Optimization of Quality, Reliability, and Warranty Policies for Micromachines under Wear Degradation

Abstract

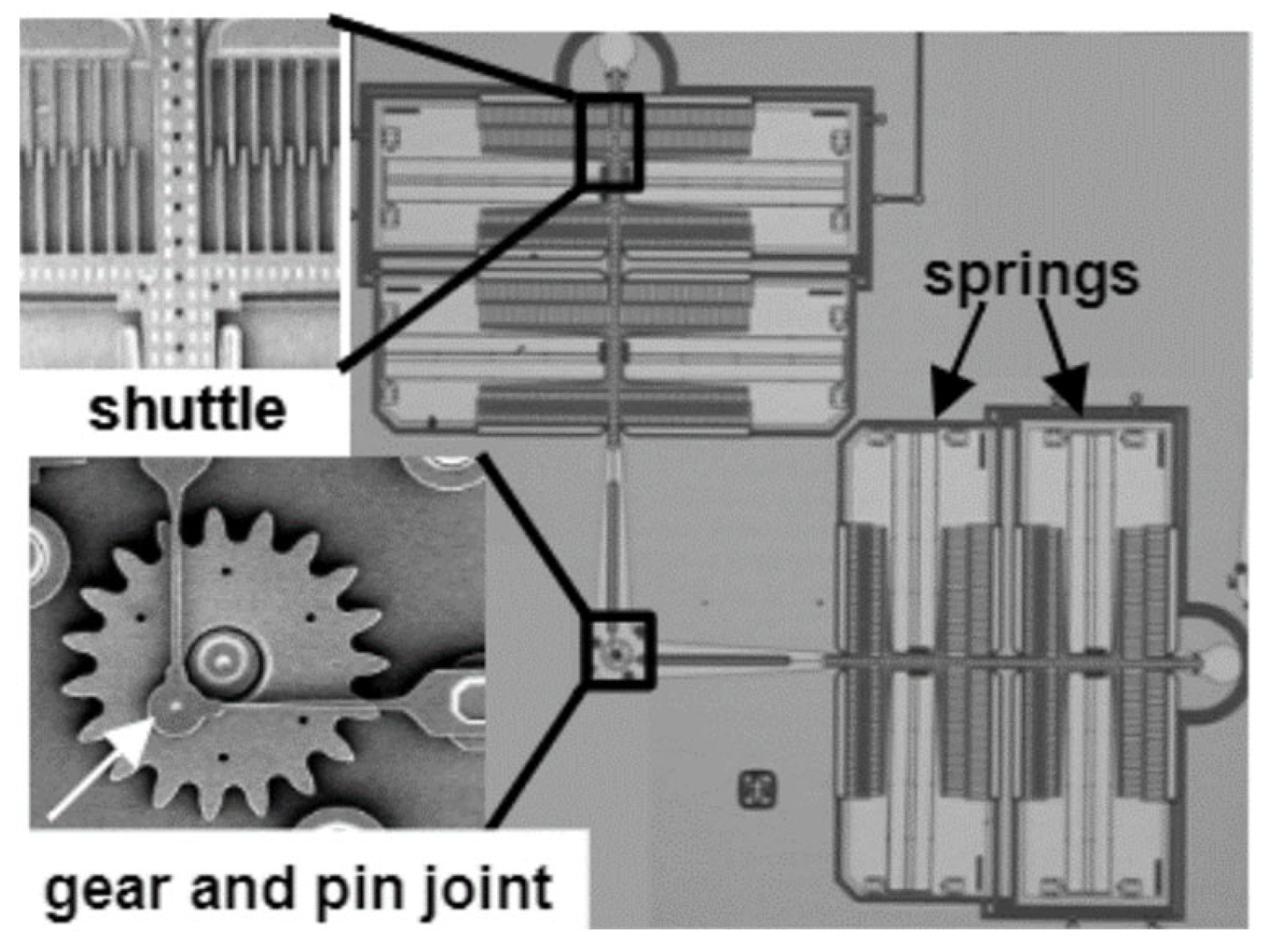

1. Introduction

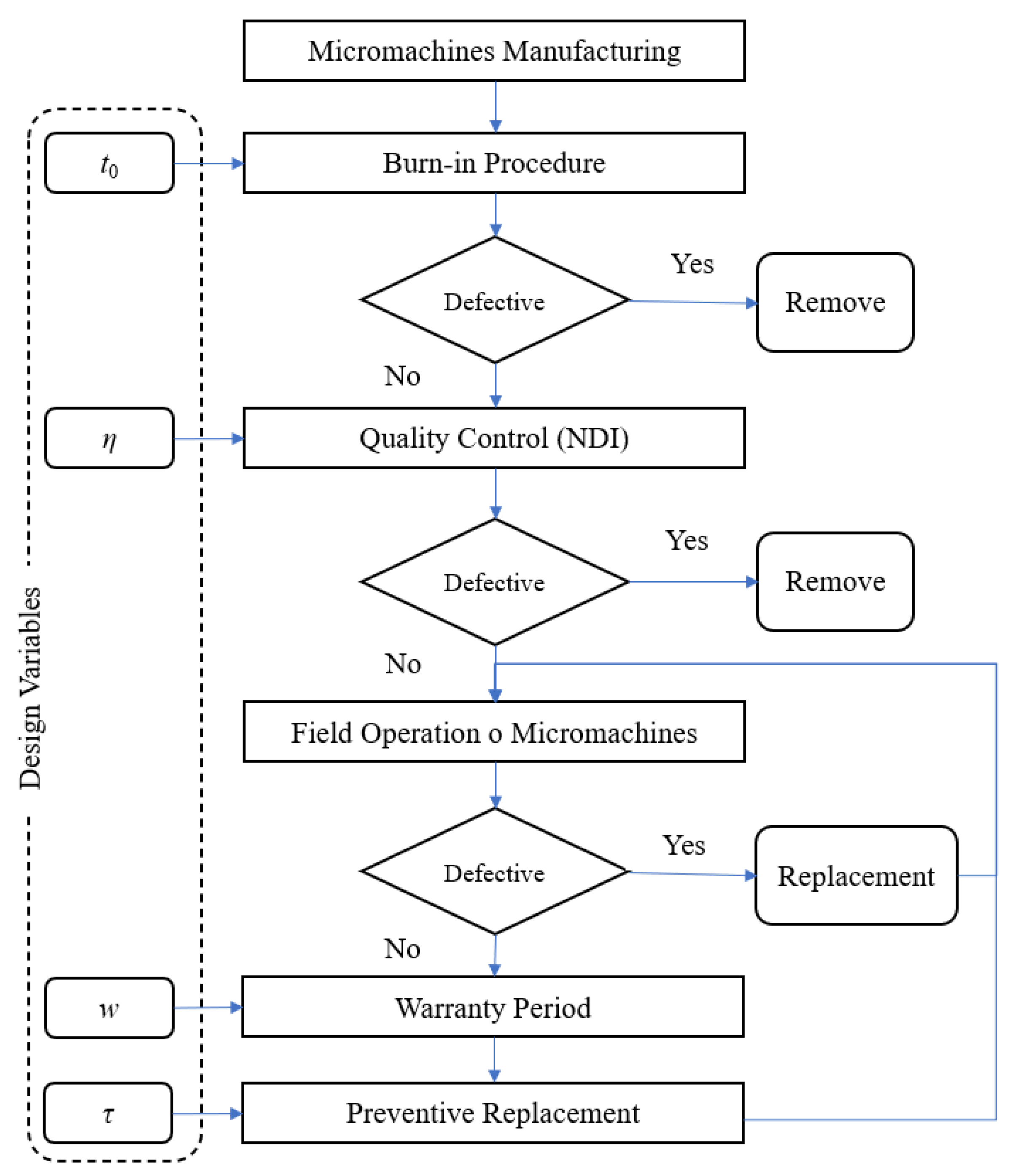

2. Optimization Model

2.1. Degradation Model

2.2. Effect of Quality Control on Reliability

2.3. Quality and Reliability

2.3.1. Quality Cost

2.3.2. Failure Cost—Preventive Replacement Cost

2.3.3. Expected Time of Use

2.4. Effect of the Warranty

2.5. Total Cost and Optimization

3. Results and Discussion

3.1. Numerical Data

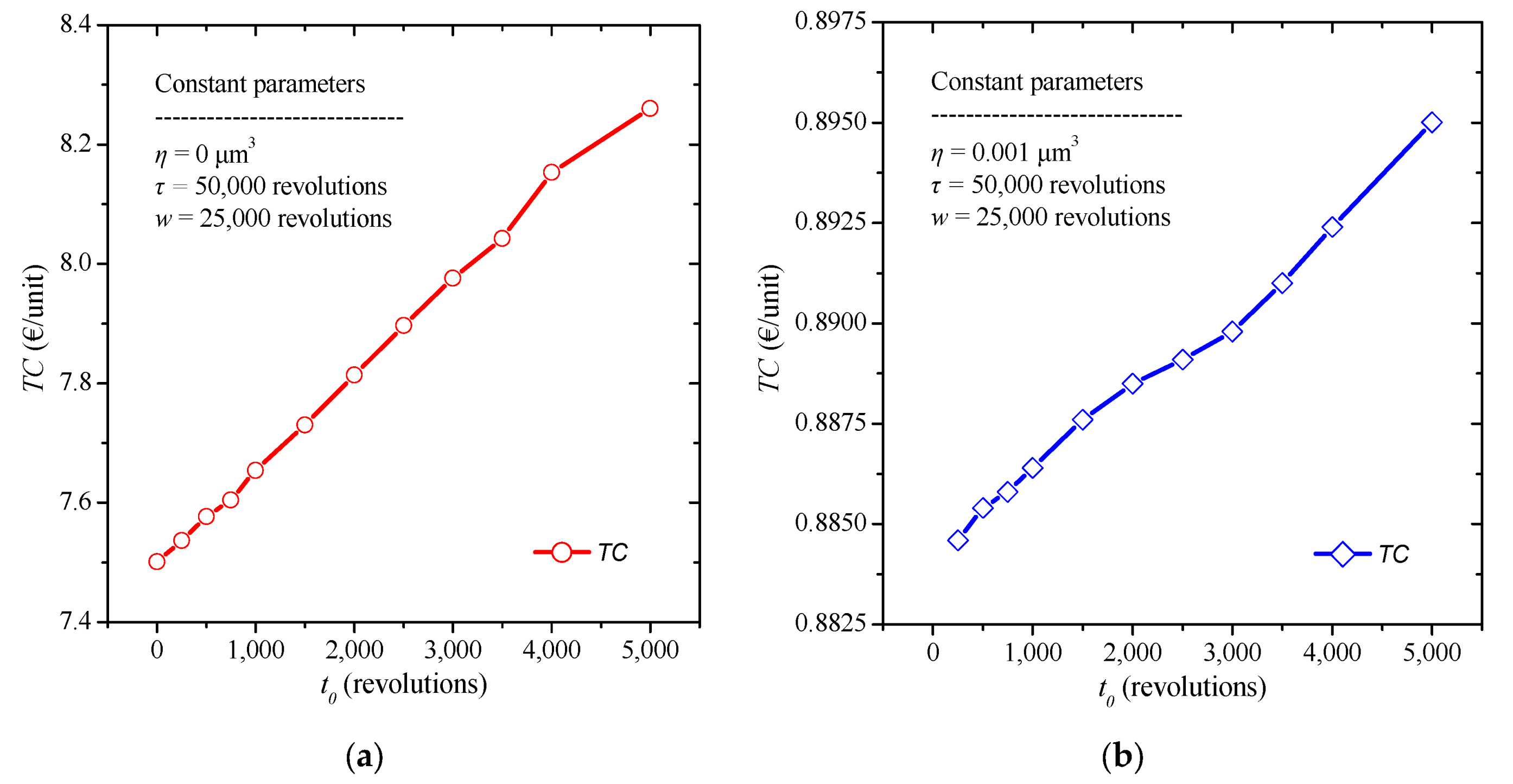

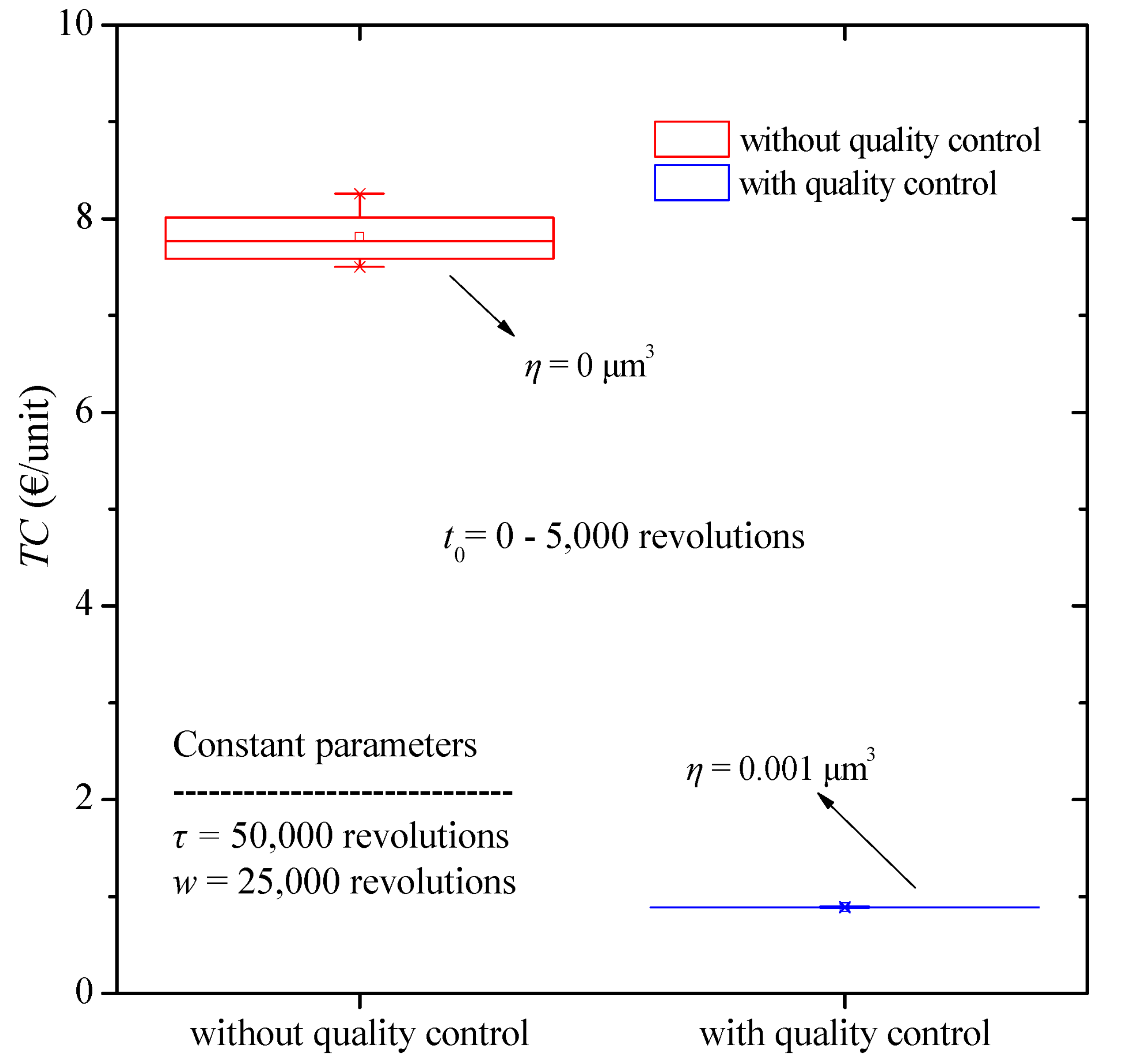

3.2. Comparison of Quality Policies

4. Conclusions

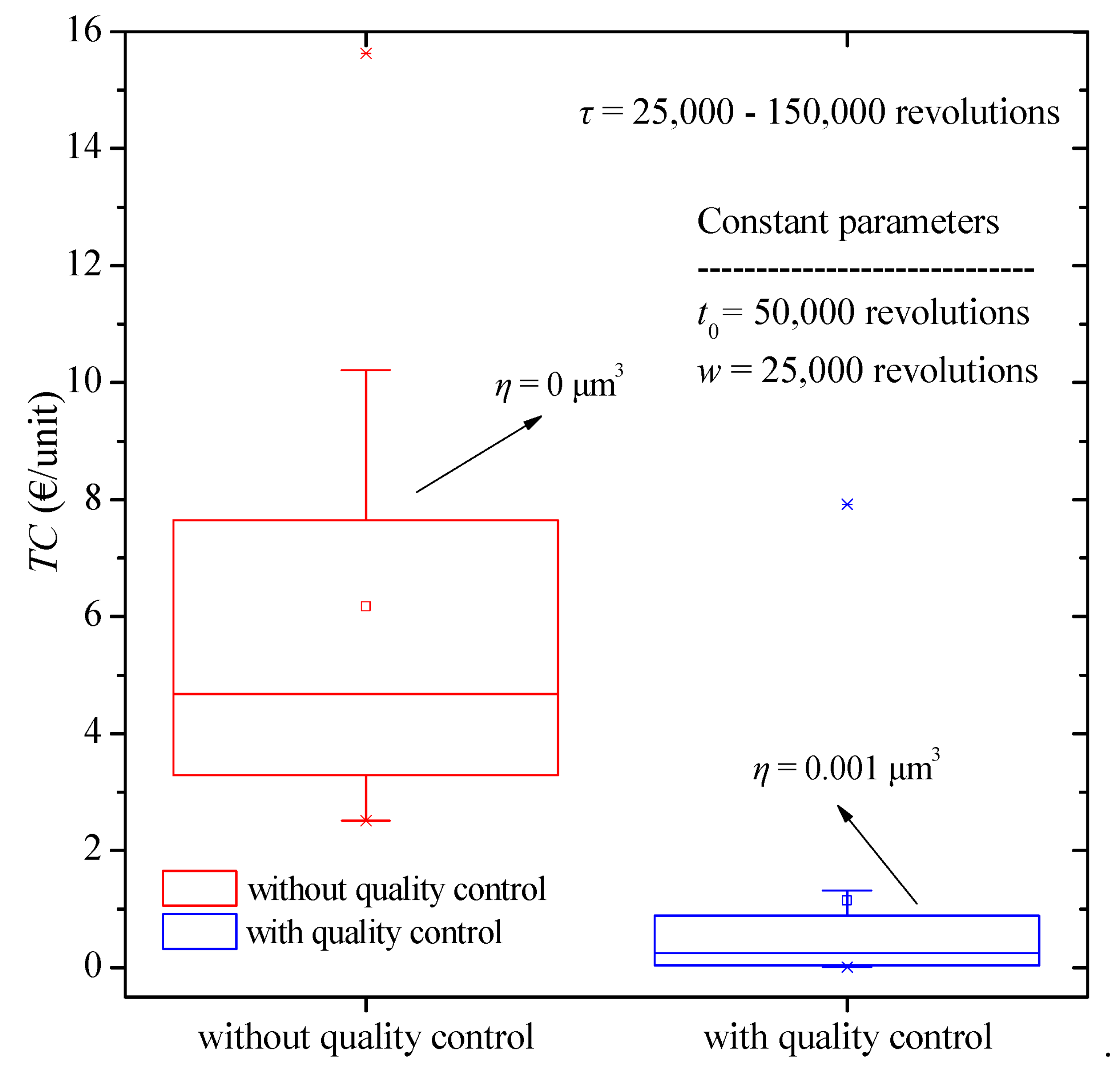

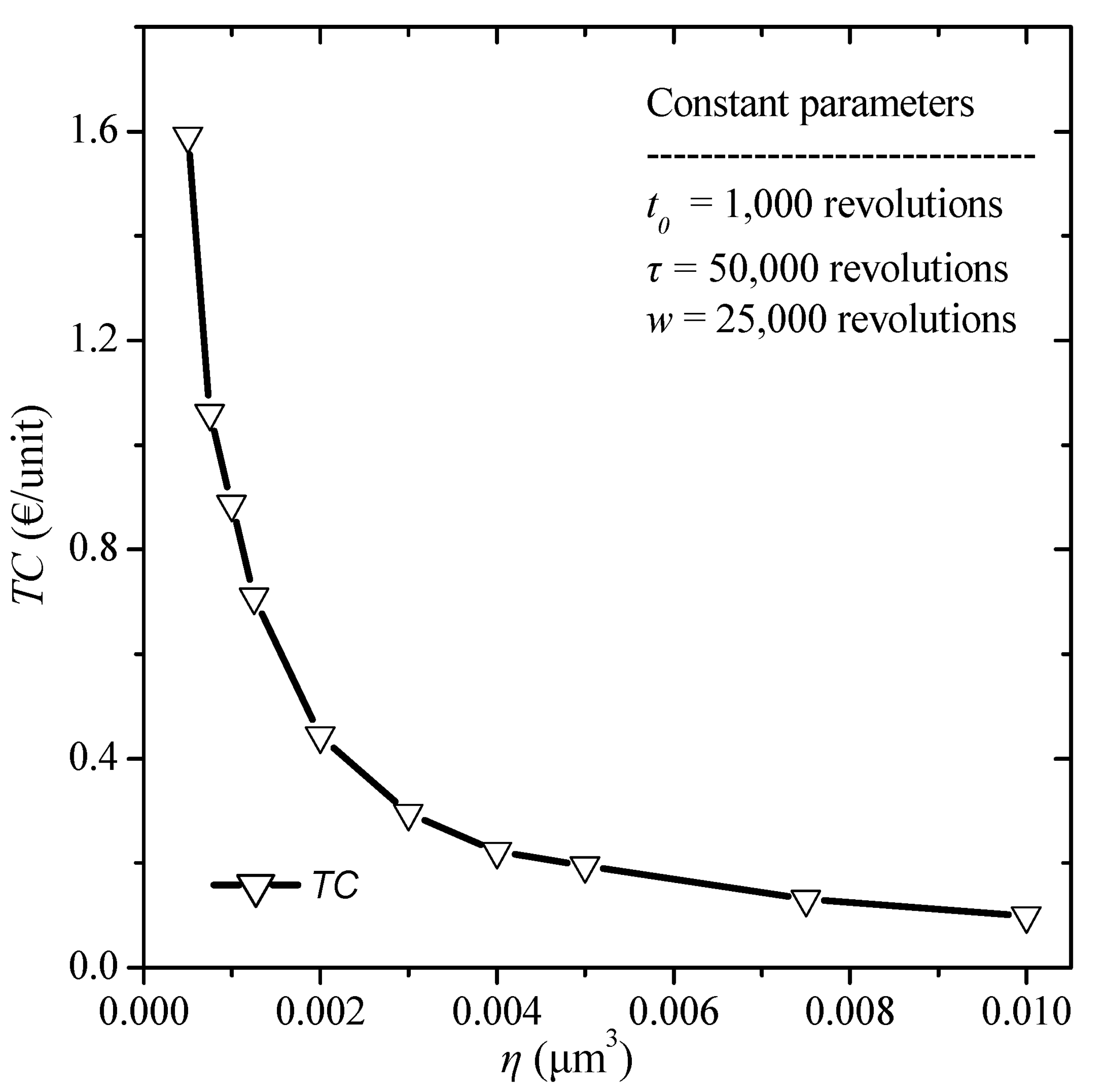

- the presence of quality control significantly reduces the total costs for all the decision variables. Concerning the numerical example, the total cost is reduced more than ten times (1000%) when quality control is applied in most cases.

- a large dispersion from the mean with a large range from the minimum and maximum values exists without a quality control, while when a quality control is implemented, the results are clustered around the mean for all the decision variables.

- the increase in the burn-in time slightly increases the overall cost, while its application for longer time contributes to the detection of more defective units which are not passed on to the consumer. Concerning the numerical example, increasing by 1000 revolutions the burn-in time the total cost increases by less than 5% in all cases.

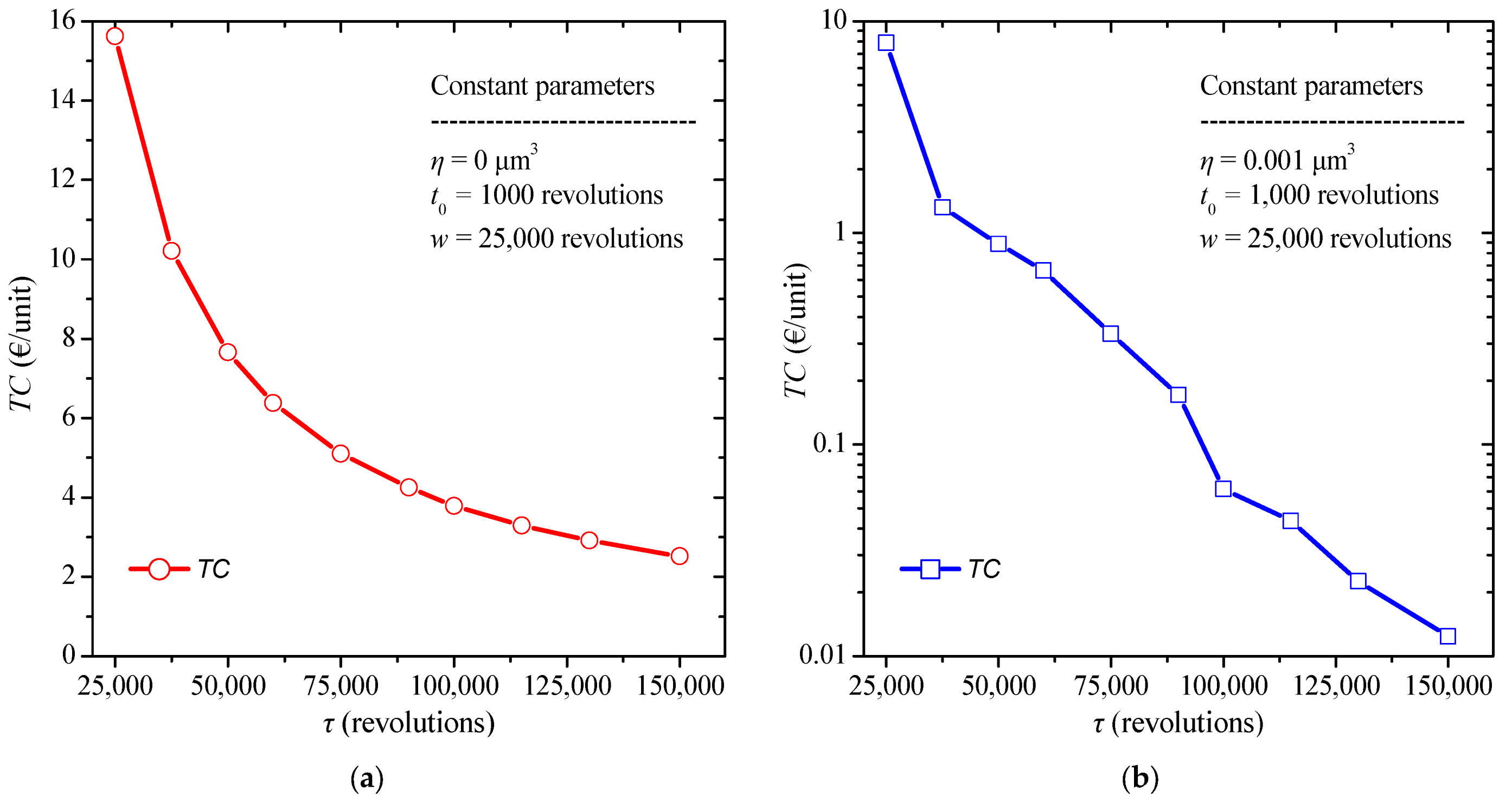

- the increase in the replacement interval is observed to contribute significantly to the reduction of total cost since the sooner a component is replaced, the less likely it is to fail.

- the increase in the warranty period provided by the manufacturer increases the total cost significantly.

Author Contributions

Funding

Conflicts of Interest

References

- Peng, H.; Feng, Q.; Coit, D.W. Simultaneous quality and reliability optimization for microengines subject to degradation. IEEE Trans. Reliab. 2009, 58, 98–105. [Google Scholar] [CrossRef]

- Chien, Y.H.; Chen, M. An optimal age for preventive replacement under fully renewing combination free replacement and pro rata warranty. Commun. Stat.-Theory Methods 2010, 39, 2422–2439. [Google Scholar] [CrossRef]

- Chien, Y.H.; Sheu, S.H. Extended optimal age-replacement policy with minimal repair of a system subject to shocks. Eur. J. Oper. Res. 2006, 174, 169–181. [Google Scholar] [CrossRef]

- Cha, J.H. On a better burn-in procedure. J. Appl. Probab. 2000, 37, 1099–1103. [Google Scholar] [CrossRef]

- Ye, Z.S.; Xie, M.; Tang, L.C.; Shen, Y. Degradation-based burn-in planning under competing risks. Technometrics 2012, 54, 159–168. [Google Scholar] [CrossRef]

- Hu, J.; Sun, Q.; Ye, Z.S.; Ling, X. Sequential degradation-based burn-in test with multiple periodic inspections. Front. Eng. Manag. 2021, 8, 519–530. [Google Scholar] [CrossRef]

- Yu, M.; Lu, H.; Wang, H.; Xiao, C.; Lan, D.; Chen, J. Computational Intelligence-Based Prognosis for Hybrid Mechatronic System Using Improved Wiener Process. Actuators 2021, 10, 213. [Google Scholar] [CrossRef]

- Shafiee, M.; Finkelstein, M.; Zuo, M.J. Optimal burn-in and preventive maintenance warranty strategies with time-dependent maintenance costs. IIE Trans. 2013, 45, 1024–1033. [Google Scholar] [CrossRef]

- Belhaj Salem, M.; Fouladirad, M.; Deloux, E. Prognostic and Classification of Dynamic Degradation in a Mechanical System Using Variance Gamma Process. Mathematics 2021, 9, 254. [Google Scholar] [CrossRef]

- Bogdanoff, J.L.; Kozin, F. Probabilistic Models of Cumulative Damage; Wiley-Interscience: New York, NY, USA, 1985; 350p. [Google Scholar]

- Van Noortwijk, J.M. A survey of the application of gamma processes in maintenance. Reliab. Eng. Syst. Saf. 2009, 94, 2–21. [Google Scholar] [CrossRef]

- Frangopol, D.M.; Kallen, M.J.; Noortwijk, J.M.V. Probabilistic models for life-cycle performance of deteriorating structures: Review and future directions. Prog. Struct. Eng. Mater. 2004, 6, 197–212. [Google Scholar] [CrossRef]

- Abdel-Hameed, M. Degradation processes: An overview. In Advances in Degradation Modeling; Springer: Berlin/Heidelberg, Germany, 2010; pp. 17–25. [Google Scholar]

- Shahraki, A.F.; Yadav, O.P.; Liao, H. A review on degradation modelling and its engineering applications. Int. J. Perform. Eng. 2017, 13, 299. [Google Scholar] [CrossRef]

- Li, J.; Zhang, X.; Zhou, X.; Lu, L. Reliability assessment of wind turbine bearing based on the degradation-Hidden-Markov model. Renew. Energy 2019, 132, 1076–1087. [Google Scholar] [CrossRef]

- Cholette, M.E.; Yu, H.; Borghesani, P.; Ma, L.; Kent, G. Degradation modeling and condition-based maintenance of boiler heat exchangers using gamma processes. Reliab. Eng. Syst. 2019, 183, 184–196. [Google Scholar]

- Zhang, Z.; Si, X.; Hu, C.; Lei, Y. Degradation data analysis and remaining useful life estimation: A review on Wiener-process-based methods. Eur. J. Oper. Res. 2018, 271, 775–796. [Google Scholar] [CrossRef]

- Jiang, L.; Li, B.; Hu, J. Preventive Replacement Policy of a System Considering Multiple Maintenance Actions upon a Failure. Qual. Reliab. Eng. Int. 2022; early view. [Google Scholar] [CrossRef]

- An, Y.; Chen, X.; Hu, J.; Zhang, L.; Li, Y.; Jiang, J. Joint Optimization of Preventive Maintenance and Production Rescheduling with New Machine Insertion and Processing Speed Selection. Reliab. Eng. Syst. Saf. 2022, 220, 108269. [Google Scholar] [CrossRef]

- Dong, W.; Liu, S.; Cao, Y.; Javed, S.A.; Du, Y. Reliability Modeling and Optimal Random Preventive Maintenance Policy for Parallel Systems with Damage Self-Healing. Comput. Ind. Eng. 2020, 142, 106359. [Google Scholar] [CrossRef]

- Dong, W.; Liu, S.; Bae, S.J.; Cao, Y. Reliability Modelling for Multi-Component Systems Subject to Stochastic Deterioration and Generalized Cumulative Shock Damages. Reliab. Eng. Syst. Saf. 2021, 205, 107260. [Google Scholar] [CrossRef]

- Hashemi, M.; Tavangar, M.; Asadi, M. Optimal Preventive Maintenance for Coherent Systems Whose Failure Occurs Due to Aging or External Shocks. Comput. Ind. Eng. 2022, 163, 107829. [Google Scholar] [CrossRef]

- Walraven, J.A.; Headley, T.J.; Campbell, A.B.; Tanner, D.M. Failure analysis of worn surface-micromachined microengines. In MEMS Reliability for Critical and Space Applications; SPIE: Bellingham, WA, USA, 1999; Volume 3880, pp. 30–39. [Google Scholar] [CrossRef]

- Tavrow, L.S.; Bart, S.F.; Lang, J.H. Operational characteristics of microfabricated electric motors. Sens. Actuator A Phys. 1992, 35, 33–44. [Google Scholar] [CrossRef]

- Tanner, D.M.; Dugger, M.T. Wear mechanisms in a reliability methodology. In Reliability, Testing, and Characterization of MEMS/MOEMS II, Proceedings of the Micromachining and Microfabrication, San Jose, CA, USA, 25–31 January 2003; SPIE: Bellingham, WA, USA, 2003. [Google Scholar]

- Wen, Y.; Liu, B.; Shi, H.; Kang, S.; Feng, Y. Reliability Evaluation and Optimization of a System with Mixed Run Shock. Axioms 2022, 11, 366. [Google Scholar] [CrossRef]

- Gao, H.; Cui, L. Reliability analysis for a degradation system subject to dependent soft and hard failure processes. In Proceedings of the 2017 IEEE International Conference on Software Quality, Reliability and Security Companion, Prague, Czech Republic, 25–29 July 2017. [Google Scholar]

- Walraven, J.A. Failure Mechanisms in Mems. In Proceedings of the International Test Conference, Charlotte, NC, USA, 30 September–2 October 2003; Volume 1, pp. 828–833. [Google Scholar]

- Nocedal, J.; Wright, S. Numerical Optimization; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2006. [Google Scholar]

- Tanner, D.M.; Miller, W.M.; Peterson, K.A.; Dugger, M.T.; Eaton, W.P.; Irwin, L.W.; Senft, D.C.; Smith, N.F.; Tangyunyong, P.; Miller, S.L. Frequency dependence of the lifetime of a surface micromachined microengine driving a load. Microelectron. Reliab. 1999, 39, 401–414. [Google Scholar] [CrossRef]

| c (μm2/N) | r (μm) | F (N) | s.d. of r (μm) | s.d. of F (N) | Quality Loss Factor | (€/Unit) | RC (€/Unit) | Rejection Cost (€/unit) | c2 (€/Unit) |

|---|---|---|---|---|---|---|---|---|---|

| 0.0003 | 1.5 | 3 × 10−6 | 0.075 | 1.5 × 10−7 | 1010 | 1000 | 50 | 50 | 70 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tseni, A.D.; Sotiropoulos, P.; Georgantzinos, S.K. Optimization of Quality, Reliability, and Warranty Policies for Micromachines under Wear Degradation. Micromachines 2022, 13, 1899. https://doi.org/10.3390/mi13111899

Tseni AD, Sotiropoulos P, Georgantzinos SK. Optimization of Quality, Reliability, and Warranty Policies for Micromachines under Wear Degradation. Micromachines. 2022; 13(11):1899. https://doi.org/10.3390/mi13111899

Chicago/Turabian StyleTseni, Alexandra D., Panagiotis Sotiropoulos, and Stelios K. Georgantzinos. 2022. "Optimization of Quality, Reliability, and Warranty Policies for Micromachines under Wear Degradation" Micromachines 13, no. 11: 1899. https://doi.org/10.3390/mi13111899

APA StyleTseni, A. D., Sotiropoulos, P., & Georgantzinos, S. K. (2022). Optimization of Quality, Reliability, and Warranty Policies for Micromachines under Wear Degradation. Micromachines, 13(11), 1899. https://doi.org/10.3390/mi13111899