Calibration Method of Accelerometer Based on Rotation Principle Using Double Turntable Centrifuge

Abstract

:1. Introduction

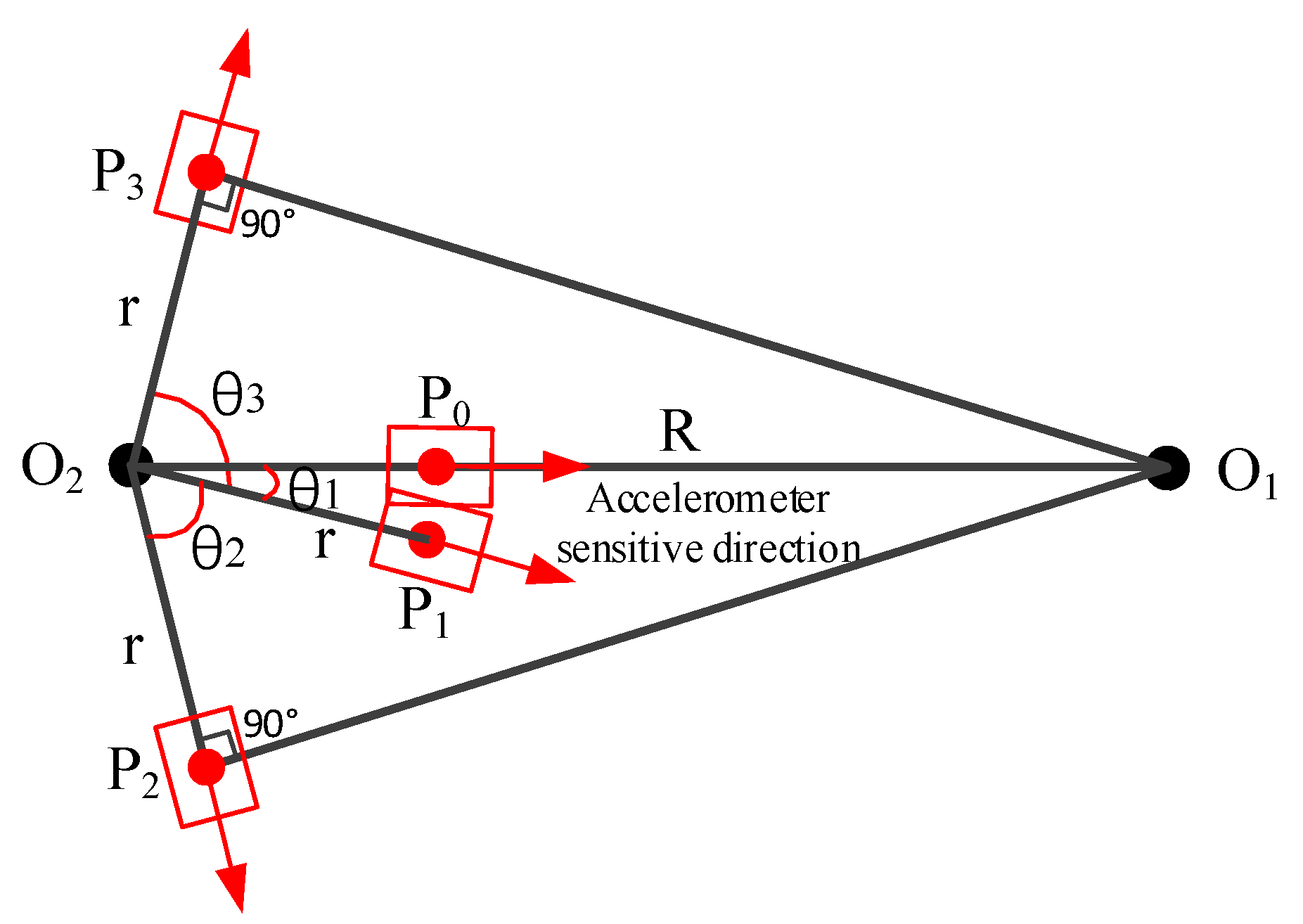

2. Mathematical Model Based on Rotation Method in Double Turntable Centrifuge

2.1. Principle of Double Turntable Centrifuge

2.2. Errors of Calibration

2.3. Model of Our Proposed Calibration Method

3. Measurement Method of the Calibration

3.1. Procedure of Calibration

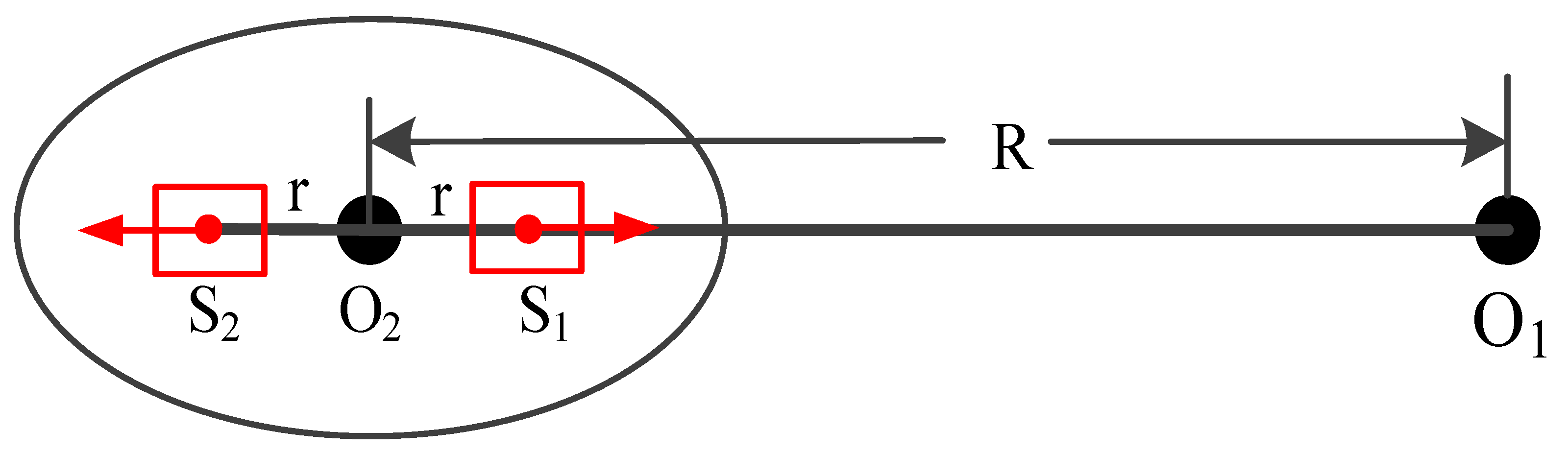

3.2. Theory of Measuring the Rotation Angle

3.3. Procedure of Measuring the Rotation Angle

4. Calibration Results and Discussion

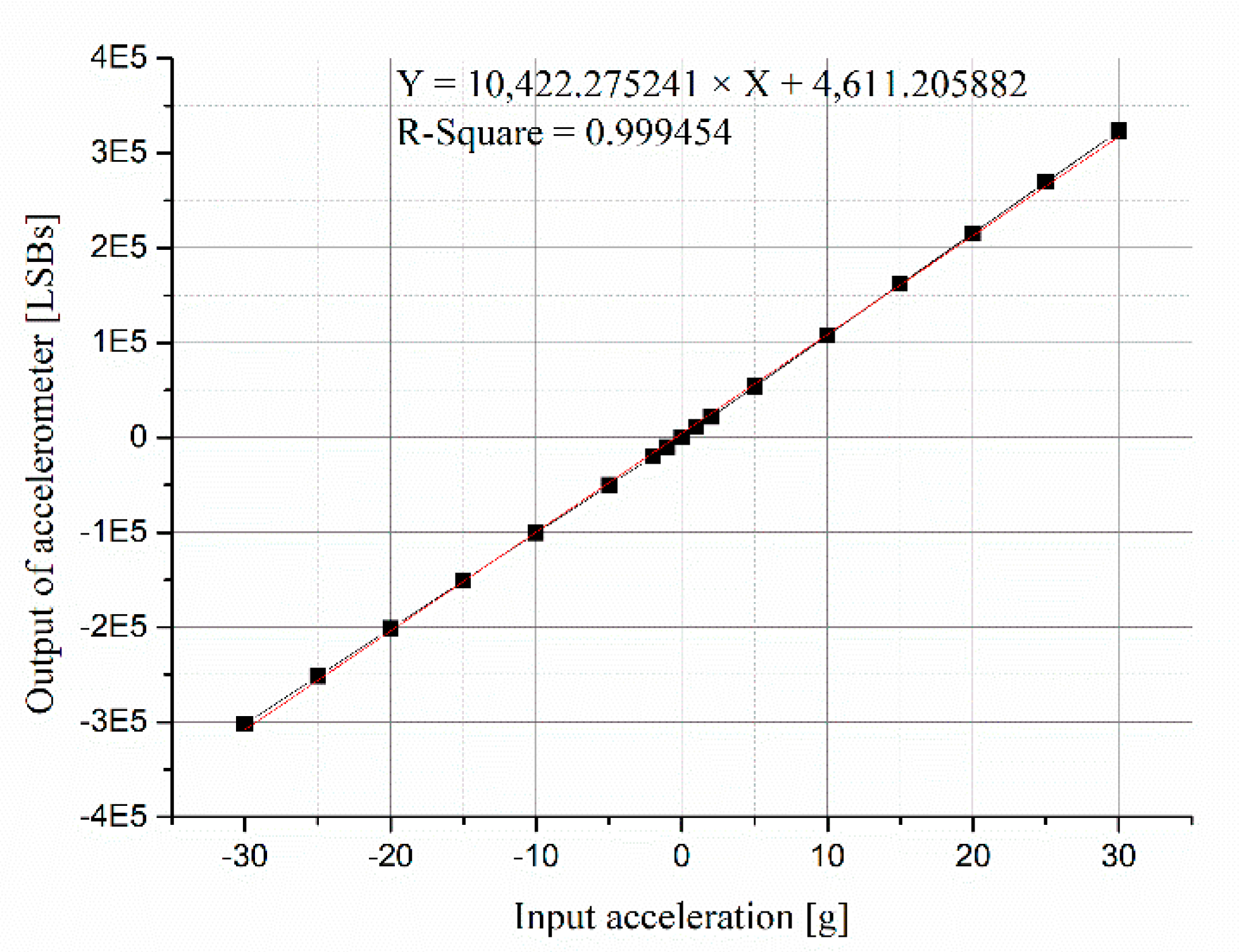

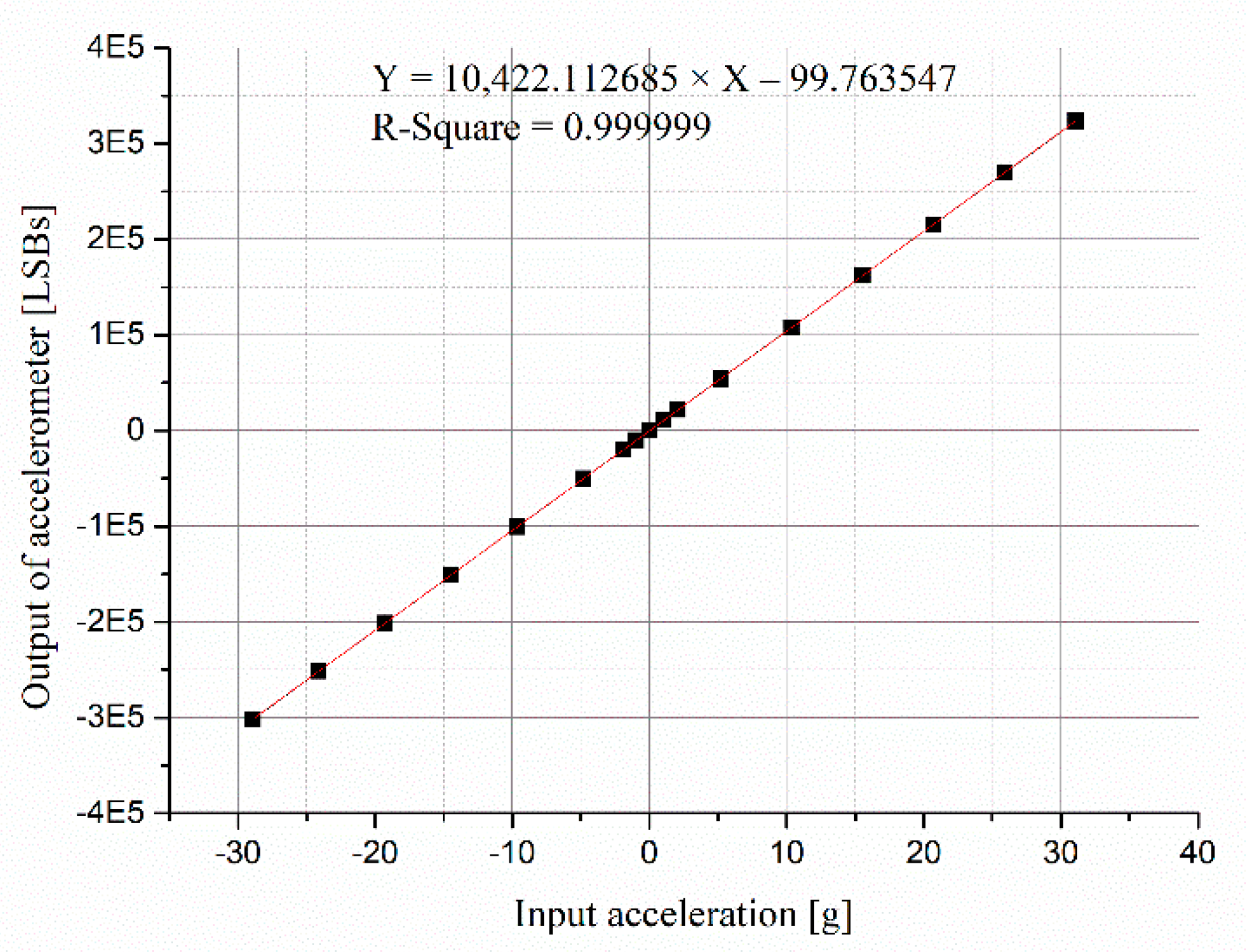

4.1. Measurement of Calibration Error Model Parameters

4.2. Calibration Test of MEMS Accelerometer

4.3. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Li, Z.; Wu, W.J.; Zheng, P.P.; Liu, J.Q.; Fan, J.; Tu, L.C. Novel capacitive sensing system design of a microelectromechanical systems accelerometer for gravity measurement applications. Micromachines 2016, 7, 167. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhang, B.; Sun, Z.; Ouyang, N.; Wen, X.; Tian, Y. Development of high accuracy dynamic tilt sensor based on MEMS device. Instrum. Tech. Sens. 2020, 9, 6–11. [Google Scholar]

- Lu, Q.; Pang, L.; Huang, H.; Shen, C.; Cao, H.; Shi, Y.; Liu, J. High-G Calibration Denoising Method for High-G MEMS Accelerometer Based on EMD and Wavelet Threshold. Micromachines 2019, 10, 134. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhu, J.; Wang, W.; Huang, S.; Ding, W. An improved calibration technique for mems accelerometer-based inclinometers. Sensors 2020, 20, 452. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Frosio, I.; Pedersini, F.; Borghese, N.A. Autocalibration of triaxial MEMS accelerometers with automatic sensor model selection. IEEE Sens. J. 2012, 12, 2100–2108. [Google Scholar] [CrossRef]

- Won, S.P.; Golnaraghi, F. A triaxial accelerometer calibration method using a mathematical model. IEEE Trans. Instrum. Meas. 2010, 59, 2144–2153. [Google Scholar] [CrossRef]

- Lu, X.; Liu, Z.; He, J. Maximum likelihood approach for low-cost mems triaxial accelerometer calibration. In Proceedings of the 2016 8th International Conference on Intelligent Human-Machine Systems and Cybernetics (IHMSC), Hangzhou, China, 27–28 August 2016; pp. 179–182. [Google Scholar]

- Zhan, W.W.; Cai, L. A method reducing effect of installation error in accelerometer gravimetric calibration. J. Vib. Shock 2019, 13, 249–252. [Google Scholar]

- Pan, J.Y.; Zhang, C.X.; Cai, Q.Z. An accurate calibration method of accelerometer nonlinear scale factor on a low-cost three-axis turntable. Meas. Sci. Technol. 2014, 25, 025102. [Google Scholar] [CrossRef]

- IEEE Std 836-2009. IEEE Recommended Practice for Precision Centrifuge Testing of Linear Accelerometer; IEEE-SA Standards Board: New York, NY, USA, 2009. [Google Scholar]

- Wang, S.M.; Wang, Y.; Yi, G.X.; Ren, S.Q.; Lu, J.R. Calibration of accelerometers fixed in SINS on precision centrifuge. J. Chin. Inert. Technol. 2013, 21, 264–270. [Google Scholar]

- Sohrabi, H.; Ebadollahi, S. Accuracy enhancement of MEMS accelerometer by determining its nonlinear coefficients using centrifuge test. Measurement 2017, 112, 29–37. [Google Scholar] [CrossRef]

- Ren, S.Q.; Liu, Q.B.; Zeng, M.; Wang, C.H. Calibration method of accelerometer's high order error model coefficients on precision centrifuge. IEEE Trans. Instrum. Meas. 2020, 69, 2277–2286. [Google Scholar] [CrossRef]

- Liu, F.; Su, Z.; Li, Q.; Li, C.; Zhao, H. Error characteristics and compensation methods of MIMU with non-centroid configurations. In Proceedings of the 37th Chinese Control Conference, Wuhan, China, 1 July 2018; pp. 4877–4882. [Google Scholar]

- Ren, S.Q.; Wang, S.M. Impacts of installation errors on the calibration accuracy of gyro accelerometer tested on centrifuge. In Proceedings of the 2nd International Symposium on Instrumentation & Measurement, Toronto, ON, Canada, 27 February 2014; pp. 914–918. [Google Scholar]

- Ling, M.X.; Li, M.H.; Yang, X.; Li, Q.; Wang, J. Measurement method of static radius of high precision centrifuge and its application. Chin. J. Sci. Instrum. 2014, 35, 1072–1078. [Google Scholar]

- Yin, X.Q. The Measurement Method and Error Analysis for the Working Radius of Precision Centrifuge. Master’s Thesis, Harbin Institute of Technology, Harbin, China, 2013. [Google Scholar]

- Liao, J.P.; Yin, X.L.; Li, X.T. Tumbling calibration method for accelerometer in centrifuge acceleration field. J. Chin. Inert. Technol. 2017, 25, 550–554. [Google Scholar]

- Jiang, X.X.; Liu, Y.; Su, B.K. Calibration test method of high-precision accelerometer in gravitational field. J. Jilin Univ. 2010, 40, 287–292. [Google Scholar]

- Sun, C.; Ren, S.Q.; Wang, C.H. Revised error calibration model of linear accelerometer on precision centrifuge. Rev. Sci. Instrum. 2019, 90, 085002. [Google Scholar] [CrossRef] [PubMed]

- Sun, C.; Ren, S.Q.; Wang, Z.H. Calibration method of accelerometer on precision centrifuge and its error analysis. J. Chin. Inert. Technol. 2019, 27, 121–128. [Google Scholar]

- Huang, Q.W.; Yang, S.H.; Dong, X.; Wang, Y. Elimination of static radius error term in accelerometer calibration. J. Chin. Inert. Technol. 2018, 26, 122–126. [Google Scholar]

- JJF 1427-2013. Calibration Specification for MEMS Linear Accelerometers; China’s General Administration of Quality Supervision, Inspection and Quarantine: Beijing, China, 2013. [Google Scholar]

- Xiong, L.; He, Z.J.; Yu, Z. Dynamic calibration device of accelerometer based on double turntable centrifuge. Meas. Control Technol. 2016, 1, 134–137. [Google Scholar]

- IEEE Std 1554-2005. IEEE Recommended Practice for Inertial Sensor Test Equipment, Instrumentation, Data Acquisition and Analysis; IEEE Aerospace and Electronic System Society: Big Sky, MT, USA, 2005. [Google Scholar]

| Lateral Acceleration (g) | Output of Accelerometer (mg) |

|---|---|

| 5 | −60.7116 |

| 4 | −60.7106 |

| 3 | −60.7094 |

| 2 | −60.7100 |

| 1 | −60.6948 |

| 0 | −60.7131 |

| Acceleration of Centrifuge (g) | Calibrated Input Acceleration (g) | Output of Accelerometer (LSBs) |

|---|---|---|

| 0 | 0 | 0 |

| −1 | −0.964425 | −10,058.2 |

| −2 | −1.928849 | −20,111.8 |

| −5 | −4.822123 | −50,294.5 |

| −10 | −9.644246 | −100,598.1 |

| −15 | −14.466369 | −150,900.9 |

| −20 | −19.288492 | −201,214.5 |

| −25 | −24.110615 | −251,524.6 |

| −30 | −28.932738 | −301,832.3 |

| Acceleration of Centrifuge (g) | Calibrated Input Acceleration (g) | Output of Accelerometer (LSBs) |

|---|---|---|

| 0 | 0 | 0 |

| 1 | 1.035575 | 10,801.9 |

| 2 | 2.071151 | 21,604.2 |

| 5 | 5.177877 | 53,998.7 |

| 10 | 10.355754 | 107,954.5 |

| 15 | 15.533631 | 161,871.5 |

| 20 | 20.711508 | 215,757.5 |

| 25 | 25.889385 | 269,586.4 |

| 30 | 31.067262 | 323,350.7 |

| Parameter | Before Calibration | After Calibration |

|---|---|---|

| K1+ (LSB/g) | 10,780.33 | 10,409.99 |

| K1− (LSB/g) | 10,061.18 | 10,432.32 |

| K1 (LSB/g) | 10,422.28 | 10,422.11 |

| asymmetry (ppm) | 69,011 | 2142 |

| nonlinearity (ppm) | 9957 | 537 |

| Parameter | Our Method | Back-Calculation Method |

|---|---|---|

| K1+ (LSB/g) | 10,409.99 | 10,409.90 |

| K1− (LSB/g) | 10,432.32 | 10,434.28 |

| K1 (LSB/g) | 10,422.11 | 10,423.08 |

| asymmetry (ppm) | 2142 | 2339 |

| nonlinearity (ppm) | 537 | 565 |

| Parameter | Position 1 | Position 2 |

|---|---|---|

| θ2 | 86.9020° | 89.5128° |

| θ3 | 89.0205° | 90.4210° |

| θ1 | 1.05925° | 0.4541° |

| r (m) | 0.01423016 | 0.00023108 |

| K1 (LSB/g) | 10,422.11 | 10,421.67 |

| asymmetry (ppm) | 2142 | 2118 |

| nonlinearity (ppm) | 538 | 530 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dong, X.; Huang, X.; Du, G.; Huang, Q.; Huang, Y.; Huang, Y.; Lai, P. Calibration Method of Accelerometer Based on Rotation Principle Using Double Turntable Centrifuge. Micromachines 2022, 13, 62. https://doi.org/10.3390/mi13010062

Dong X, Huang X, Du G, Huang Q, Huang Y, Huang Y, Lai P. Calibration Method of Accelerometer Based on Rotation Principle Using Double Turntable Centrifuge. Micromachines. 2022; 13(1):62. https://doi.org/10.3390/mi13010062

Chicago/Turabian StyleDong, Xianshan, Xinlong Huang, Guizhen Du, Qinwen Huang, Yixiong Huang, Yun Huang, and Ping Lai. 2022. "Calibration Method of Accelerometer Based on Rotation Principle Using Double Turntable Centrifuge" Micromachines 13, no. 1: 62. https://doi.org/10.3390/mi13010062

APA StyleDong, X., Huang, X., Du, G., Huang, Q., Huang, Y., Huang, Y., & Lai, P. (2022). Calibration Method of Accelerometer Based on Rotation Principle Using Double Turntable Centrifuge. Micromachines, 13(1), 62. https://doi.org/10.3390/mi13010062