A Multi-Point Contact Model Considering Rough Surface for Linear Ultrasonic Motors: Validation and Simulation

Abstract

1. Introduction

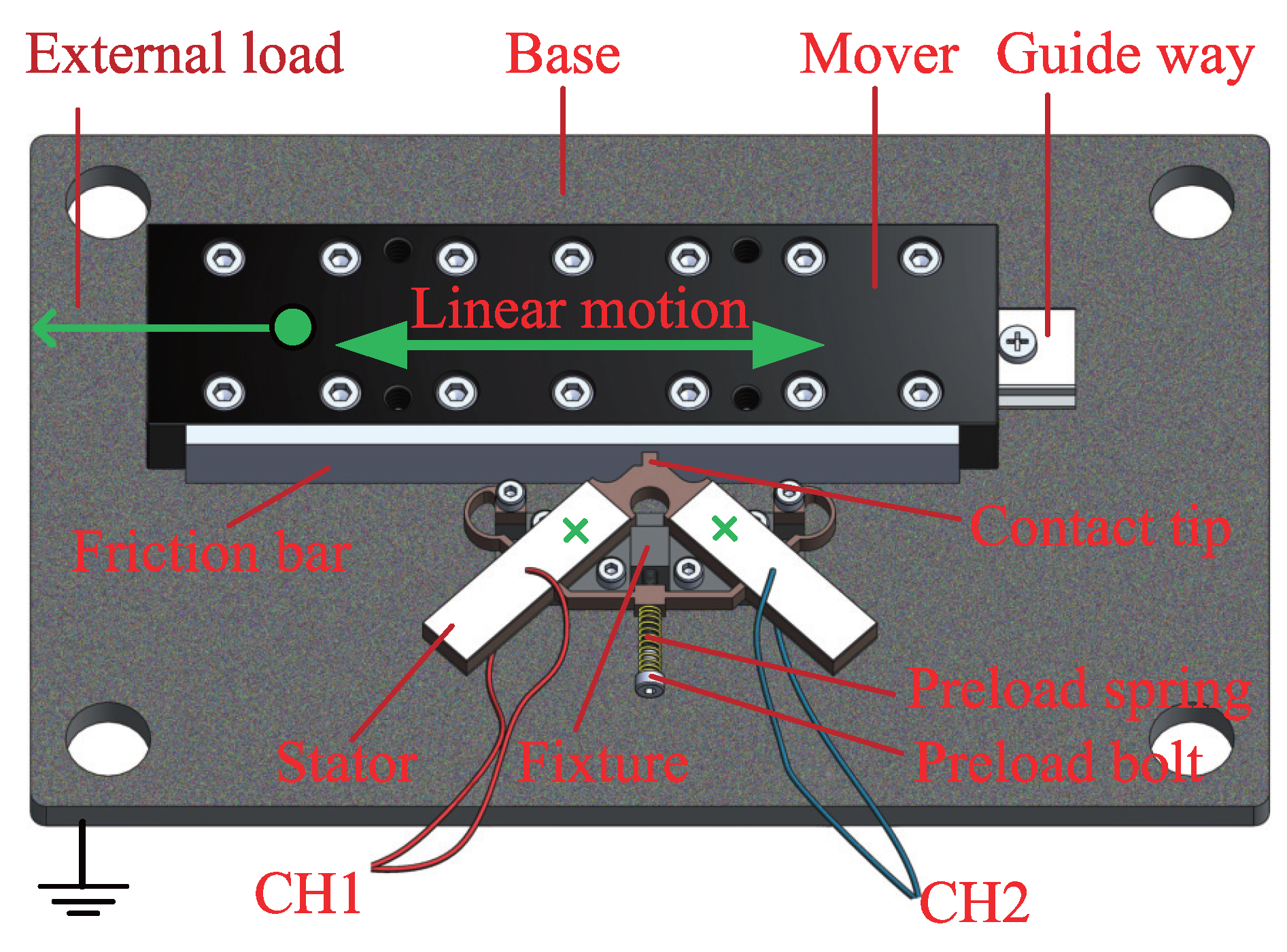

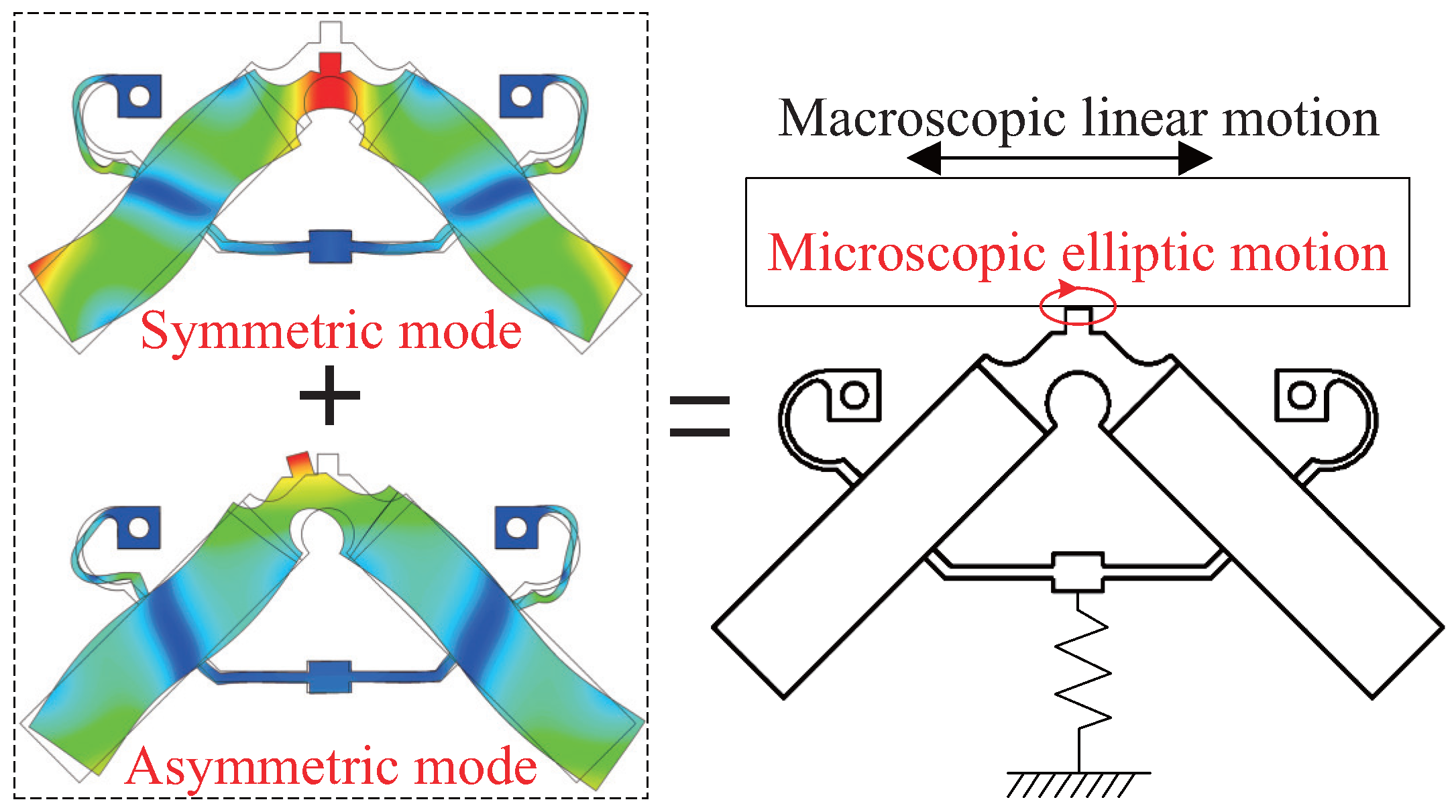

2. The LUM Prototype and Operating Principle

3. Numerical Modeling and Algorithm

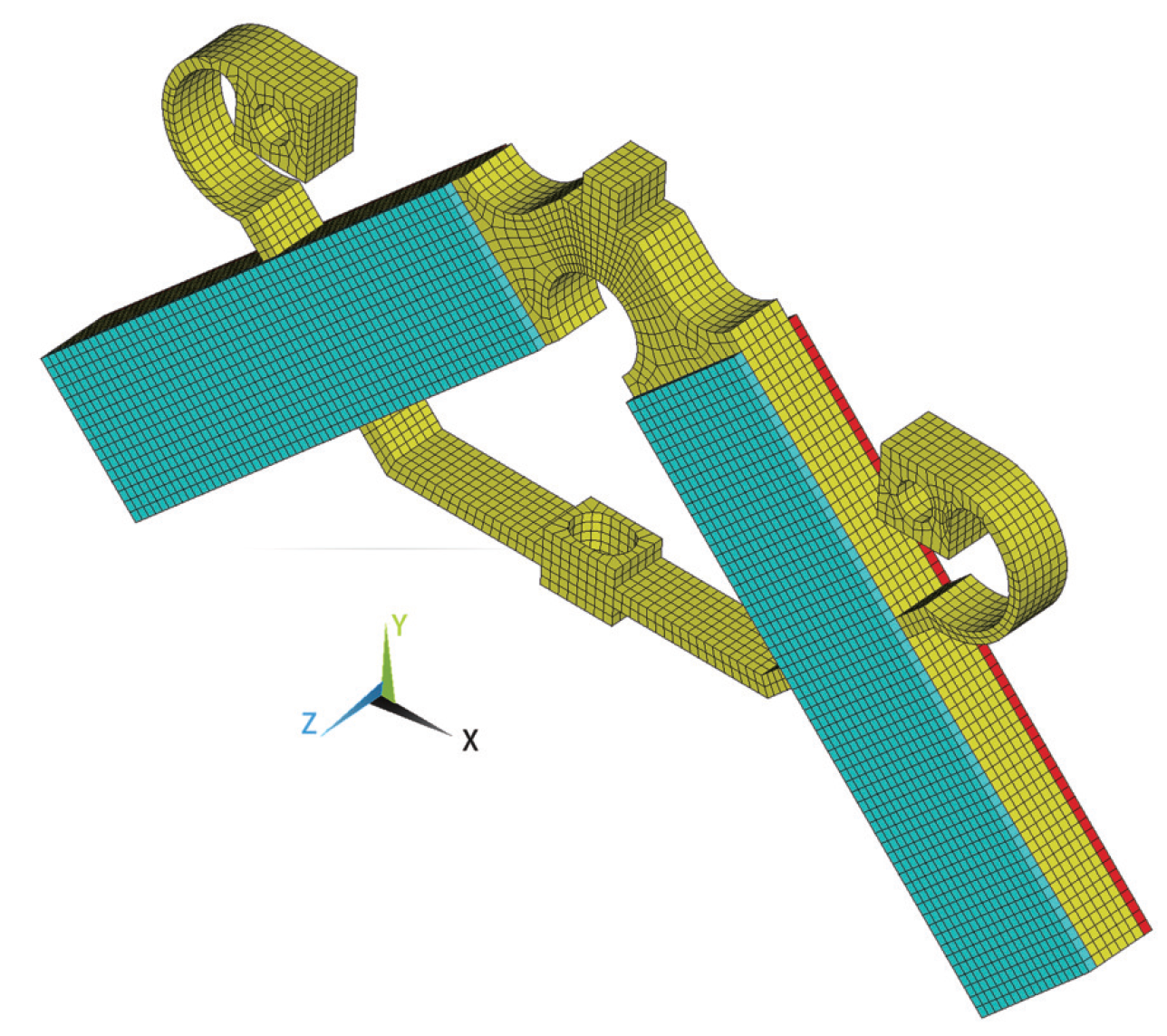

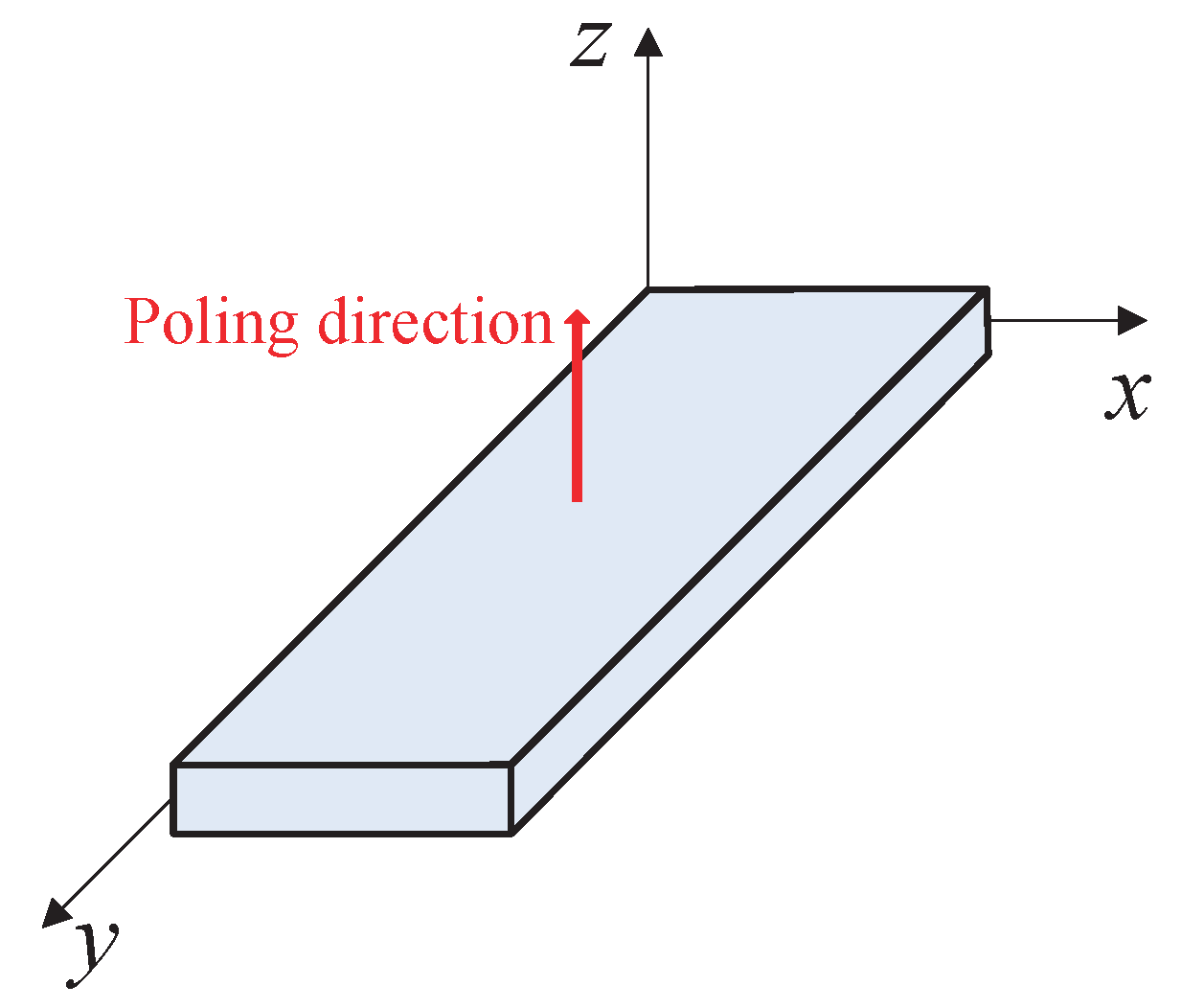

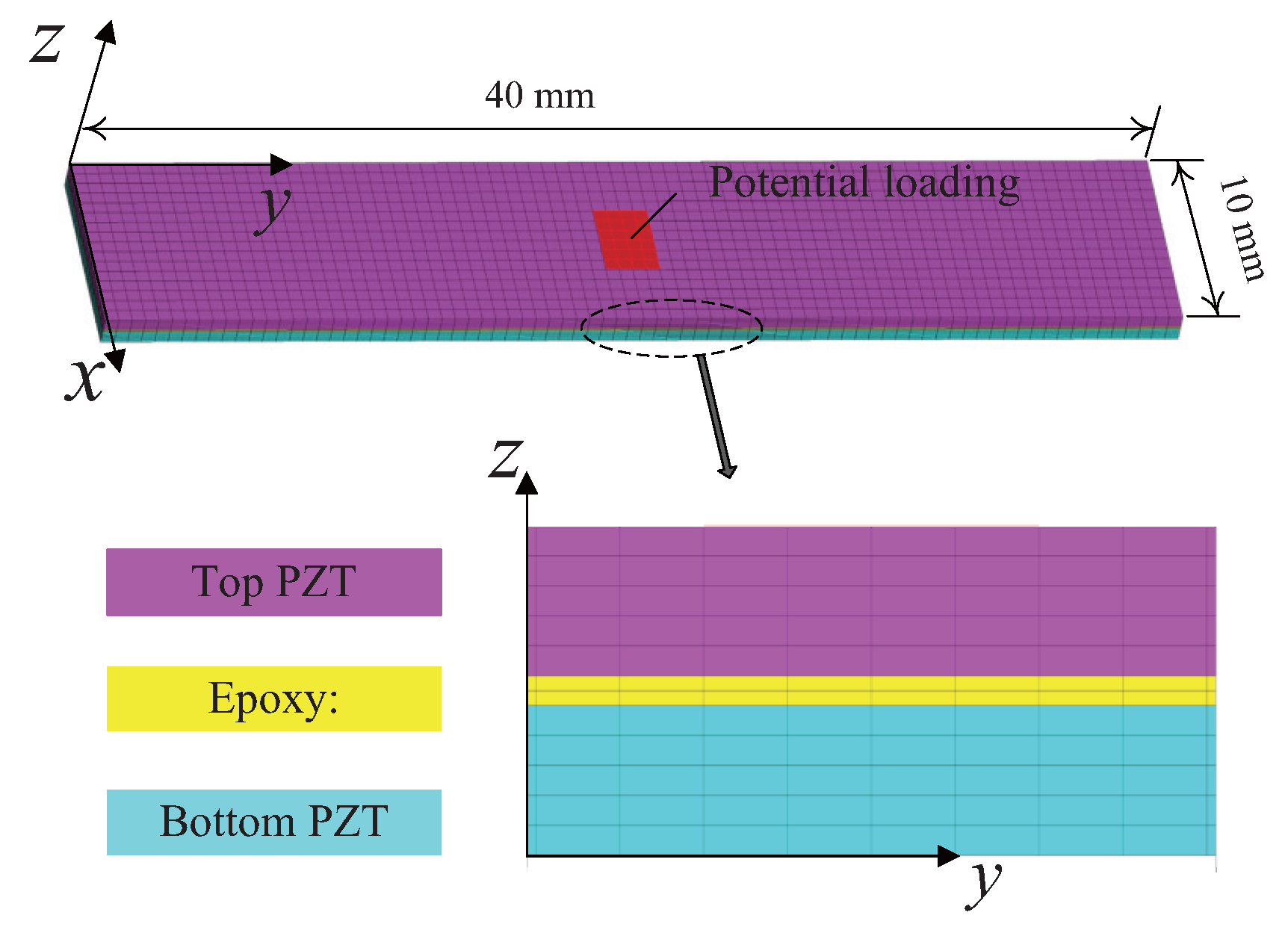

3.1. Stator and Mover Model

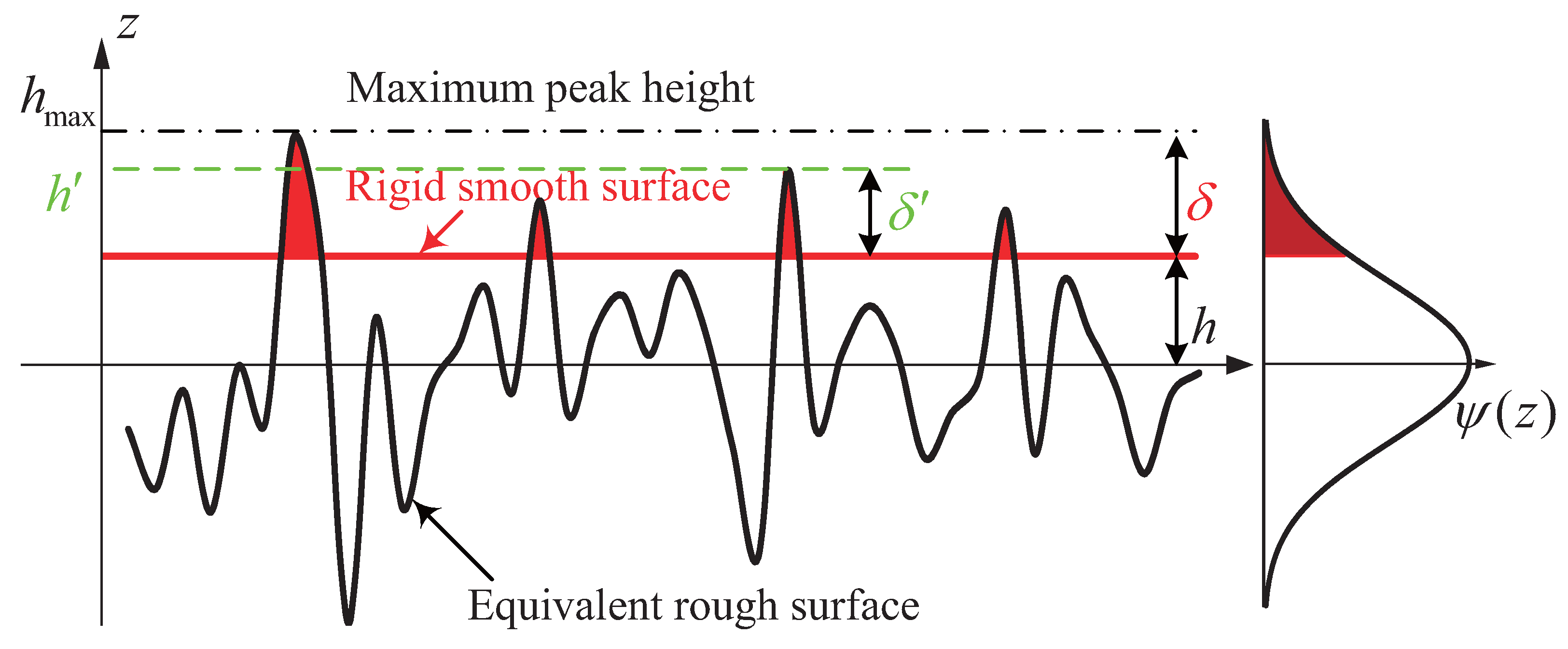

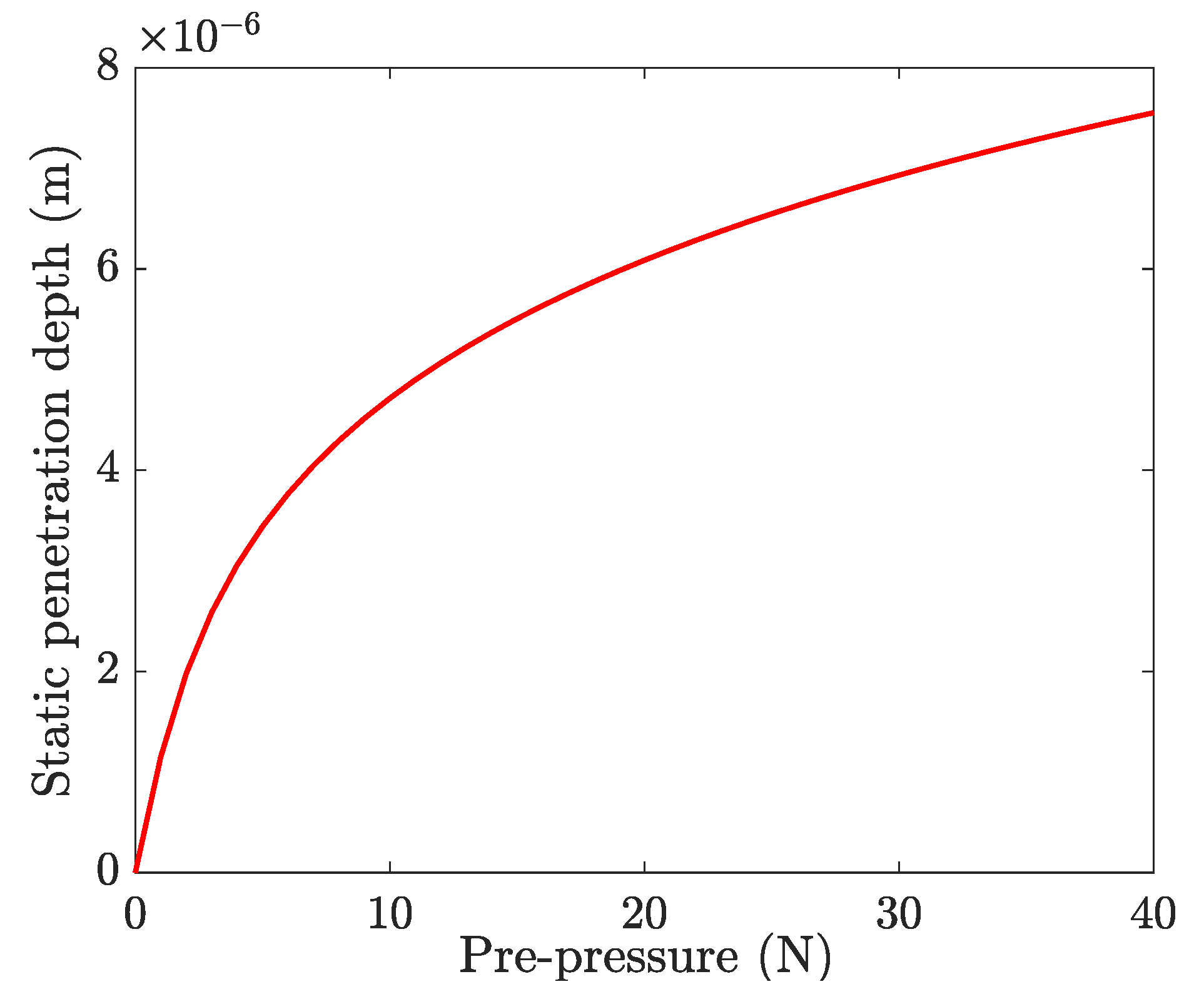

3.2. Normal Contact Model Considering Rough Surface

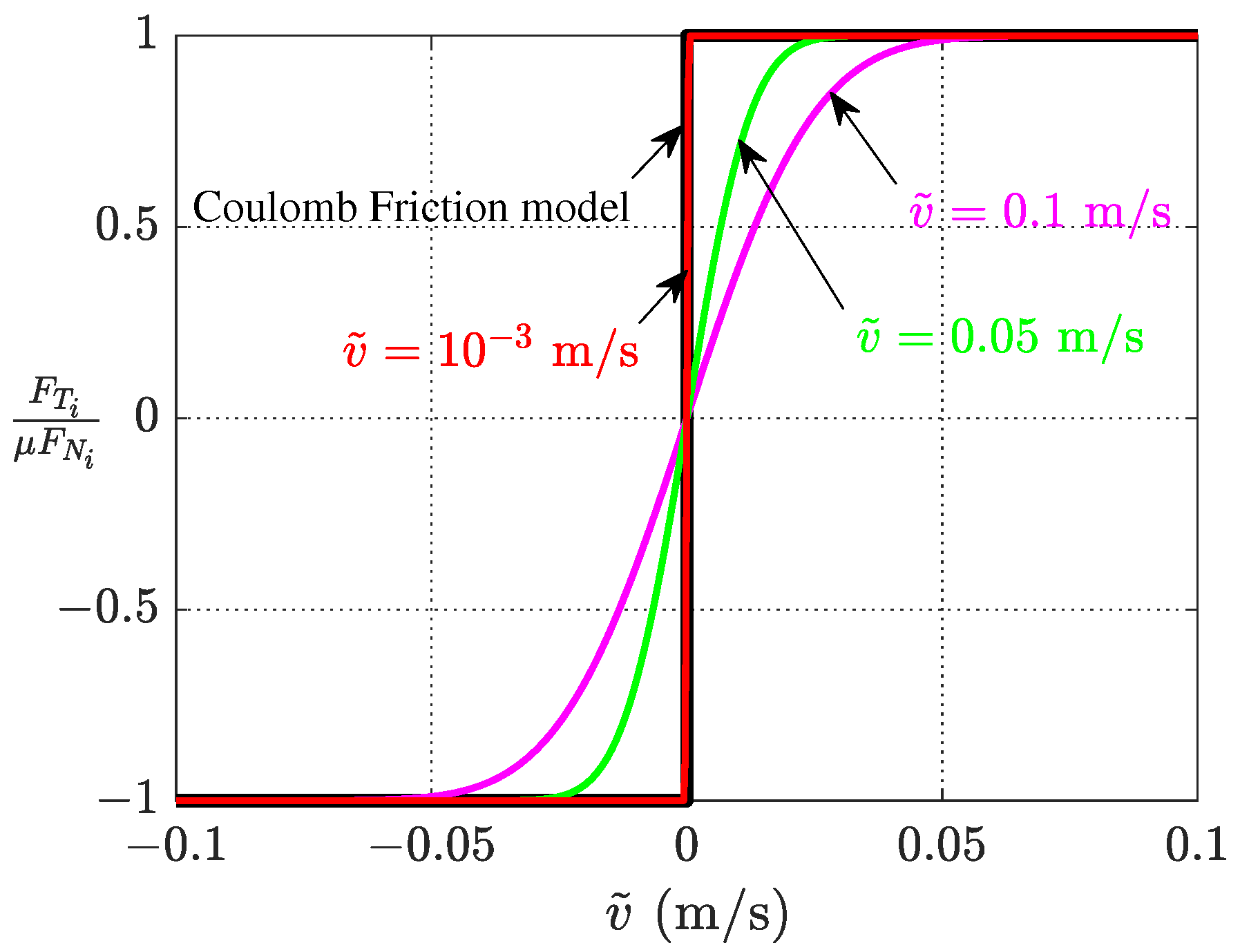

3.3. Regularization Friction Model

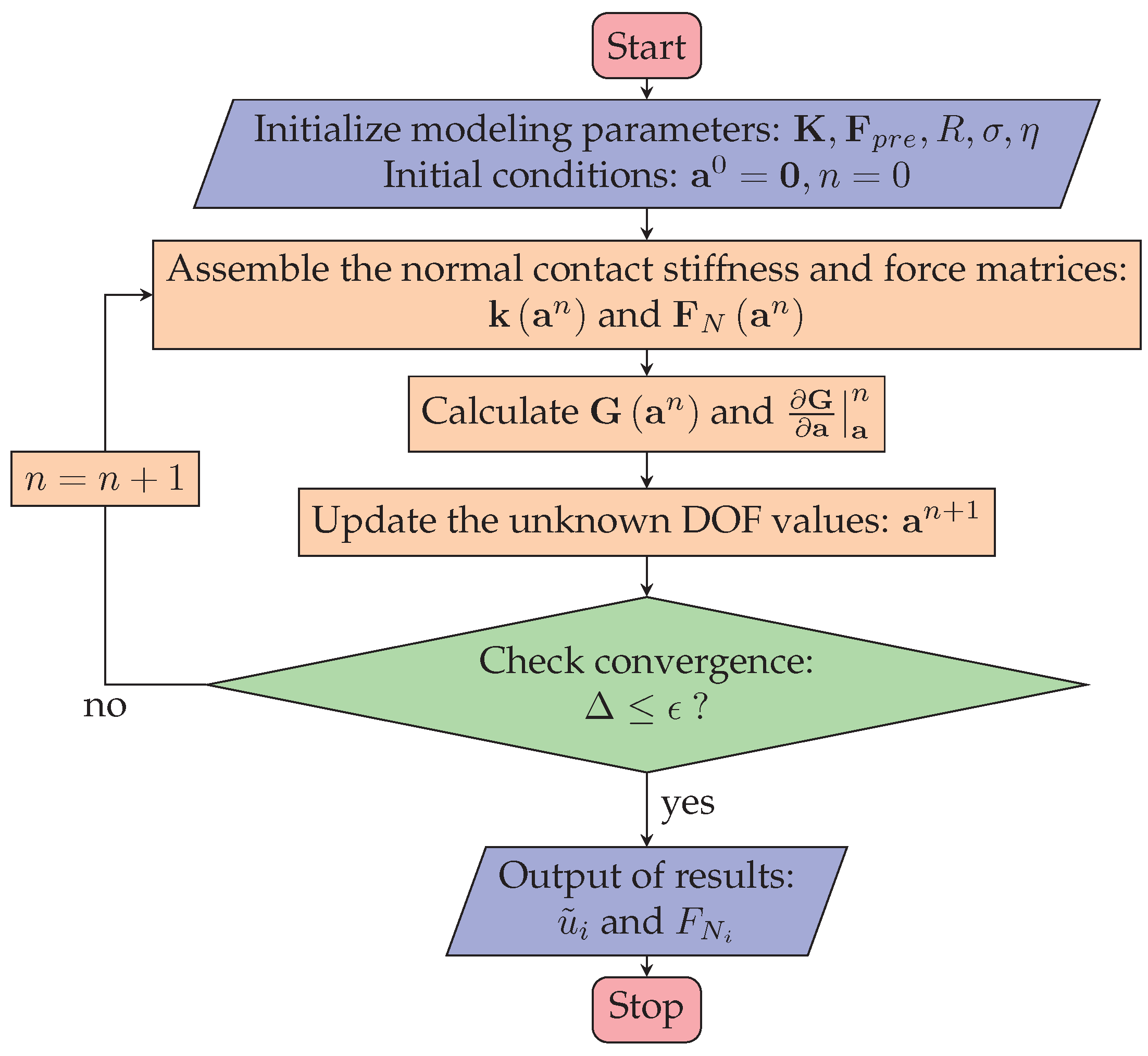

3.4. Static Contact Algorithm

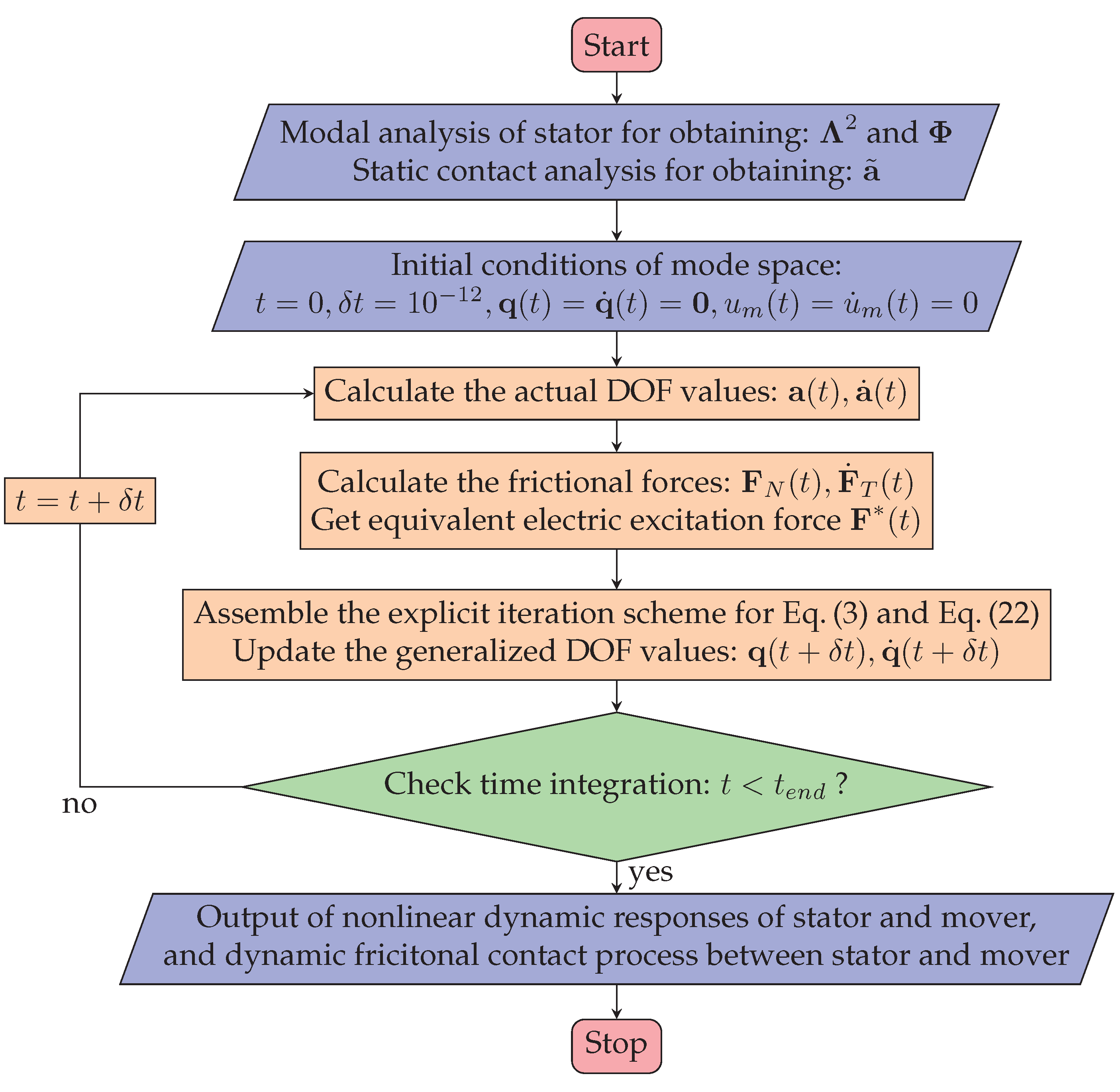

3.5. Dynamic Contact Algorithm

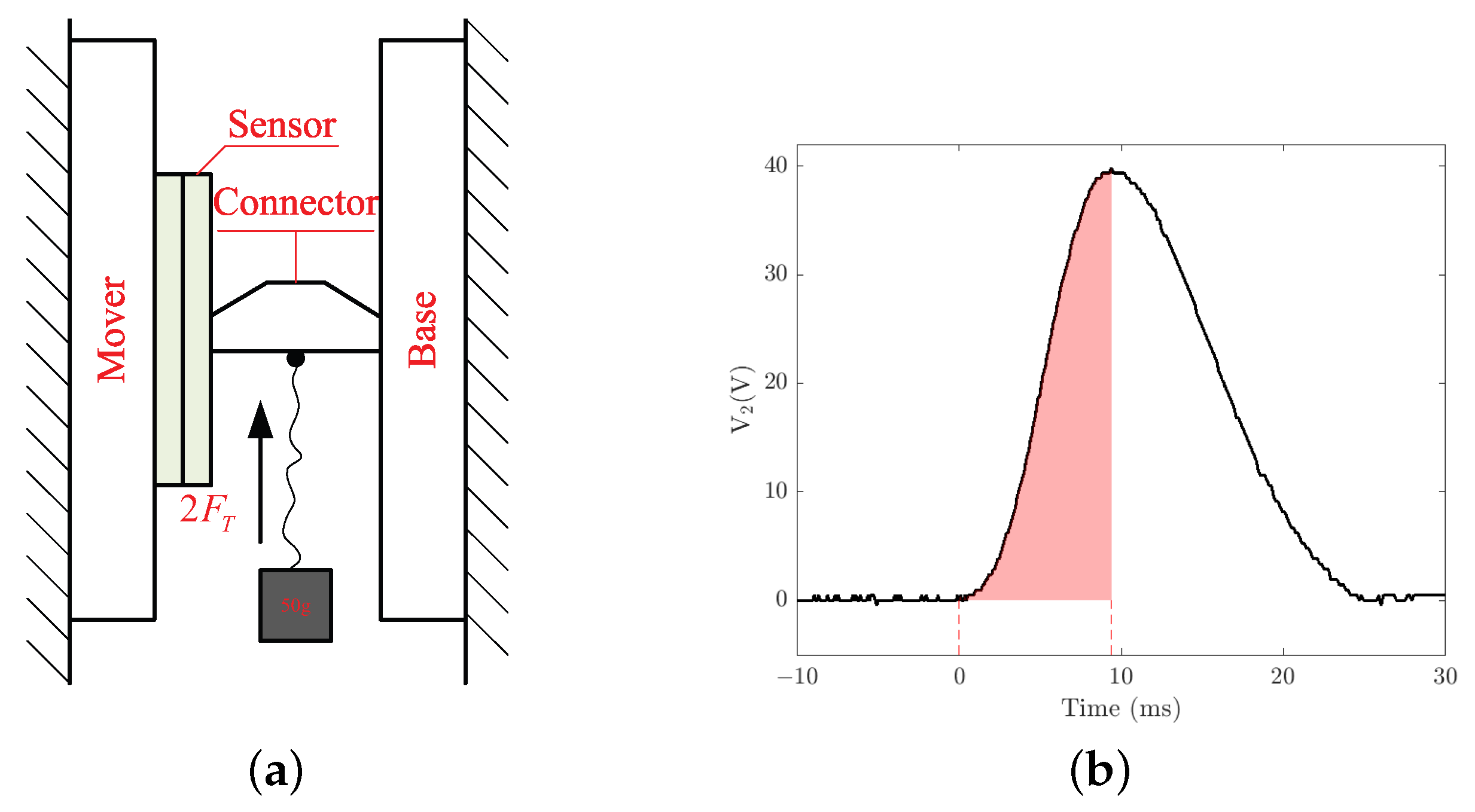

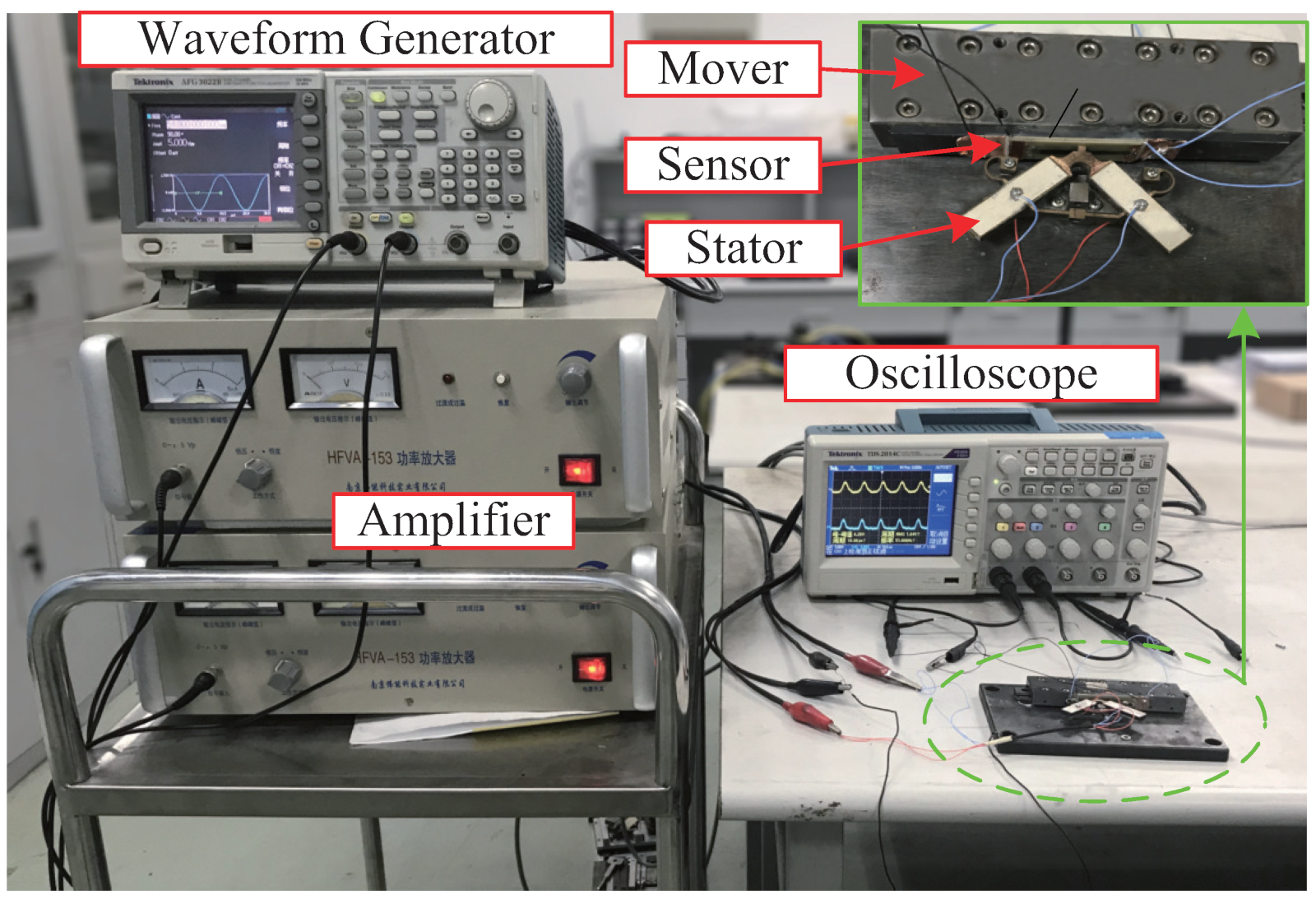

4. Measurement System of Stator–Mover Frictional Contact Forces

4.1. Measurement Principle

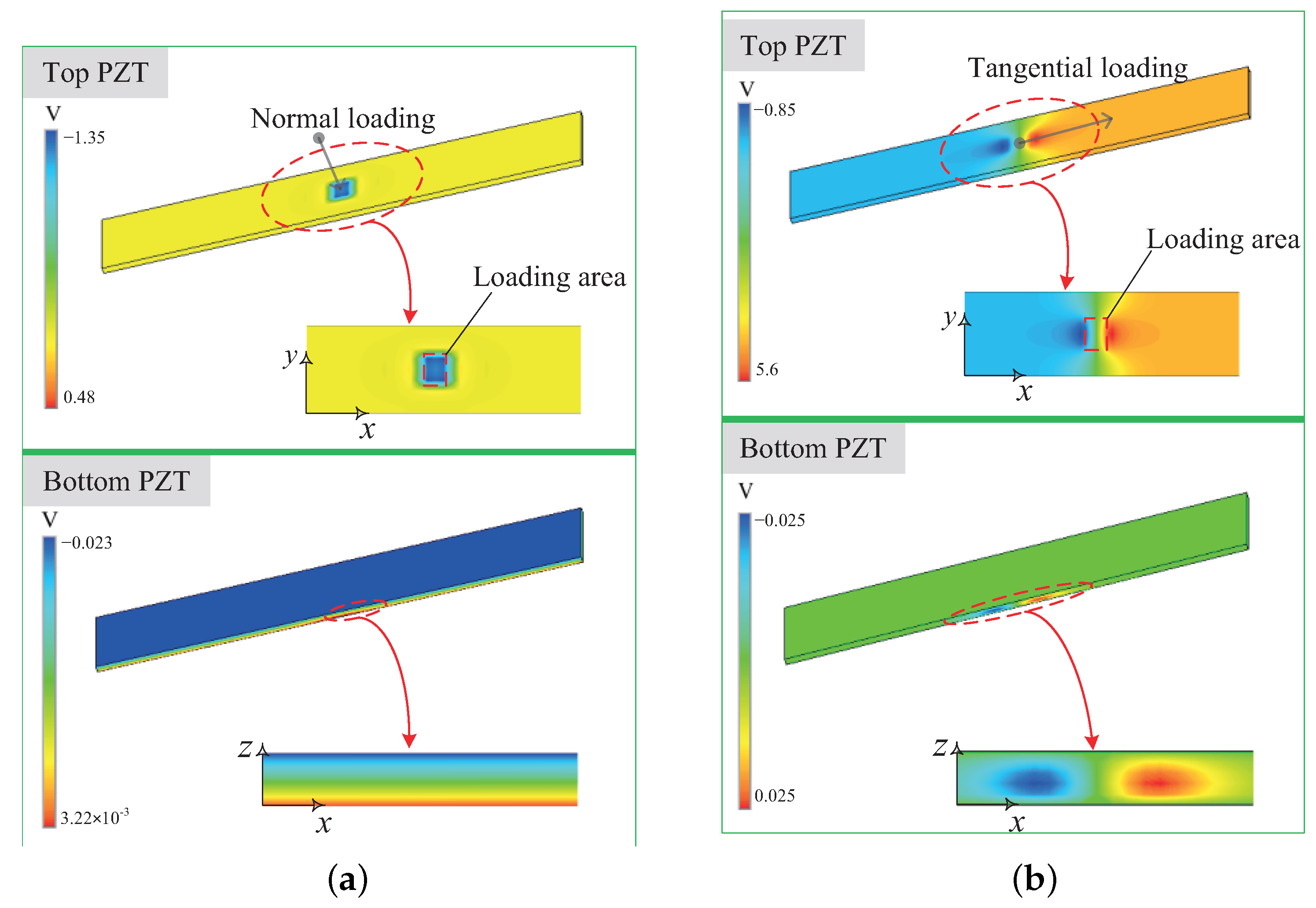

4.2. Feasibility Analysis

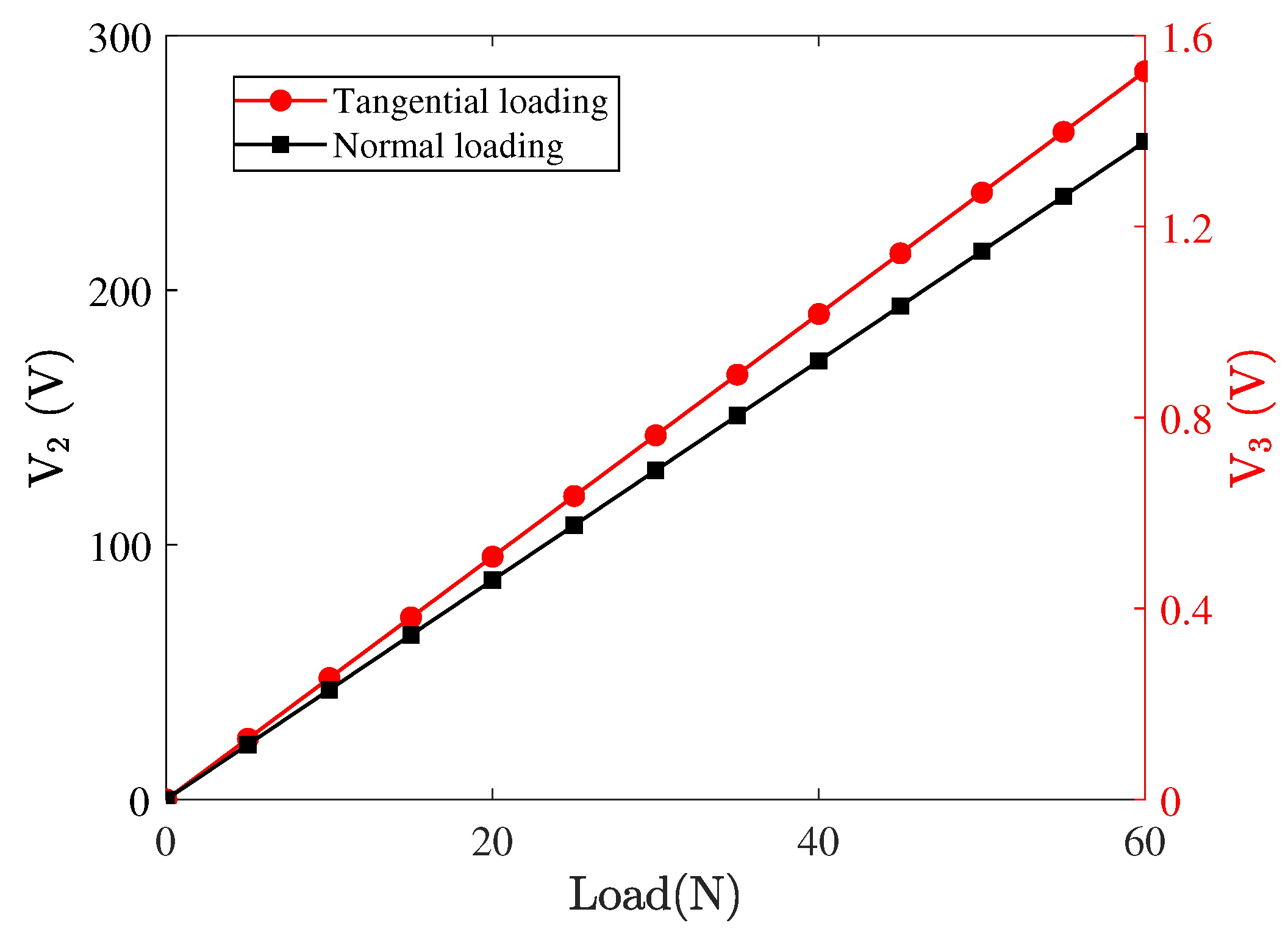

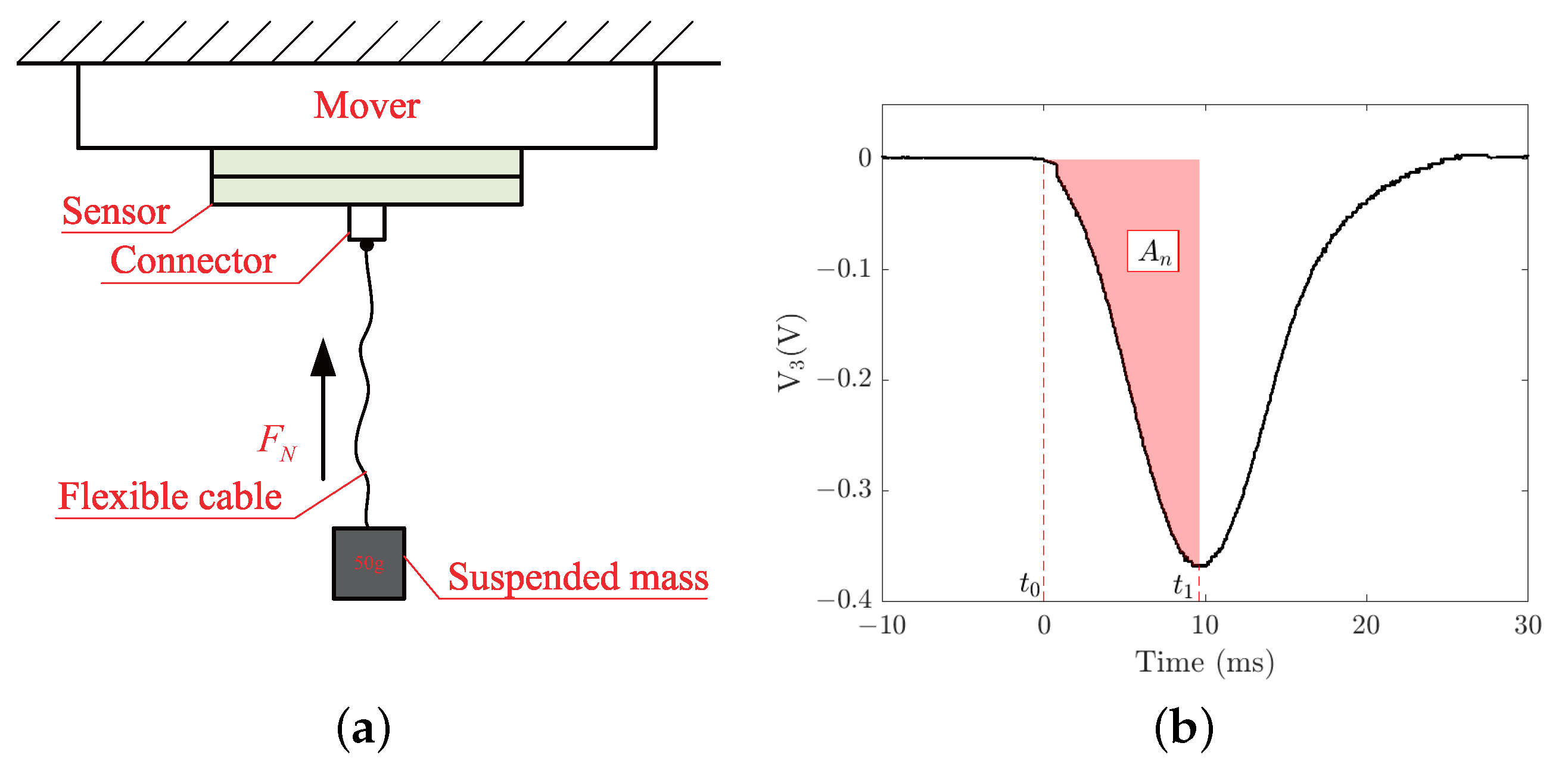

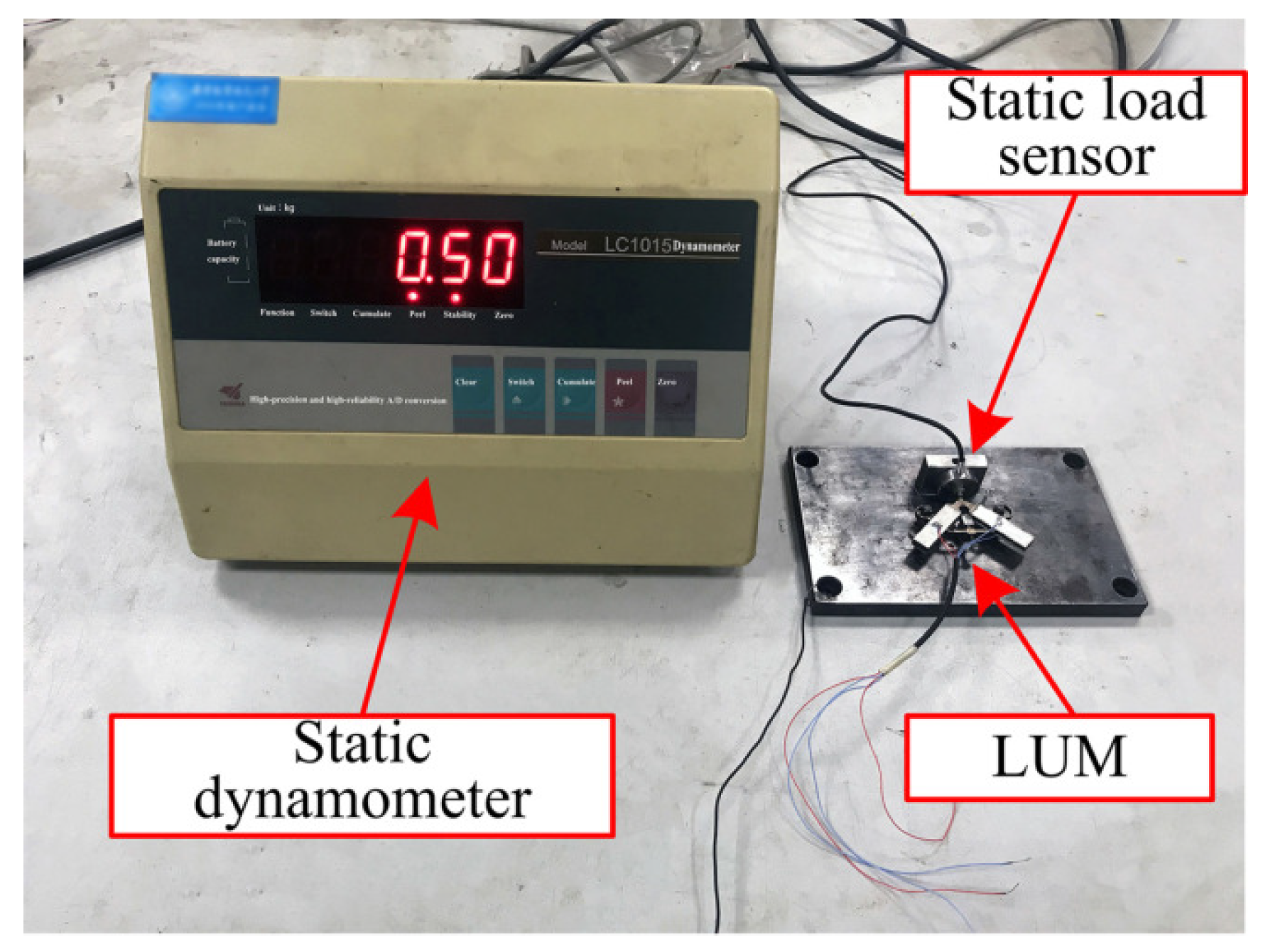

4.3. Experimental Calibration

4.4. Measurement System

5. Experimental Validation and Numerical Simulation

5.1. Static Stator–Mover Contact

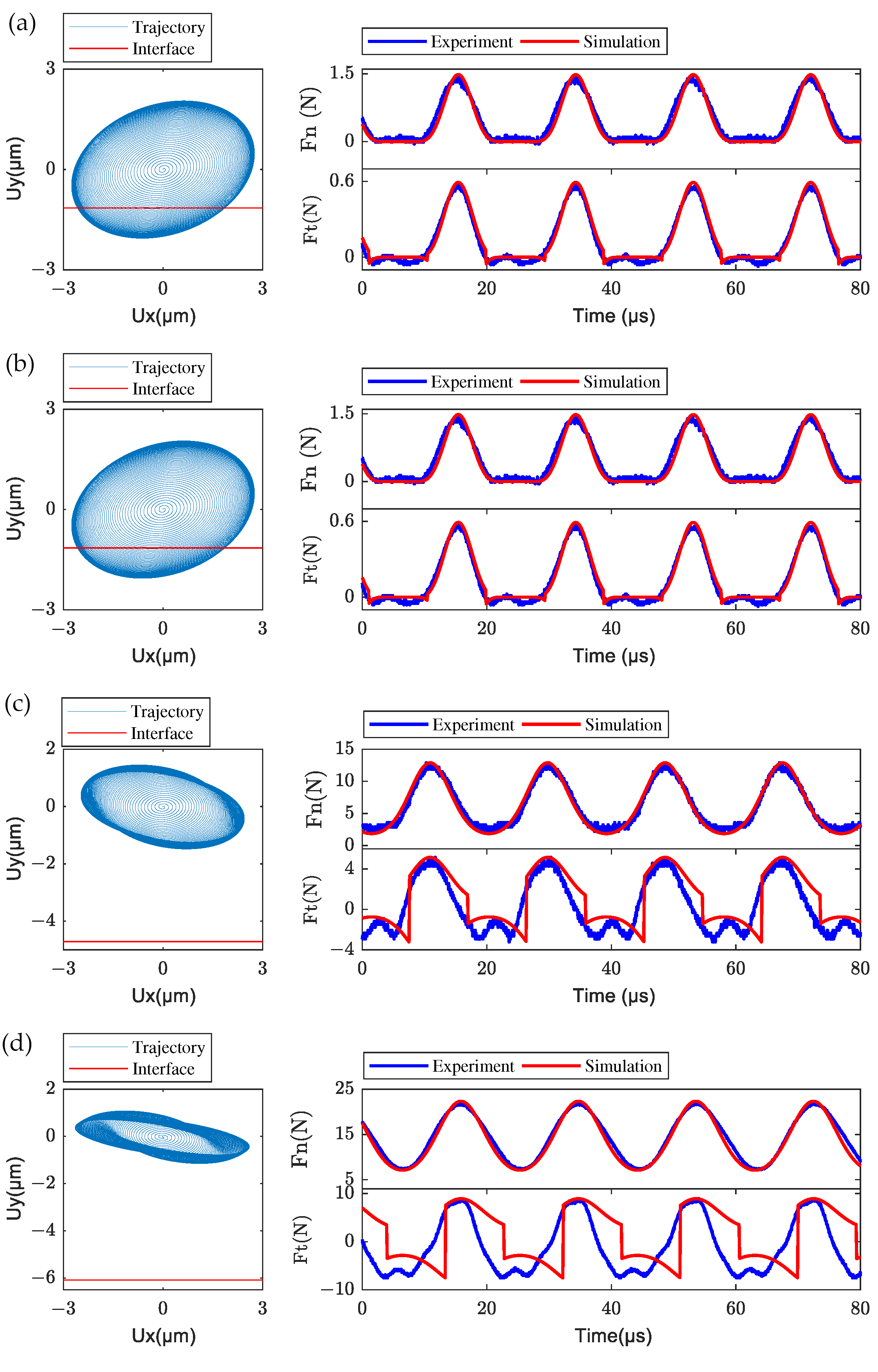

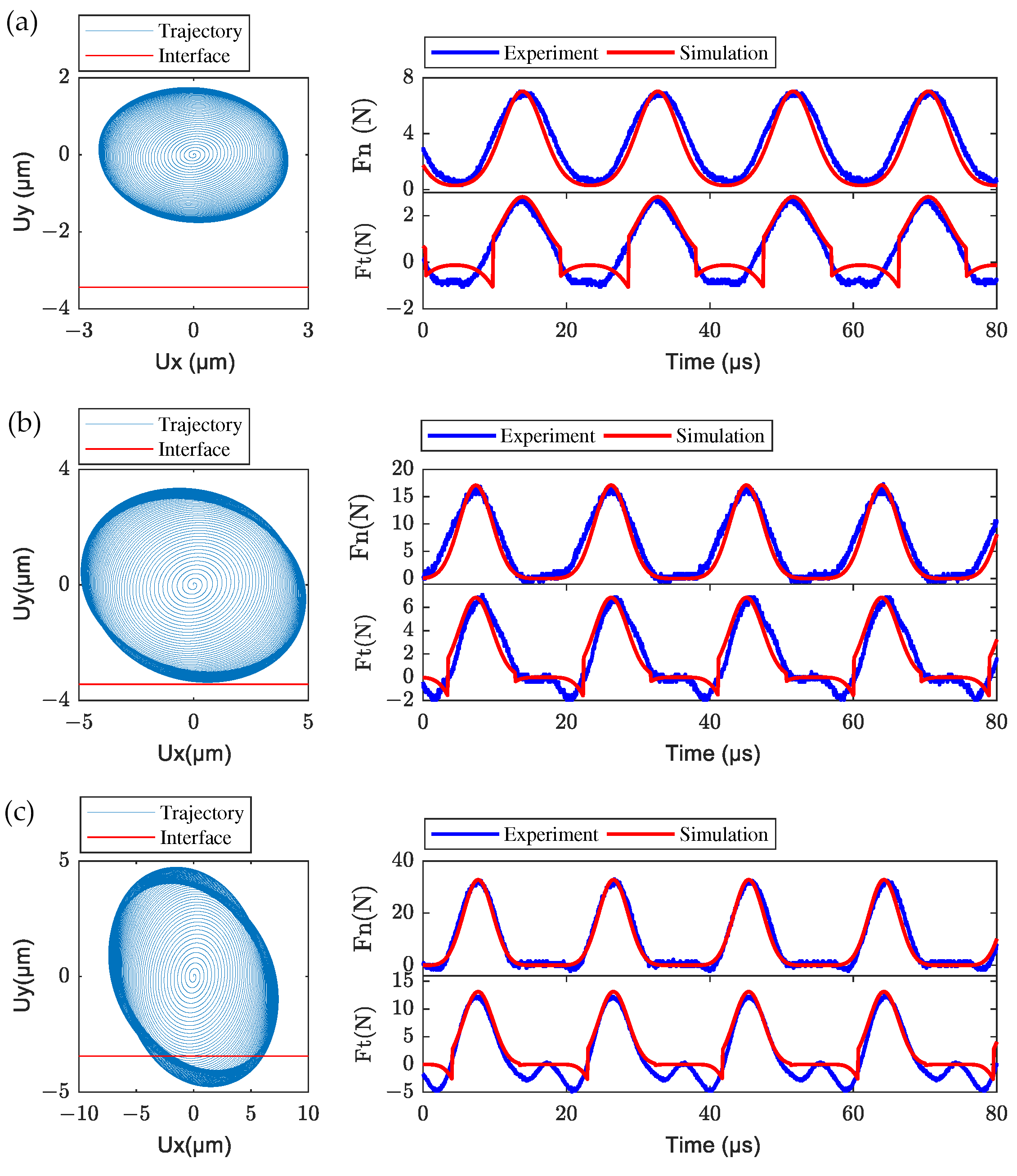

5.2. Dynamic Stator–Mover Contact

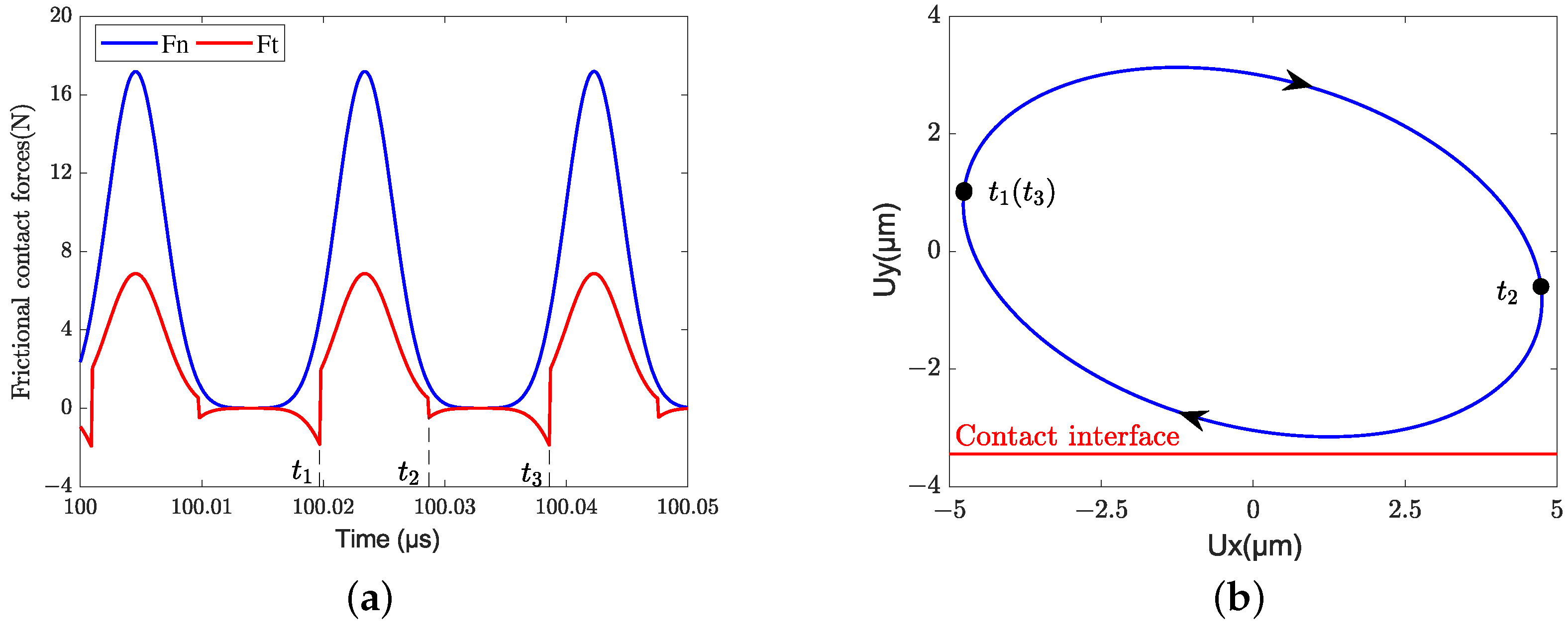

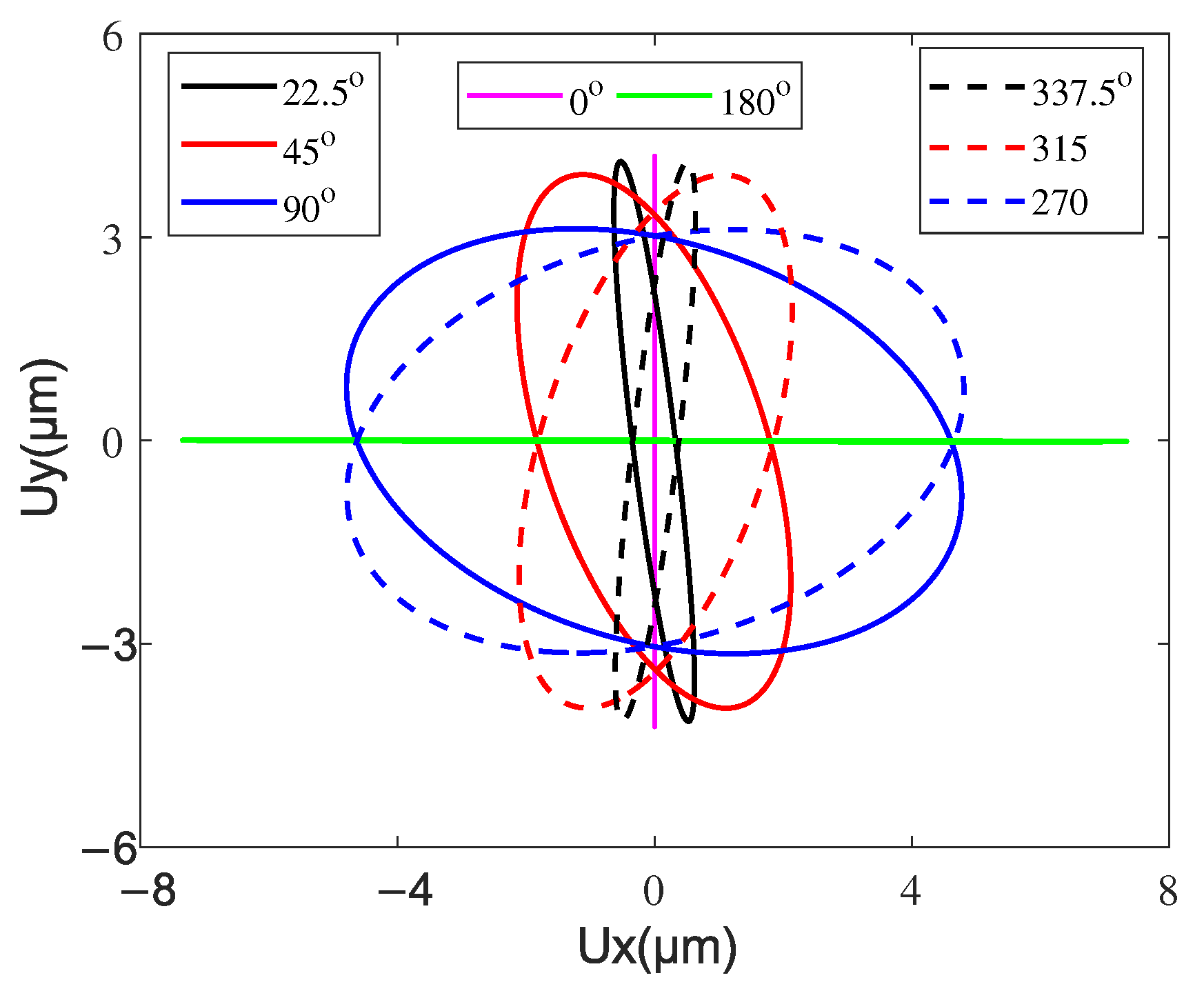

5.2.1. Validation of the Dynamic Contact Algorithm

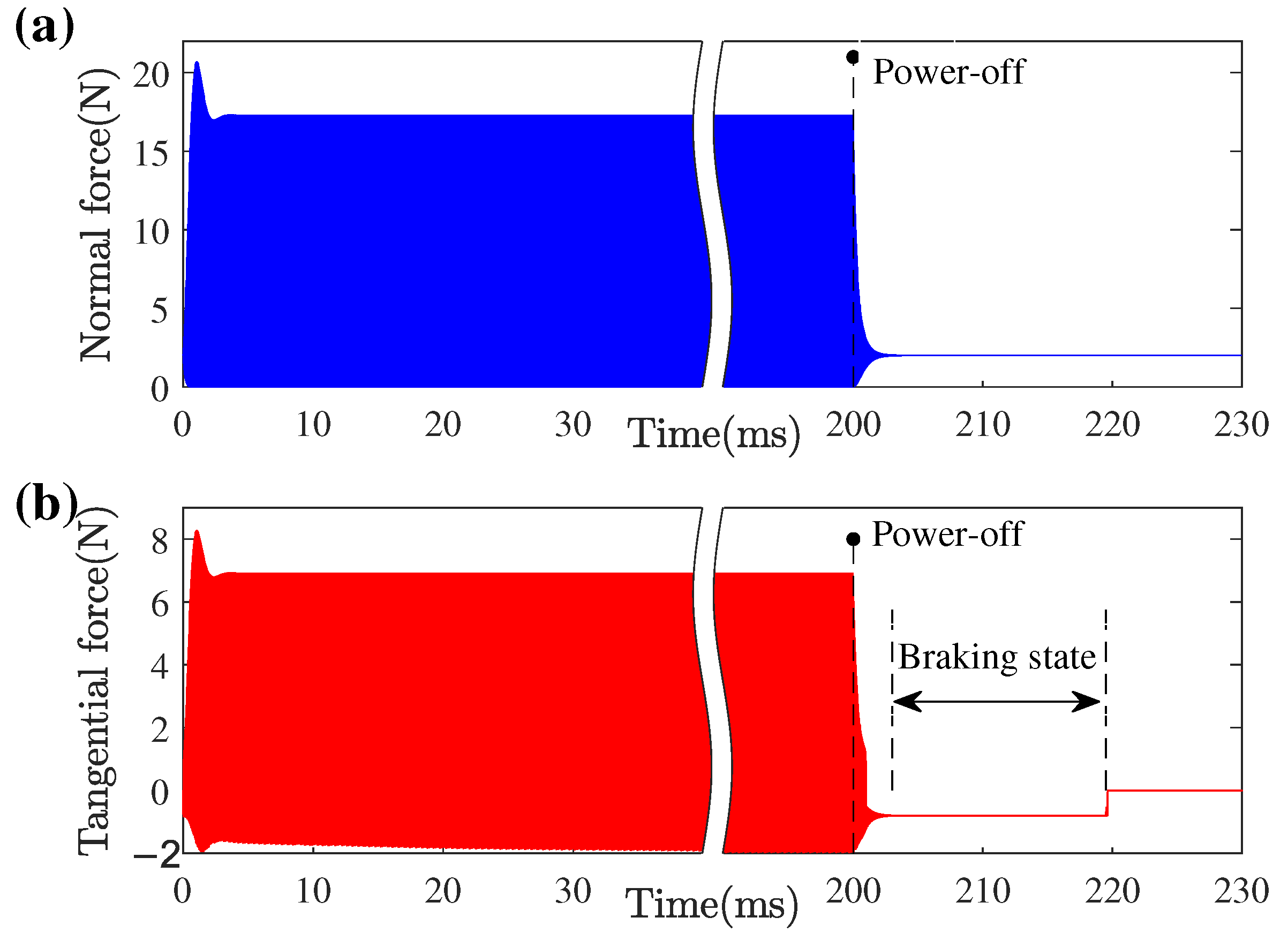

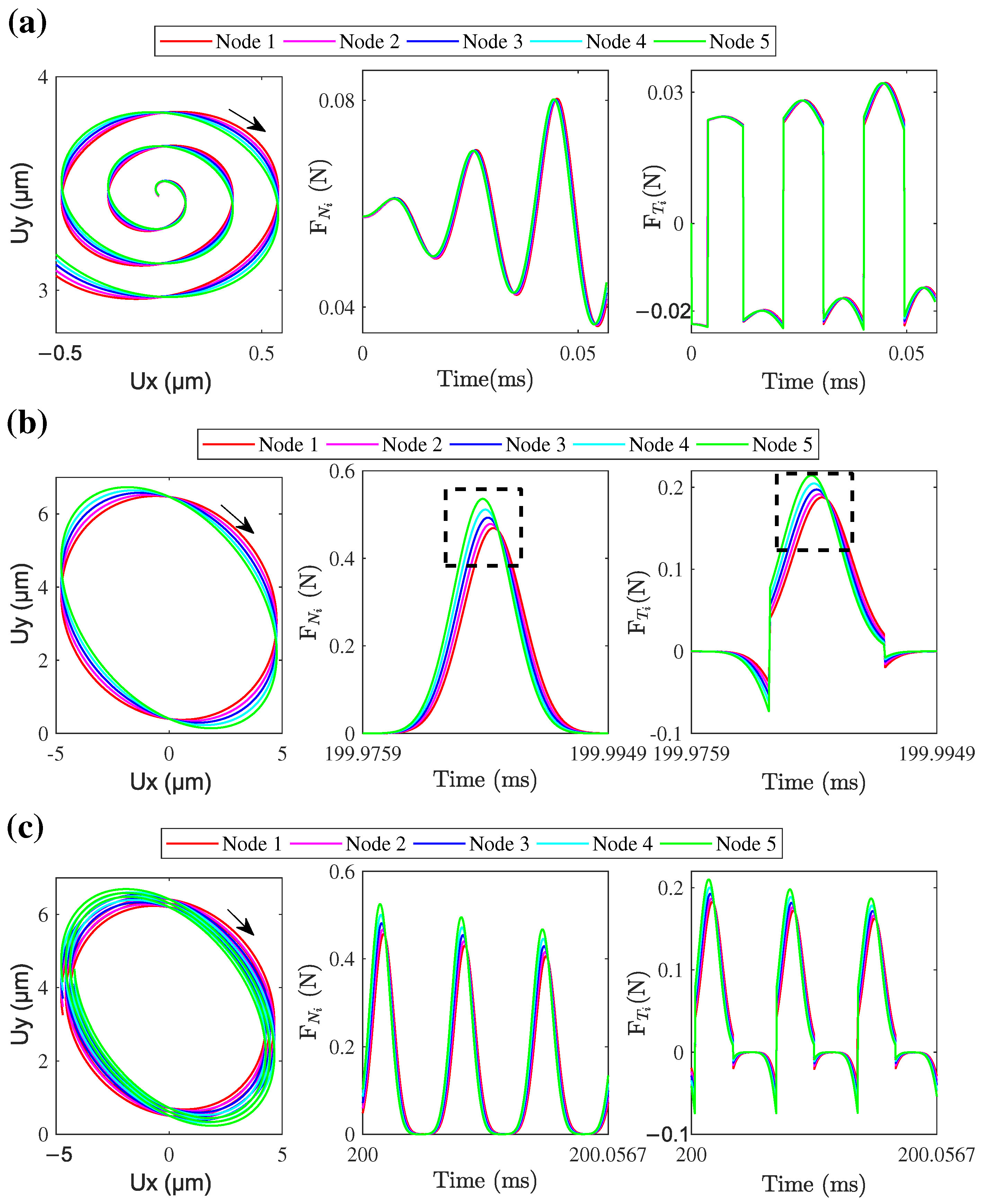

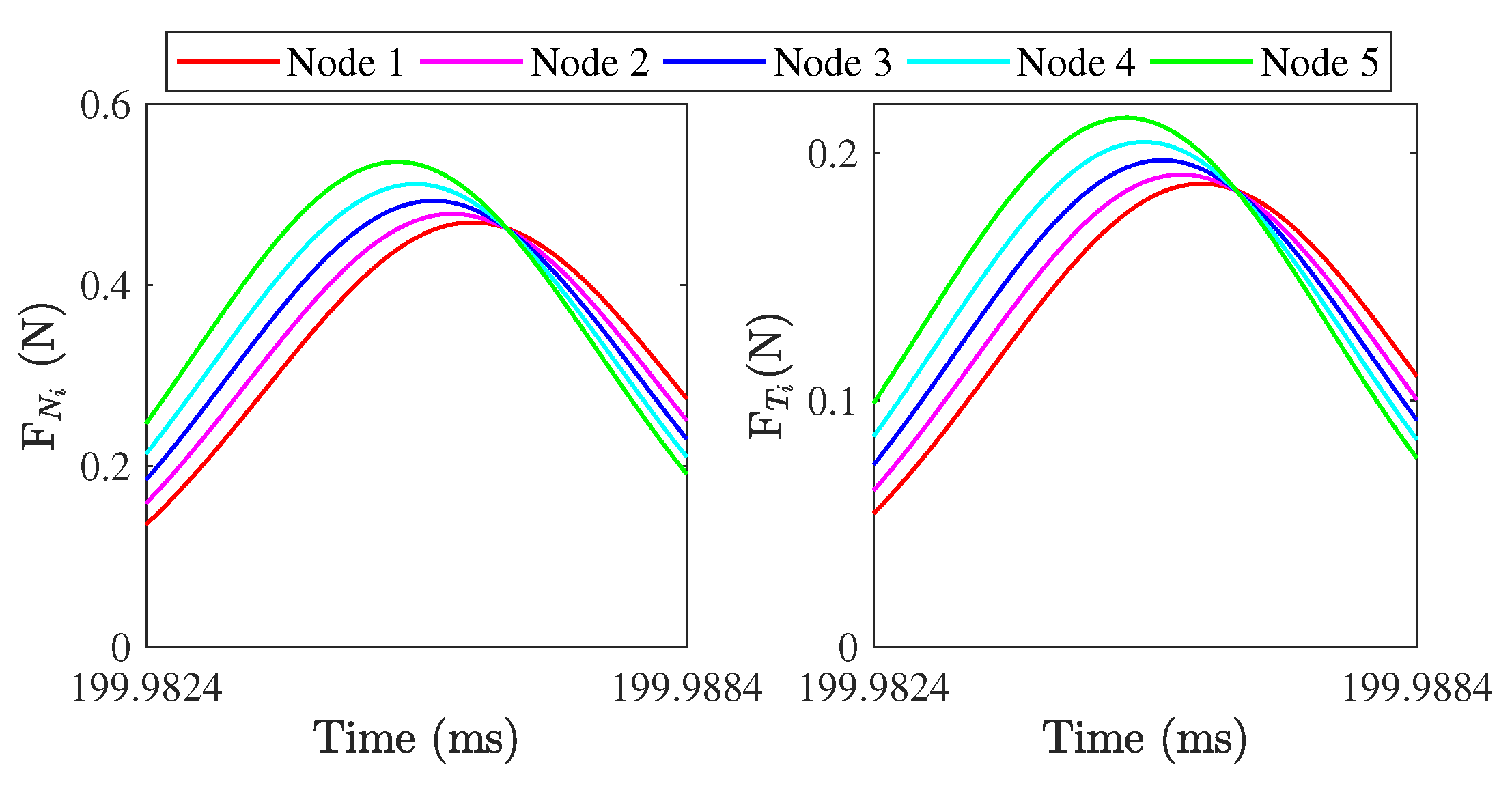

5.2.2. Transient Analysis of the Force Transmission at Contact Interfaces

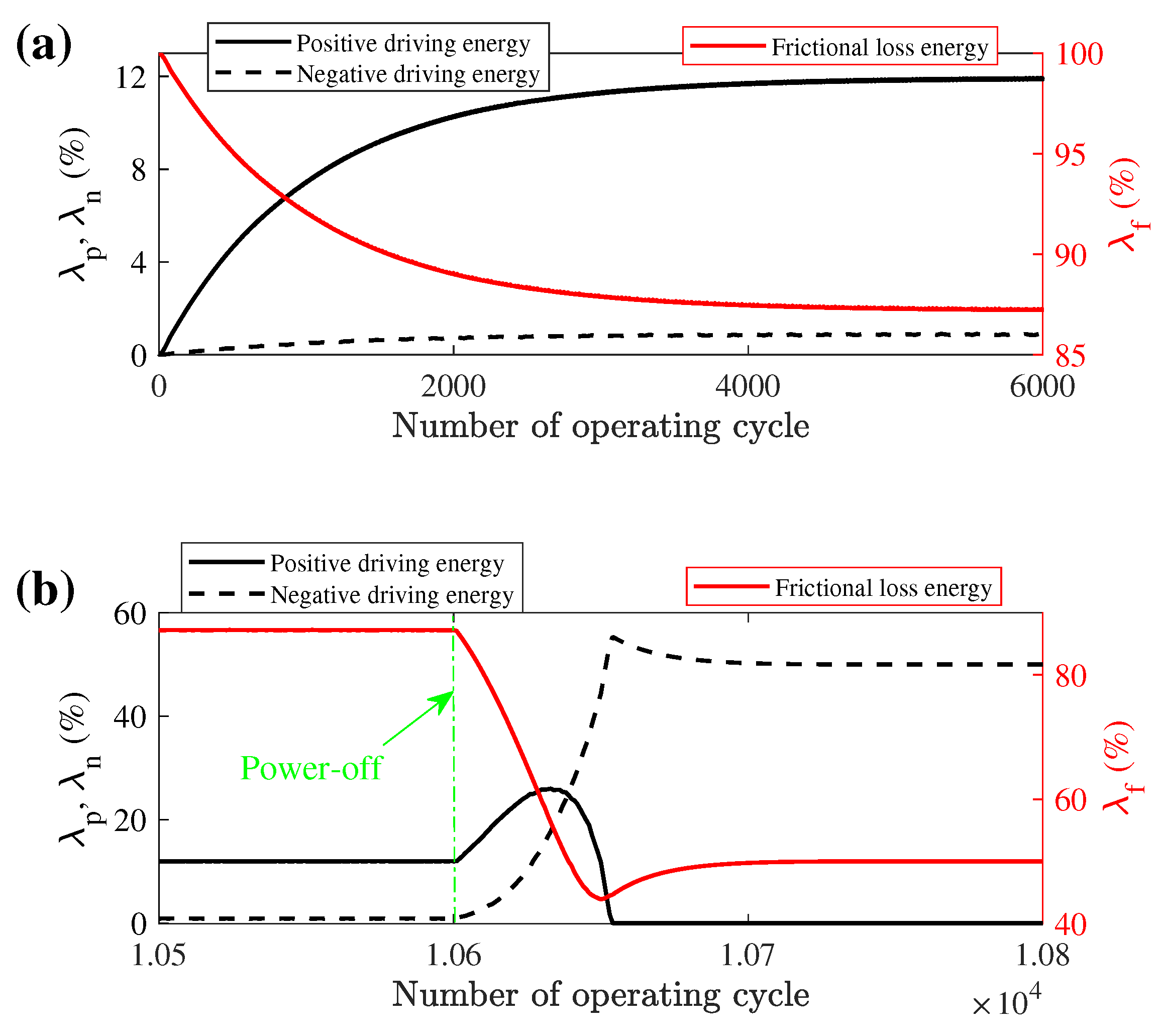

5.2.3. Energy Transmission at Contact Interfaces

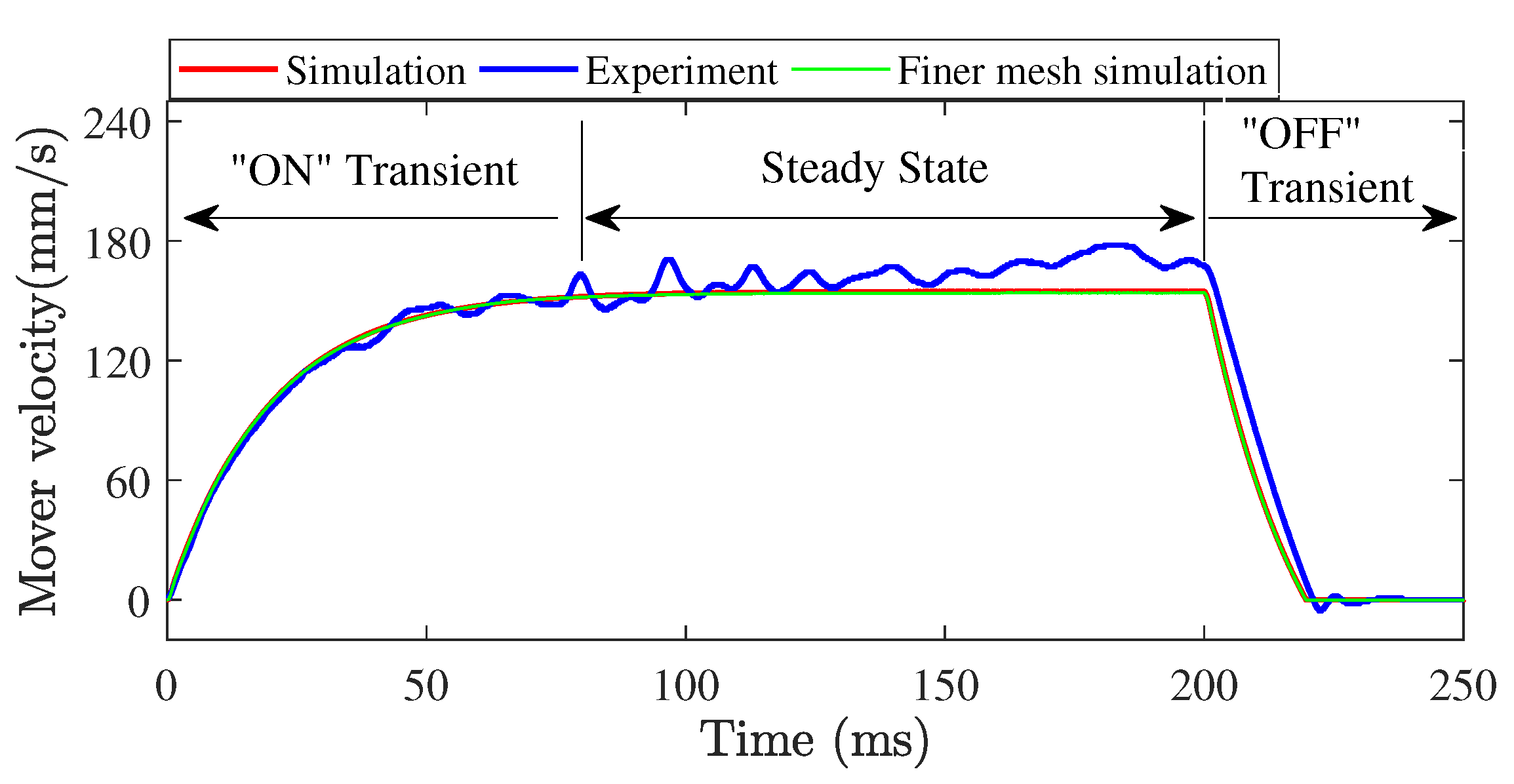

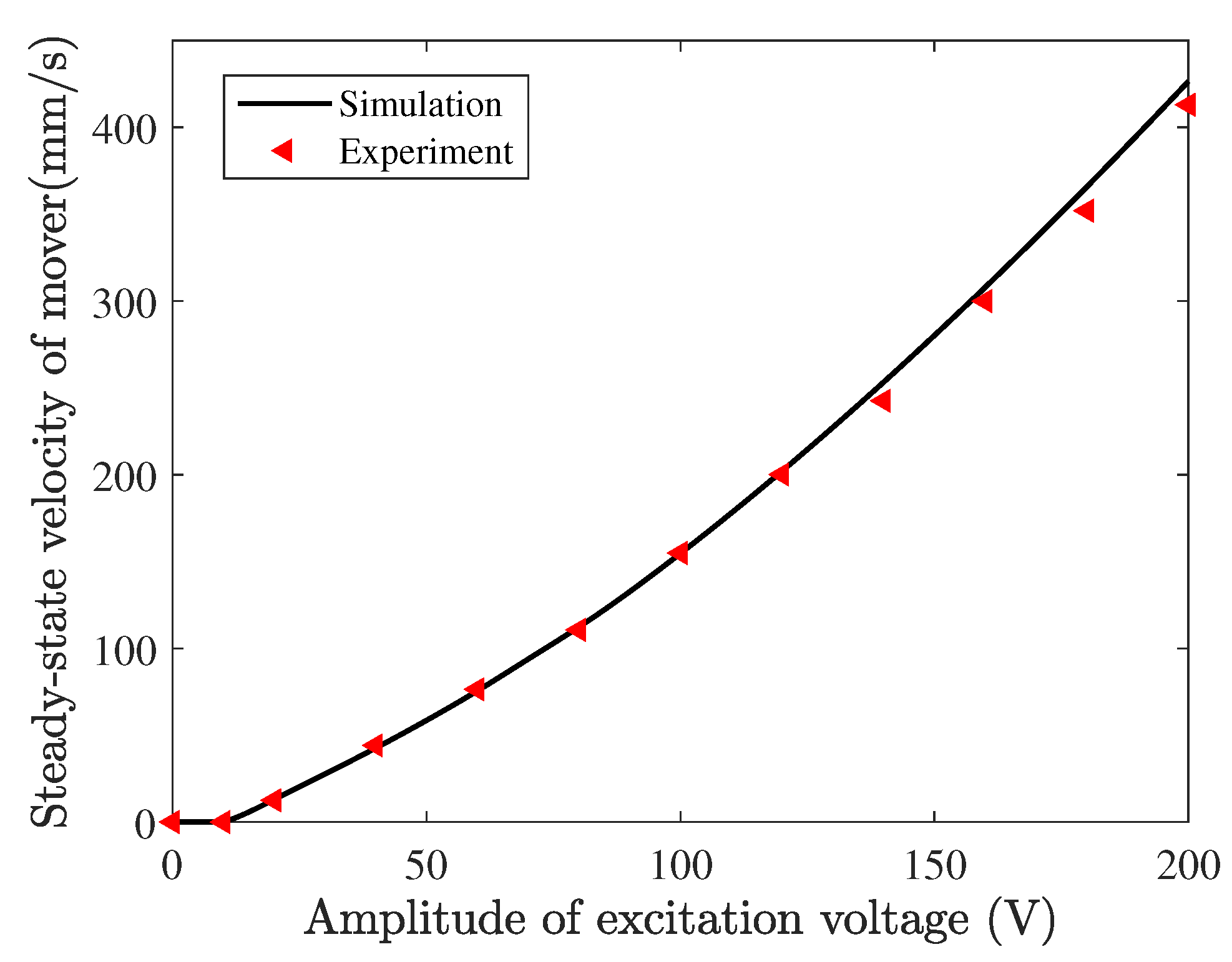

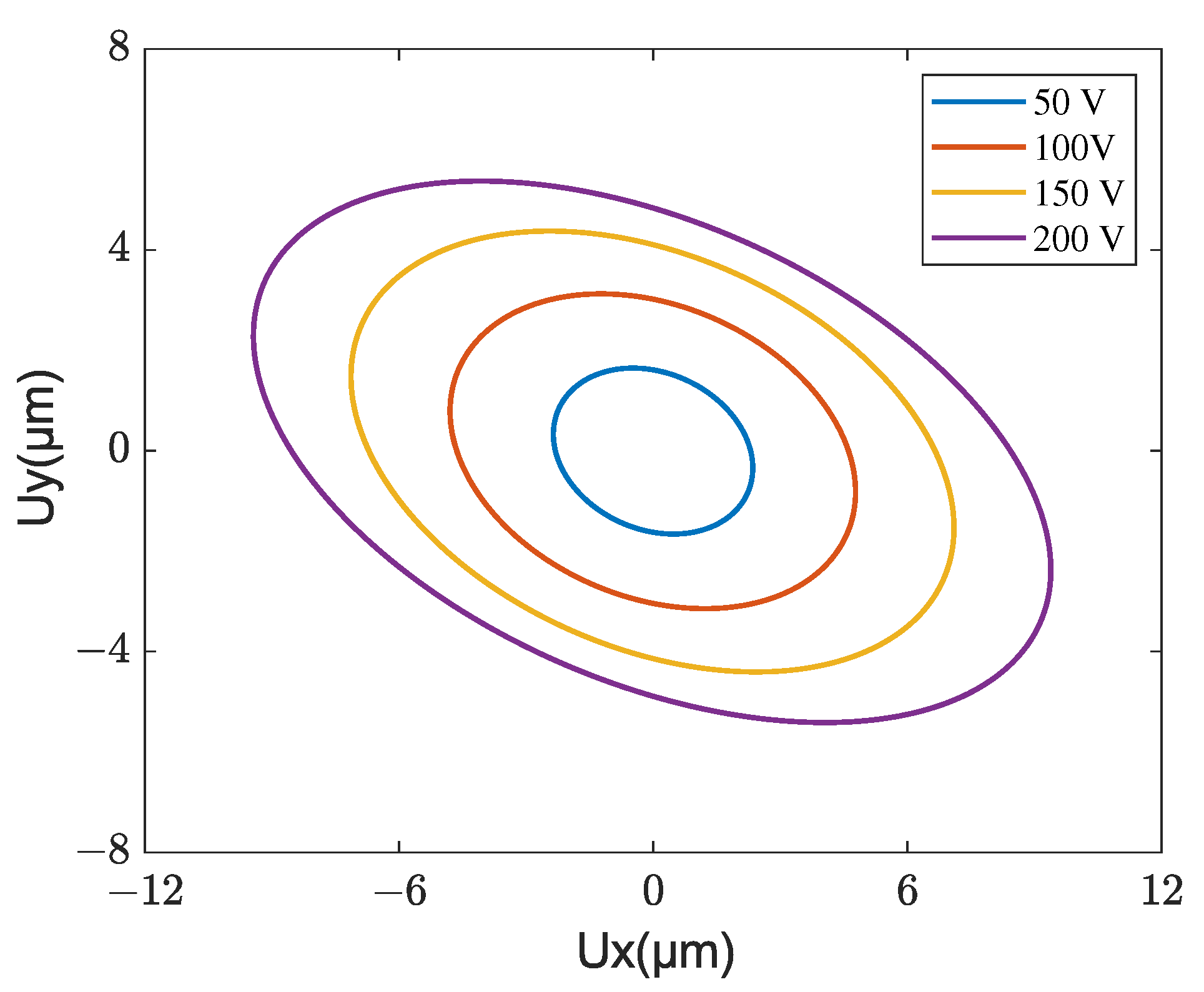

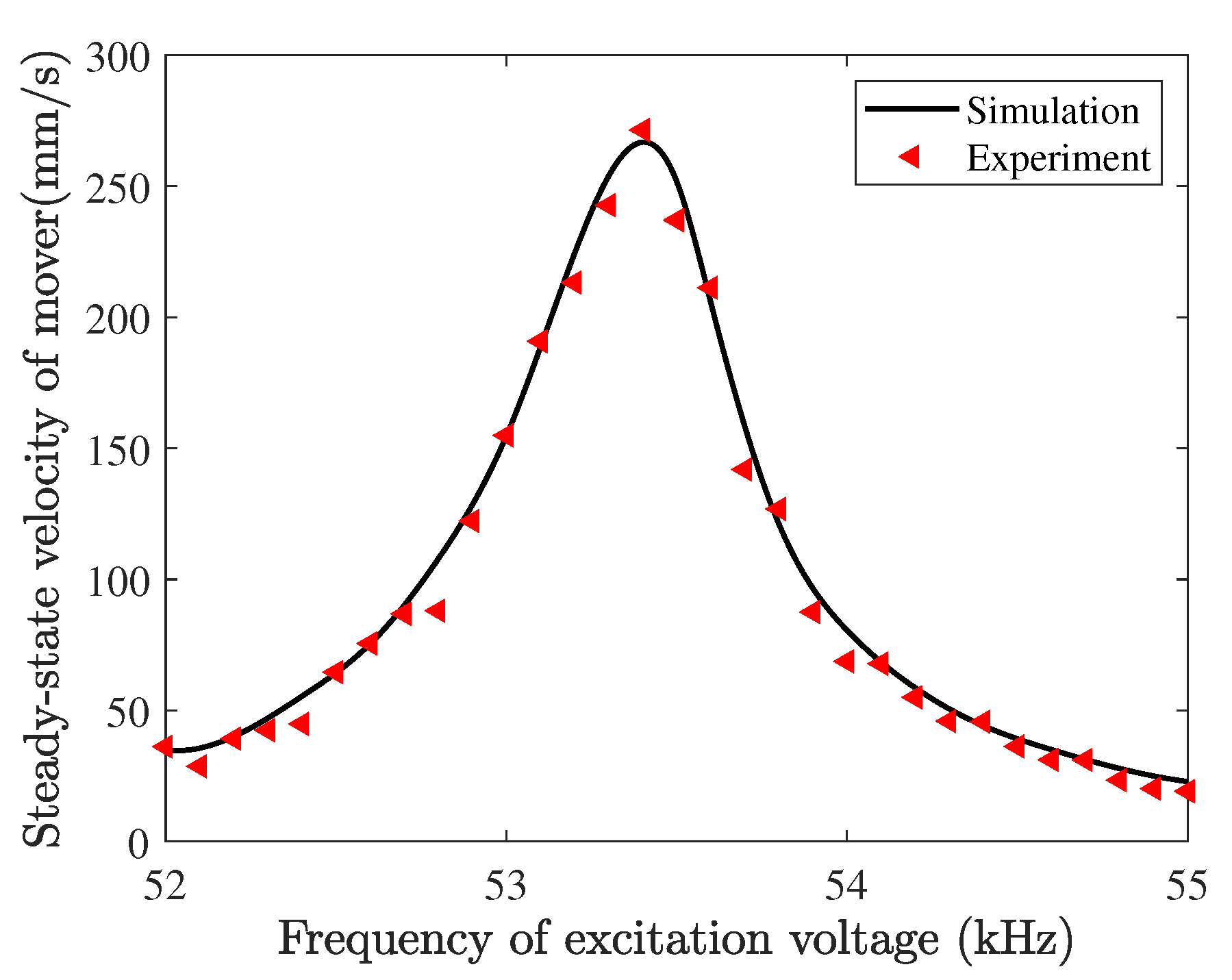

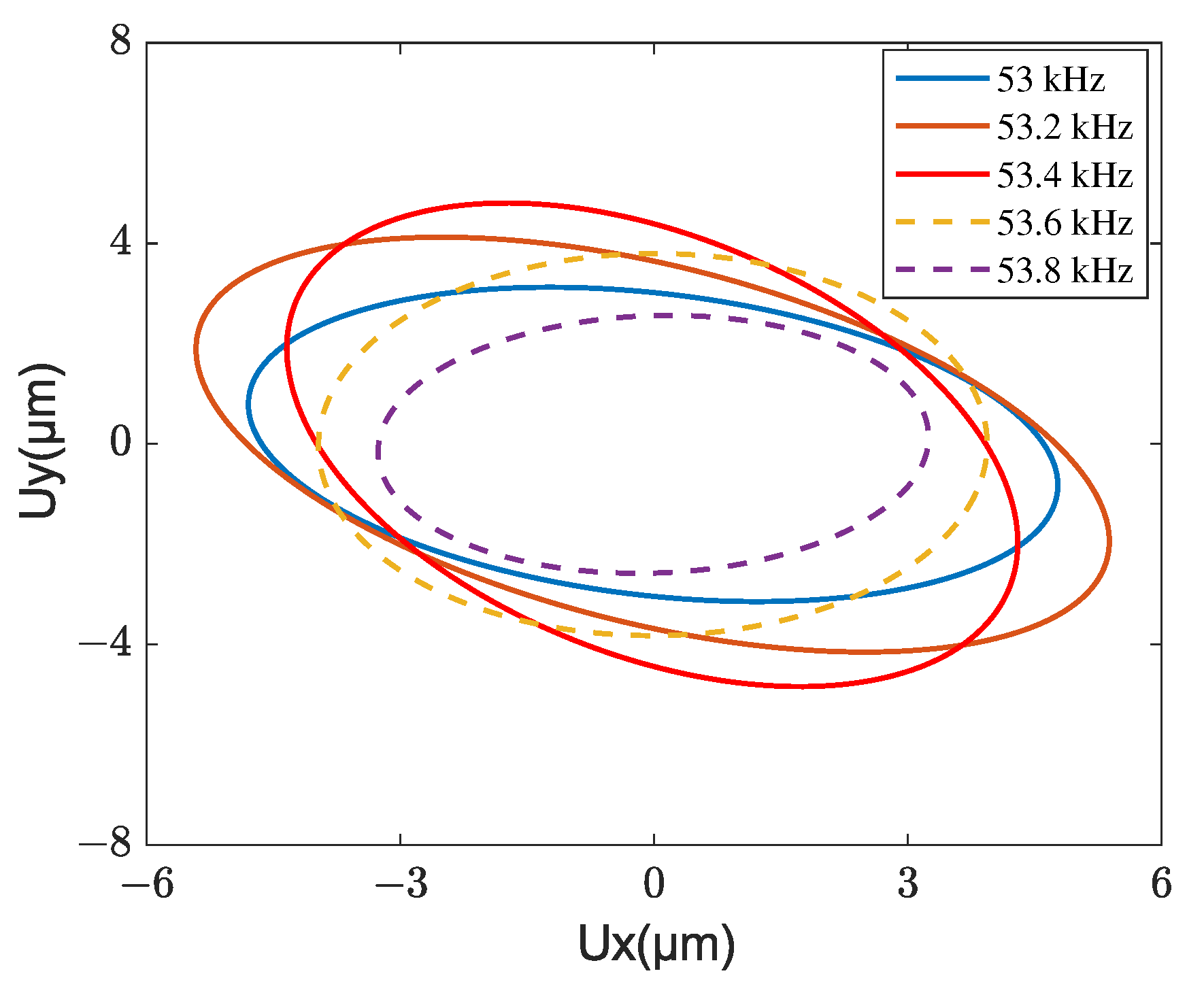

5.3. Evaluation of the LUM’s Output Performance

5.4. Effect of Micro-Topography Parameters on the Interfacial Force Transmission

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A. Equivalent Contact of Two Rough Surfaces

References

- Liu, Y.; Deng, J.; Su, Q. Review on Multi-Degree-of-Freedom Piezoelectric Motion Stage. IEEE Access 2018, 6, 59986–60004. [Google Scholar] [CrossRef]

- Hamamoto, M.; Kotani, T.; Nakano, I.; Ohta, Y.; Hara, K.; Murakami, Y.; Hisada, T. Investigation on force transmission of direct-drive thorax unit with four ultrasonic motors for a flapping microaerial vehicle. Adv. Robot. 2014, 28, 133–144. [Google Scholar] [CrossRef]

- Kiong Tan, K.; Liang, W.; Huang, S.; Pham, L.P.; Chen, S.; Wee Gan, C.; Yee Lim, H. Precision Control of Piezoelectric Ultrasonic Motor for Myringotomy With Tube Insertion. J. Dyn. Syst. Meas. Control 2015, 137. [Google Scholar] [CrossRef]

- Tavallaei, M.A.; Thakur, Y.; Haider, S.; Drangova, M. A Magnetic resonance imaging compatible remote catheter navigation system. IEEE Trans. Biomed. Eng. 2013, 60, 899–905. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Lau, J.Y.; Liang, W.; Liaw, H.C.; Tan, K.K. Sliding Mode Disturbance Observer-based Motion Control for a Piezoelectric Actuator-based Surgical Device. Asian J. Control 2018, 20, 1194–1203. [Google Scholar] [CrossRef]

- Peled, G.; Yasinov, R.; Karasikov, N. Performance and applications of L1B2 ultrasonic motors. Actuators 2016, 5, 15. [Google Scholar] [CrossRef]

- Tsai, M.S.; Lee, C.H.; Hwang, S.H. Dynamic modeling and analysis of a bimodal ultrasonic motor. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2003, 50, 245–256. [Google Scholar] [CrossRef]

- Li, X.; Yao, Z.; Lv, Q.; Liu, Z. Modeling stick-slip-separation dynamics in a bimodal standing wave ultrasonic motor. J. Sound Vib. 2016, 382, 140–157. [Google Scholar] [CrossRef]

- Lv, Q.; Yao, Z.; Li, X. Contact analysis and experimental investigation of a linear ultrasonic motor. Ultrasonics 2017, 81, 32–38. [Google Scholar] [CrossRef]

- Deng, Y.; Zhao, G.; Yi, X.; Xiao, W. Contact modeling and input-voltage-region based parametric identification for speed control of a standing wave linear ultrasonic motor. Sens. Actuators A Phys. 2019, 295, 456–468. [Google Scholar] [CrossRef]

- Shi, Y.; Zhao, C.; Zhang, J. Contact analysis and modeling of standing wave linear ultrasonic motor. J. Wuhan Univ. Technol. Mater. Sci. Ed. 2011, 26, 1235–1242. [Google Scholar] [CrossRef]

- Zhang, Y.; Qu, J.; Li, J. Friction and wear behavior of linear standing-wave ultrasonic motors with V-shape transducers. Tribol. Int. 2016, 95, 95–108. [Google Scholar] [CrossRef]

- Zhang, Y.; Fu, Y.; Hua, X.; Quan, L.; Qu, J. Wear debris of friction materials for linear standing-wave ultrasonic motors: Theory and experiments. Wear 2020, 448–449, 1–8. [Google Scholar] [CrossRef]

- He, Y.; Yao, Z.; Dai, S.; Zhang, B. Hybrid simulation for dynamic responses and performance estimation of linear ultrasonic motors. Int. J. Mech. Sci. 2019, 153–154, 219–229. [Google Scholar] [CrossRef]

- Rho, J.S.; Kim, B.J.; Lee, C.H.; Joo, H.W.; Jung, H.K. Design and characteristic analysis of L1B4 ultrasonic motor considering contact mechanism. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2005, 52, 2054–2064. [Google Scholar] [CrossRef]

- Sharp, S.L.; Paine, J.S.; Blotter, J.D. Design of a linear ultrasonic piezoelectric motor. J. Intell. Mater. Syst. Struct. 2010, 21, 961–973. [Google Scholar] [CrossRef]

- Wan, Z.; Hu, H. Modeling and experimental analysis of the linear ultrasonic motor with in-plane bending and longitudinal mode. Ultrasonics 2014, 54, 921–928. [Google Scholar] [CrossRef]

- Le, A.Y.; Mills, J.K.; Benhabib, B. A design methodology for linear ultrasonic motors under contact-based operating conditions. J. Intell. Mater. Syst. Struct. 2016, 27, 39–50. [Google Scholar] [CrossRef]

- Li, X.; Yao, Z.; Li, R.; Wu, D. Dynamics modeling and control of a V-shaped ultrasonic motor with two Langevin-type transducers. Smart Mater. Struct. 2020, 29, 025018. [Google Scholar] [CrossRef]

- Moal, P.L.; Joseph, E.; Ferniot, J.C. Mechanical energy transductions in standing wave ultrasonic motors: Analytical modelling and experimental investigations. Eur. J. Mech. A Solids 2000, 19, 849–871. [Google Scholar] [CrossRef]

- Li, X.; Chen, Z.; Yao, Z. Contact analysis and performance evaluation of standing-wave linear ultrasonic motors via a physics-based contact model. Smart Mater. Struct. 2018, 28, 015032. [Google Scholar] [CrossRef]

- Lezgy-Nazargah, M.; Vidal, P.; Polit, O. An efficient finite element model for static and dynamic analyses of functionally graded piezoelectric beams. Compos. Struct. 2013, 104, 71–84. [Google Scholar] [CrossRef][Green Version]

- Wang, S. A finite element model for the static and dynamic analysis of a piezoelectric bimorph. Int. J. Solids Struct. 2004, 41, 4075–4096. [Google Scholar] [CrossRef]

- Wen, S.; Huang, P. Principles of Tribology; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2017; Chapter 9; pp. 209–224. [Google Scholar] [CrossRef]

- Popov, V.L. Contact Mechanics and Friction: Physical Principles and Applications, 2nd ed.; Springer: Berlin/Heidelberg, Germany, 2017; Chapter 7; pp. 16–97. [Google Scholar] [CrossRef]

- Lv, Q.; Yao, Z.; Li, X. Modeling and experimental validation of a linear ultrasonic motor considering rough surface contact. Smart Mater. Struct. 2017, 26. [Google Scholar] [CrossRef]

- Belytschko, T.; Liu, W.K.; Moran, B.; Elkhodary, K. Nonlinear Finite Elements for Continua and Structures; John Wiley & Sons.: Hoboken, NJ, USA, 2014; Chapter 7; pp. 597–642. [Google Scholar] [CrossRef]

- Amat, S.; Busquier, S.; Gutiérrez, J.M. Geometric constructions of iterative functions to solve nonlinear equations. J. Comput. Appl. Math. 2003, 157, 197–205. [Google Scholar] [CrossRef]

- Cheney, E.W.; Kincaid, D.R. Numerical Mathematics and Computing, 7th ed.; Cengage Learning: Boston, MA, USA, 2012. [Google Scholar]

- Kohnke, P. ANSYS Mechanical APDL Theory Reference; ANSYS Inc.: Canonsburg, PA, USA, 2013. [Google Scholar]

- Shampine, L.F.; Reichelt, M.W. The matlab ode suite. SIAM J. Sci. Comput. 1997, 18, 1–22. [Google Scholar] [CrossRef]

- Jung, J.; Lee, W.; Kang, W.; Shin, E.; Ryu, J.; Choi, H. Review of piezoelectric micromachined ultrasonic transducers and their applications. J. Micromech. Microeng. 2017, 27, 113001. [Google Scholar] [CrossRef]

- Gao, J. Application of Finite Element Analysis in Calibration of Non-Contact Magnetic Piezoelectric Type of Displacement Sensor; Springer: Singapore, 2020; Volume 179, pp. 405–411. [Google Scholar] [CrossRef]

- Gautschi, G. Piezoelectric Sensors. In Piezoelectric Sensorics: Force Strain Pressure Acceleration and Acoustic Emission Sensors Materials and Amplifiers; Springer: Berlin/Heidelberg, Germany, 2002; pp. 73–91. [Google Scholar] [CrossRef]

- Sirohi, J.; Chopra, I. Fundamental understanding of piezoelectric strain sensors. J. Intell. Mater. Syst. Struct. 2000, 11, 246–257. [Google Scholar] [CrossRef]

- Yu, H.; Lu, L.; Qiao, P.; Wang, Z. Actuating and sensing mechanism of embedded piezoelectric transducers in concrete. Smart Mater. Struct. 2020, 29. [Google Scholar] [CrossRef]

- Sarac, S.; Adin, H.; Temiz, S. Experimental determination of the static and fatigue strength of the adhesive joints bonded by epoxy adhesive including different particles. Compos. Part B Eng. 2018, 155, 92–103. [Google Scholar] [CrossRef]

- Delibas, B.; Koc, B. A method to realize low velocity movability and eliminate friction induced noise in piezoelectric ultrasonic motors. IEEE ASME Trans. Mechatronics 2020, 25, 2677–2687. [Google Scholar] [CrossRef]

- Li, S.; Zhang, N.; Yang, Z.; Li, X.; Zhao, G.; Wang, T.; Wang, Q.; Zhang, X. Tailoring friction interface with surface texture for high-performance ultrasonic motor friction materials. Tribol. Int. 2019, 136, 412–420. [Google Scholar] [CrossRef]

- Zeng, S.; Li, J.; Zhou, N.; Zhang, J.; Yu, A.; He, H. Improving the wear resistance of PTFE-based friction material used in ultrasonic motors by laser surface texturing. Tribol. Int. 2020, 141, 105910. [Google Scholar] [CrossRef]

| h (cm) | 5 | 10 | 15 | 20 | 30 |

|---|---|---|---|---|---|

| (N/V) | 44.34 | 44.02 | 43.81 | 43.61 | 43.24 |

| (N/V) | 0.201 | 0.205 | 0.208 | 0.212 | 0.209 |

| Parameter | Description | Value | Units |

|---|---|---|---|

| Elastic constant for contact tip surface | Pa | ||

| Elastic constant for mover surface | Pa | ||

| Poisson’s ratio for contact tip surface | - | ||

| Poisson’s ratio for mover surface | - | ||

| Roughness of mover surface | m | ||

| Roughness of contact tip surface | m | ||

| Curvature radius of asperity | R | 1.6 | m |

| Areal density of asperity | |||

| Stator–mover friction coefficient | 0.4 | - | |

| Stick–slip characteristic velocity | m/s | ||

| Convergence tolerance | - | ||

| Time step of dynamic algorithm | s | ||

| Mass of mover | m | 0.2 | kg |

| Modal damping ratio | |||

| Damping coefficient of mover | c | 1 | N/(m/s) |

| Stiffness of preload spring | - | 8 | N/mm |

| Work frequency | - | 53 | kHz |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

He, Y.; Yao, Z.; Xu, H. A Multi-Point Contact Model Considering Rough Surface for Linear Ultrasonic Motors: Validation and Simulation. Micromachines 2022, 13, 1988. https://doi.org/10.3390/mi13111988

He Y, Yao Z, Xu H. A Multi-Point Contact Model Considering Rough Surface for Linear Ultrasonic Motors: Validation and Simulation. Micromachines. 2022; 13(11):1988. https://doi.org/10.3390/mi13111988

Chicago/Turabian StyleHe, Ying, Zhiyuan Yao, and Hao Xu. 2022. "A Multi-Point Contact Model Considering Rough Surface for Linear Ultrasonic Motors: Validation and Simulation" Micromachines 13, no. 11: 1988. https://doi.org/10.3390/mi13111988

APA StyleHe, Y., Yao, Z., & Xu, H. (2022). A Multi-Point Contact Model Considering Rough Surface for Linear Ultrasonic Motors: Validation and Simulation. Micromachines, 13(11), 1988. https://doi.org/10.3390/mi13111988