A Review of Electrically Driven Soft Actuators for Soft Robotics

Abstract

1. Background

2. Dielectric Elastomer Actuator

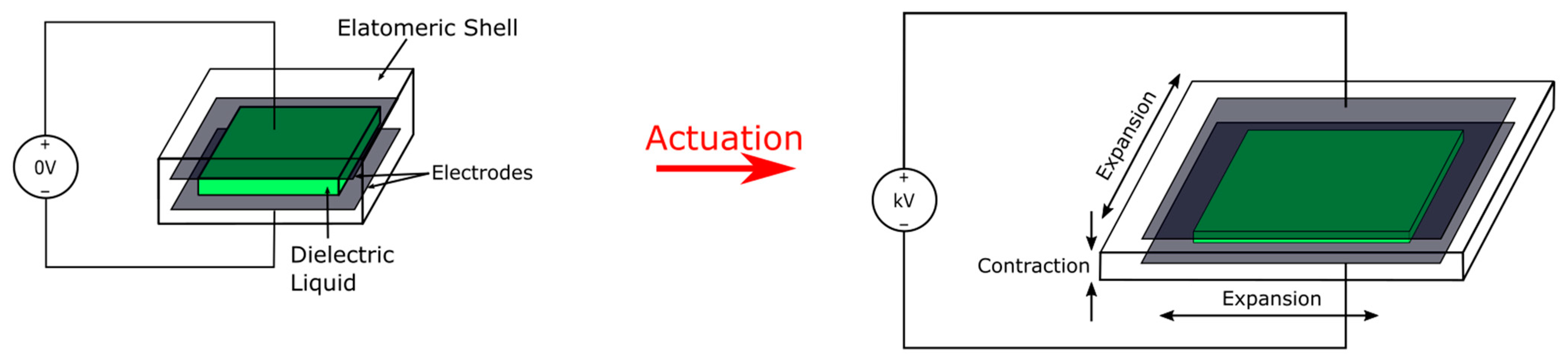

3. Electrohydraulic Soft Actuators

4. Electro-Ribbon Actuator

5. Electro-Thermal Actuators

5.1. Twisted and Coiled Actuator

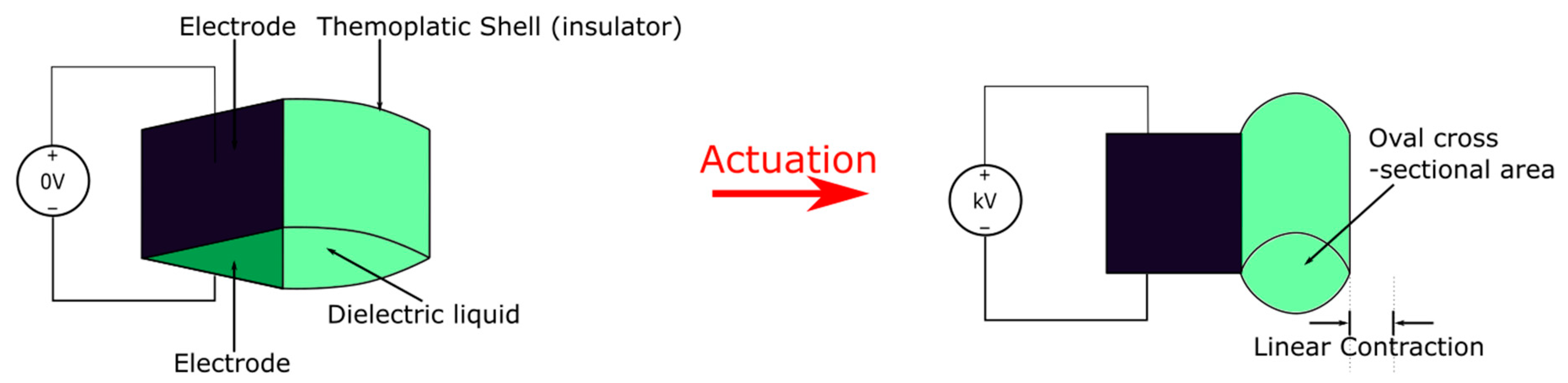

5.2. Phase-Changing Actuator

6. Electrically Driven Soft Pumps

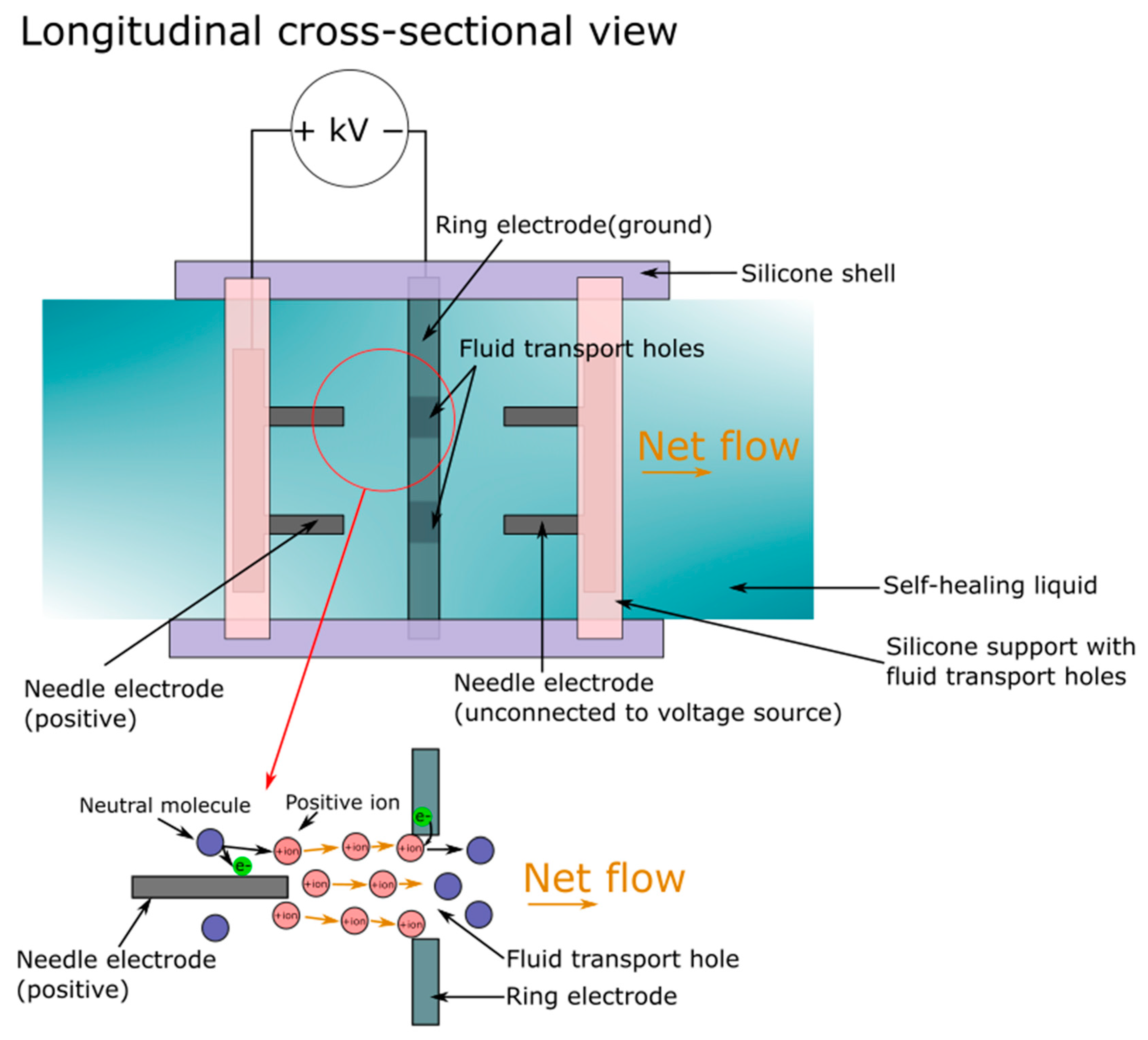

7. Electrohydrodynamic Pumps

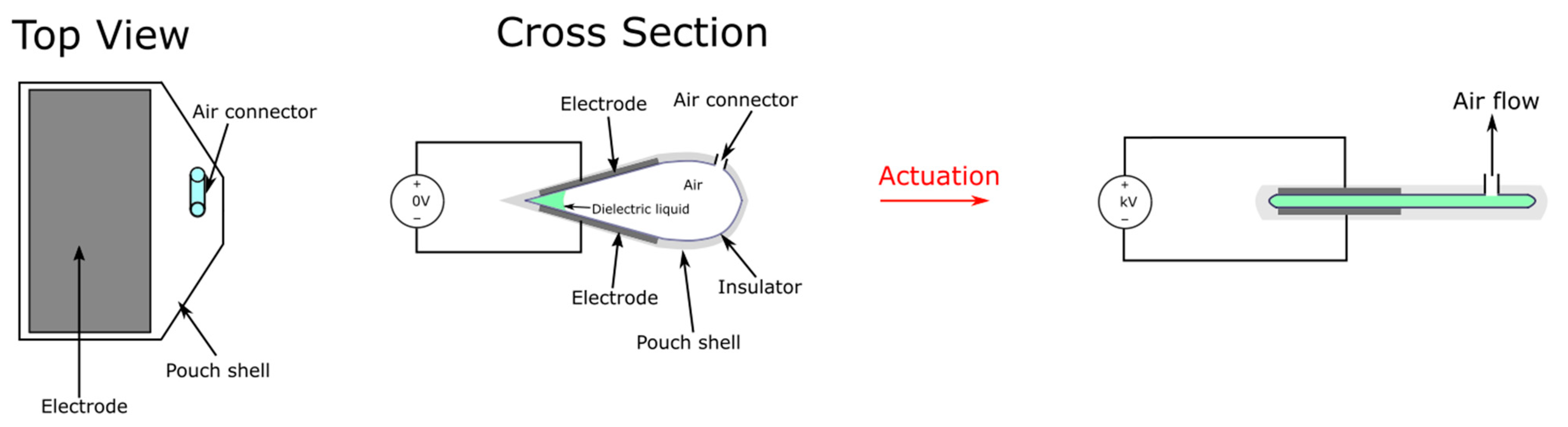

8. Electro-Pneumatic Pump

9. DEA Pump

10. TCP Pump

11. Summary

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Walker, J.; Zidek, T.; Harbel, C.; Yoon, S.; Strickland, F.S.; Kumar, S.; Shin, M. Soft robotics: A review of recent developments of pneumatic soft actuators. Actuators 2020, 9, 3. [Google Scholar] [CrossRef]

- Su, H.; Hou, X.; Zhang, X.; Qi, W.; Cai, S.; Xiong, X.; Guo, J. Pneumatic Soft Robots: Challenges and Benefits. Actuators 2022, 11, 92. [Google Scholar] [CrossRef]

- Do, T.N.; Phan, H.; Nguyen, T.Q.; Visell, Y. Miniature soft electromagnetic actuators for robotic applications. Adv. Funct. Mater. 2018, 28, 1800244. [Google Scholar] [CrossRef]

- Mao, G.; Drack, M.; Karami-Mosammam, M.; Wirthl, D.; Stockinger, T.; Schwödiauer, R.; Kaltenbrunner, M. Soft electromagnetic actuators. Sci. Adv. 2020, 6, eabc0251. [Google Scholar] [CrossRef]

- Doerger, S.R.; Harnett, C.K. Force-Amplified Soft Electromagnetic Actuators. Actuators 2018, 7, 76. [Google Scholar] [CrossRef]

- Ahn, J.; Gu, J.; Choi, J.; Han, C.; Jeong, Y.; Park, J.; Cho, S.; Oh, Y.S.; Jeong, J.H.; Amjadi, M. A Review of Recent Advances in Electrically Driven Polymer-Based Flexible Actuators: Smart Materials, Structures, and Their Applications. Adv. Mater. Technol. 2022, 2200041. [Google Scholar] [CrossRef]

- Carpi, F.; De Rossi, D.; Kornbluh, R.; Pelrine, R.E.; Sommer-Larsen, P. Dielectric Elastomers as Electromechanical Transducers: Fundamentals, Materials, Devices, Models and Applications of an Emerging Electroactive Polymer Technology; Elsevier: Amsterdam, The Netherlands, 2011. [Google Scholar]

- de Saint-Aubin, C.; Rosset, S.; Schlatter, S.; Shea, H. High-cycle electromechanical aging of dielectric elastomer actuators with carbon-based electrodes. Smart Mater. Struct. 2018, 27, 074002. [Google Scholar] [CrossRef]

- Duduta, M.; Hajiesmaili, E.; Zhao, H.; Wood, R.J.; Clarke, D.R. Realizing the potential of dielectric elastomer artificial muscles. Proc. Natl. Acad. Sci. USA 2019, 116, 2476–2481. [Google Scholar] [CrossRef]

- O’Halloran, A.; O’malley, F.; McHugh, P. A review on dielectric elastomer actuators, technology, applications, and challenges. J. Appl. Phys. 2008, 104, 9. [Google Scholar] [CrossRef]

- Shankar, R.; Ghosh, T.K.; Spontak, R.J. Dielectric elastomers as next-generation polymeric actuators. Soft Matter 2007, 3, 1116–1129. [Google Scholar] [CrossRef]

- Shigemune, H.; Sugano, S.; Nishitani, J.; Yamauchi, M.; Hosoya, N.; Hashimoto, S.; Maeda, S. Dielectric elastomer actuators with carbon nanotube electrodes painted with a soft brush. Actuators 2018, 7, 51. [Google Scholar] [CrossRef]

- Kofod, G. Dielectric elastomer actuators. Ph.D. Thesis, The Technical University of Denmark, Kongens Lyngby, Denmark, September 2001. [Google Scholar]

- Kornbluh, R.D.; Pelrine, R.; Pei, Q.; Oh, S.; Joseph, J. Ultrahigh strain response of field-actuated elastomeric polymers. In Proceedings of the Smart Structures and Materials 2000: Electroactive Polymer Actuators and Devices (Eapad), Newport Beach, CA, USA, 7 June 2000; pp. 51–64. [Google Scholar]

- Youn, J.-H.; Jeong, S.M.; Hwang, G.; Kim, H.; Hyeon, K.; Park, J.; Kyung, K.-U. Dielectric elastomer actuator for soft robotics applications and challenges. Appl. Sci. 2020, 10, 640. [Google Scholar] [CrossRef]

- Niu, X.; Stoyanov, H.; Hu, W.; Leo, R.; Brochu, P.; Pei, Q. Synthesizing a new dielectric elastomer exhibiting large actuation strain and suppressed electromechanical instability without prestretching. J. Polym. Sci. Part B Polym. Phys. 2013, 51, 197–206. [Google Scholar] [CrossRef]

- Chen, Y.; Zhao, H.; Mao, J.; Chirarattananon, P.; Helbling, E.F.; Hyun, N.-S.P.; Clarke, D.R.; Wood, R.J. Controlled flight of a microrobot powered by soft artificial muscles. Nature 2019, 575, 324–329. [Google Scholar] [CrossRef]

- Ji, X.; Liu, X.; Cacucciolo, V.; Imboden, M.; Civet, Y.; El Haitami, A.; Cantin, S.; Perriard, Y.; Shea, H. An autonomous untethered fast soft robotic insect driven by low-voltage dielectric elastomer actuators. Sci. Robot. 2019, 4, eaaz6451. [Google Scholar] [CrossRef]

- Li, G.; Chen, X.; Zhou, F.; Liang, Y.; Xiao, Y.; Cao, X.; Zhang, Z.; Zhang, M.; Wu, B.; Yin, S. Self-powered soft robot in the Mariana Trench. Nature 2021, 591, 66–71. [Google Scholar] [CrossRef]

- Zhao, X.; Suo, Z. Method to analyze programmable deformation of dielectric elastomer layers. Appl. Phys. Lett. 2008, 93, 251902. [Google Scholar] [CrossRef]

- Madden, J.D.; Vandesteeg, N.A.; Anquetil, P.A.; Madden, P.G.; Takshi, A.; Pytel, R.Z.; Lafontaine, S.R.; Wieringa, P.A.; Hunter, I.W. Artificial muscle technology: Physical principles and naval prospects. IEEE J. Ocean. Eng. 2004, 29, 706–728. [Google Scholar] [CrossRef]

- Cai, J. 4D Printing Dielectric Elastomer Actuator Based Soft Robots; University of Arkansas: Fayetteville, AR, USA, 2016. [Google Scholar]

- Chortos, A.; Mao, J.; Mueller, J.; Hajiesmaili, E.; Lewis, J.A.; Clarke, D.R. Printing reconfigurable bundles of dielectric elastomer fibers. Adv. Funct. Mater. 2021, 31, 2010643. [Google Scholar] [CrossRef]

- Haghiashtiani, G.; Habtour, E.; Park, S.-H.; Gardea, F.; McAlpine, M.C. 3D printed electrically-driven soft actuators. Extrem. Mech. Lett. 2018, 21, 1–8. [Google Scholar] [CrossRef]

- Kofod, G.; Wirges, W.; Paajanen, M.; Bauer, S. Energy minimization for self-organized structure formation and actuation. Appl. Phys. Lett. 2007, 90, 081916. [Google Scholar] [CrossRef]

- Ho, T.Y.K.; Nirmal, A.; Kulkarni, M.R.; Accoto, D.; Mathews, N. Soft actuator materials for electrically driven haptic interfaces. Adv. Intell. Syst. 2022, 4, 2100061. [Google Scholar]

- Xu, S.; Chen, Y.; Hyun, N.-s.P.; Becker, K.P.; Wood, R.J. A dynamic electrically driven soft valve for control of soft hydraulic actuators. Proc. Natl. Acad. Sci. USA 2021, 118, e2103198118. [Google Scholar] [CrossRef] [PubMed]

- Romasanta, L.J.; López-Manchado, M.A.; Verdejo, R. Increasing the performance of dielectric elastomer actuators: A review from the materials perspective. Prog. Polym. Sci. 2015, 51, 188–211. [Google Scholar] [CrossRef]

- Yu, L.; Skov, A.L. Molecular strategies for improved dielectric elastomer electrical breakdown strengths. Macromol. Rapid Commun. 2018, 39, 1800383. [Google Scholar] [CrossRef]

- Pelrine, R.; Kornbluh, R.; Pei, Q.; Joseph, J. High-speed electrically actuated elastomers with strain greater than 100%. Science 2000, 287, 836–839. [Google Scholar] [CrossRef]

- Rosset, S.; Araromi, O.A.; Schlatter, S.; Shea, H.R. Fabrication process of silicone-based dielectric elastomer actuators. J. Vis. Exp. 2016, 108, 53423. [Google Scholar] [CrossRef]

- Wang, W.; Ren, G.; Zhou, M.; Deng, W. Preparation and characterization of CCTO/PDMS dielectric elastomers with high dielectric constant and low dielectric loss. Polymers 2021, 13, 1075. [Google Scholar] [CrossRef]

- Wang, G.; Wang, J.; Zhou, S.; Wu, S. Enhanced dielectric properties of acrylic resin elastomer based nanocomposite with thermally reduced graphene nanosheets. RSC Adv. 2016, 6, 98440–98448. [Google Scholar] [CrossRef]

- Wu, S.-Q.; Wang, J.-W.; Wang, G.-Q.; Ren, H. Enhanced dielectric properties of all-organic acrylic resin elastomer-based composite with doped polyaniline. Polym. Bull. 2018, 75, 2901–2916. [Google Scholar] [CrossRef]

- Hunt, S.; McKay, T.G.; Anderson, I.A. A self-healing dielectric elastomer actuator. Appl. Phys. Lett. 2014, 104, 113701. [Google Scholar] [CrossRef]

- Duan, L.; Lai, J.-C.; Li, C.-H.; Zuo, J.-L. A dielectric elastomer actuator that can self-heal integrally. ACS Appl. Mater. Interfaces 2020, 12, 44137–44146. [Google Scholar] [CrossRef] [PubMed]

- La, T.-G.; Lau, G.-K. Enhanced dielectric strength and actuation of acrylic elastomer with silicone gel encapsulation. In Proceedings of the Electroactive Polymer Actuators and Devices (EAPAD), Las Vegas, NV, USA, 15 April 2016; pp. 13–20. [Google Scholar]

- Peng, Z.; Shi, Y.; Chen, N.; Li, Y.; Pei, Q. Stable and High-Strain Dielectric Elastomer Actuators Based on a Carbon Nanotube-Polymer Bilayer Electrode. Adv. Funct. Mater. 2021, 31, 2008321. [Google Scholar] [CrossRef]

- Wang, D.-P.; Zhao, Z.-H.; Li, C.-H.; Zuo, J.-L. An ultrafast self-healing polydimethylsiloxane elastomer with persistent sealing performance. Mater. Chem. Front. 2019, 3, 1411–1421. [Google Scholar] [CrossRef]

- Zhang, L.; Liang, J.; Jiang, C.; Liu, Z.; Sun, L.; Chen, S.; Xuan, H.; Lei, D.; Guan, Q.; Ye, X. Peptidoglycan-inspired autonomous ultrafast self-healing bio-friendly elastomers for bio-integrated electronics. Natl. Sci. Rev. 2021, 8, nwaa154. [Google Scholar] [CrossRef]

- Poulin, A.; Rosset, S.; Shea, H.R. Printing low-voltage dielectric elastomer actuators. Appl. Phys. Lett. 2015, 107, 244104. [Google Scholar] [CrossRef]

- Acome, E.; Mitchell, S.K.; Morrissey, T.; Emmett, M.; Benjamin, C.; King, M.; Radakovitz, M.; Keplinger, C. Hydraulically amplified self-healing electrostatic actuators with muscle-like performance. Science 2018, 359, 61–65. [Google Scholar] [CrossRef]

- Kellaris, N.; Gopaluni Venkata, V.; Smith, G.M.; Mitchell, S.K.; Keplinger, C. Peano-HASEL actuators: Muscle-mimetic, electrohydraulic transducers that linearly contract on activation. Sci. Robot. 2018, 3, eaar3276. [Google Scholar] [CrossRef]

- Rothemund, P.; Kellaris, N.; Mitchell, S.K.; Acome, E.; Keplinger, C. HASEL artificial muscles for a new generation of lifelike robots—Recent progress and future opportunities. Adv. Mater. 2021, 33, 2003375. [Google Scholar] [CrossRef]

- Schunk, C.; Pearson, L.; Acome, E.; Morrissey, T.G.; Correll, N.; Keplinger, C.; Rentschler, M.E.; Humbert, J.S. System identification and closed-loop control of a hydraulically amplified self-healing electrostatic (HASEL) actuator. In Proceedings of the 2018 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Madrid, Spain, 1–5 October 2018; pp. 6417–6423. [Google Scholar]

- O’Neill, M.R.; Acome, E.; Bakarich, S.; Mitchell, S.K.; Timko, J.; Keplinger, C.; Shepherd, R.F. Rapid 3D printing of electrohydraulic (HASEL) tentacle actuators. Adv. Funct. Mater. 2020, 30, 2005244. [Google Scholar] [CrossRef]

- Kim, S.; Cha, Y. Rotary motion and manipulation using electro-hydraulic actuator with asymmetric electrodes. IEEE Robot. Autom. Lett. 2020, 5, 3945–3951. [Google Scholar] [CrossRef]

- Park, T.; Kim, K.; Oh, S.-R.; Cha, Y. Electrohydraulic actuator for a soft gripper. Soft Robot. 2020, 7, 68–75. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Mitchell, S.K.; Rumley, E.H.; Rothemund, P.; Keplinger, C. High-strain peano-HASEL actuators. Adv. Funct. Mater. 2020, 30, 1908821. [Google Scholar] [CrossRef]

- Ly, K.; Kellaris, N.; McMorris, D.; Johnson, B.K.; Acome, E.; Sundaram, V.; Naris, M.; Humbert, J.S.; Rentschler, M.E.; Keplinger, C. Miniaturized circuitry for capacitive self-sensing and closed-loop control of soft electrostatic transducers. Soft Robot. 2021, 8, 673–686. [Google Scholar] [CrossRef] [PubMed]

- Mitchell, S.K.; Wang, X.; Acome, E.; Martin, T.; Ly, K.; Kellaris, N.; Venkata, V.G.; Keplinger, C. An Easy-to-Implement Toolkit to Create Versatile and High-Performance HASEL Actuators for Untethered Soft Robots. Adv. Sci. 2019, 6, 1900178. [Google Scholar] [CrossRef]

- Kellaris, N.; Rothemund, P.; Zeng, Y.; Mitchell, S.K.; Smith, G.M.; Jayaram, K.; Keplinger, C. Spider-Inspired Electrohydraulic Actuators for Fast, Soft-Actuated Joints. Adv. Sci. 2021, 8, 2100916. [Google Scholar] [CrossRef] [PubMed]

- Acome, E.; Keplinger, C.; Gross, M.D.; Bruns, C.; Leithinger, D. Soft Electrohydraulic Actuators for Origami Inspired Shape-Changing Interfaces. In Proceedings of the Extended Abstracts of the 2021 CHI Conference on Human Factors in Computing Systems, Yokohama, Japan, 8–13 May 2021; pp. 1–6. [Google Scholar]

- Novack, S.M.; Acome, E.; Keplinger, C.; Alistar, M.; Gross, M.D.; Bruns, C.; Leithinger, D. Electriflow: Soft Electrohydraulic Building Blocks for Prototyping Shape-changing Interfaces. In Proceedings of the Designing Interactive Systems Conference 2021, New York, NY, USA, 28 June–2 July 2021; pp. 1280–1290. [Google Scholar]

- Yoder, Z.; Kellaris, N.; Chase-Markopoulou, C.; Ricken, D.; Mitchell, S.K.; Emmett, M.B.; Segil, J.; Keplinger, C. Design of a high-speed prosthetic finger driven by Peano-HASEL actuators. Front. Robot. AI 2020, 7, 586216. [Google Scholar] [CrossRef] [PubMed]

- Cheng, X.; Yu, M.; Ma, J.; Li, B.; Zhang, Y.; Wang, P.; Jiao, Z. An entirely soft varifocal lens based on an electro-hydraulic actuator. Smart Mater. Struct. 2020, 29, 045017. [Google Scholar] [CrossRef]

- Ma, J.; Cheng, X.; Wang, P.; Jiao, Z.; Yu, Y.; Yu, M.; Luo, B.; Yang, W. A Haptic Feedback Actuator Suitable for the Soft Wearable Device. Appl. Sci. 2020, 10, 8827. [Google Scholar] [CrossRef]

- Kellaris, N.; Venkata, V.G.; Rothemund, P.; Keplinger, C. An analytical model for the design of Peano-HASEL actuators with drastically improved performance. Extrem. Mech. Lett. 2019, 29, 100449. [Google Scholar] [CrossRef]

- Taghavi, M.; Helps, T.; Rossiter, J. Electro-ribbon actuators and electro-origami robots. Sci. Robot. 2018, 3, eaau9795. [Google Scholar] [CrossRef]

- Pohl, H.A. The motion and precipitation of suspensoids in divergent electric fields. J. Appl. Phys. 1951, 22, 869–871. [Google Scholar] [CrossRef]

- Taghavi, M.; Helps, T.; Rossiter, J. Characterisation of self-locking high-contraction electro-ribbon actuators. In Proceedings of the 2020 IEEE International Conference on Robotics and Automation (ICRA), Paris, France, 31 May–31 August 2020; pp. 5856–5861. [Google Scholar]

- Bluett, S.; Helps, T.; Taghavi, M.; Rossiter, J. Self-sensing electro-ribbon actuators. IEEE Robot. Autom. Lett. 2020, 5, 3931–3936. [Google Scholar] [CrossRef]

- Diteesawat, R.S.; Fishman, A.; Helps, T.; Taghavi, M.; Rossiter, J. Closed-loop control of electro-ribbon actuators. Front. Robot. AI 2020, 7, 557624. [Google Scholar] [CrossRef]

- Chen, S.; Tan, M.W.M.; Gong, X.; Lee, P.S. Low-Voltage Soft Actuators for Interactive Human–Machine Interfaces. Adv. Intell. Syst. 2022, 4, 2100075. [Google Scholar] [CrossRef]

- Luong, T.; Kim, K.; Seo, S.; Jeon, J.; Park, C.; Doh, M.; Koo, J.C.; Choi, H.R.; Moon, H. Long short term memory model based position-stiffness control of antagonistically driven twisted-coiled polymer actuators using model predictive control. IEEE Robot. Autom. Lett. 2021, 6, 4141–4148. [Google Scholar] [CrossRef]

- Luong, T.; Kim, K.; Seo, S.; Park, J.H.; Kim, Y.; Yang, S.Y.; Cho, K.H.; Koo, J.C.; Choi, H.R.; Moon, H. Impedance control of a high performance twisted-coiled polymer actuator. In Proceedings of the 2018 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Madrid, Spain, 1–5 October 2018; pp. 8701–8706. [Google Scholar]

- Luong, T.; Seo, S.; Kim, K.; Jeon, J.; Yumbla, F.; Koo, J.C.; Choi, H.R.; Moon, H. Realization of a simultaneous position-stiffness controllable antagonistic joint driven by twisted-coiled polymer actuators using model predictive control. IEEE Access 2021, 9, 26071–26082. [Google Scholar] [CrossRef]

- Yip, M.C.; Niemeyer, G. On the control and properties of supercoiled polymer artificial muscles. IEEE Trans. Robot. 2017, 33, 689–699. [Google Scholar] [CrossRef]

- Lima, M.D.; Li, N.; Jung de Andrade, M.; Fang, S.; Oh, J.; Spinks, G.M.; Kozlov, M.E.; Haines, C.S.; Suh, D.; Foroughi, J. Electrically, chemically, and photonically powered torsional and tensile actuation of hybrid carbon nanotube yarn muscles. Science 2012, 338, 928–932. [Google Scholar] [CrossRef]

- Haines, C.S.; Lima, M.D.; Li, N.; Spinks, G.M.; Foroughi, J.; Madden, J.D.; Kim, S.H.; Fang, S.; Jung de Andrade, M.; Göktepe, F. Artificial muscles from fishing line and sewing thread. Science 2014, 343, 868–872. [Google Scholar] [CrossRef]

- Simeonov, A.; Henderson, T.; Lan, Z.; Sundar, G.; Factor, A.; Zhang, J.; Yip, M. Bundled super-coiled polymer artificial muscles: Design, characterization, and modeling. IEEE Robot. Autom. Lett. 2018, 3, 1671–1678. [Google Scholar] [CrossRef]

- Bombara, D.; Mansurov, V.; Konda, R.; Fowzer, S.; Zhang, J. Self-sensing for twisted string actuators using conductive supercoiled polymers. In Proceedings of the Smart Materials, Adaptive Structures and Intelligent Systems, Louisville, KY, USA, 9–11 September 2019. [Google Scholar]

- Cho, K.H.; Song, M.G.; Jung, H.; Park, J.; Moon, H.; Koo, J.C.; Nam, J.-D.; Choi, H.R. A robotic finger driven by twisted and coiled polymer actuator. In Proceedings of the Electroactive Polymer Actuators and Devices (EAPAD), Las Vegas, NV, USA, 15 April 2016; pp. 275–281. [Google Scholar]

- Kim, K.; Cho, K.H.; Jung, H.S.; Yang, S.Y.; Kim, Y.; Park, J.H.; Jang, H.; Nam, J.D.; Koo, J.C.; Moon, H. Double helix twisted and coiled soft actuator from spandex and nylon. Adv. Eng. Mater. 2018, 20, 1800536. [Google Scholar] [CrossRef]

- Sun, J.; Tighe, B.; Liu, Y.; Zhao, J. Twisted-and-coiled actuators with free strokes enable soft robots with programmable motions. Soft Robot. 2021, 8, 213–225. [Google Scholar] [CrossRef]

- Almubarak, Y.; Tadesse, Y. Twisted and coiled polymer (TCP) muscles embedded in silicone elastomer for use in soft robot. Int. J. Intell. Robot. Appl. 2017, 1, 352–368. [Google Scholar] [CrossRef]

- Wu, L.; Karami, F.; Hamidi, A.; Tadesse, Y. Biorobotic systems design and development using TCP muscles. In Proceedings of the Electroactive Polymer Actuators and Devices (EAPAD) XX, Denver, CO, USA, 27 March 2018; pp. 240–250. [Google Scholar]

- Wu, L.; Wang, X. A modular twisted and coiled polymer actuator unit for robotic tentacles. In Proceedings of the Electroactive Polymer Actuators and Devices (EAPAD) XXI, Denver, CO, USA, 13 March 2019; pp. 59–67. [Google Scholar]

- Yang, Y.; Tse, Y.A.; Zhang, Y.; Kan, Z.; Wang, M.Y. A low-cost inchworm-inspired soft robot driven by supercoiled polymer artificial muscle. In Proceedings of the 2019 2nd IEEE International Conference on Soft Robotics (RoboSoft), Seoul, Korea, 14–18 April 2019; pp. 161–166. [Google Scholar]

- Chossat, J.-B.; Chen, D.K.; Park, Y.-L.; Shull, P.B. Soft wearable skin-stretch device for haptic feedback using twisted and coiled polymer actuators. IEEE Trans. Haptics 2019, 12, 521–532. [Google Scholar] [CrossRef]

- Yang, Y.; Kan, Z.; Zhang, Y.; Tse, Y.A.; Wang, M.Y. A novel variable stiffness actuator based on pneumatic actuation and supercoiled polymer artificial muscles. In Proceedings of the 2019 International Conference on Robotics and Automation (ICRA), Montreal, QC, Canada, 20–24 May 2019; pp. 3983–3989. [Google Scholar]

- Tse, Y.A.; Wong, K.W.; Yang, Y.; Wang, M.Y. Novel Design of a Soft Pump Driven by Super-Coiled Polymer Artificial Muscles. In Proceedings of the 2020 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Las Vegas, NV, USA, 24 October 2020–24 January 2021; pp. 8789–8794. [Google Scholar]

- Goswami, D.; Liu, S.; Pal, A.; Silva, L.G.; Martinez, R.V. 3D-architected soft machines with topologically encoded motion. Adv. Funct. Mater. 2019, 29, 1808713. [Google Scholar] [CrossRef]

- Bilodeau, R.A.; Miriyev, A.; Lipson, H.; Kramer-Bottiglio, R. All-soft material system for strong soft actuators. In Proceedings of the 2018 IEEE International Conference on Soft Robotics (RoboSoft), Livorno, Italy, 24–28 April 2018; pp. 288–294. [Google Scholar]

- Li, X.; Duan, H.; Lv, P.; Yi, X. Soft actuators based on liquid–vapor phase change composites. Soft Robot. 2021, 8, 251–261. [Google Scholar] [CrossRef]

- Miriyev, A.; Stack, K.; Lipson, H. Soft material for soft actuators. Nat. Commun. 2017, 8, 596. [Google Scholar] [CrossRef]

- Sanchez, V.; Payne, C.J.; Preston, D.J.; Alvarez, J.T.; Weaver, J.C.; Atalay, A.T.; Boyvat, M.; Vogt, D.M.; Wood, R.J.; Whitesides, G.M. Smart thermally actuating textiles. Adv. Mater. Technol. 2020, 5, 2000383. [Google Scholar] [CrossRef]

- Noguchi, T.; Tsumori, F. Soft actuator with large volumetric change using vapor–liquid phase transition. Jpn. J. Appl. Phys. 2020, 59, SIIL08. [Google Scholar] [CrossRef]

- Han, J.; Jiang, W.; Niu, D.; Li, Y.; Zhang, Y.; Lei, B.; Liu, H.; Shi, Y.; Chen, B.; Yin, L. Untethered soft actuators by liquid–vapor phase transition: Remote and programmable actuation. Adv. Intell. Syst. 2019, 1, 1900109. [Google Scholar] [CrossRef]

- Kapłon, T.; Lindner, T.; Wyrwał, D. Induction heating for a silicone/ethanol composite actuator. In Proceedings of the 2020 International Conference Mechatronic Systems and Materials (MSM), Bialystok, Poland, 1–3 July 2020; pp. 1–4. [Google Scholar]

- Boyvat, M.; Vogt, D.M.; Wood, R.J. Ultrastrong and High-Stroke Wireless Soft Actuators through Liquid–Gas Phase Change. Adv. Mater. Technol. 2019, 4, 1800381. [Google Scholar] [CrossRef]

- Nishikawa, Y.; Matsumoto, M. A design of fully soft robot actuated by gas–liquid phase change. Adv. Robot. 2019, 33, 567–575. [Google Scholar] [CrossRef]

- Mann, A.; Germann, T.; Ruiter, M.; Groche, P. The challenge of upscaling paraffin wax actuators. Mater. Des. 2020, 190, 108580. [Google Scholar] [CrossRef]

- Li, J.; Sun, M.; Wu, Z. Design and fabrication of a low-cost silicone and water-based soft actuator with a high load-to-weight ratio. Soft Robot. 2021, 8, 448–461. [Google Scholar] [CrossRef]

- Miriyev, A.; Caires, G.; Lipson, H. Functional properties of silicone/ethanol soft-actuator composites. Mater. Des. 2018, 145, 232–242. [Google Scholar] [CrossRef]

- Xia, B.; Miriyev, A.; Trujillo, C.; Chen, N.; Cartolano, M.; Vartak, S.; Lipson, H. Improving the actuation speed and multi-cyclic actuation characteristics of silicone/ethanol soft actuators. Actuators 2022, 9, 62. [Google Scholar] [CrossRef]

- Narumi, K.; Sato, H.; Nakahara, K.; Seong, Y.a.; Morinaga, K.; Kakehi, Y.; Niiyama, R.; Kawahara, Y. Liquid Pouch Motors: Printable Planar Actuators Driven by Liquid-to-Gas Phase Change for Shape-Changing Interfaces. IEEE Robot. Autom. Lett. 2020, 5, 3915–3922. [Google Scholar] [CrossRef]

- Decroly, G.; Raffoul, R.; Deslypere, C.; Leroy, P.; Van Hove, L.; Delchambre, A.; Lambert, P. Optimization of Phase-Change Material–Elastomer Composite and Integration in Kirigami-Inspired Voxel-Based Actuators. Front. Robot. AI 2021, 8, 672934. [Google Scholar] [CrossRef]

- Matsuoka, H.; Kanda, T.; Wakimoto, S.; Suzumori, K.; Lambert, P. Development of a rubber soft actuator driven with gas/liquid phase change. Int. J. Autom. Technol. 2016, 10, 517–524. [Google Scholar] [CrossRef]

- Hirai, S.; Nagatomo, T.; Hiraki, T.; Ishizuka, H.; Kawahara, Y.; Miki, N. Micro elastic pouch motors: Elastically deformable and miniaturized soft actuators using liquid-to-gas phase change. IEEE Robot. Autom. Lett. 2021, 6, 5373–5380. [Google Scholar] [CrossRef]

- Miriyev, A.; Xia, B.; Joseph, J.C.; Lipson, H. Additive manufacturing of silicone composites for soft actuation. 3d Print. Addit. Manuf. 2019, 6, 309–318. [Google Scholar] [CrossRef]

- Miriyev, A.; Trujillo, C.; Caires, G.; Lipson, H. Rejuvenation of soft material–actuator. MRS Commun. 2018, 8, 556–561. [Google Scholar] [CrossRef]

- Chellattoan, R.; Yudhanto, A.; Lubineau, G. Low-voltage-driven large-amplitude soft actuators based on phase transition. Soft Robot. 2020, 7, 688–699. [Google Scholar] [CrossRef]

- Uramune, R.; Ishizuka, H.; Hiraki, T.; Kawahara, Y.; Ikeda, S.; Oshiro, O. HaPouch: Soft and Wearable Haptic Display Devices using Liquid-to-gas Phase Change Actuator. In Proceedings of the Adjunct Publication of the 33rd Annual ACM Symposium on User Interface Software and Technology, New York, NY, USA, 20–23 October 2020; pp. 53–55. [Google Scholar]

- Wang, Y.; Wang, Z.; He, Q.; Iyer, P.; Cai, S. Electrically controlled soft actuators with multiple and reprogrammable actuation modes. Adv. Intell. Syst. 2020, 2, 1900177. [Google Scholar] [CrossRef]

- Taccola, S.; Greco, F.; Sinibaldi, E.; Mondini, A.; Mazzolai, B.; Mattoli, V. Toward a new generation of electrically controllable hygromorphic soft actuators. Adv. Mater. 2015, 27, 1668–1675. [Google Scholar] [CrossRef]

- Tian, Y.; Li, Y.-T.; Tian, H.; Yang, Y.; Ren, T.-L. Recent progress of soft electrothermal actuators. Soft Robot. 2021, 8, 241–250. [Google Scholar] [CrossRef]

- Shian, S.; Huang, J.; Zhu, S.; Clarke, D.R. Optimizing the electrical energy conversion cycle of dielectric elastomer generators. Adv. Mater. 2014, 26, 6617–6621. [Google Scholar] [CrossRef]

- Aryana, K.; Ghiami, A.; Edalatpour, M.; Passandideh-Fard, M. A review on Electrohydrodynamic (EHD) pumps. In Proceedings of the 24th Annual International Conference on Mechanical Engineering, Yazd, Iran, 26–28 April 2016. [Google Scholar] [CrossRef]

- Feng, Y.; Seyed-Yagoobi, J. Understanding of electrohydrodynamic conduction pumping phenomenon. Phys. Fluids 2004, 16, 2432–2441. [Google Scholar] [CrossRef]

- Cacucciolo, V.; Shintake, J.; Kuwajima, Y.; Maeda, S.; Floreano, D.; Shea, H. Stretchable pumps for soft machines. Nature 2019, 572, 516–519. [Google Scholar] [CrossRef]

- Tang, W.; Zhang, C.; Zhong, Y.; Zhu, P.; Hu, Y.; Jiao, Z.; Wei, X.; Lu, G.; Wang, J.; Liang, Y. Customizing a self-healing soft pump for robot. Nat. Commun. 2021, 12, 1–11. [Google Scholar] [CrossRef]

- Diteesawat, R.S.; Helps, T.; Taghavi, M.; Rossiter, J. Electro-pneumatic pumps for soft robotics. Sci. Robot. 2021, 6, eabc3721. [Google Scholar] [CrossRef]

- Diteesawat, R.S.; Helps, T.; Taghavi, M.; Rossiter, J. High strength bubble artificial muscles for walking assistance. In Proceedings of the 2018 IEEE International Conference on Soft Robotics (RoboSoft), Livorno, Italy, 24–28 April 2018; pp. 388–393. [Google Scholar]

- Diteesawat, R.S.; Helps, T.; Taghavi, M.; Rossiter, J. Characteristic analysis and design optimization of bubble artificial muscles. Soft Robot. 2021, 8, 186–199. [Google Scholar] [CrossRef]

- Cao, C.; Gao, X.; Conn, A.T. A magnetically coupled dielectric elastomer pump for soft robotics. Adv. Mater. Technol. 2019, 4, 1900128. [Google Scholar] [CrossRef]

| Type of Actuator | Working Principle | Best Applications | Merits | Drawbacks |

|---|---|---|---|---|

| DEA | Maxwell stress created by electrostatic force |

|

|

|

| Elastomeric HASEL | Maxwell stress created by electrostatic force |

|

|

|

| Thermoplastic HASEL | Electrostatic zipping amplified by a dielectric liquid |

|

|

|

| Electro-ribbon | Electrostatic zipping amplified by a small drop of dielectric liquid |

|

|

|

| Twisted and coiled polymer | Contraction or expansion upon Joule heating |

|

|

|

| Elastomer composite and elastomeric pouch phase changing actuators | Volumetric expansion due to the vaporization of a phase changing material |

|

|

|

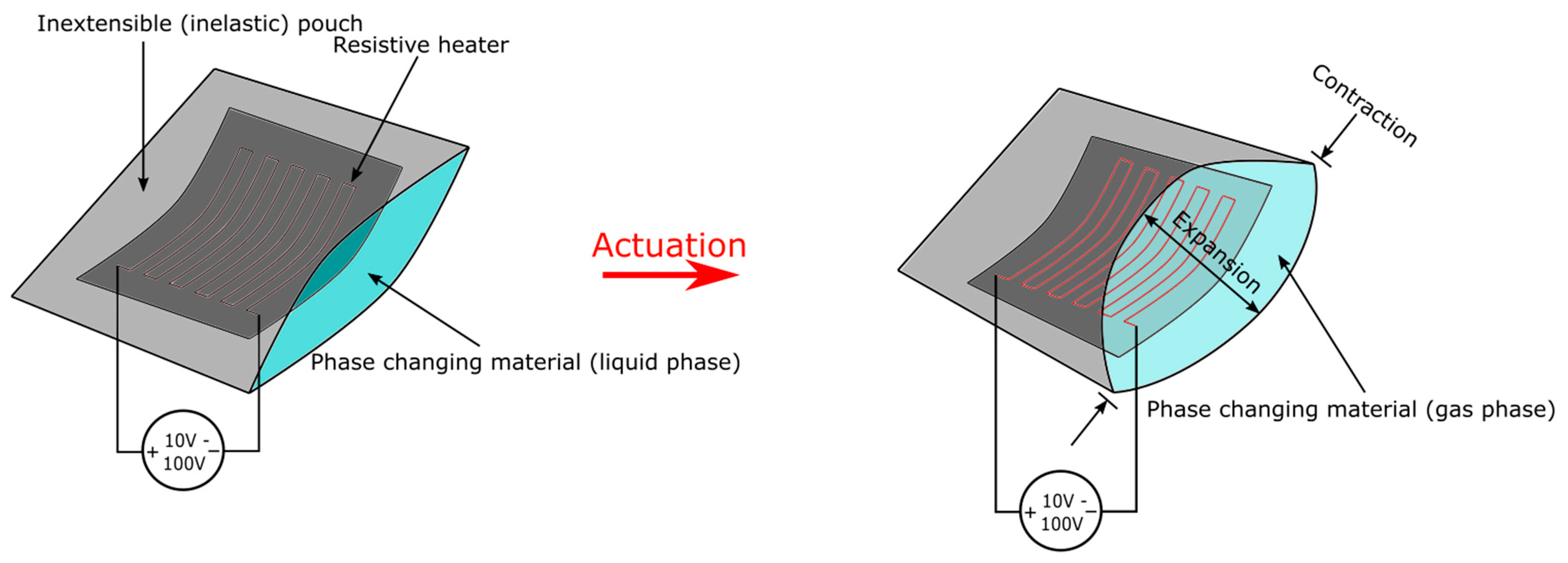

| Type of Actuator | Linear Strain | Operating Frequency | Specific Energy | Specific Work | Maximum Stress | Energy Efficiency |

|---|---|---|---|---|---|---|

| DEA | 3–30% typical (Max at 215% [14]) | 0–550 Hz typical (Max > 1000 Hz [17,18]) | <20 J/kg typical (Max at 1150 J/kg [108]) | 100–200 W/kg typical (Max at 1000 W/kg [18]) | <1 MPa typical (Max at 7.2 MPa [14])) | 1–30% typical (Max at 90% [14]) |

| Elastomeric HASEL | 30–50% typical (Max at 124% [42]) | 0–20 Hz typical | 70 J/kg typical [42] | Average specific work of 337 W/kg typical (Peak power at 614 W/kg [42]) | 0.002–0.3 MPa typical [42] | 21% typical (Data from donut HASEL [42]) |

| Thermoplastic HASEL | 10–25% typical (Max 118% [51]) | 0–25 Hz typical (Max at 50 Hz [43]) | 5–12 J/kg typical (Max at 12 J/kg [44,51]) | Average specific work of 100–180 W/kg typical (Peak power at 365 W/kg [49]) | 0.03–0.2 MPa typical (Max at 0.21 MPa [43,44]) | 13.6–19% Typical [51] |

| Electro-ribbon | 99.84% [59] | 0.125 Hz for full actuation [59] | 6.88 J/kg [59] | 51.45 W Average (Peak power at 104 W/kg [59]) | 0.048 MPa [59] | 70% [59] |

| Twisted and coiled polymer | 20–50% typical (Max at 55% [75] from a free-stroke TCP) | <1 Hz typical (Max at 20 Hz, [70], 3% actuation at this frequency) | 1000–2000 J/kg typical (Max at 2480 J/kg [70]) | 1000–27,900 W/kg typical (27,900 W/kg [69]. 27,100 W/kg [70]) | 5–85 MPa typical (Max at 105 MPa [69], tensile contraction during this actuation was above 1%) | <1% typical (Max at 1.32% [70]) |

| Phase-changing actuator | 140% (Theoretical maximum at 140% (with no applied force) linear strain [86]) | <0.007 Hz typical (Actuation cycle of over 150 s [86]. The lowest reported actuation cycle is 20 s, which converts to 0.05 Hz. [88,94]) | - | - | 0.05–1.3 MPa typical (Max at 1.3 MPa [86]) | 0.2% (Calculated from the expansion process of a 20 vol% ethanol + PDMS matrix elastomer composite actuator [86]. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, Z.; Sameoto, D. A Review of Electrically Driven Soft Actuators for Soft Robotics. Micromachines 2022, 13, 1881. https://doi.org/10.3390/mi13111881

Ma Z, Sameoto D. A Review of Electrically Driven Soft Actuators for Soft Robotics. Micromachines. 2022; 13(11):1881. https://doi.org/10.3390/mi13111881

Chicago/Turabian StyleMa, Zhaoqi, and Dan Sameoto. 2022. "A Review of Electrically Driven Soft Actuators for Soft Robotics" Micromachines 13, no. 11: 1881. https://doi.org/10.3390/mi13111881

APA StyleMa, Z., & Sameoto, D. (2022). A Review of Electrically Driven Soft Actuators for Soft Robotics. Micromachines, 13(11), 1881. https://doi.org/10.3390/mi13111881