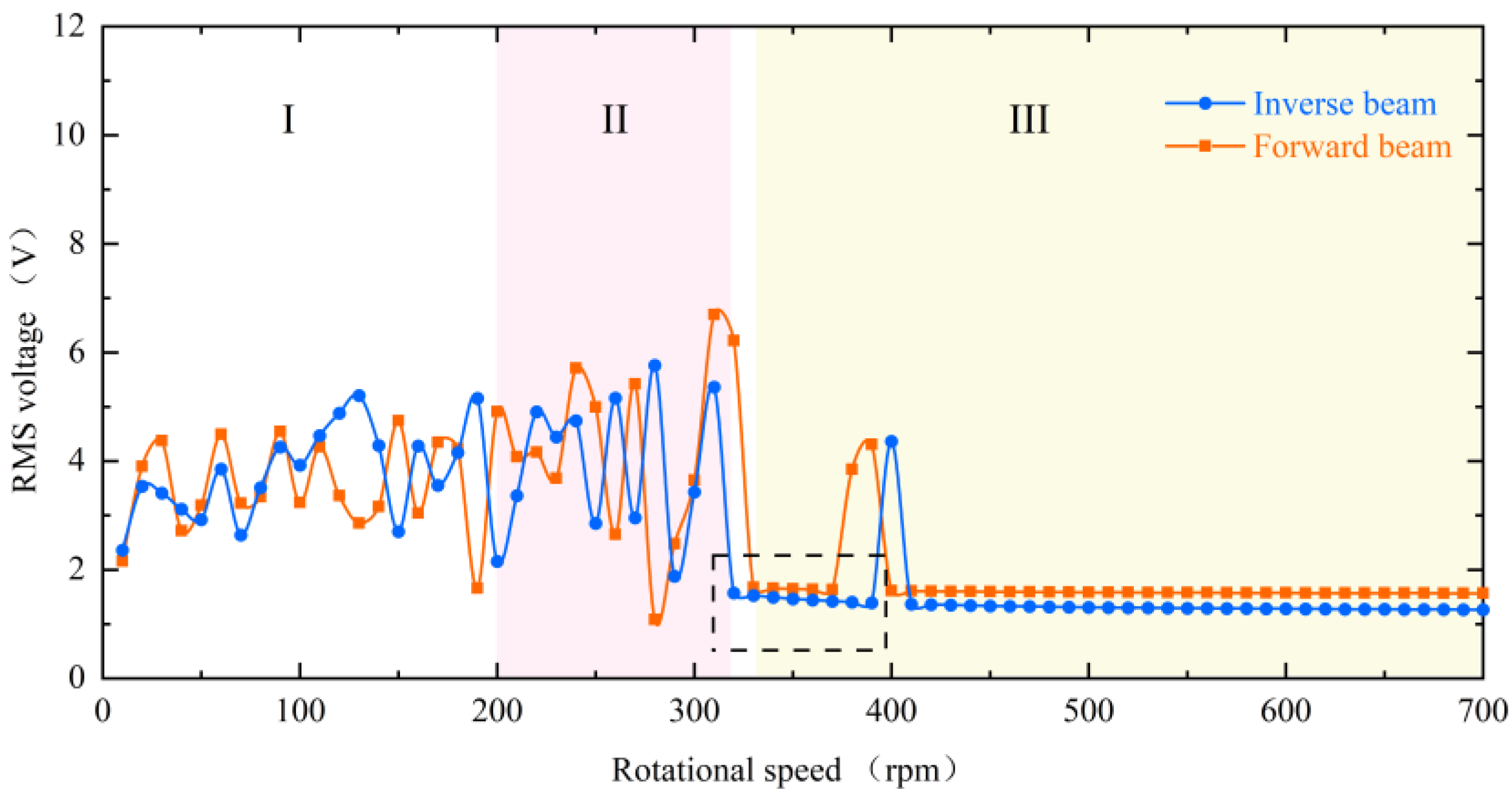

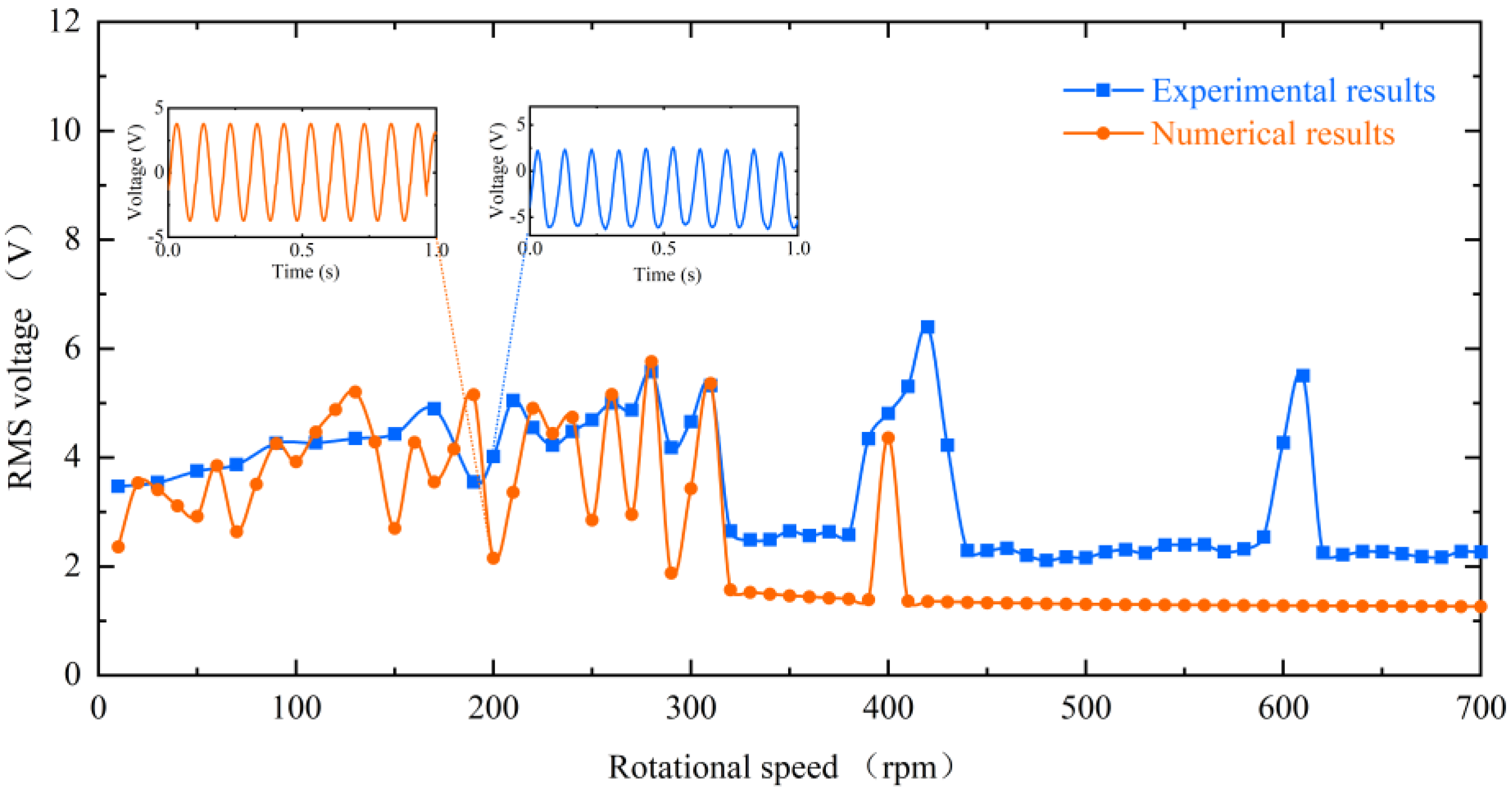

4.2. Experimental Results and Discussion

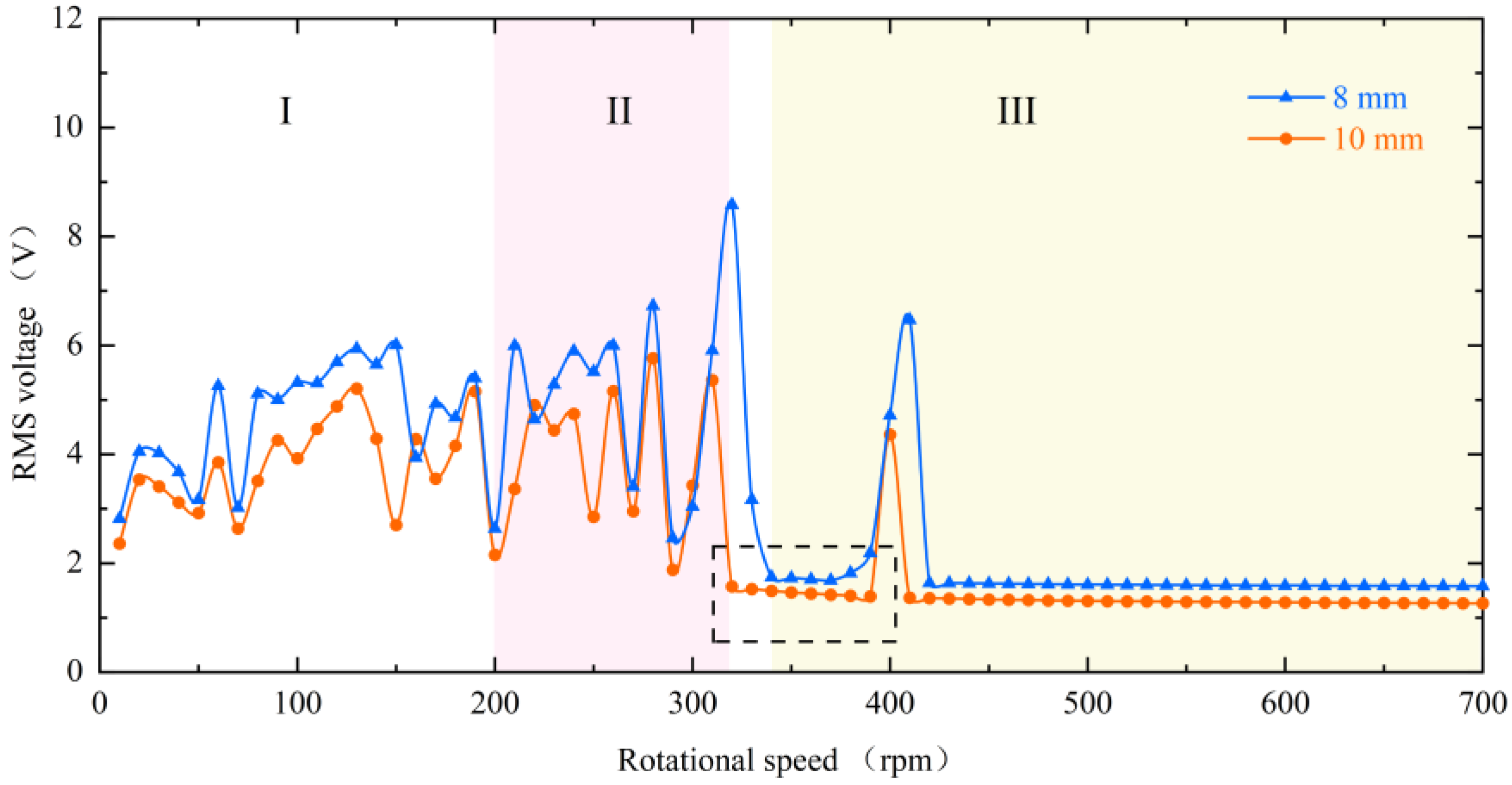

5. Parametric Studies

6. Conclusions

- (1)

- The proposed energy harvester has a wider working bandwidth benefiting from the frequency up-conversion mechanism at low-frequency conditions and the frequency down-conversion mechanism at high-frequency.

- (2)

- The gap distance of interaction magnets decreasing and the softening effect produced by the forward beam both lead to a wider bandwidth of the energy harvester.

- (3)

- The optimal load resistance for 10 mm pitch is about 150 KΩ. The maximum average power of the forward and inverse beams at 310 rpm (15.5 Hz) was 93.8 μW and 58.5 μW, respectively. At 420 rpm (21 Hz), the maximum average power of the two beams can reach 177 μW and 85.2 μW, respectively.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Jiang, J.; Liu, S.; Feng, L.; Zhao, D. A Review of Piezoelectric Vibration Energy Harvesting with Magnetic Coupling Based on Different Structural Characteristics. Micromachines 2021, 12, 436. [Google Scholar] [CrossRef] [PubMed]

- Safaei, M.; Sodano, H.A.; Anton, S.R. A Review of Energy Harvesting Using Piezoelectric Materials: State-of-the-Art a Decade Later (2008–2018). Smart Mater. Struct. 2019, 28, 113001. [Google Scholar] [CrossRef]

- Moradian, S.; Akhkandi, P.; Huang, J.; Gong, X.; Abdolvand, R. A Battery-Less Wireless Respiratory Sensor Using Micro-Machined Thin-Film Piezoelectric Resonators. Micromachines 2021, 12, 363. [Google Scholar] [CrossRef] [PubMed]

- Han, R.; Wang, N.; He, Q.; Wang, J.; Li, X. An Energy Harvester with Temperature Threshold Triggered Cycling Generation for Thermal Event Autonomous Monitoring. Micromachines 2021, 12, 425. [Google Scholar] [CrossRef]

- Samal, N.; Shiney, O.J.; Patra, A. Study of Piezoelectric transducers used for Energy Harvesting Applications. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1085, 012031. [Google Scholar] [CrossRef]

- Abedini, A.; Wang, F. Energy Harvesting of a Frequency Up-Conversion Piezoelectric Harvester with Controlled Impact. Eur. Phys. J. Spec. Top. 2019, 228, 1459–1474. [Google Scholar] [CrossRef]

- Li, K.; He, Q.; Wang, J.; Zhou, Z.; Li, X. Wearable Energy Harvesters Generating Electricity from Low-Frequency Human Limb Movement. Microsyst. Nanoeng. 2018, 4, 24. [Google Scholar] [CrossRef]

- Nezami, S.; Jung, H.; Lee, S. Design of a Disk-Swing Driven Piezoelectric Energy Harvester for Slow Rotary System Application. Smart Mater. Struct. 2019, 28, 074001. [Google Scholar] [CrossRef]

- Wen, S.; Wu, Z.; Xu, Q. Design of a Novel Two-Directional Piezoelectric Energy Harvester with Permanent Magnets and Multistage Force Amplifier. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2019, 67, 840–849. [Google Scholar] [CrossRef]

- Sun, C.; Shang, G. On Broadband Nonlinear Piezoelectric Energy Harvesting Techniques. IOP Conf. Ser. Mater. Sci. Eng. 2020, 730, 012039. [Google Scholar] [CrossRef]

- Yang, Z.; Tang, L.; Xie, M.; Sun, S.; Li, W.; Aw, K. Soft Magneto-Sensitive Elastomer and Polyvinylidene Fluoride Polymer Based Nonlinear Piezoelectric Energy Harvesting: Design, Modelling and Experiment. Smart Mater. Struct. 2018, 28, 015031. [Google Scholar] [CrossRef]

- Krishnasamy, M.; Upadrashta, D.; Yang, Y.; Lenka, T.R. Distributed Parameter Modelling of Cutout 2-DOF Cantilevered Piezo-Magneto-Elastic Energy Harvester. J. Microelectromechanical Syst. 2018, 27, 1160–1170. [Google Scholar] [CrossRef]

- Li, X.; Upadrashta, D.; Yu, K.; Yang, Y. Analytical Modeling and Validation of Multi-Mode Piezoelectric Energy Harvester. Mech. Syst. Signal Processing 2019, 124, 613–631. [Google Scholar] [CrossRef]

- Sun, R.; Li, Q.; Yao, J.; Scarpa, F.; Rossiter, J. Tunable, Multi-Modal, and Multi-Directional Vibration Energy Harvester Based on Three-Dimensional Architected Metastructures. Appl. Energy 2020, 264, 114615. [Google Scholar] [CrossRef]

- Shi, G.; Yang, Y.; Chen, J.; Peng, Y.; Xia, H.; Xia, Y. A Broadband Piezoelectric Energy Harvester with Movable Mass for Frequency Active Self-Tuning. Smart Mater. Struct. 2020, 29, 055023. [Google Scholar] [CrossRef]

- Dechant, E.; Fedulov, F.; Fetisov, L.Y.; Shamonin, M. Bandwidth Widening of Piezoelectric Cantilever Beam Arrays by Mass-Tip Tuning for Low-Frequency Vibration Energy Harvesting. Appl. Sci. 2017, 7, 1324. [Google Scholar] [CrossRef]

- Bouhedma, S.; Zheng, Y.; Lange, F.; Hohlfeld, D. Magnetic Frequency Tuning of a Multimodal Vibration Energy Harvester. Sensors 2019, 19, 1149. [Google Scholar] [CrossRef]

- Lai, S.-K.; Wang, C.; Zhang, L.-H. A Nonlinear Multi-Stable Piezomagnetoelastic Harvester Array for Low-Intensity, Low-Frequency, and Broadband Vibrations. Mech. Syst. Signal Processing 2019, 122, 87–102. [Google Scholar] [CrossRef]

- Jiang, J.; Liu, S.; Zhao, D.; Feng, L. Broadband Power Generation of Piezoelectric Vibration Energy Harvester with Magnetic Coupling. J. Intell. Mater. Syst. Struct. 2019, 30, 2272–2282. [Google Scholar] [CrossRef]

- Fu, H.; Yeatman, E.M. Rotational Energy Harvesting Using Bi-Stability and Frequency Up-Conversion for Low-Power Sensing Applications: Theoretical Modelling and Experimental Validation. Mech. Syst. Signal Processing 2019, 125, 229–244. [Google Scholar] [CrossRef]

- Hu, X.; Li, Y.; Xie, X. A Study on a U-Shaped Piezoelectric Coupled Beam and Its Corresponding Ingenious Harvester. Energy 2019, 185, 938–950. [Google Scholar] [CrossRef]

- Xue, T.; Roundy, S. On Magnetic Plucking Configurations for Frequency Up-Converting Mechanical Energy Harvesters. Sens. Actuators A Phys. 2017, 253, 101–111. [Google Scholar] [CrossRef]

- Egbe, K.-J.I.; Nazar, A.M.; Jiao, P.; Yang, Y.; Ye, X.; Wang, H. Vibrational Turbine Piezoelectric Nanogenerators for Energy Harvesting in Multiphase Flow Fields. Energy Rep. 2021, 7, 6384–6393. [Google Scholar] [CrossRef]

- Zhao, L.-C.; Zou, H.-X.; Yan, G.; Liu, F.-R.; Tan, T.; Zhang, W.-M.; Peng, Z.-K.; Meng, G. A Water-Proof Magnetically Coupled Piezoelectric-Electromagnetic Hybrid Wind Energy Harvester. Appl. Energy 2019, 239, 735–746. [Google Scholar] [CrossRef]

- Xie, Z.; Kitio Kwuimy, C.; Wang, Z.; Huang, W. A Piezoelectric Energy Harvester for Broadband Rotational Excitation Using Buckled Beam. AIP Adv. 2018, 8, 015125. [Google Scholar] [CrossRef]

- Zou, H.-X.; Zhang, W.-M.; Li, W.-B.; Wei, K.-X.; Hu, K.-M.; Peng, Z.-K.; Meng, G. Magnetically Coupled Flextensional Transducer for Wideband Vibration Energy Harvesting: Design, Modeling and Experiments. J. Sound Vib. 2018, 416, 55–79. [Google Scholar] [CrossRef]

- Liao, Y.; Liang, J. Maximum Power, Optimal Load, and Impedance Analysis of Piezoelectric Vibration Energy Harvesters. Smart Mater. Struct. 2018, 27, 075053. [Google Scholar] [CrossRef]

| Parameters | Symbol | Value |

|---|---|---|

| Cantilever beam | ||

| Length × Width × Thickness | L × b × tb | 90 × 12 × 0.25 mm3 |

| Density | ρb | 7765 Kg/m3 |

| Young’s modulus | Eb | 210 Gpa |

| Mechanical damping coefficient | C | 0.005 N∙s/m |

| Equivalent stiffness | K | 16.85 N/m |

| Piezoelectric patch | ||

| Length × Width × Thickness | L × b × tp | 25 × 12 × 0.13 mm3 |

| Density | ρp | 7800 Kg/m3 |

| Young’s modulus | Ep | 66 Gpa |

| Coupling coefficient | d31 | −320 × 1012 C/N |

| Permittivity constant | ε33 | 4000 ε0 |

| Permittivity of free space | ε0 | 8.854 × 1012 F/m |

| Electromechanical coupling coefficient | ϑp | 1.197 × 10−5 |

| Equivalent capacitance | Cp | 1.15 × 10−7 F |

| Permanent magnets | ||

| Density | ρm | 7500 Kg/m3 |

| Magnet’s residual flux density | Br | 1.5 T |

| Permeability of free space | μ0 | 4 π × 10−7 |

| Magnet A | D × tm | D12 × 2 mm3 |

| Magnet B | D × tm | D12 × 2 mm3 |

| Other parameters | ||

| Equivalent stiffness of gravity | Kg Kg′ | 0.6 N/m |

| Whole load resistance | Rl | 1000 KΩ |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, F.; Dong, R.; Zhou, R.; Xu, F.; Mei, X. Theoretical and Experimental Investigation of a Rotational Magnetic Couple Piezoelectric Energy Harvester. Micromachines 2022, 13, 936. https://doi.org/10.3390/mi13060936

Sun F, Dong R, Zhou R, Xu F, Mei X. Theoretical and Experimental Investigation of a Rotational Magnetic Couple Piezoelectric Energy Harvester. Micromachines. 2022; 13(6):936. https://doi.org/10.3390/mi13060936

Chicago/Turabian StyleSun, Feng, Runhong Dong, Ran Zhou, Fangchao Xu, and Xutao Mei. 2022. "Theoretical and Experimental Investigation of a Rotational Magnetic Couple Piezoelectric Energy Harvester" Micromachines 13, no. 6: 936. https://doi.org/10.3390/mi13060936

APA StyleSun, F., Dong, R., Zhou, R., Xu, F., & Mei, X. (2022). Theoretical and Experimental Investigation of a Rotational Magnetic Couple Piezoelectric Energy Harvester. Micromachines, 13(6), 936. https://doi.org/10.3390/mi13060936