Simulation Study of FEUDT Structure Optimization and Sensitive Film Loading of SAW Devices

Abstract

:1. Introduction

2. Modeling of SAW Sensors

2.1. Simulation and Experimental Discussion

2.2. Mathematical Model Establishment

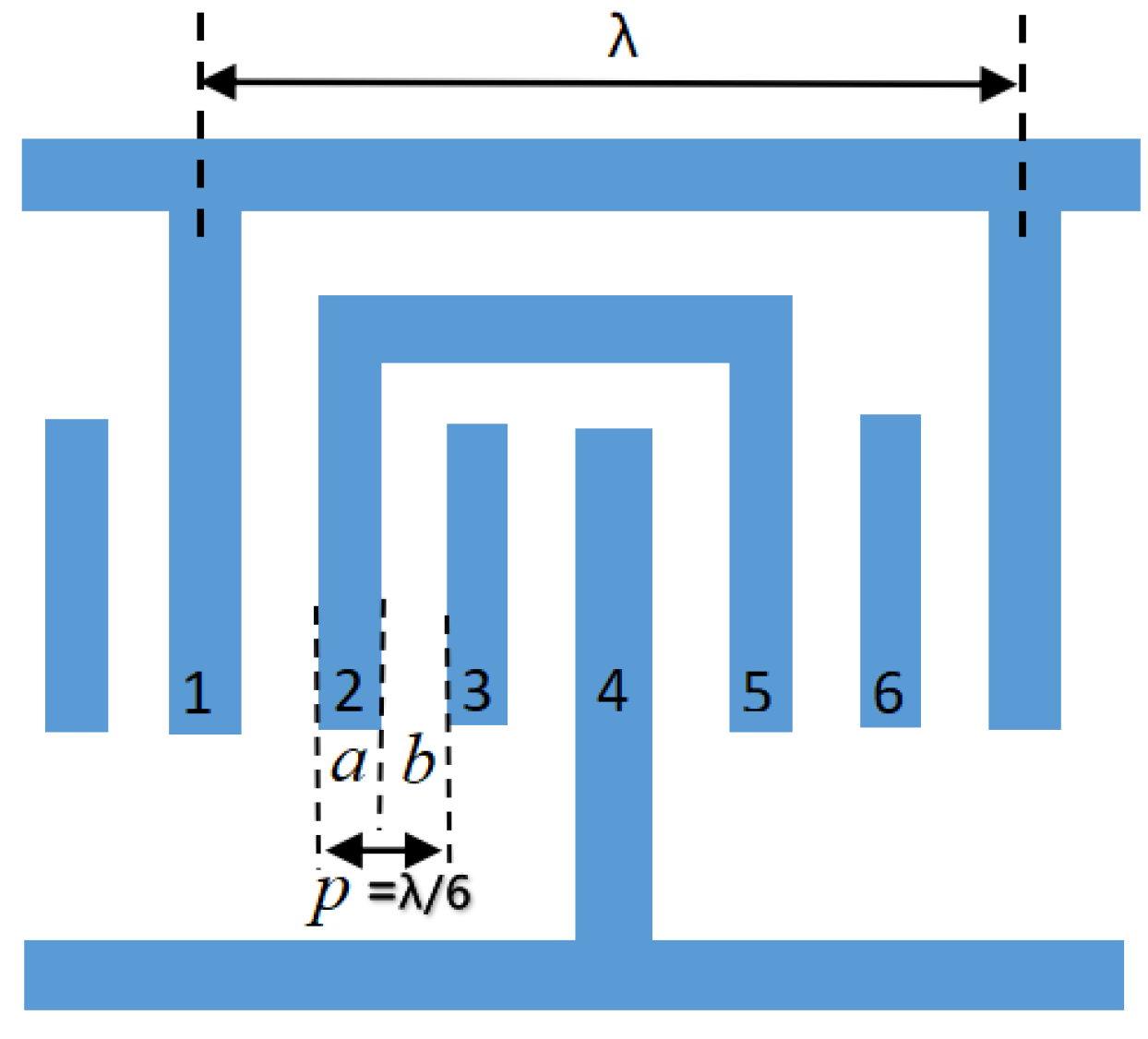

2.3. Two-Dimensional Modeling

3. Results and Discussion

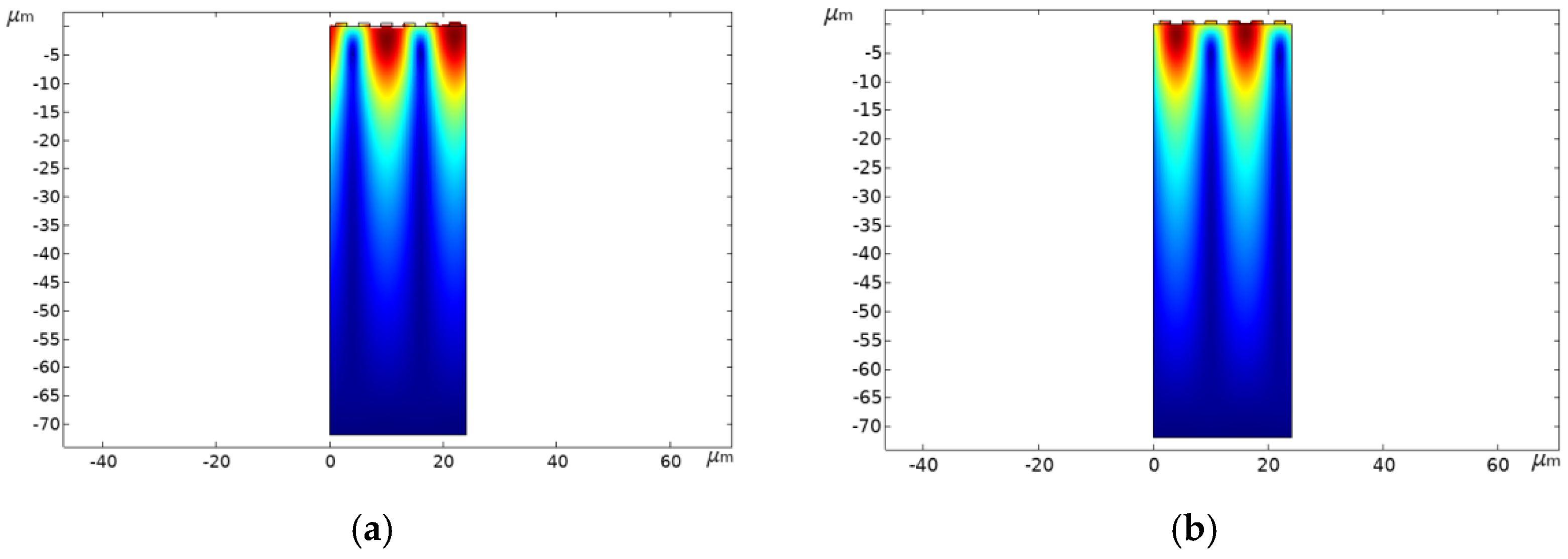

3.1. Modal Analysis

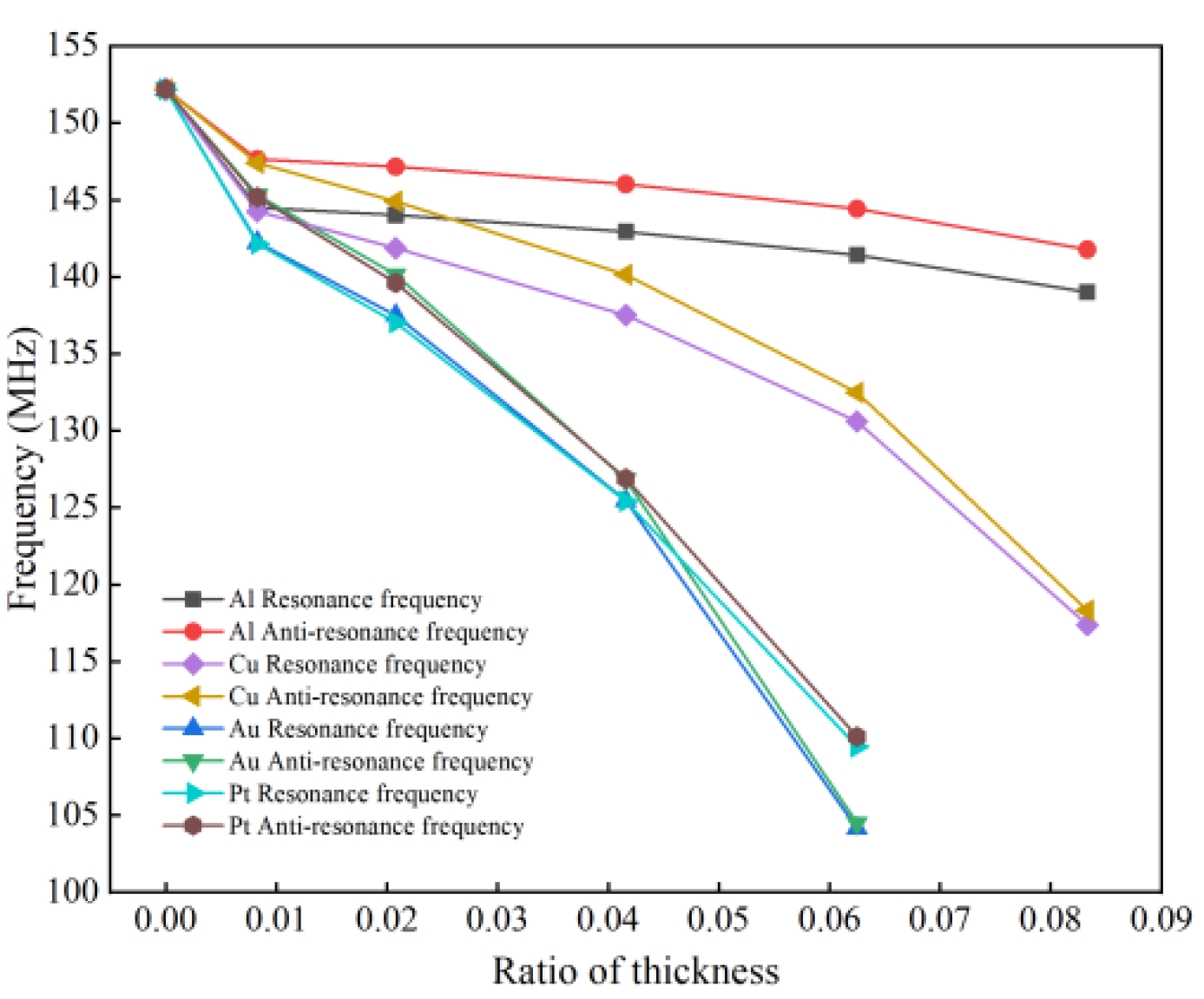

3.2. Thickness Ratio Analysis

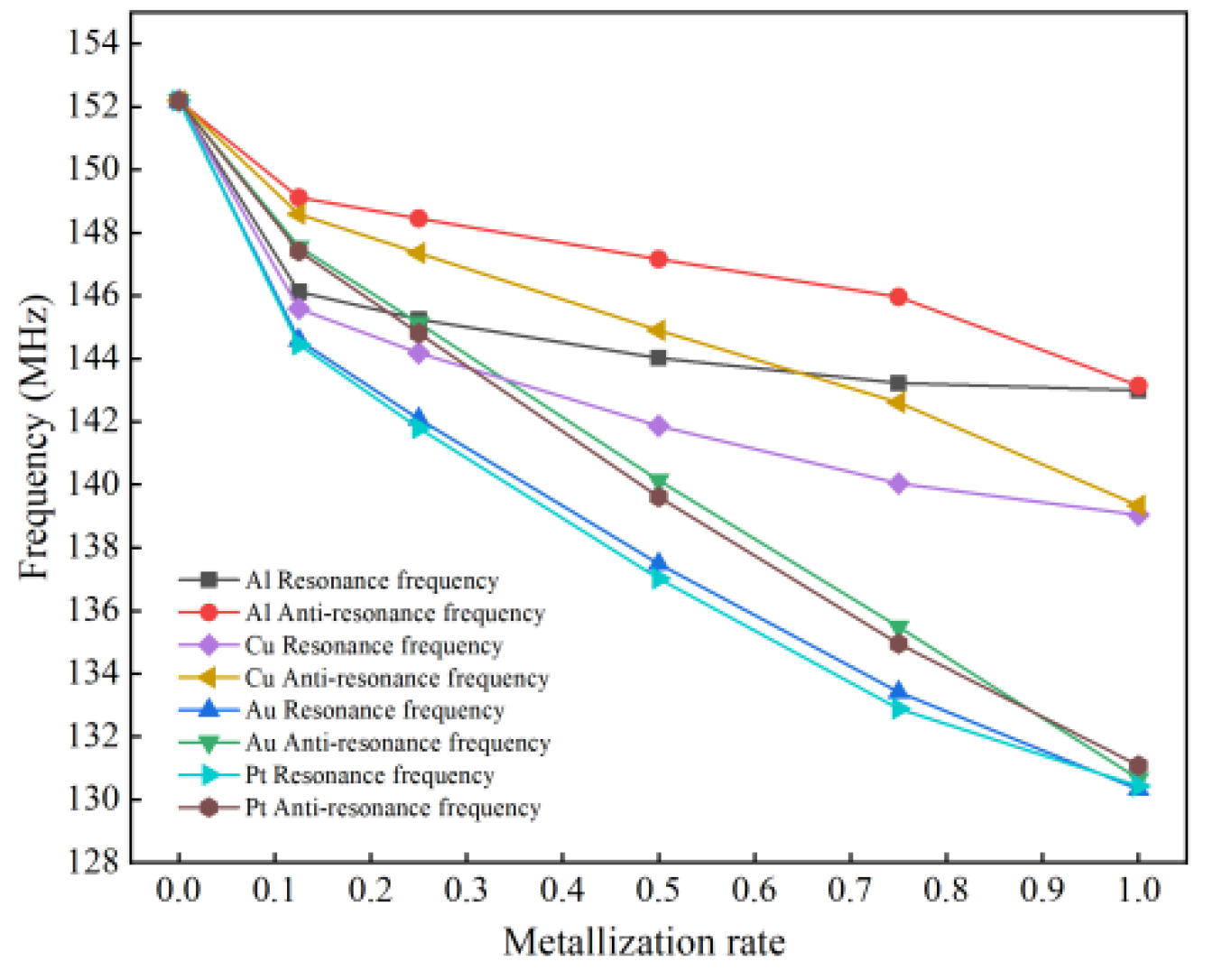

3.3. Metallization Rate Analysis

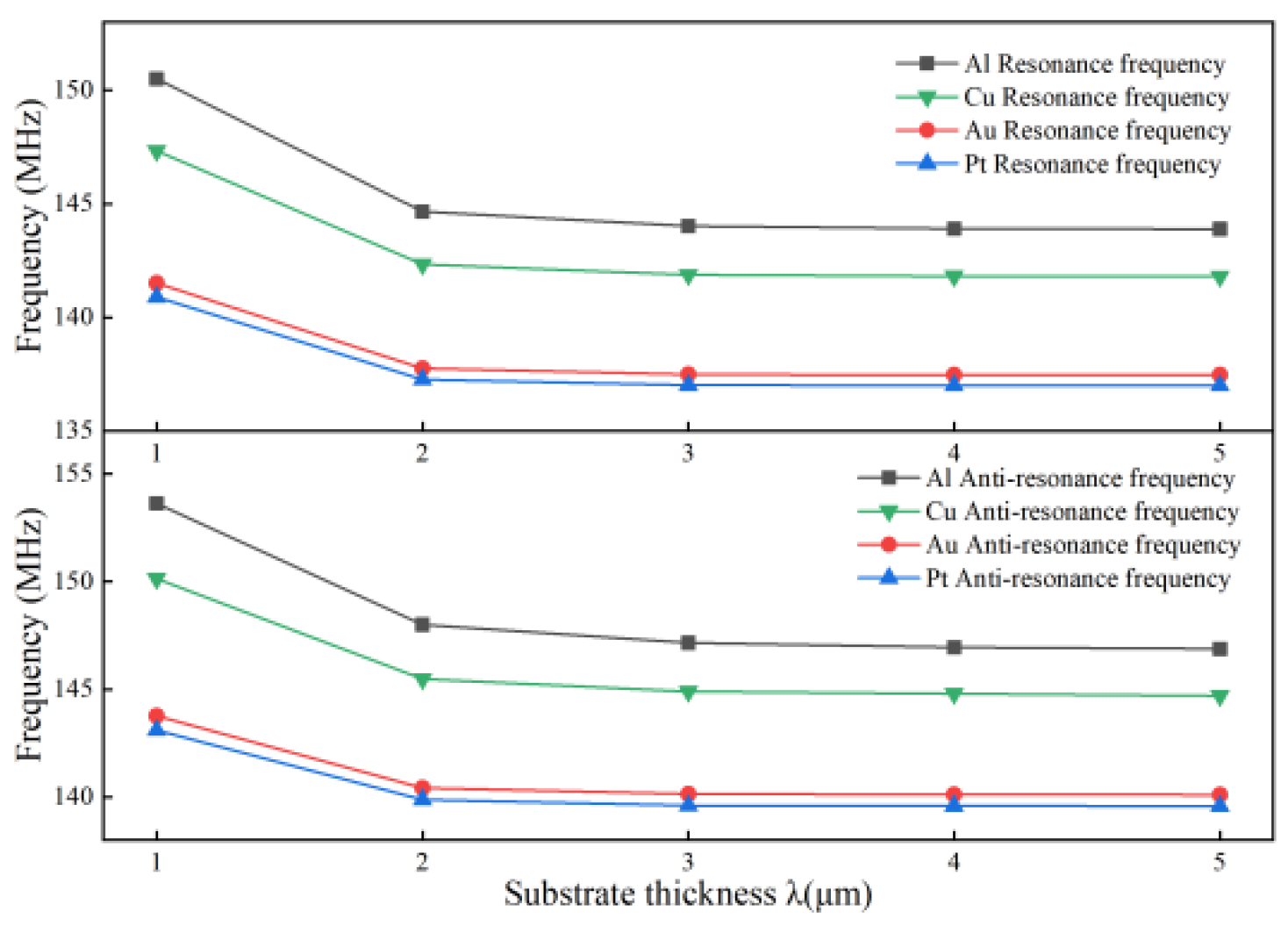

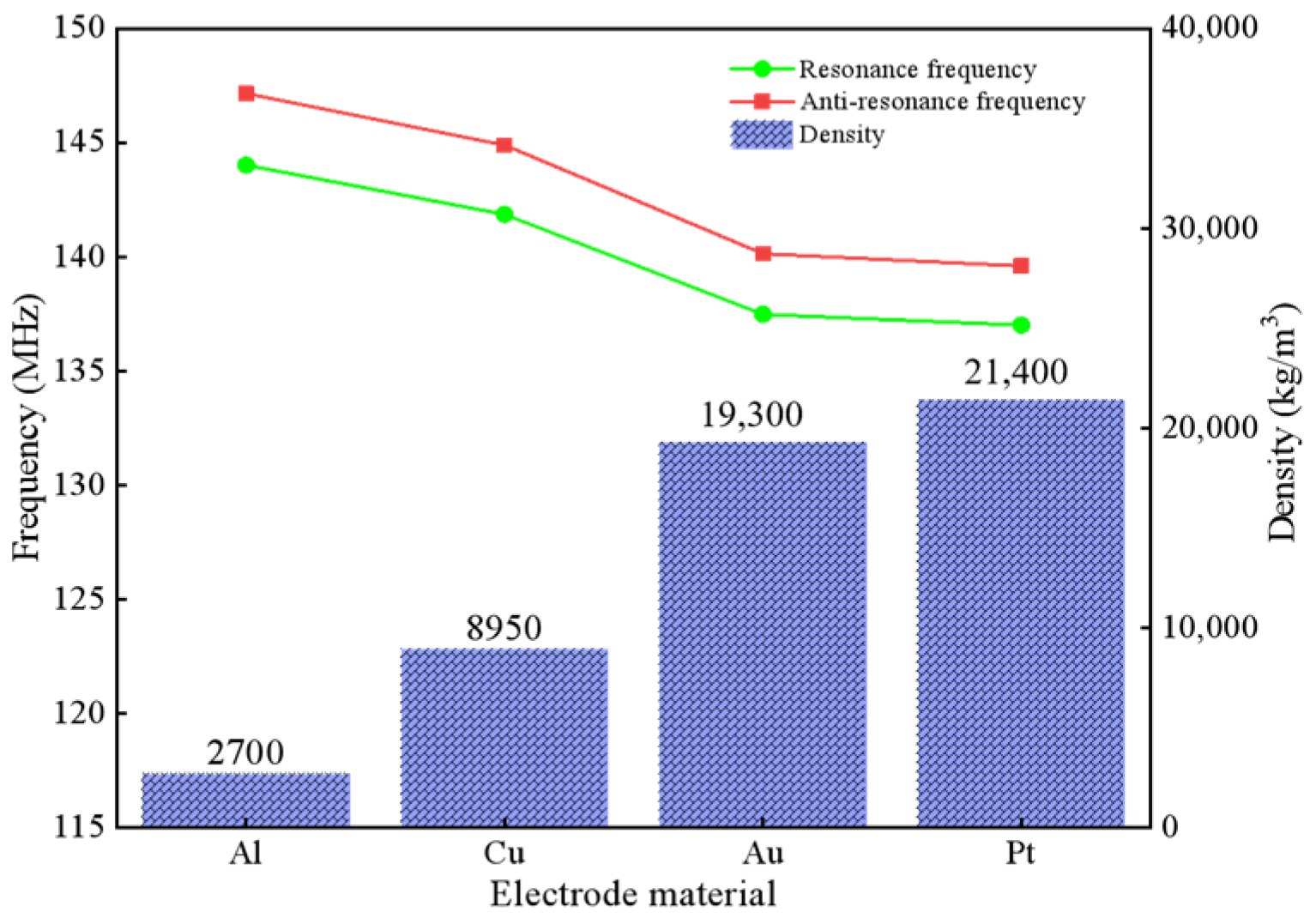

3.4. Electrode Material Analysis

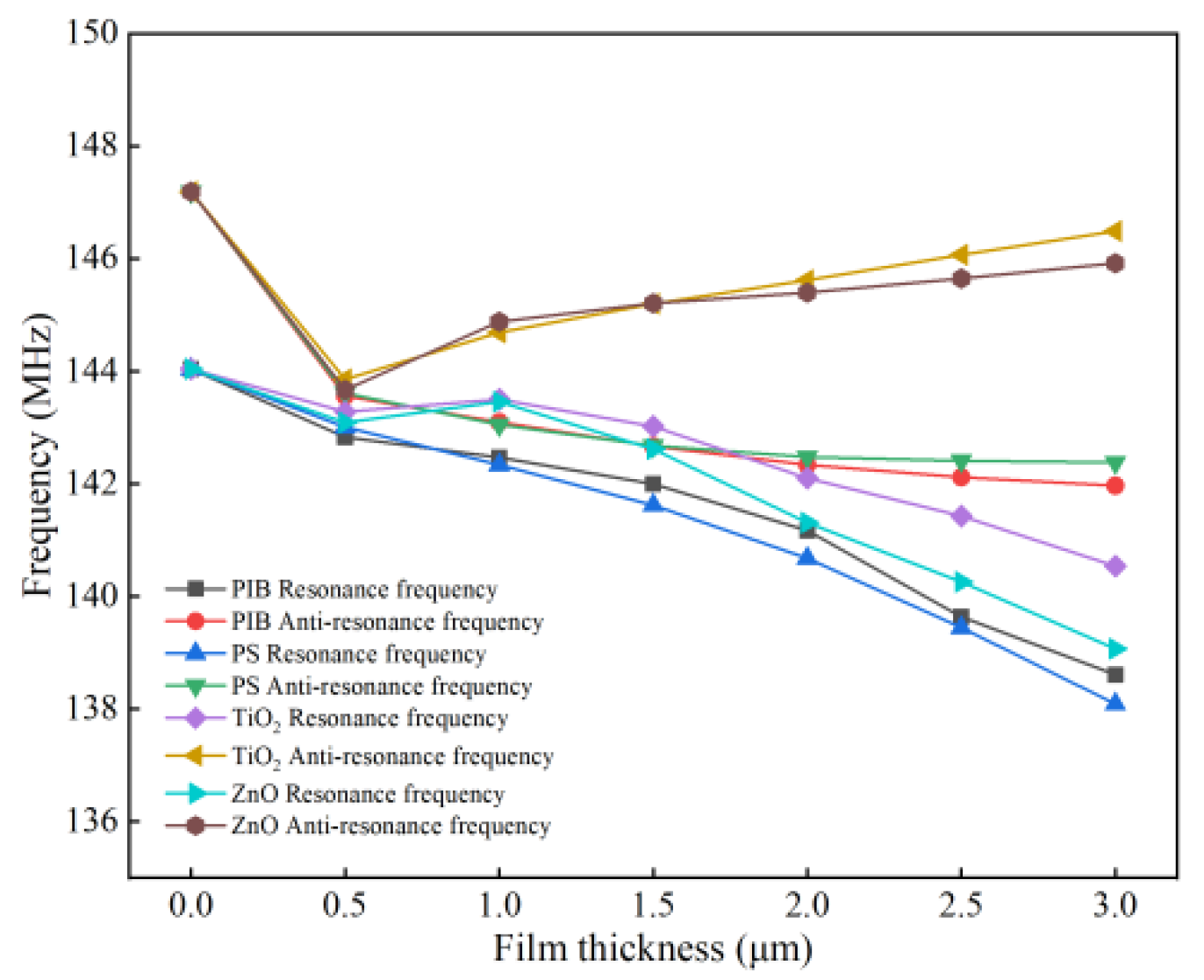

3.5. Film Thickness Analysis

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wen, W.; Xu, F.; He, S.; Li, S.; Lee, K. A new microrate sensor based on shear horizontal surface acoustic wave gyroscopic effect. Jpn. J. Appl. Phys. 2010, 49, 6602. [Google Scholar] [CrossRef]

- Yang, S.; Yu, J.; Zhang, Y.; Cheng, Z.; Lian, J.; Li, F. Impact of device parameters on performance of one—port type SAW resonators on AIN/sapphire. J. Micromech. Microeng. 2018, 28, 8. [Google Scholar] [CrossRef]

- Zhai, J.; Chen, C. Low-loss floating electrode unidirectional transducer for SAW sensor. Acoust. Phys. 2019, 65, 178–184. [Google Scholar] [CrossRef]

- Zhai, J. Optimized Design of SAW Gas Sensor and Sensitive Film Preparation. Master’s Thesis, Changchun University of Science and Technology, Changchun, China, 2019. [Google Scholar]

- Li, K. IDT Structure Optimization and SAW Device Research. Master’s Thesis, Tianjin University of Technology, Tianjin, China, 2021. [Google Scholar] [CrossRef]

- Liu, Z. Research on Wireless Passive Surface Acoustic Wave Devices and Sensor System. Master’s Thesis, Zhejiang University, Zhejiang, China, 2018. [Google Scholar]

- Xu, F.; Wang, W.; Xue, X.; Hu, H.; Liu, X.; Yong, P. Development of a Wireless and Passive SAW—Based Chemical Sensor for Organophosphorous Compound Detection. Sensors 2015, 15, 30187–30198. [Google Scholar] [CrossRef]

- He, K. Computational Simulation Study of COMSOL Finite Element for Stress—Assisted Diffusion Problem. Master’s Thesis, Harbin Institute of Technology, Harbin, China, 2019. [Google Scholar] [CrossRef]

- Liu, X. Research on Novel Structural Sound Surface Wave Devices. Master’s Thesis, Nanjing University of Posts and Telecommunications, Nanjing, China, 2020. [Google Scholar] [CrossRef]

- Xue, Q.; Sun, C.; Sun, Y. Finite element simulation of YX128-LiNbO_3 SAW sensor IDT. J. Harbin Inst. Technol. 2010, 42, 364–367. [Google Scholar] [CrossRef]

- Zhou, Z.; Tan, J.; Zhang, J.; Qin, M. Structural optimization and analysis of surface acoustic wave biosensor based on numerical method. Int. J. Distrib. Sens. Netw. 2019, 15, 9. [Google Scholar] [CrossRef]

- Pei, P. Design and Application of Aluminum Nitride Based Sound Surface Wave Sensor. Master’s Thesis, Nanjing University of Posts and Telecommunications, Nanjing, China, 2020. [Google Scholar] [CrossRef]

- Li, Y.; Shao, M.; Jiang, B.; Cao, L. Surface acoustic wave pressure sensor and its matched antenna design. Meas. Control 2019, 52, 947–954. [Google Scholar] [CrossRef]

- Peng, R.; Chen, Z.; Fu, D.; Zhang, Y.; Wang, M. Simulation of COMSOL—Based surface acoustic wave devices. J. Test Technol. 2012, 26, 422–428. [Google Scholar] [CrossRef]

- Lu, X.; Chen, Z.; Huang, X.; Chen, T.; Xia, Q. Soung surface wave label simulation based on COMSOL. Piezoelectricity Sound Light 2012, 34, 494–497. [Google Scholar] [CrossRef]

- Qi, J. Key Technology and Application Research of Acoustic Surface Wave Gas—Sensitive Sensor System. Ph.D. dissertation, Chongqing University, Chongqing, China, 2017. [Google Scholar]

- Sun, C. Simulation of High Frequency SAW Gas Sensor Modeling Based on Finite Element Method. Master’s Thesis, Harbin Institute of Technology, Harbin, China, 2007. [Google Scholar] [CrossRef]

- Zhang, Y.; Guo, T.; Tan, Q.; Zhang, L. COMSOL—based three-dimensional structure simulation of acoustic surface wave devices. Piezoelectricity Sound Light 2019, 41, 497–500. [Google Scholar] [CrossRef]

- Achour, B.; Attia, G.; Zerrouki, C.; Fourati, N.; Raoof, K.; Yaakoubi, N. Simulation/Experiment Confrontation, an Efficient Approach for Sensitive SAW Sensors Design. Sensors 2020, 20, 4994. [Google Scholar] [CrossRef]

- Xie, X.; Wang, W.; Ming, L.; Shi, H. A Simulation Method of Gas Sensor with Two-End-To-Resonator Structure of Sound Surface Wave Covered with Polymer Sensitive Film. 2012’Western China Acoustics Academic Exchange Conference Proceedings(I). 2012, pp. 128–130. Available online: https://xueshu.baidu.com/usercenter/paper/show?paperid=7d3a09732c35bfb7797dc690e4732dc4&site=xueshu_se (accessed on 25 August 2022). (In Chinese).

- Xiao, X. Study of Metal Oxide Thin Film Based Sound Surface Wave Gas/Moisture Sensitive Sensor. Master’s Thesis, University of Electronic Science and Technology, Chengdu, China, 2020. [Google Scholar] [CrossRef]

- Sharma, D.M.K.; Bhadu, D. Design Performance and Frequency Response Analysis of SAW—Based Sensor for Dichloromethane Gas Sensing Amidst the COVID-19. J. Vib. Eng. Technol. 2021, 9, 725–732. [Google Scholar] [CrossRef]

| Variable | Parameter (μm) |

|---|---|

| Wavelength (λ) | 24 |

| Electrode center spacing (p) | 4 |

| Electrode width (a) | 2 |

| Electrode thickness (h) | 0.5 |

| Piezoelectric substrate thickness (d) | 72 |

| Variable | Al Parameter | Cu Parameter | Au Parameter | Pt Parameter |

|---|---|---|---|---|

| Young’s modulus E(1010 Pa) | 7 | 11 | 7.95 | 16.9 |

| Poisson ratio μ | 0.33 | 0.326 | 0.42 | 0.38 |

| Density ρ (104 kg/m3) | 0.27 | 0.895 | 1.93 | 2.14 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bin, S.; Yang, H.; Jiang, L.; Liu, X. Simulation Study of FEUDT Structure Optimization and Sensitive Film Loading of SAW Devices. Micromachines 2022, 13, 1643. https://doi.org/10.3390/mi13101643

Bin S, Yang H, Jiang L, Liu X. Simulation Study of FEUDT Structure Optimization and Sensitive Film Loading of SAW Devices. Micromachines. 2022; 13(10):1643. https://doi.org/10.3390/mi13101643

Chicago/Turabian StyleBin, Shen, Haiyang Yang, Leiming Jiang, and Xinlei Liu. 2022. "Simulation Study of FEUDT Structure Optimization and Sensitive Film Loading of SAW Devices" Micromachines 13, no. 10: 1643. https://doi.org/10.3390/mi13101643

APA StyleBin, S., Yang, H., Jiang, L., & Liu, X. (2022). Simulation Study of FEUDT Structure Optimization and Sensitive Film Loading of SAW Devices. Micromachines, 13(10), 1643. https://doi.org/10.3390/mi13101643