Abstract

In this study, the grain growth behaviour of ZnO-V2O5-based ceramics with 0.25–0.75 mol% additions of PrMnO3 was systematically investigated during sintering from 850 °C to 925 °C. with the aim to control the ZnO grain size for their application as varistors. It was found that with the increased addition of PrMnO3, in addition to the decrease in the average grain size, the grain size distribution also narrowed and eventually changed from a bimodal to unimodal distribution after a 0.75 mol% PrMnO3 addition. The grain growth control was achieved by a pinning effect of the secondary ZnCr2O4 and PrVO4 phases at the ZnO grain boundaries. The apparent activation energy of the ZnO grain growth in these ceramics was found to increase with increased additions of PrVO4, hence the observed reduction in the ZnO grain sizes.

1. Introduction

ZnO-Bi2O3 ceramics are an established class of ZnO-based varistors. It is well known that the nonlinear current–voltage (I–V) characteristics of these ZnO-Bi2O3 varistors are directly dependent on their microstructures, mainly the average grain size and size distribution of ZnO [1]. Typically, a large average grain size of >30 μm is required for low-voltage applications, and a small average grain size of <10 μm is needed for high-voltage applications [2]. Additionally, a narrow grain size distribution is also critical for achieving stability of the electrical field strength of these materials [3].

It has been found that ZnO-V2O5 ceramics also exhibit a nonlinear I–V behaviour comparable to ZnO-Bi2O3 ceramics [4,5,6] and, thus, have the potential to be a new class of varistors [7]. One of the significant advantages of ZnO-V2O5 ceramics is that they can be sintered at a relatively low temperature of ~900 °C [8,9,10,11]. This outstanding feature allows these ceramics to be co-fired with Ag (m.p. 961 °C). This enables Ag, instead of expensive Pd or Pt, to be used as inner electrodes for applications in multilayer chip components [12]. Moreover, V2O5 is also a better sintering aid, compared with Bi2O3 for ZnO, enabling ZnO-V2O5 based ceramics to be densified to the same density at a lower temperature than ZnO-Bi2O3 based ceramics [13,14,15,16].

However, ZnO-V2O5 based ceramics suffer from a distinct disadvantage in that they have been shown to exhibit abnormal ZnO grain growth [17]. This is commonly attributed to the high reactivity of the V2O5-rich liquid phase formed during sintering. This phase assists in the diffusion of Zn2+ and thus promotes ZnO grain growth, which results in the formation of abnormally grown grains (AGG) of ZnO.

One approach to curb the formation of AGG in ZnO-V2O5 ceramics is to induce the formation of a secondary phase to hinder ZnO grain growth by the addition of a third oxide to the system [18,19]. The two commonly used additives are Cr2O3 and Sb2O3, as Cr2O3 can react with ZnO to form a ZnCr2O4 spinel phase, while Sb2O3 and ZnO form spinel phases of ZnSb2O6 and Zn2.33Sb0.67O4 [20,21,22]. However, these two additives have their own specific limitations. With Cr2O3, an addition greater than 1 mol% is required to effectively counter the AGG and refine the ZnO grain size in ZnO-V2O5 ceramics. However, at this required addition level, Cr2O3 has also been found to segregate at grain-boundary regions, leading to the deterioration of I–V behaviour due to high leakage current. With Sb2O3, the addition of up to 2 mol% is needed to control the grain growth of ZnO-V2O5; however, the addition of Sb2O3 increases the required sintering temperature for the system. At an Sb2O3 content greater than 0.5 mol%, the sintering temperature could increase to 1200 °C [23], nullifying the advantage of having the ZnO-V2O5-based system in the first place.

This study investigated the effect of increased additions of PrMnO3 on the grain growth of ZnO-V2O5 ceramics, with the aim to control the average grain size and size distribution of ZnO to improve their electrical properties as practical varistors.

2. Experimental

2.1. Sample Preparation

All reagents used in this research were of analytical grade (>99.5% purity) and were supplied by SINOPHARM. PrMnO3 powder was prepared in-house by mixing Pr6O11 and MnCO3 at a molar ratio of 1:6 and allowing the mixture to react at 1000 °C for 5 h in air. The formation of the PrMnO3 phase was confirmed by X-ray powder diffraction (XRD) analysis.

Table 1 summarises the nominal compositions of constituent powders used to prepare four ZnO-V2O5 ceramic samples and their designated sample names. The PrMnO3 powder was introduced with the aim to regulate the grain growth in these ceramics.

Table 1.

Basic compositions of the ZnO ceramics studied in this study.

For each nominal composition, the powder mixture was homogenised by ball milling in absolute alcohol using zirconia balls in a polypropylene container on a planetary mill for 24 h. After milling, the powder mixture was dried at 80 °C for 24 h. The dried powder mixture was then mixed with a 5 wt% polyvinyl alcohol (PVA) binder and pressed into pellets of Φ12 mm × 1 mm under a uniaxial pressure of 130 MPa. The green pellets were first fired at 500 °C for 1 h to remove the binder before being subjected to different sintering temperature/time regimes in an alumina crucible at a heating rate of 4 °C/min. In this study, seven sintered ceramic discs for each nominal composition were produced at 850 °C, 900 °C, and 925 °C for 4 h and at 875 °C for 2, 4, 6, and 8 h. After sintering, the furnace was powered off to allow the sintered discs to cool down naturally within the furnace.

2.2. Sample Characterisation

The phase compositions of the sintered and quenched samples were analysed by XRD patterns obtained using a diffractometer (PANalytical X’pert Powder) with Cu Kα1 radiation (λ = 0.1541 nm).

The microstructure of the sintered samples was observed and analysed by scanning electron microscopy (SEM) using a ZEISS Supra 55 electron microscope. A polished cross-sectional area along the thickness of the sintered disc was prepared and chemically etched in a dilute HCl solution to reveal the grain and phase structures for SEM observation.

The average ZnO grain size and grain size distribution were analysed using a representative SEM image of each sintered sample.

To determine the average grain size, the method reported by Mendelson [24] was used. Basically, the average grain-boundary intercept length () was first determined by measuring along 10 randomly drawn lines across the SEM image. The average grain size G is then calculated by Equation (1) as follows:

To determine the ZnO grain size distribution, the dimensions around 500–800 ZnO grains of each sample were measured from its SEM images using a dedicated image analysis software. The surface area (S) of each grain was then estimated, and the equivalent diameter (d) of each grain was obtained by transforming the surface area of the irregularly shaped grain into a circle of the same area using the method reported by Daneu [25].

The grain growth behaviour was analysed using a phenomenological kinetic grain growth equation established by Nicholson et al., which has been widely used for ZnO-based ceramic systems. The equation is expressed as follows:

where G is the average grain size of the ZnO ceramic at time t, G0 is the initial grain size of the ZnO powder, n is the kinetic grain growth exponent, Q is the apparent activation energy, R is the universal gas constant, T is the absolute temperature, and K0 is a T-independent constant. In the case where G0 is significantly smaller than G, then Equation (2) is simplified to

Equation (3) was used throughout this study to analyse the sintering behaviour of the ZnO-V2O5 samples studied in this study.

2.3. Sample I–V Characteristics

The DC current-voltage () behaviour of the sintered samples was measured using a withstand voltage tester (MS2671A, Xi’an Instruments Inc., Xi’an, China). The sintered discs (~Φ8 mm × 1 mm thickness) were painted with a silver paste on both surfaces to enable the measurements. The curve was determined by measuring the current at a stepwise-increased applied voltage until reached 10 mA. The field strength () is defined as the applied voltage per sample thickness, and the current density () is the measured current per sample area. The switching field strength E1mA/cm2 is the field strength at J = 1 mA·cm−2. The nonlinear coefficient (α) is calculated by Equation (4) as

where and are the field strengths at 10Ma·cm−2 and 1mA·cm−2, respectively. The higher the value of is, the better it is for a varistor.

3. Results and Discussion

3.1. Phase Compositions and Distributions in Sintered Samples

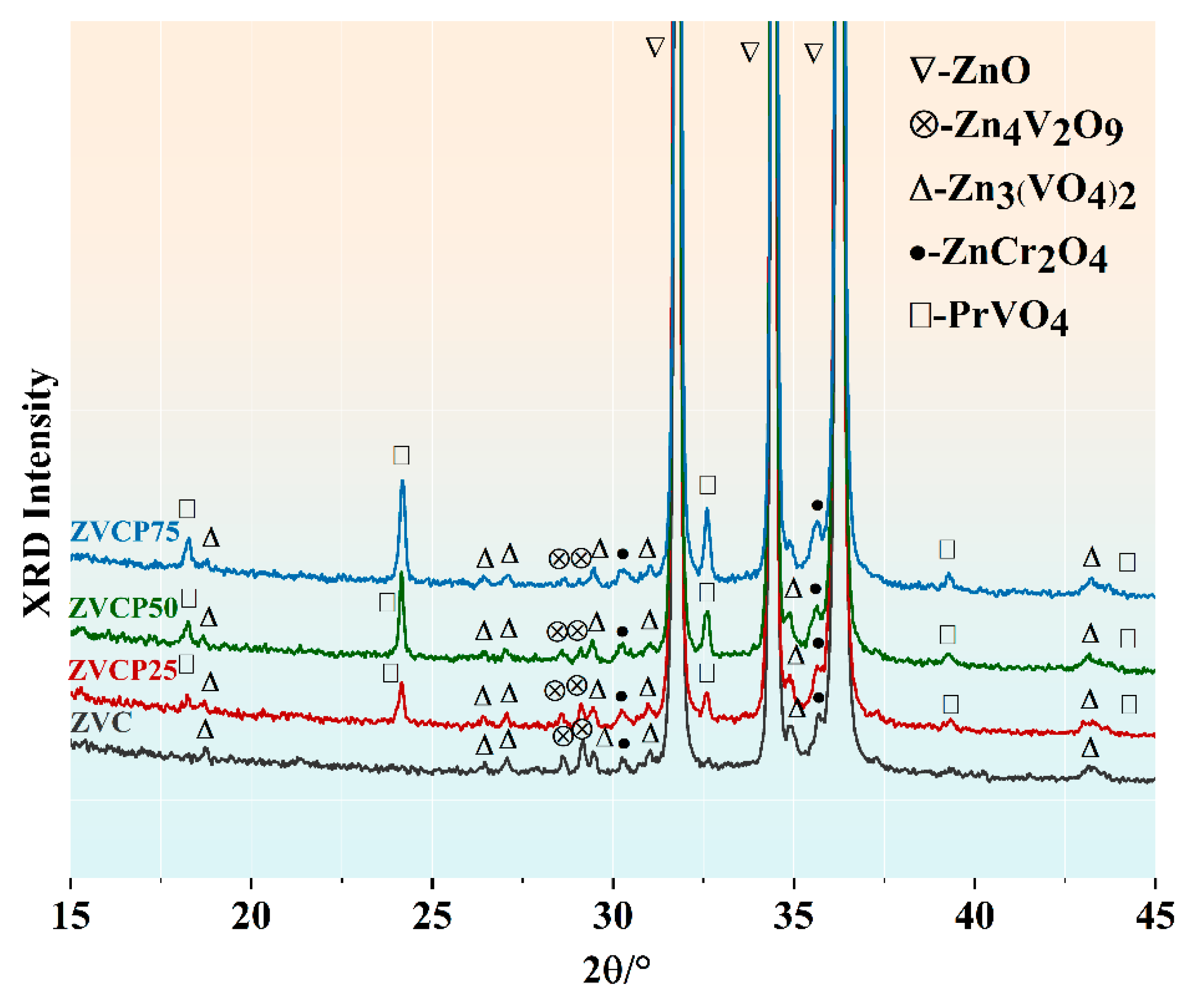

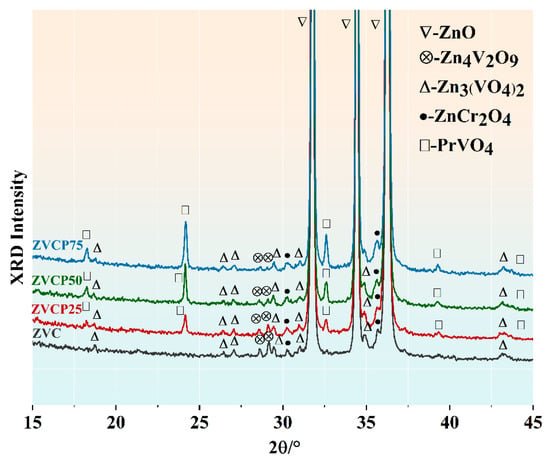

Figure 1 shows the XRD patterns of the four ZVCP samples sintered at 875 °C for 4 h. For the ZVC sample, in addition to the main ZnO phase, several minor phases were also detected, including Zn4V2O9, α-Zn3(VO4)2, and ZnCr2O4. These minor phases have been commonly observed and reported in sintered ZnO-V2O5 systems. With the addition of PrMnO3, a new minor phase of PrVO4 was also observed in the ZVCP25, ZVCP50, and ZVCP75 samples. Consequently, this experimental result stated that the generation of PrVO4 could be attributed to the reaction between PrMnO3 and the V-contained phase. According to previous research studies, the formation of PrVO4 was reported as a product of phase transition between PrMnO3 and α-Zn3(VO4)2 with the following reaction:

Figure 1.

XRD patterns of the ZVC, ZVCP25, ZVCP50, and ZVCP75 samples sintered at 875 °C for 4 h.

It should be noted that the mentioned phase transition did not produce only the PrVO4 phase. Additionally, the formation of the Mn2O3 phase was obtained in the same reaction. However, few lines of evidence indicating Mn2O3 in this phase observation can be found. As we know, Mn2O3 was helpful to generate the non-Ohm electrical property in ZnO varistor ceramic. Hence, the application of Mn2O3 was widely investigated by researchers. Related experimental results supported that Mn ion could easily be dissolved in ZnO grain. Thus, once the solid solution of ZnO-Mn2O3 formed, the diffraction peaks assigned to Mn2O3 vanished.

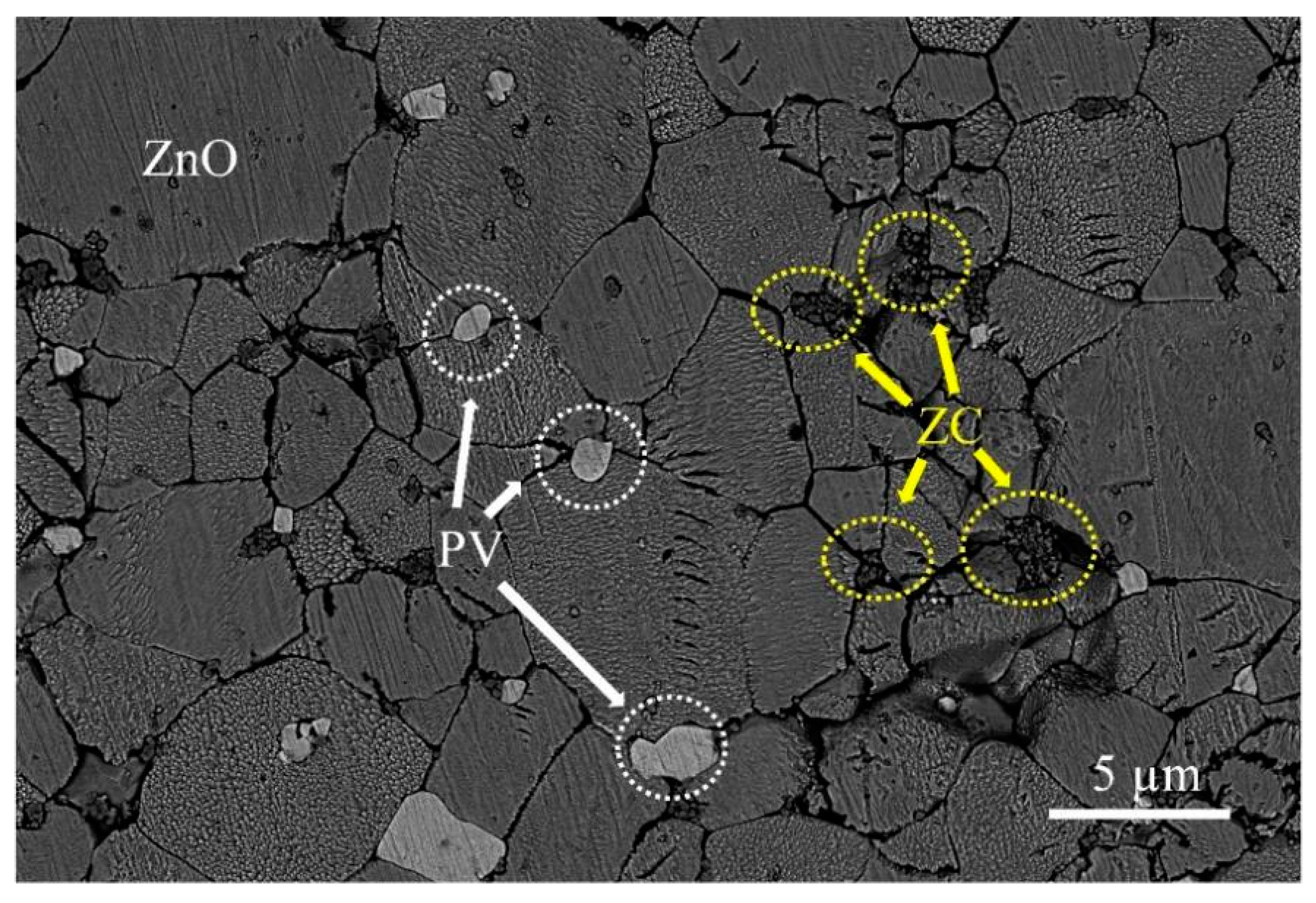

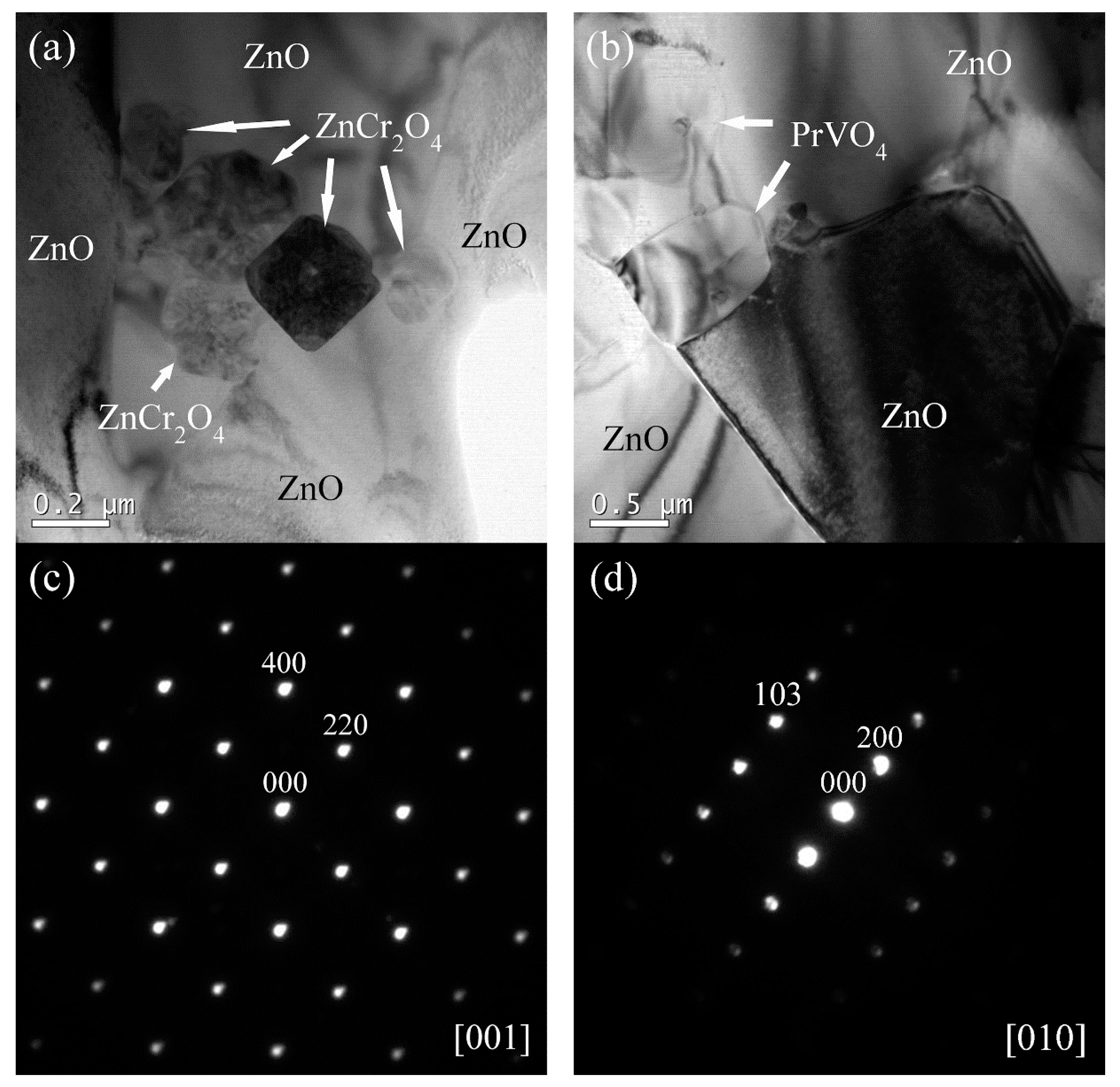

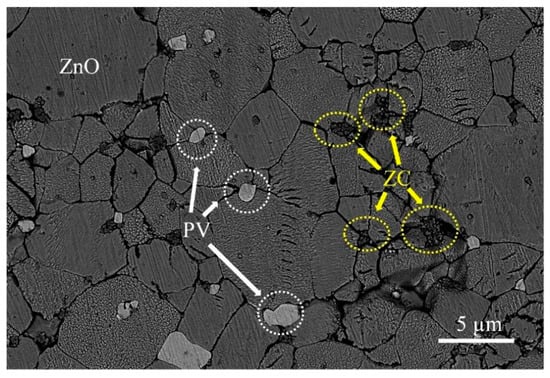

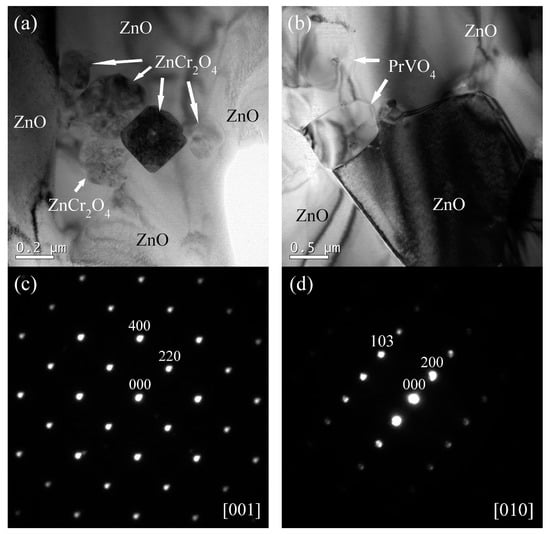

Figure 2 shows a typical microstructure of a sintered ZVCP50 sample. As expected, the dominant morphology included grains of the ZnO phase, and the focus here was on the appearance and distribution of the minor phases. As seen in the micrograph, in addition to ZnCr2O4 (ZC) clusters (circled in yellow-dashed lines), PrVO4 (PV) grains (circled in white-dashed lines) were clearly seen to also distribute at the junctions of ZnO grains. In some cases, ZnO grains were observed to grow around either ZnCr2O4 clusters or PrVO4 grains. Figure 3 shows the TEM images, revealed the microstructural differences between PrVO4 and ZnCr2O4 phases. The electron diffraction pattern in Figure 3 further confirmed the existence of PrVO4 and ZnCr2O4. The ZnCr2O4 grains are very small—the grain size is below 0.2 µm—but the PrVO4 grains have a relatively larger size than ZnCr2O4, ranging from 0.5 µm to 4 µm. Most grains of ZnCr2O4 and PrVO4 were found located at the ZnO grain boundaries, and ZnCr2O4 grains tend to aggregate to form a heap of ~1 µm in size. This observation suggests that these secondary minor phases could exert a ‘pinning’ effect, which hindered the migration of ZnO grain boundaries and limited its grain growth.

Figure 2.

Back-scattered electron (BSE) image of a ZVCP50 sample sintered at 875 °C for 4 h.

Figure 3.

TEM micrographs and SAED patterns from secondary particle grains: (a) bright-field image of ZnCr2O4 grains from a sample with the composition of ZVCP75 sintered at 875 °C for 4 h, (b) bright-field image of PrVO4 grains from a sample with the composition of ZVCP75 sintered at 875 °C for 4 h, (c) electron diffraction pattern from the [001] zone of ZnCr2O4 grain in (a), and (d) electron diffraction pattern from the [010] zone of PrVO4 grain in (b).

3.2. Average ZnO Grain Sizes in Sintered Samples

For all four sintered samples, the average grain size of each sample under all sintering conditions was determined following the procedure described in Section 2.2, and the results are summarised in Table 2.

Table 2.

Average grain sizes estimated from SEM analysis of ZVC and ZVCP samples sintered at different conditions.

3.3. Kinetic Grain Growth Parameters

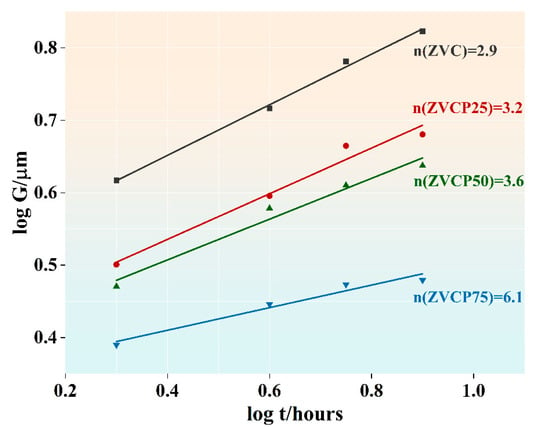

To reveal the effect of PrMnO3 addition on the sintering behaviour of the ZnO-V2O5 ceramics, the isothermal grain growth behaviour at 875 °C was first analysed using a rearranged Equation (3), as shown below:

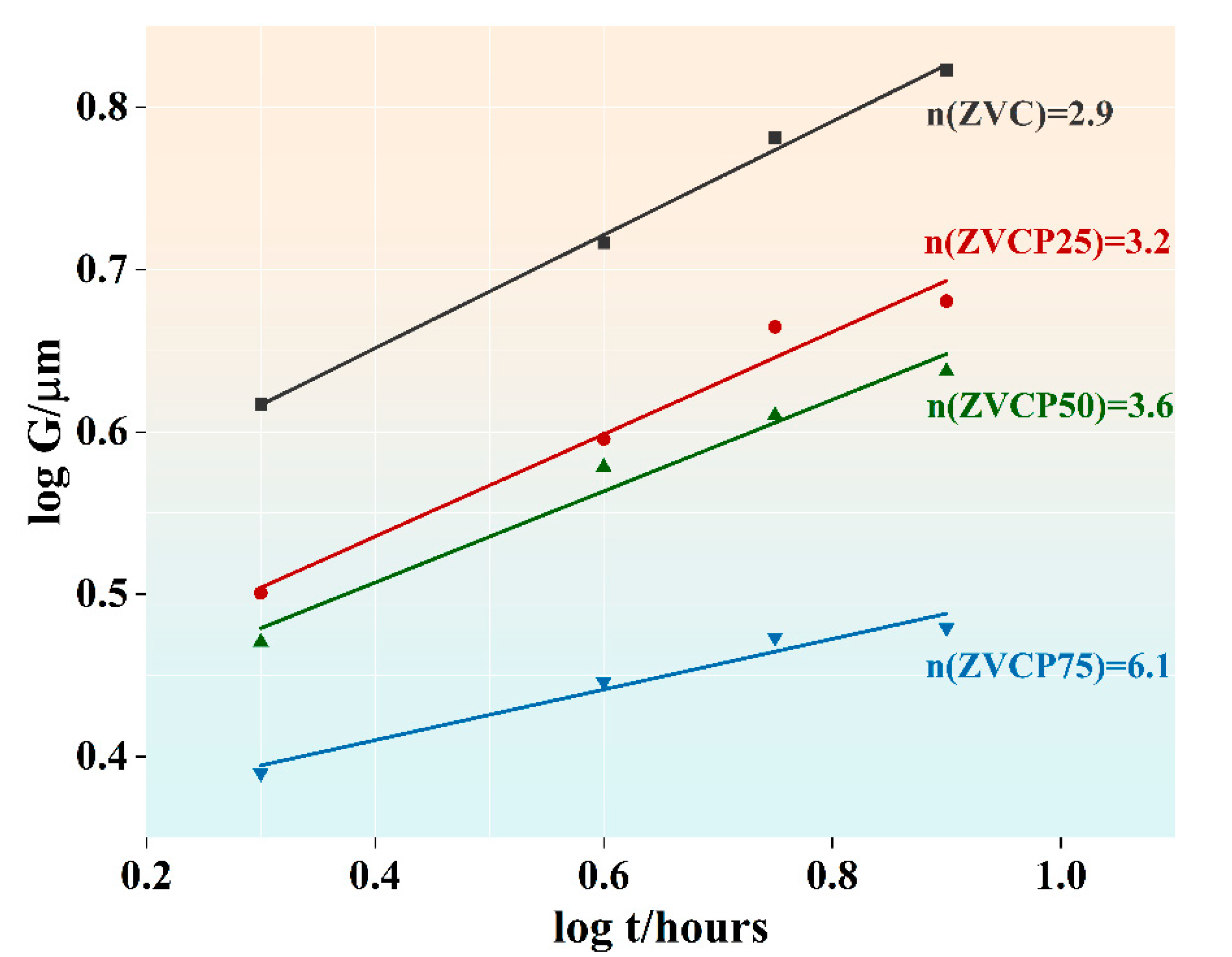

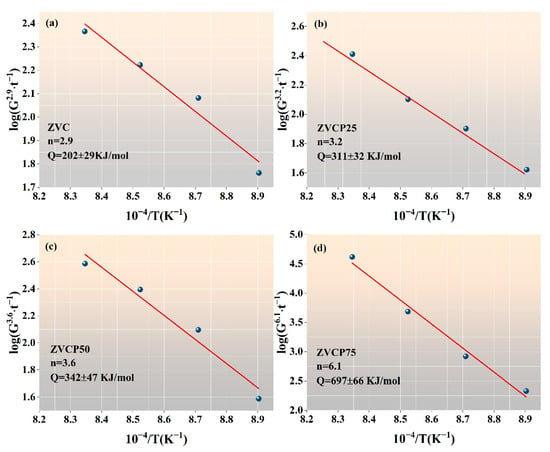

Figure 4 illustrates vs. curves, which show the isothermal grain growth behaviour of the four samples sintered at 875 °C for 2–8 h. A linear fit of the curves enabled the determination of the kinetic grain growth exponent from the slope of the linear fit for each sample. The values so determined are also shown in Figure 4. Notably, with the increased addition of PrMnO3, in addition to the decrease in the average grain size , the grain growth rate also decreased, as indicated by the increased values.

Figure 4.

Grain growth behavior of the four samples sintered at 875 °C for 2–8 h.

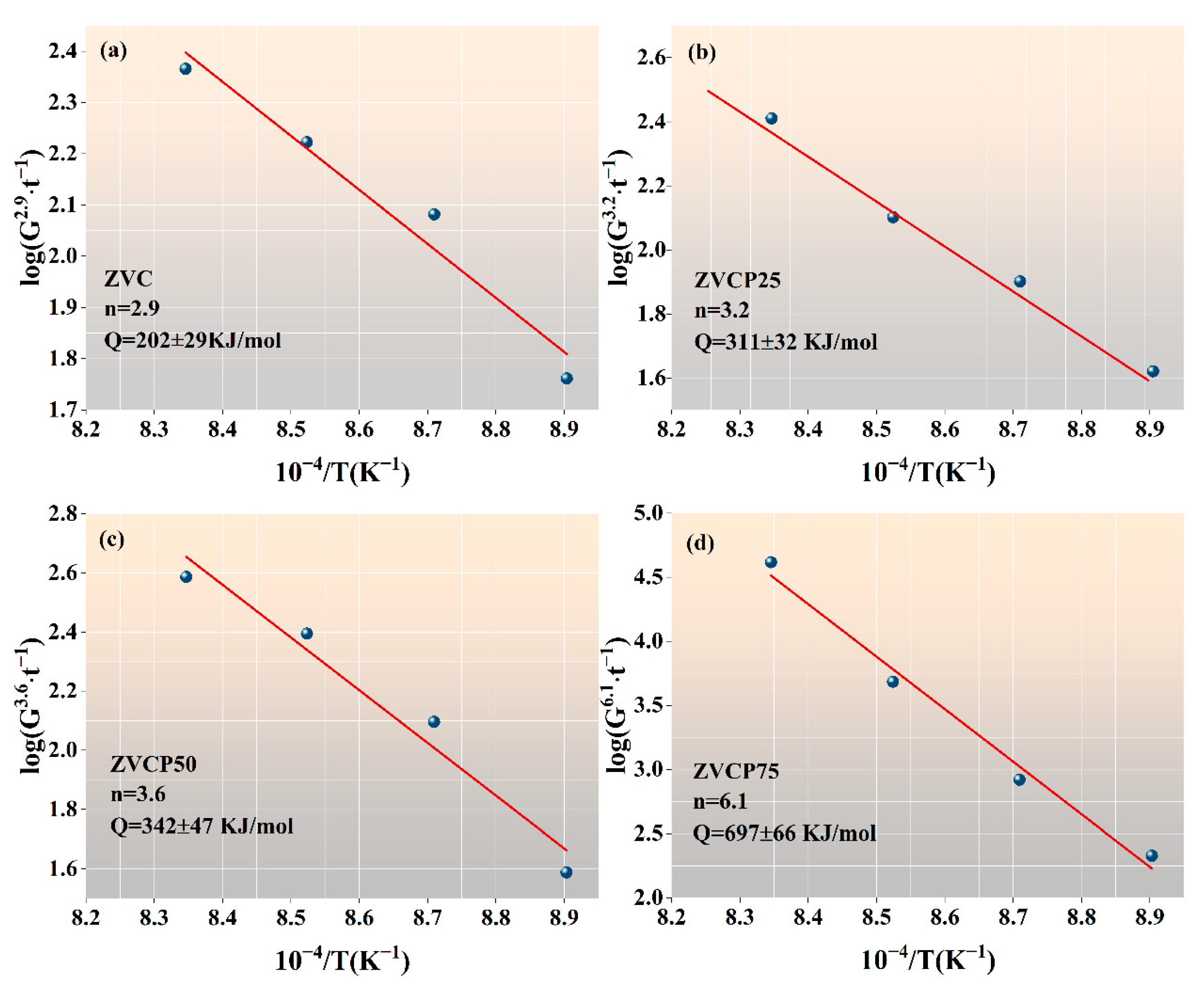

To determine the apparent activation energy Q associated with the grain growth, Equation (3) is rearranged as

Q can then be calculated from the slope of the Arrhenius plot of log(Gn/t) vs. (1/T). Figure 5 shows the Arrhenius plots of the four samples from the G values obtained at different sintering temperatures shown in Table 2. The apparent activation energy values determined from Figure 5 are summarised in Table 3, together with the values determined from Figure 4.

Figure 5.

The log(Gn/t) vs. (1/T) Arrhenius plots for grain growth of the four sintered samples: (a) ZVC, (b) ZVCP25, (c) ZVCP50, and (d) ZVCP75.

Table 3.

Summary of ZnO grain growth exponents and apparent activation energy for grain growth.

As seen in Table 3, in both this study and other published studies, the basic ZnO-V2O5 binary systems had a kinetic grain growth exponent value spanning 1.5–1.8. This value was lower than the observed for pure ZnO, indicating that the addition of V2O5 encouraged the grain growth of ZnO. This was attributed to the high reactivity of the V2O5-rich liquid phase during sintering, promoting the formation of abnormally grown ZnO grains.

The addition of a third component—e.g., the 0.35 mol% of Cr2O3 in this study or 0.5 mol% Sb2O3 as reported elsewhere—has been shown to increase the value to 2.9 and 4.0, respectively. This means that the addition of a third component could hinder ZnO grain growth in basic ZnO-V2O5 binary systems. In both cases, this was attributed to the formation of spinel ZnCr2O4 or a ZnSb2O4 secondary phase, which exerts a pinning effect on ZnO grain boundaries and thus hinders ZnO grain growth.

It was clear that the addition of PrMnO3 to the ZnO + V2O5 (1 mol%) + Cr2O3 (0.35 mol%) ceramics resulted in a further increase in the n value, which increased to 6.1 after a nominal addition of 0.75 mol% of PrMnO3 for ZVCP75, demonstrating the high effectiveness of PrMnO3 in suppressing ZnO grain growth. As seen in the XRD and SEM analyses, the addition of PrMnO3 resulted in the formation of an additional spinel PrVO4 phase, which was also found to be distributed at the grain boundaries of ZnO similarly to ZnCr2O4 in the sintered ceramics. A similar pinning effect was thus believed to be the main reason for the hindered ZnO grain growth by the addition of PrMnO3.

As expected, it is clearly seen in Table 3 that the apparent activation energy values for the grain growth followed an inverse behaviour, compared with the values. Generally, the higher the activation energy, the higher the values, the slower the grain growth rate, and the smaller the average ZnO grain sizes.

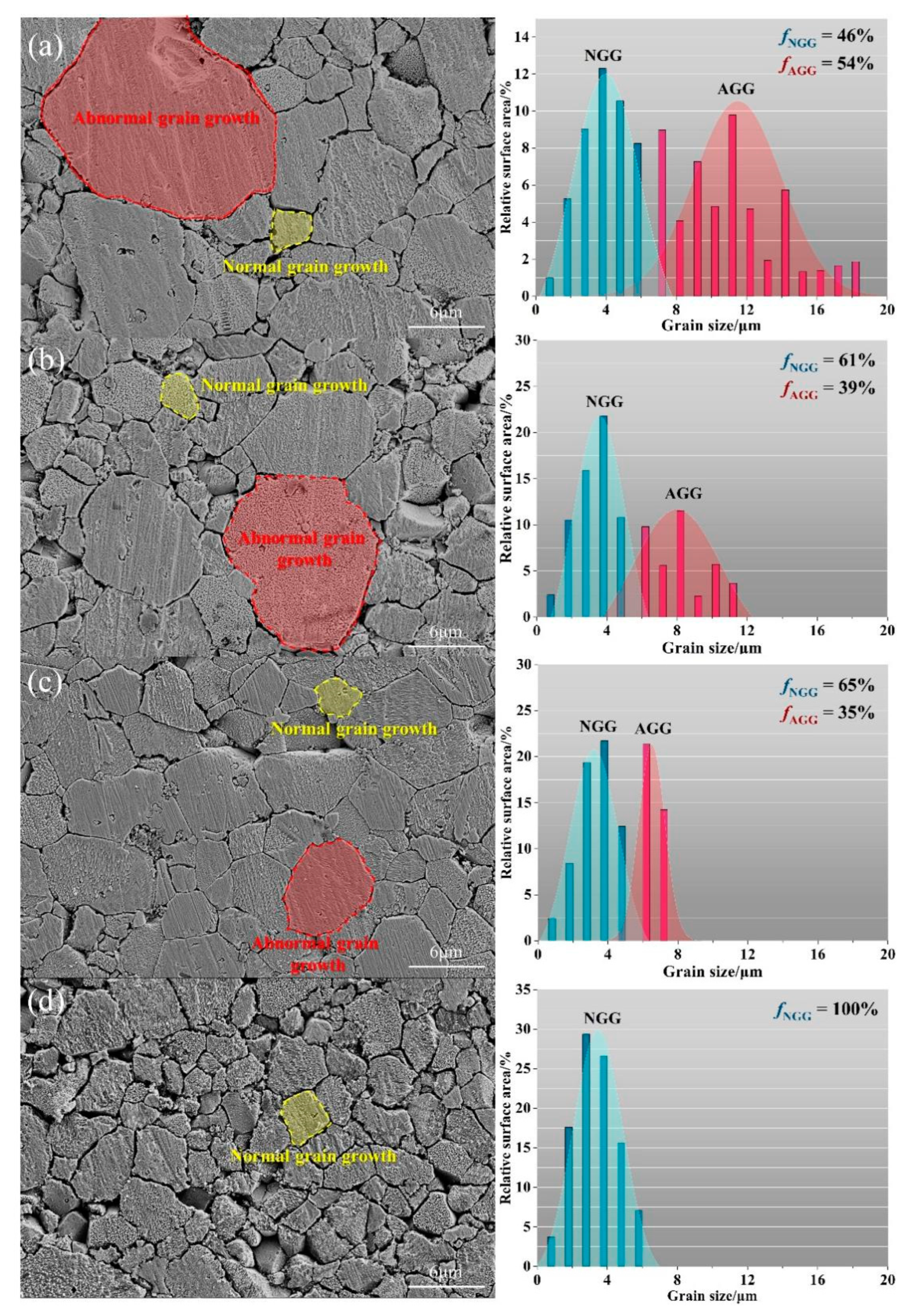

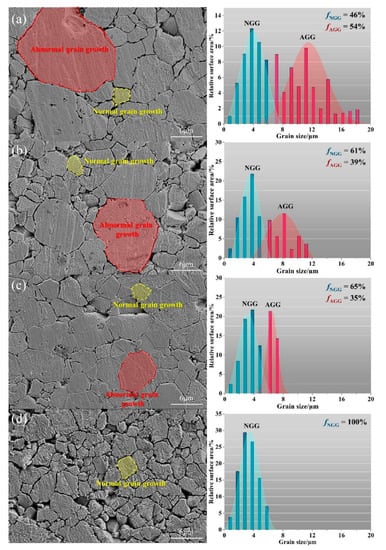

3.4. Grain Size Distribution in Sintered Samples

Figure 6 shows SEM images and grain size distribution histograms of the four samples sintered at 875 °C for 4 h. It is clear from the SEM images that with increased additions of PrMnO3, in addition to the decrease in the average grain size of ZnO, the size distribution also narrowed significantly.

Figure 6.

SEM microstructures and grain size distribution histograms of the samples sintered at 875 °C for 4 h: (a) ZVC, (b) ZVCP25, (c) ZVCP50, and (d) ZVCP75. NGG and refers to the normally grown grain and its number fraction. AGG and refer to the abnormally grown grain and its number fraction.

It can be seen that the ZVC sample without the addition of PrMnO3 exhibited a broad and bimodal grain size distribution. In the context of this research, larger grains are considered to be the AGG, and the relatively smaller grains are considered as the normally grown grains (NGG). The area fractions of AGG and NGG for each sample are also included in the size distribution histograms in the figure. The addition of PrMnO3 resulted in the reduction and narrowing of the grain size range, in addition to diminishing the bimodal distribution. For ZVCP75, the grain size distribution became unimodal.

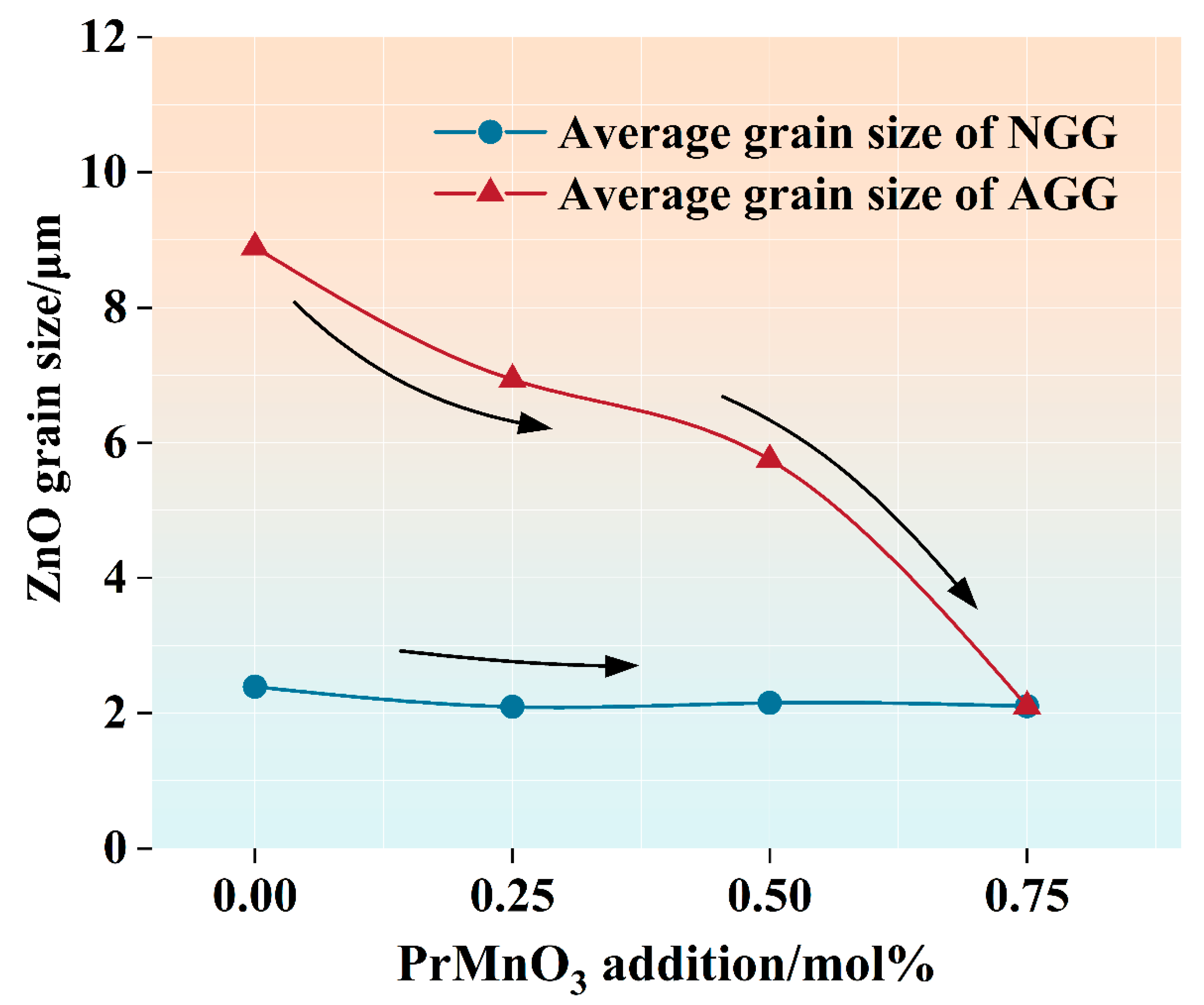

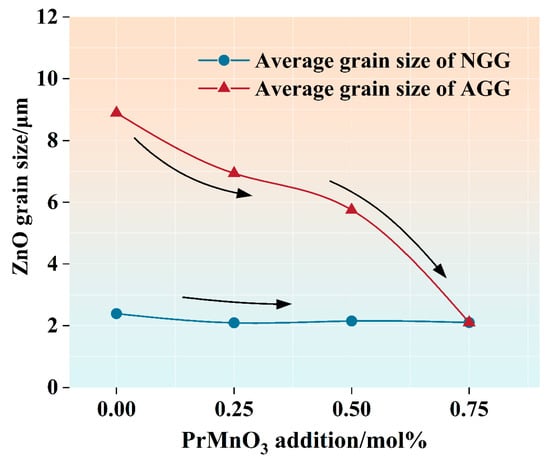

Figure 7 shows the average grain sizes of the AGG and NGG vs. the nominal addition of PrMnO3. This revealed the impact of PrMnO3 addition. Notably, the average grain size of NGG did not change much; however, the average grain size of the AGG decreased dramatically. This indicated the effectiveness of PrMnO3 addition in suppressing the coarsening of ZnO grains in this system. The number fractions of AGG () and NGG () were also determined for the sintered samples and are provided in the histograms.

Figure 7.

Effect of nominal addition of PrMnO3 on the average grain sizes of the AGG and NGG in ZVCP samples sintered at 875 °C for 4 h.

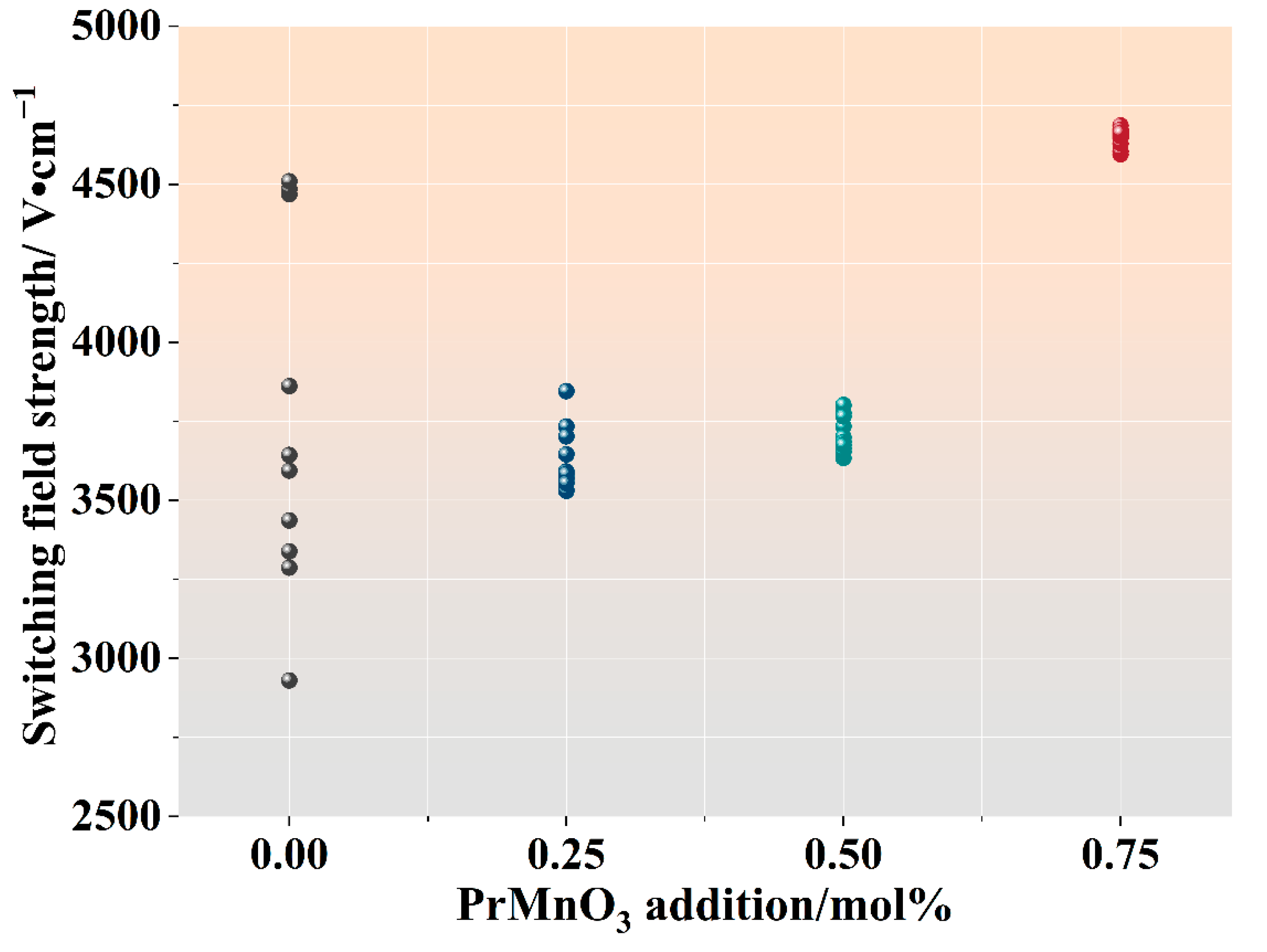

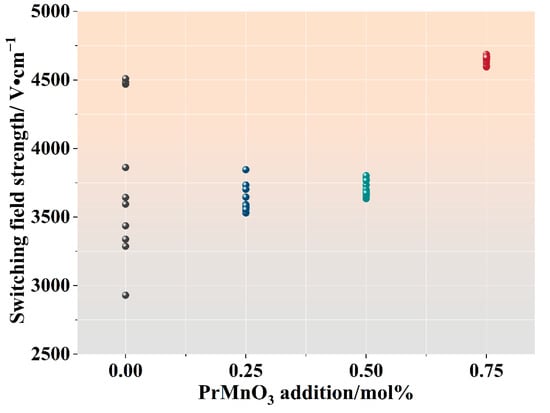

3.5. Electrical Behaviour of Sintered Samples

Figure 8 shows the switching field strength of the four samples sintered at 875 °C for 4 h. For each sample, 10 specimens were prepared, their I–V curves were measured, and their values were determined. Figure 8 shows all measured data for the four samples. As seen, the basic ZVC sample displayed a very broad range of . Clearly, a 0.25 mol% nominal addition of PrMnO3 resulted in a remarkable narrowing of the range for the ZVCP25 sample. Further increasing the PrMnO3 addition to 0.75 mol% produced a continuous narrowing of the range.

Figure 8.

Measured switching field strength data vs. nominal addition amount of PrMnO3.

This significant stabilisation of the switching field strength was attributed to the uniformisation of the ZnO grain size as the result of PrMnO3 addition. As seen in Figure 6, a 0.75 mol% addition of PrMnO3 in ZVC effectively eliminated the formation of abnormally grown ZnO grains. The resulting ZVCP75 sample was shown to have a markedly improved stability in its switching field strength. This was also consistent with the results reported by Hng et al. [12], which showed that the presence of just a few abnormally grown ZnO grains could have a pronounced destabilisation effect on the switching field strength of ZnO-V2O5 varistors.

Furthermore, with a 0.75 mol% addition of PrMnO3, there was also a marked increase in the value for the ZVCP75 sample. This increase in switch field strength was mostly due to the refined ZnO grain size.

Table 4 summarises the relative density and number fraction of AGG and the average grain size of the sintered samples, together with the nonlinear coefficient and the average and range of the switching field strength of these samples.

Table 4.

Relative density, number fraction of AGG and average grain size, and electrical properties of the sintered samples at 875 °C for 4 h.

It was noted that all the samples possessed a high sintering density at close to 95% of the theoretical density of ZnO. While the addition of PrMnO3 had little effect on the sintering density, it effectively reduced and eliminated the fraction of AGG and progressively refined the grain sizes of the resulting ceramics.

The electrical properties are attributed to the developed microstructures. The nonlinear coefficient also increased marginally from 7.2 to 8.9 from ZVC to ZVCP75, respectively, as seen in Table 4.

It was believed that a better sintering ability of ZnO ceramic can be achieved by adding V2O5 addition. During the sintering process, the generated α-Zn3(VO4)2 existed in the form of a liquid phase. Thus, the sintering mechanism was governed by solution–precipitation process. However, since the absolute homogeneous distribution of V2O5 in raw material was hardly achieved, regions that were rich in V2O5 produced more content of V-enriching liquid. In this case, the abnormal grain growth of ZnO begins in this liquid-phase-rich area, preferentially. To fix this problem, the traditional method needs the introduction of a secondary particle phase to hinder the migration of ZnO grain boundaries, such as the ZnCr2O4 spinel phase. However, a single ZnCr2O4 phase was insufficient to suppress all abnormally grown ZnO grains, as the distribution of the V-enriching liquid phase was still heterogeneous. Comparably, the PrVO4 particle phase plays a double role in the whole sintering process. Firstly, the PrVO4 particle hindered the migration of ZnO grain boundaries, similarly to ZnCr2O4. Additionally, the PrVO4 particle phase actually was the product of the reaction between PrMnO3 and α-Zn3(VO4)2. In a way, the generation of PrVO4 means the rearrangement of α-Zn3(VO4)2 in the ZnO matrix, which benefits the microstructural homogeneity. Moreover, the Mn2O3 generated by the mentioned reaction could optimise electrical properties. This was the reason why nonlinear coefficients were slightly enhanced by adding PrMnO3, even though α-Zn3(VO4)2 was sequentially consumed by added PrMnO3. In summary, we recognised that PrMnO3 addition can be treated as a potential additive in ZnO-V2O5-based varistor ceramic for its good performance on the repairmen of both grain growth control and electrical properties.

4. Conclusions

In this study, the effect of PrMnO3 addition (0.25 to 0.75 mol%) on the grain growth behaviour of ZnO-V2O5 (1 mol%)-Cr2O3 (0.35 mol%) ceramics was systematically investigated during sintering from 850 °C to 925 °C, with the aim to refine the ZnO grain structure. The main findings were as follows:

- (1)

- The addition of PrMnO3 uniformised and refined the ZnO grains in the resulting ceramics. At a 0.75 mol% PrMnO3 addition, the bimodal grain size distribution was completely eliminated, and the average ZnO grain size was reduced by more than 45%, compared with the sample without PrMnO3 addition.

- (2)

- The addition of PrMnO3 resulted in remarkably improved stability of the switching field strength, narrowing its range of variation from 1580 V/cm (without PrMnO3 addition) to only 91 V/cm (with 0.75 mol% PrMnO3 addition). The homogenisation and reduction in the ZnO grain sizes were responsible for the observed stabilisation of the switching field strength.

- (3)

- A phenomenological analysis of the ZnO grain growth kinetics showed that the kinetic grain growth exponent n increased from 2.9 without PrMnO3 to 6.1 after a 0.75 mol% PrMnO3 addition, corresponding to an increase in apparent activation energy from 202 ± 29 to 697 ± 66 kJ/mol, respectively.

- (4)

- The formation of a PrVO4 secondary phase as the result of PrMnO3 addition was responsible for the grain growth behaviour observed. The PrVO4 phase was found to be mostly located at the ZnO grain boundaries, thus hindering and eventually eliminating the abnormal growth of ZnO grains.

Author Contributions

Writing—original draft preparation, M.X. (Maofeng Xu); writing—review and editing, C.C., Y.S. and S.A.; data curation, M.X. (Manyi Xie); validation, Y.W.; resources, Y.L., J.P. and J.B. All authors have read and agreed to the published version of the manuscript.

Funding

The project was supported by the Program for Innovative Research Team in Universities of Inner Mongolia Autonomous Region. No.NMGIRT2215.

Conflicts of Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

- Qinghuang, Z.; Yun, G.; Jiwei, X.; Ting, W.; Linjun, W. Effect of Deposition Temperature on Structural and Optical Properties of Zno Films Based on Tourmaline Substrates. Rare Met. Mater. Eng. 2017, 46, 3228–3232. [Google Scholar] [CrossRef]

- Hongtao, S.; Qin, Z.; Zhang, L.; Yao, X. Inhomogeneity of grain boundaries of ZnO varistor. J. Mater. Sci. Technol. 1994, 10, 273. [Google Scholar]

- Nan, C.W.; Clarke, D.R. Effect of variations in grain size and grain boundary barrier heights on the current-voltage characteristics of ZnO varistors. J. Am. Ceram. Soc. 1996, 79, 3185–3192. [Google Scholar] [CrossRef]

- Tsai, J.K.; Wu, T.B. Non-ohmic characteristics of ZnO-V2O5 ceramics. J. Appl. Phys. 1994, 76, 4817–4822. [Google Scholar] [CrossRef]

- Tsai, J.; Wu, T. Microstructure and nonohmic properties of binary ZnO-V2O5 ceramics sintered at 900 °C. Mater. Lett. 1996, 26, 199–203. [Google Scholar] [CrossRef]

- Yan, Q.; Chen, J.Z.; Tu, M.J. Influence of Nd2O3 on voltage and microstructure of ZnO varistor materials. Rare Met. Mater. Eng. 2005, 34, 154–157. [Google Scholar]

- Shaohua, L.; Zilong, T.; Hongyun, L. The Effect of CeO2 on the Electric Properties of TiO2 Based Capacitor-Varistor Multi-Function Ceramics. Rare Met. Mater. Eng. 2004, 33, 748–751. [Google Scholar]

- Hng, H.H.; Chan, P.L. Effects of MnO2 doping in V2O5-doped ZnO varistor system. Mater. Chem. Phys. 2002, 75, 61–66. [Google Scholar] [CrossRef]

- Pfeiffer, H.; Knowles, K.M. Effects of vanadium and manganese concentrations on the composition, structure and electrical properties of ZnO-rich MnO2–V2O5–ZnO varistors. J. Eur. Ceram. Soc. 2004, 24, 1199–1203. [Google Scholar] [CrossRef]

- Nahm, C. Microstructure and electrical properties of ZnO–V2O5–MnO2–Co3O4–Dy2O3–Nb2O5-based varistors. J. Alloy. Compd. 2010, 490, L52–L54. [Google Scholar] [CrossRef]

- Senda, T.; Bradt, R.C. Grain growth in sintered ZnO and ZnO-Bi2O3 ceramics. J. Am. Ceram. Soc. 1990, 73, 106–114. [Google Scholar] [CrossRef]

- Hng, H.H.; Knowles, K.M. Microstructure and current–voltage characteristics of multicomponent vanadium-doped zinc oxide varistors. J. Am. Ceram. Soc. 2000, 83, 2455–2462. [Google Scholar] [CrossRef]

- Wang, Q.; Xu, L.; Zhang, Y.; Wang, X.; Xie, M. Surface Modification of Li1.6(Fe0.2Ni0.2Mn0.6)O2.6 by V2O5-Coating. Rare Met. Mater. Eng. 2014, 43, 530–534. [Google Scholar] [CrossRef]

- Cao, P.; Bai, Y.; Qu, Z.; Zhao, D.; Shen, D.; Fan, X. Structural and optical properties of Mn-doped ZnO nanocolumns grown by cathodic electrodeposition. Chin. J. Lumin. 2010, 20, 326–328. [Google Scholar]

- Hng, H.H.; Halim, L. Grain growth in sintered ZnO–1 mol% V2O5 ceramics. Mater. Lett. 2003, 57, 1411–1416. [Google Scholar] [CrossRef]

- Hng, H.H.; Chan, P.L. Cr2O3 doping in ZnO–0.5 mol% V2O5 varistor ceramics. Ceram. Int. 2009, 35, 409–413. [Google Scholar] [CrossRef]

- Ming, Z.; Yu, S.; Sheng, T.C. Grain growth of ZnO–V2O5 based varistor ceramics with different antimony dopants. J. Eur. Ceram. Soc. 2011, 31, 2331–2337. [Google Scholar] [CrossRef]

- Lao, Y.; Kuo, S.; Tuan, W. Effect of powder bed on the microstructure and electrical properties of Bi2O3-and Sb2O3-doped ZnO. J. Mater. Sci. Mater. Electron. 2009, 20, 234–241. [Google Scholar] [CrossRef]

- Gerlt, A.R.; Criner, A.K.; Semiatin, L.; Payton, E.J. On the grain size proportionality constants calculated in MI Mendelson’s “Average grain size in polycrystalline ceramics”. J. Am. Ceram. Soc. 2019, 102, 37–41. [Google Scholar] [CrossRef] [Green Version]

- Daneu, N.; Rečnik, A.; Bernik, S. Grain-growth phenomena in ZnO ceramics in the presence of inversion boundaries. J. Am. Ceram. Soc. 2011, 94, 1619–1626. [Google Scholar] [CrossRef]

- Han, J.; Mantas, P.Q.; Senos, A. Grain growth in Mn-doped ZnO. J. Eur. Ceram. Soc. 2000, 20, 2753–2758. [Google Scholar] [CrossRef]

- Yang, S.C.; German, R.M. Grain Growth Kinetics in Liquid-Phase-Sintered Zinc Oxide–Barium Oxide Ceramics. J. Am. Ceram. Soc. 1991, 74, 3085–3090. [Google Scholar] [CrossRef]

- Han, J. Microstructure and non-linearity characterization of ZnVTiO based varistor ceramics doped with PrMnO3 typed precursor. J. Synth. Cryst. 2014, 43, 2258–2264. [Google Scholar]

- Daneu, N.; Rečnik, A.; Bernik, S. Grain growth control in Sb2O3-doped zinc oxide. J. Am. Ceram. Soc. 2003, 86, 1379–1384. [Google Scholar] [CrossRef]

- Pianaro, S.A.; Pereira, E.C.; Bulhoes, L.; Longo, E.; Varela, J.A. Effect of Cr2O3 on the electrical properties of multicomponent ZnO varistors at the pre-breakdown region. J. Mater. Sci. 1995, 30, 133–141. [Google Scholar] [CrossRef]

- Hng, H.H.; Tse, K.Y. Grain growth of ZnO in binary ZnO–V2O5 ceramics. J. Mater. Sci. 2003, 38, 2367–2372. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).