Extrusion-Based 3D Printing of Stretchable Electronic Coating for Condition Monitoring of Suction Cups

Abstract

1. Introduction

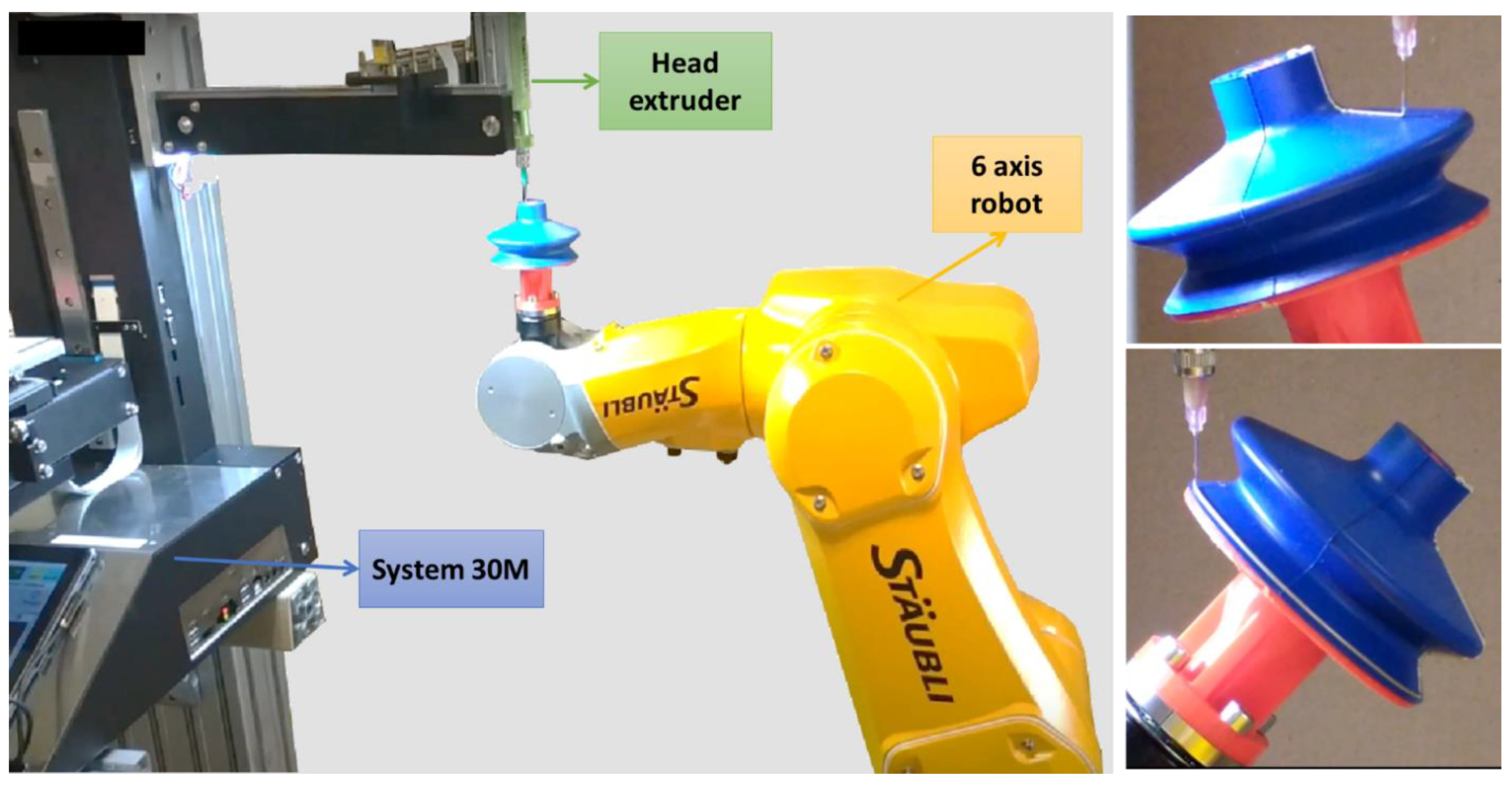

2. Design Strategy and Printing Process

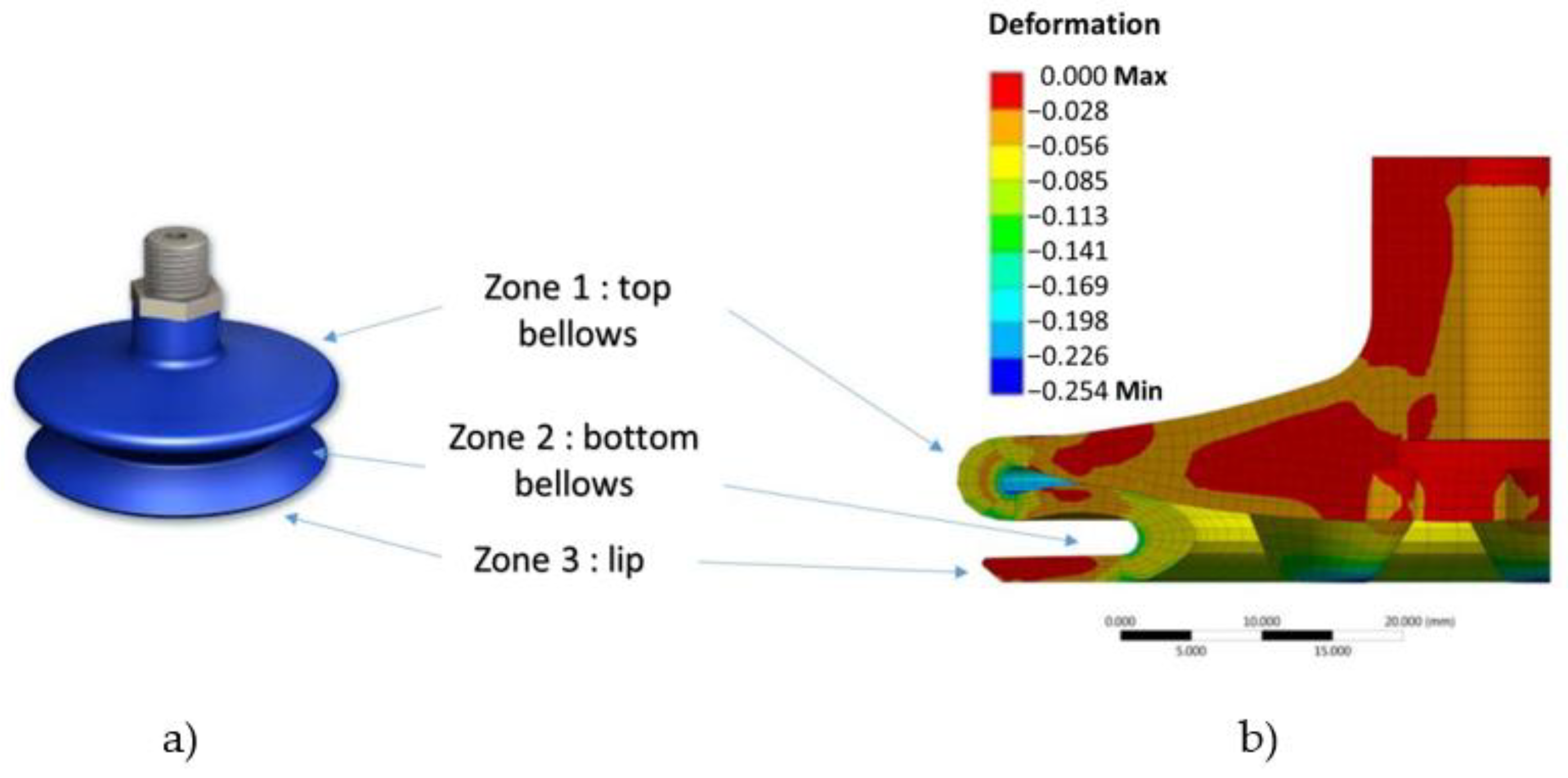

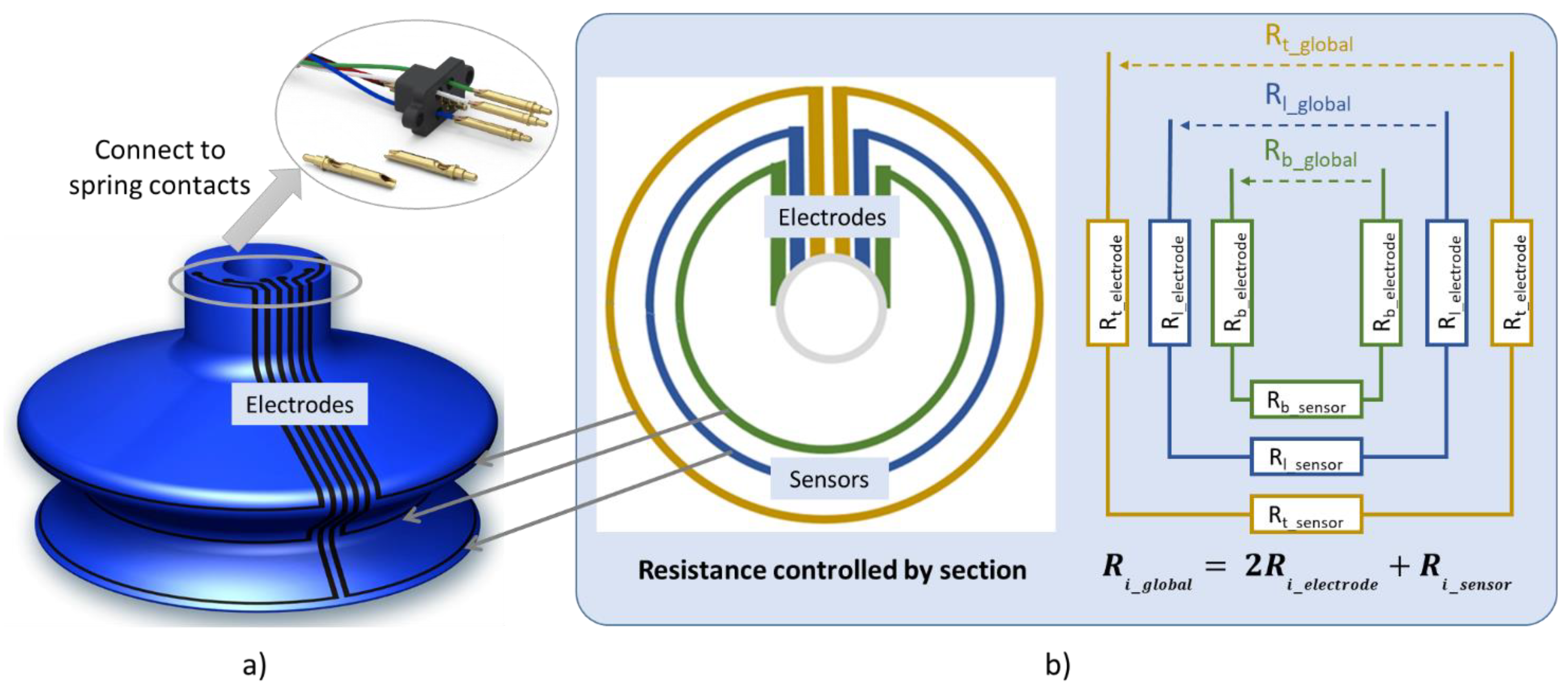

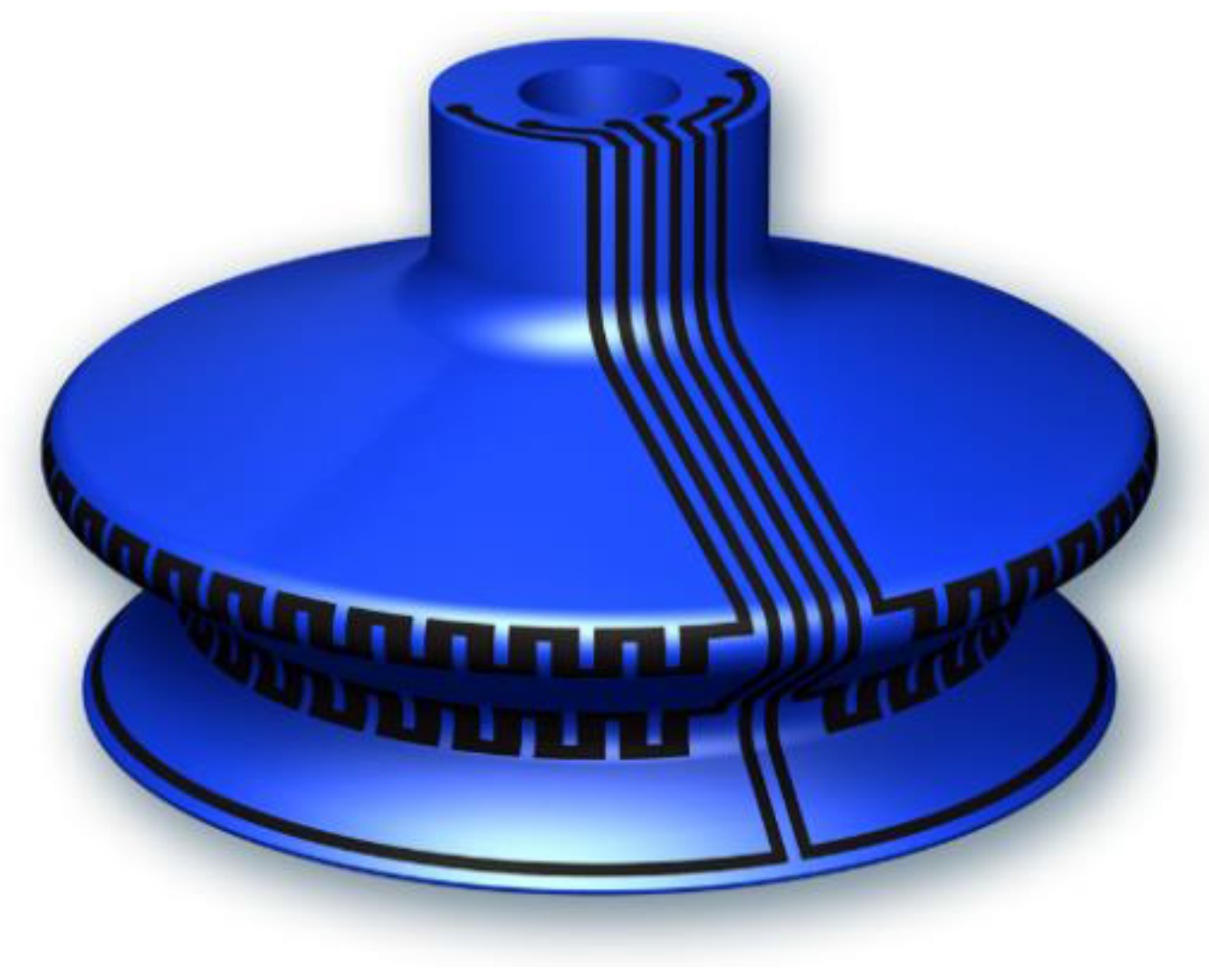

2.1. Design of Sensor Coating

2.2. Ink Selection

- good adhesion to the SC’s materials (HNBR), particularly for the curved-surface bellows;

- excellent stretchability to resist high deformation under static and dynamic conditions;

- adequate electrical conductivity to counterbalance the electrode effect;

- high viscosity to achieve shape fidelity (as no thermal treatment is performed throughout the printing process);

- stable electrical behavior under aging test.

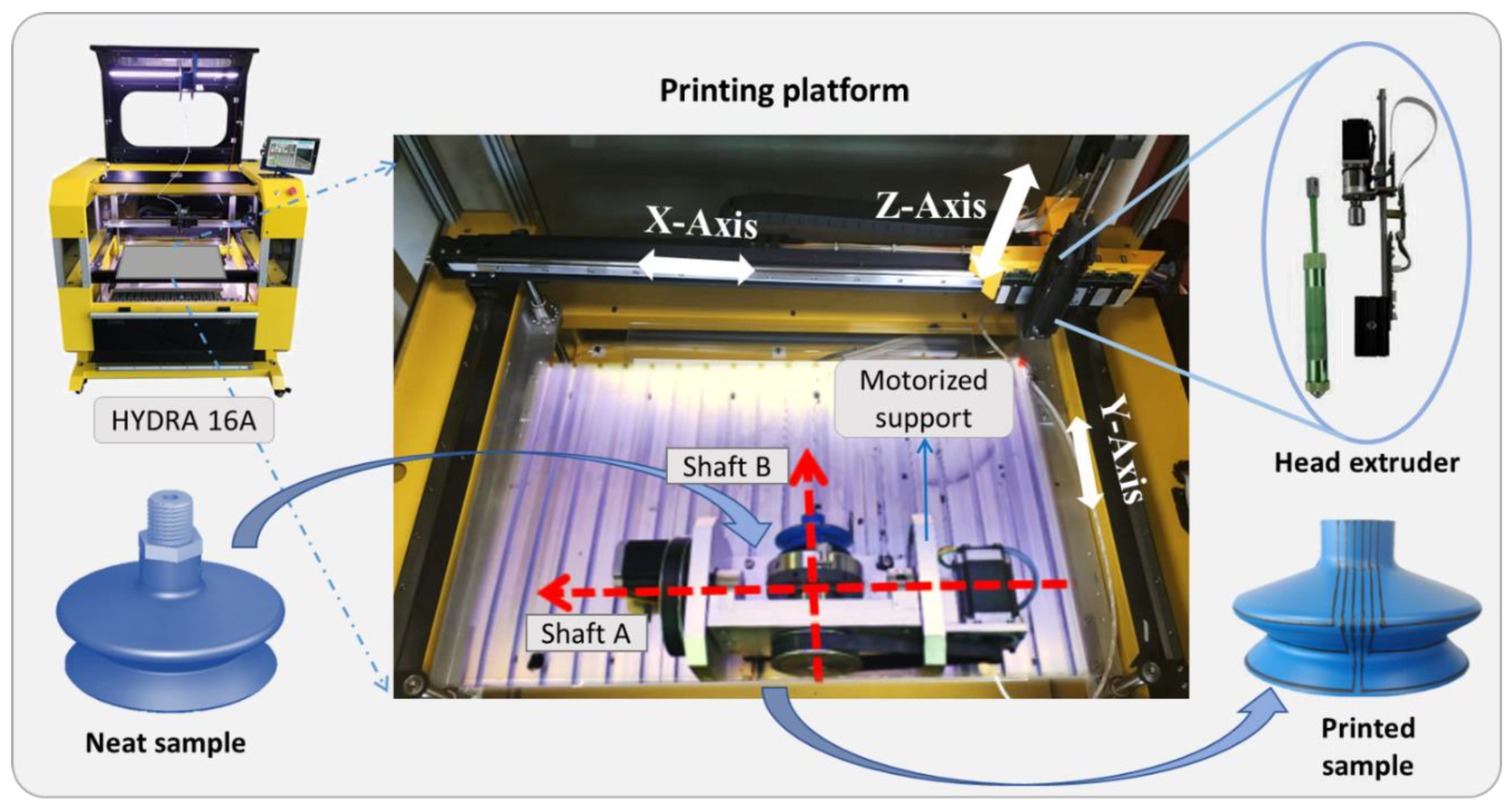

2.3. Printing Process

3. Characterization Methods

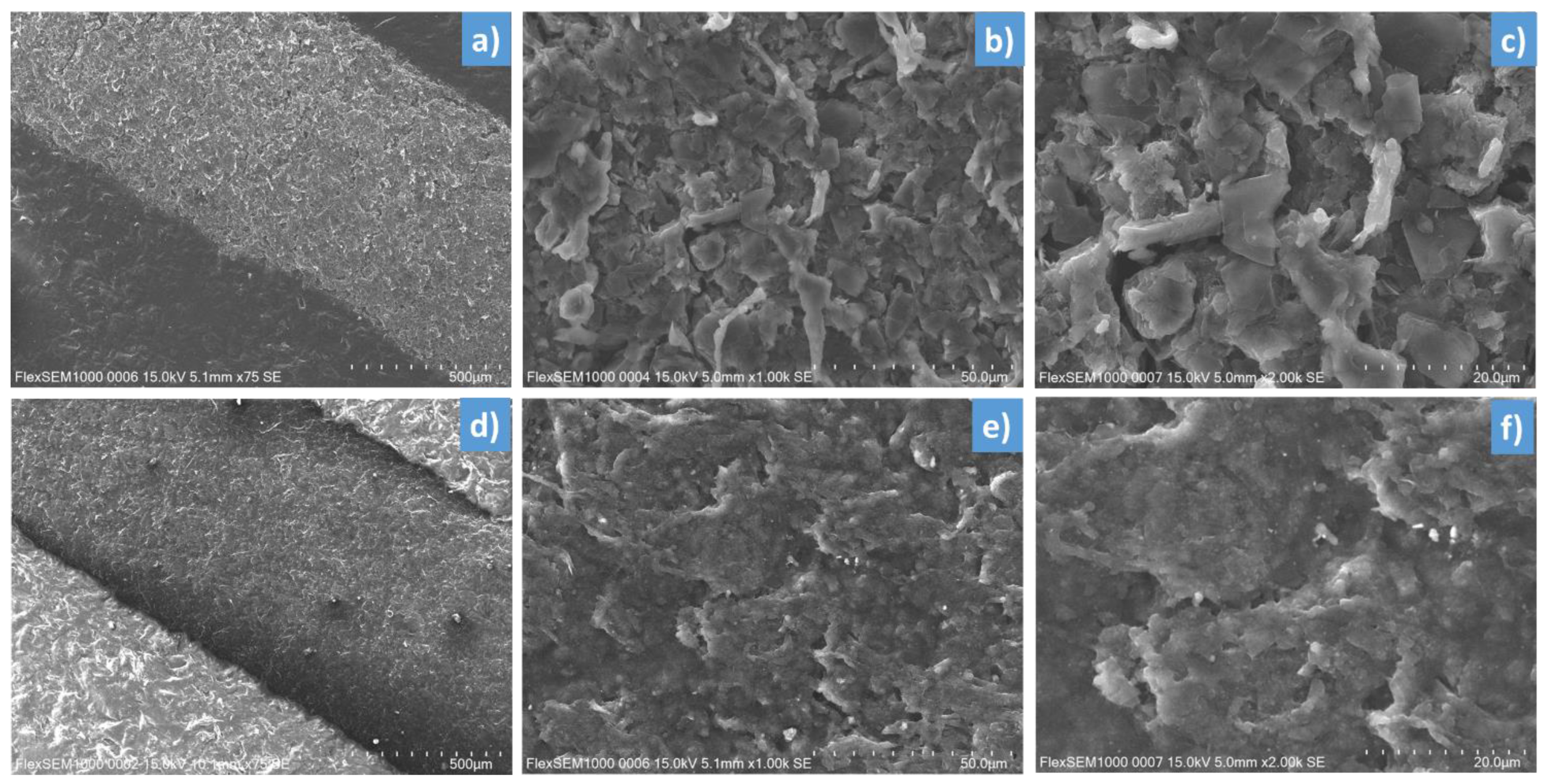

3.1. Morphological Characterization

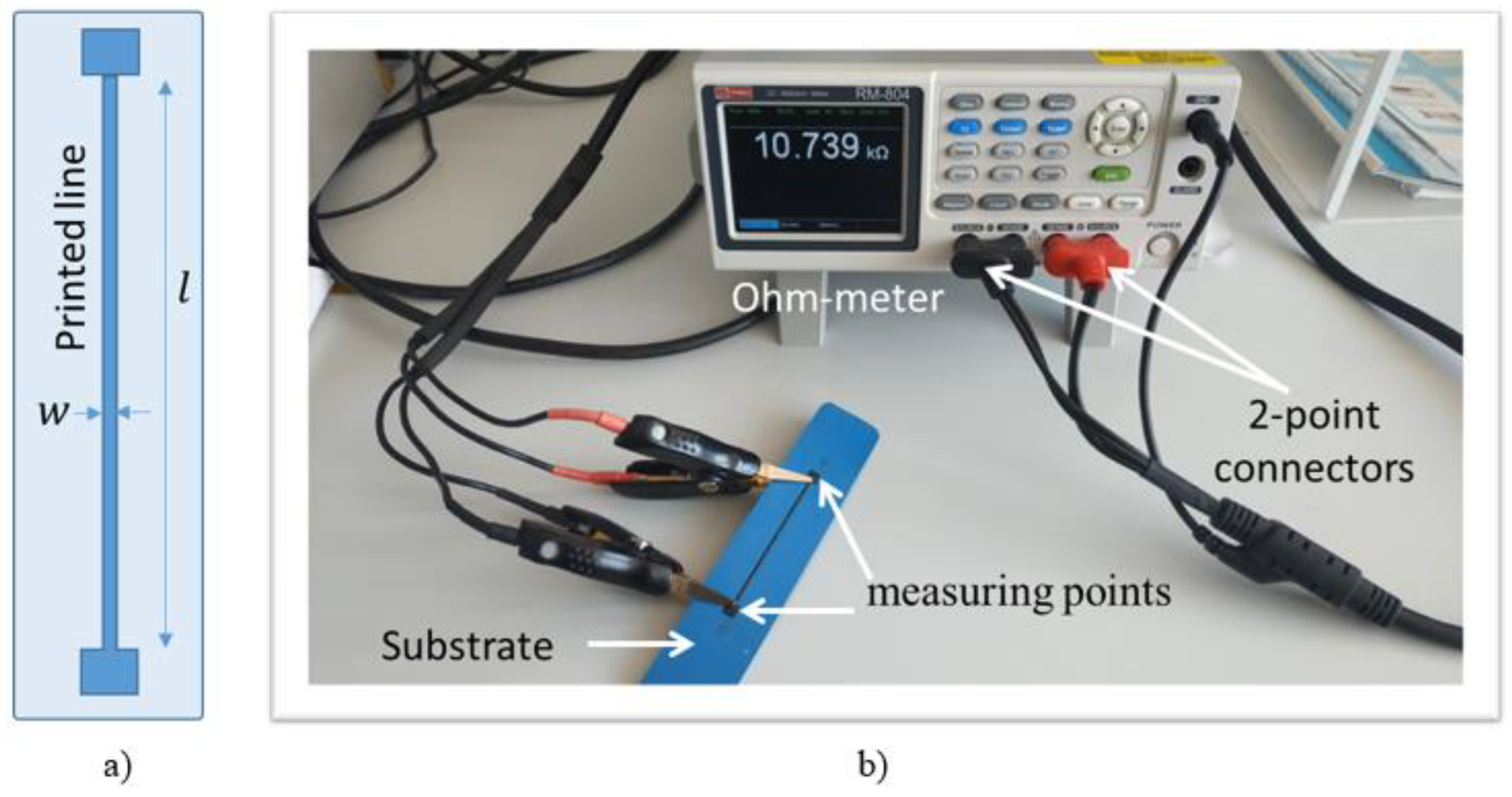

3.2. Electrical Characterization

3.3. Piezoresistive Characterization

3.3.1. D Rectangular-Shaped Sample

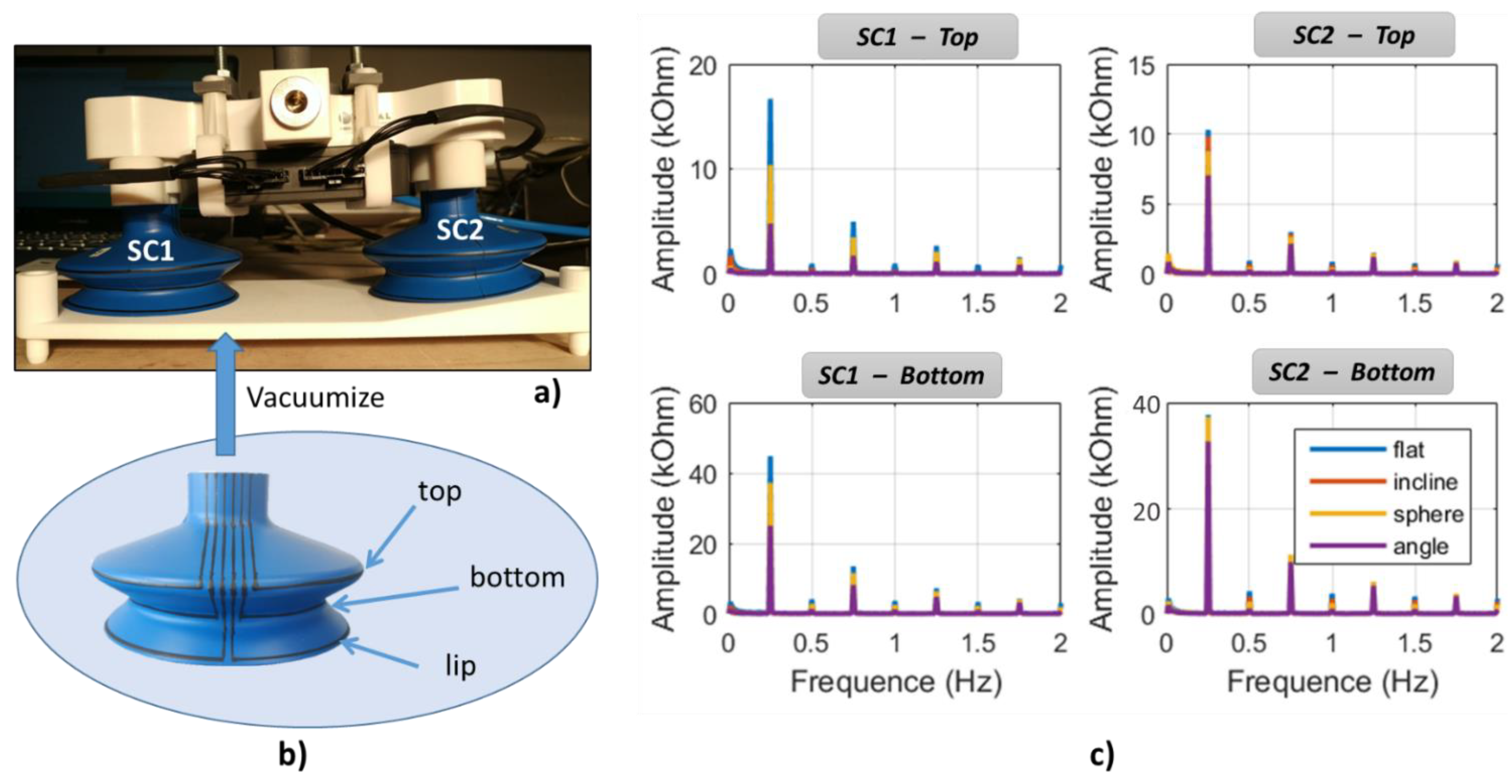

3.3.2. D Suction Cup

4. Results and Discussion

4.1. Morphological Properties

4.2. Electrical Properties

4.3. Piezoresistive Properties

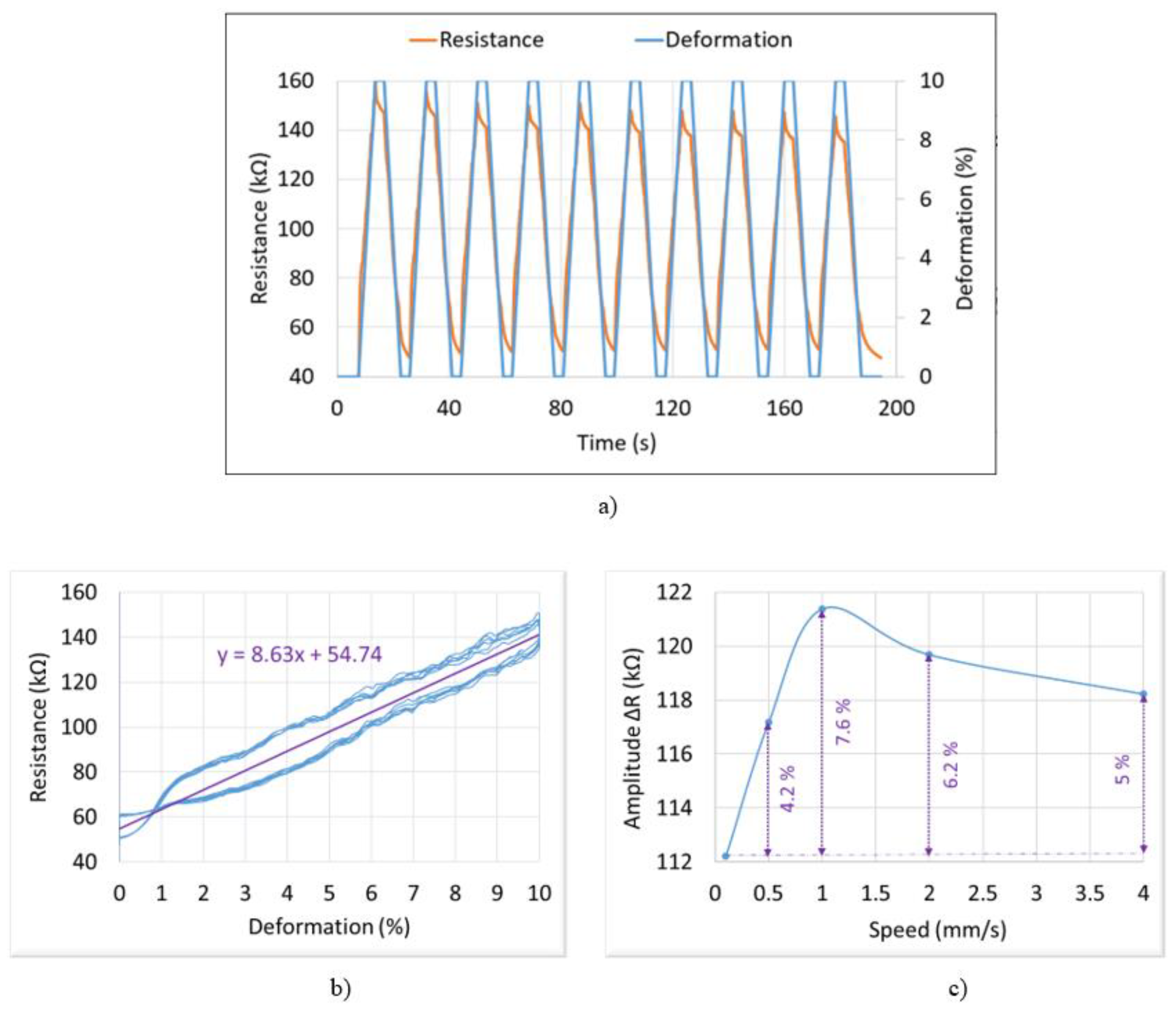

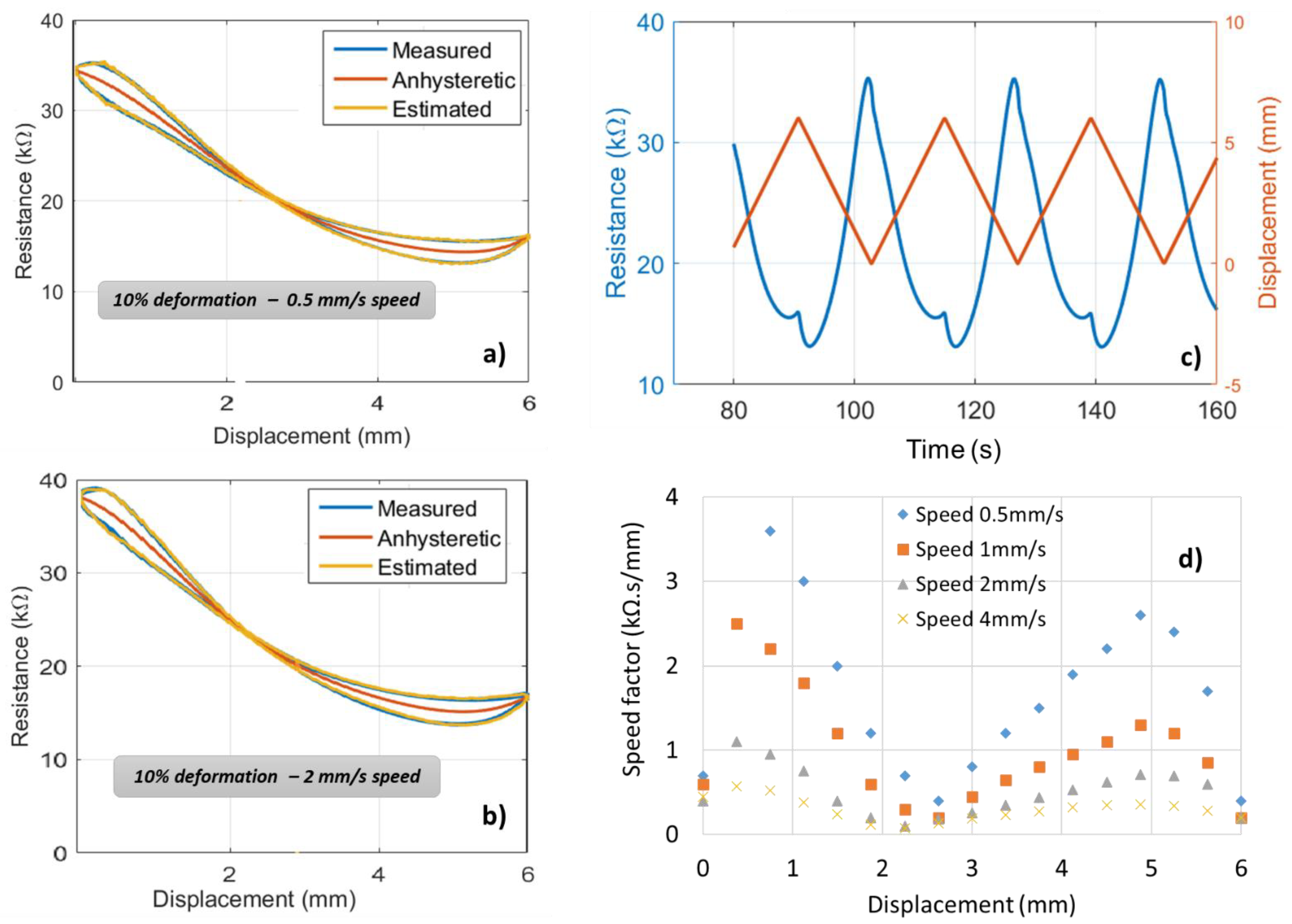

4.3.1. D Rectangular-Shaped Sample

- (a)

- First ink

- (b) Second ink

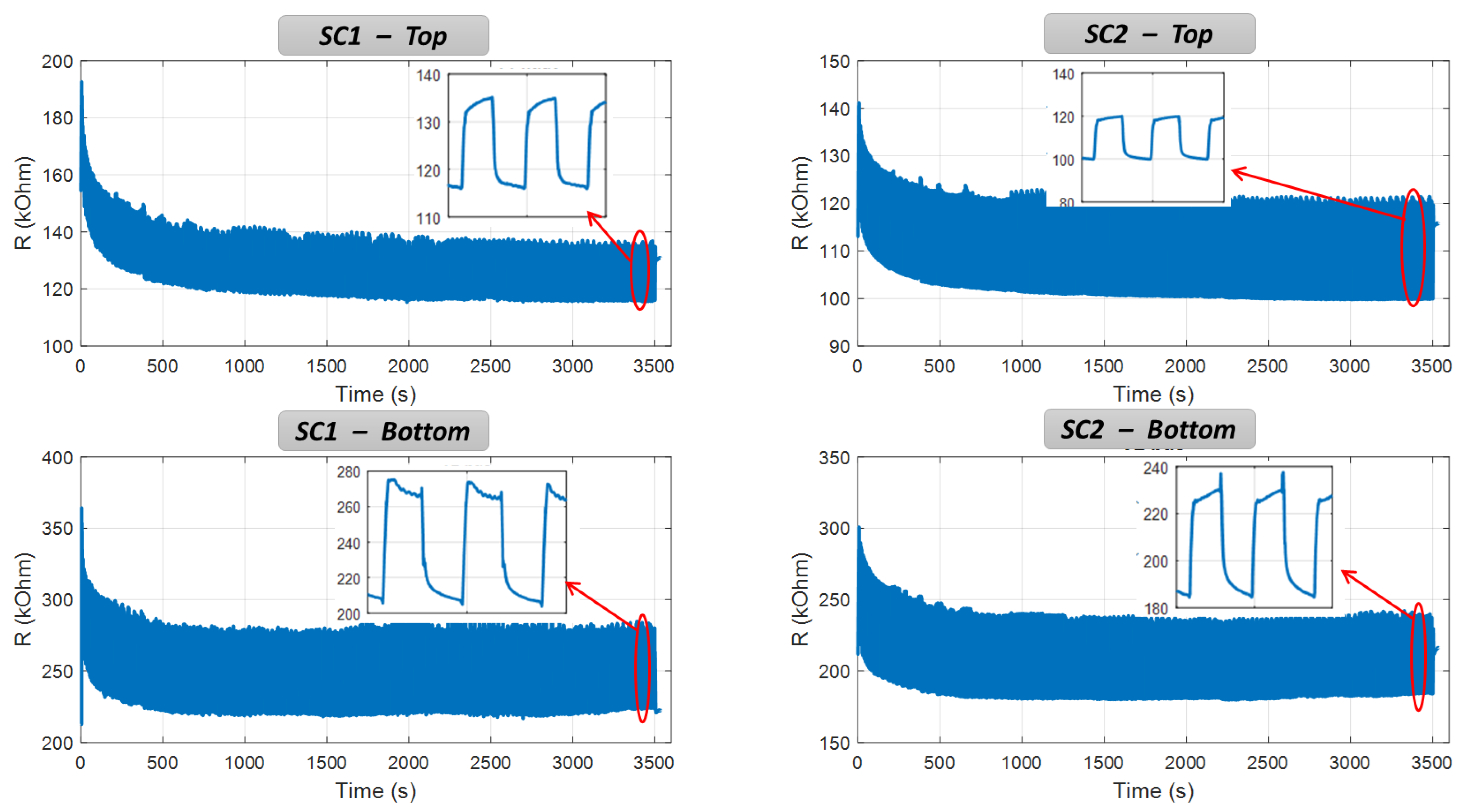

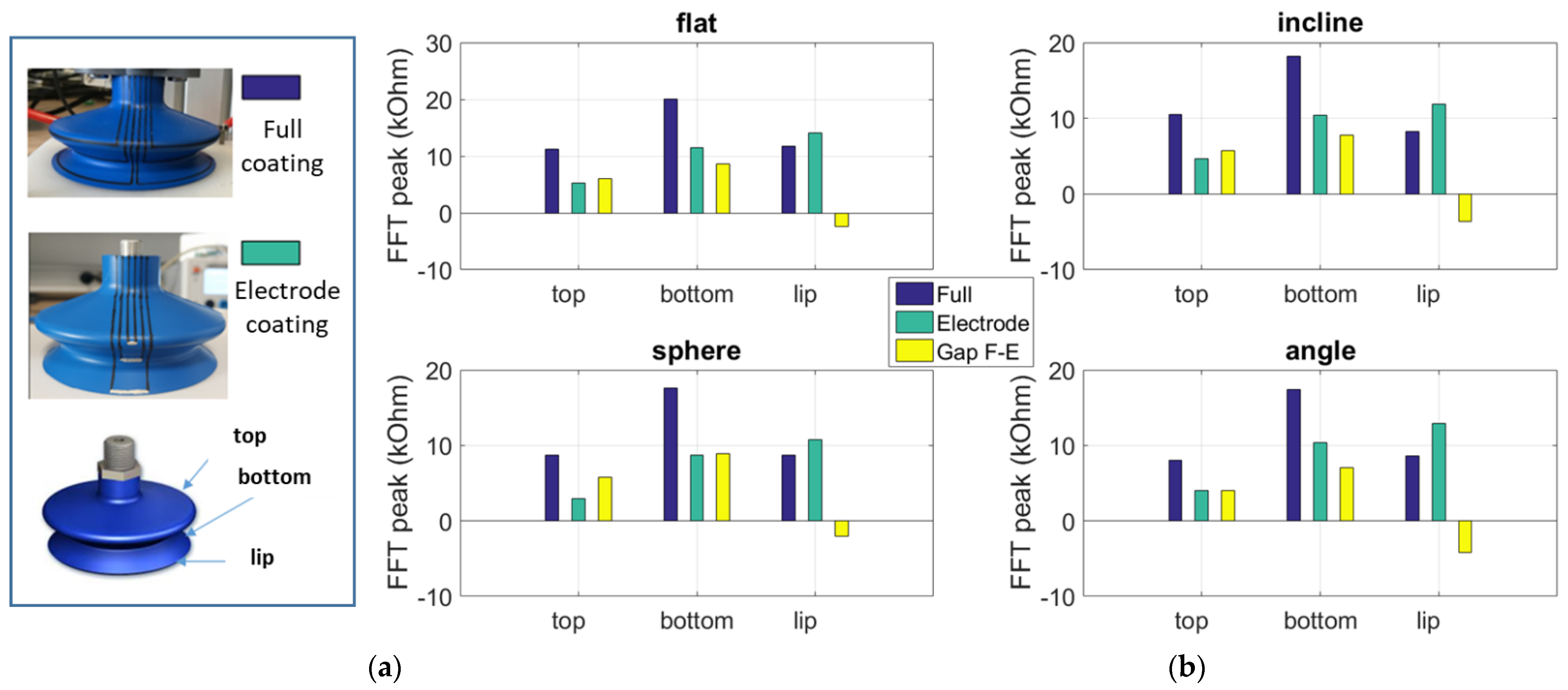

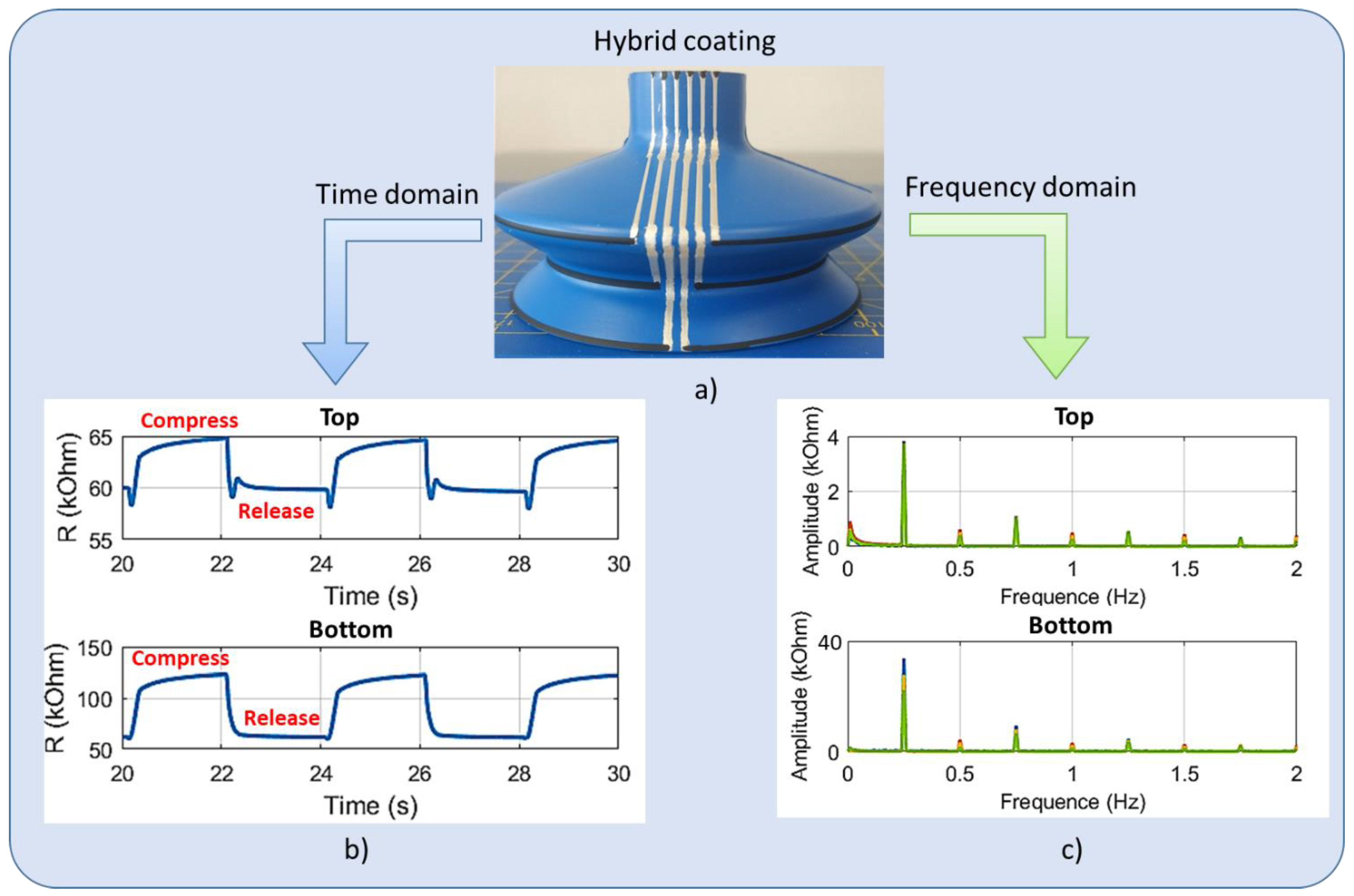

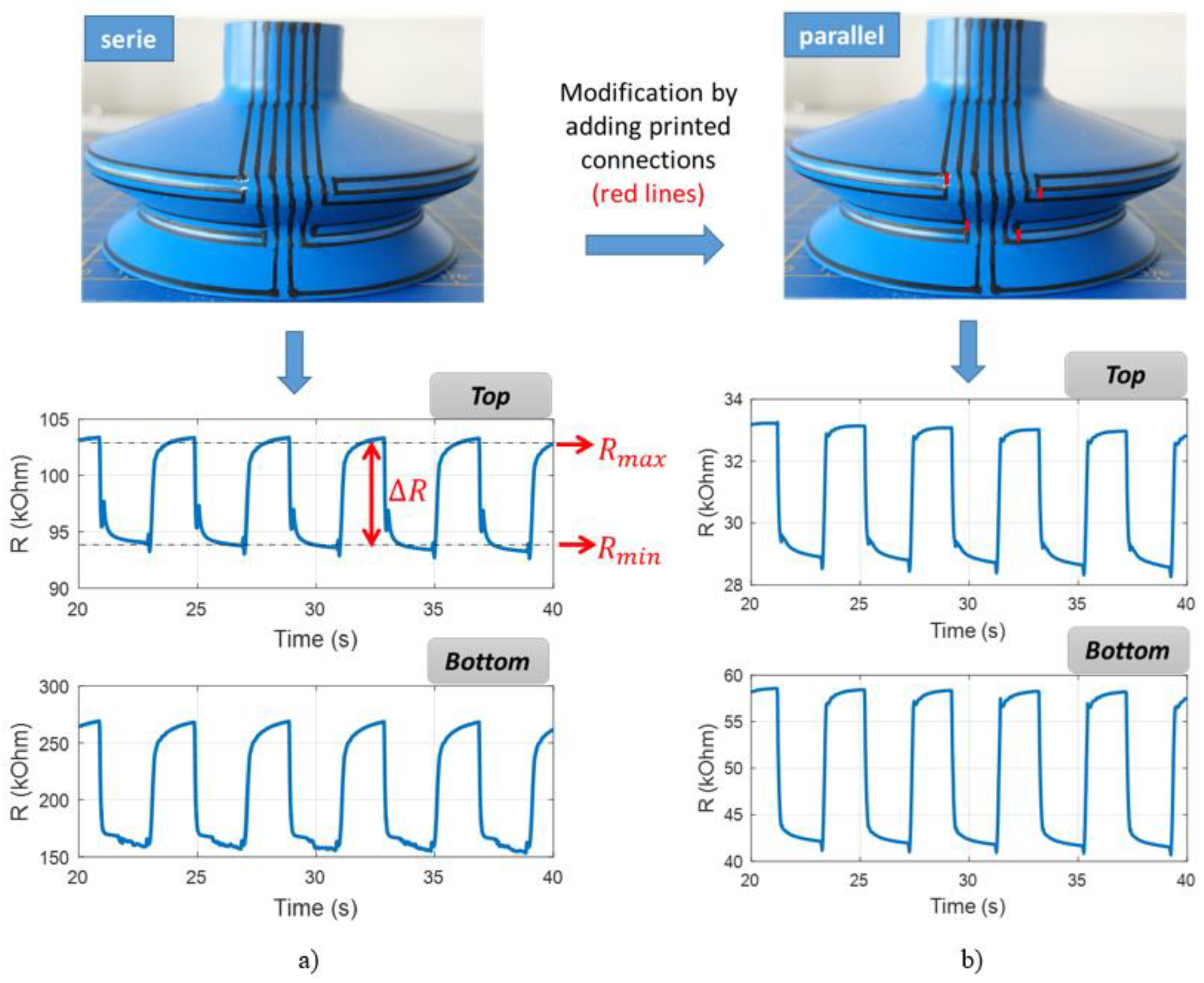

4.3.2. D Suction Cup

- Adhesion of the printed lines are better in the 2D planar specimen than in the 3D curved structure, regardless of which ink is chosen.

- The second ink is well adhered in both 2D and 3D samples under extended mechanical solicitations, while the first ink could only withstand with the 2D structure. Actually, dynamic test using the vacuum pump system carried on the 3D structure is faster than the tensile test performed on the 2D specimen.

- The 3D cup with such complex curves makes the ink selection challenging. Among several tested inks, only one could meet our expectations in terms of technical feasibility. However, this ink exhibits nonlinear and negative piezoresistance, leading to complex sensor calibration and data analyses, to some extent.

5. Future Developments for Printing-Process Enhancement

6. Conclusions

Supplementary Materials

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mobley, R.K. An Introduction to Predictive Maintenance; Elsevier: Amsterdam, The Netherlands, 2002. [Google Scholar]

- Cui, Z. Printed Electronics: Materials, Technologies and Applications; John Wiley & Sons: Hoboken, NJ, USA, 2016. [Google Scholar]

- Alberto, M.; Micaela, D.; Sarbjeet, S. Applications and Challenges of Maintenance and Safety Engineering in Industry 4.0; IGI Global: Hershey, PA, USA, 2020. [Google Scholar]

- Le, M.Q.; Capsal, J.-F.; Lallart, M.; Hebrard, Y.; Van Der Ham, A.; Reffe, N.; Geynet, L.; Cottinet, P.-J. Review on energy harvesting for structural health monitoring in aeronautical applications. Prog. Aerosp. Sci. 2015, 79, 147–157. [Google Scholar] [CrossRef]

- D’Ambrogio, G.; Zahhaf, O.; Hebrard, Y.; Le, M.Q.; Cottinet, P.; Capsal, J. Micro-Structuration of Piezoelectric Composites Using Dielectrophoresis: Toward Application in Condition Monitoring of Bearings. Adv. Eng. Mater. 2021, 23, 2000773. [Google Scholar] [CrossRef]

- Morales, R.; Badesa, F.J.; Garcia-Aracil, N.; Sabater, J.M.; Zollo, L. Soft Robotic Manipulation of Onions and Artichokes in the Food Industry. Adv. Mech. Eng. 2014, 6, 345291. [Google Scholar] [CrossRef]

- Bahr, B.; Li, Y.; Najafi, M. Design and suction cup analysis of a wall climbing robot. Comput. Electr. Eng. 1996, 22, 193–209. [Google Scholar] [CrossRef]

- Kirsch, S.-M.; Welsch, F.; Schmidt, M.; Motzki, P.; Seelecke, S. Bistable SMA Vacuum Suction Cup, in: ACTUATOR 2018. In Proceedings of the 16th International Conference on New Actuators, Bremen, Germany, 25–27 June 2018; pp. 1–4. [Google Scholar]

- Hehr, A.; Norfolk, M.; Wenning, J.; Sheridan, J.; Leser, P.; Leser, P.; Newman, J.A. Integrating Fiber Optic Strain Sensors into Metal Using Ultrasonic Additive Manufacturing. JOM 2018, 70, 315–320. [Google Scholar] [CrossRef] [PubMed]

- Namuduri, S.; Narayanan, B.N.; Davuluru, V.S.P.; Burton, L.; Bhansali, S. Review—Deep Learning Methods for Sensor Based Predictive Maintenance and Future Perspectives for Electrochemical Sensors. J. Electrochem. Soc. 2020, 167, 037552. [Google Scholar] [CrossRef]

- Nguyen, V.-C.; Le, M.-Q.; Fimbel, A.; Bernadet, S.; Hebrard, Y.; Mogniotte, J.-F.; Capsal, J.-F.; Cottinet, P.-J. Printing smart coating of piezoelectric composite for application in condition monitoring of bearings. Mater. Des. 2022, 215, 110529. [Google Scholar] [CrossRef]

- Le, M.Q.; Ganet, F.; Audigier, D.; Capsal, J.-F.; Cottinet, P.-J. Printing of microstructure strain sensor for structural health monitoring. Appl. Phys. A 2017, 123, 354. [Google Scholar] [CrossRef]

- Hologne-Carpentier, M.; Mogniotte, J.-F.; Le, M.-Q.; Allard, B.; Clerc, G.; Cottinet, P.-J. A multi-physics approach to condition monitoring of SiC power module. Microelectron. Eng. 2021, 250, 111633. [Google Scholar] [CrossRef]

- Suganuma, K. Introduction to Printed Electronics; Springer Science & Business Media: Berlin, Germany, 2014. [Google Scholar] [CrossRef]

- Shabaniverki, S.; Juárez, J. Directed Assembly of Particles for Additive Manufacturing of Particle-Polymer Composites. Micromachines 2021, 12, 935. [Google Scholar] [CrossRef]

- Arefin, A.; Khatri, N.; Kulkarni, N.; Egan, P. Polymer 3D Printing Review: Materials, Process, and Design Strategies for Medical Applications. Polymers 2021, 13, 1499. [Google Scholar] [CrossRef] [PubMed]

- Thetpraphi, K.; Kanlayakan, W.; Chaipo, S.; Moretto, G.; Kuhn, J.; Audigier, D.; Le, M.Q.; Cottinet, P.-J.; Petit, L.; Capsal, J.-F. 3D-printed electroactive polymer force-actuator for large and high precise optical mirror applications. Addit. Manuf. 2021, 47, 102199. [Google Scholar] [CrossRef]

- Grinberg, D.; Siddique, S.; Le, M.-Q.; Liang, R.; Capsal, J.-F.; Cottinet, P.-J. 4D Printing based piezoelectric composite for medical applications. J. Polym. Sci. Part B Polym. Phys. 2019, 57, 109–115. [Google Scholar] [CrossRef]

- DeGraff, J.; Liang, R.; Le, M.Q.; Capsal, J.-F.; Ganet, F.; Cottinet, P.-J. Printable low-cost and flexible carbon nanotube buckypaper motion sensors. Mater. Des. 2017, 133, 47–53. [Google Scholar] [CrossRef]

- Liu, Q.; Le, M.Q.; Richard, C.; Liang, R.; Cottinet, P.-J.; Capsal, J.-F. Enhanced pseudo-piezoelectric dynamic force sensors based on inkjet-printed electrostrictive terpolymer. Org. Electron. 2019, 67, 259–271. [Google Scholar] [CrossRef]

- Xiang, Z.; Nguyen, V.; Ducharne, B.; Della Schiava, N.; Capsal, J.; Cottinet, P.; Le, M. 3D Printing of Flexible Composites via Magnetophoresis: Toward Medical Application Based on Low-Frequency Induction Heating Effect. Macromol. Mater. Eng. 2021, 306, 2100211. [Google Scholar] [CrossRef]

- Cruz, S.M.F.; Rocha, L.A.; Viana, J.C. Printing Technologies on Flexible Substrates for Printed Electronics. In Flexible Electronics; IntechOpen: London, UK, 2018. [Google Scholar] [CrossRef]

- Kim, Y.; Hone, J. Screen printing of 2D semiconductors. Nature 2017, 544, 167–168. [Google Scholar] [CrossRef]

- Secor, E.B. Principles of aerosol jet printing. Flex. Print. Electron. 2018, 3, 035002. [Google Scholar] [CrossRef]

- Zhou, H.; Qin, W.; Yu, Q.; Cheng, H.; Yu, X.; Wu, H. Transfer Printing and its Applications in Flexible Electronic Devices. Nanomaterials 2019, 9, 283. [Google Scholar] [CrossRef]

- Direct Patterning of Carbon Nanotube via Stamp Contact Printing Process for Stretchable and Sensitive Sensing Devices|SpringerLink, (n.d.). Available online: https://link.springer.com/article/10.1007/s40820-019-0323-8 (accessed on 9 March 2022).

- El Maanaoui, H.; Egelkamp, C.; Meier, J. Influence of the tensile static preload dependency on the dynamic lifetime prediction for an HNBR elastomer. J. Mech. Behav. Biomed. Mater. 2021, 119, 104502. [Google Scholar] [CrossRef]

- Zymelka, D.; Yamashita, T.; Sun, X.; Kobayashi, T. Printed Strain Sensors Based on an Intermittent Conductive Pattern Filled with Resistive Ink Droplets. Sensors 2020, 20, 4181. [Google Scholar] [CrossRef] [PubMed]

- PCB Track Width and Track Resistance—Importance, Calculation, and Design Tips, (n.d.). Available online: https://pcbdesignworld.com/article/pcb-track-width-and-track-resistance-importance-calculation-and-design-tips (accessed on 27 July 2022).

- Carbone, C.; Benwadih, M.; D’Ambrogio, G.; LE, M.-Q.; Capsal, J.-F.; Cottinet, P.-J. Influence of Matrix and Surfactant on Piezoelectric and Dielectric Properties of Screen-Printed BaTiO3/PVDF Composites. Polymers 2021, 13, 2166. [Google Scholar] [CrossRef]

- Izak, P.; Mastalska-Poplawska, J.; Lis, J.; Stempkowska, A. Modification of the rheological properties of screen printing ceramic paints containing gold. J. Phys. Conf. Ser. 2017, 790, 012011. [Google Scholar] [CrossRef]

- Nguyen, V.-C.; Le, M.-Q.; Fimbel, A.; Bernadet, S.; Hebrard, Y.; Mogniotte, J.-F.; Capsal, J.-F.; Cottinet, P.-J. Evaluation of electromechanical characteristics for screen printed piezoelectric sensor-based Pu/PZT composite. In Electroactive Polymer Actuators and Devices (EAPAD) XXIV; SPIE: Washington, WA, USA, 2022; pp. 326–334. [Google Scholar] [CrossRef]

- Nasrazadani, S.; Hassani, S. Chapter 2—Modern analytical techniques in failure analysis of aerospace, chemical, and oil and gas industries. In Handbook of Materials Failure Analysis with Case Studies from the Oil and Gas Industry; Makhlouf, A.S.H., Aliofkhazraei, M., Eds.; Butterworth-Heinemann: Oxford, UK, 2016; pp. 39–54. [Google Scholar] [CrossRef]

- Resistance and Resistivity, (n.d.). Available online: http://hyperphysics.phy-astr.gsu.edu/hbase/electric/resis.html (accessed on 9 March 2022).

- Standard Test Method for Tensile Properties of Plastics, (n.d.). Available online: https://www.astm.org/d0638-14.html (accessed on 16 September 2022).

- Khan, A.S.; Baig, M.; Hamid, S.; Zhang, H. Thermo-mechanical large deformation responses of Hydrogenated Nitrile Butadiene Rubber (HNBR): Experimental results. Int. J. Solids Struct. 2010, 47, 2653–2659. [Google Scholar] [CrossRef]

- Kumar, M.; Sharma, A.; Hait, S.; Wießner, S.; Heinrich, G.; Arief, I.; Naskar, K.; Stöckelhuber, K.W.; Das, A. Effect of Prestrain on the Actuation Characteristics of Dielectric Elastomers. Polymers 2020, 12, 2694. [Google Scholar] [CrossRef] [PubMed]

- Nurprasetio, I.P.; Budiman, B.A.; Afwan, A.A.; Halimah, P.N.; Utami, S.T.; Aziz, M. Nonlinear Piezoresistive Behavior of Plain-Woven Carbon Fiber Reinforced Polymer Composite Subjected to Tensile Loading. Appl. Sci. 2020, 10, 1366. [Google Scholar] [CrossRef]

- Chang, Y.; Wang, D.-Y.; Tai, Y.-L.; Yang, Z.-G. Preparation, characterization and reaction mechanism of a novel silver-organic conductive ink. J. Mater. Chem. 2012, 22, 25296–25301. [Google Scholar] [CrossRef]

- Wang, S.; Chung, D.D.L. Negative piezoresistivity in continuous carbon fiber epoxy-matrix composite. J. Mater. Sci. 2007, 42, 4987–4995. [Google Scholar] [CrossRef]

- Mei, Z.; Guerrero, V.H.; Kowalik, D.P.; Chung, D.D.L. Mechanical damage and strain in carbon fiber thermoplastic-matrix composite, sensed by electrical resistivity measurement. Polym. Compos. 2002, 23, 425–432. [Google Scholar] [CrossRef]

- Todoroki, A.; Yoshida, J. Electrical Resistance Change of Unidirectional CFRP Due to Applied Load. JSME Int. J. Ser. A Solid Mech. Mater. Eng. 2004, 47, 357–364. [Google Scholar] [CrossRef]

- Jeon, E.-B.; Fujimura, T.; Takahashi, K.; Kim, H.-S. An investigation of contact resistance between carbon fiber/epoxy composite laminate and printed silver electrode for damage monitoring. Compos. Part A Appl. Sci. Manuf. 2014, 66, 193–200. [Google Scholar] [CrossRef]

- Nowicki, M. Anhysteretic Magnetization Measurement Methods for Soft Magnetic Materials. Materials 2018, 11, 2021. [Google Scholar] [CrossRef] [PubMed]

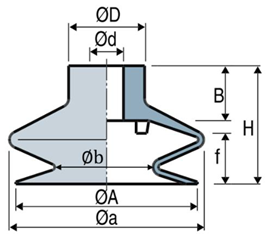

| Lip diameter (ØA) | 78 mm |  |

| SCstroke (f) | 14 mm | |

| Depth of housing fitting (B) | 20 mm | |

| Height (H) | 46.8 mm | |

| External neck diameter (ØD) | 25 mm | |

| Internal neck diameter (Ød) | 12 mm | |

| Internal volume (Vi) | 76 cm3 | |

| Top bellow diameter (Øa) | 83 mm | |

| Bottom bellow diameter (Øb) | 43.7 mm | |

| Tensile force (Ft) | 110 N | |

| Slipping force (Fg) | 55 N |

| First Ink | Second Ink | |

|---|---|---|

| Viscosity (cps) | 30,000–35,000 | 57,000 |

| Useful temperature range (°C) | −55 to 120 | −50 to 100 |

| Curing temperature range (°C) | 50–180 | 50–120 |

| First Ink | Second Ink | |

|---|---|---|

| Width d (mm) | 1.18 | 0.9 |

| Length L (mm) | 60 | 60 |

| Thickness e (µm) | 36 | 22 |

| Electrical resistance (kΩ) | 10 | 34 |

| Type of Suction Cup | |||

|---|---|---|---|

| 1-Circle Hybrid Coating | 3-Circle Serial Coating | 3-Circle Parallel Coating | |

| Top bellows | ∆R = 7 kΩ | ∆R = 10 kΩ | ∆R = 4.5 kΩ |

| ∆m = 5% | ∆m = 5.1% | ∆m = 7.3% | |

| Bottom bellows | ∆R = 60 kΩ | ∆R = 110 kΩ | ∆R = 16 kΩ |

| ∆m = 35.2% | ∆m = 26.2% | ∆m = 16% | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nguyen, V.-C.; Le, M.-Q.; Mogniotte, J.-F.; Capsal, J.-F.; Cottinet, P.-J. Extrusion-Based 3D Printing of Stretchable Electronic Coating for Condition Monitoring of Suction Cups. Micromachines 2022, 13, 1606. https://doi.org/10.3390/mi13101606

Nguyen V-C, Le M-Q, Mogniotte J-F, Capsal J-F, Cottinet P-J. Extrusion-Based 3D Printing of Stretchable Electronic Coating for Condition Monitoring of Suction Cups. Micromachines. 2022; 13(10):1606. https://doi.org/10.3390/mi13101606

Chicago/Turabian StyleNguyen, Van-Cuong, Minh-Quyen Le, Jean-François Mogniotte, Jean-Fabien Capsal, and Pierre-Jean Cottinet. 2022. "Extrusion-Based 3D Printing of Stretchable Electronic Coating for Condition Monitoring of Suction Cups" Micromachines 13, no. 10: 1606. https://doi.org/10.3390/mi13101606

APA StyleNguyen, V.-C., Le, M.-Q., Mogniotte, J.-F., Capsal, J.-F., & Cottinet, P.-J. (2022). Extrusion-Based 3D Printing of Stretchable Electronic Coating for Condition Monitoring of Suction Cups. Micromachines, 13(10), 1606. https://doi.org/10.3390/mi13101606