Three-Dimensional Polymer Variable Optical Attenuator Based on Vertical Multimode Interference with Graphene Heater

Abstract

1. Introduction

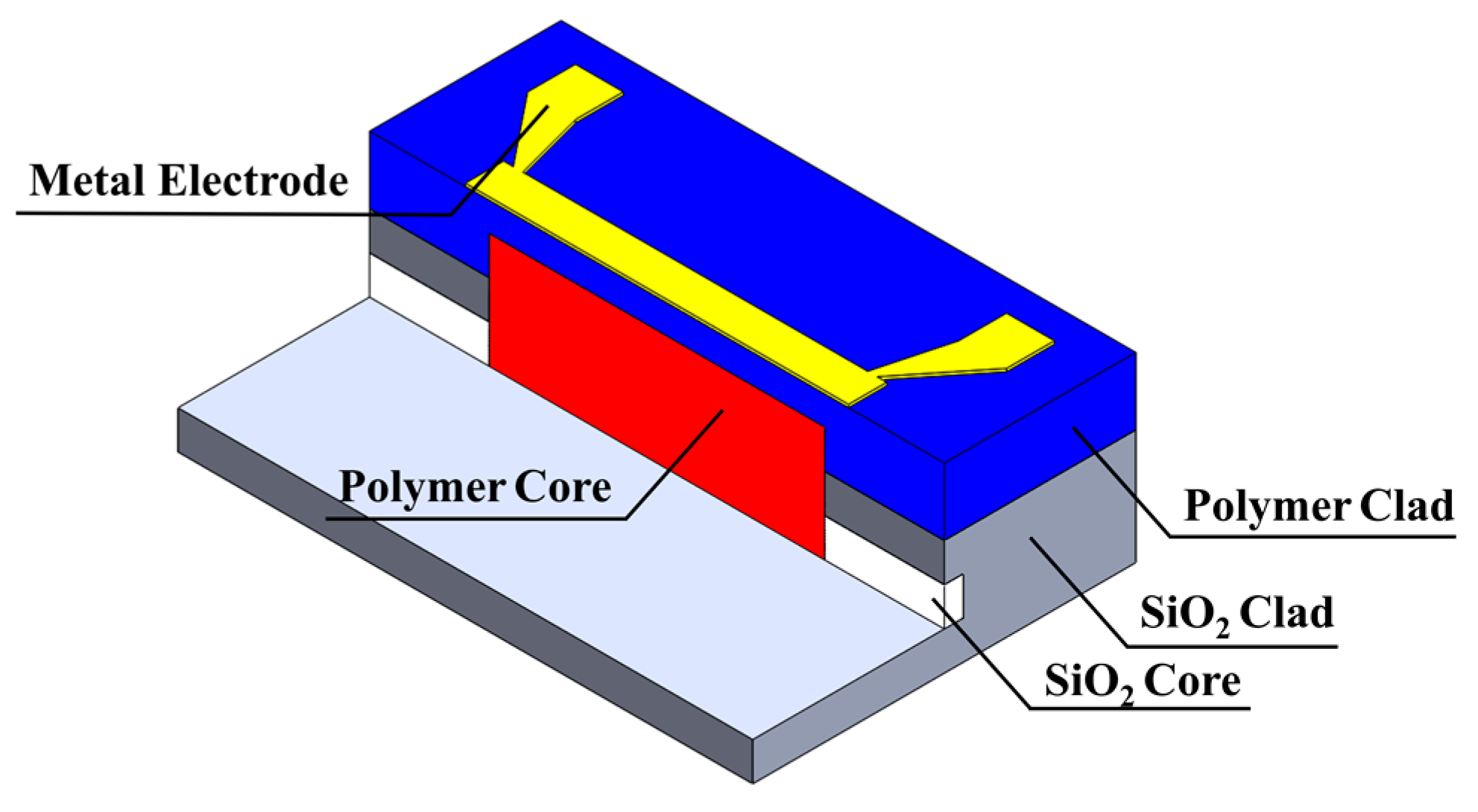

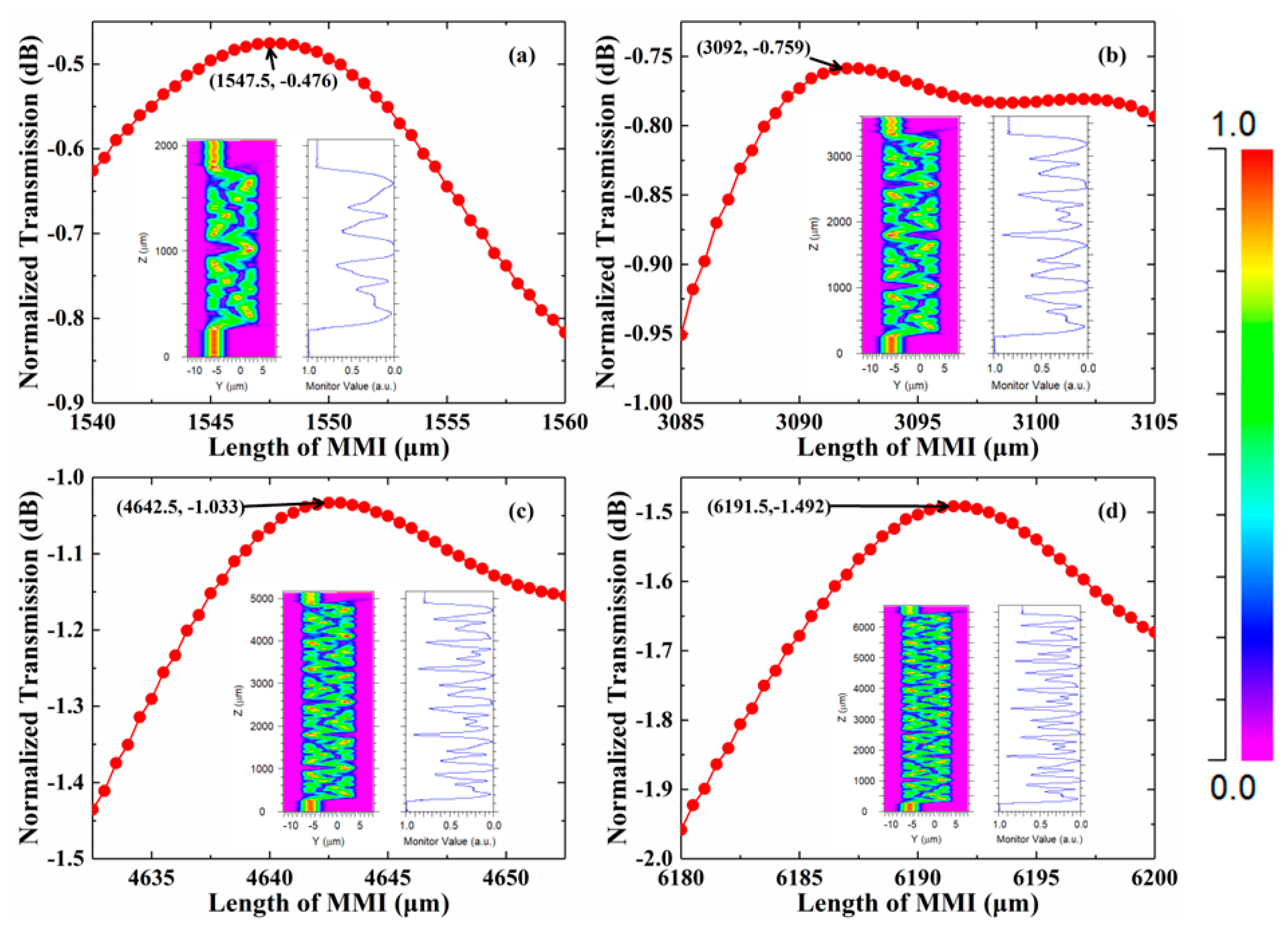

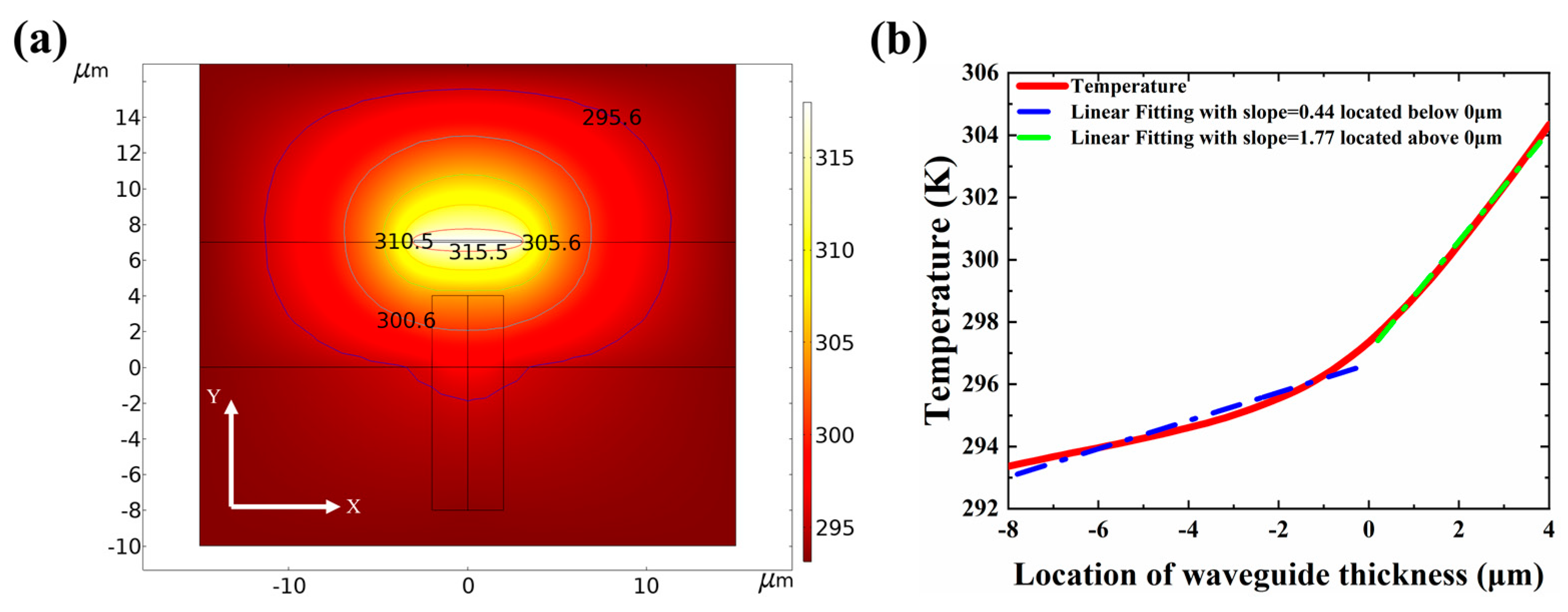

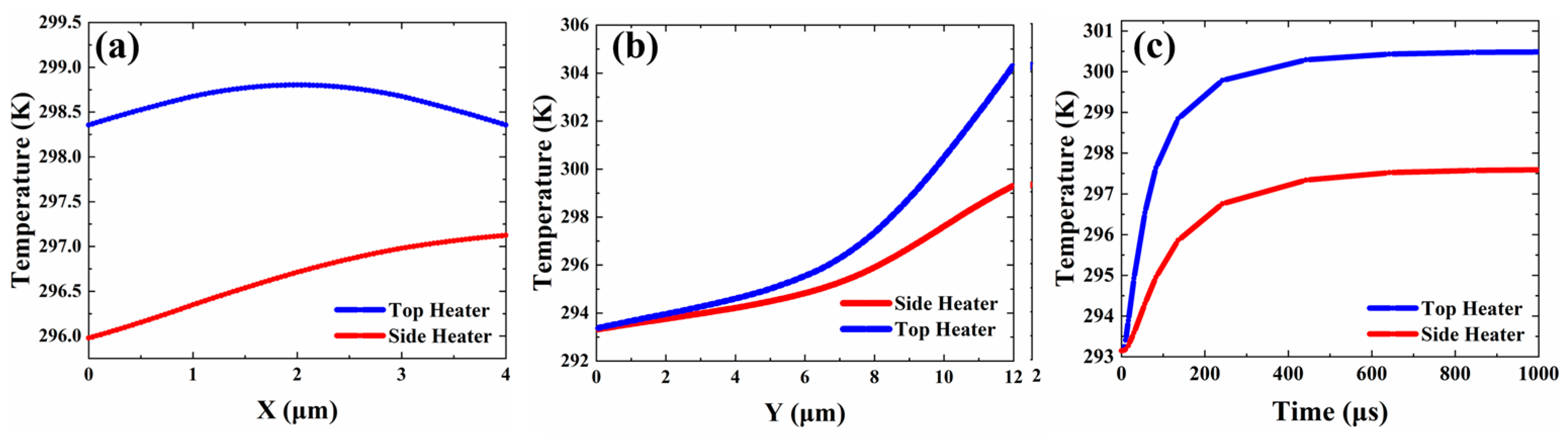

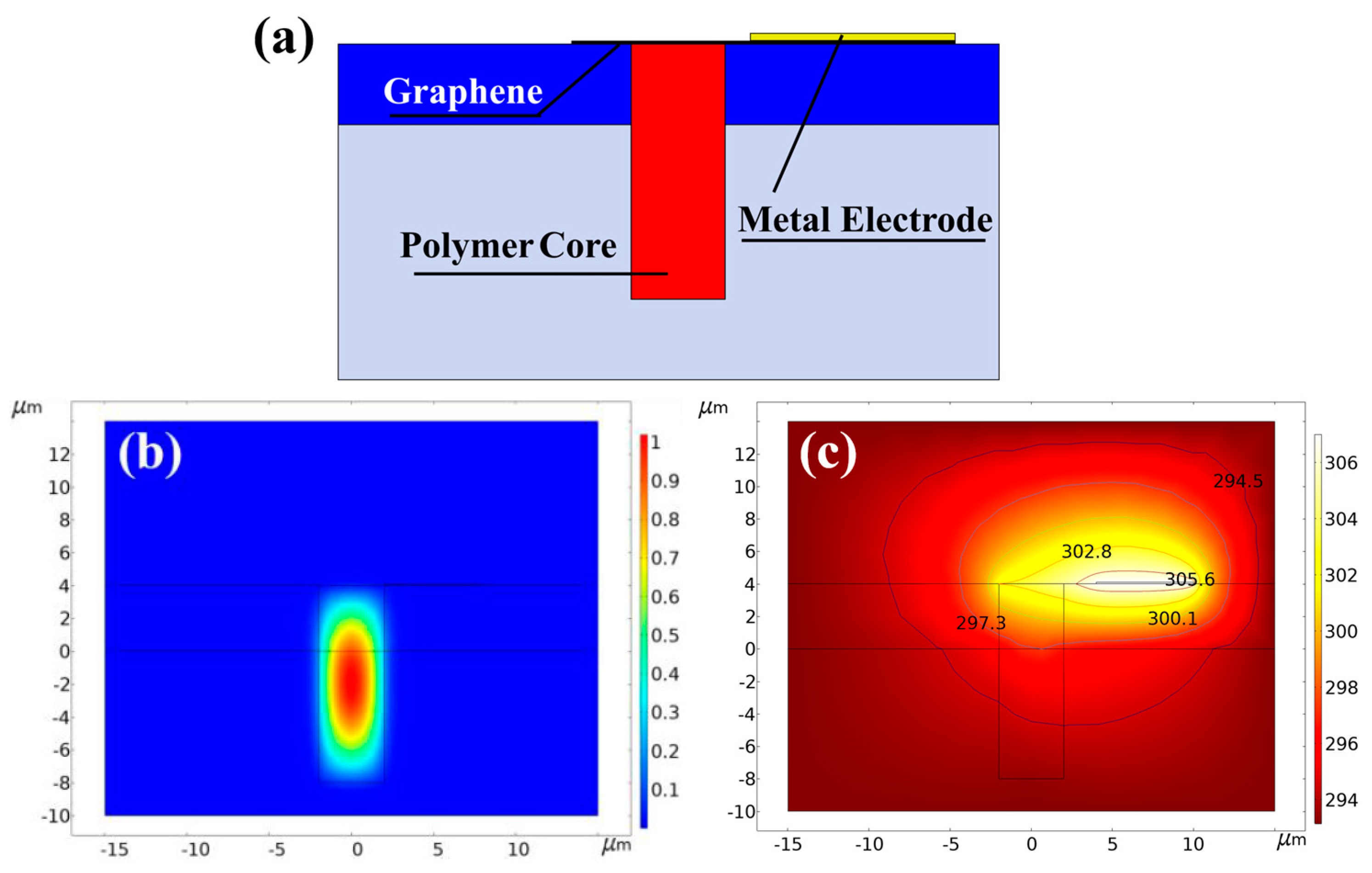

2. Device Design and Simulation

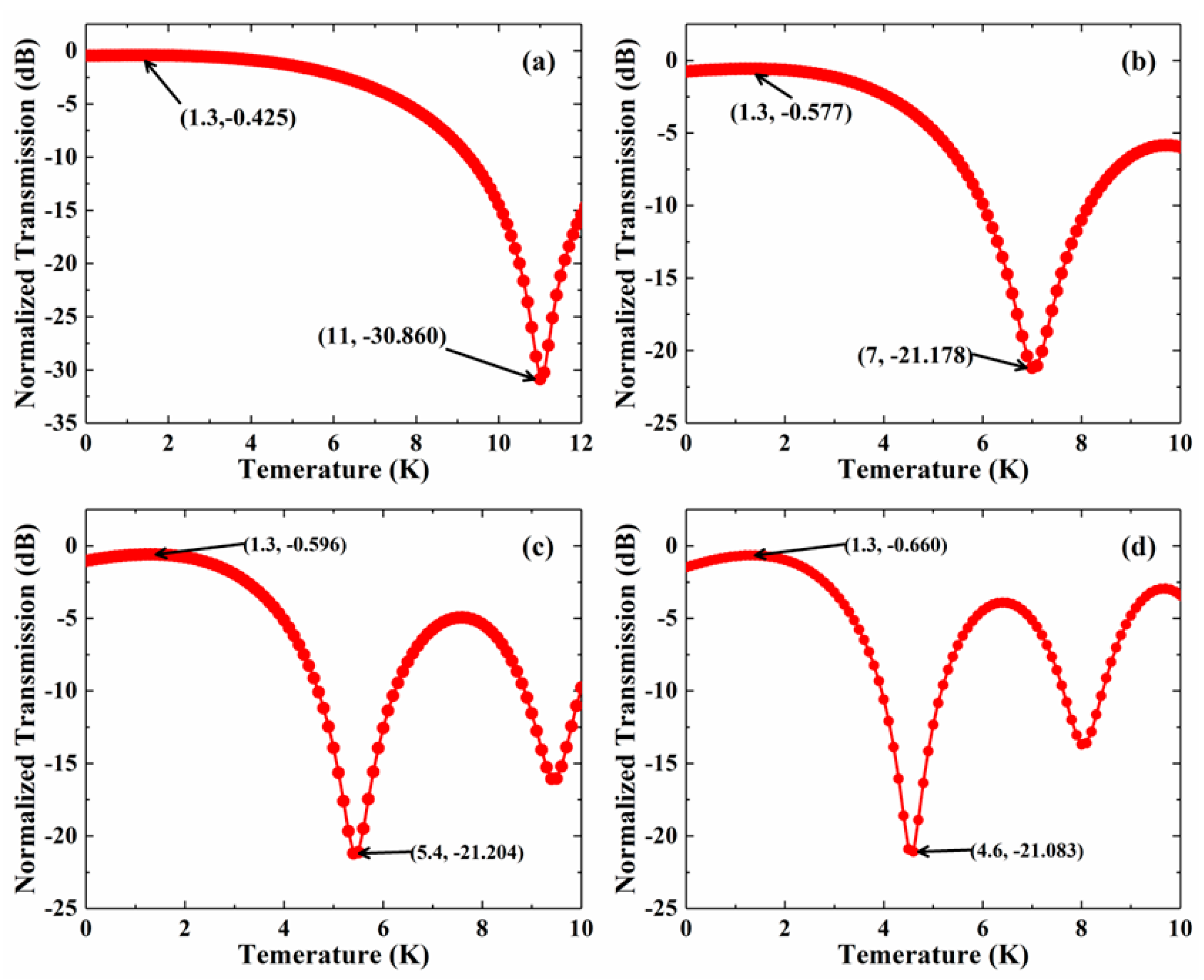

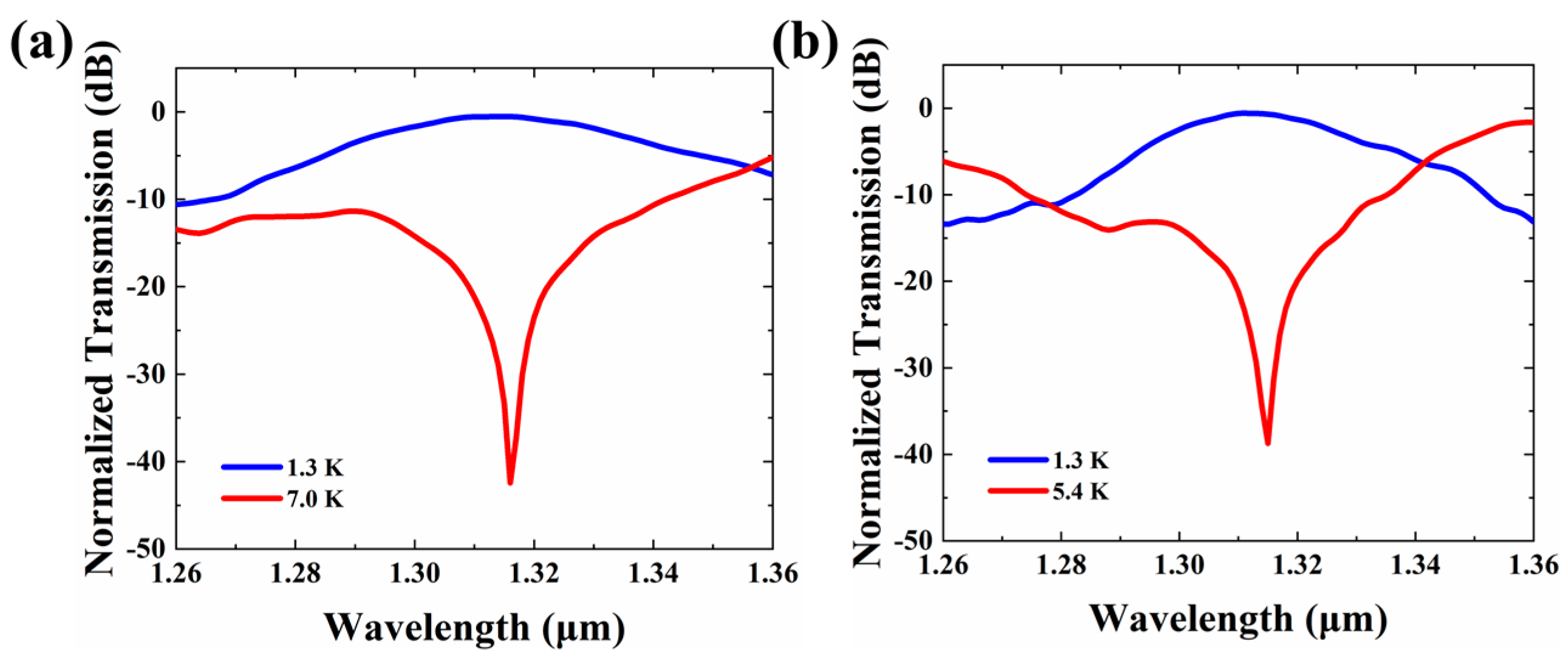

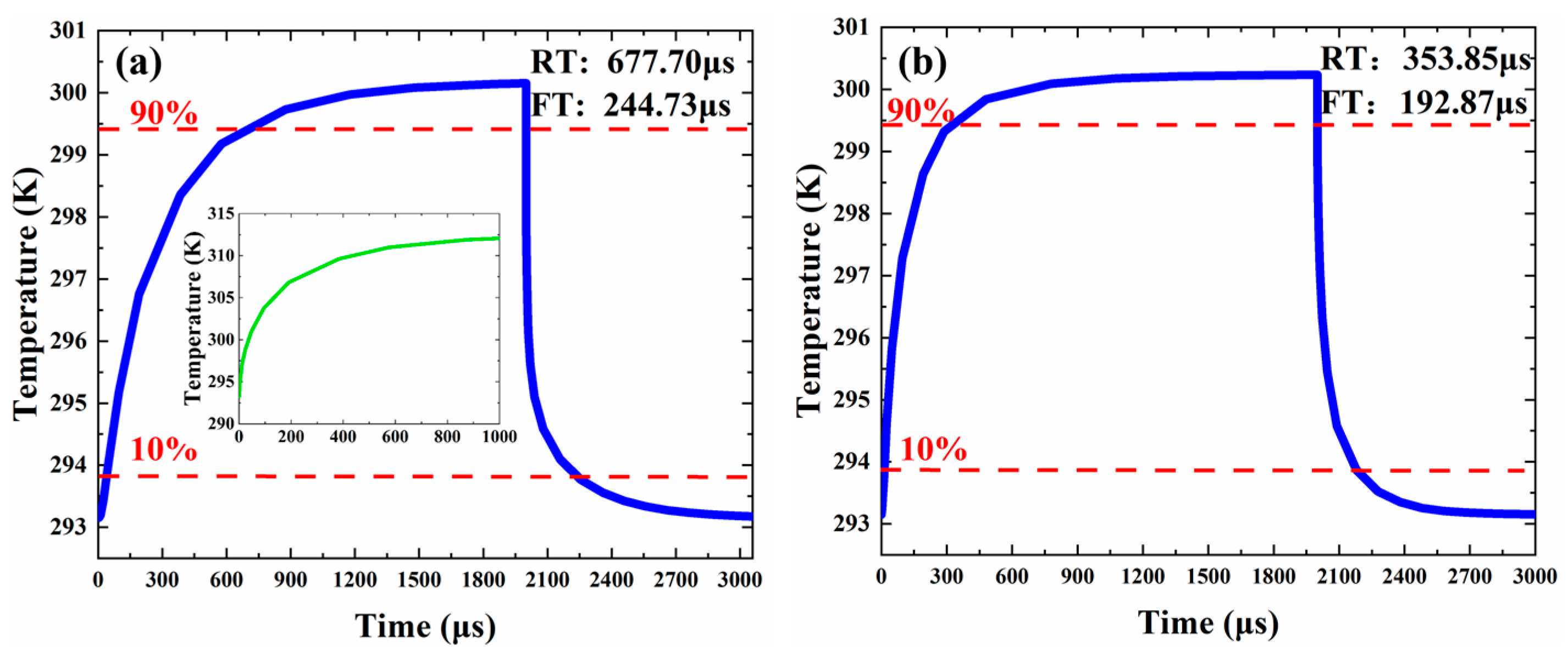

3. Thermal Field Analysis and Optimization

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Akca, B.I.; Doerr, C.R. Interleaved silicon nitride awg spectrometers. IEEE Photonics Technol. Lett. 2019, 31, 90–93. [Google Scholar] [CrossRef]

- Suzuki, K.; Seno, K.; Ikuma, Y. Application of waveguide/free-space optics hybrid to roadm device. J. Light. Technol. 2017, 35, 596–606. [Google Scholar] [CrossRef]

- Cheung, S.; Tiehui, S.; Okamoto, K.; Yoo, S.J.B. Ultra-compact silicon photonic 512 × 512 25 ghz arrayed waveguide grating router. IEEE J. Sel. Top. Quantum Electron. 2014, 20, 310–316. [Google Scholar] [CrossRef]

- Zhang, Z.; Sun, F.; Lin, P.; Xiao, G.; Wu, Y. Heat control of an integrated silica vmux using constant working power. IEEE J. Sel. Top. Quantum Electron. 2006, 12, 1054–1059. [Google Scholar] [CrossRef]

- Wu, X.; Liu, W.; Yuan, Z.; Liang, X.; Chen, H.; Xu, X.; Tang, F. Low power consumption voa array with air trenches and curved waveguide. IEEE Photonics J. 2018, 10, 1–8. [Google Scholar] [CrossRef]

- Qing, F.; Junfeng, S.; Gang, Z.; Mingbin, Y.; Yuliang, L.; Guo-Qiang, L.; Dim-Lee, K. Monolithic integration of a multiplexer/demultiplexer with a thermo-optic voa array on an soi platform. IEEE Photonics Technol. Lett. 2009, 21, 319–321. [Google Scholar] [CrossRef]

- Watanabe, K.; Hashizume, Y.; Nasu, Y.; Kohtoku, M.; Itoh, M.; Inoue, Y. Ultralow power consumption silica-based plc-voa/switches. J. Light. Technol. 2008, 26, 2235–2244. [Google Scholar] [CrossRef]

- Goh, T.; Yasu, M.; Hattori, K.; Himeno, A.; Okuno, M.; Ohmori, Y. Low-loss and high-extinction-ratio silica-based strictly nonblocking 16 × 16 thermooptic matrix switch. IEEE Photonics Technol. Lett. 1998, 10, 810–812. [Google Scholar] [CrossRef]

- Kasahara, R.; Yanagisawa, M.; Goh, T.; Sugita, A.; Himeno, A.; Yasu, M.; Matsui, S. New structure of silica-based planar lightwave circuits for low-power thermooptic switch and its application to 8 × 8 optical matrix switch. J. Light. Technol. 2002, 20, 993–1000. [Google Scholar] [CrossRef]

- Zhang, S.; Yin, Y.; Lv, Z.; Gao, D.; Wang, X. 5-channel polymer/silica hybrid arrayed waveguide grating. Polymers 2020, 12, 629. [Google Scholar] [CrossRef]

- Yin, Y.; Yao, M.; Ding, Y.; Xu, X.; Li, Y.; Wu, Y.; Zhang, D. Polymer/silica hybrid waveguide thermo-optic voa covering o-band. Micromachines 2022, 13, 511. [Google Scholar] [CrossRef] [PubMed]

- Harjanne, M.; Kapulainen, M.; Aalto, T.; Heimala, P. Sub-μs switching time in silicon-on-insulator mach–zehnder thermooptic switch. IEEE Photonics Technol. Lett. 2004, 16, 2039–2041. [Google Scholar] [CrossRef]

- Liu, M.; Yin, X.; Ulin-Avila, E.; Geng, B.; Zentgraf, T.; Ju, L.; Wang, F.; Zhang, X. A graphene-based broadband optical modulator. Nature 2011, 474, 64–67. [Google Scholar] [CrossRef]

- Jin, M.; Wei, Z.; Meng, Y.; Shu, H.; Tao, Y.; Bai, B.; Wang, X. Silicon-based graphene electro-optical modulators. Photonics 2022, 9, 82. [Google Scholar] [CrossRef]

- Mao, D.; Cheng, C.; Wang, F.; Xiao, Y.; Li, T.; Chang, L.; Soman, A.; Kananen, T.; Zhang, X.; Krainak, M.; et al. Device architectures for low voltage and ultrafast graphene integrated phase modulators. IEEE J. Sel. Top. Quantum Electron. 2021, 27, 1–9. [Google Scholar] [CrossRef] [PubMed]

- Yu, L.; Yin, Y.; Shi, Y.; Dai, D.; He, S. Thermally tunable silicon photonic microdisk resonator with transparent graphene nanoheaters. Optica 2016, 3, 159–166. [Google Scholar] [CrossRef]

- Sun, Y.; Cao, Y.; Yi, Y.; Tian, L.; Zheng, Y.; Zheng, J.; Wang, F.; Zhang, D. A low-power consumption mzi thermal optical switch with a graphene-assisted heating layer and air trench. RSC Adv. 2017, 7, 39922–39927. [Google Scholar] [CrossRef]

- Wang, X.; Jin, W.; Chang, Z.; Chiang, K.S. Buried graphene electrode heater for a polymer waveguide thermo-optic device. Opt. Lett. 2019, 44, 1480–1483. [Google Scholar] [CrossRef]

- Song, Q.Q.; Chen, K.X.; Hu, Z.F. Low-power broadband thermo-optic switch with weak polarization dependence using a segmented graphene heater. J. Light. Technol. 2020, 38, 1358–1364. [Google Scholar] [CrossRef]

- Li, J.; Huang, Y.; Song, Y.; Li, L.; Zheng, H.; Wang, H.; Gu, T.; Richardson, K.; Kong, J.; Hu, J.; et al. High-performance graphene-integrated thermo-optic switch: Design and experimental validation [invited]. Opt. Mater. Express 2020, 10, 387–396. [Google Scholar] [CrossRef]

- Li, J.; Yin, Y.; Guo, J.; Liu, C.; Dai, D. Hybrid ultrathin-silicon/graphene waveguide photodetector with a loop mirror reflector. Opt Express 2020, 28, 10725–10736. [Google Scholar] [CrossRef] [PubMed]

- Guo, J.; Li, J.; Liu, C.; Yin, Y.; Wang, W.; Ni, Z.; Fu, Z.; Yu, H.; Xu, Y.; Shi, Y.; et al. High-performance silicon-graphene hybrid plasmonic waveguide photodetectors beyond 1.55 mum. Light Sci. Appl. 2020, 9, 29. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Yin, Y.; Yu, L.; Shi, Y.; Liang, D.; Dai, D. Silicon-graphene conductive photodetector with ultra-high responsivity. Sci. Rep. 2017, 7, 40904. [Google Scholar] [CrossRef] [PubMed]

- Cheng, Z.; Liao, J.; He, B.; Zhang, F.; Zhang, F.; Huang, X.; Zhou, L. One-step fabrication of graphene oxide enhanced magnetic composite gel for highly efficient dye adsorption and catalysis. ACS Sustain. Chem. Eng. 2015, 3, 1677–1685. [Google Scholar] [CrossRef]

- Chen, H.; Chen, Z.; Yang, H.; Wen, L.; Yi, Z.; Zhou, Z.; Dai, B.; Zhang, J.; Wu, X.; Wu, P. Multi-mode surface plasmon resonance absorber based on dart-type single-layer graphene. RSC Adv. 2022, 12, 7821–7829. [Google Scholar] [CrossRef]

- Shangguan, Q.; Chen, Z.; Yang, H.; Cheng, S.; Yang, W.; Yi, Z.; Wu, X.; Wang, S.; Yi, Y.; Wu, P. Design of ultra-narrow band graphene refractive index sensor. Sensors 2022, 22, 6483. [Google Scholar] [CrossRef]

- Su, W.; Geng, Z.; Qi, J.; Wu, H. Multi-fano resonances in graphene coated all-dielectric metasurface for refractive index sensing with high figure of merits. IEEE J. Sel. Top. Quantum Electron. 2021, 27, 1–6. [Google Scholar] [CrossRef]

- Chang, Z.; Chiang, K.S. Ultra-broadband mode filters based on graphene-embedded waveguides. Opt. Lett. 2017, 42, 3868–3871. [Google Scholar] [CrossRef]

- Jia, H.; Zhou, T.; Fu, X.; Ding, J.; Zhang, L.; Yang, L. Four-port mode-selective silicon optical router for on-chip optical interconnect. Opt. Express 2018, 26, 9740–9748. [Google Scholar] [CrossRef]

- Zhang, M.; Zhang, W.; Wang, F.; Zhao, D.; Qu, C.; Wang, X.; Yi, Y.; Cassan, E.; Zhang, D. High-gain polymer optical waveguide amplifiers based on core-shell nayf4/naluf4: Yb(3+), er(3+) nps-pmma covalent-linking nanocomposites. Sci. Rep. 2016, 6, 36729. [Google Scholar] [CrossRef]

- Wang, C.; Zhang, D.; Yue, J.; Zhang, X.; Wu, Z.; Zhang, T.; Chen, C.; Fei, T. Optical waveguide sensors for measuring human temperature and humidity with gel polymer electrolytes. ACS Appl Mater. Interfaces 2021, 13, 60384–60392. [Google Scholar] [CrossRef] [PubMed]

- Yin, Y.; Yin, X.; Zhang, X.; Yan, G.; Wang, Y.; Wu, Y.; An, J.; Wang, L.; Zhang, D. High-q-factor silica-based racetrack microring resonators. Photonics 2021, 8, 43. [Google Scholar] [CrossRef]

- Yin, Y.; Zhang, X.; Yin, X.; Li, Y.; Xu, X.; An, J.; Wu, Y.; Liu, X.; Zhang, D. High-q-factor tunable silica-based microring resonators. Photonics 2021, 8, 256. [Google Scholar] [CrossRef]

- Soldano, L.B.; Pennings, E.C.M. Optical multi-mode interference devices based on self-imaging: Principles and applications. J. Light. Technol. 1995, 13, 615–627. [Google Scholar] [CrossRef]

- Zhang, Z.; Keil, N. Thermo-optic devices on polymer platform. Opt. Commun. 2016, 362, 101–114. [Google Scholar] [CrossRef]

- Maese-Novo, A.; Zhang, Z.; Irmscher, G.; Polatynski, A.; Mueller, T.; de Felipe, D.; Kleinert, M.; Brinker, W.; Zawadzki, C.; Keil, N. Thermally optimized variable optical attenuators on a polymer platform. Appl. Opt. 2015, 54, 569–575. [Google Scholar] [CrossRef]

- Ren, M.-Z.; Zhang, J.-S.; An, J.-M.; Wang, Y.; Wang, L.-L.; Li, J.-G.; Wu, Y.-D.; Yin, X.; Hu, X.-W. Low power consumption 4-channel variable optical attenuator array based on planar lightwave circuit technique. Chin. Phys. B 2017, 26, 74221. [Google Scholar] [CrossRef]

- Wu, Q.; Zhou, L.; Sun, X.; Zhu, H.; Lu, L.; Chen, J. Silicon thermo-optic variable optical attenuators based on mach–zehnder interference structures. Opt. Commun. 2015, 341, 69–73. [Google Scholar] [CrossRef]

- Noh, Y.-O.; Lee, C.-H.; Kim, J.-M.; Hwang, W.-Y.; Won, Y.-H.; Lee, H.-J.; Han, S.-G.; Oh, M.-C. Polymer waveguide variable optical attenuator and its reliability. Opt. Commun. 2004, 242, 533–540. [Google Scholar] [CrossRef]

- Young-Tak, H.; Jang-Uk, S.; Sang-Ho, P.; Sang-Pil, H.; Yongsoon, B.; Chul-Hee, L.; Young-Ouk, N.; Hyung-Jong, L.; Hyo-Hoon, P. Fabrication of 10-channel polymer thermo-optic digital optical switch array. IEEE Photonics Technol. Lett. 2009, 21, 1556–1558. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, X.; Yin, Y.; Yao, M.; Yin, X.; Gao, F.; Wu, Y.; Chen, C.; Wang, F.; Zhang, D. Three-Dimensional Polymer Variable Optical Attenuator Based on Vertical Multimode Interference with Graphene Heater. Micromachines 2022, 13, 2116. https://doi.org/10.3390/mi13122116

Xu X, Yin Y, Yao M, Yin X, Gao F, Wu Y, Chen C, Wang F, Zhang D. Three-Dimensional Polymer Variable Optical Attenuator Based on Vertical Multimode Interference with Graphene Heater. Micromachines. 2022; 13(12):2116. https://doi.org/10.3390/mi13122116

Chicago/Turabian StyleXu, Xinru, Yuexin Yin, Mengke Yao, Xiaojie Yin, Feifei Gao, Yuanda Wu, Changming Chen, Fei Wang, and Daming Zhang. 2022. "Three-Dimensional Polymer Variable Optical Attenuator Based on Vertical Multimode Interference with Graphene Heater" Micromachines 13, no. 12: 2116. https://doi.org/10.3390/mi13122116

APA StyleXu, X., Yin, Y., Yao, M., Yin, X., Gao, F., Wu, Y., Chen, C., Wang, F., & Zhang, D. (2022). Three-Dimensional Polymer Variable Optical Attenuator Based on Vertical Multimode Interference with Graphene Heater. Micromachines, 13(12), 2116. https://doi.org/10.3390/mi13122116