Broadband Silicon Nitride Power Splitter Based on Bent Directional Couplers with Low Thermal Sensitivity

Abstract

:1. Introduction

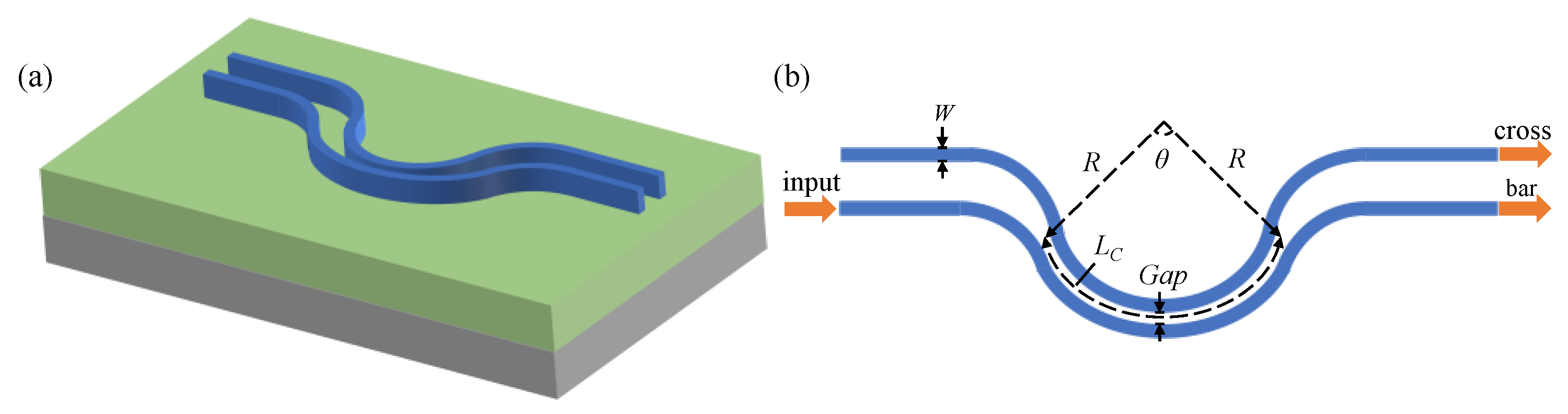

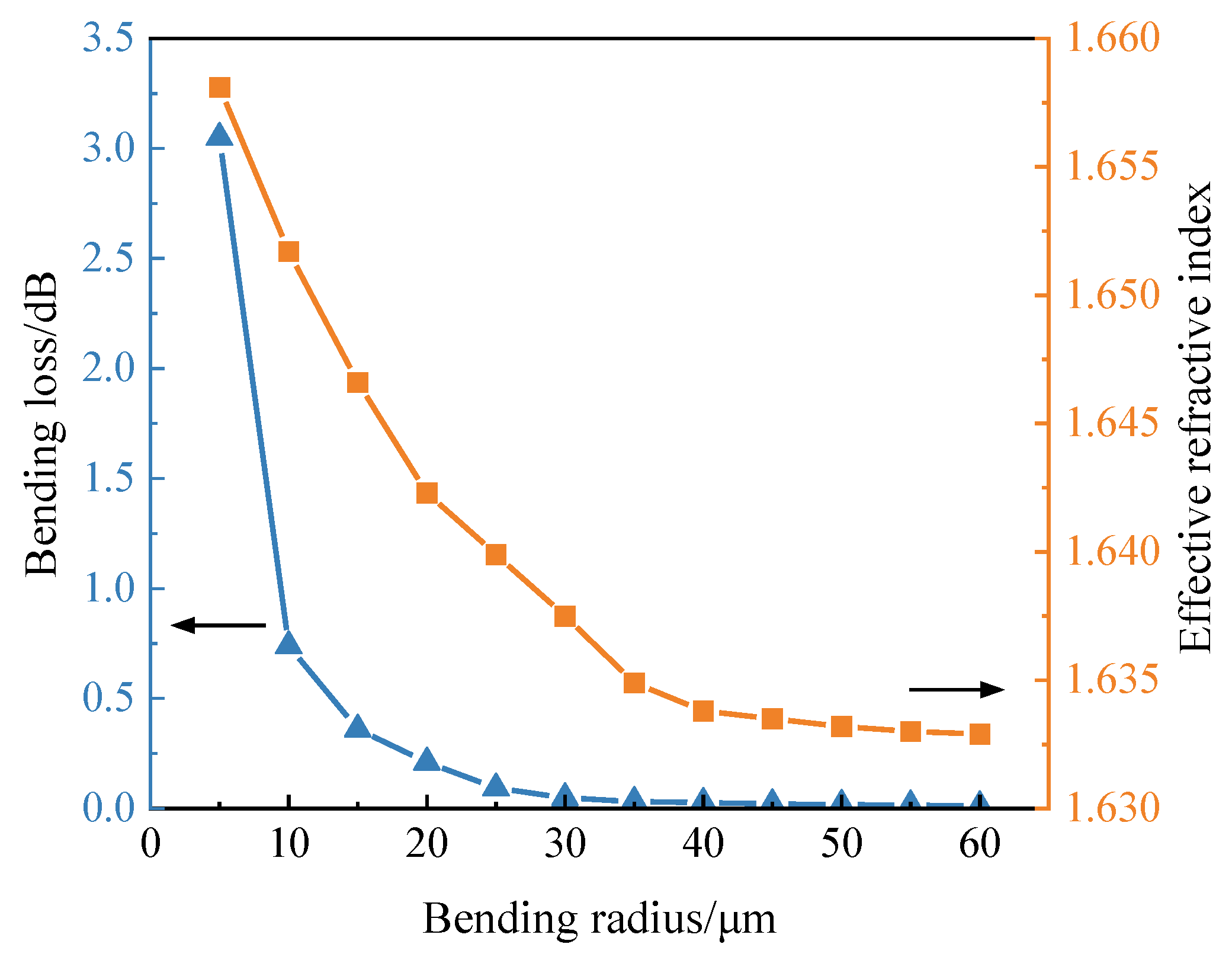

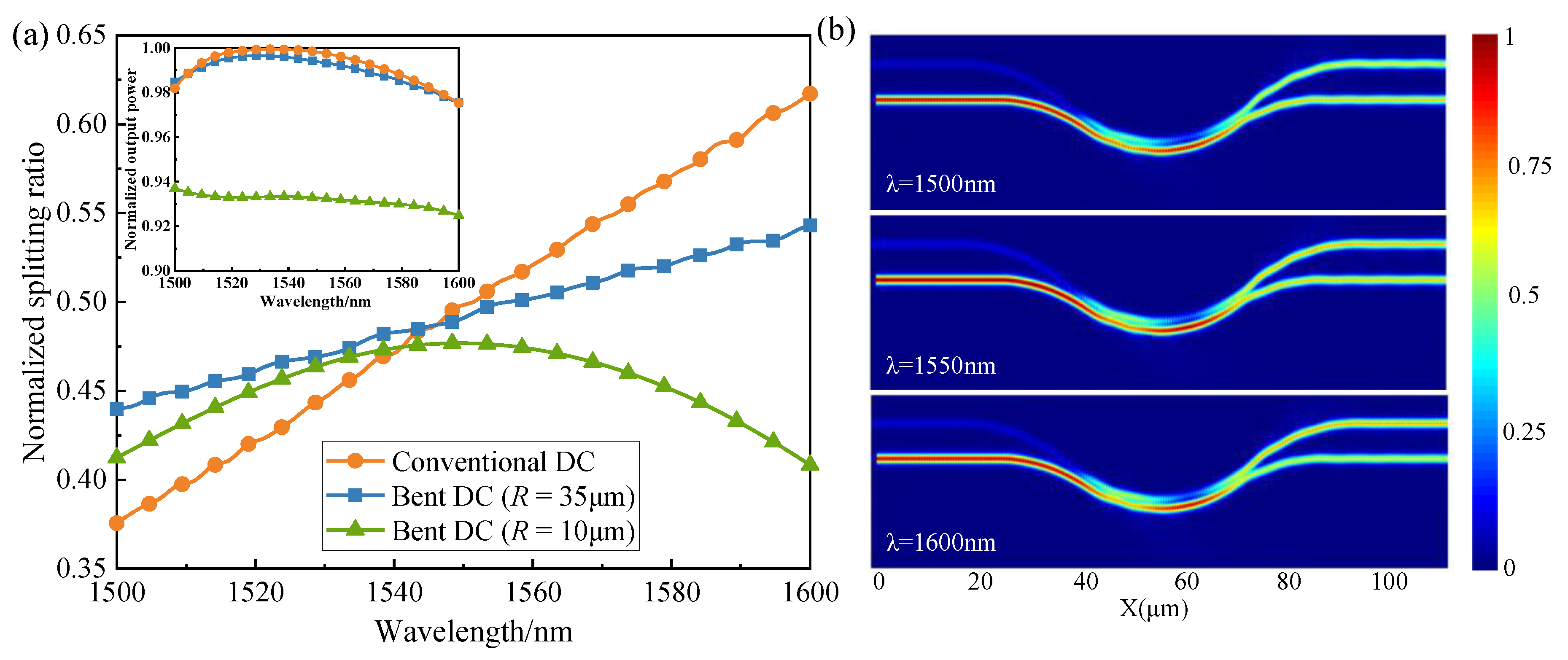

2. Working Principle and Design Structure

3. Fabrication and Characterization

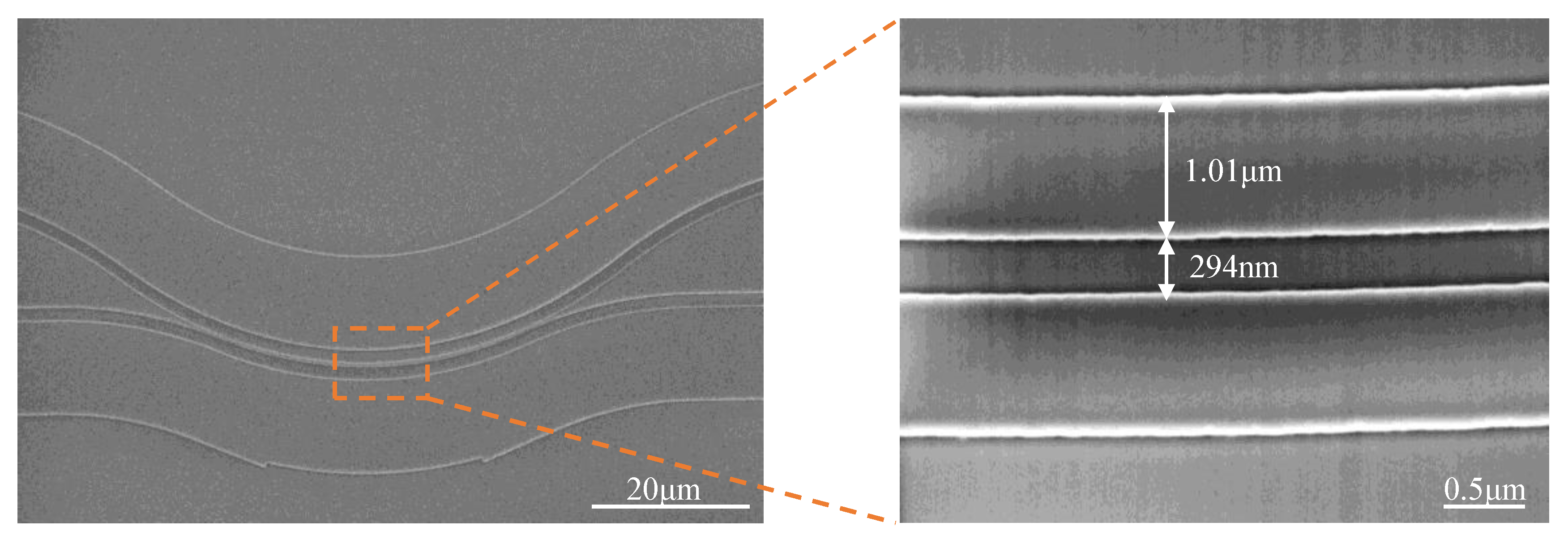

3.1. Fabrication Process

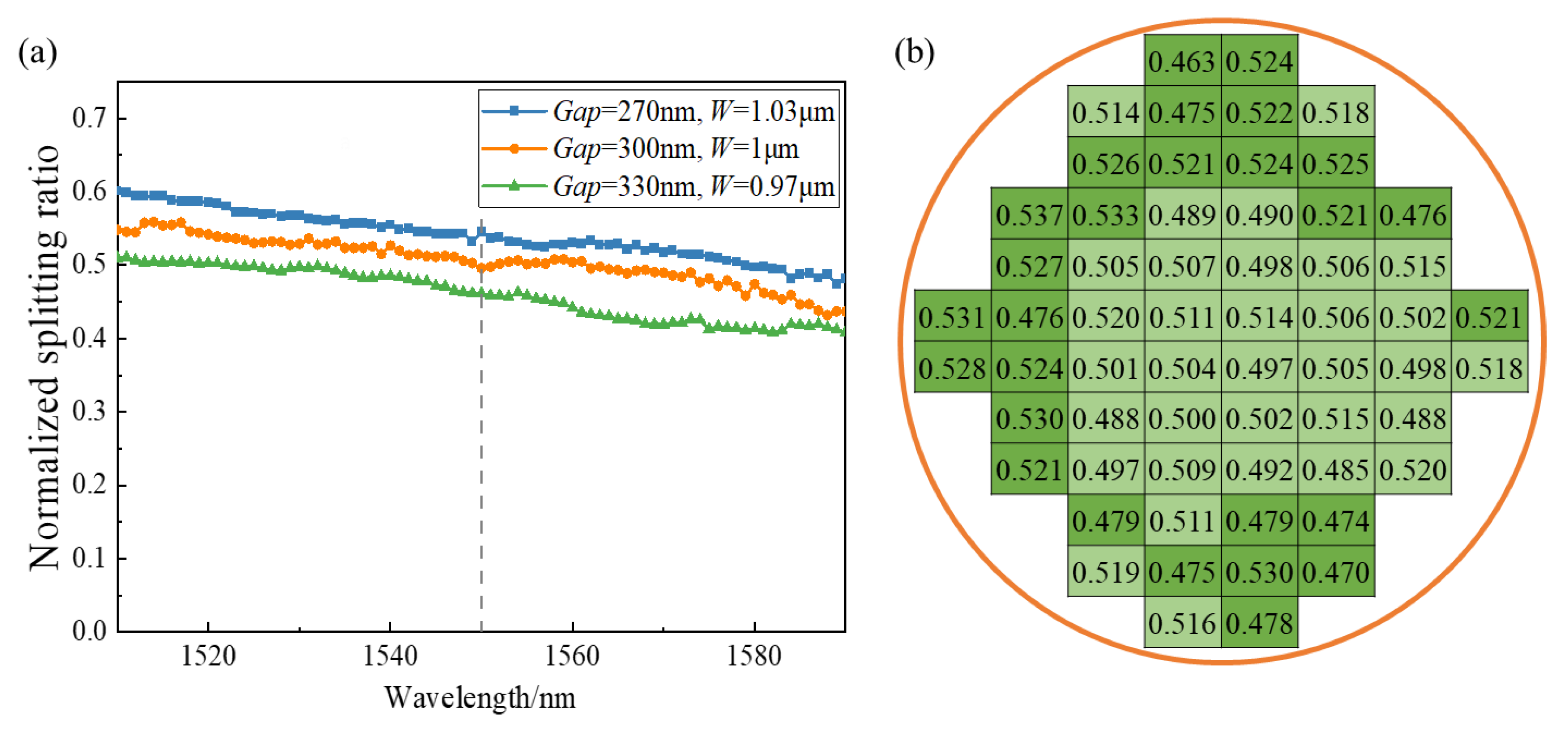

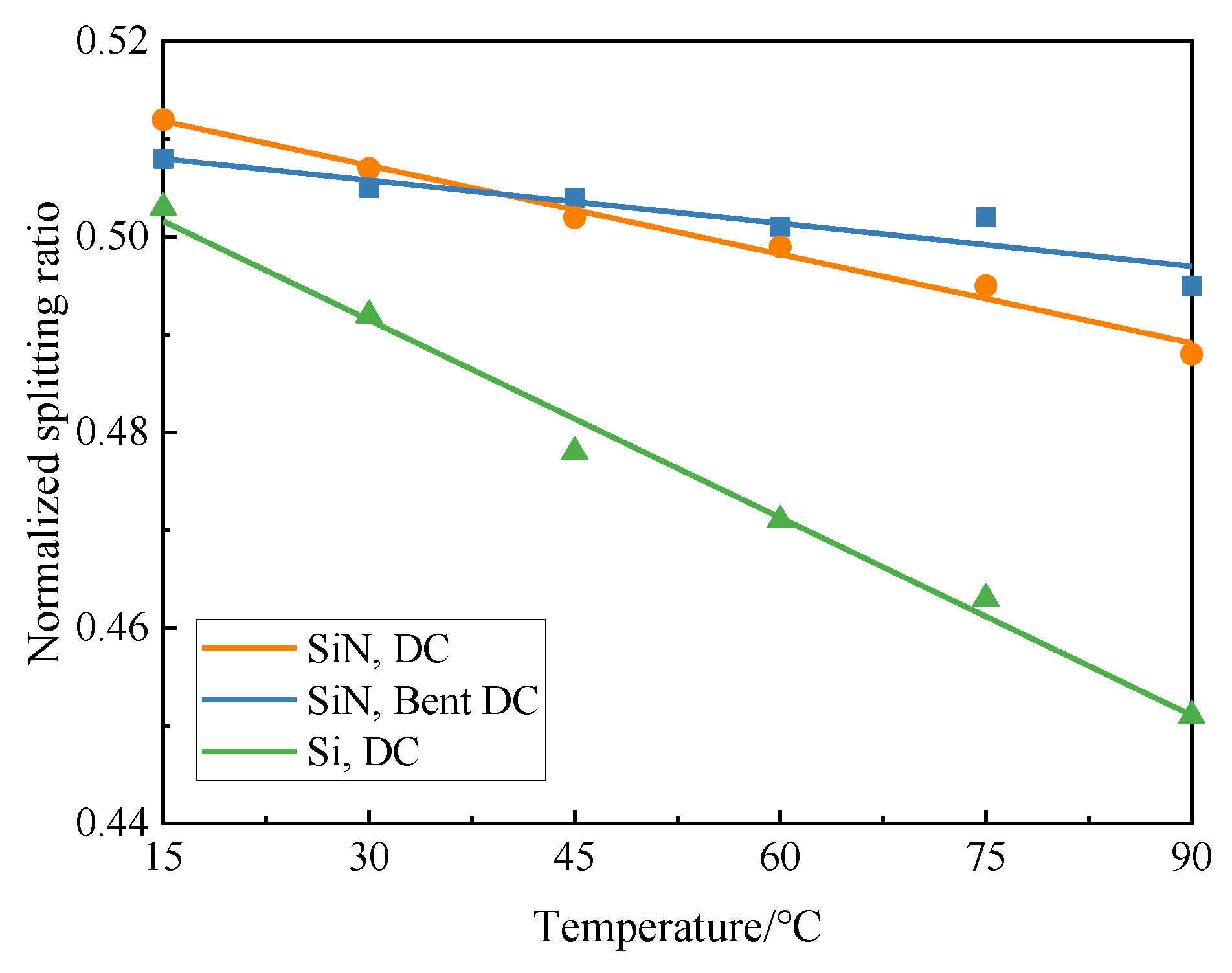

3.2. Characterization of the Bent Directional Coupler

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Teng, M.; Honardoost, A.; Alahmadi, Y.; Polkoo, S.S.; Kojima, K.; Wen, H.; Renshaw, C.K.; LiKamwa, P.; Li, G.; Fathpour, S.; et al. Miniaturized Silicon Photonics Devices for Integrated Optical Signal Processors. J. Light. Technol. 2020, 38, 6–17. [Google Scholar] [CrossRef]

- Feng, C.; Ying, Z.; Zhao, Z.; Gu, J.; Pan, D.Z.; Chen, R.T. Toward High-Speed and Energy-Efficient Computing: A WDM-Based Scalable On-Chip Silicon Integrated Optical Comparator. Laser Photonic Rev. 2021, 15, 2000275. [Google Scholar] [CrossRef]

- Keiser, G. Wavelength Division Multiplexing (WDM). In Fiber Optic Communications; Keiser, G., Ed.; Springer: Singapore, 2021; pp. 383–435. [Google Scholar] [CrossRef]

- Onawa, Y.; Okayama, H.; Shimura, D.; Yaegashi, H.; Sasaki, H.; Kashima, M. Multimode-based polarization independent WDM devices using different order modes for TE and TM polarizations. Opt. Express 2020, 28, 39227–39240. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Kwon, K.; Henriksson, J.; Luo, J.; Wu, C. Large-scale Silicon Photonics Focal Plane Switch Array for Optical Beam Steering. In Proceedings of the Optical Fiber Communication Conference, Washington, DC, USA, 6–11 June 2021. [Google Scholar]

- Gupta, R.K.; Chandran, S.; Das, K. Wavelength-Independent Directional Couplers for Integrated Silicon Photonics. J. Light. Technol. 2017, 35, 4916–4923. [Google Scholar] [CrossRef]

- Ni, B.; Xiao, J. Ultracompact and broadband silicon-based TE-pass 1 × 2 power splitter using subwavelength grating couplers and hybrid plasmonic gratings. Opt. Express 2018, 26, 33942–33955. [Google Scholar] [CrossRef] [PubMed]

- Xu, Q.; Tao, J.; Sun, C.; Zhao, J.; Wang, Z.; Du, L.; Li, X. Broadband Polarization-Independent Directional Coupler Using Asymmetric-Waveguides. IEEE Photonics J. 2019, 11, 6603506. [Google Scholar] [CrossRef]

- Yun, H.; Wang, Y.; Zhang, F.; Lu, Z.; Lin, S.; Chrostowski, L.; Jaeger, F. Broadband 2 × 2 adiabatic 3 dB coupler using silicon-on-insulator sub-wavelength grating waveguides. Opt. Lett. 2016, 41, 3041–3044. [Google Scholar] [CrossRef] [PubMed]

- Morino, H.; Maruyama, T.; Iiyama, K. Reduction of Wavelength Dependence of Coupling Characteristics Using Si Optical Waveguide Curved Directional Coupler. J. Light. Technol. 2014, 32, 2188–2192. [Google Scholar] [CrossRef]

- Su, Y.; Zhang, Y.; Qiu, C.; Guo, X.; Sun, L. Silicon Photonics: Silicon Photonic Platform for Passive Waveguide Devices: Materials, Fabrication, and Applications. Adv. Mater. Technol. 2020, 5, 2070046. [Google Scholar] [CrossRef]

- Wilmart, Q.; El Dirani, H.; Tyler, N.; Fowler, D.; Malhouitre, S.; Garcia, S.; Casale, M.; Kerdiles, S.; Hassan, K.; Monat, C.; et al. A Versatile Silicon-Silicon Nitride Photonics Platform for Enhanced Functionalities and Applications. Appl. Sci. 2019, 9, 255. [Google Scholar] [CrossRef] [Green Version]

- Rahim, A.; Ryckeboer, E.; Subramanian, Z.; Clemmen, S.; Kuyken, B.; Dhakal, A.; Raza, A.; Hermans, A.; Muneeb, M.; Dhoore, S.Y.; et al. Expanding the Silicon Photonics Portfolio with Silicon Nitride Photonic Integrated Circuits. J. Light. Technol. 2017, 35, 639–649. [Google Scholar] [CrossRef]

- Yariv, A. Coupled-mode theory for guided-wave optics. IEEE J. Quantum Electron. 1973, 9, 919–933. [Google Scholar] [CrossRef] [Green Version]

- Heiblum, M.; Harris, J. Analysis of curved optical waveguides by conformal transformation. IEEE J. Quantum Electron. 1975, 11, 75. [Google Scholar] [CrossRef]

- Melloni, A.; Carniel, F.; Costa, R.; Martinelli, M. Determination of bend mode characteristics in dielectric waveguides. J. Light. Technol. 2002, 19, 571. [Google Scholar] [CrossRef]

- El Dirani, H.; Casale, M.; Kerdiles, S.; Socquet, C.; Letartre, X.; Monat, C.; Sciancalepor, C. Crack-Free Silicon-Nitride-on-Insulator Nonlinear Circuits for Continuum Generation in the C-Band. IEEE Photonics Technol. Lett. 2018, 30, 355–358. [Google Scholar] [CrossRef]

- Li, D.; Li, B.; Tang, B.; Zhang, P.; Yang, Y.; Liu, R.; Xie, L.; Li, Z. Characteristics of Crack-Free Silicon Nitride Films Deposited by LPCVD for Photonic Applications. J. Electron. Mater. 2021, 50, 6862–6869. [Google Scholar] [CrossRef]

- Tao, S.; Huang, Q.; Zhu, L.; Liu, J.; Zhang, Y.; Huang, Y.; Wang, Y.; Xia, J. Athermal 4-channel (de-)multiplexer in silicon nitride fabricated at low temperature. Photonic Res. 2018, 6, 686–691. [Google Scholar] [CrossRef]

- Lu, Z.; Jhoja, J.; Klein, J.; Wang, X.; Liu, A.; Flueckiger, J.; Pond, J.; Chrostowski, L. Performance prediction for silicon photonics integrated circuits with layout-dependent correlated manufacturing variability. Opt. Express 2017, 25, 9712–9733. [Google Scholar] [CrossRef] [PubMed]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, D.; Li, B.; Tang, B.; Zhang, P.; Yang, Y.; Liu, R.; Xie, L.; Li, Z. Broadband Silicon Nitride Power Splitter Based on Bent Directional Couplers with Low Thermal Sensitivity. Micromachines 2022, 13, 559. https://doi.org/10.3390/mi13040559

Li D, Li B, Tang B, Zhang P, Yang Y, Liu R, Xie L, Li Z. Broadband Silicon Nitride Power Splitter Based on Bent Directional Couplers with Low Thermal Sensitivity. Micromachines. 2022; 13(4):559. https://doi.org/10.3390/mi13040559

Chicago/Turabian StyleLi, Donghao, Bin Li, Bo Tang, Peng Zhang, Yan Yang, Ruonan Liu, Ling Xie, and Zhihua Li. 2022. "Broadband Silicon Nitride Power Splitter Based on Bent Directional Couplers with Low Thermal Sensitivity" Micromachines 13, no. 4: 559. https://doi.org/10.3390/mi13040559

APA StyleLi, D., Li, B., Tang, B., Zhang, P., Yang, Y., Liu, R., Xie, L., & Li, Z. (2022). Broadband Silicon Nitride Power Splitter Based on Bent Directional Couplers with Low Thermal Sensitivity. Micromachines, 13(4), 559. https://doi.org/10.3390/mi13040559