Simulation and Printing of Microdroplets Using Straight Electrode-Based Electrohydrodynamic Jet for Flexible Substrate

Abstract

1. Introduction

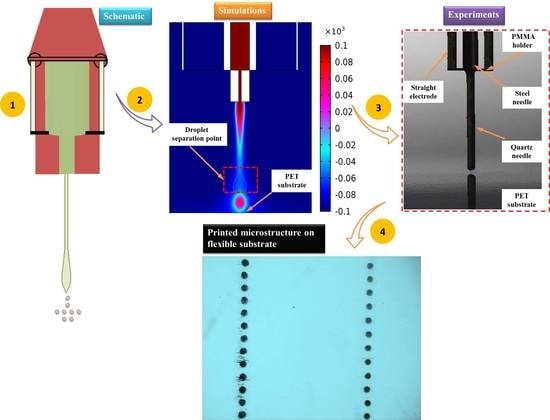

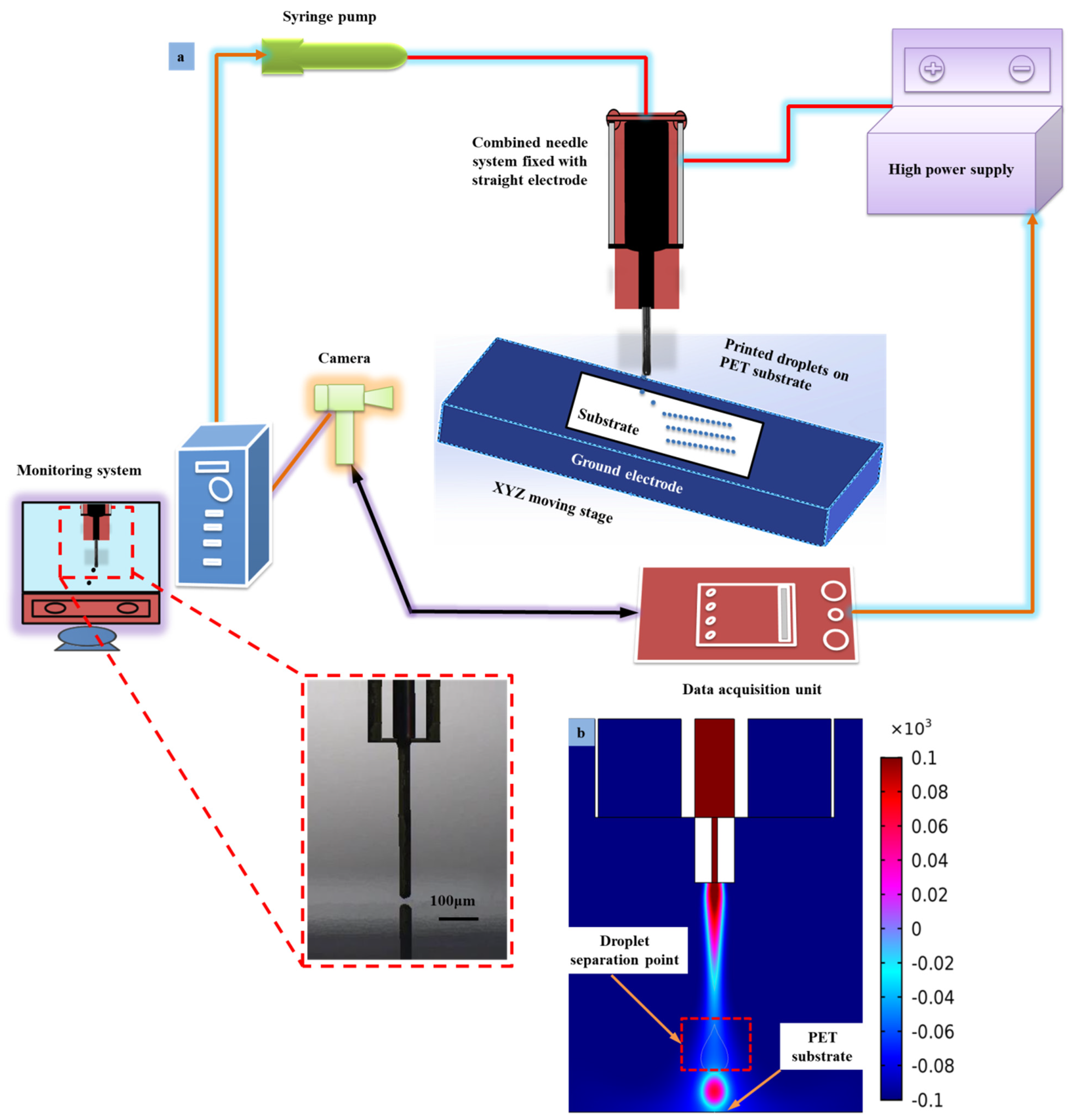

2. Computer Simulation and Experimentation

2.1. Materials

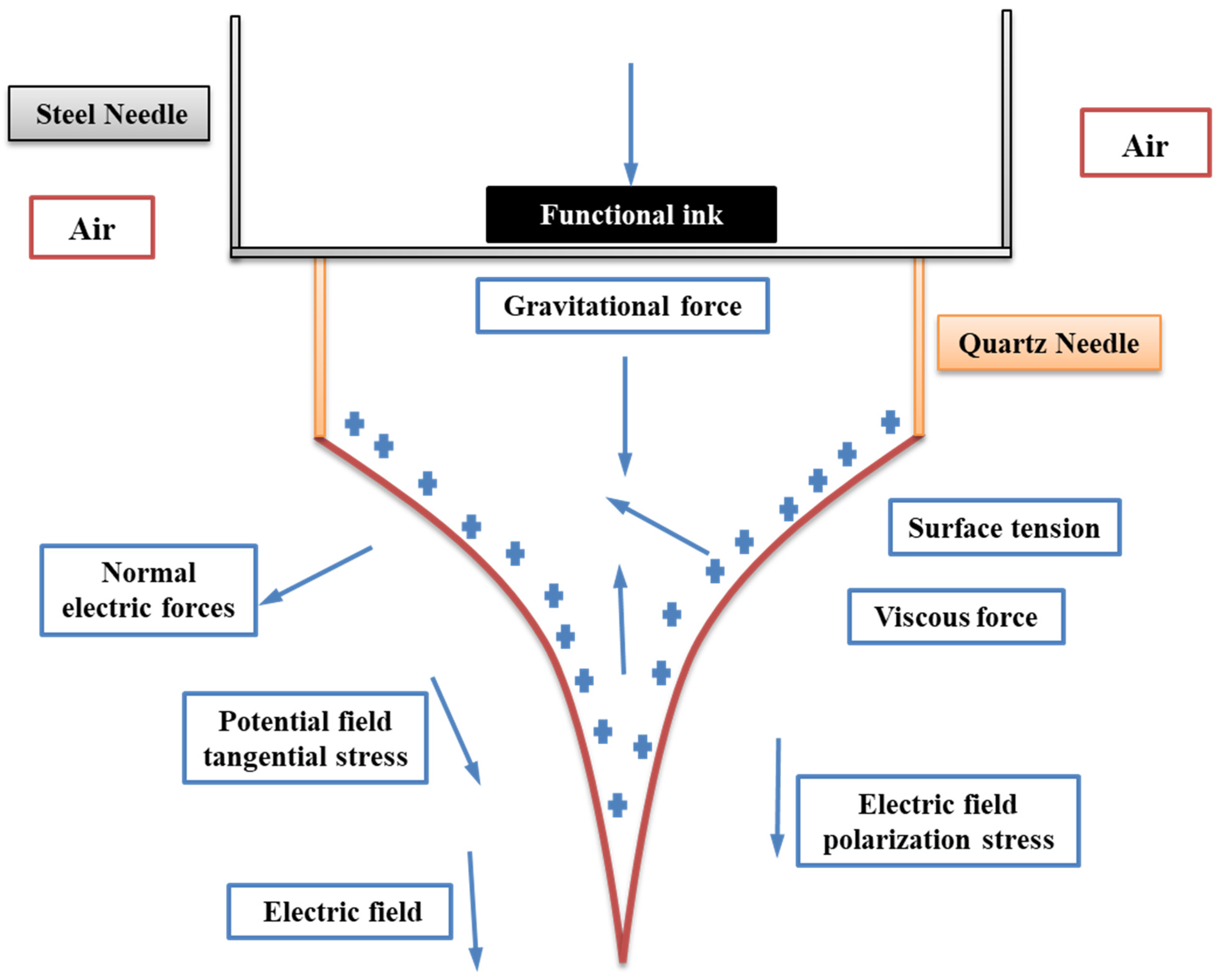

2.2. Formulations for Fluid Flow

2.3. Formulations for Electric Field

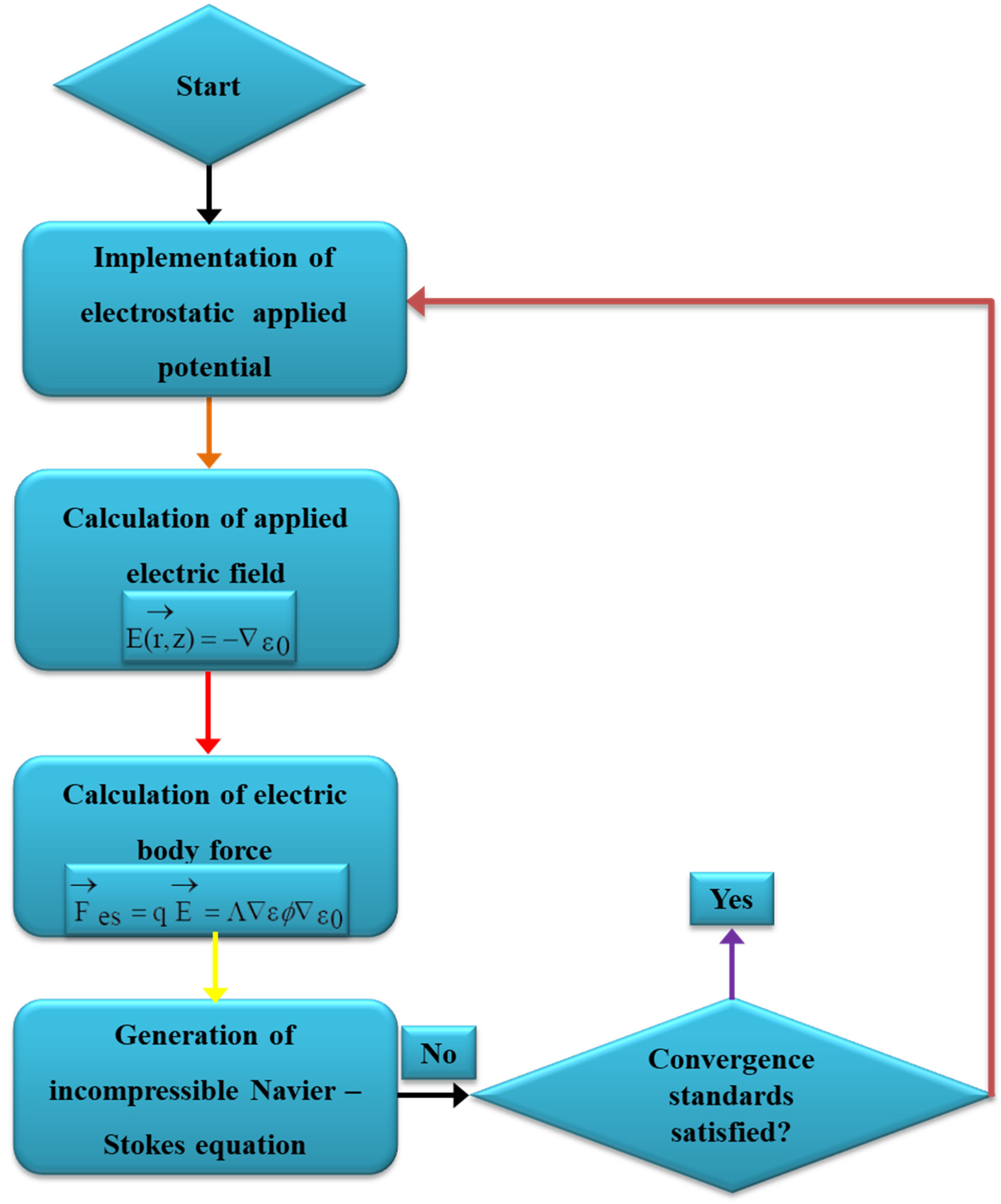

2.4. Process of Numerical Simulation

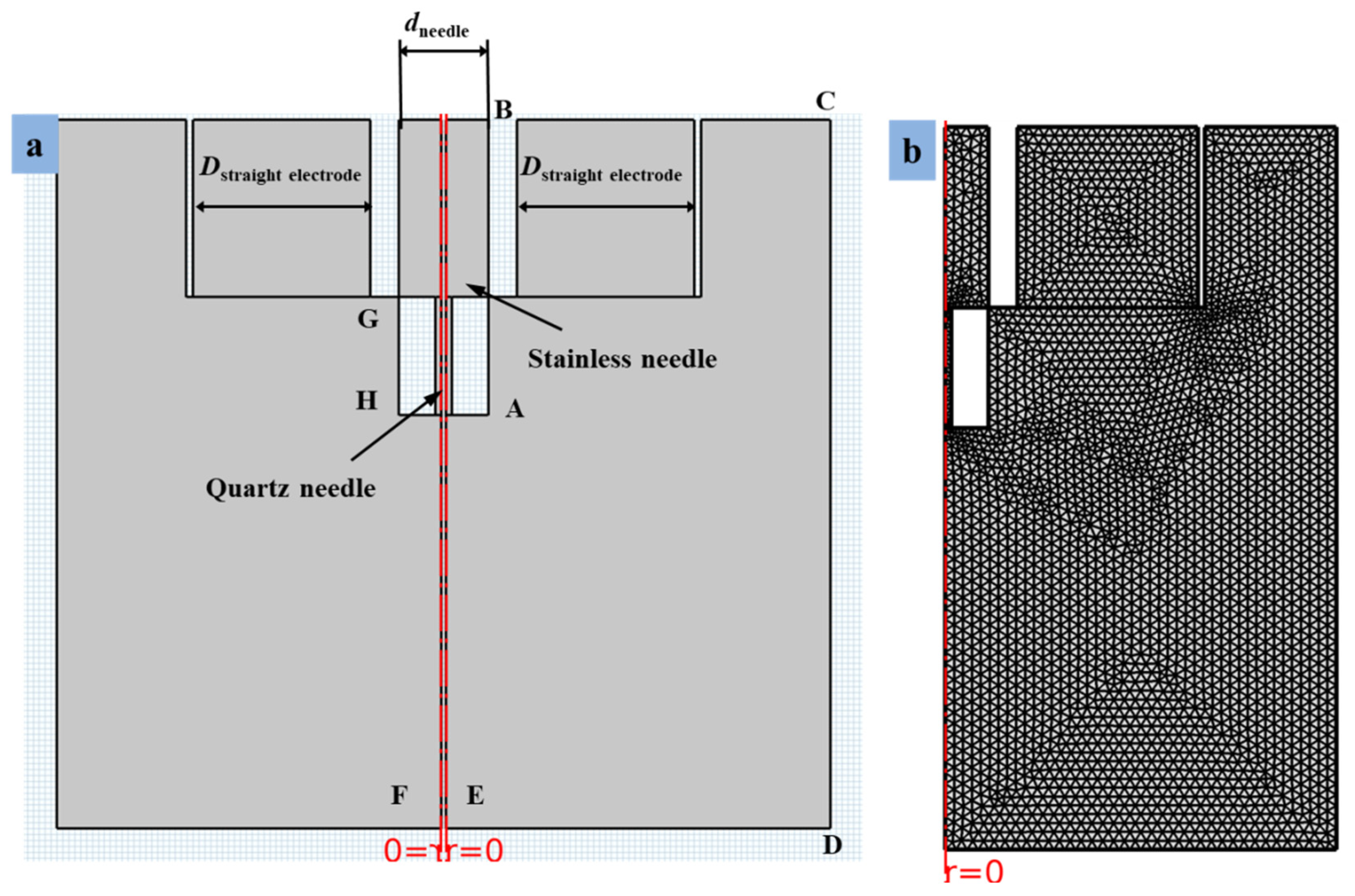

Establishment of Phase-Field Simulation Model

- (1)

- The transformation of a three-dimensional model into a two-dimensional axisymmetric model.

- (2)

- Disregard the needle’s outer diameter.

3. Results and Discussion

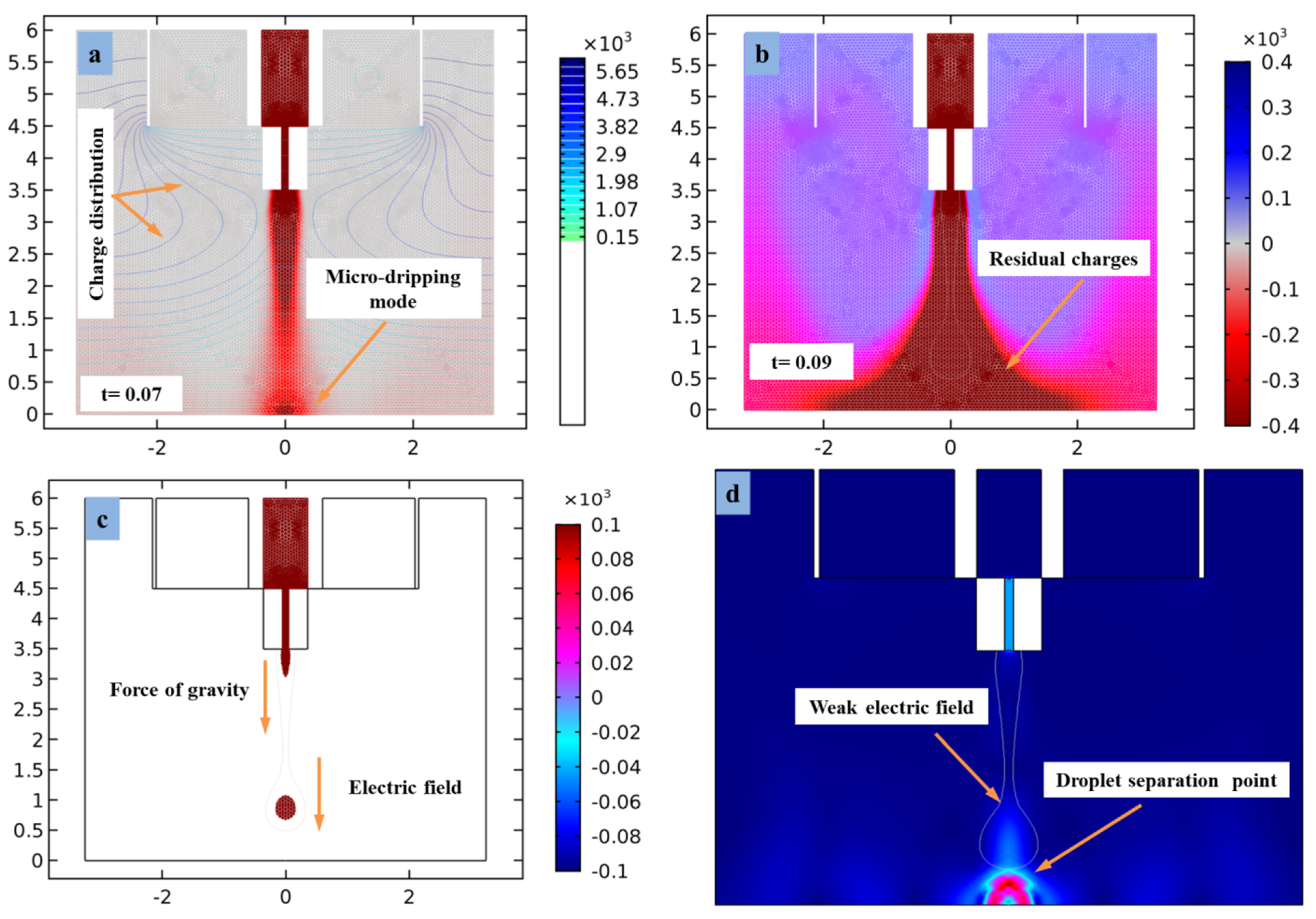

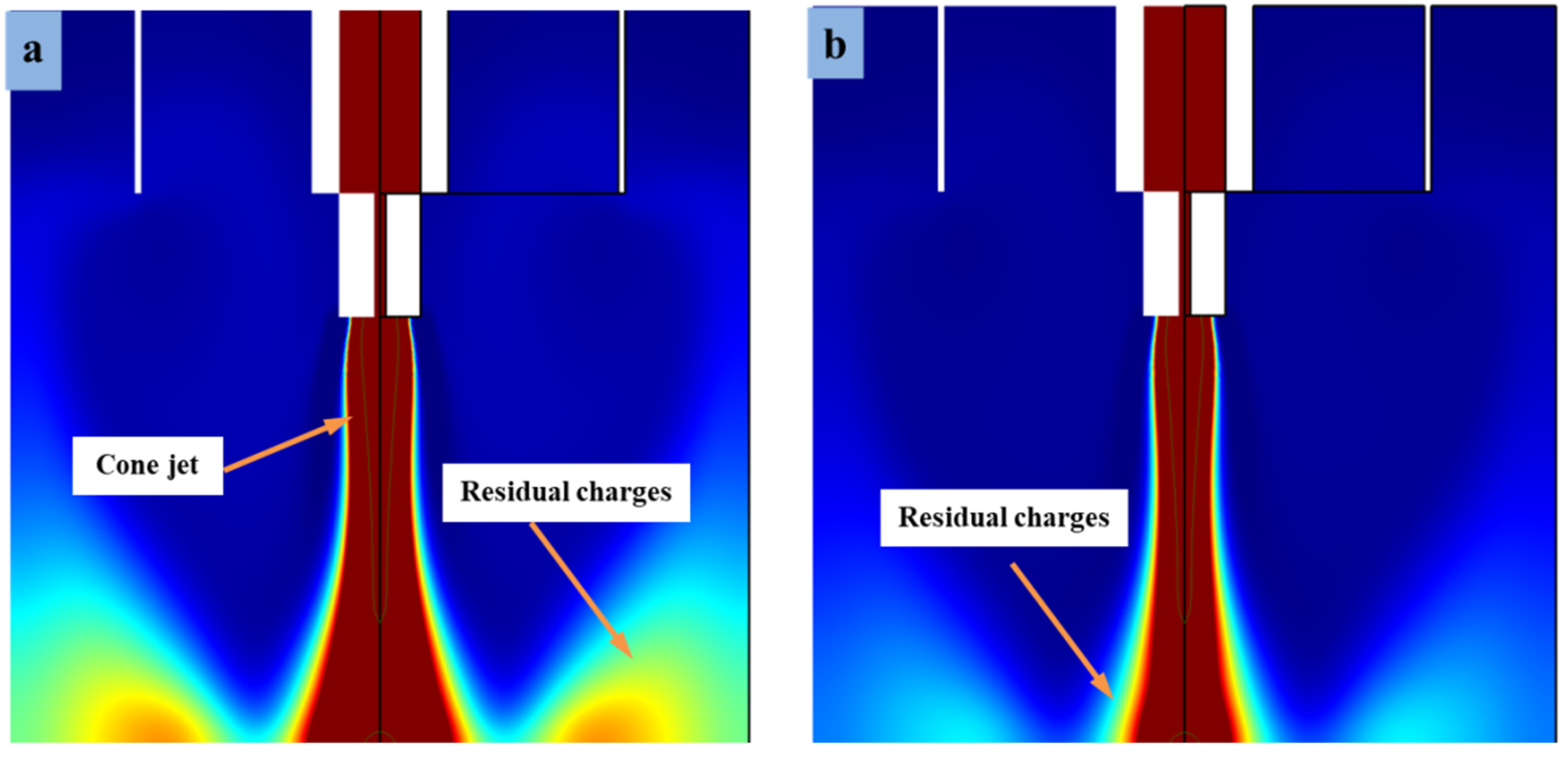

3.1. Electric Potential Influence on Cone Jet during 2D Plot Assembly

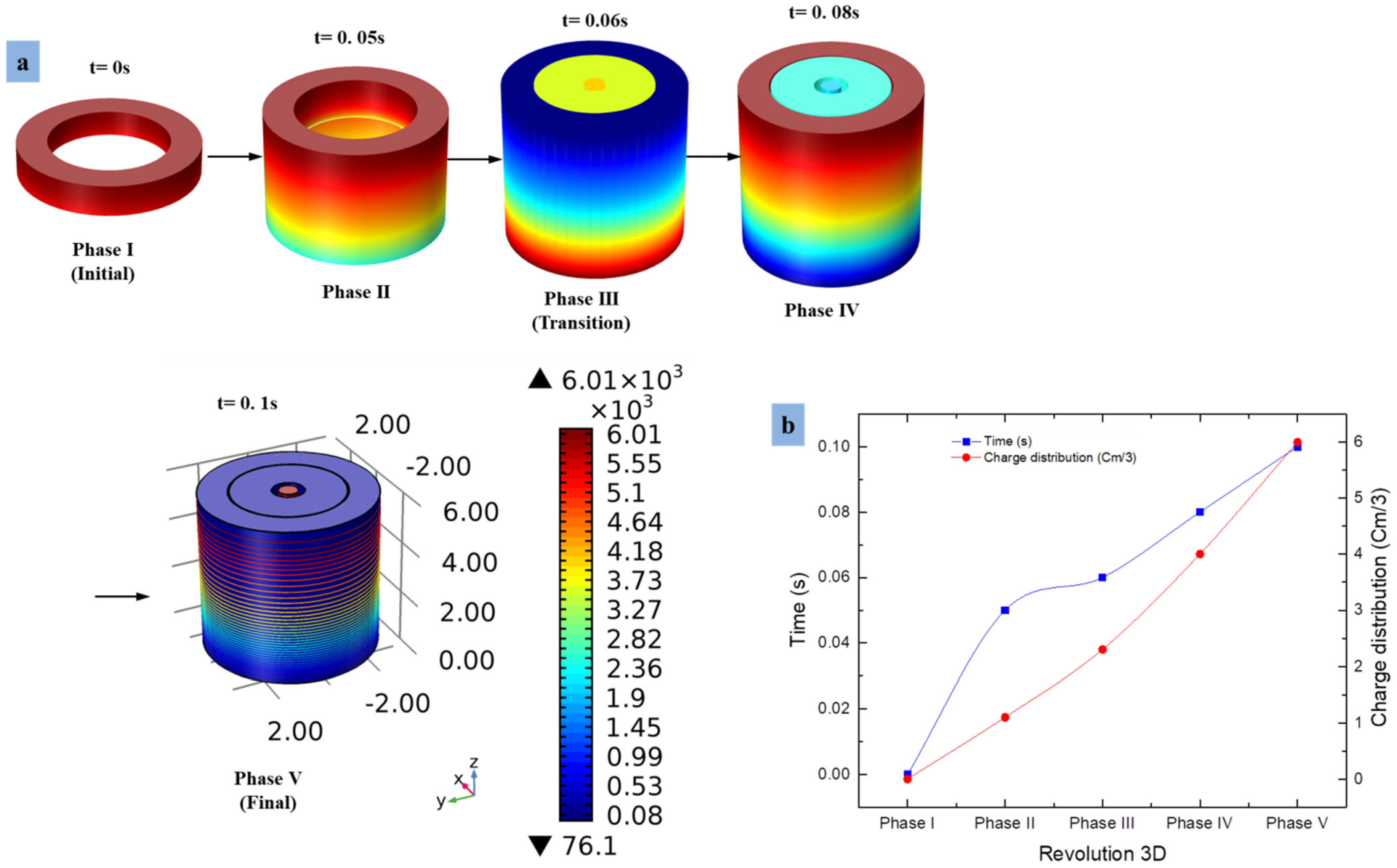

3.2. Electric Potential Evaluation during 3D Plot Assembly

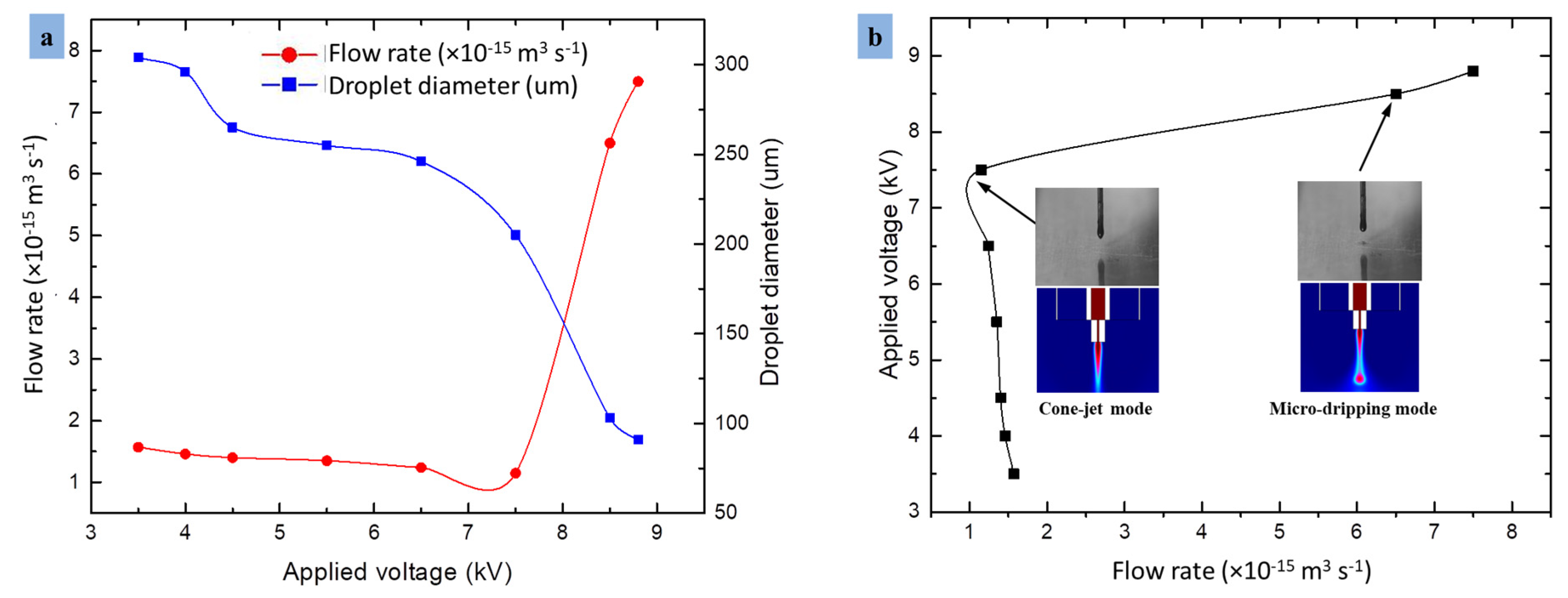

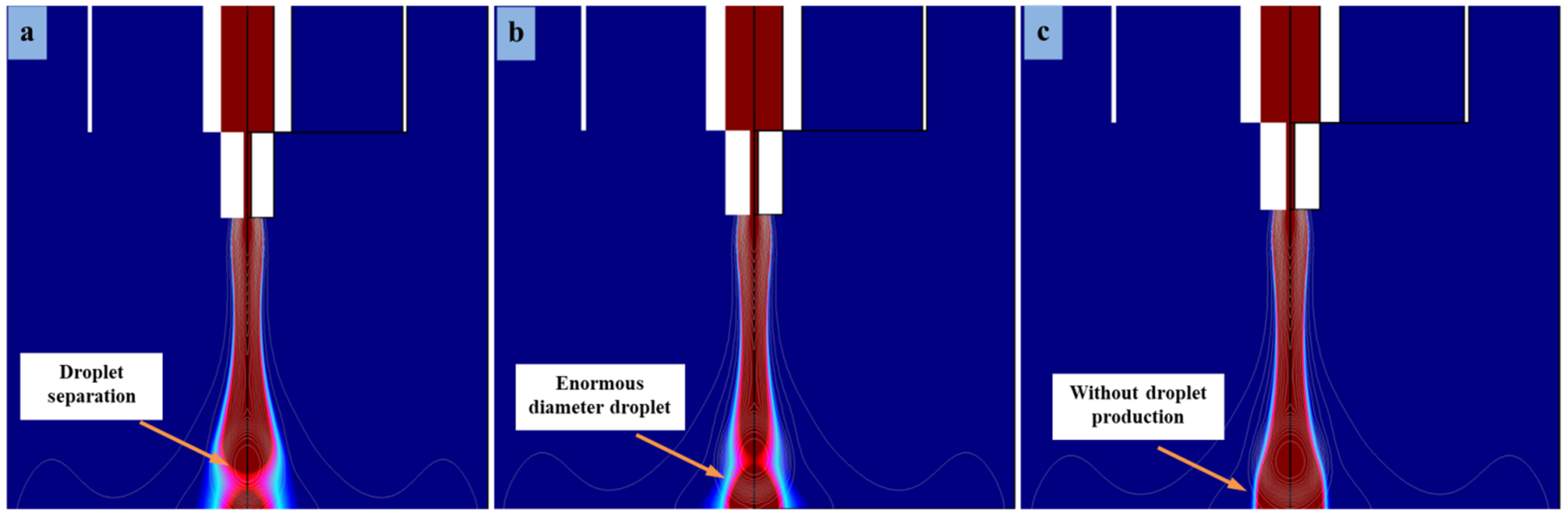

3.3. Influence of Applied Pulse Voltage on Microdroplet Generation

3.4. Influence of Flow Rate on Microdroplet Generation

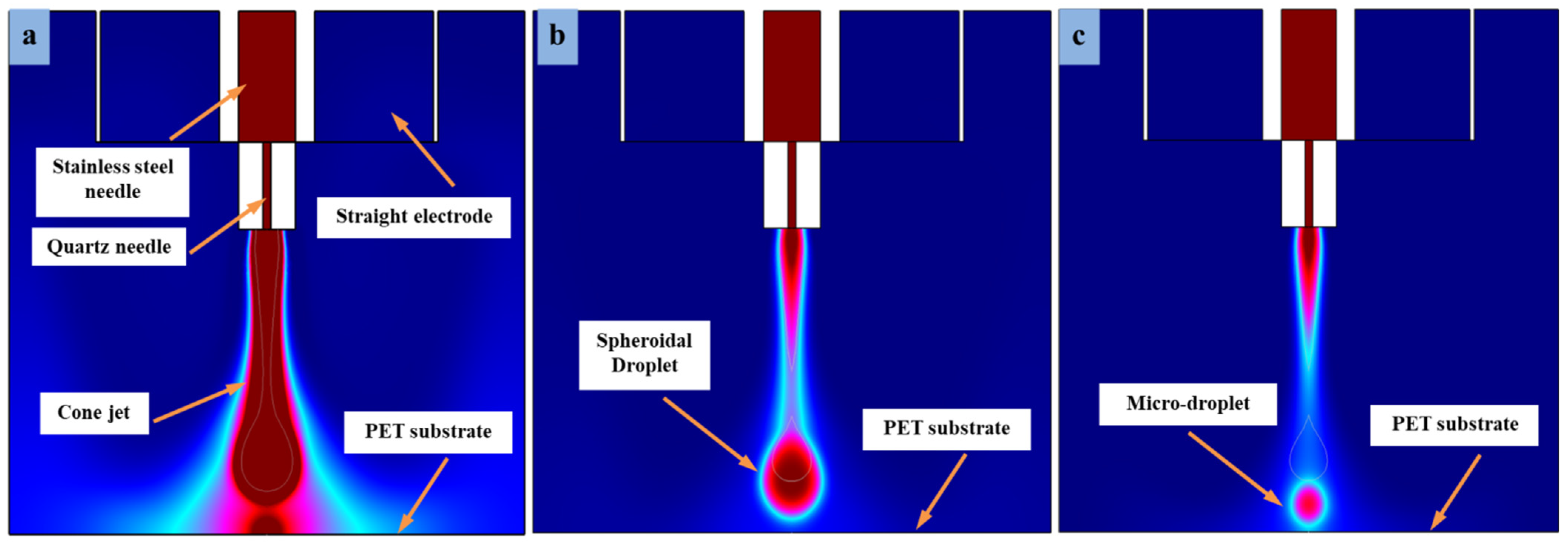

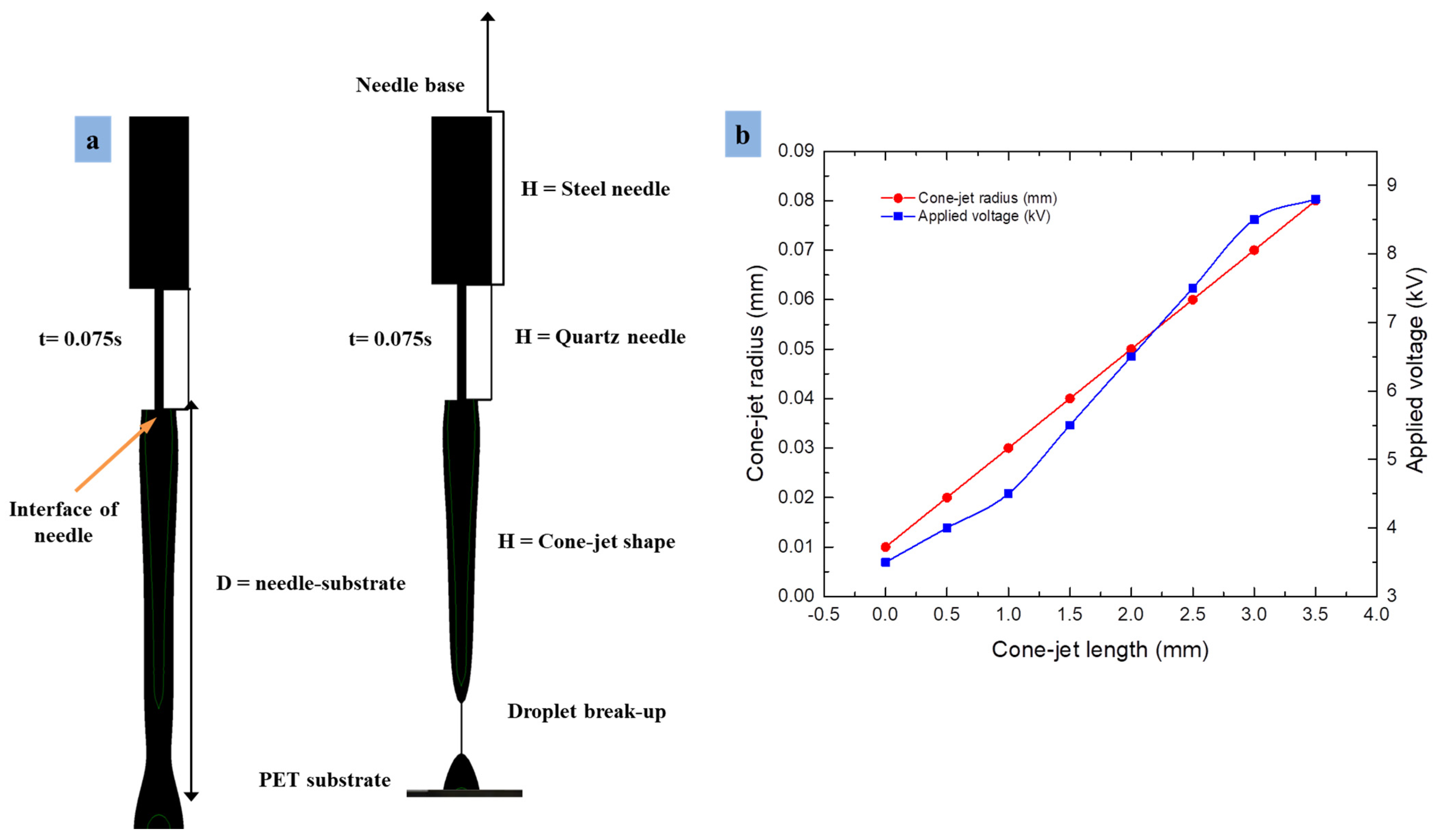

3.5. Influence of Needle–Substrate Distance on Cone-Jet Shape

3.6. Experimental Study under Optimized Simulation Results

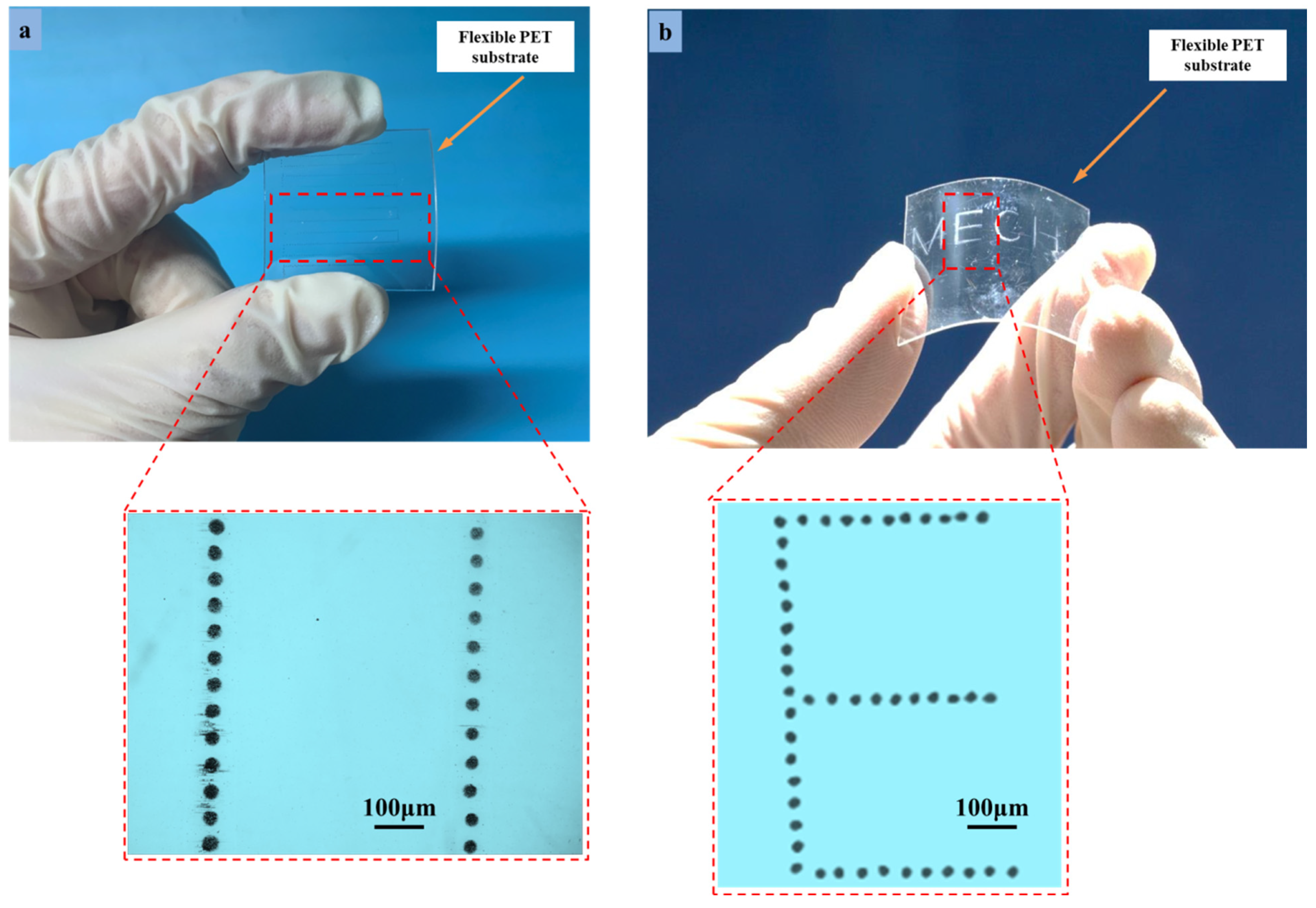

Printing of Droplets on Flexible Substrate

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Abbas, Z.; Wang, D.; Du, Z.; Qian, J.; Zhao, K.; Du, Z. Numerical simulation of electrohydrodynamic jet and printing micro- structures on flexible substrate. Microsyst. Technol. 2020, 27, 3125–3139. [Google Scholar] [CrossRef]

- Byun, D. Retreat behavior of a charged droplet for electrohydrodynamic inkjet printing. Appl. Phys. Lett. 2011, 98, 083501. [Google Scholar]

- Khan, A.; Rahman, K.; Kim, D.S.; Choi, K.H. Direct printing of copper conductive micro-tracks by multi-nozzle electrohydrodynamic inkjet printing process. J. Mater. Process. Technol. 2012, 212, 700–706. [Google Scholar] [CrossRef]

- Jayasinghe, S.N.; Edirisinghe, M.J.; Wang, D.Z. Controlled deposition of nanoparticle clusters by electrohydrodynamic atomization. Nanotechnology 2004, 15, 1519. [Google Scholar] [CrossRef]

- Nguyen, T.K.; Dat Nguyen, V.; Byun, D.; Park, J. Stabilizing meniscus shape to improve pattern uniformity in Drop-on-demand EHD inkjet printing using visual feedback. In Proceedings of the 2012 12th International Conference on Control, Automation and Systems, Jeju, Korea, 17–21 October 2012; pp. 392–394. [Google Scholar]

- Park, Y.; Oh, O.; Noh, M.D. Ejection Feasibility of High Viscosity Fluid with Magnetostrictive Inkjet Printhead. Int. J. Precis. Eng. Manuf. 2015, 16, 1369–1374. [Google Scholar] [CrossRef]

- Abbas, Z.; Wang, D.; Du, Z.; Zhao, K.; Du, Z.; Lu, L. Microelectronic Engineering Numerical simulation of stable electrohydrodynamic cone-jet formation and printing on flexible substrate. Microelectron. Eng. 2021, 237, 111496. [Google Scholar] [CrossRef]

- Sirringhaus, H.; Kawase, T.; Friend, R.H.; Shimoda, T.; Inbasekaran, M.; Wu, W.; Woo, E.P. High-resolution inkjet printing of all-polymer transistor circuits. Science 2000, 290, 2123–2126. [Google Scholar] [CrossRef]

- Hebner, T.R.; Wu, C.C.; Marcy, D.; Lu, M.H.; Sturm, J.C. Ink-jet printing of doped polymers for organic light emitting devices. Appl. Phys. Lett. 1998, 72, 519–521. [Google Scholar] [CrossRef]

- Townsend-Nicholson, A.; Jayasinghe, S.N. Cell electrospinning: A unique biotechnique for encapsulating living organisms for generating active biological microthreads/scaffolds. Biomacromolecules 2006, 7, 3364–3369. [Google Scholar] [CrossRef]

- Mabrook, M.F.; Pearson, C.; Petty, M.C. An inkjet-printed chemical fuse. Appl. Phys. Lett. 2005, 86, 1–4. [Google Scholar] [CrossRef]

- Choi, J.; Lee, S.; Kim, Y.J.; Son, S.U.; An, K.C. High aspect ratio EHD printing with high viscosity ink ejection. In Technical Proceedings of the 2012 NSTI Nanotechnology Conference and Expo, NSTI-Nanotech 2012; TechConnect Briefs: Washington, DC, USA; Volume 2, pp. 267–270.

- Choi, J.; Kim, Y.J.; Lee, S.; Son, S.U.; Ko, H.S.; Nguyen, V.D.; Byun, D. Drop-on-demand printing of conductive ink by electrostatic field induced inkjet head. Appl. Phys. Lett. 2008, 93, 87–90. [Google Scholar] [CrossRef]

- Wei, C.; Qin, H.; Chiu, C.; Lee, Y.; Dong, J. Drop-on-demand E-jet printing of continuous interconnects with AC-pulse modulation on highly insulating substrates. J. Manuf. Syst. 2015, 37, 505–510. [Google Scholar] [CrossRef]

- Yuan, S.; Si, T.; Liu, Z.; Xu, R.X. Microfabrication of curcumin-loaded microparticles using coaxial electrohydrodynamic atomization. Rep. Mrk. Dye. Nanoparticles Mol. Probes Biomed. Appl. VI 2014, 8956, 895618. [Google Scholar]

- Lee, Y. Direct Printing and Electrical Characterization of Conductive Micro-Silver Tracks by Alternating Current-Pulse Modulated Electrohydrodynamic Jet Printing. J. Manuf. Sci. Eng. 2017, 139, 21008. [Google Scholar]

- Hartman, R.P.A.; Brunner, D.J.; Camelot, D.M.A.; Marijnissen, J.C.M.; Scarlett, B. Jet break-up in electrohydrodynamic atomization in the cone-jet mode. J. Aerosol Sci. 2000, 31, 65–95. [Google Scholar] [CrossRef]

- Wei, C.; Qin, H.; Ramírez-Iglesias, N.A.; Chiu, C.P.; Lee, Y.S.; Dong, J. High-resolution ac-pulse modulated electrohydrodynamic jet printing on highly insulating substrates. J. Micromech. Microeng. 2014, 24, 045010. [Google Scholar] [CrossRef]

- Jung, D.; Kim, Y.; Byun, D.; Kol, H.S.; Leel, S. Investigations of the Mechanisms of the Electrostatic Droplet E jections. In Proceedings of the 2006 1st IEEE International Conference on Nano/Micro Engineered and Molecular Systems, Zhuhai, China, 18–21 January 2006; pp. 2–5. [Google Scholar]

- Kim, J.; Oh, H.; Kim, S.S. Electrohydrodynamic drop-on-demand patterning in pulsed cone-jet mode at various frequencies. J. Aerosol Sci. 2008, 39, 819–825. [Google Scholar] [CrossRef]

- Yang, G.H.; Mun, F.; Kim, G.H. Direct electrospinning writing for producing 3D hybrid constructs consisting of microfibers and macro-struts for tissue engineering. Chem. Eng. J. 2016, 288, 648–658. [Google Scholar] [CrossRef]

- Singh, S.K.; Subramanian, A. Phase-field simulations of electrohydrodynamic jetting for printing nano-to-microscopic constructs. RSC Adv. 2020, 10, 25022–25028. [Google Scholar] [CrossRef]

- Pan, Y. Simulation and Validation of Droplet Generation Process for Revealing Three Design Constraints in Electrohydrodynamic Jet Printing. Micromachines 2019, 10, 94. [Google Scholar] [CrossRef]

- Pan, Y.; Zeng, L. Fabrication and evaluation of a printhead with integrated electrodes for electrohydrodynamic jet printing on insulating substrate Fabrication and evaluation of a printhead with integrated electrodes for electrohydrodynamic jet printing on insulating subst. J. Phys. Conf. Ser. 2019, 1213, 052118. [Google Scholar] [CrossRef]

- Panahi, A.; Pishevar, A.R.; Tavakoli, M.R. Numerical simulation of jet mode in electrospraying of Newtonian and viscoelastic fluids. Int. J. Multiph. Flow 2020, 129, 103302. [Google Scholar] [CrossRef]

- Wang, C.; Smith, K.A. Numerical Simulation of Cone-Jet Formation in Electrohydrodynamic Atomization. AIChE J. 2011, 57, 57–78. [Google Scholar]

- Jaworek, A.; Sobczyk, A.T.; Krupa, A. Electrospray application to powder production and surface coating. J. Aerosol Sci. 2018, 125, 57–92. [Google Scholar] [CrossRef]

- Schnitzer, O.; Yariv, E. The Taylor-Melcher leaky dielectric model as a macroscale electrokinetic description. J. Fluid Mech. 2015, 773, 1–33. [Google Scholar] [CrossRef]

- Saville, D.A. Electrohydrodynamics:The Taylor-Melcher Leaky Dielectric Model. Annu. Rev. Fluid Mech. 1997, 29, 27–64. [Google Scholar] [CrossRef]

- Jacqmin, D. Calculation of Two-Phase Navier-Stokes Flows Using Phase-Field Modeling. J. Comput. Phys. 1999, 155, 96–127. [Google Scholar] [CrossRef]

- Herrada, M.A.; Vega, E.J.; Montanero, J.M.; Popinet, S. Numerical simulation of electrospray in the cone-jet mode. Phys. Rev. E 2012, 86, 026305. [Google Scholar] [CrossRef]

- Boyer, F.; Lapuerta, C.; Minjeaud, S.; Piar, B.; Quintard, M. Cahn-Hilliard/Navier-Stokes model for the simulation of three-phase flows. Transp. Porous Media 2010, 82, 463–483. [Google Scholar] [CrossRef]

- Sheehy, P.; Owkes, M. Numerical study of electric reynolds number on electrohydrodynamic (EHD) assisted atomization. At. Sprays 2017, 27, 645–664. [Google Scholar] [CrossRef]

- Kim, S.Y.; Kim, Y.; Park, J.; Hwang, J. Design and evaluation of single nozzle with a non-conductive tip for reducing applied voltage and pattern width in electrohydrodynamic jet printing (EHDP). J. Micromech. Microeng. 2010, 20, 055009. [Google Scholar] [CrossRef]

- Zhao, X.; Wang, D.; Lin, Y.; Sun, Y.; Ren, T.; Liang, J.; Madou, M. Numerical simulation of coaxial electrohydrodynamic jet and printing nanoscale structures. Microsyst. Technol. 2019, 25, 4651–4661. [Google Scholar] [CrossRef]

- Lastow, O.; Balachandran, W. Numerical simulation of electrohydrodynamic (EHD) atomization. J. Electrost. 2006, 64, 850–859. [Google Scholar] [CrossRef]

- Abbas, Z.; Wang, D.; Lu, L.; Du, Z.; Zhao, X.; Zhao, K.; Si, M.; Yin, P.; Zhang, X.; Cui, Y.; et al. The Focused Electrode Ring for Electrohydrodynamic Jet and Printing on Insulated Substrate. Int. J. Precis. Eng. Manuf. 2022, 23, 545–563. [Google Scholar] [CrossRef]

- Wang, D.; Abbas, Z.; Lu, L.; Zhao, X.; Xu, P.; Zhao, K.; Yin, P.; Liang, J. Numerical modeling and analysis of coaxial electrohydrodynamic jet printing. Sci. Rep. 2022, 12, 1924. [Google Scholar] [CrossRef]

- Wang, D.; Abbas, Z.; Lu, L.; Liang, S.; Zhao, X.; Xu, P.; Zhao, K.; Suo, L.; Cui, Y.; Yin, P.; et al. Simulation of Cone-Jet and Micro-Drip Regimes and Printing of Micro-Scale Patterns on PET Substrate. Polymers 2022, 14, 2683. [Google Scholar] [CrossRef]

- Wang, D.; Abbas, Z.; Du, Z.; Du, Z.; Lu, L.; Zhao, K.; Zhao, X.; Yuan, Y.; Zong, H.; Cui, Y.; et al. Phase field simulation of electrohydrodynamic jet droplets and printing microstructures on insulating substrates. Microelectron. Eng. 2022, 261, 111817. [Google Scholar] [CrossRef]

- Mkhize, N.; Bhaskaran, H. Electrohydrodynamic Jet Printing: Introductory Concepts and Considerations. Small Sci. 2022, 2, 2100073. [Google Scholar] [CrossRef]

- Kwon, H.J.; Hong, J.; Nam, S.Y.; Choi, H.H.; Li, X.; Jeong, Y.J.; Kim, S.H. Overview of recent progress in electrohydrodynamic jet printing in practical printed electronics: Focus on the variety of printable materials for each component. Mater. Adv. 2021, 2, 5593–5615. [Google Scholar] [CrossRef]

| Properties | Values |

|---|---|

| Dynamic viscosity | 360 mPa·s |

| Specific gravity | 1.16 |

| Shelf life | 365 days |

| Surface tension | 0.031 N/m |

| Dielectric constant | 3.24 |

| Storage modulus | 260 N/mm2 |

| Dissipation factor | 0.0088 |

| Boundary | Electrostatic Condition | Hydrodynamic Condition |

|---|---|---|

| A: Needle inlet | = 0 | u = Qinner/Ainner |

| B: Needle wall | = V0 | w = 0, u = 0 |

| C: Straight electrode wall | = V0 | w = 0, u = 0 |

| D: Straight electrode charge | = V0 | w = 0, u = 0 |

| E: Needle outlet | = 0 | u = Qouter/Aouter |

| G: Axi-symmetry | = 0 | = 0 |

| F: Boundary of computational territory | = 0 | p = 0, u = 0 |

| H: Air territory | = 0 | p = 0, u = 0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, D.; Abbas, Z.; Lu, L.; Liu, C.; Zhang, J.; Pu, C.; Li, Y.; Yin, P.; Zhang, X.; Liang, J. Simulation and Printing of Microdroplets Using Straight Electrode-Based Electrohydrodynamic Jet for Flexible Substrate. Micromachines 2022, 13, 1727. https://doi.org/10.3390/mi13101727

Wang D, Abbas Z, Lu L, Liu C, Zhang J, Pu C, Li Y, Yin P, Zhang X, Liang J. Simulation and Printing of Microdroplets Using Straight Electrode-Based Electrohydrodynamic Jet for Flexible Substrate. Micromachines. 2022; 13(10):1727. https://doi.org/10.3390/mi13101727

Chicago/Turabian StyleWang, Dazhi, Zeshan Abbas, Liangkun Lu, Chang Liu, Jie Zhang, Changchang Pu, Yikang Li, Penghe Yin, Xi Zhang, and Junsheng Liang. 2022. "Simulation and Printing of Microdroplets Using Straight Electrode-Based Electrohydrodynamic Jet for Flexible Substrate" Micromachines 13, no. 10: 1727. https://doi.org/10.3390/mi13101727

APA StyleWang, D., Abbas, Z., Lu, L., Liu, C., Zhang, J., Pu, C., Li, Y., Yin, P., Zhang, X., & Liang, J. (2022). Simulation and Printing of Microdroplets Using Straight Electrode-Based Electrohydrodynamic Jet for Flexible Substrate. Micromachines, 13(10), 1727. https://doi.org/10.3390/mi13101727